fuel filter ACURA NSX 1997 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 99 of 1503

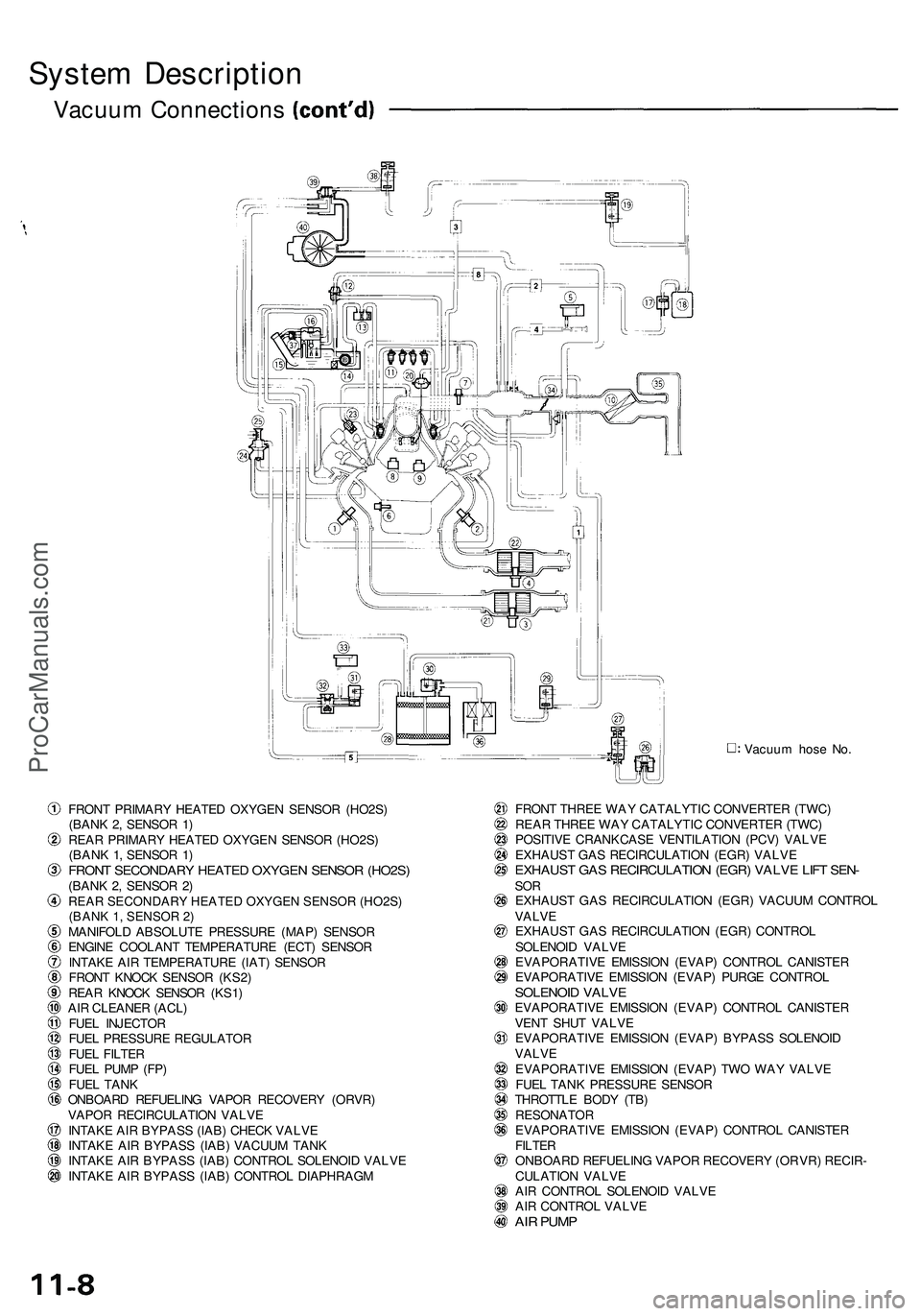

System Descriptio n

Vacuum Connection s

FRONT PRIMAR Y HEATE D OXYGE N SENSO R (HO2S )

(BAN K 2 , SENSO R 1 )

REA R PRIMAR Y HEATE D OXYGE N SENSO R (HO2S )

(BAN K 1 , SENSO R 1 )

FRON T SECONDAR Y HEATE D OXYGE N SENSO R (HO2S )(BANK 2 , SENSO R 2 )REAR SECONDARY HEATED OXYGEN SENSOR (HO2S)

(BANK 1, SENSOR 2)

MANIFOL D ABSOLUT E PRESSUR E (MAP ) SENSO R

ENGIN E COOLAN T TEMPERATUR E (ECT ) SENSO R

INTAK E AI R TEMPERATUR E (IAT ) SENSO R

FRON T KNOC K SENSO R (KS2 )

