battery ACURA RL KA9 1996 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 558 of 1954

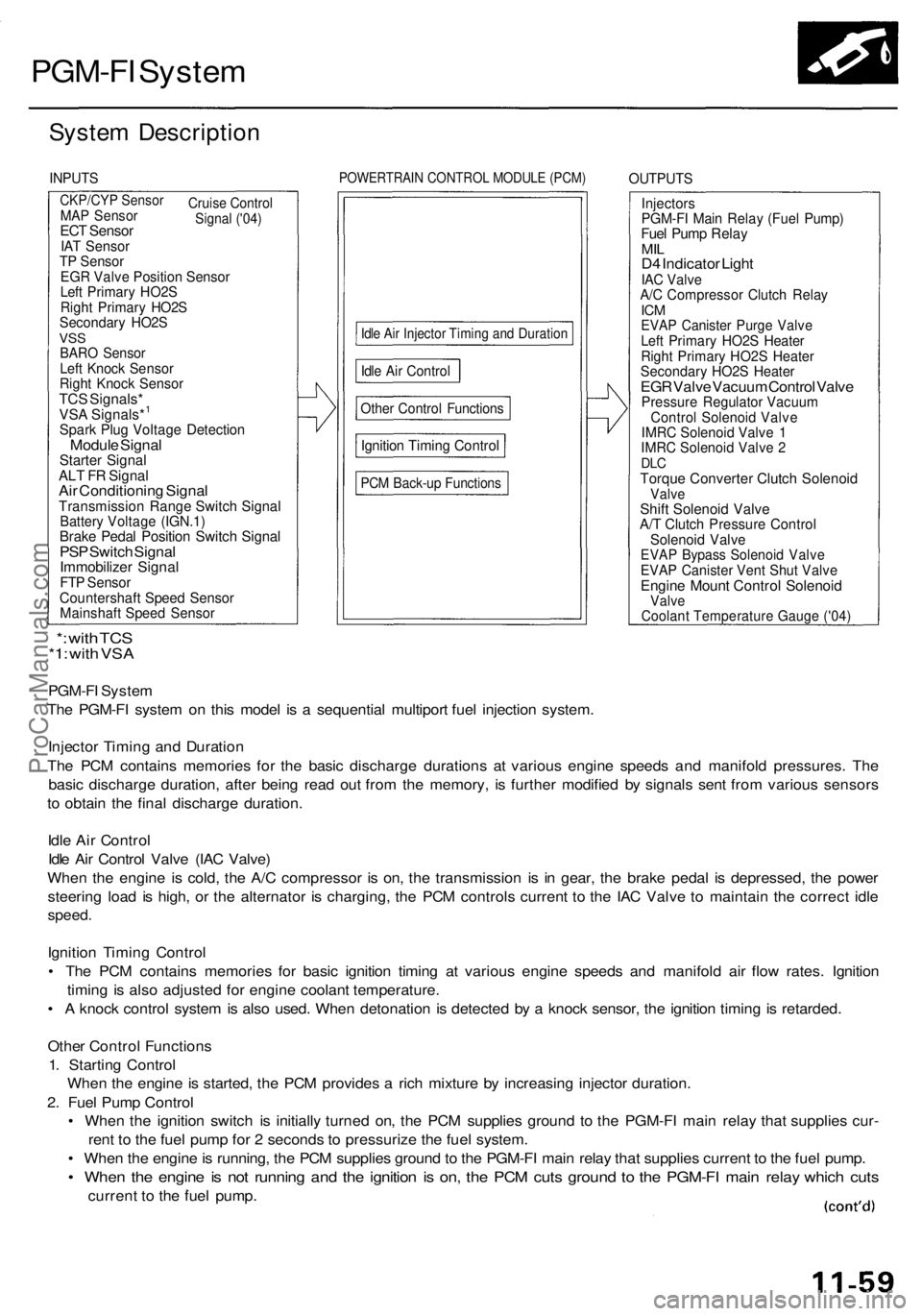

PGM-FI Syste m

System Descriptio n

INPUTSPOWERTRAI N CONTRO L MODUL E (PCM )OUTPUT S

CKP/CYP Senso r

Cruise

Control

Signal ('04)MA P Senso rECT Senso rIAT Senso rTP Senso rEGR Valv e Positio n Senso rLeft Primar y HO2 SRight Primar y HO2 SSecondar y HO2 SVSSBAR O Senso rLeft Knoc k Senso rRight Knoc k Senso rTCS Signals *VSA Signals*1

Spar k Plu g Voltag e Detectio nModule Signa lStarte r Signa lALT F R Signa lAir Conditionin g Signa lTransmissio n Rang e Switc h Signa lBattery Voltag e (IGN.1 )Brake Peda l Positio n Switc h Signa lPSP Switc h Signa lImmobilize r Signa lFTP Senso rCountershaf t Spee d Senso rMainshaf t Spee d Senso r

Idle Ai r Injecto r Timin g an d Duratio n

Other Contro l Function s

Ignition Timin g Contro l

PCM Back-u p Function s

InjectorsPGM-FI Mai n Rela y (Fue l Pump )Fuel Pum p Rela yMILD4 Indicato r Ligh tIAC Valv eA/C Compresso r Clutc h Rela yICMEVA P Caniste r Purg e Valv eLeft Primar y HO2 S Heate rRight Primar y HO2 S Heate rSecondar y HO2 S Heate rEGR Valv e Vacuu m Contro l Valv ePressur e Regulato r Vacuu mControl Solenoi d Valv eIMRC Solenoi d Valv e 1IMR C Solenoi d Valv e 2DL CTorqu e Converte r Clutc h Solenoi dValveShift Solenoi d Valv eA/T Clutc h Pressur e Contro lSolenoid Valv eEVAP Bypas s Solenoi d Valv eEVAP Caniste r Ven t Shu t Valv eEngin e Moun t Contro l Solenoi dValve

PGM-F I Syste m

Th e PGM-F I syste m o n thi s mode l i s a sequentia l multipor t fue l injectio n system .

