check engine ACURA RL KA9 1996 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 1239 of 1954

Troubleshooting Precaution s

System Indicator s

If th e syste m is OK , th e AB S indicato r goe s of f onc e afte r turnin g th e ignitio n switc h O N (II ) withou t startin g th e engine ,

an d the n com e o n agai n an d g o of f severa l second s late r afte r startin g th e engine . Thi s occur s becaus e th e VS A contro l

uni t i s turne d o n b y th e IG 2 powe r source .

Th e AB S indicato r o r VS A syste m indicato r come s o n whe n th e VS A contro l uni t detect s a proble m in th e system .

Th e AB S indicato r o r VS A syste m indicato r wil l als o com e o n unde r thes e conditions , eve n thoug h th e syste m is oper -

atin g properly :

— Th e vehicl e goe s int o a spi n

— Th e AB S continue s t o operat e fo r a lon g tim e

— Th e vehicl e is subjecte d to a n electrica l signa l disturbanc e

I f ther e is a faul t i n th e PGM-F I system , onl y th e VS A syste m indicato r come s on .

Th e VS A Activatio n Indicato r wil l flas h whe n onl y th e driv e wheel s rotat e o r on e o f th e driv e wheel s is stuck . Whe n thi s

occurs , th e AB S indicato r an d VS A syste m indicato r d o no t com e on .

T o determin e th e actua l caus e o f th e problem , questio n th e custome r abou t th e problem , takin g thes e condition s int o con -

sideration .

Whe n a proble m is detecte d an d th e AB S o r VS A indicato r come s on , ther e ar e case s whe n th e indicato r stay s o n unti l

th e ignitio n switc h i s turne d OFF , an d case s whe n th e indicato r goe s of f automaticall y whe n th e syste m return s t o nor -

mal . Fo r DT C 6 1 an d 62 , th e indicato r goe s of f automaticall y whe n th e syste m return s t o normal . Fo r al l othe r codes ,

th e indicato r stay s o n unti l th e ignitio n switc h is turne d OFF .

Fo r DTC s 12 , 14 , 16 , 18 , 51 , 52 , 53 , 66 , 6 8 an d 84 , th e AB S indicato r goe s of f whe n th e vehicl e is drive n agai n an d th e

syste m is O K afte r th e ignitio n switc h is turne d fro m OF F to O N (II) . However , i f th e DT C is cleared , th e CP U reset s an d

th e indicato r goe s of f righ t afte r th e engin e is starte d if th e syste m is OK .

Th e AB S is no t operationa l whe n th e AB S indicato r i s ON ; th e VS A is no t operationa l whe n th e VS A indicato r i s ON .

Whe n th e VS A indicato r an d MI L ar e bot h ON , troubleshoo t th e PGM-F I syste m first .

Diagnosti c Troubl e Cod e (DTC )

Th e memor y ca n hol d an y numbe r o f DTCs . However , whe n th e sam e DT C is detecte d mor e tha n once , th e mor e recen t

DT C is writte n ove r th e earlie r one . Therefore , whe n th e sam e proble m is detecte d repeatedly , i t i s memorize d a s a sin -

gle DTC .

The DTC s ar e indicate d in ascendin g numbe r order , no t i n th e orde r the y occur .

Th e DTC s ar e memorize d in th e EEPRO M (non-volatil e memory) . Therefore , th e memorize d DTC s canno t b e cancele d

b y disconnectin g th e battery . Perfor m th e specifie d procedure s to clea r th e DTCs .

Self-diagnosi s

Self-diagnosis can be classifie d int o tw o categories :

— Initia l diagnosis : Performe d righ t afte r th e engin e start s an d unti l th e AB S o r VS A indicato r goe s off .

— Regula r diagnosis : Performe d righ t afte r th e initia l diagnosi s unti l th e ignitio n switc h is turne d OFF .

When a proble m is detecte d b y self-diagnosis , th e VS A contro l uni t shift s to fail-saf e mode .

Kickbac k

The pum p moto r operate s whe n th e AB S is functioning , an d th e flui d in th e reservoi r i s force d ou t t o th e maste r cylinder ,

causing kickbac k a t th e brak e pedal .

Pum p Moto r

Th e pum p moto r operate s whe n th e AB S is functioning .

The VS A contro l uni t check s th e pum p moto r operatio n durin g initia l diagnosi s whe n th e vehicl e is started .

You ma y hea r th e moto r operat e a t thi s time , bu t i t i s normal .

Brak e Flui d Replacement/Ai r Bleedin g

Brak e flui d replacemen t an d ai r bleedin g procedure s ar e identica l t o th e procedure s us e o n vehicle s no t equippe d wit h

VSA . T o eas e bleeding , star t wit h th e fron t wheels .