REA R KNOC K SENSO R (KS1 )

AI R CLEANE R (ACL )

FUE L INJECTO R

FUE L PRESSUR E REGULATO R

FUE L FILTE R

FUE L PUM P (FP )

FUE L TAN K

ONBOAR D REFUELIN G VAPO R RECOVER Y (ORVR )

VAPO R RECIRCULATIO N VALV E

INTAK E AI R BYPAS S (IAB ) CHEC K VALV E

INTAK E AI R BYPAS S (IAB ) VACUU M TAN K

INTAK E AI R BYPAS S (IAB ) CONTRO L SOLENOI D VALV E

INTAK E AI R BYPAS S (IAB ) CONTRO L DIAPHRAG M Vacuu

m hos e No .

FRON T THRE E WA Y CATALYTI C CONVERTE R (TWC )

REA R THRE E WA Y CATALYTI C CONVERTE R (TWC )

POSITIV E CRANKCAS E VENTILATIO N (PCV ) VALV E

EXHAUS T GA S RECIRCULATIO N (EGR ) VALV E

EXHAUS T GA S RECIRCULATIO N (EGR ) VALV E LIF T SEN -SOREXHAUS T GA S RECIRCULATIO N (EGR ) VACUU M CONTRO L

VALV E

EXHAUS T GA S RECIRCULATIO N (EGR ) CONTRO L

SOLENOI D VALV E

EVAPORATIV E EMISSIO N (EVAP ) CONTRO L CANISTE R

EVAPORATIV E EMISSIO N (EVAP ) PURG E CONTRO L

SOLENOID VALV EEVAPORATIV E EMISSIO N (EVAP ) CONTRO L CANISTE R

VEN T SHU T VALV E

EVAPORATIV E EMISSIO N (EVAP ) BYPAS S SOLENOI D

VALV E

EVAPORATIV E EMISSIO N (EVAP ) TW O WA Y VALV E

FUE L TAN K PRESSUR E SENSO R

THROTTL E BOD Y (TB )

