ECU ACURA NSX 1997 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 917 of 1503

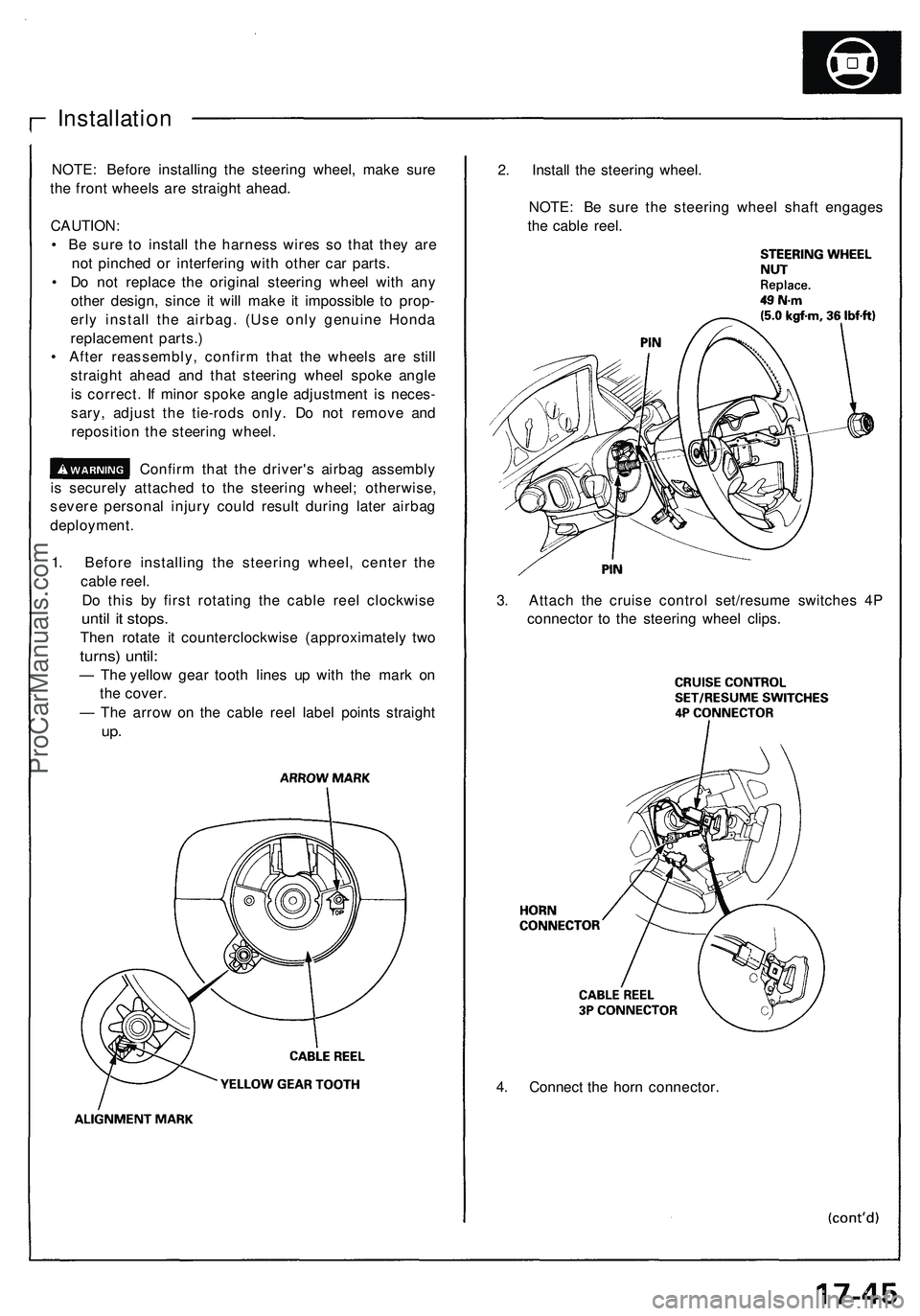

4. Connect the horn connector.

Installation

NOTE: Before installing the steering wheel, make sure

the front wheels are straight ahead.

CAUTION:

• Be sure to install the harness wires so that they are

not pinched or interfering with other car parts.

• Do not replace the original steering wheel with any

other design, since it will make it impossible to prop-

erly install the airbag. (Use only genuine Honda

replacement parts.)

• After reassembly, confirm that the wheels are still

straight ahead and that steering wheel spoke angle

is correct. If minor spoke angle adjustment is neces-

sary, adjust the tie-rods only. Do not remove and

reposition the steering wheel.

Confirm that the driver's airbag assembly

is securely attached to the steering wheel; otherwise,

severe personal injury could result during later airbag

deployment.

1. Before installing the steering wheel, center the

cable reel.

Do this by first rotating the cable reel clockwise

until it stops.

Then rotate it counterclockwise (approximately two

turns) until:

— The yellow gear tooth lines up with the mark on

the cover.

— The arrow on the cable reel label points straight

up.

2. Install the steering wheel.

NOTE: Be sure the steering wheel shaft engages

the cable reel.

3. Attach the cruise control set/resume switches 4P

connector to the steering wheel clips.ProCarManuals.com

Page 922 of 1503

Steering Colum n

Installatio n

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S ( sectio n 24 ) befor e performin g repair s o r ser -

vice .