ProCarManuals.com

Page 1256 of 1954

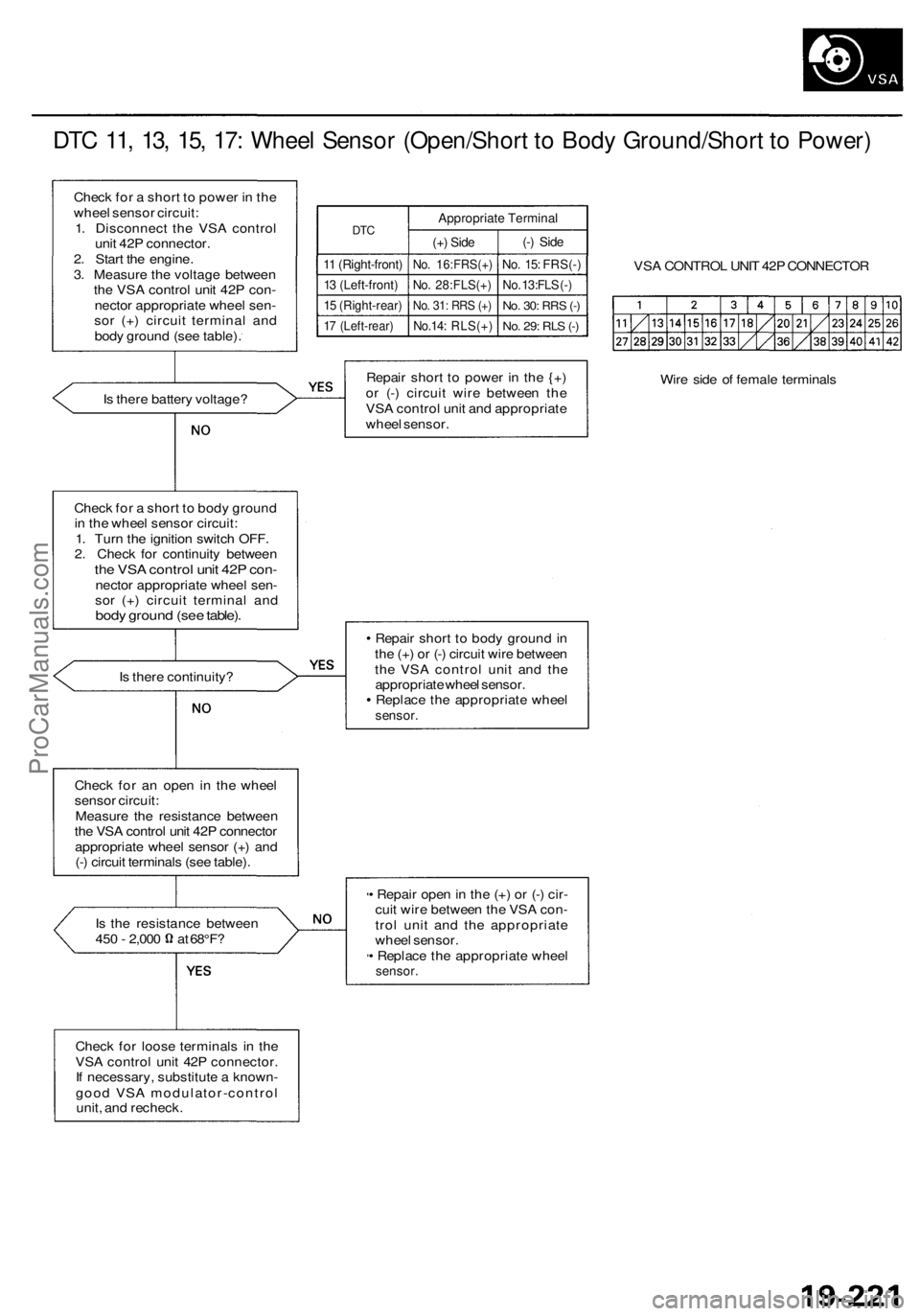

DTC 11, 13, 15, 17: Wheel Sensor (Open/Short to Body Ground/Short to Power)

Check for a short to power in the

wheel sensor circuit:

1. Disconnect the VSA control

unit 42P connector.

2. Start the engine.

3. Measure the voltage between

the VSA control unit 42P con-

nector appropriate wheel sen-

sor (+) circuit terminal and

body ground (see table).

DTC

11 (Right-front)

13 (Left-front)

15 (Right-rear)

17 (Left-rear)

Appropriate Terminal

(+) Side

No. 16:FRS(+)

No. 28:FLS(+)

No. 31: RRS (+)

No.14: RLS(+)

(-) Side

No. 15: FRS(-)

No. 13:FLS (-)

No. 30:

RRS

(-)

No. 29: RLS (-)

VSA CONTROL UNIT 42P CONNECTOR

Is there battery voltage?

Repair short to power in the {+)

or (-) circuit wire between the

VSA control unit and appropriate

wheel sensor.

Wire side of female terminals

Check for a short to body ground

in the wheel sensor circuit:

1. Turn the ignition switch OFF.

2. Check for continuity between

the VSA control unit 42P con-

nector appropriate wheel sen-

sor (+) circuit terminal and

body ground (see table).

Is there continuity?

Repair short to body ground in

the (+) or (-) circuit wire between

the VSA control unit and the

appropriate wheel sensor.

Replace the appropriate wheel

sensor.

Check for an open in the wheel

sensor circuit:

Measure the resistance between

the VSA control unit 42P connector

appropriate wheel sensor (+) and

(-) circuit terminals (see table).

Is the resistance between

450 - 2,000 at 68°F?

• Repair open in the (+) or (-) cir-

cuit wire between the VSA con-

trol unit and the appropriate

wheel sensor.

• Replace the appropriate wheel

sensor.

Check for loose terminals in the

VSA control unit 42P connector.

