check engine ACURA RL KA9 1996 Service Service Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 661 of 1954

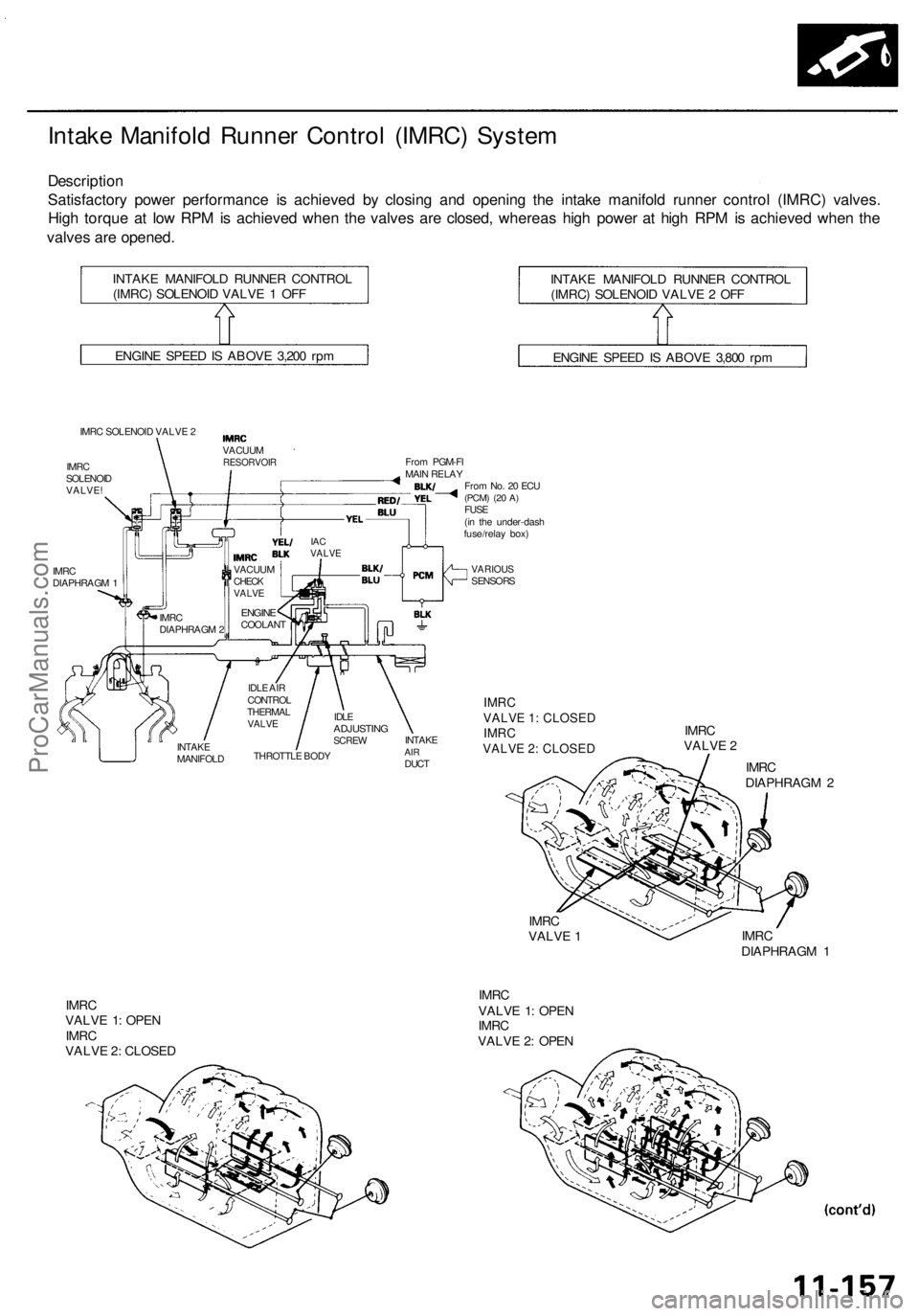

Intake Manifol d Runne r Contro l (IMRC ) Syste m

Descriptio n

Satisfactor y powe r performanc e i s achieve d b y closin g an d openin g th e intak e manifol d runne r contro l (IMRC ) valves .

Hig h torqu e a t lo w RP M is achieve d whe n th e valve s ar e closed , wherea s hig h powe r a t hig h RP M is achieve d whe n th e

valve s ar e opened .