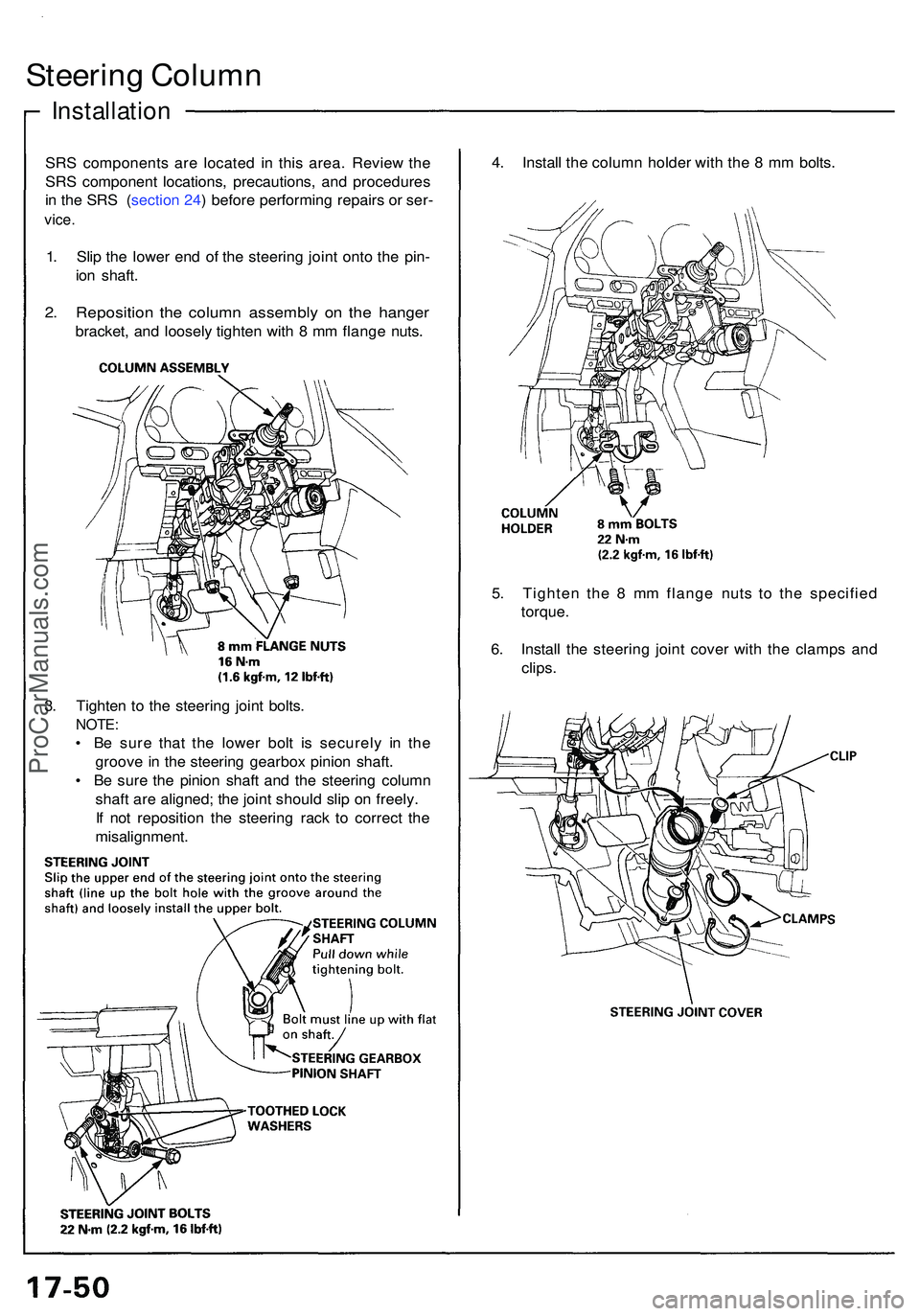

1. Sli p th e lowe r en d o f th e steerin g join t ont o th e pin -

io n shaft .

2. Repositio n th e colum n assembl y o n th e hange r

bracket , an d loosel y tighte n wit h 8 m m flang e nuts . 4

. Instal l th e colum n holde r wit h th e 8 m m bolts .

3 . Tighte n t o th e steerin g join t bolts .

NOTE :

• B e sur e tha t th e lowe r bol t i s securel y i n th e

groov e in th e steerin g gearbo x pinio n shaft .

• B e sur e th e pinio n shaf t an d th e steerin g colum n

shaf t ar e aligned ; th e join t shoul d sli p o n freely .

I f no t repositio n th e steerin g rac k t o correc t th e

misalignment . 5

. Tighte n th e 8 m m flang e nut s t o th e specifie d

torque .

6 . Instal l th e steerin g join t cove r wit h th e clamp s an d

clips .

ProCarManuals.com

Page 928 of 1503

24. Sli p th e lowe r sid e o f th e steerin g join t ont o th e pin -

io n shaf t (lin e u p th e bol t hol e wit h th e groov e

aroun d th e shaft ) an d loosel y instal l th e lowe r bolt .

NOTE :

• B e sur e tha t th e lowe r steerin g join t bol t i s

securel y i n th e groov e i n th e steerin g gearbo x

pinion .

• I f th e steerin g whee l an d rac k ar e no t aligne d

centered , repositio n th e serration s a t lowe r sid e

o f th e steerin g joint .

25 . Adjus t th e fron t to e afte r installin g th e gearbo x (se e

sectio n 18 ).