RESONATO R

EVAPORATIV E EMISSIO N (EVAP ) CONTRO L CANISTE R

FILTERONBOAR D REFUELIN G VAPO R RECOVER Y (ORVR ) RECIR -

CULATIO N VALV E

AI R CONTRO L SOLENOI D VALV E

AI R CONTRO L VALV E

AIR PUM P

ProCarManuals.com

Page 374 of 1503

4-5

Y

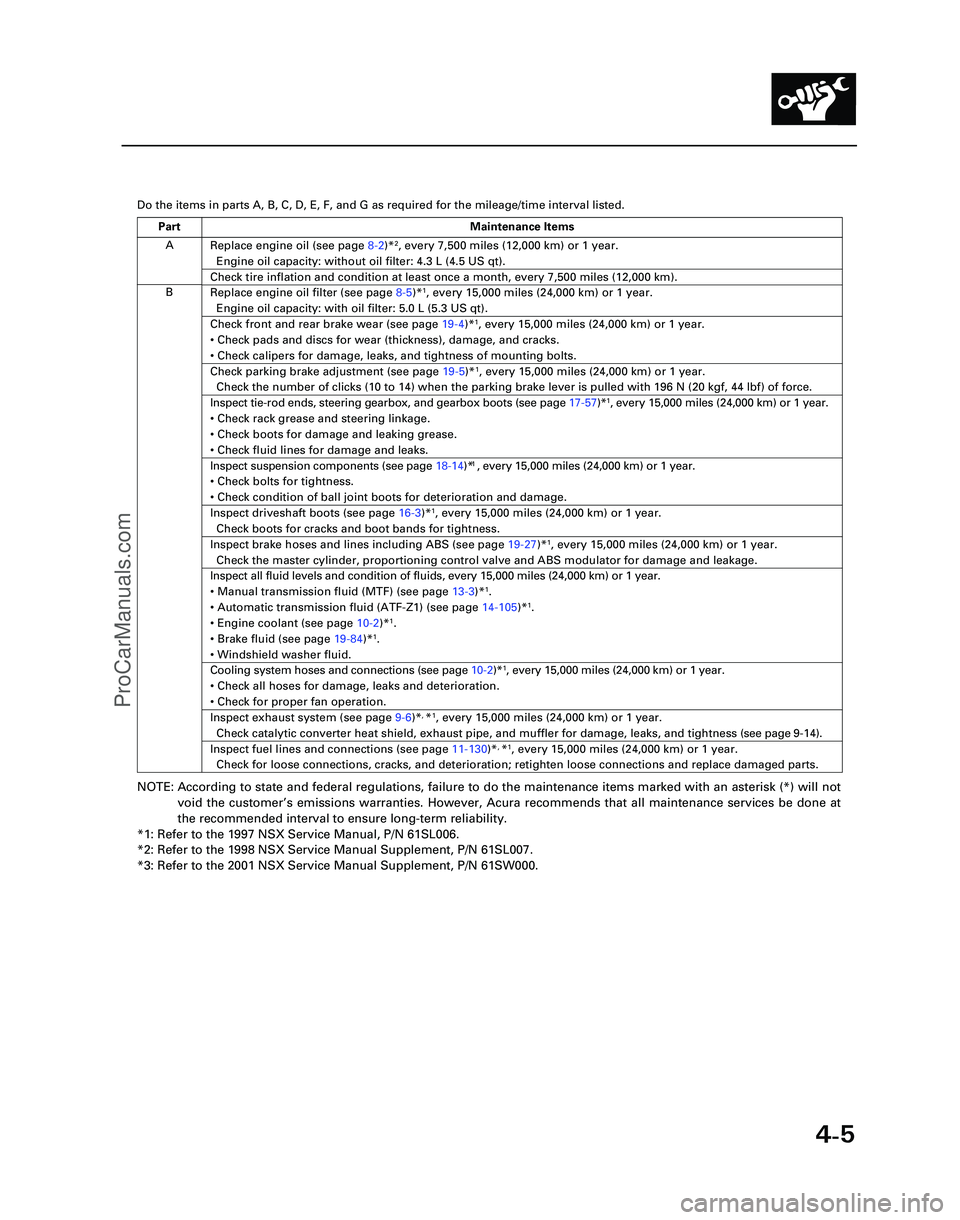

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

A

B Replace engine oil (see page

8-2)*

2, every 7,500 miles (12,000 km) or 1 year.

Engine oil capacity: without oil filter: 4.3 L (4.5 US qt).

Check tire inflation and condition at least once a month, every 7,500 mi\

les (12,000 km).

Replace engine oil filter (see page 8-5)*1, every 15,000 miles (24,000 km) or 1 year.

Engine oil capacity: with oil filter: 5.0 L (5.3 US qt).

Check front and rear brake wear (see page 19-4)*1, every 15,000 miles (24,000 km) or 1 year.

• Check pads and discs for wear (thickness), damage, and cracks.

• Check calipers for damage, leaks, and tightness of mounting bolts.

Check parking brake adjustment (see page 19-5)*1, every 15,000 miles (24,000 km) or 1 year.

Check the number of clicks (10 to 14) when the parking brake lever is pulled with 196 N (20 kgf,\

44 lbf) of force.

Inspect tie-rod ends, steering gearbox, and gearbox boots (see page 17-57)*1, every 15,000 miles (24,000 km) or 1 year.

• Check rack grease and steering linkage.

• Check boots for damage and leaking grease.

• Check fluid lines for damage and leaks.1

• Check bolts for tightness.

• Check condition of ball joint boots for deterioration and damage.

Inspect driveshaft boots (see page 16-3)*1, every 15,000 miles (24,000 km) or 1 year.

Check boots for cracks and boot bands for tightness.

Inspect brake hoses and lines including ABS (see page 19-27)*1, every 15,000 miles (24,000 km) or 1 year.

Check the master cylinder, proportioning control valve and ABS modulator\

for damage and leakage.

Inspect all fluid levels and condition of fluids, every 15,000 miles (2\

4,000 km) or 1 year.

• Manual transmission fluid (MTF) (see page 13-3)*

1.

• Automatic transmission fluid (ATF-Z1) (see page 14-105)*1.

• Engine coolant (see page 10-2)*1.

• Brake fluid (see page 19-84)*1.

• Windshield washer fluid.

Cooling system hoses and connections (see page 10-2)*1, every 15,000 miles (24,000 km) or 1 year.

• Check all hoses for damage, leaks and deterioration.

• Check for proper fan operation.

Inspect exhaust system (see page 9-6)*, *1, every 15,000 miles (24,000 km) or 1 year.

Check catalytic converter heat shield, exhaust pipe, and muffler for dam\

age, leaks, and tightness ( see page 9-14 ).

Inspect fuel lines and connections (see page 11-130)*, *1, every 15,000 miles (24,000 km) or 1 year.

Check for loose connections, cracks, and deterioration; retighten loose \

connections and replace damaged parts.

Part Maintenance Items

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-5

Inspect suspension components (see page 18-14)* , every 15,000 miles (24,000 km) or 1 year.

