check engine ACURA RL KA9 1996 Service Manual PDF

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 1140 of 1954

Troubleshooting

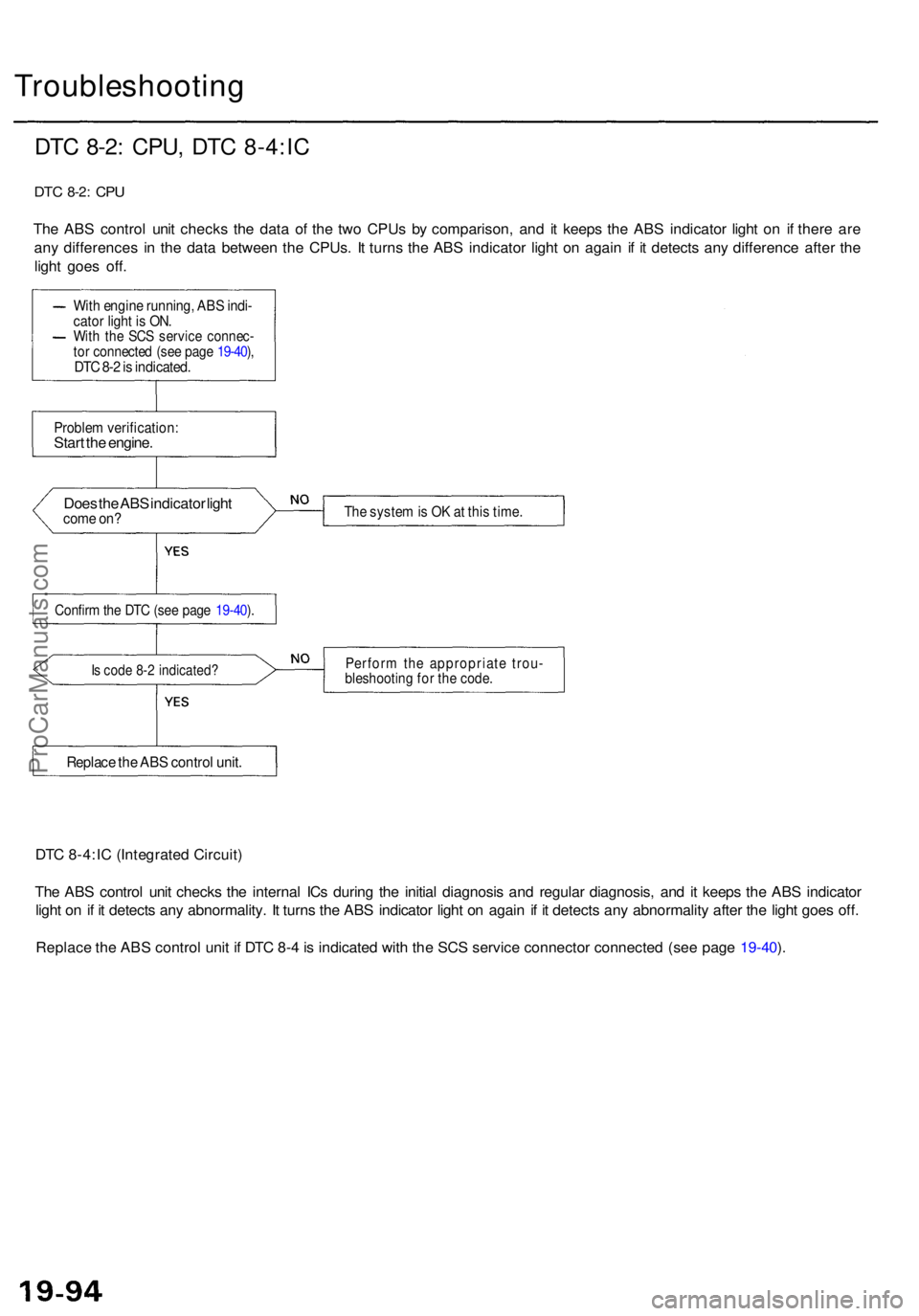

DTC 8-2 : CPU , DT C 8-4:I C

DTC 8-2 : CPU

The AB S contro l uni t check s th e dat a o f th e tw o CPU s b y comparison , an d i t keep s th e AB S indicato r ligh t o n i f ther e ar e

an y difference s i n th e dat a betwee n th e CPUs . I t turn s th e AB S indicato r ligh t o n agai n i f i t detect s an y differenc e afte r th e

ligh t goe s off .

Doe s th e AB S indicato r ligh t

com e on ?

Is cod e 8- 2 indicated ?

The syste m is O K at thi s time .

Perfor m th e appropriat e trou -

bleshootin g fo r th e code .

DTC 8-4:I C (Integrate d Circuit )

Th e AB S contro l uni t check s th e interna l IC s durin g th e initia l diagnosi s an d regula r diagnosis , an d i t keep s th e AB S indicato r

ligh t o n if i t detect s an y abnormality . I t turn s th e AB S indicato r ligh t o n agai n if i t detect s any abnormalit y afte r th e ligh t goe s off .

Replac e th e AB S contro l uni t i f DT C 8- 4 is indicate d wit h th e SC S servic e connecto r connecte d (se e pag e 19-40 ).

Wit h engin e running , AB S indi -cato r ligh t i s ON .With th e SC S servic e connec -

to r connecte d (se e pag e 19-40 ),

DT C 8- 2 is indicated .

Problem verification :Start th e engine .

Confirm th e DT C (se e pag e 19-40 ).

Replac e th e AB S contro l unit .