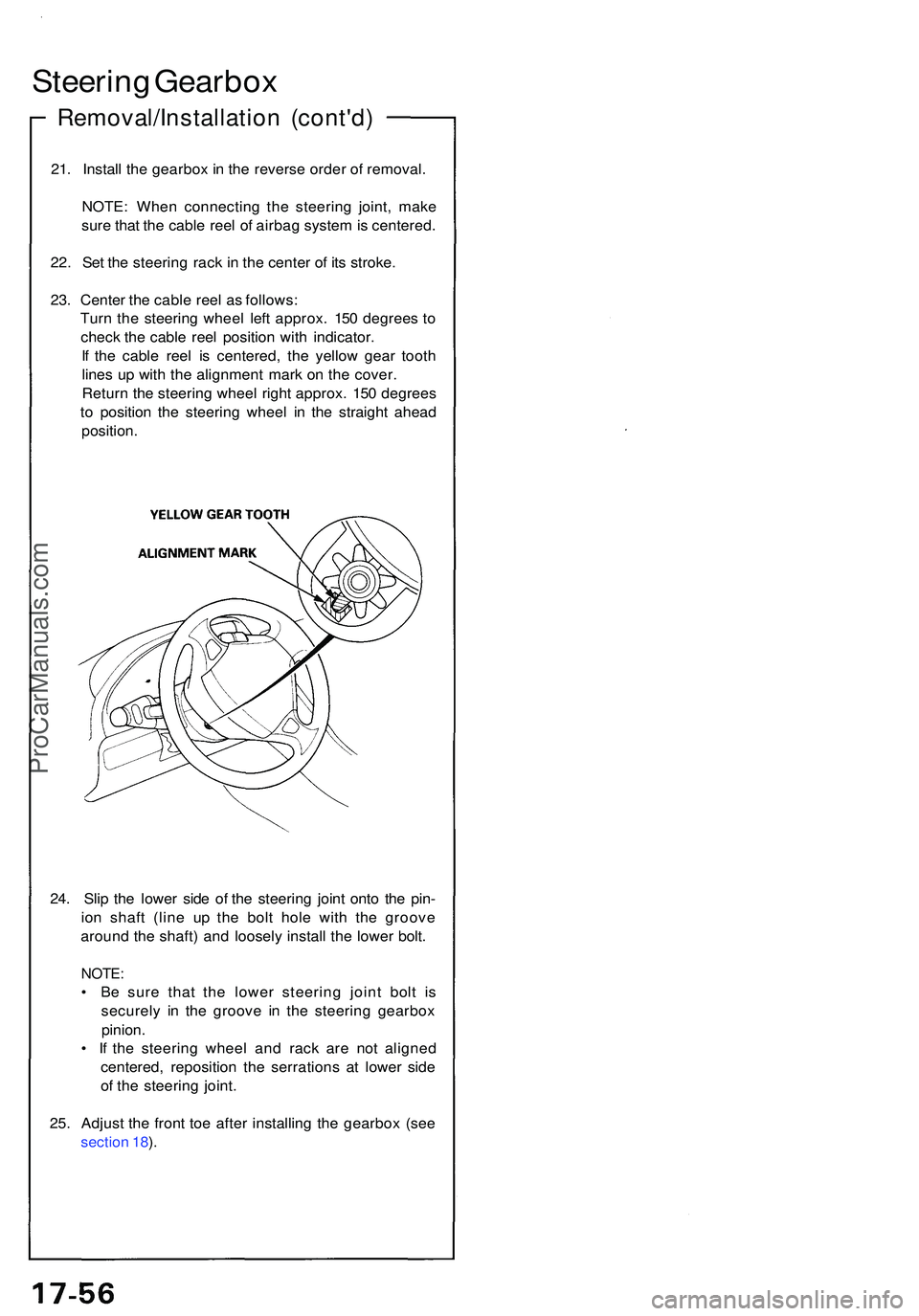

21

. Instal l th e gearbo x in th e revers e orde r o f removal .

NOTE : Whe n connectin g th e steerin g joint , mak e

sur e tha t th e cabl e ree l o f airba g syste m is centered .

22 . Se t th e steerin g rac k i n th e cente r o f it s stroke .

23 . Cente r th e cabl e ree l a s follows :

Tur n th e steerin g whee l lef t approx . 15 0 degree s t o

chec k th e cabl e ree l positio n wit h indicator .

I f th e cabl e ree l i s centered , th e yello w gea r toot h

line s u p wit h th e alignmen t mar k o n th e cover .

Retur n th e steerin g whee l righ t approx . 15 0 degree s

t o positio n th e steerin g whee l i n th e straigh t ahea d

position .

Steering Gearbo x

Removal/Installatio n (cont'd )

ProCarManuals.com

Page 931 of 1503

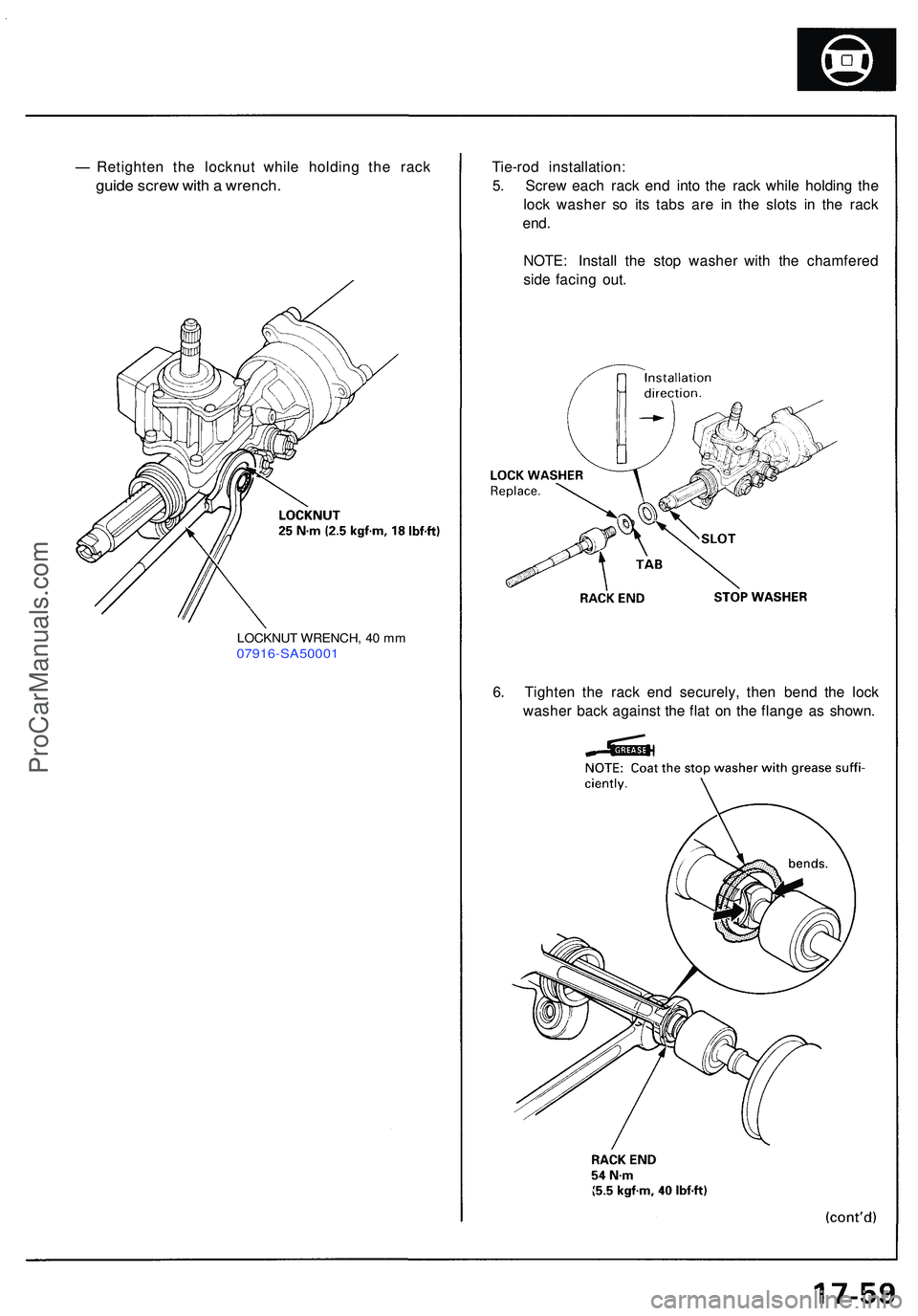

Tie-rod installation :

5 . Scre w eac h rac k en d int o th e rac k whil e holdin g th e

loc k washe r s o it s tab s ar e i n th e slot s i n th e rac k

end.

NOTE : Instal l th e sto p washe r wit h th e chamfere d

sid e facin g out .

6 . Tighte n th e rac k en d securely , the n ben d th e loc k

washe r bac k agains t th e fla t o n th e flang e a s shown .

Retighte

n th e locknu t whil e holdin g th e rac k

guide scre w wit h a wrench .

LOCKNU T WRENCH , 4 0 m m07916-SA5000 1

ProCarManuals.com

Page 933 of 1503

4. Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air .

3

. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , the n pac k th e lowe r are a wit h fres h grease .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n material s

t o ente r th e boot .