ProCarManuals.com

Page 375 of 1503

4-6

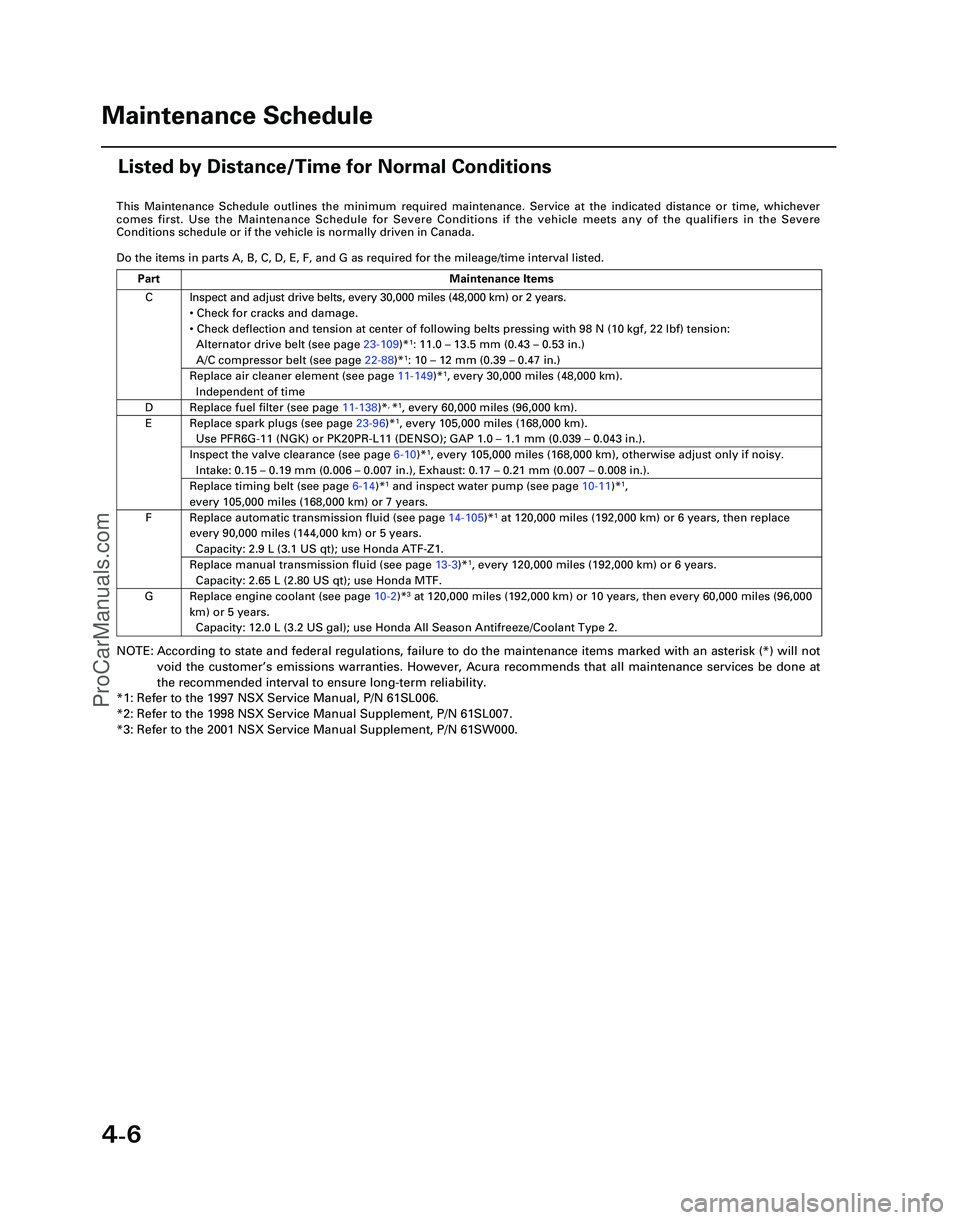

This Maintenance Schedule outlines the minimum required maintenance. Ser\

vice at the indicated distance or time, whichever

comes first. Use the Maintenance Schedule for Severe Conditions if the v\

ehicle meets any of the qualifiers in the Severe

Conditions schedule or if the vehicle is normally driven in Canada.

Do the items in parts A, B, C, D, E, F, and G as required for the mileag\

e/time interval listed.

NOTE: According to state and federal regulations, failure to do the maintenanc\

e items marked with an asterisk (*) will not

void the customer ’s emissions warranties. However, Acura recommends that all maintenance s\

ervices be done at

the recommended interval to ensure long-term reliability.

*1: Refer to the 1997 NSX Service Manual, P/N 61SL006.

*2: Refer to the 1998 NSX Service Manual Supplement, P/N 61SL007.