If necessary, substitute a known-

good VSA modulator-control

unit, and recheck.ProCarManuals.com

Page 1271 of 1954

Troubleshooting

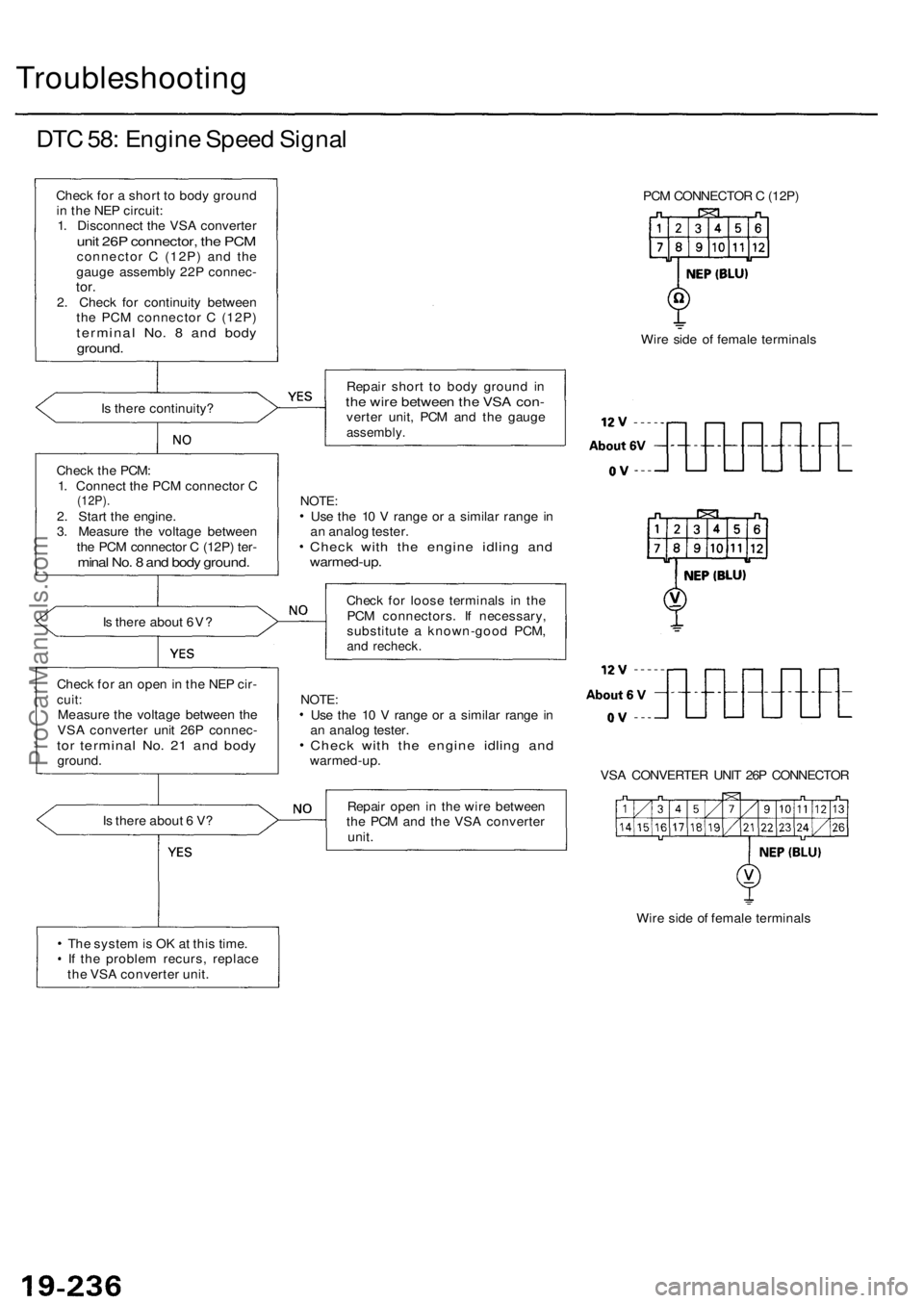

DTC 58: Engine Speed Signal

Check for a short to body ground

in the NEP circuit:

1. Disconnect the VSA converter

unit 26P connector, the PCM

connector C (12P) and the

gauge assembly 22P connec-

tor.

2. Check for continuity between

the PCM connector C (12P)

terminal No. 8 and body

ground.

Is there continuity?

Check the PCM:

1. Connect the PCM connector C

(12P).

2. Start the engine.

3. Measure the voltage between

the PCM connector C (12P) ter-

minal No. 8 and body ground.

Is there about 6V?

Check for an open in the NEP cir-

cuit:

Measure the voltage between the

VSA converter unit 26P connec-

tor terminal No. 21 and body

ground.

Is there about 6 V?

The system is OK at this time.

If the problem recurs, replace

the VSA converter unit.

PCM CONNECTOR C (12P)

Wire side of female terminals

Repair short to body ground in

the wire between the VSA con-

verter unit, PCM and the gauge

assembly.

NOTE:

Use the 10 V range or a similar range in

an analog tester.

Check with the engine idling and

warmed-up.

Check for loose terminals in the

PCM connectors. If necessary,

substitute a known-good PCM,

and recheck.

NOTE:

Use the 10 V range or a similar range in

an analog tester.

Check with the engine idling and

warmed-up.

VSA CONVERTER UNIT 26P CONNECTOR

Repair open in the wire between

the PCM and the VSA converter

unit.

Wire side of female terminalsProCarManuals.com

Page 1283 of 1954

Troubleshooting

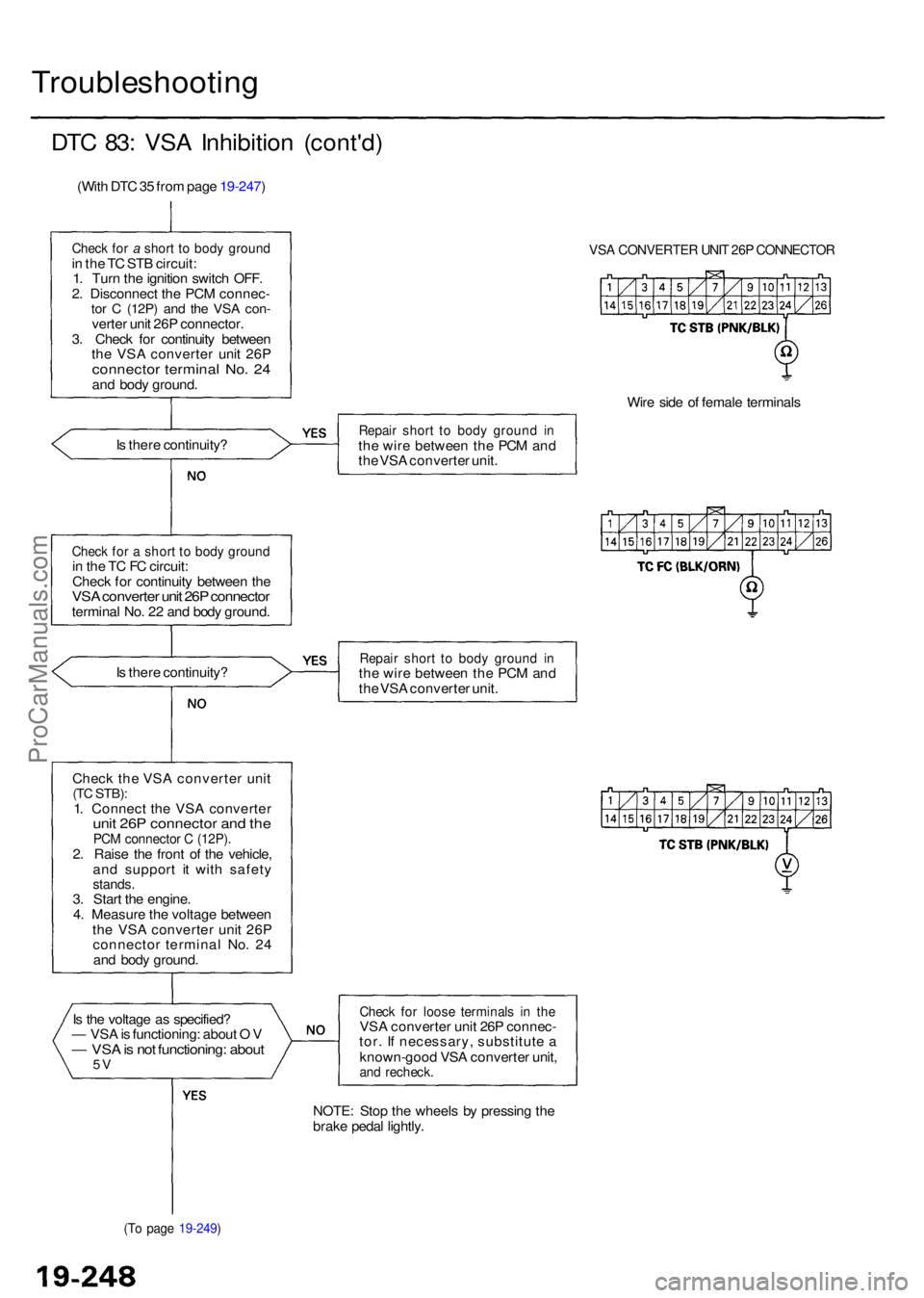

DTC 83 : VS A Inhibitio n (cont'd )

(With DT C 35 fro m pag e 19-247 )

Check fo r a shor t t o bod y groun din th e T C ST B circuit :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e PC M connec -

tor C (12P ) and th e VS A con -verte r uni t 26 P connector .