ProCarManuals.com

Page 1154 of 1954

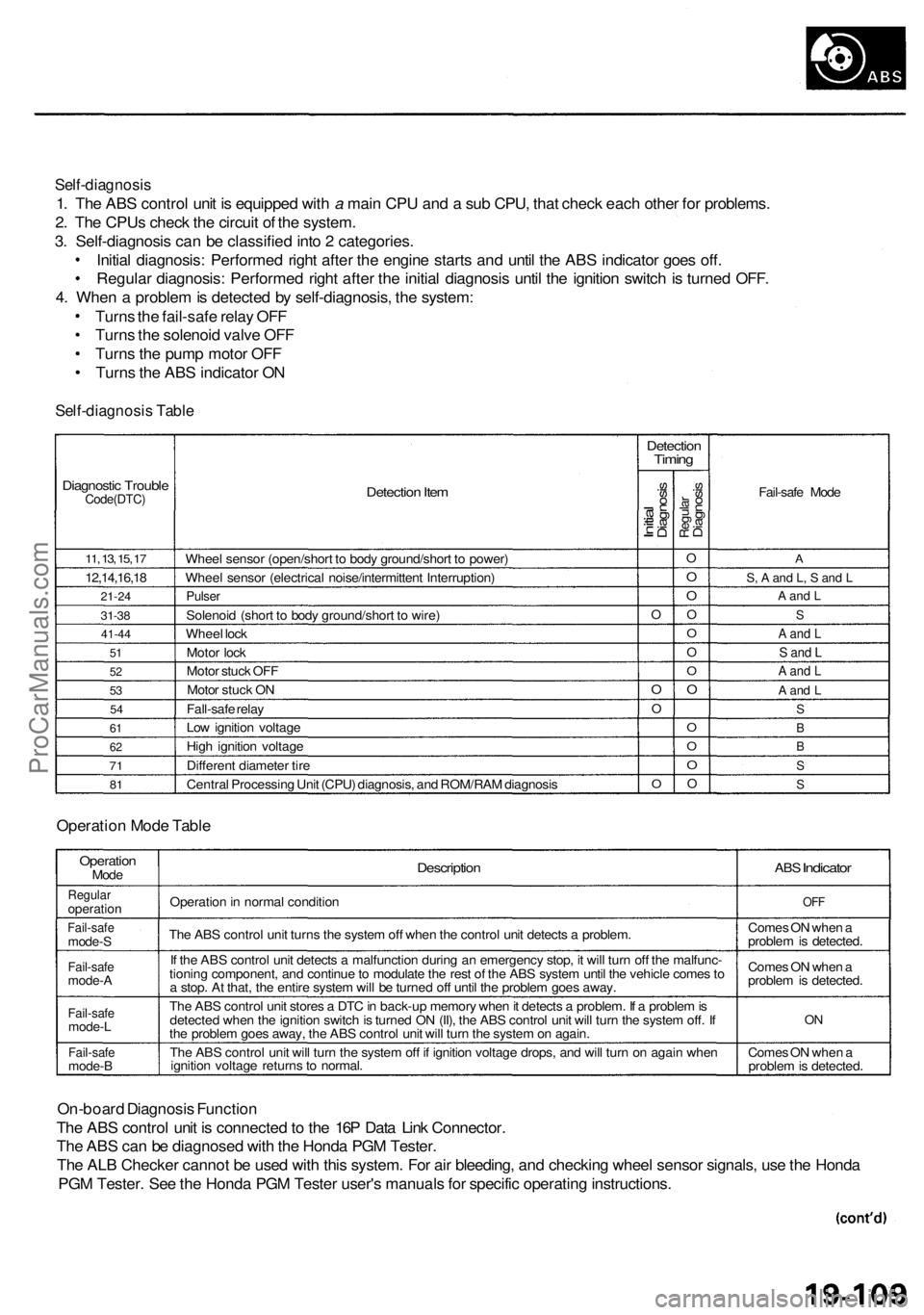

Self-diagnosis

1. The ABS control unit is equipped with a main CPU and a sub CPU, that check each other for problems.

2. The CPUs check the circuit of the system.

3. Self-diagnosis can be classified into 2 categories.

Initial diagnosis: Performed right after the engine starts and until the ABS indicator goes off.

Regular diagnosis: Performed right after the initial diagnosis until the ignition switch is turned OFF.

4. When a problem is detected by self-diagnosis, the system:

Turns the fail-safe relay OFF

Turns the solenoid valve OFF

Turns the pump motor OFF

Turns the ABS indicator ON

Self-diagnosis Table

Diagnostic Trouble

Code(DTC)

11, 13, 15, 17

12,14,16,18

21-24

31-38

41-44

51

52

53

54

61

62

71

81

Detection Item

Wheel sensor (open/short to body ground/short to power)

Wheel sensor (electrical noise/intermittent Interruption)

Pulser

Solenoid (short to body ground/short to wire)

Wheel lock

Motor lock

Motor stuck OFF

Motor stuck ON

Fall-safe relay

Low ignition voltage

High ignition voltage

Different diameter tire

Central Processing Unit (CPU) diagnosis, and ROM/RAM diagnosis

Detection

Timing

Initial

Diagnosis

O

O

O

O

Regular

Diagnosis

O

O

O

O

O

O

O

O

O

O

O

O

Fail-safe Mode

A

S, A and L, S and L

A and L

S

A and L

S and L

A and L

A and L

S

B

B

S

S

Operation Mode Table

Operation

Mode

Regular

operation

Fail-safe

mode-S

Fail-safe

mode-A

Fail-safe

mode-L

Fail-safe

mode-B

Description

Operation in normal condition

The ABS control unit turns the system off when the control unit detects a problem.

If the ABS control unit detects a malfunction during an emergency stop, it will turn off the malfunc-

tioning component, and continue to modulate the rest of the ABS system until the vehicle comes to

a stop. At that, the entire system will be turned off until the problem goes away.

The ABS control unit stores a DTC in back-up memory when it detects a problem. If a problem is

detected when the ignition switch is turned ON (II), the ABS control unit will turn the system off. If

the problem goes away, the ABS control unit will turn the system on again.

The ABS control unit will turn the system off if ignition voltage drops, and will turn on again when

ignition voltage returns to normal.

ABS

Indicator

OFF

Comes ON when a

problem is detected.

Comes ON when a

problem is detected.

ON

Comes ON when a

problem is detected.

On-board Diagnosis Function

The ABS control unit is connected to the 16P Data Link Connector.

The ABS can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding, and checking wheel sensor signals, use the Honda

PGM Tester. See the Honda PGM Tester user's manuals for specific operating instructions.