Injecto r Timin g an d Duratio n

Th e PC M contain s memorie s fo r th e basi c discharg e duration s a t variou s engin e speed s an d manifol d pressures . Th e

basi c discharg e duration , afte r bein g rea d ou t fro m th e memory , i s furthe r modifie d b y signal s sen t fro m variou s sensor s

t o obtai n th e fina l discharg e duration .

Idl e Ai r Contro l

Idl e Ai r Contro l Valv e (IA C Valve )

Whe n th e engin e i s cold , th e A/ C compresso r i s on , th e transmissio n i s i n gear , th e brak e peda l i s depressed , th e powe r

steerin g loa d i s high , o r th e alternato r i s charging , th e PC M control s curren t t o th e IA C Valv e t o maintai n th e correc t idl e

speed .

Ignition Timin g Contro l

• Th e PC M contain s memorie s fo r basi c ignitio n timin g a t variou s engin e speed s an d manifol d ai r flo w rates . Ignitio n

timin g i s als o adjuste d fo r engin e coolan t temperature .

• A knoc k contro l syste m is als o used . Whe n detonatio n i s detecte d b y a knoc k sensor , th e ignitio n timin g is retarded .

Othe r Contro l Function s

1 . Startin g Contro l

Whe n th e engin e is started , th e PC M provide s a ric h mixtur e b y increasin g injecto r duration .

2 . Fue l Pum p Contro l

• Whe n th e ignitio n switc h i s initiall y turne d on , th e PC M supplie s groun d t o th e PGM-F I mai n rela y tha t supplie s cur -

ren t t o th e fue l pum p fo r 2 second s t o pressuriz e th e fue l system .

• Whe n th e engin e is running , th e PC M supplie s groun d to th e PGM-F I mai n rela y tha t supplie s current to th e fue l pump .

• Whe n th e engin e is no t runnin g an d th e ignitio n i s on , th e PC M cut s groun d t o th e PGM-F I mai n rela y whic h cut s

curren t t o th e fue l pump .

*: wit h TC S*1: wit h VS A

Idle Ai r Contro l

Coolant Temperature Gauge ('04)

ProCarManuals.com

Page 560 of 1954

How to Set Readiness Codes

Catalytic Converter

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine. Hold it at 3,000 rpm with no load

(in Park or neutral) until the radiator fan comes on.

3. Drive for about 10 minutes without stopping on a

highway or freeway. Your speed can vary.

4. '96 - 97 models:

With the transmission in D4 position, drive at a

steady speed between 33 - 37 mph (53 - 59 km/h)

for 30 seconds.

'98 - 01 models:

With the A/T in D4 position, drive at a steady speed

between 50 - 62 mph (80 - 100 km/h) for 30 sec-

onds.

5. Do step 4 three times. Between each repetition,

close the throttle completely for 1 - 2 seconds. If the

engine is stopped during this part of the procedure,

go to step 3 and do the procedure again.

6. Check for the readiness code with the scan tool.

EGR Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

Altitude below 2,400 m (7,874 ft.).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Drive at a steady speed with the transmission in D4

position, between 50 - 62 mph (80 - 100 km/h) for

more than 10 seconds.

4. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 3 and do the procedure

again.

5. Check for the readiness code with the scan tool.

EVAP Leak Monitor

NOTE:

• When the battery negative cable is disconnected, all

readiness codes are cleared.

• If the engine is stopped while doing the procedure

between stops 6 and 16, do this procedure from step

1 again.

1. Make sure the gasoline level is 60 - 90% of fuel tank

capacity (not full).

2. Turn the ignition switch OFF.

3. Let the vehicle sit more than 8 hours.

4. '96 - 97 models:

Make sure the outside temperature is 32 - 95°F (0 -

35°C).

'98 - 01 models:

Make sure the outside temperature is 20 - 95°F (-7 -

35°C).

5. Connect the scan tool to the Data Link Connector

(DLC).

6. Start the engine and drive for about 15 minutes.

7. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

8. Stop the vehicle (do not stop engine).

9. Repeat steps 7 and 8 two more times.

10. Check for the readiness code with the scan tool. If

the readiness code does not set, go to step 11.

11. When ambient temperature is less than 32°F (0°C),

hold the engine at 3,000 rpm with no load (in Park

or neutral) until the radiator fan comes on.

12. When ambient temperature is more than 86°F

(30°C), remove the fuel fill cap, then install the fuel

fill cap.

13. After step 12, drive for about 20 minutes on a free-

way.

14. '96 - 97 models:

Keep the vehicle at a steady speed between 50 - 62

mph (80 - 100 km/h), without moving the accelera-

tor pedal, for about 1 minute.

'98 - 01 models:

Keep the vehicle at a steady speed between 50 - 70

mph (80 - 114 km/h), without moving the accelera-

tor pedal, for about 1 minute.

15. Stop the vehicle (do not stop the engine).

16. Repeat steps 14 and 15 two more times.

17. Check for the readiness code with the scan tool.ProCarManuals.com

Page 561 of 1954

PGM-FI System

How to Set Readiness Codes (cont'd)

HO2S Monitor

NOTE:

• Do not turn the ignition switch OFF.

• When the battery negative cable is disconnected, all

readiness codes are cleared.

Required condition ('96 - 97 models):

• Ambient temperature between 32 - 95°F (0 - 35°C).

• Altitude below 2,400 m (7,874 ft.).

Required condition ('98 - 01 models):

Ambient temperature between 20 - 95°F (-7 - 35°C).

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and hold it at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on.

3. Let the engine idle for 5 seconds.

4. Drive at a steady speed between 50 - 62 mph (80 -

100 km/h) for about 2 minutes.

5. With the A/T in D4 position, decelerate from 62 mph

(100 km/h) by completely releasing the throttle for

at least 5 seconds. If the engine is stopped during

this procedure, go to step 4 and do the procedure

again.

6. Check for the readiness code with the scan tool.

HO2S Heater Monitor

NOTE: When the battery negative cable is disconnected,

all readiness codes are cleared.

1. Connect the scan tool to the Data Link Connector

(DLC).

2. Start the engine, and let the engine idle for 10 min-

utes.