3 . Chec k fo r continuit y betwee n

th e VS A converte r uni t 26 P

connecto r termina l No . 2 4an d bod y ground .

I s ther e continuity ?

Check fo r a shor t t o bod y groun din th e T C F C circuit :

Chec k fo r continuit y betwee n th e

VS A converte r uni t 26 P connecto rterminal No . 2 2 an d bod y ground .

I s ther e continuity ?

Chec k the VSA converte r uni t

(TC STB) :1. Connec t th e VS A converte runit 26 P connecto r an d th ePC M connecto r C (12P) .2. Rais e th e fron t o f th e vehicle ,

an d suppor t i t wit h safet y

stands.3. Star t th e engine .

4 . Measur e th e voltag e betwee n

th e VS A converte r uni t 26 P

connecto r termina l No . 2 4

an d bod y ground .

I s th e voltag e a s specified ?

— VS A is functioning : abou t O V

— VS A is no t functioning : abou t5V

(T o pag e 19-249 )

VSA CONVERTE R UNI T 26 P CONNECTO R

Wire sid e o f femal e terminal s

Repair shor t t o bod y groun d i nth e wir e betwee n th e PC M an d

th e VS A converte r unit .

Repai r shor t t o bod y groun d i nth e wir e betwee n th e PC M an d

th e VS A converte r unit .

Chec k fo r loos e terminal s i n th eVS A converte r uni t 26 P connec -

tor . I f necessary , substitut e a

known-goo d VS A converte r unit ,

and recheck .

NOTE: Sto p th e wheel s b y pressin g th e

brak e peda l lightly .

ProCarManuals.com

Page 1304 of 1954

VSA Modulator-Control Unit

Removal/Installation

NOTE:

Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off imme-

diately with water.

Take care not to damage or deform the brake lines during removal and installation.

To prevent the brake fluid from flowing, plug and cover the hose ends and joints with a shop towel or equivalent material.

Removal

1. Disconnect the pressure sensor 3P connector.

2. Pull the locking lever of the VSA control unit 42P connec-

tor up, then disconnect the connector.

3. Disconnect the six brake lines.

4. Remove the two 8 mm nuts.

5. Remove the VSA modulator-control unit.

Installation

1. Install the VSA modulator-control unit, then tighten the

two 8 mm nuts.

2. Align the connecting surfaces of the VSA control unit 42P

connector.

3. Push the locking lever of the VSA control unit 42P connec-

tor down until you hear a click.

4. Connect the pressure sensor 3P connector.

5. Connect the six brake lines.

6. Perform the precharge brake line bleeding (see page 19-

271).

7. Bleed the brake system, starting with the front wheels.

8. Start the engine, and check that the ABS indicator goes

off.

9. Test-drive the vehicle, and check that the ABS indicator

does not come on.

To right-rear

To left-rear

PRESSURE SENSOR

3P CONNECTOR

VSA MODULATOR

CONTROL UNIT

LOCKING LEVER

VSA CONTROL UNIT

42P CONNECTOR

To right-front

To left-front

FLARE NUT

15 N-m (1.5 kgf-m, 11 Ibf-ft)

MOUNTING BOLT

VSA CONTROL UNIT 42P CONNECTOR

8 mm BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)

8 mm NUT

9 N-m (0.9 kgf-m, 7 Ibf-ft)

RUBBER MOUNT

BRACKETProCarManuals.com

Page 1451 of 1954

Troubleshooting

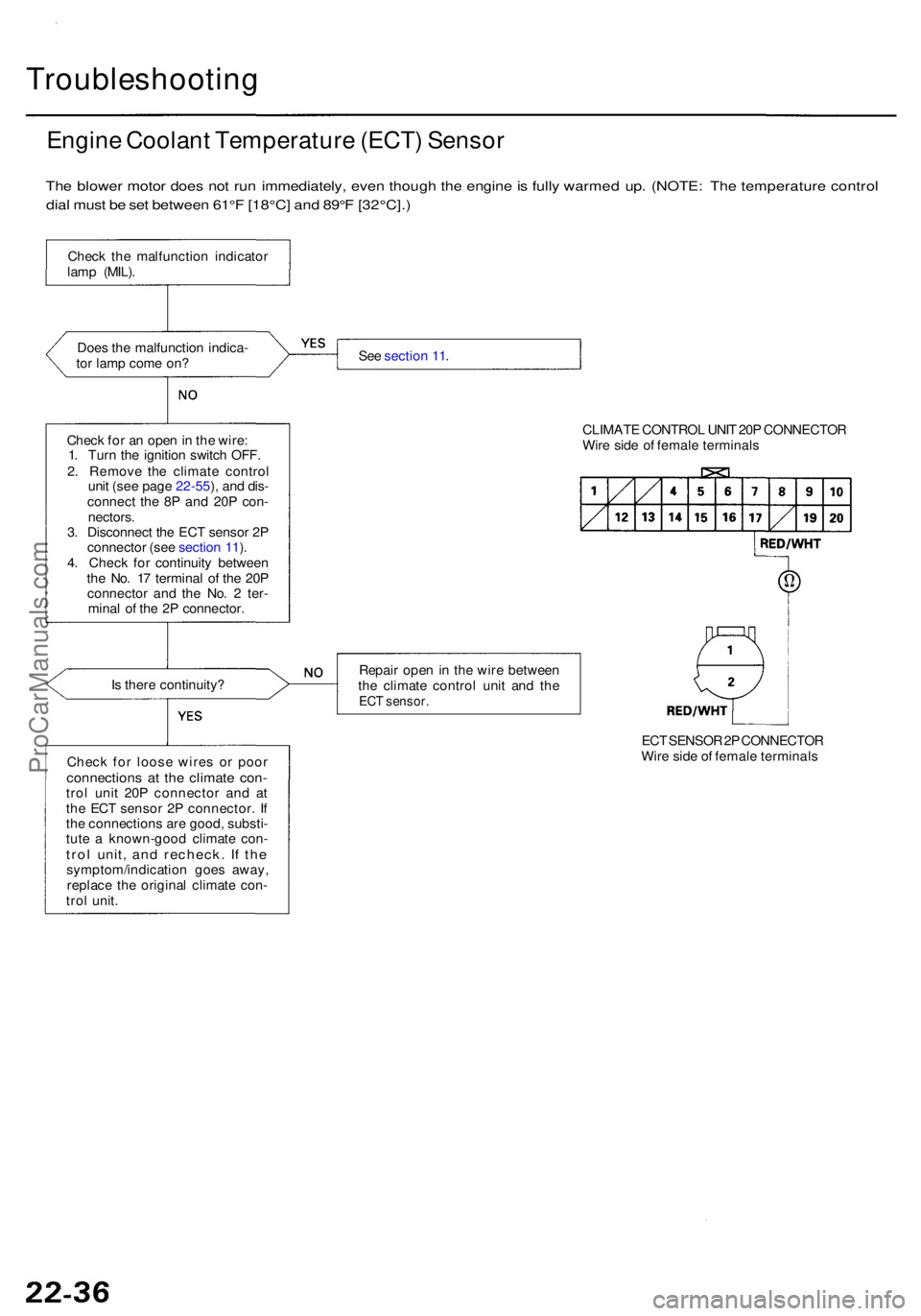

Engine Coolan t Temperatur e (ECT ) Senso r

The blowe r moto r doe s no t ru n immediately , eve n thoug h th e engin e is full y warme d up . (NOTE : Th e temperatur e contro l