ProCarManuals.com

Page 1169 of 1954

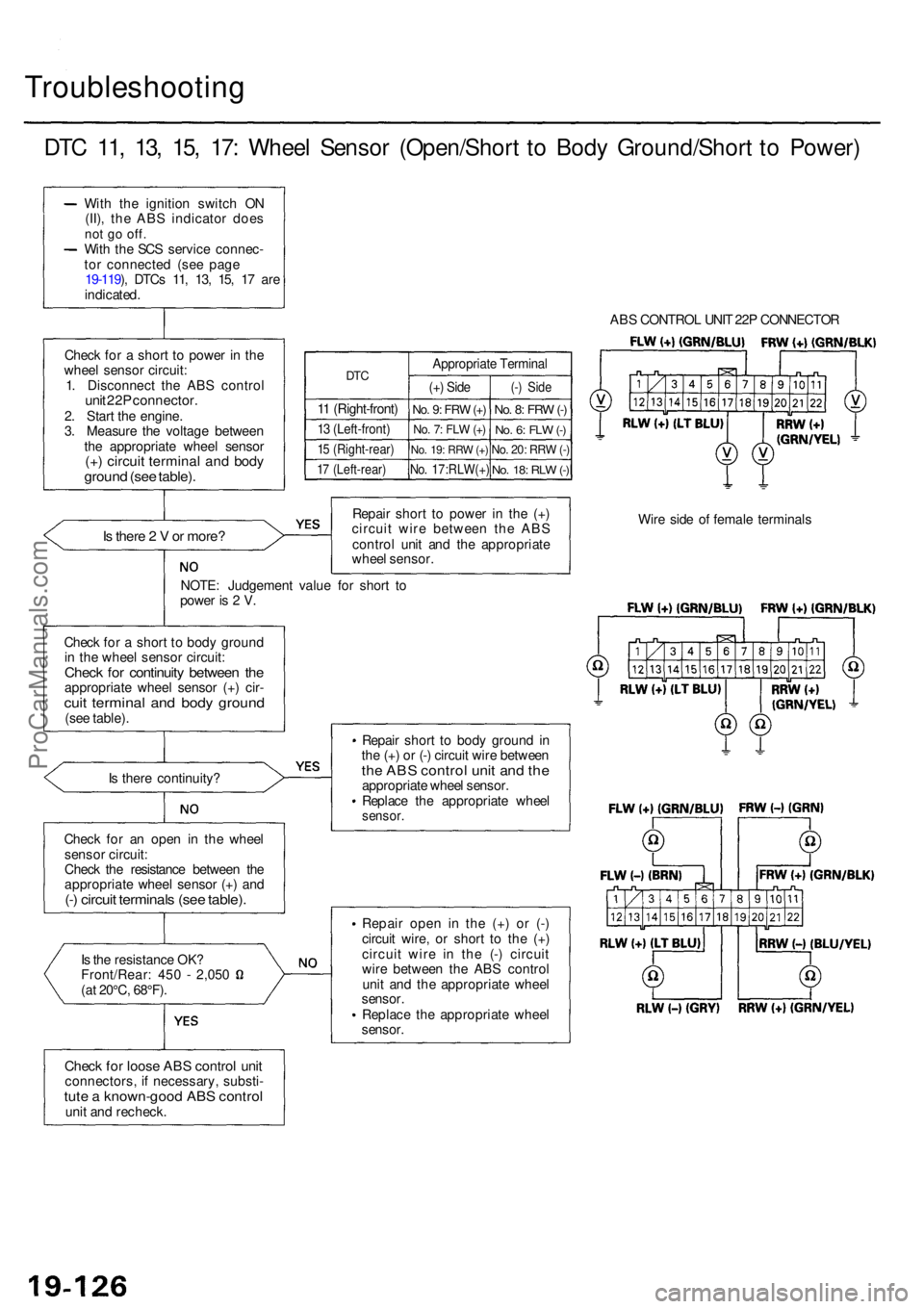

Troubleshooting

DTC 11 , 13 , 15 , 17 : Whee l Senso r (Open/Shor t t o Bod y Ground/Shor t t o Power )

With th e ignitio n switc h O N

(II) , th e AB S indicato r doe s

not g o off .With th e SC S servic e connec -

to r connecte d (se e pag e

19-119 ), DTC s 11 , 13 , 15 , 1 7 ar e

indicated .

Chec k fo r a shor t t o powe r i n th e

whee l senso r circuit :

1 . Disconnec t th e AB S contro l

unit 22 P connector .2. Star t th e engine .

3 . Measur e th e voltag e betwee n

th e appropriat e whee l senso r

(+) circui t termina l an d bod ygroun d (se e table) .

DTC

11 (Right-front )

13 (Left-front )

15 (Right-rear )

17 (Left-rear )

Appropriat e Termina l

(+) Sid e

No. 9 : FR W (+)

No . 7 : FL W (+ )

No . 19 : RR W (+ )

No . 17:RLW(+ )

(-) Sid e

No. 8 : FR W (-)

No . 6 : FL W (-)

No . 20 : RR W (-)

No . 18 : RL W (-)

Is ther e 2 V or more ?

NOTE : Judgemen t valu e fo r shor t t o

powe r i s 2 V . Repai

r shor t t o powe r i n th e (+ )

circui t wir e betwee n th e AB S

contro l uni t an d th e appropriat e

whee l sensor .

Chec k fo r a shor t t o bod y groun d

i n th e whee l senso r circuit :

Check fo r continuit y betwee n th eappropriat e whee l senso r (+ ) cir -cuit termina l an d bod y groun d(see table) .

I s ther e continuity ?

Chec k fo r a n ope n i n th e whee l

senso r circuit :

Chec k th e resistanc e betwee n th e

appropriat e whee l senso r (+ ) an d

(-) circui t terminal s (se e table) .

Is th e resistanc e OK ?Front/Rear : 45 0 - 2,05 0

(a t 20°C , 68°F) .

Check fo r loos e AB S contro l uni tconnectors , i f necessary , substi -tute a known-goo d AB S contro lunit an d recheck . Repai

r shor t t o bod y groun d in

th e (+ ) o r (- ) circui t wir e betwee n

the AB S contro l uni t an d th eappropriat e whee l sensor .

Replac e th e appropriat e whee l

sensor .

Repair ope n i n the (+) o r (- )

circui t wire , o r shor t t o th e (+ )

circui t wir e i n th e (- ) circui t

wir e betwee n th e AB S contro l

uni t an d th e appropriat e whee l

sensor .