3. Check for the readiness code with the scan tool.ProCarManuals.com

Page 617 of 1954

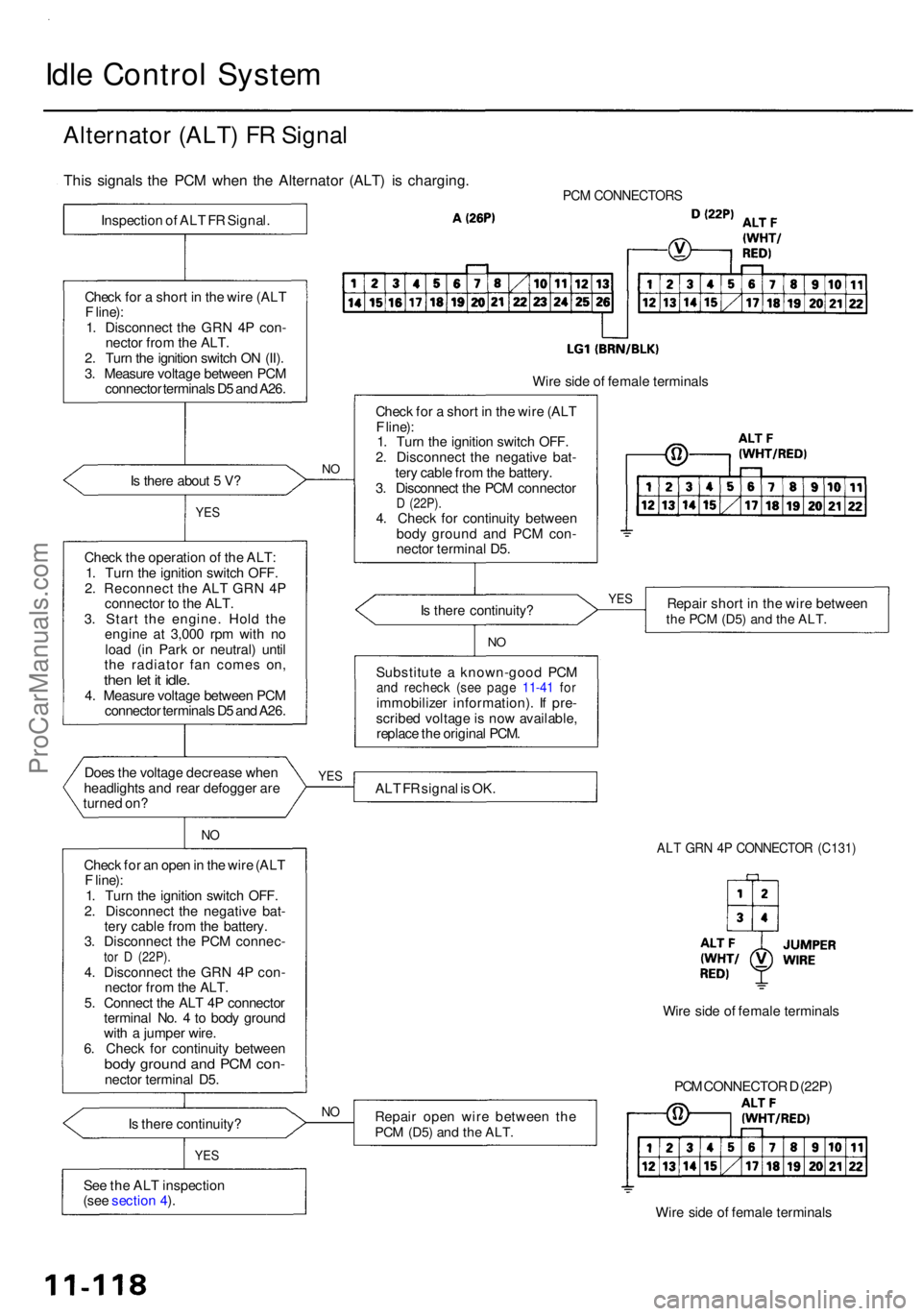

Idle Contro l Syste m

Alternato r (ALT ) F R Signa l

PCM CONNECTOR S

Is ther e abou t 5 V ?

YE S

Chec k th e operatio n o f th e ALT :

1 . Tur n th e ignitio n switc h OFF .

2 . Reconnec t th e AL T GR N 4 P

connecto r t o th e ALT .

3 . Star t th e engine . Hol d th e

engin e a t 3,00 0 rp m wit h n o

loa d (i n Par k o r neutral ) unti l

th e radiato r fa n come s on ,

then le t i t idle .4. Measur e voltag e betwee n PC M

connecto r terminal s D 5 an d A26 .

Doe s th e voltag e decreas e whe n

headlight s an d rea r defogge r ar e

turne d on ?

NO

Chec k fo r a n ope n in th e wir e (AL T

F line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e PC M connec -

tor D (22P) .4. Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

5 . Connec t th e AL T 4 P connecto r

termina l No . 4 to bod y groun d

wit h a jumpe r wire .

6 . Chec k fo r continuit y betwee n

body groun d an d PC M con -necto r termina l D5 .

I s ther e continuity ?

YES

See th e AL T inspectio n

(see sectio n 4 ).

N O

Wir e sid e o f femal e terminal s

Chec k fo r a shor t i n th e wir e (AL T

F line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e negativ e bat -

ter y cabl e fro m th e battery .

3 . Disconnec t th e PC M connecto r

D (22P) .4. Chec k fo r continuit y betwee n

bod y groun d an d PC M con -

necto r termina l D5 .

I s ther e continuity ? Repai

r shor t i n th e wir e betwee n

the PC M (D5 ) and th e ALT .

NO

Substitut e a known-goo d PC Mand rechec k (se e pag e 11-4 1 fo rimmobilize r information) . I f pre -

scribe d voltag e is no w available ,

replac e th e origina l PCM .

AL T F R signa l i s OK .

ALT GR N 4 P CONNECTO R (C131 )

Repair ope n wir e betwee n th ePCM (D5 ) and th e ALT .

PCM CONNECTO R D (22P )

Wir e sid e o f femal e terminal s

NO

Wir e sid e o f femal e terminal s

YES YE

S

This signal s th e PC M whe n th e Alternato r (ALT ) i s charging .

Inspection o f AL T F R Signal .

Chec k fo r a shor t i n th e wir e (AL T

F line) :

1 . Disconnec t th e GR N 4 P con -

necto r fro m th e ALT .