dia l mus t b e se t betwee n 61° F [18°C ] an d 89° F [32°C]. )

Does th e malfunctio n indica -

to r lam p com e on ?

Chec k fo r a n ope n in th e wire :

1 . Tur n th e ignitio n switc h OFF .

2 . Remov e th e climat e contro l

uni t (se e pag e 22-55 ), an d dis -

connec t th e 8 P an d 20 P con -

nectors .

3 . Disconnec t th e EC T senso r 2 P

connecto r (se e sectio n 11 ).

4 . Chec k fo r continuit y betwee n

th e No . 1 7 termina l o f th e 20 P

connecto r an d th e No . 2 ter -

mina l o f th e 2 P connector .

I s ther e continuity ?

Chec k fo r loos e wire s o r poo r

connection s a t th e climat e con -trol uni t 20 P connecto r an d a t

th e EC T senso r 2 P connector . I f

th e connection s ar e good , substi -

tut e a known-goo d climat e con -

trol unit , an d recheck . I f th esymptom/indicatio n goe s away ,

replac e th e origina l climat e con -

tro l unit . Se

e sectio n 11 .

CLIMATE CONTRO L UNI T 20 P CONNECTO R

Wir e sid e o f femal e terminal s

Repai r ope n in th e wir e betwee n

th e climat e contro l uni t an d th e

EC T sensor .

ECT SENSO R 2P CONNECTO R

Wir e side of femal e terminal s

Chec

k th e malfunctio n indicato r

lam p (MIL) .

ProCarManuals.com

Page 1462 of 1954

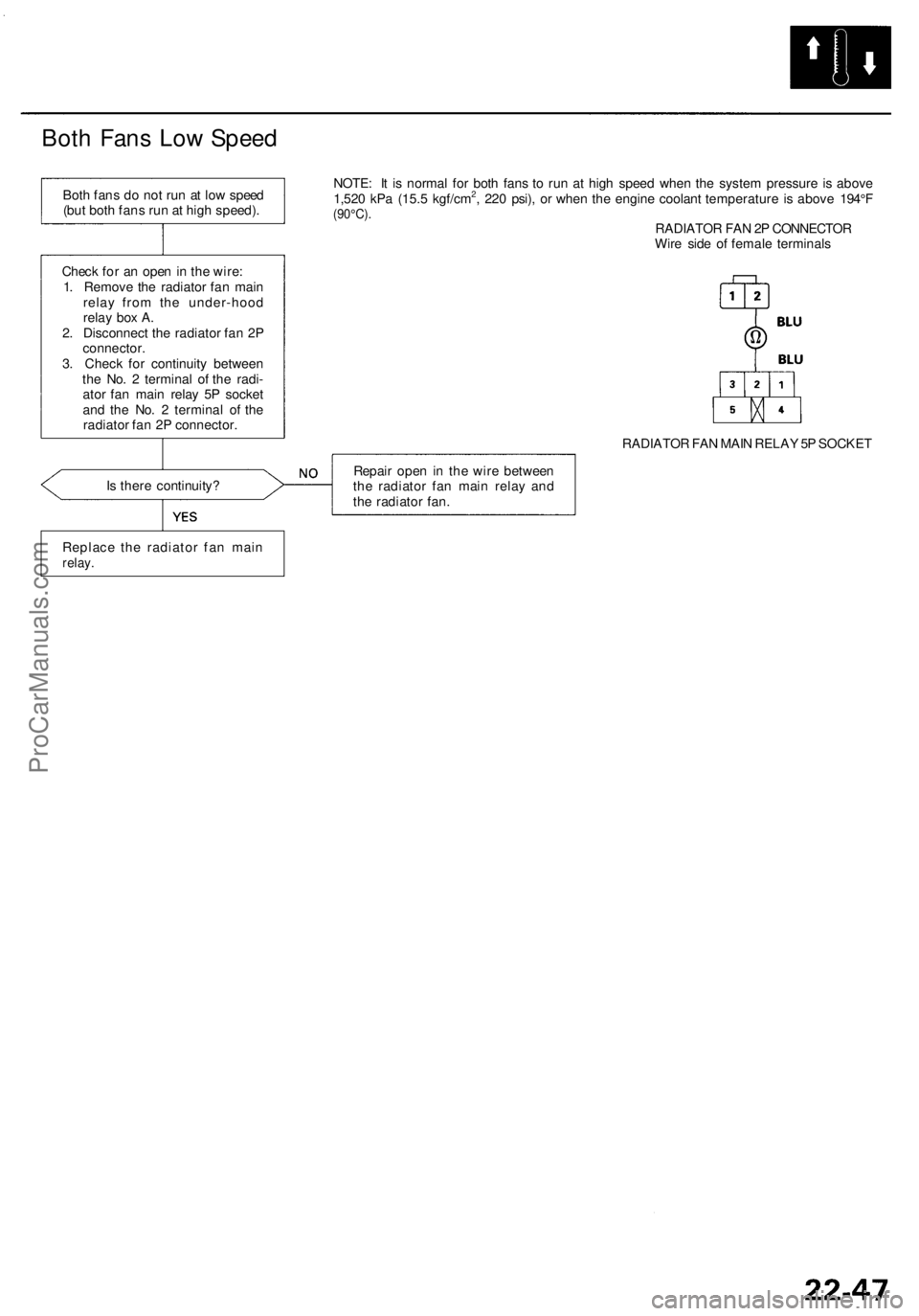

Both Fans Low Speed

Both fans do not run at low speed

(but both fans run at high speed).

Check for an open in the wire:

1. Remove the radiator fan main

relay from the under-hood

relay box A.

2. Disconnect the radiator fan 2P

connector.