*3: Refer to the 2001 NSX Service Manual Supplement, P/N 61SW000.

C

D

E

F

G Inspect and adjust drive belts, every 30,000 miles (48,000 km) or 2 ye\

ars.

•

Check for cracks and damage.

• Check deflection and tension at center of following belts pressing with\

98 N (10 kgf, 22 lbf) tension:

Alternator drive belt (see page 23-109)*

1: 11.0 – 13.5 mm (0.43 – 0.53 in.)

A/C compressor belt (see page 22-88)*1: 10 – 12 mm (0.39 – 0.47 in.)

Replace air cleaner element (see page 11-149)*1, every 30,000 miles (48,000 km).

Independent of time

Replace fuel filter (see page 11-138)*, *1, every 60,000 miles (96,000 km).

Replace spark plugs (see page 23-96)*1, every 105,000 miles (168,000 km).

Use PFR6G-11 (NGK) or PK20PR-L11 (DENSO); GAP 1.0 – 1.1 mm (0.039 – 0.043 in.).

Inspect the valve clearance (see page 6-10)*1, every 105,000 miles (168,000 km), otherwise adjust only if noisy.

Intake: 0.15 – 0.19 mm (0.006 – 0.007 in.), Exhaust: 0.17 – 0.21 mm (0.007 – 0.008 in.).

Replace timing belt (see page 6-14)*1 and inspect water pump (see page 10-11)*1,

every 105,000 miles (168,000 km) or 7 years.

Replace automatic transmission fluid (see page 14-105)*1 at 120,000 miles (192,000 km) or 6 years, then replace

every 90,000 miles (144,000 km) or 5 years.

Capacity: 2.9 L (3.1 US qt); use Honda ATF-Z1.

Replace manual transmission fluid (see page 13-3)*1, every 120,000 miles (192,000 km) or 6 years.

Capacity: 2.65 L (2.80 US qt); use Honda MTF.

Replace engine coolant (see page 10-2 )*3 at 120,000 miles (192,000 km) or 10 years, then every 60,000 miles (9\

6,000

km) or 5 years. Capacity: 12.0 L (3.2 US gal); use Honda All Season Antifreeze/Coolant\

Type 2.

Part Maintenance Items

Maintenance Schedule

Listed by Distance/Time for Normal Conditions

*05-NSX (61SW004)SEC04(01-10) 9/22/04 1:49 PM Page 4-6

ProCarManuals.com

Page 607 of 1503

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high-pressure fuel pump, fuel pump relay, fuel pump