Replac e th e appropriat e whee l

sensor . AB

S CONTRO L UNI T 22 P CONNECTO R

Wir e sid e o f femal e terminal s

ProCarManuals.com

Page 1186 of 1954

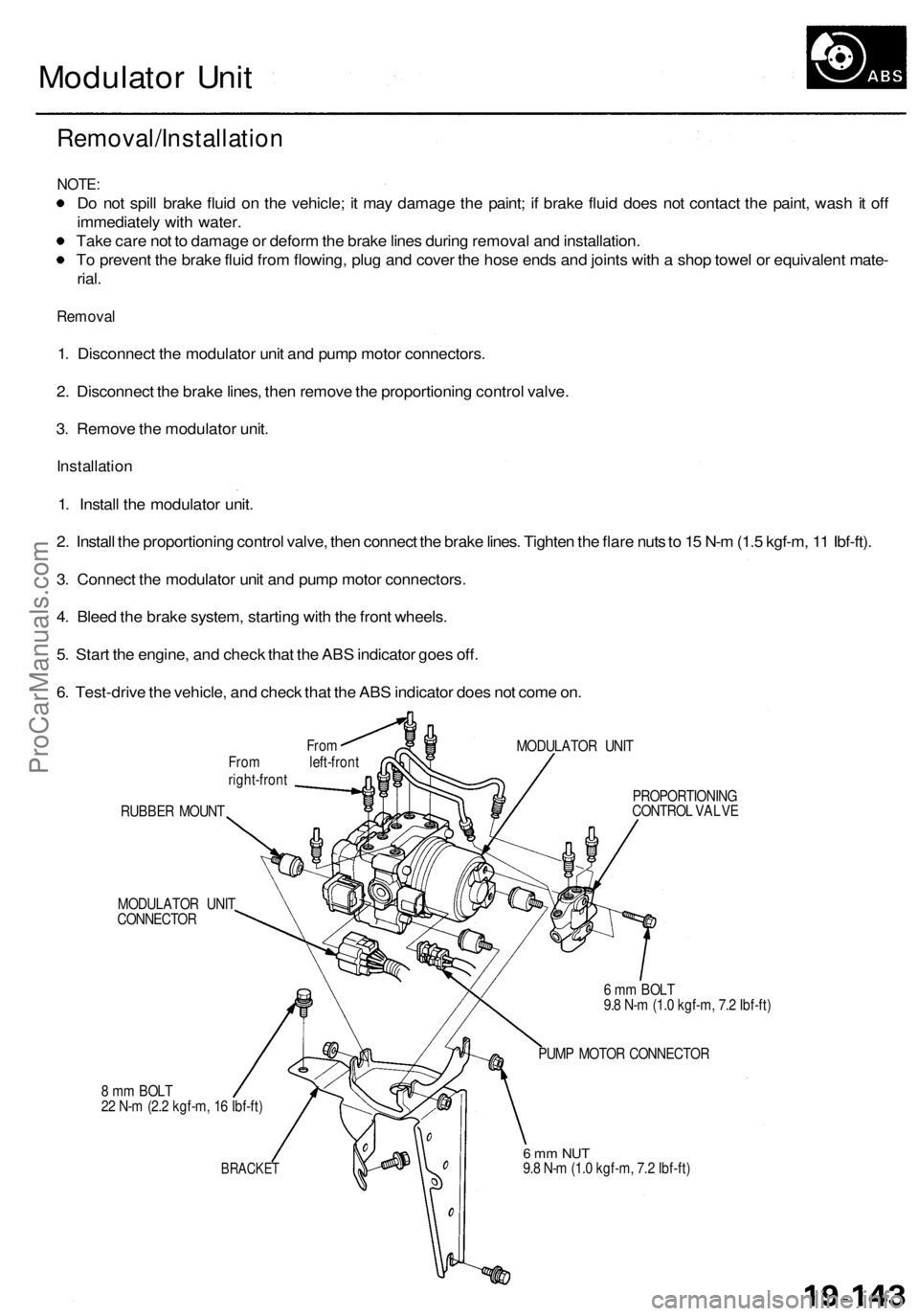

Modulator Unit

Removal/Installation

NOTE:

Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does not contact the paint, wash it off

immediately with water.

Take care not to damage or deform the brake lines during removal and installation.

To prevent the brake fluid from flowing, plug and cover the hose ends and joints with a shop towel or equivalent mate-

rial.

Removal

1. Disconnect the modulator unit and pump motor connectors.

2. Disconnect the brake lines, then remove the proportioning control valve.

3. Remove the modulator unit.

Installation

1. Install the modulator unit.

2. Install the proportioning control valve, then connect the brake lines. Tighten the flare nuts to 15 N-m (1.5 kgf-m, 11 Ibf-ft).

3. Connect the modulator unit and pump motor connectors.

4. Bleed the brake system, starting with the front wheels.

5. Start the engine, and check that the ABS indicator goes off.

6. Test-drive the vehicle, and check that the ABS indicator does not come on.

From

From left-front

right-front

MODULATOR UNIT

RUBBER MOUNT

MODULATOR UNIT

CONNECTOR

8 mm BOLT

22 N-m (2.2 kgf-m, 16 Ibf-ft)

BRACKET

PROPORTIONING

CONTROL VALVE

6 mm BOLT

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)

PUMP MOTOR CONNECTOR

6 mm NUT

9.8 N-m (1.0 kgf-m, 7.2 Ibf-ft)ProCarManuals.com

Page 1196 of 1954

TCS CONTROL UNIT 20P CONNECTOR

Wire side of female terminals

VB: Battery Voltage

Terminal

number

1

2

4

5

6

9

10

11

12

13

14

15

16

17

20

Wire

color

BLK/YEL

GRN/RED

BLU

PNK/BLU

BLK/WHT

BLK

BRN/WHT

GRN/WHT

BLU

GRN/ORN

BLK/ORN

BRN/BLK

WHT/BLU

BLU/GRY

GRN

BRN

Terminal sign

(Terminal name)

IG1

(Ignition 1)

PARK

(Parking)

SCS

(Service check

signal)

STR-GND

(Steering ground)

AT-SHIFT

(AT shift)

FSR

(Fail-safe relay)

PMG

(Power motor

Ground)

VPM

(Voltage power

motor)

STOP

(Stop)

NEP (Engine

speed pulse)

BARO

(Barometric)

TC-FC

(Traction control

fuel cut)

LG2

(Logic ground 2)

STR-VCC (Steer-

ing power supply)

WARN2

(Warning 2)

SH-MOT

(Shield motor)

MOT +

(Motor +)

MOT-

(Motor -)

Description

Detects ignition switch

IG1 signal

Detects parking brake

switch signal

Detects service check

connector signal

(Diagnostic trouble

code indication)

Ground for the steering

angle sensor

Detects A/T shift posi-

tion signal

Drives fail-safe relay

Power ground for the

TCS control valve

actuator motor

Power source for the

TCS control valve

actuator motor

Detects brake pedal

position switch signal

Detects engine speed

signal

Detects barometric

sensor signal

TCS Fl, Fuel cut

(torque down) signal

Ground for the logic

circuit

Power source for the

steering angle sensor

Drives TCS indicator light

(The indicator light comes

on by the self-bias)

Shield for the TCS con-

trol valve actuator motor

Drives TCS control

valve actuator motor

Drives TCS control

valve actuator motor

Measurement

terminals

1-GND

2

3-GND

4-GND

5-GND

6-GND

9-GND

10-GND

11-GND

12-GND

13-GND

14-GND

15-GND

16-GND

17-GND

19-20

20-19

Voltage

Conditions

(Ignition Switch ON (II))

Depress the parking

brake pedal.

Release the parking

brake pedal.

SCS service connector

connected.

SCS service connector

disconnected.

Shift the transmission

to position, then

start the engine.

Start the engine.

Start the engine.

Brake pedal depressed.

Brake pedal released.

Engine idling

TCS is functioning,

(maximum fuel cut)

TCS is not functioning.

Indicator light ON

Indicator light OFF

TCS is functioning.

TCS is not functioning.

TCS is functioning.

TCS is not functioning.

Output

voltage

VB

Below 0.6 V

VB

0V

5V

Below 0.3V

About 4V

(5V 0V)

VB

1.5V

Below 0.3 V

0V

VB

VB

0V

About 6V

(12V

0V)

About 3 V

About 1.5V

About 4.5 V

(5 V,

PWM)