3. Check for continuity between

the No. 2 terminal of the radi-

ator fan main relay 5P socket

and the No. 2 terminal of the

radiator fan 2P connector.

NOTE: It is normal for both fans to run at high speed when the system pressure is above

1,520 kPa (15.5 kgf/cm2, 220 psi), or when the engine coolant temperature is above 194°F

(90°C).

RADIATOR FAN 2P CONNECTOR

Wire side of female terminals

RADIATOR FAN MAIN RELAY 5P SOCKET

Is there continuity?

Repair open in the wire between

the radiator fan main relay and

the radiator fan.

Replace the radiator fan main

relay.ProCarManuals.com

Page 1466 of 1954

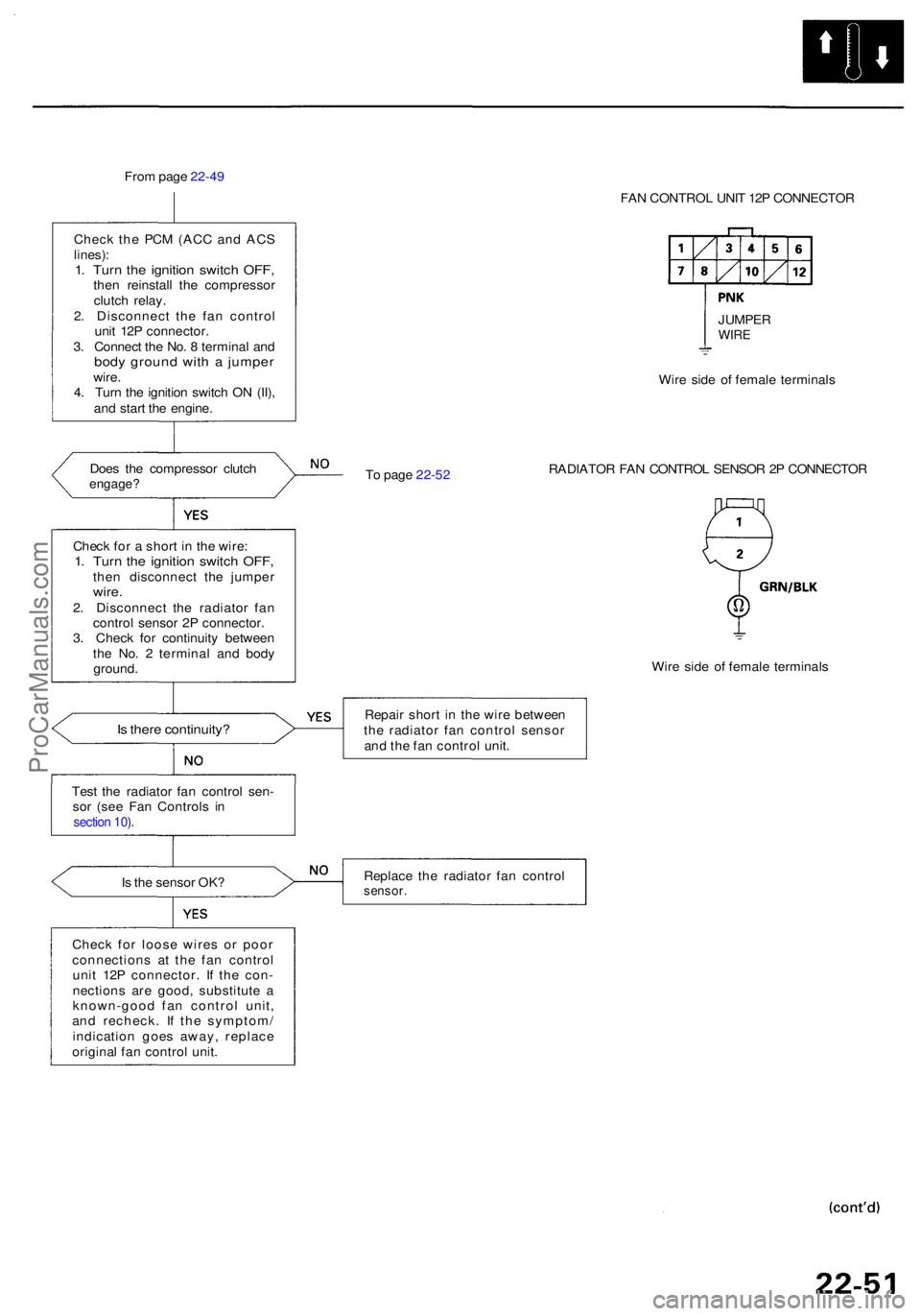

From pag e 22-4 9

Chec k th e PC M (AC C an d AC S

lines) :1. Tur n th e ignitio n switc h OFF ,then reinstal l th e compresso r

clutc h relay .

2 . Disconnec t th e fa n contro l

uni t 12 P connector .

3 . Connec t th e No . 8 termina l an d

bod y groun d wit h a jumpe rwire.

4 . Tur n th e ignitio n switc h O N (II) ,

an d star t th e engine .

Doe s th e compresso r clutc h

engage ?

Is ther e continuity ?

Test th e radiato r fa n contro l sen -

so r (se e Fa n Control s i n

section 10 ).

Is th e senso r OK ?

Chec k fo r loos e wire s o r poo r

connection s a t th e fa n contro l

uni t 12 P connector . I f th e con -

nection s ar e good , substitut e a

known-goo d fa n contro l unit ,

an d recheck . I f th e symptom /

indicatio n goe s away , replac e

origina l fa n contro l unit . FA

N CONTRO L UNI T 12 P CONNECTO R

T o pag e 22-5 2 Wir

e sid e o f femal e terminal s

RADIATO R FA N CONTRO L SENSO R 2 P CONNECTO R

Wir e sid e o f femal e terminal s

Repai r shor t i n th e wir e betwee n

th e radiato r fa n contro l senso r

an d th e fa n contro l unit .

Replac e th e radiato r fa n contro lsensor.

Check fo r a shor t i n th e wire :1. Tur n th e ignitio n switc h OFF ,then disconnec t th e jumpe rwire.2. Disconnec t th e radiato r fa n

contro l senso r 2 P connector .