resistor PGM-FI main relay, fuel filter, fuel pressure regu-

lator, fuel injectors, injector resistor (A/T), and fuel deliv-

ery and return lines. This system delivers pressure-regu-

lated fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.ProCarManuals.com

Page 608 of 1503

Fuel Pressur e

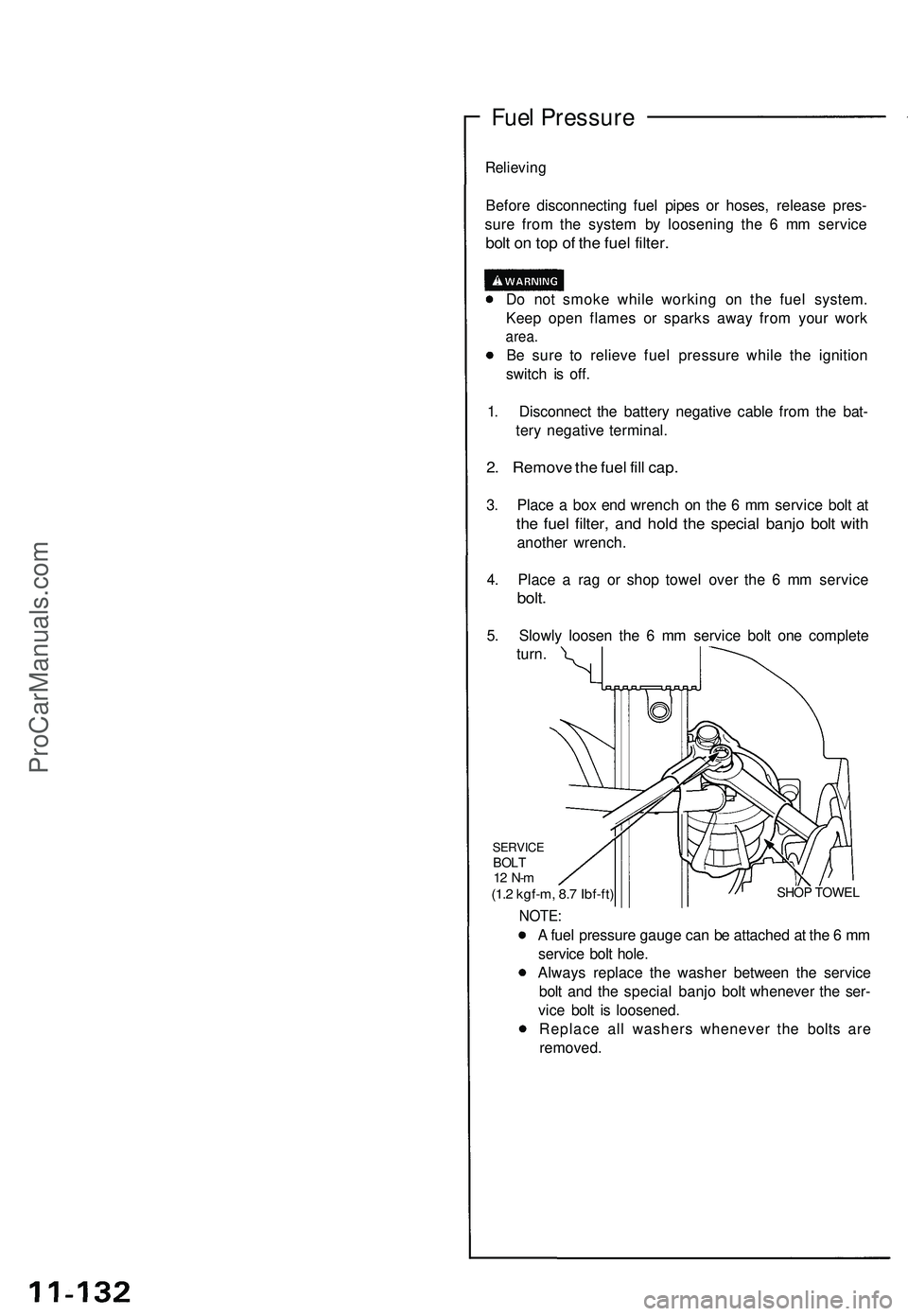

Relieving

Before disconnectin g fue l pipe s o r hoses , releas e pres -

sur e fro m th e syste m b y loosenin g th e 6 m m servic e

bolt o n to p o f th e fue l filter .

Do no t smok e whil e workin g o n th e fue l system .

Kee p ope n flame s o r spark s awa y fro m you r wor k

area.

Be sur e t o reliev e fue l pressur e whil e th e ignitio n

switc h i s off .

1 . Disconnec t th e batter y negativ e cabl e fro m th e bat -

ter y negativ e terminal .

2. Remov e th e fue l fil l cap .

3. Plac e a bo x en d wrenc h o n th e 6 m m servic e bol t a t

the fue l filter , an d hol d th e specia l banj o bol t wit h

anothe r wrench .

4 . Plac e a ra g o r sho p towe l ove r th e 6 m m servic e

bolt.

5. Slowl y loose n th e 6 m m servic e bol t on e complet e

turn .

SHO P TOWE L

SERVIC EBOLT12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

NOTE :

A fue l pressur e gaug e ca n b e attache d a t th e 6 m m

servic e bol t hole .

Alway s replac e th e washe r betwee n th e servic e

bol t an d th e specia l banj o bol t wheneve r th e ser -

vic e bol t i s loosened .

Replac e al l washer s wheneve r th e bolt s ar e

removed .