Below 0.3V

About 5 V

About 2 V

VB

VB

0V

VB

0VProCarManuals.com

Page 1211 of 1954

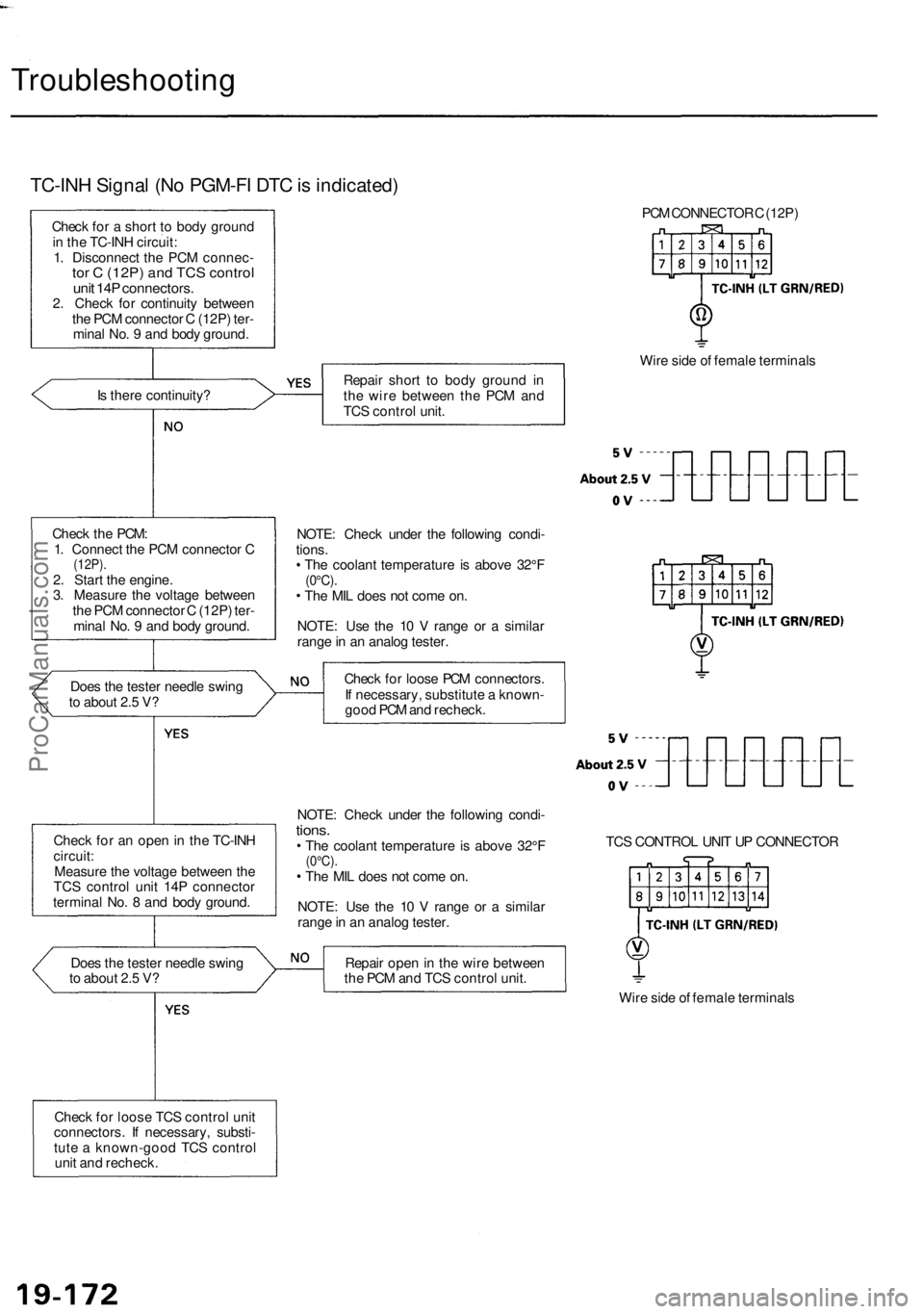

Troubleshooting

TC-INH Signal (No PGM-FI DTC is indicated)

Check for a short to body ground

in the TC-INH circuit:

1. Disconnect the PCM connec-

tor C (12P) and TCS control

unit 14P connectors.

2. Check for continuity between

the PCM connector C (12P) ter-

minal No. 9 and body ground.

Is there continuity?

Check the PCM:

1. Connect the PCM connector C

(12P).

2. Start the engine.

3. Measure the voltage between

the PCM connector C (12P) ter-

minal No. 9 and body ground.

Does the tester needle swing

to about 2.5 V?

Check for an open in the TC-INH

circuit:

Measure the voltage between the

TCS control unit 14P connector

terminal No. 8 and body ground.

Does the tester needle swing

to about 2.5 V?

Check for loose TCS control unit

connectors. If necessary, substi-

tute a known-good TCS control

unit and recheck.

PCM CONNECTOR C (12P)

Repair short to body ground in

the wire between the PCM and

TCS control unit.

Wire side of female terminals

NOTE: Check under the following condi-

tions.

The coolant temperature is above 32°F

(0°C).

The MIL does not come on.

NOTE: Use the 10 V range or a similar

range in an analog tester.

Check for loose PCM connectors.

If necessary, substitute a known-

good PCM and recheck.

NOTE: Check under the following condi-

tions.

The coolant temperature is above 32°F

(0°C).

The MIL does not come on.

NOTE: Use the 10 V range or a similar

range in an analog tester.

TCS CONTROL UNIT UP CONNECTOR

Repair open in the wire between

the PCM and TCS control unit.

Wire side of female terminalsProCarManuals.com

Page 1212 of 1954

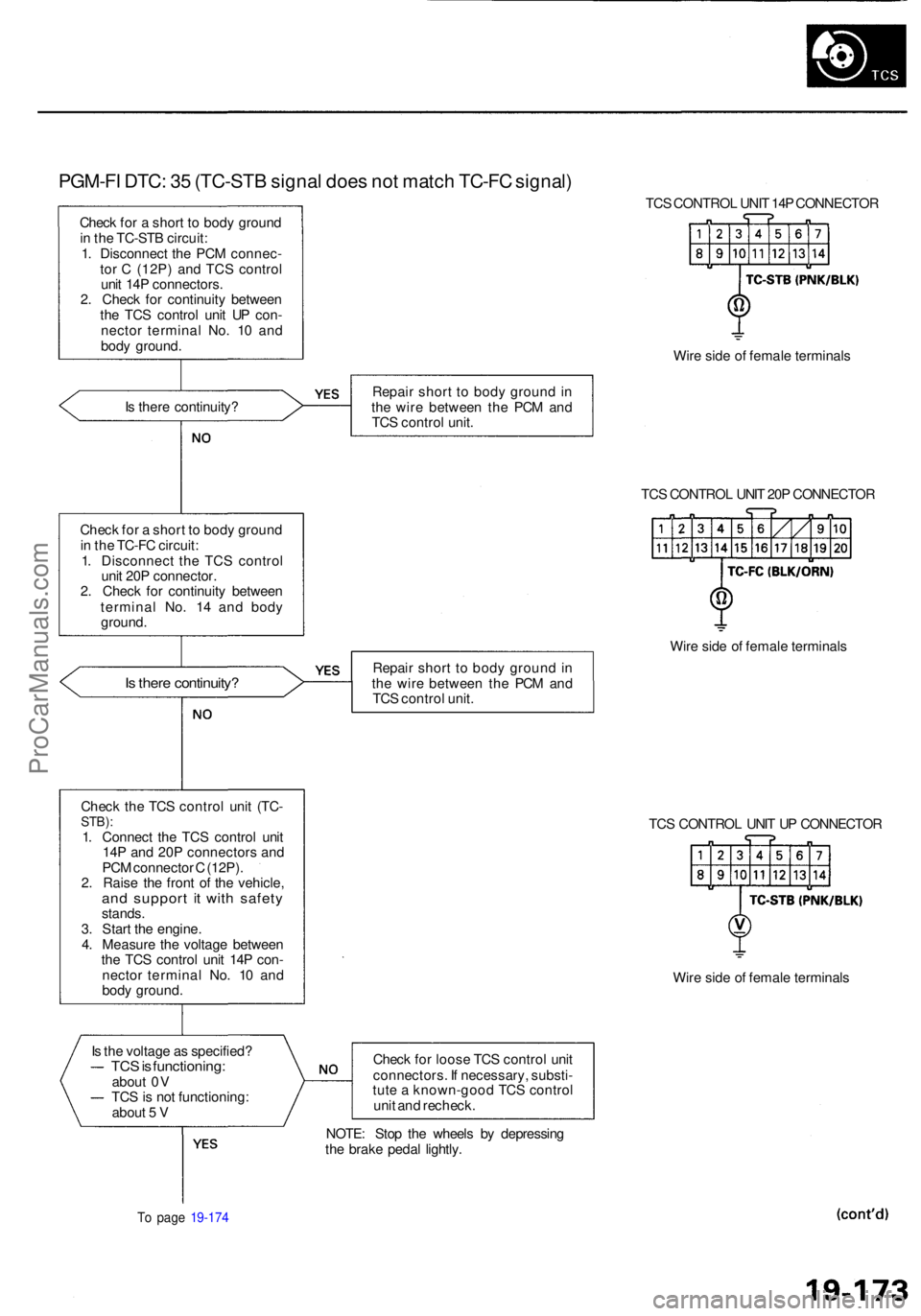

PGM-FI DTC : 3 5 (TC-ST B signa l doe s no t matc h TC-F C signal )