3 . Chec k fo r continuit y betwee n

th e No . 2 termina l an d bod y

ground . JUMPE

R

WIRE

ProCarManuals.com

Page 1595 of 1954

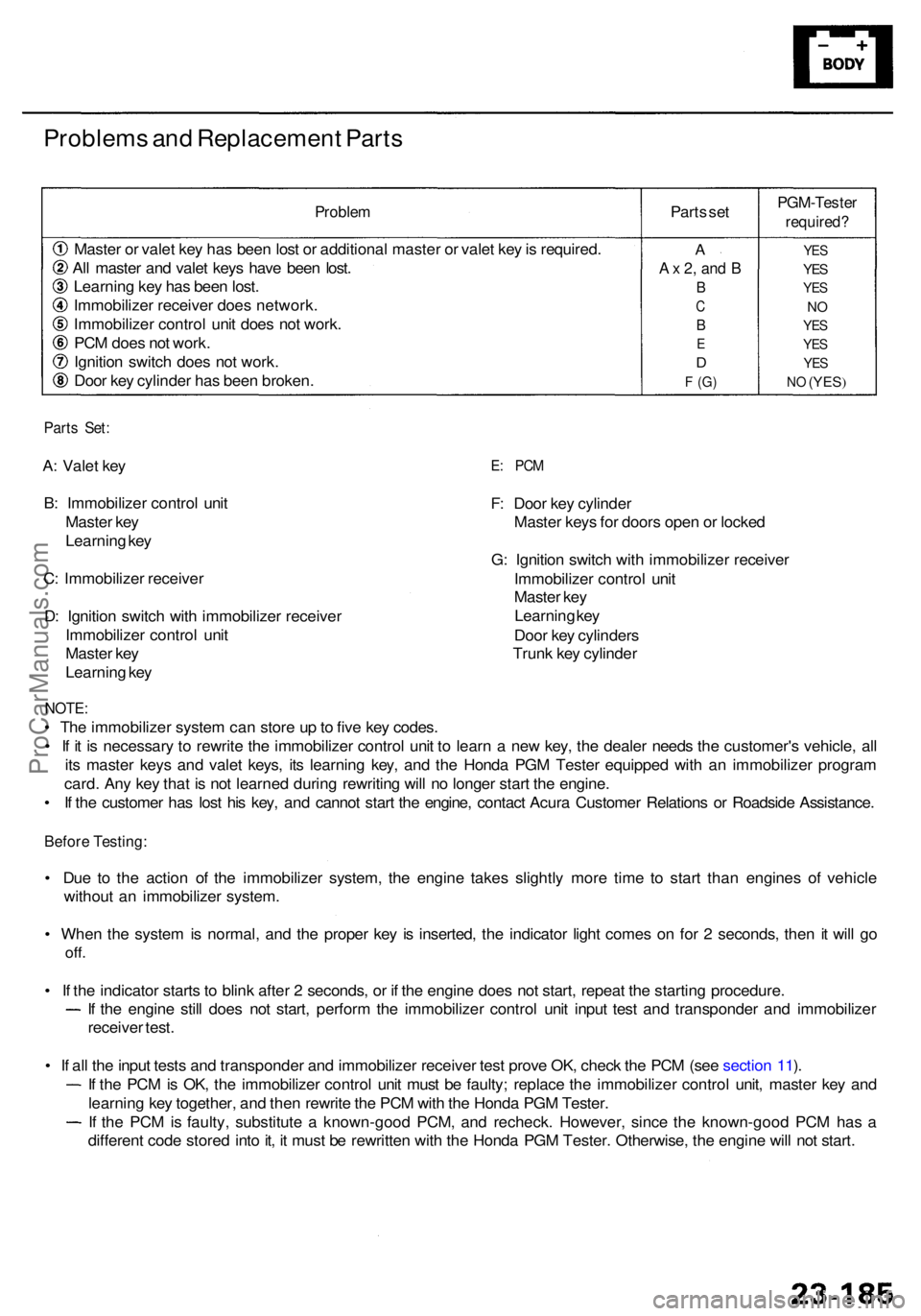

Problems an d Replacemen t Part s

Proble m

Master o r vale t ke y ha s bee n los t o r additiona l maste r o r vale t ke y is required .

Al l maste r an d vale t key s hav e bee n lost .

Learnin g ke y ha s bee n lost .

Immobilize r receive r doe s network .

Immobilize r contro l uni t doe s no t work .

PC M doe s no t work .

Ignitio n switc h doe s no t work .

Doo r ke y cylinde r ha s bee n broken . Part

s se t

PGM-Teste r

required?

YES

YES

YE S

NO

YE S

YE S

YES

NO (YES )

A

A x 2 , an d B

B

C

B

E

D

F (G )

Part s Set :

A: Vale t ke y

B : Immobilize r contro l uni t

Maste r ke y

Learnin g ke y

C : Immobilize r receive r

D : Ignitio n switc h wit h immobilize r receive r

Immobilize r contro l uni t

Maste r ke y

Learnin g ke yE: PC M

F: Doo r ke y cylinde r

Maste r key s fo r door s ope n o r locke d

G : Ignitio n switc h wit h immobilize r receive r

Immobilize r contro l uni t

Maste r ke y

Learnin g ke y

Doo r ke y cylinder s

Trun k ke y cylinde r

NOTE:

• Th e immobilize r syste m ca n stor e u p to fiv e ke y codes .

• I f i t i s necessar y t o rewrit e th e immobilize r contro l uni t t o lear n a ne w key , th e deale r need s th e customer' s vehicle , al l

it s maste r key s an d vale t keys , it s learnin g key , an d th e Hond a PG M Teste r equippe d wit h a n immobilize r progra m

card . An y ke y tha t i s no t learne d durin g rewritin g wil l n o longe r star t th e engine .

• I f th e custome r ha s los t hi s key , an d canno t star t th e engine , contac t Acur a Custome r Relation s o r Roadsid e Assistance .

Before Testing :

• Du e t o th e actio n o f th e immobilize r system , th e engin e take s slightl y mor e tim e t o star t tha n engine s o f vehicl e

withou t a n immobilize r system .

• Whe n th e syste m is normal , an d th e prope r ke y i s inserted , th e indicato r ligh t come s o n fo r 2 seconds , the n i t wil l g o

off .

• I f th e indicato r start s t o blin k afte r 2 seconds , o r i f th e engin e doe s no t start , repea t th e startin g procedure .

If th e engin e stil l doe s no t start , perfor m th e immobilize r contro l uni t inpu t tes t an d transponde r an d immobilize r

receive r test .

• I f al l th e inpu t test s an d transponde r an d immobilize r receive r tes t prov e OK , chec k th e PC M (se e sectio n 11 ).

I f th e PC M is OK , th e immobilize r contro l uni t mus t b e faulty ; replac e th e immobilize r contro l unit , maste r ke y an d

learnin g ke y together , an d the n rewrit e th e PC M wit h th e Hond a PG M Tester .

If th e PC M is faulty , substitut e a known-goo d PCM , an d recheck . However , sinc e th e known-goo d PC M ha s a

differen t cod e store d int o it , i t mus t b e rewritte n wit h th e Hond a PG M Tester . Otherwise , th e engin e wil l no t start .