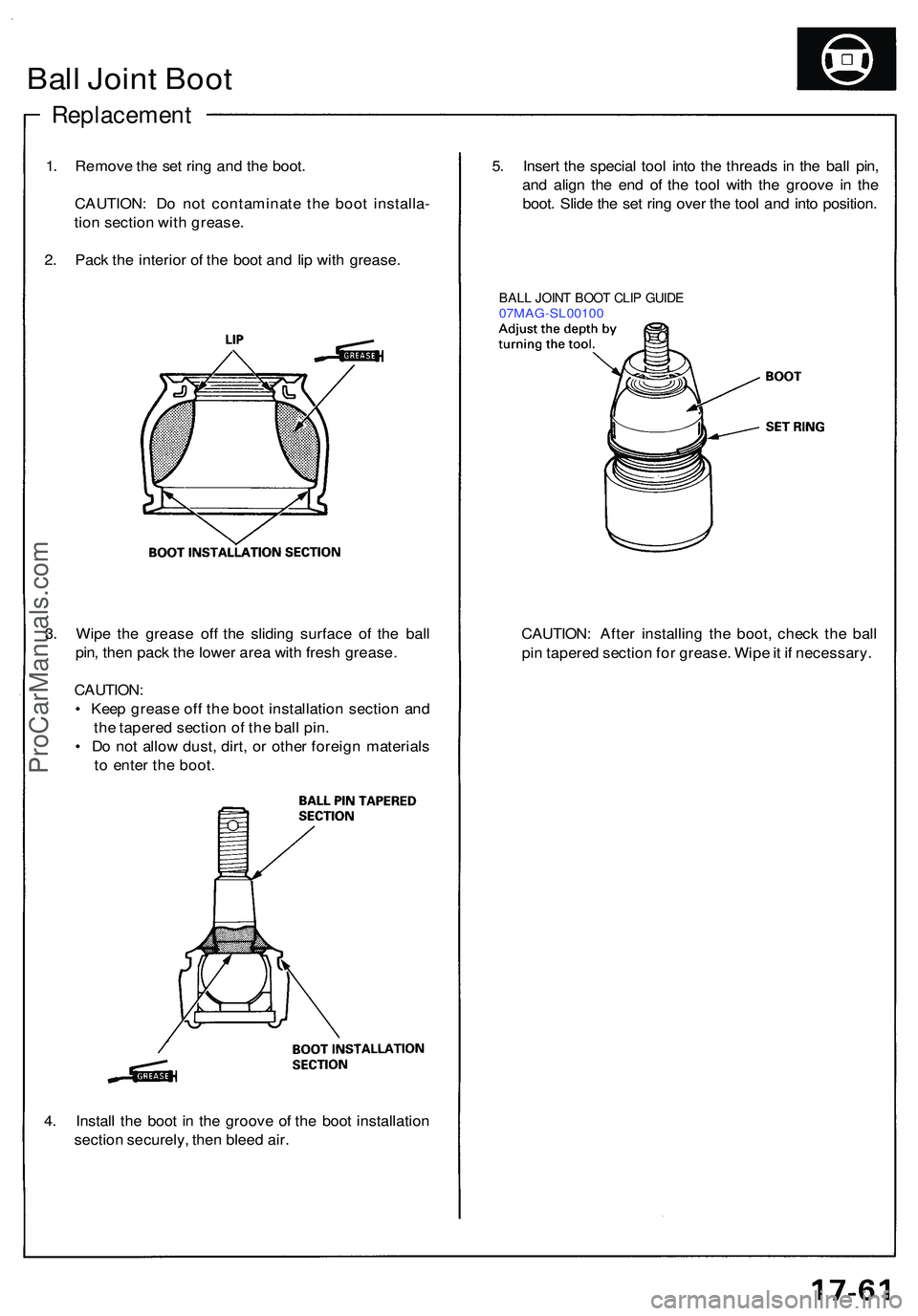

Ball Join t Boo t

Replacemen t

1. Remov e th e se t rin g an d th e boot .

CAUTION : D o no t contaminat e th e boo t installa -

tio n sectio n wit h grease .

2 . Pac k th e interio r o f th e boo t an d li p wit h grease . 5

. Inser t th e specia l too l int o th e thread s i n th e bal l pin ,

an d alig n th e en d o f th e too l wit h th e groov e i n th e

boot . Slid e th e se t rin g ove r th e too l an d int o position .

BALL JOIN T BOO T CLI P GUID E07MAG-SL0010 0

CAUTION: Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r grease . Wip e it i f necessary .