2 . Tur n th e ignitio n switc h O N (II) .

3 . Measur e voltag e betwee n PC M

connecto r terminal s D 5 an d A26 .

ProCarManuals.com

Page 625 of 1954

PCM Memory Setting

NOTE: The PCM reset procedure and disconnecting the

battery or the BACK UP RADIO (7.5 A) fuse cancels the

PCM memory for idle control. The following procedure

is needed after the PCM reset procedure and reconnect-

ing the battery or the BACK UP RADIO (7.5 A) fuse.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on.

2. Let the engine idle for approx. 5 minutes under the

following conditions:

• Transmission in Park or neutral

• A/C switch OFF

• Headlights OFF

• Rear defogger OFFProCarManuals.com

Page 632 of 1954

Fuel Suppl y Syste m

System Descriptio n

The fue l suppl y syste m consist s o f a fue l tank , in-tan k

high-pressur e fue l pump , PGM-F I mai n relay , fue l filter ,

fue l pressur e regulator , fue l pressur e regulato r contro l

solenoi d valve , injectors , an d fue l deliver y an d retur n

lines . Thi s syste m deliver s pressure-regulate d fue l t o th e

injector s an d cut s th e fue l deliver y whe n th e engin e i s

no t running .

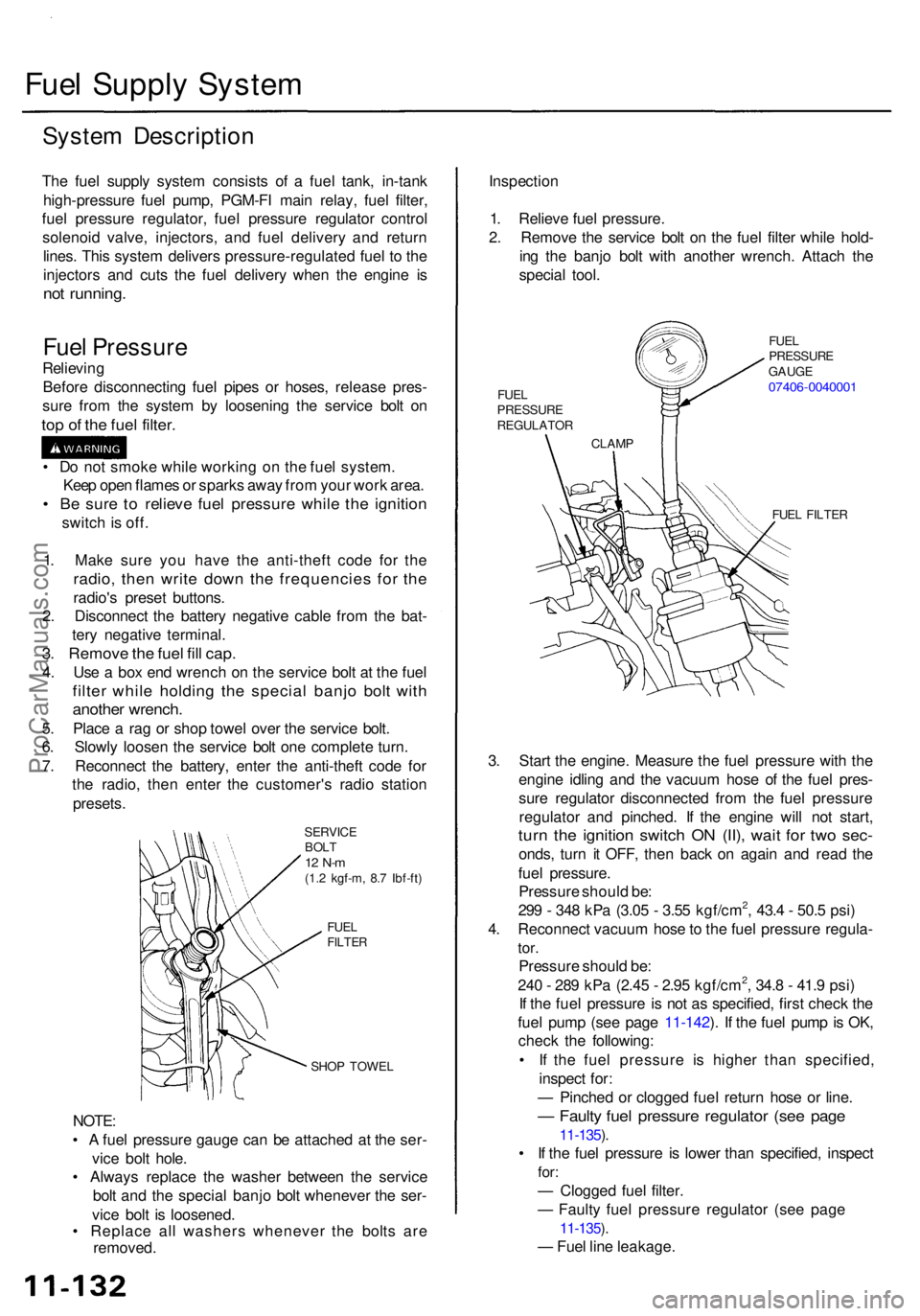

Fuel Pressur e

Relieving

Befor e disconnectin g fue l pipe s o r hoses , releas e pres -

sur e fro m th e syste m b y loosenin g th e servic e bol t o n

top o f th e fue l filter .

SERVIC E

BOL T

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

FUE L

FILTE R

SHOP TOWE L

NOTE:

• A fue l pressur e gaug e can be attache d a t th e ser -

vic e bol t hole .

• Alway s replac e th e washe r betwee n th e servic e

bol t an d th e specia l banj o bol t wheneve r th e ser -

vic e bol t i s loosened .

• Replac e al l washer s wheneve r th e bolt s ar e

removed . Inspectio

n

1 . Reliev e fue l pressure .

2 . Remov e th e servic e bol t o n th e fue l filte r whil e hold -

in g th e banj o bol t wit h anothe r wrench . Attac h th e

specia l tool .