ProCarManuals.com

Page 609 of 1503

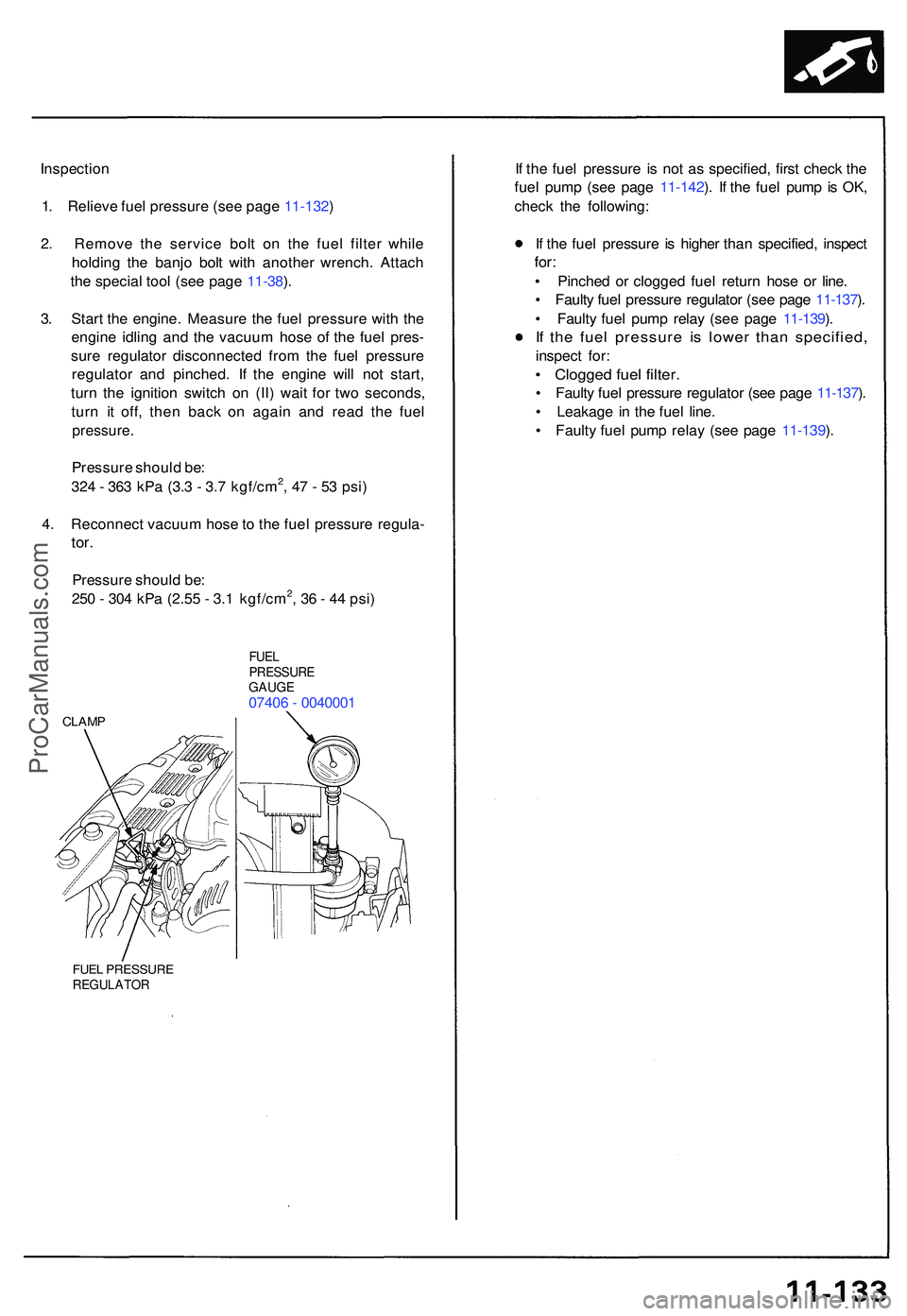

Inspection

1 . Reliev e fue l pressur e (se e pag e 11-132 )

2 . Remov e th e servic e bol t o n th e fue l filte r whil e

holdin g th e banj o bol t wit h anothe r wrench . Attac h

th e specia l too l (se e pag e 11-38 ).

3 . Star t th e engine . Measur e th e fue l pressur e wit h th e

engin e idlin g an d th e vacuu m hos e o f th e fue l pres -

sur e regulato r disconnecte d fro m th e fue l pressur e

regulato r an d pinched . I f th e engin e wil l no t start ,

tur n th e ignitio n switc h o n (II ) wai t fo r tw o seconds ,

tur n i t off , the n bac k o n agai n an d rea d th e fue l

pressure .

Pressure shoul d be :

32 4 - 36 3 kP a (3. 3 - 3. 7 kgf/cm2, 4 7 - 5 3 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

25 0 - 30 4 kP a (2.5 5 - 3. 1 kgf/cm2, 3 6 - 4 4 psi )

FUE LPRESSUR EGAUGE07406 - 004000 1

CLAMP

FUEL PRESSUR EREGULATO R

If th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p is OK ,

chec k th e following :

I f th e fue l pressur e i s highe r tha n specified , inspec t

for:

• Pinche d o r clogge d fue l retur n hos e o r line .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Fault y fue l pum p rela y (se e pag e 11-139 ).

If th e fue l pressur e i s lowe r tha n specified ,

inspect for :

• Clogge d fue l filter .

• Fault y fue l pressur e regulato r (se e pag e 11-137 ).

• Leakag e i n th e fue l line .

• Fault y fue l pum p rela y (se e pag e 11-139 ).