ProCarManuals.com

Page 959 of 1503

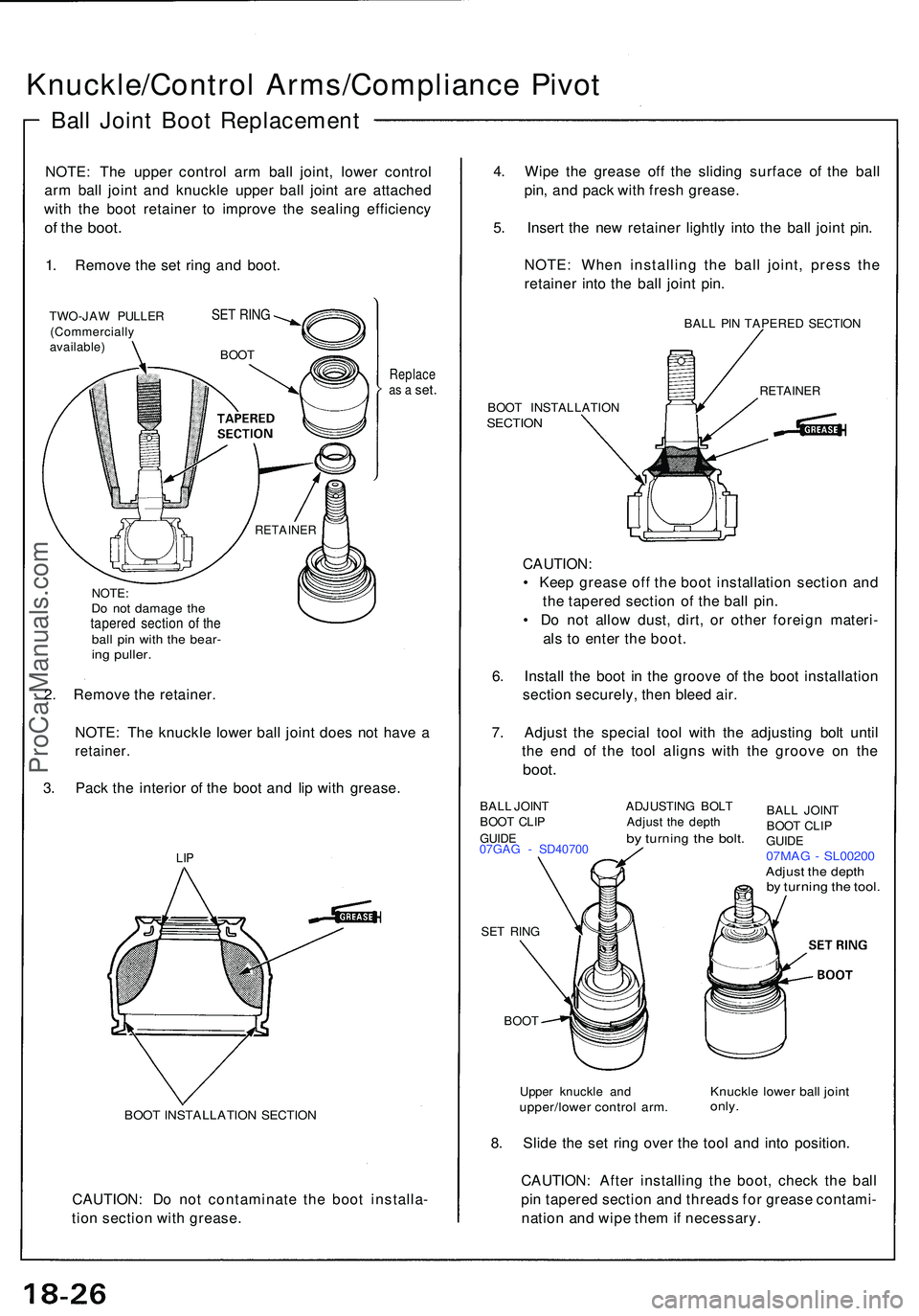

Knuckle/Control Arms/Complianc e Pivo t

Ball Join t Boo t Replacemen t

NOTE: Th e uppe r contro l ar m bal l joint , lowe r contro l

ar m bal l join t an d knuckl e uppe r bal l join t ar e attache d

wit h th e boo t retaine r t o improv e th e sealin g efficienc y

of th e boot .

1. Remov e th e se t rin g an d boot .

TWO-JA W PULLE R

(Commerciall y

available )

Replaceas a set .

NOTE :Do no t damag e th etapere d sectio n o f th ebal l pi n wit h th e bear -ing puller .

2. Remov e th e retainer .

NOTE : Th e knuckl e lowe r bal l join t doe s no t hav e a

retainer .

3. Pac k th e interio r o f th e boo t an d li p wit h grease .

BOOT INSTALLATIO N SECTIO N

CAUTION : D o no t contaminat e th e boo t installa -

tio n sectio n wit h grease . 4

. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , an d pac k wit h fres h grease .

5 . Inser t th e ne w retaine r lightl y int o th e bal l join t pin .

NOTE : Whe n installin g th e bal l joint , pres s th e

retaine r int o th e bal l join t pin .

BAL L PI N TAPERE D SECTIO N

BOO T INSTALLATIO N

SECTION

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n materi -

al s t o ente r th e boot .

6 . Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air .

7 . Adjus t th e specia l too l wit h th e adjustin g bol t unti l

th e en d o f th e too l align s wit h th e groov e o n th e

boot .

BAL L JOIN T ADJUSTIN G BOL T

BOO T CLI P Adjus t th e dept h

GUIDE by turnin g the bolt .07GA G - SD4070 0

SE T RIN G

BOO T

Uppe r knuckl e an d

upper/lowe r contro l arm .

BALL JOIN T

BOO T CLI P

GUID E

07MA G - SL0020 0Adjust th e dept hby turnin g th e tool .

Knuckl e lowe r bal l join tonly.

8. Slid e th e se t rin g ove r th e too l an d int o position .

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n an d thread s fo r greas e contami -

natio n an d wip e the m if necessary .