INTAKE MANIFOL D RUNNE R CONTRO L

(IMRC ) SOLENOI D VALV E 1 OF F INTAK

E MANIFOL D RUNNE R CONTRO L

(IMRC ) SOLENOI D VALV E 2 OF F

ENGIN E SPEE D IS ABOV E 3,20 0 rp m

ENGINE SPEE D IS ABOV E 3,80 0 rp m

IMR C SOLENOI D VALV E 2

IMR C

SOLENOI D

VALVE !

IMR C

DIAPHRAG M 1

VARIOU SSENSOR S

IMRC

VALVE 1: CLOSED IMRC

VALVE 2: CLOSED

IMR C

VALV E 2

IMR C

DIAPHRAG M 2

IMR C

VALV E 1 IMR

C

DIAPHRAG M 1

IMR C

VALV E 1 : OPE N

IMR C

VALV E 2 : CLOSE D IMR

C

VALV E 1 : OPE N

IMR C

VALV E 2 : OPE N

From No . 2 0 EC U(PCM ) (20 A )FUS E

(i n th e under-das h

fuse/rela y box )

Fro

m PGM-F I

MAI N RELA Y

IACVALV E

ENGIN ECOOLAN T

VACUU

M

RESORVOI R

IMRC

DIAPHRAG M 2 VACUU

M

CHECKVALV E

INTAK E

MANIFOL DTHROTTL

E BOD Y

IDL

E AI R

CONTRO L

THERMA L

VALVEIDLEADJUSTIN GSCREWINTAK EAIRDUC T

ProCarManuals.com

Page 712 of 1954

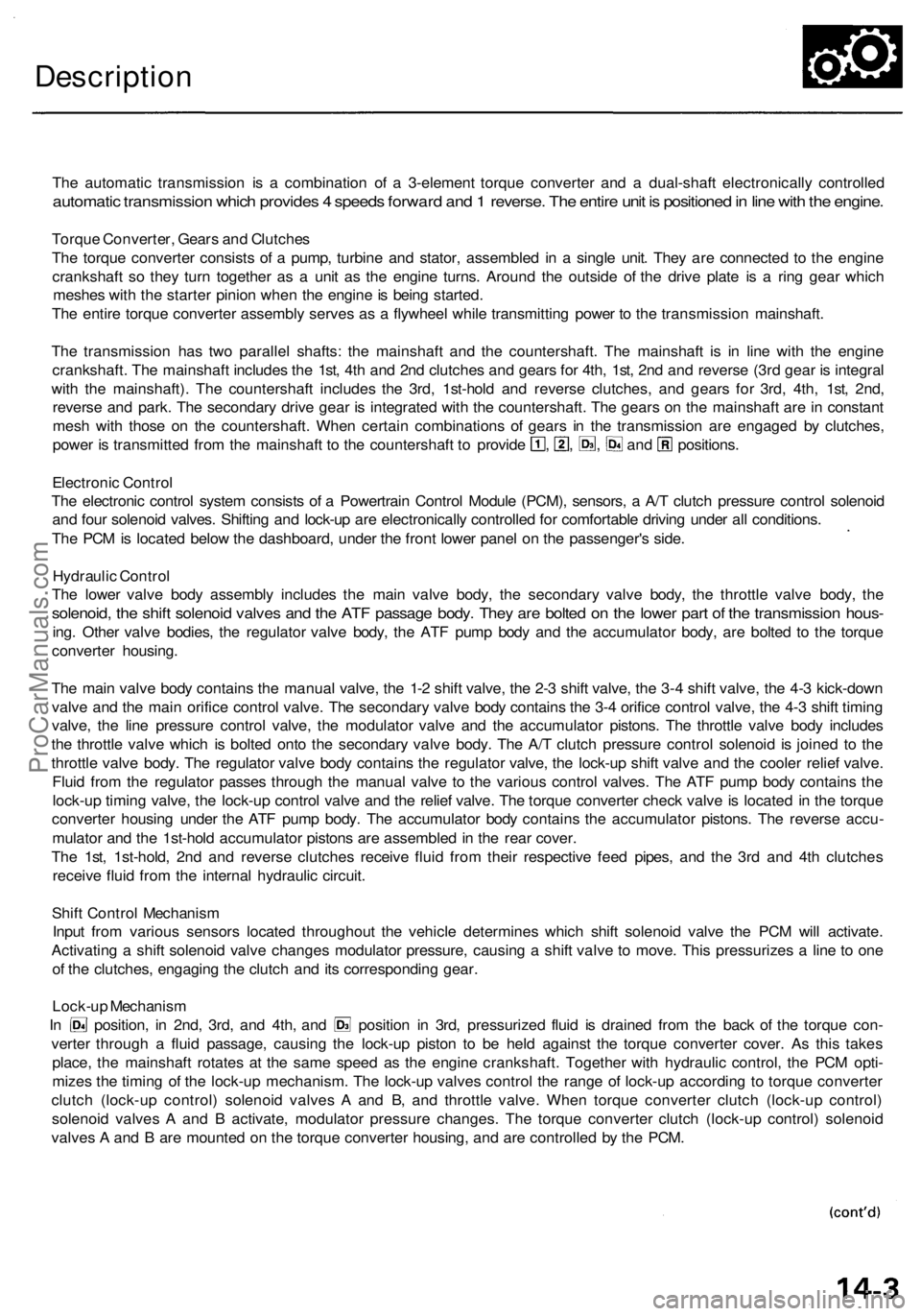

Description

The automatic transmission is a combination of a 3-element torque converter and a dual-shaft electronically controlled

automatic transmission which provides 4 speeds forward and 1 reverse. The entire unit is positioned in line with the engine.

Torque Converter, Gears and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the drive plate is a ring gear which

meshes with the starter pinion when the engine is being started.

The entire torque converter assembly serves as a flywheel while transmitting power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in line with the engine

crankshaft. The mainshaft includes the 1st, 4th and 2nd clutches and gears for 4th, 1st, 2nd and reverse (3rd gear is integral

with the mainshaft). The countershaft includes the 3rd, 1st-hold and reverse clutches, and gears for 3rd, 4th, 1st, 2nd,

reverse and park. The secondary drive gear is integrated with the countershaft. The gears on the mainshaft are in constant

mesh with those on the countershaft. When certain combinations of gears in the transmission are engaged by clutches,

power is transmitted from the mainshaft to the countershaft to provide , , , and positions.

Electronic Control

The electronic control system consists of a Powertrain Control Module (PCM), sensors, a A/T clutch pressure control solenoid

and four solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions.

The PCM is located below the dashboard, under the front lower panel on the passenger's side.

Hydraulic Control

The lower valve body assembly includes the main valve body, the secondary valve body, the throttle valve body, the