Check fo r a shor t t o bod y groun d

i n th e TC-ST B circuit :

1 . Disconnec t th e PC M connec -

to r C (12P ) an d TC S contro l

uni t 14 P connectors .

2 . Chec k fo r continuit y betwee n

th e TC S contro l uni t U P con -

necto r termina l No . 1 0 an d

bod y ground . TC

S CONTRO L UNI T 14 P CONNECTO R

Wir e sid e o f femal e terminal s

I s ther e continuity ? Repai

r shor t t o bod y groun d in

th e wir e betwee n th e PC M an d

TC S contro l unit .

TCS CONTRO L UNI T 20 P CONNECTO R

Chec k fo r a shor t t o bod y groun d

i n th e TC-F C circuit :

1 . Disconnec t th e TC S contro l

uni t 20 P connector .

2 . Chec k fo r continuit y betwee n

termina l No . 1 4 an d bod y

ground .

Is ther e continuity ?Repair shor t t o bod y groun d in

th e wir e betwee n th e PC M an d

TC S contro l unit . Wir

e sid e o f femal e terminal s

Chec k th e TC S contro l uni t (TC -

STB) :1. Connec t th e TC S contro l uni t

14 P an d 20 P connector s an d

PC M connecto r C (12P) .

2 . Rais e th e fron t o f th e vehicle ,

and suppor t i t wit h safet ystands.

3 . Star t th e engine .

4 . Measur e th e voltag e betwee n

th e TC S contro l uni t 14 P con -

necto r termina l No . 1 0 an d

bod y ground . TC

S CONTRO L UNI T U P CONNECTO R

Wir e sid e o f femal e terminal s

I s th e voltag e a s specified ?

TCS is functioning :about 0 V

TC S is no t functioning :

abou t 5 V Chec

k fo r loos e TC S contro l uni t

connectors . I f necessary , substi -

tut e a known-goo d TC S contro l

uni t an d recheck .

To pag e 19-17 4

NOTE : Sto p th e wheel s b y depressin g

th e brak e peda l lightly .

ProCarManuals.com

Page 1215 of 1954

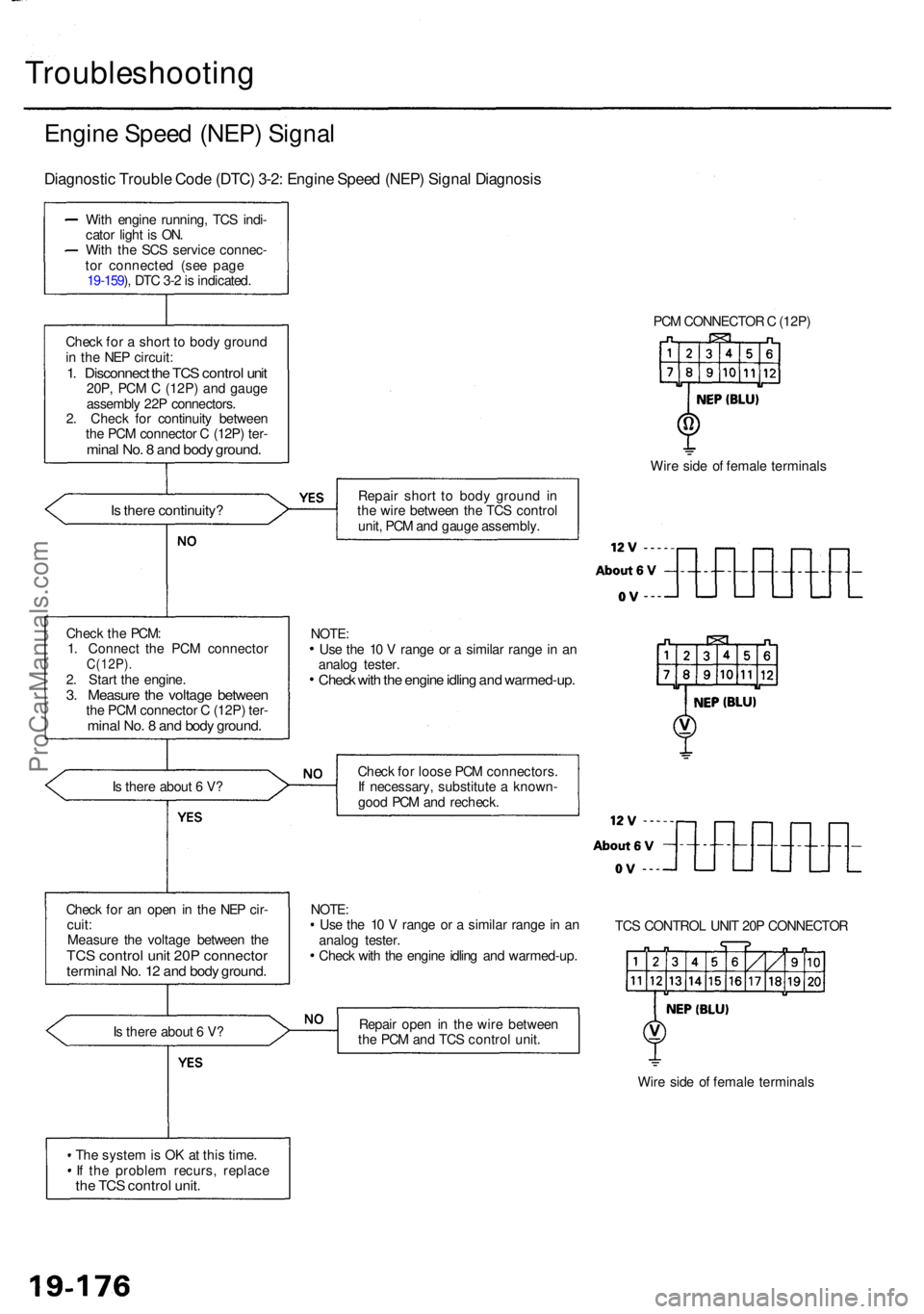

Troubleshooting

Engine Spee d (NEP ) Signa l

Diagnosti c Troubl e Cod e (DTC ) 3-2 : Engin e Spee d (NEP ) Signa l Diagnosi s

With engin e running , TC S indi -

cato r ligh t i s ON .

Wit h th e SC S servic e connec -

to r connecte d (se e pag e

19-159 ), DT C 3- 2 is indicated .