SET RIN G

BOO T

RETAINE R

RETAINER

LIP

ProCarManuals.com

Page 961 of 1503

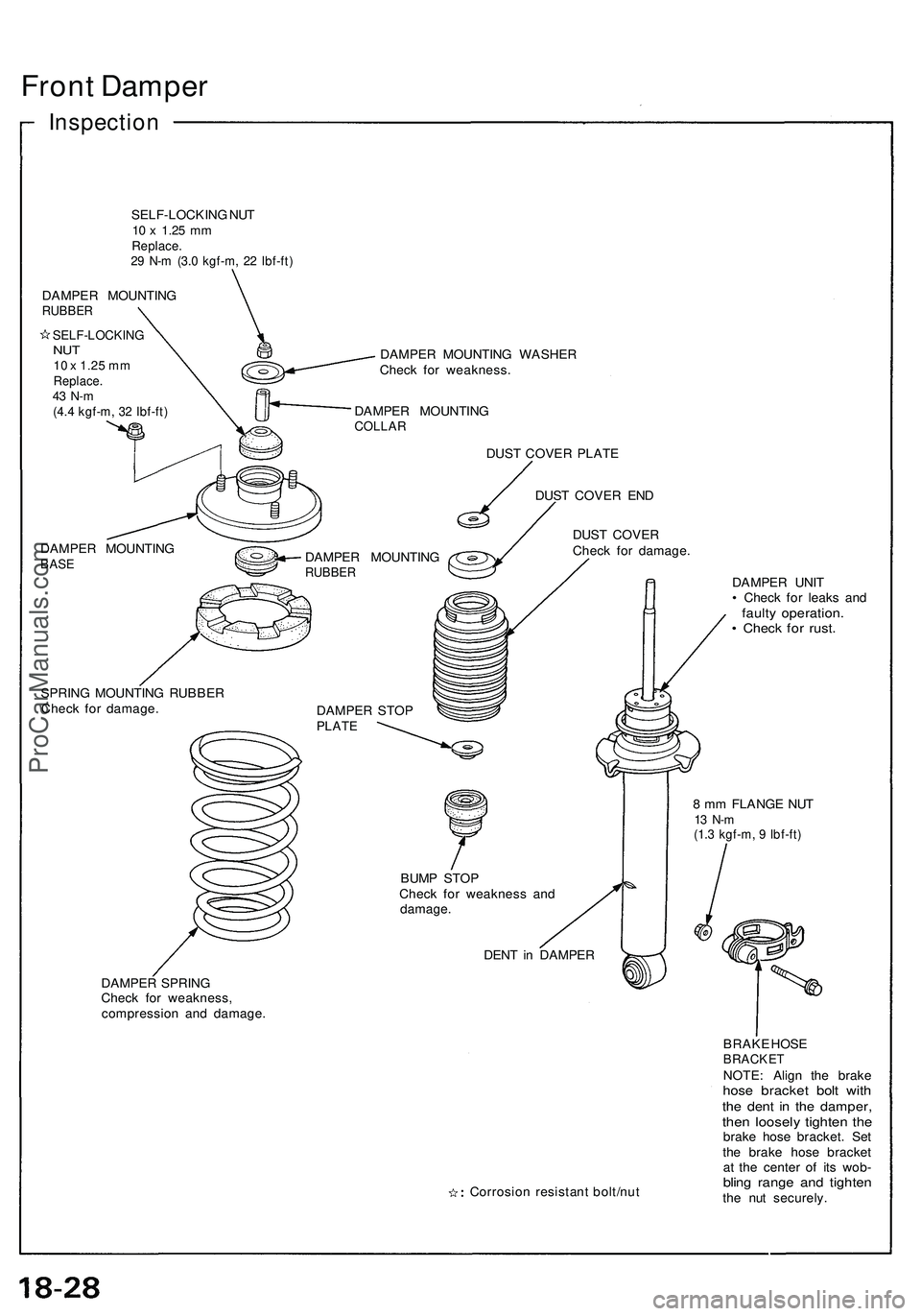

Front Dampe r

Inspectio n

SELF-LOCKIN G NU T10 x 1.2 5 mmReplace .29 N- m (3. 0 kgf-m , 2 2 Ibf-ft )

DAMPE R MOUNTIN GRUBBER

SELF-LOCKIN GNUT10 x 1.25 mmReplace .43 N- m(4.4 kgf-m , 3 2 Ibf-ft )

DAMPE R MOUNTIN GBASE

DAMPE R MOUNTIN G WASHE R

Chec k fo r weakness .

DAMPE R MOUNTIN G

COLLAR

DAMPE R MOUNTIN GRUBBER

DUST COVE R PLAT E

DUS T COVE R EN D

DUS T COVE R

Chec k fo r damage .

SPRIN G MOUNTIN G RUBBE R

Chec k fo r damage .

DAMPER STO P

PLAT E

DAMPE R SPRIN G

Chec k fo r weakness ,

compressio n an d damage . DAMPE

R UNI T

• Chec k fo r leak s an d

fault y operation .• Chec k fo r rust .

8 m m FLANG E NU T13 N- m(1.3 kgf-m , 9 Ibf-ft )

BUMP STO P

Chec k fo r weaknes s an d

damage .

DENT i n DAMPE R

Corrosio n resistan t bolt/nu t BRAK

E HOS E

BRACKETNOTE : Alig n th e brak ehose bracke t bol t wit hthe den t i n th e damper ,then loosel y tighte n th ebrak e hos e bracket . Se t

th e brak e hos e bracke t

a t th e cente r o f it s wob -

bling rang e an d tighte nthe nu t securely .

ProCarManuals.com

Page 962 of 1503

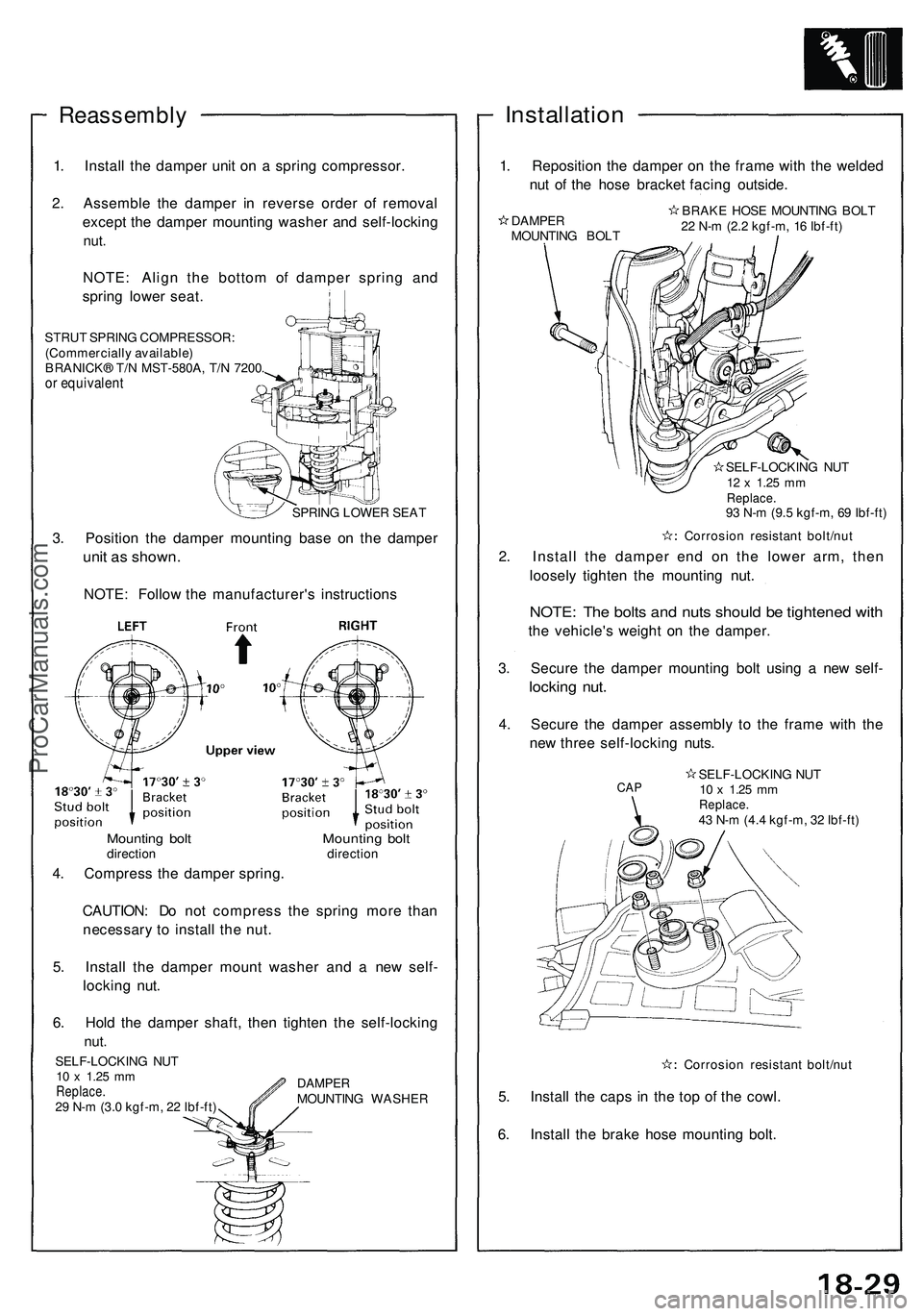

Reassembly

1. Install the damper unit on a spring compressor.

2. Assemble the damper in reverse order of removal

except the damper mounting washer and self-locking

nut.

NOTE: Align the bottom of damper spring and

spring lower seat.

STRUT SPRING COMPRESSOR:

(Commercially available)

BRANICK® T/N MST-580A, T/N 7200.

or equivalent

SPRING LOWER SEAT

3. Position the damper mounting base on the damper

unit as shown.