FUEL FILTE R

3. Star t th e engine . Measur e th e fue l pressur e wit h th e

engin e idlin g an d th e vacuu m hos e o f th e fue l pres -

sur e regulato r disconnecte d fro m th e fue l pressur e

regulato r an d pinched . I f th e engin e wil l no t start ,

turn th e ignitio n switc h O N (II) , wai t fo r tw o sec -

onds , tur n i t OFF , the n bac k o n agai n an d rea d th e

fue l pressure .

Pressur e shoul d be :

29 9 - 34 8 kP a (3.0 5 - 3.5 5 kgf/cm

2, 43. 4 - 50. 5 psi )

4 . Reconnec t vacuu m hos e to th e fue l pressur e regula -

tor.

Pressur e shoul d be :

24 0 - 28 9 kP a (2.4 5 - 2.9 5 kgf/cm2, 34. 8 - 41. 9 psi )

I f th e fue l pressur e i s no t a s specified , firs t chec k th e

fue l pum p (se e pag e 11-142 ). I f th e fue l pum p is OK ,

chec k th e following :

• I f th e fue l pressur e i s highe r tha n specified ,

inspec t for :

— Pinche d o r clogge d fue l retur n hos e o r line .

— Fault y fue l pressur e regulato r (se e pag e

11-135 ).

• I f th e fue l pressur e i s lowe r tha n specified , inspec t

for:

— Clogge d fue l filter .

— Fault y fue l pressur e regulato r (se e pag e

11-135 ).

— Fue l lin e leakage .

1

. Mak e sur e yo u hav e th e anti-thef t cod e fo r th e

radio , the n writ e dow n th e frequencie s fo r th e

radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e cabl e fro m th e bat -

ter y negativ e terminal .

3. Remov e th e fue l fil l cap .

4. Us e a bo x en d wrenc h o n th e servic e bol t a t th e fue l

filte r whil e holdin g th e specia l banj o bol t wit h

anothe r wrench .

5. Plac e a ra g o r sho p towe l ove r th e servic e bolt .

6 . Slowl y loose n th e servic e bol t on e complet e turn .

7 . Reconnec t th e battery , ente r th e anti-thef t cod e fo r

th e radio , the n ente r th e customer' s radi o statio n

presets .

•

D o no t smok e whil e workin g o n th e fue l system .

Kee p ope n flame s o r spark s awa y fro m you r wor k area .

• B e sur e t o reliev e fue l pressur e whil e th e ignitio n

switch is off .

CLAM P

FUE

L

PRESSUR E

REGULATO R FUE

L

PRESSUR E

GAUG E

07406-004000 1

ProCarManuals.com

Page 817 of 1954

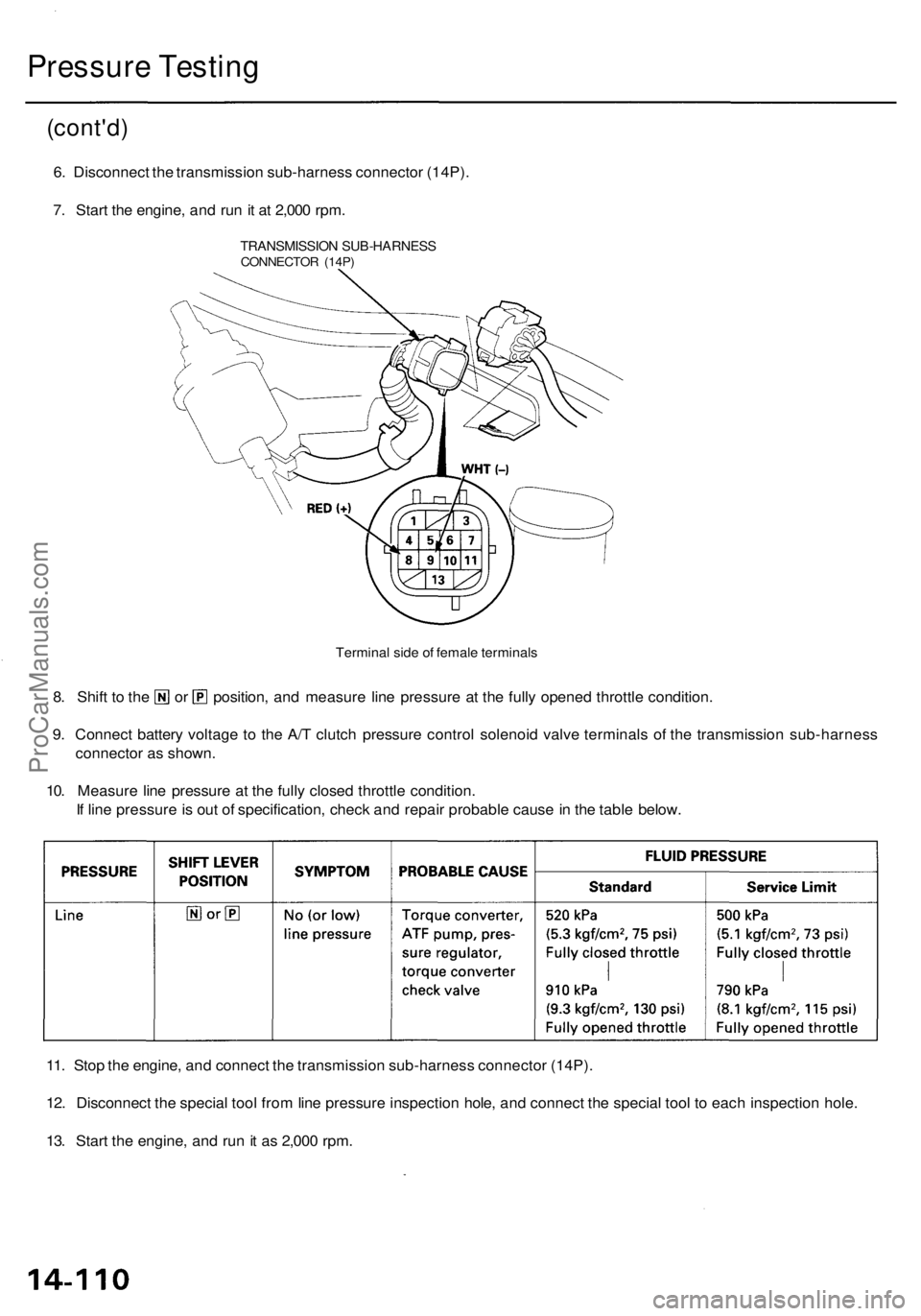

Pressure Testing

(cont'd)

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

Terminal side of female terminals

8. Shift to the or position, and measure line pressure at the fully opened throttle condition.

9. Connect battery voltage to the A/T clutch pressure control solenoid valve terminals of the transmission sub-harness

connector as shown.