Chec k fo r a shor t t o bod y groun d

i n th e NE P circuit :

1. Disconnec t th e TC S contro l uni t20P , PC M C (12P ) an d gaug e

assembl y 22 P connectors .

2 . Chec k fo r continuit y betwee n

th e PC M connecto r C (12P ) ter -

mina l No . 8 an d bod y ground .

Is ther e continuity ?

Is ther e abou t 6 V ?

Chec k fo r a n ope n in th e NE P cir -

cuit :

Measur e th e voltag e betwee n th e

TC S contro l uni t 20 P connecto rterminal No . 1 2 an d bod y ground .

Is ther e abou t 6 V ?

Th e syste m is O K a t thi s time .

I f th e proble m recurs , replac e

the TC S contro l unit .

PCM CONNECTO R C (12P )

Wir e sid e o f femal e terminal s

Repai r shor t t o bod y groun d i n

th e wir e betwee n th e TC S contro l

unit , PC M an d gaug e assembly .

Chec k fo r loos e PC M connectors .

I f necessary , substitut e a known -

goo d PC M an d recheck .

NOTE :

Us e th e 1 0 V rang e o r a simila r rang e in a n

analo g tester .

Chec k wit h th e engin e idlin g an d warmed-up .TC

S CONTRO L UNI T 20 P CONNECTO R

Repai r ope n in th e wir e betwee n

th e PC M an d TC S contro l unit .

Wire sid e o f femal e terminal s

Chec

k th e PCM :

1 . Connec t th e PC M connecto r

C(12P).2. Star t th e engine .3. Measur e th e voltag e betwee nthe PC M connecto r C (12P ) ter -mina l No . 8 an d bod y ground .

Use th e 1 0 V rang e o r a simila r rang e in a n

analo g tester .

Check wit h th e engin e idlin g an d warmed-up .

NOTE:

ProCarManuals.com

Page 1226 of 1954

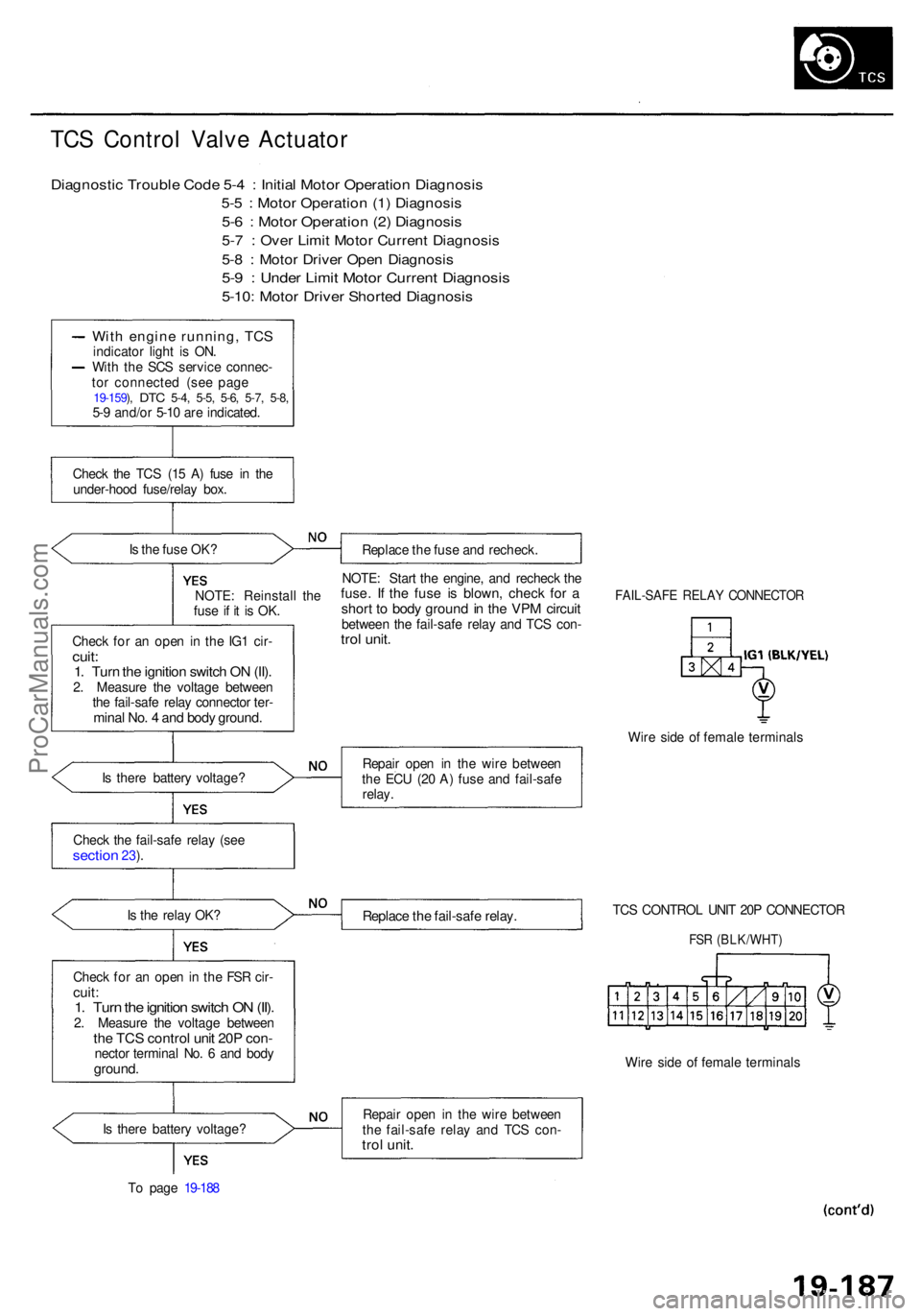

TCS Contro l Valv e Actuato r

Diagnosti c Troubl e Cod e 5- 4 : Initia l Moto r Operatio n Diagnosi s

5-5 : Moto r Operatio n (1 ) Diagnosi s

5-6 : Moto r Operatio n (2 ) Diagnosi s

5-7 : Ove r Limi t Moto r Curren t Diagnosi s

5-8 : Moto r Drive r Ope n Diagnosi s

5-9 : Unde r Limi t Moto r Curren t Diagnosi s

5-10: Moto r Drive r Shorte d Diagnosi s

With engin e running , TC Sindicato r ligh t i s ON .

Wit h th e SC S servic e connec -

to r connecte d (se e pag e

19-159 ), DT C 5-4 , 5-5 , 5-6 , 5-7 , 5-8 ,5-9 and/o r 5-1 0 ar e indicated .

Chec k th e TC S (1 5 A ) fus e i n th e

under-hoo d fuse/rela y box .

I s th e fus e OK ?

Replace th e fus e an d recheck .

NOTE : Reinstal l th e

fus e i f i t i s OK .

Chec k fo r a n ope n i n th e IG 1 cir -

cuit:1. Tur n th e ignitio n switc h O N (II) .2. Measur e th e voltag e betwee n

th e fail-saf e rela y connecto r ter -

mina l No . 4 an d bod y ground .