ProCarManuals.com

Page 615 of 1503

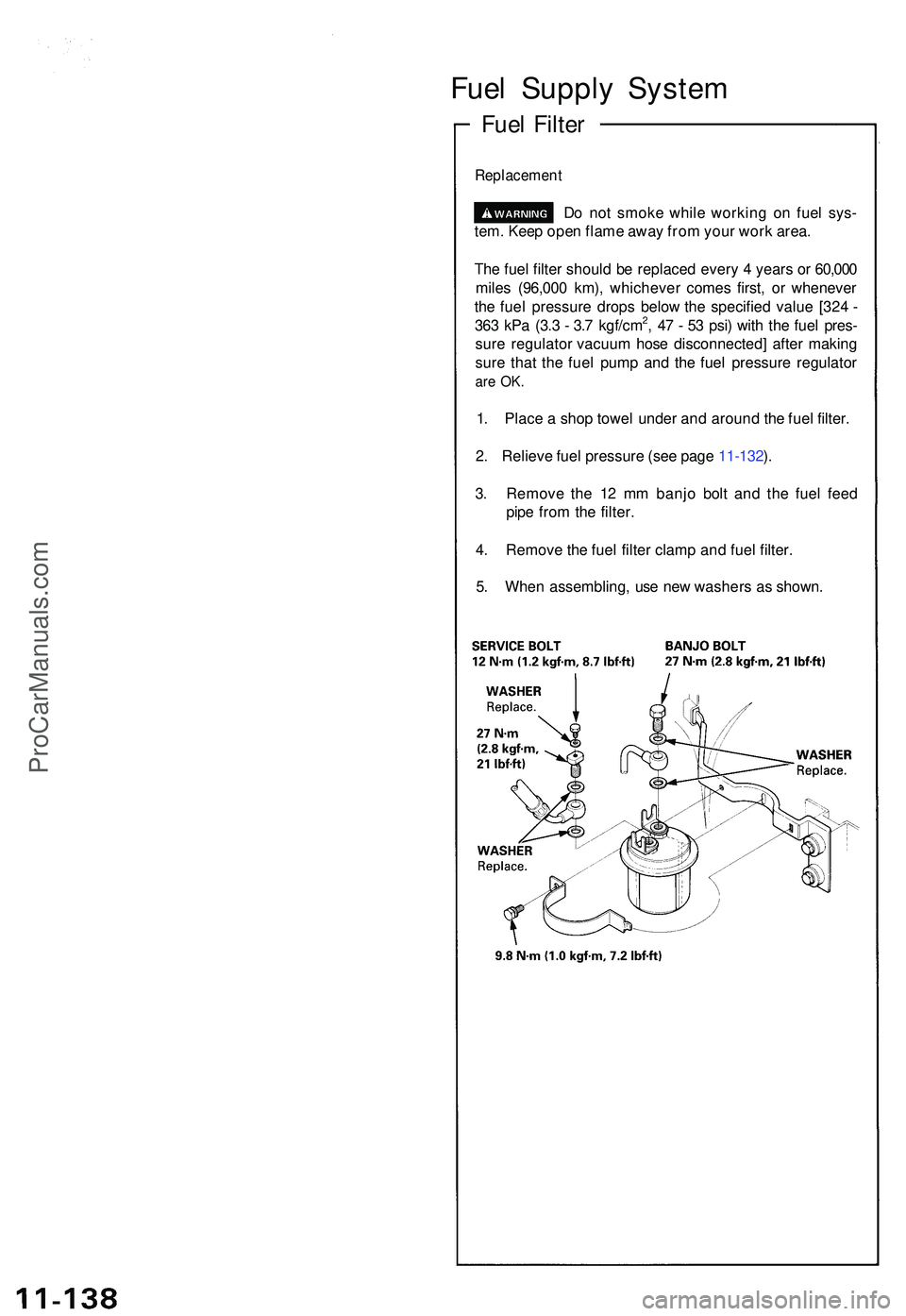

Fuel Suppl y Syste m

Fuel Filte r

Replacemen t

Do no t smok e whil e workin g o n fue l sys -

tem . Kee p ope n flam e awa y fro m you r wor k area .

Th e fue l filte r shoul d b e replace d ever y 4 year s o r 60,00 0

mile s (96,00 0 km) , whicheve r come s first , o r wheneve r

th e fue l pressur e drop s belo w th e specifie d valu e [32 4 -

36 3 kP a (3. 3 - 3. 7 kgf/cm

2, 4 7 - 5 3 psi ) wit h th e fue l pres -

sur e regulato r vacuu m hos e disconnected ] afte r makin g

sur e tha t th e fue l pum p an d th e fue l pressur e regulato r

are OK .

1. Plac e a sho p towe l unde r an d aroun d th e fue l filter .

2 . Reliev e fue l pressur e (se e pag e 11-132 ).

3 . Remov e th e 1 2 m m banj o bol t an d th e fue l fee d

pip e fro m th e filter .

4 . Remov e th e fue l filte r clam p an d fue l filter .

5 . Whe n assembling , us e ne w washer s a s shown .

ProCarManuals.com