10. Measure line pressure at the fully closed throttle condition.

If line pressure is out of specification, check and repair probable cause in the table below.

11. Stop the engine, and connect the transmission sub-harness connector (14P).

12. Disconnect the special tool from line pressure inspection hole, and connect the special tool to each inspection hole.

13. Start the engine, and run it as 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)ProCarManuals.com

Page 818 of 1954

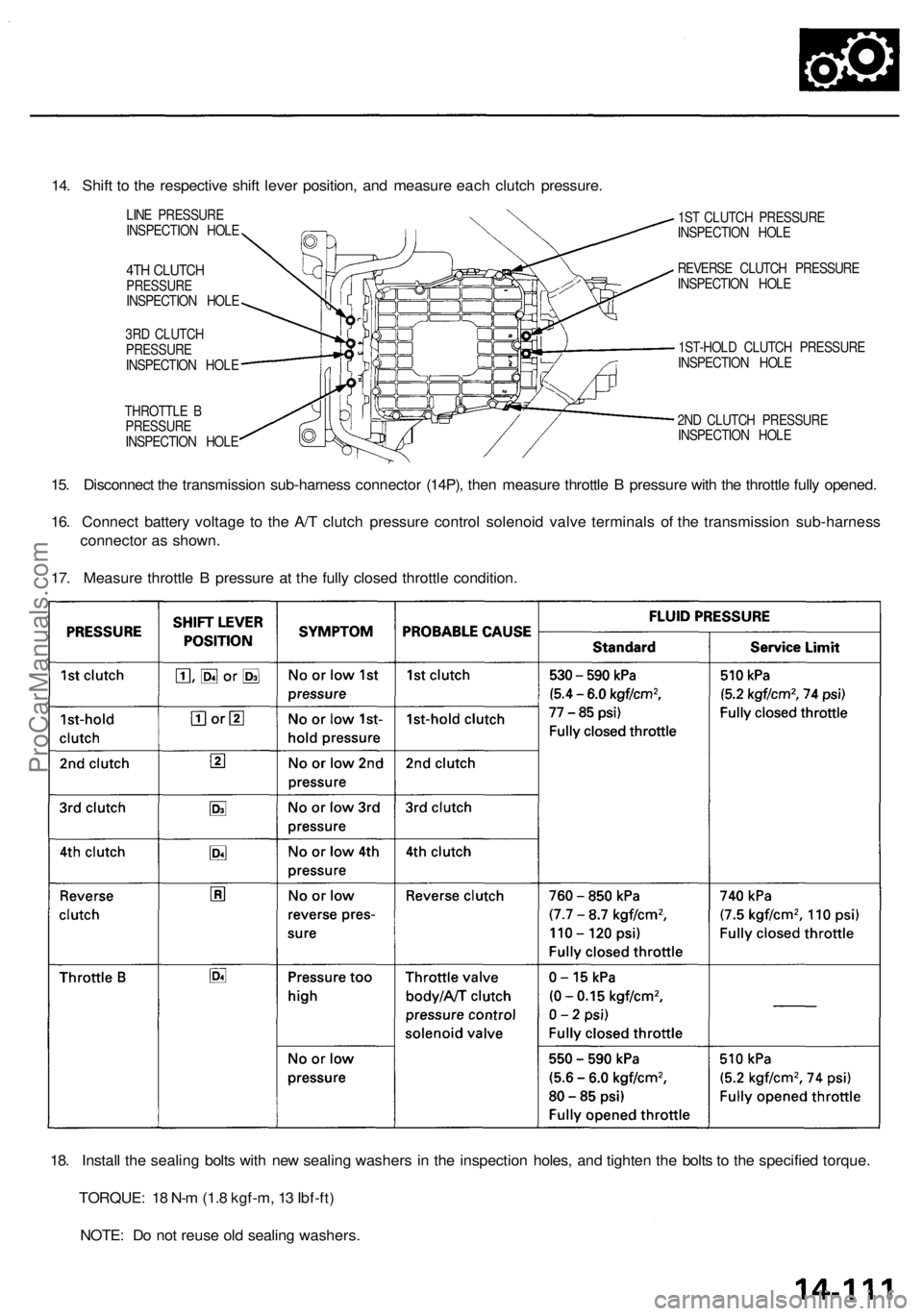

14. Shift to the respective shift lever position, and measure each clutch pressure.

4TH CLUTCH

PRESSURE

INSPECTION HOLE

3RD CLUTCH

PRESSURE

INSPECTION HOLE

THROTTLE B

PRESSURE

INSPECTION HOLE

1ST CLUTCH PRESSURE

INSPECTION HOLE

REVERSE CLUTCH PRESSURE

INSPECTION HOLE

1ST-HOLD CLUTCH PRESSURE

INSPECTION HOLE

2ND CLUTCH PRESSURE

INSPECTION HOLE

15. Disconnect the transmission sub-harness connector (14P), then measure throttle B pressure with the throttle fully opened.

16. Connect battery voltage to the A/T clutch pressure control solenoid valve terminals of the transmission sub-harness

connector as shown.

17. Measure throttle B pressure at the fully closed throttle condition.

18. Install the sealing bolts with new sealing washers in the inspection holes, and tighten the bolts to the specified torque.

TORQUE: 18 N-m (1.8 kgf-m, 13 Ibf-ft)

NOTE: Do not reuse old sealing washers.