ProCarManuals.com

Page 1858 of 1954

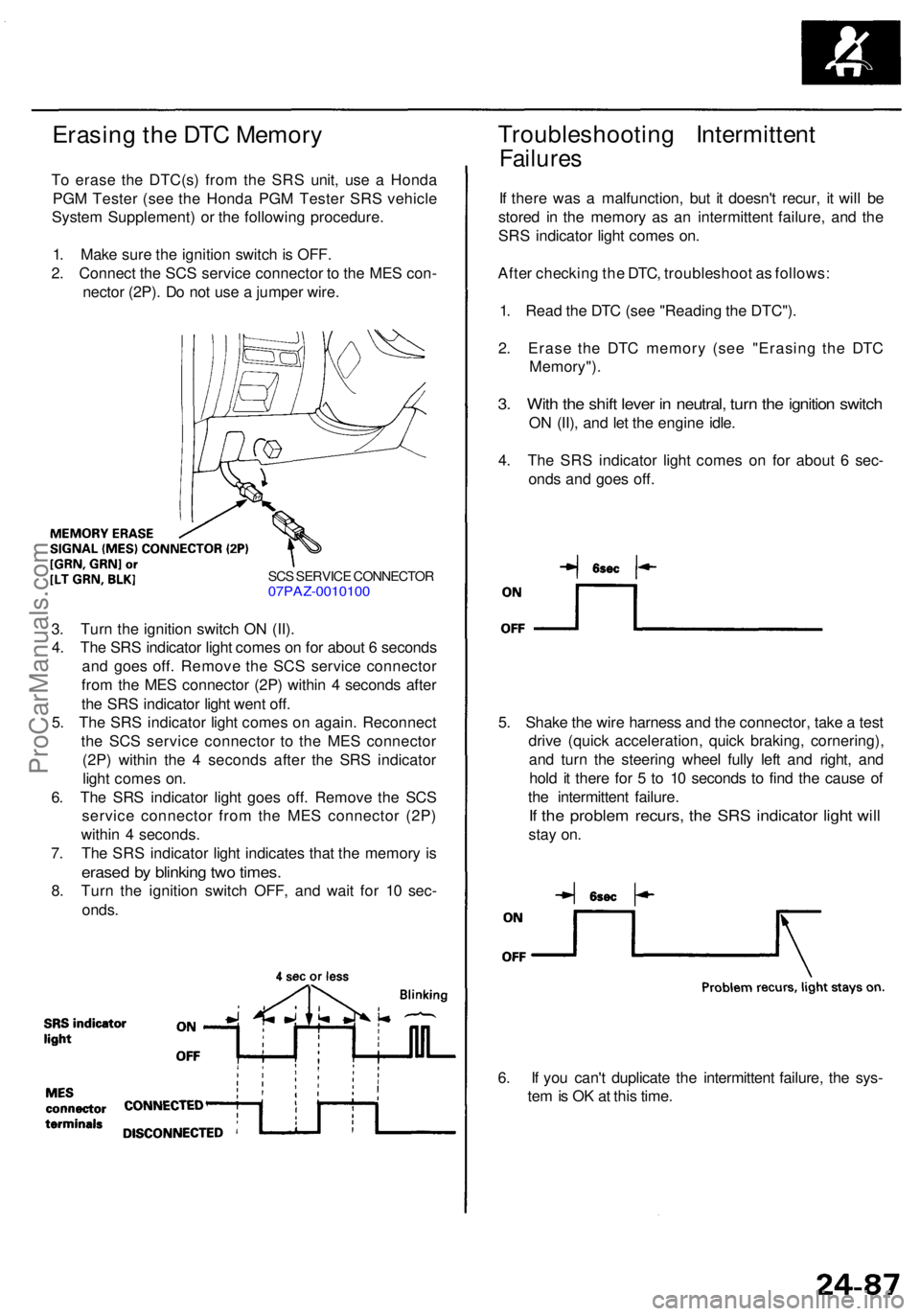

Erasing th e DT C Memor y

To eras e th e DTC(s ) fro m th e SR S unit , us e a Hond a

PG M Teste r (se e th e Hond a PG M Teste r SR S vehicl e

Syste m Supplement ) o r th e followin g procedure .

1 . Mak e sur e th e ignitio n switc h is OFF .

2 . Connec t th e SC S servic e connecto r t o th e ME S con -

necto r (2P) . D o no t us e a jumpe r wire .

Troubleshootin g Intermitten t

Failures

If ther e wa s a malfunction , bu t i t doesn' t recur , i t wil l b e

store d i n th e memor y a s a n intermitten t failure , an d th e

SR S indicato r ligh t come s on .

Afte r checkin g th e DTC , troubleshoo t a s follows :

1 . Rea d th e DT C (se e "Readin g th e DTC") .

2 . Eras e th e DT C memor y (se e "Erasin g th e DT C

Memory") .

3. Wit h th e shif t leve r i n neutral , tur n th e ignitio n switc h

ON (II) , an d le t th e engine idle.

4 . Th e SR S indicato r ligh t come s o n fo r abou t 6 sec -

ond s an d goe s off .

SCS SERVIC E CONNECTO R07PAZ-001010 0

3. Tur n th e ignitio n switc h O N (II) .

4 . Th e SR S indicato r ligh t come s o n fo r abou t 6 second s

an d goe s off . Remov e th e SC S servic e connecto r

fro m th e ME S connecto r (2P ) withi n 4 second s afte r

th e SR S indicato r ligh t wen t off .

5 . Th e SR S indicato r ligh t come s o n again . Reconnec t

th e SC S servic e connecto r t o th e ME S connecto r

(2P ) withi n th e 4 second s afte r th e SR S indicato r

ligh t come s on .

6 . Th e SR S indicato r ligh t goe s off . Remov e th e SC S

servic e connecto r fro m th e ME S connecto r (2P )

withi n 4 seconds .

7 . Th e SR S indicato r ligh t indicate s tha t th e memor y i s

erase d b y blinkin g tw o times .

8. Tur n th e ignitio n switc h OFF , an d wai t fo r 1 0 sec -

onds . 5

. Shak e th e wir e harnes s an d th e connector , tak e a tes t

driv e (quic k acceleration , quic k braking , cornering) ,

an d tur n th e steerin g whee l full y lef t an d right , an d

hol d i t ther e fo r 5 to 1 0 second s t o fin d th e caus e o f

th e intermitten t failure .

If th e proble m recurs , th e SR S indicato r ligh t wil l

stay on .

6 . I f yo u can' t duplicat e th e intermitten t failure , th e sys -

te m is O K a t thi s time .

ProCarManuals.com