NOTE: Follow the manufacturer's instructions

CAUTION: Do not compress the spring more than

necessary to install the nut.

5. Install the damper mount washer and a new self-

locking nut.

6. Hold the damper shaft, then tighten the self-locking

nut.

Installation

1. Reposition the damper on the frame with the welded

nut of the hose bracket facing outside.

DAMPER

MOUNTING BOLT

BRAKE HOSE MOUNTING BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)

SELF-LOCKING NUT

12 x

1.25

mm

Replace.

93 N-m (9.5 kgf-m, 69 Ibf-ft)

Corrosion resistant bolt/nut

2. Install the damper end on the lower arm, then

loosely tighten the mounting nut.

NOTE: The bolts and nuts should be tightened with

the vehicle's weight on the damper.

3. Secure the damper mounting bolt using a new self-

locking nut.

4. Secure the damper assembly to the frame with the

new three self-locking nuts.

Corrosion resistant bolt/nut

5. Install the caps in the top of the cowl.

6. Install the brake hose mounting bolt.

Mounting bolt Mounting bolt

direction direction

4. Compress the damper spring.

SELF-LOCKING NUT

10 x

1.25

mm

Replace.

29 N-m (3.0 kgf-m, 22 Ibf-ft)

DAMPER

MOUNTING WASHER

CAP

SELF-LOCKING NUT

10 x

1.25

mm

Replace.

43 N-m (4.4 kgf-m, 32 Ibf-ft)ProCarManuals.com

Page 965 of 1503

Rear Suspensio n

Hub Replacemen t

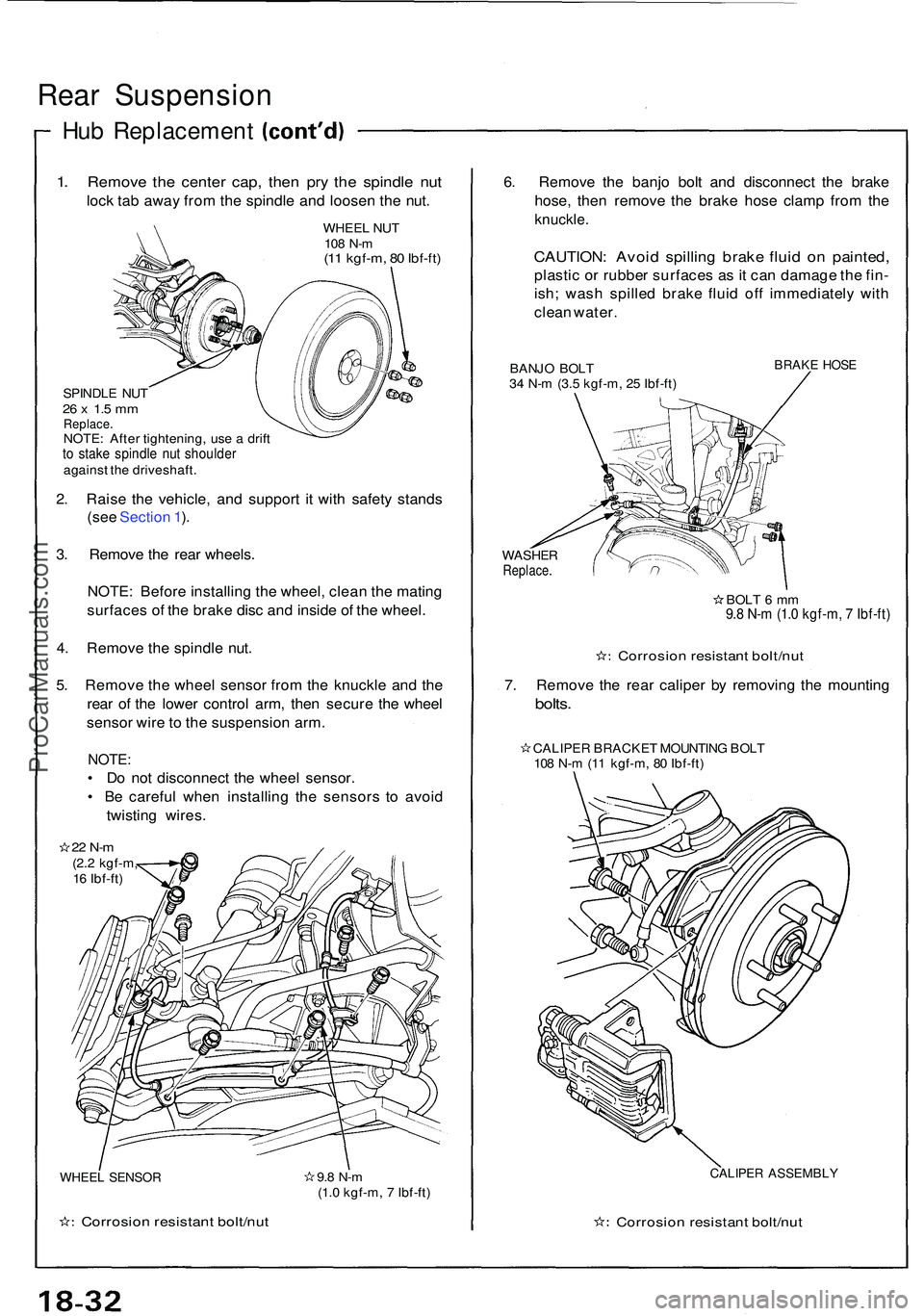

1. Remov e th e cente r cap , the n pr y th e spindl e nu t

lock ta b awa y fro m th e spindl e an d loose n th e nut .

WHEE L NU T108 N- m(11 kgf-m , 8 0 Ibf-ft )

SPINDL E NU T26 x 1. 5 m mReplace .NOTE: Afte r tightening , us e a drif tto stak e spindl e nu t shoulde ragainst th e driveshaft .

2. Rais e th e vehicle , an d suppor t i t wit h safet y stand s

(se e Sectio n 1 ).

3 . Remov e th e rea r wheels .

NOTE : Befor e installin g th e wheel , clea n th e matin g

surface s o f th e brak e dis c an d insid e o f th e wheel .

4 . Remov e th e spindl e nut .

5 . Remov e th e whee l senso r fro m th e knuckl e an d th e

rea r o f th e lowe r contro l arm , the n secur e th e whee l

senso r wir e to th e suspensio n arm .

NOTE :

• D o no t disconnec t th e whee l sensor .

• B e carefu l whe n installin g th e sensor s t o avoi d

twistin g wires .

22 N- m(2.2 kgf-m ,

1 6 Ibf-ft )

WHEE L SENSO R

Corrosio n resistan t bolt/nu t

9.8 N- m(1.0 kgf-m , 7 Ibf-ft )

6. Remov e th e banj o bol t an d disconnec t th e brak e

hose , the n remov e th e brak e hos e clam p fro m th e

knuckle .