NOTE: Star t th e engine , an d rechec k th efuse . I f th e fus e i s blown , chec k fo r ashor t t o bod y groun d in th e VP M circui tbetwee n th e fail-saf e rela y an d TC S con -trol unit .

FAIL-SAF E RELA Y CONNECTO R

Wire sid e o f femal e terminal s

I s ther e batter y voltage ? Repai

r ope n i n th e wir e betwee n

th e EC U (2 0 A ) fus e an d fail-saf e

relay .

Chec k th e fail-saf e rela y (se e

sectio n 23).

I s th e rela y OK ?

Replac e th e fail-saf e relay .TCS CONTRO L UNI T 20 P CONNECTO R

FSR (BLK/WHT )

Check fo r a n ope n in th e FS R cir -cuit :1. Tur n th e ignitio n switc h O N (II) .2. Measur e th e voltag e betwee nthe TC S contro l uni t 20 P con -necto r termina l No . 6 an d bod yground .Wire sid e o f femal e terminal s

I s ther e batter y voltage ?

T o pag e 19-18 8 Repai

r ope n i n th e wir e betwee n

th e fail-saf e rela y an d TC S con -

trol unit .

ProCarManuals.com

Page 1230 of 1954

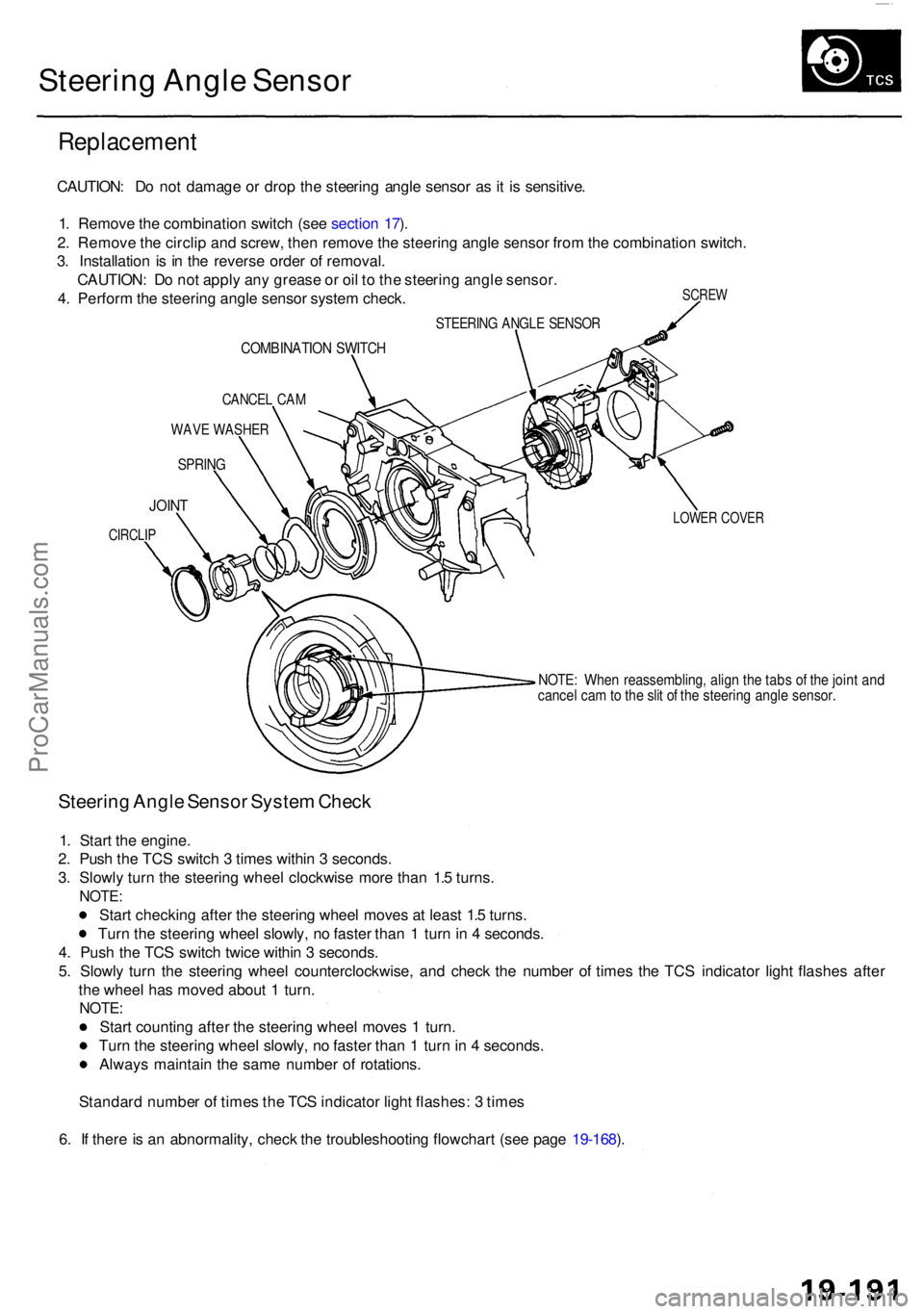

Steering Angl e Senso r

Replacemen t

SCREW

CAUTION : D o no t damag e o r dro p th e steerin g angl e senso r a s it i s sensitive .

1 . Remov e th e combinatio n switc h (se e sectio n 17 ).

2 . Remov e th e circli p an d screw , the n remov e th e steerin g angl e senso r fro m th e combinatio n switch .

3 . Installatio n i s i n th e revers e orde r o f removal .

CAUTION : D o no t appl y an y greas e o r oi l t o th e steerin g angl e sensor .

4 . Perfor m th e steerin g angl e senso r syste m check .

STEERIN G ANGL E SENSO R

COMBINATIO N SWITC H

CANCE L CA M

WAV E WASHE R

SPRING

LOWER COVE RJOINT

CIRCLI P

NOTE: Whe n reassembling , alig n th e tab s o f th e join t an dcance l ca m to th e sli t o f th e steerin g angl e sensor .

Steering Angl e Senso r Syste m Chec k

1. Star t th e engine .

2 . Pus h th e TC S switc h 3 time s withi n 3 seconds .

3 . Slowl y tur n th e steerin g whee l clockwis e mor e tha n 1. 5 turns .

NOTE :

Start checkin g afte r th e steerin g whee l move s a t leas t 1. 5 turns .

Tur n th e steerin g whee l slowly , n o faste r tha n 1 tur n in 4 seconds .

4 . Pus h th e TC S switc h twic e withi n 3 seconds .

5 . Slowl y tur n th e steerin g whee l counterclockwise , an d chec k th e numbe r o f time s th e TC S indicato r ligh t flashe s afte r

th e whee l ha s move d abou t 1 turn .

NOTE :

Start countin g afte r th e steerin g whee l move s 1 turn .

Tur n th e steerin g whee l slowly , n o faste r tha n 1 tur n in 4 seconds .

Alway s maintai n th e sam e numbe r o f rotations .

Standar d numbe r o f time s th e TC S indicato r ligh t flashes : 3 time s

6 . I f ther e is a n abnormality , chec k th e troubleshootin g flowchar t (se e pag e 19-168 ).

ProCarManuals.com