LINE PRESSURE

INSPECTION HOLEProCarManuals.com

Page 821 of 1954

Throttle Valv e Body/A/ T Clutc h Pressur e Contro l

Solenoi d Valv e

Test

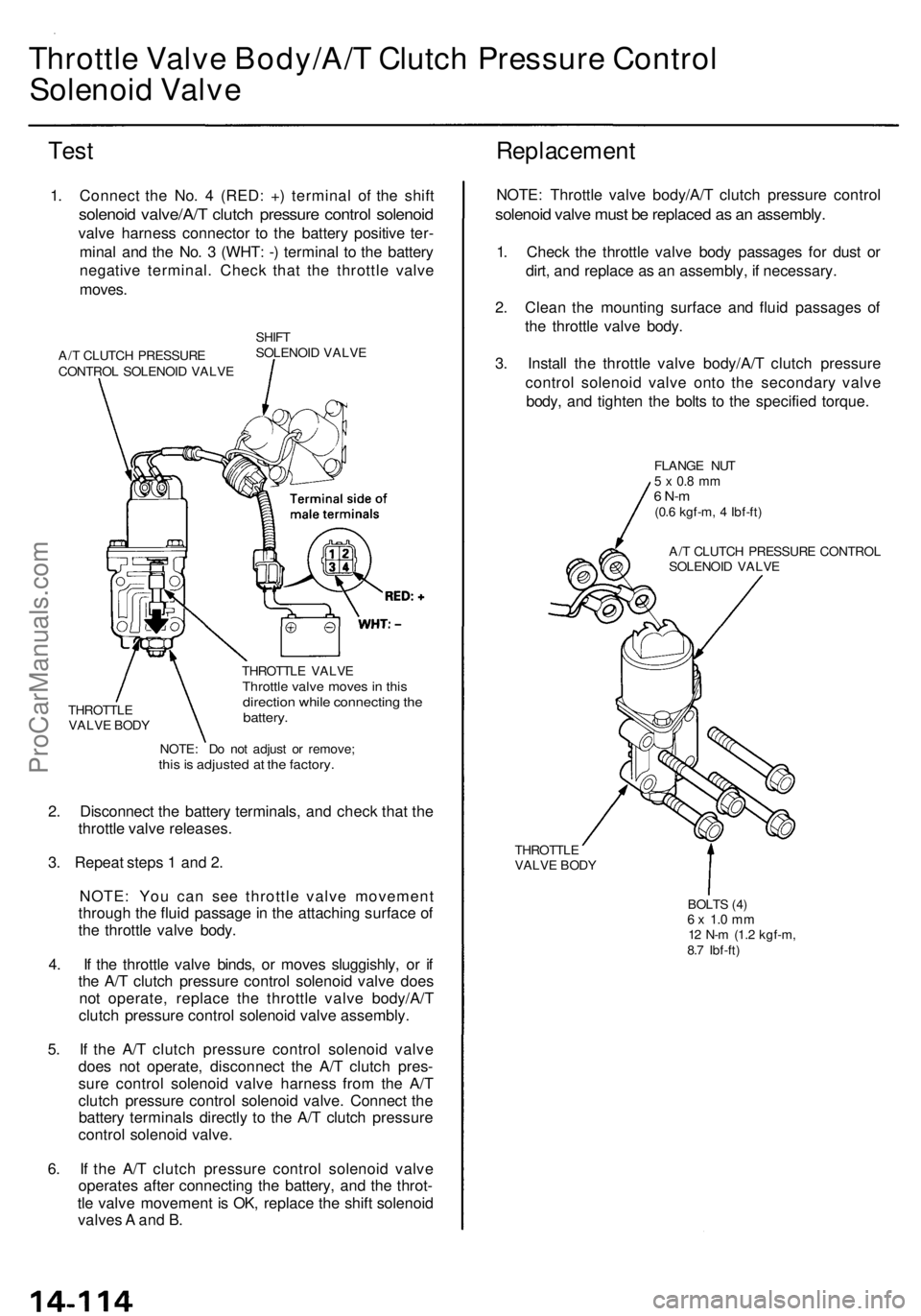

1. Connec t th e No . 4 (RED : + ) termina l of the shif t

solenoi d valve/A/ T clutc h pressur e contro l solenoi d

valve harnes s connecto r t o th e batter y positiv e ter -

mina l an d th e No . 3 (WHT : - ) termina l t o th e batter y

negativ e terminal . Chec k tha t th e throttl e valv e

moves .

Replacemen t

A/T CLUTC H PRESSUR E

CONTRO L SOLENOI D VALV ESHIF

T

SOLENOI D VALV E

THROTTL E

VALV E BOD Y THROTTL

E VALV E

Throttle valv e move s in thi sdirectio n whil e connectin g th ebattery .

NOTE: D o no t adjus t o r remove ;this is adjuste d a t th e factory .

2. Disconnec t th e batter y terminals , an d chec k tha t th e

throttl e valv e releases .

3 . Repea t step s 1 an d 2 .

NOTE : Yo u ca n se e throttl e valv e movemen t

throug h th e flui d passag e in th e attachin g surfac e o f

th e throttl e valv e body .

4 . I f th e throttl e valv e binds , o r move s sluggishly , o r i f

th e A/ T clutc h pressur e contro l solenoi d valv e doe s

no t operate , replac e th e throttl e valv e body/A/ T

clutc h pressur e contro l solenoi d valv e assembly .

5 . I f th e A/ T clutc h pressur e contro l solenoi d valv e

doe s no t operate , disconnec t th e A/ T clutc h pres -

sur e contro l solenoi d valv e harnes s fro m th e A/ T

clutc h pressur e contro l solenoi d valve . Connec t th e

batter y terminal s directl y t o th e A/ T clutc h pressur e

contro l solenoi d valve .

6 . I f th e A/ T clutc h pressur e contro l solenoi d valv e

operate s afte r connectin g th e battery , an d th e throt -

tl e valv e movemen t i s OK , replac e th e shif t solenoi d

valve s A an d B . NOTE

: Throttl e valv e body/A/ T clutc h pressur e contro l

solenoid valv e mus t b e replace d a s a n assembly .

1. Chec k th e throttl e valv e bod y passage s fo r dus t o r

dirt , an d replac e a s a n assembly , i f necessary .

2 . Clea n th e mountin g surfac e an d flui d passage s o f

th e throttl e valv e body .