CAUTION : Avoi d spillin g brak e flui d o n painted ,

plastic o r rubbe r surface s a s it ca n damag e th e fin -

ish ; was h spille d brak e flui d of f immediatel y wit h

clea n water .

BANJO BOL T

3 4 N- m (3. 5 kgf-m , 2 5 Ibf-ft )BRAK E HOS E

WASHE RReplace .

BOLT 6 m m9.8 N- m (1. 0 kgf-m , 7 Ibf-ft )

Corrosio n resistan t bolt/nu t

7. Remov e th e rea r calipe r b y removin g th e mountin g

bolts.

CALIPE R BRACKE T MOUNTIN G BOL T

10 8 N- m (1 1 kgf-m , 8 0 Ibf-ft )

CALIPE R ASSEMBL Y

Corrosion resistan t bolt/nu t

ProCarManuals.com

Page 972 of 1503

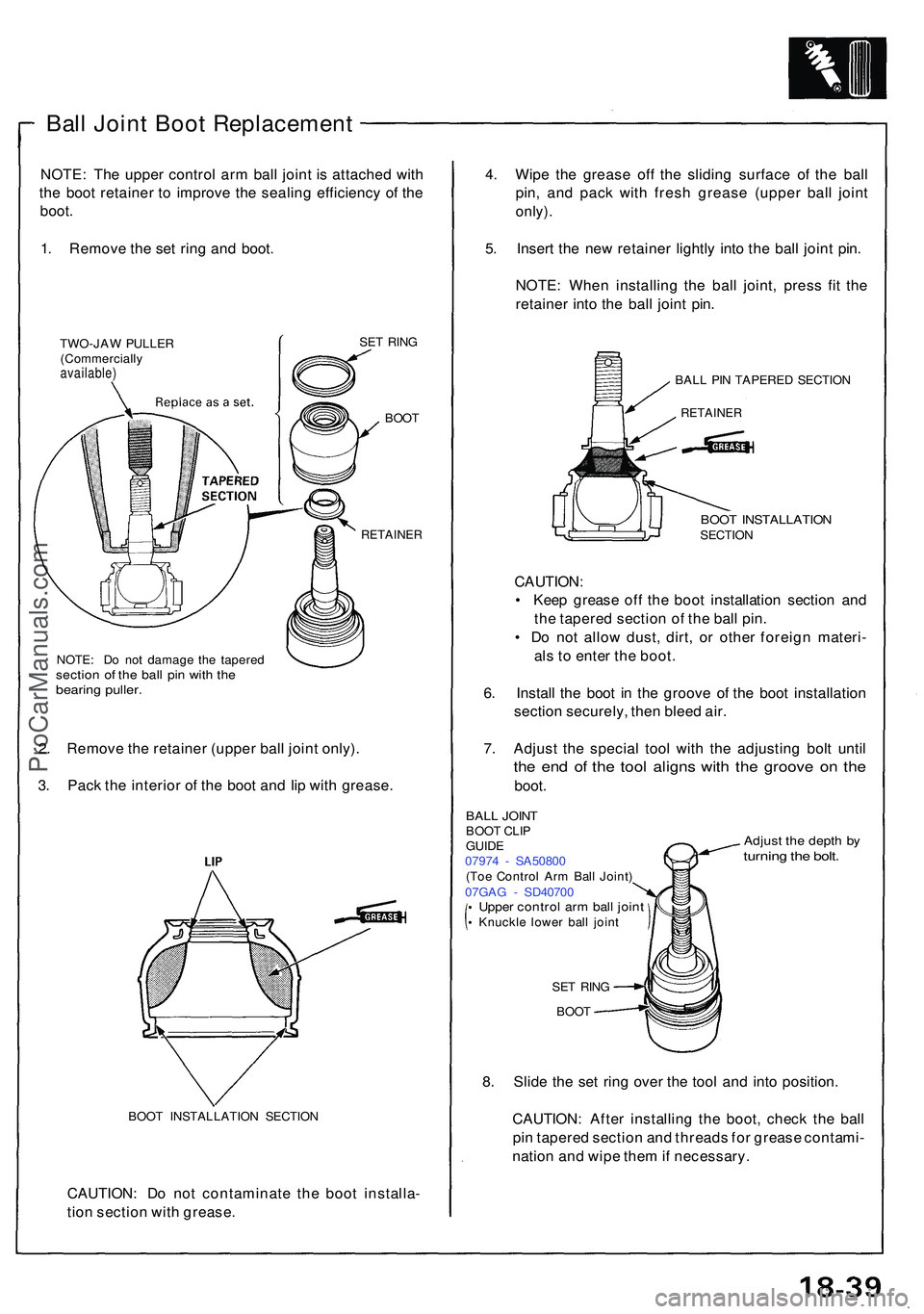

Ball Join t Boo t Replacemen t

NOTE: Th e uppe r contro l ar m bal l join t i s attache d wit h

th e boo t retaine r t o improv e th e sealin g efficienc y o f th e

boot .

1 . Remov e th e se t rin g an d boot .

TWO-JA W PULLE R

(Commerciall y

available)

SET RIN G

BOO T

RETAINE R

NOTE: D o no t damag e th e tapere dsection o f th e bal l pi n wit h th ebearin g puller .

2. Remov e th e retaine r (uppe r bal l join t only) .

3 . Pac k th e interio r o f th e boo t an d li p wit h grease .

BOOT INSTALLATIO N SECTIO N

CAUTION : D o no t contaminat e th e boo t installa -

tio n sectio n wit h grease . 4

. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , an d pac k wit h fres h greas e (uppe r bal l join t

only) .

5. Inser t th e ne w retaine r lightl y int o th e bal l join t pin .

NOTE : Whe n installin g th e bal l joint , pres s fi t th e

retaine r int o th e bal l join t pin .

BAL L PI N TAPERE D SECTIO N

RETAINE R

BOOT INSTALLATIO NSECTION

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n materi -

al s to ente r th e boot .

6 . Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air .

7 . Adjus t th e specia l too l wit h th e adjustin g bol t unti l

the en d o f th e too l align s wit h th e groov e o n th e

boot .

Adjus t th e dept h b yturnin g th e bolt .

BAL L JOIN TBOOT CLI P

GUID E

0797 4 - SA5080 0

(To e Contro l Ar m Bal l Joint )

07GA G - SD4070 0

Upper contro l ar m bal l join tKnuckl e lowe r bal l join t

SE T RIN G

BOO T

8. Slid e th e se t rin g ove r th e too l an d int o position .

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n an d thread s fo r greas e contami -

natio n an d wip e the m if necessary .

ProCarManuals.com