3 . Instal l th e throttl e valv e body/A/ T clutc h pressur e

contro l solenoi d valv e ont o th e secondar y valv e

body , an d tighte n th e bolt s t o th e specifie d torque .

FLANG E NU T5 x 0. 8 m m6 N- m(0.6 kgf-m , 4 Ibf-ft )

THROTTL E

VALV E BOD Y

BOLTS (4 )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

A/

T CLUTC H PRESSUR E CONTRO L

SOLENOI D VALV E

ProCarManuals.com

Page 822 of 1954

Shift Solenoid Valves A and B

Test

Replacement

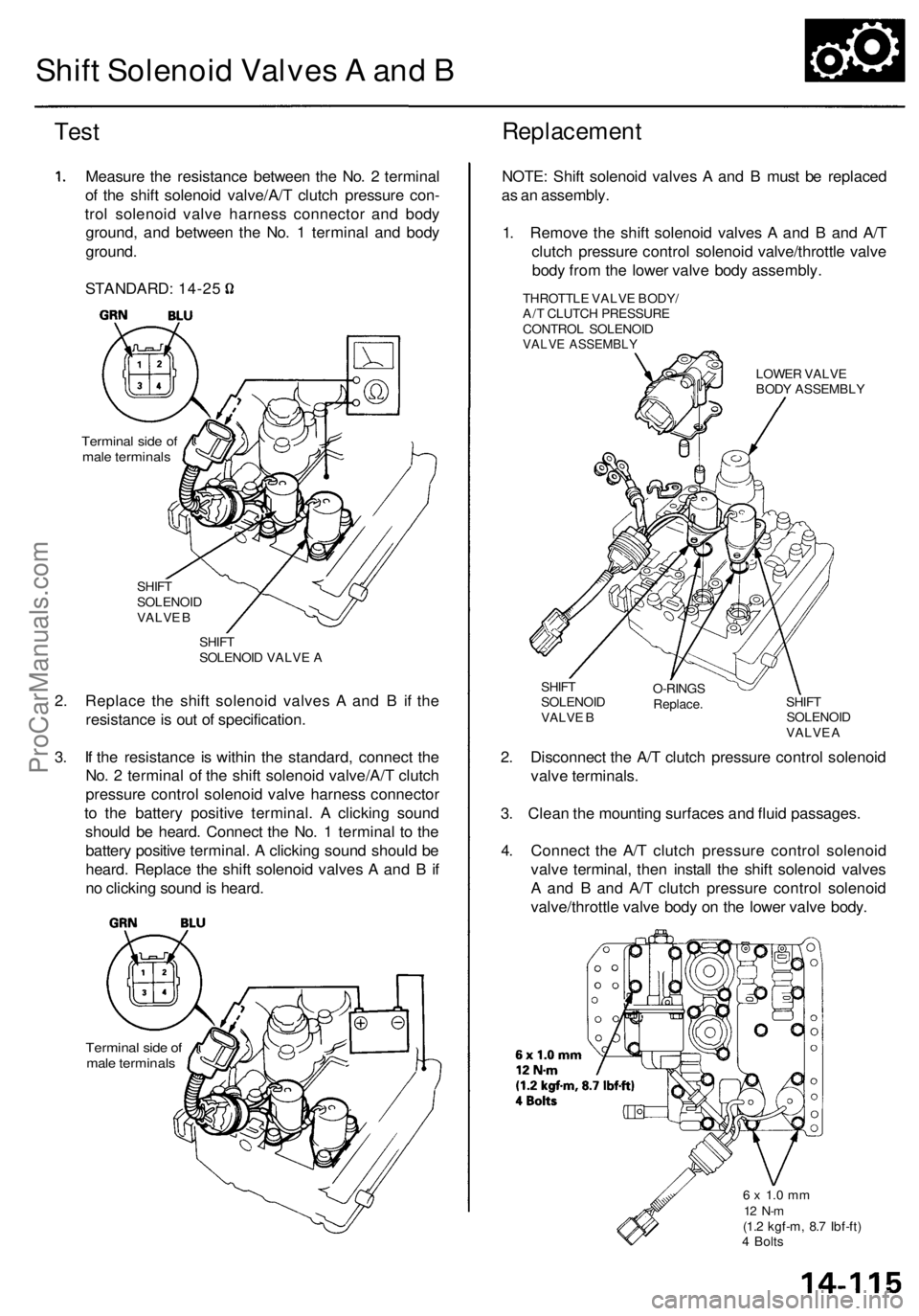

Measure the resistance between the No. 2 terminal

of the shift solenoid valve/A/T clutch pressure con-

trol solenoid valve harness connector and body

ground, and between the No. 1 terminal and body

ground.

Terminal side of

male terminals

SHIFT

SOLENOID

VALVE B

SHIFT

SOLENOID VALVE A

2. Replace the shift solenoid valves A and B if the

resistance is out of specification.

3. If the resistance is within the standard, connect the

No. 2 terminal of the shift solenoid valve/A/T clutch

pressure control solenoid valve harness connector

to the battery positive terminal. A clicking sound

should be heard. Connect the No. 1 terminal to the

battery positive terminal. A clicking sound should be

heard. Replace the shift solenoid valves A and B if

no clicking sound is heard.

Terminal side of

male terminals

NOTE: Shift solenoid valves A and B must be replaced

as an assembly.

1. Remove the shift solenoid valves A and B and A/T

clutch pressure control solenoid valve/throttle valve

body from the lower valve body assembly.

THROTTLE VALVE BODY/

A/T CLUTCH PRESSURE

CONTROL SOLENOID

VALVE ASSEMBLY

LOWER VALVE

BODY ASSEMBLY

SHIFT

SOLENOID

VALVE B

O-RINGS

Replace.

SHIFT

SOLENOID

VALVE A

2. Disconnect the A/T clutch pressure control solenoid

valve terminals.

3. Clean the mounting surfaces and fluid passages.

4. Connect the A/T clutch pressure control solenoid

valve terminal, then install the shift solenoid valves

A and B and A/T clutch pressure control solenoid

valve/throttle valve body on the lower valve body.

6 x 1.0 mm

12 N-m

(1.2 kgf-m, 8.7 Ibf-ft)

4 Bolts

STANDARD: 14-25ProCarManuals.com