solenoid, the shift solenoid valves and the ATF passage body. They are bolted on the lower part of the transmission hous-

ing. Other valve bodies, the regulator valve body, the ATF pump body and the accumulator body, are bolted to the torque

converter housing.

The main valve body contains the manual valve, the 1-2 shift valve, the 2-3 shift valve, the 3-4 shift valve, the 4-3 kick-down

valve and the main orifice control valve. The secondary valve body contains the 3-4 orifice control valve, the 4-3 shift timing

valve, the line pressure control valve, the modulator valve and the accumulator pistons. The throttle valve body includes

the throttle valve which is bolted onto the secondary valve body. The A/T clutch pressure control solenoid is joined to the

throttle valve body. The regulator valve body contains the regulator valve, the lock-up shift valve and the cooler relief valve.

Fluid from the regulator passes through the manual valve to the various control valves. The ATF pump body contains the

lock-up timing valve, the lock-up control valve and the relief valve. The torque converter check valve is located in the torque

converter housing under the ATF pump body. The accumulator body contains the accumulator pistons. The reverse accu-

mulator and the 1st-hold accumulator pistons are assembled in the rear cover.

The 1st, 1st-hold, 2nd and reverse clutches receive fluid from their respective feed pipes, and the 3rd and 4th clutches

receive fluid from the internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the vehicle determines which shift solenoid valve the PCM will activate.

Activating a shift solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line to one

of the clutches, engaging the clutch and its corresponding gear.

Lock-up Mechanism

In position, in 2nd, 3rd, and 4th, and position in 3rd, pressurized fluid is drained from the back of the torque con-

verter through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes

place, the mainshaft rotates at the same speed as the engine crankshaft. Together with hydraulic control, the PCM opti-

mizes the timing of the lock-up mechanism. The lock-up valves control the range of lock-up according to torque converter

clutch (lock-up control) solenoid valves A and B, and throttle valve. When torque converter clutch (lock-up control)

solenoid valves A and B activate, modulator pressure changes. The torque converter clutch (lock-up control) solenoid

valves A and B are mounted on the torque converter housing, and are controlled by the PCM.ProCarManuals.com

Page 728 of 1954

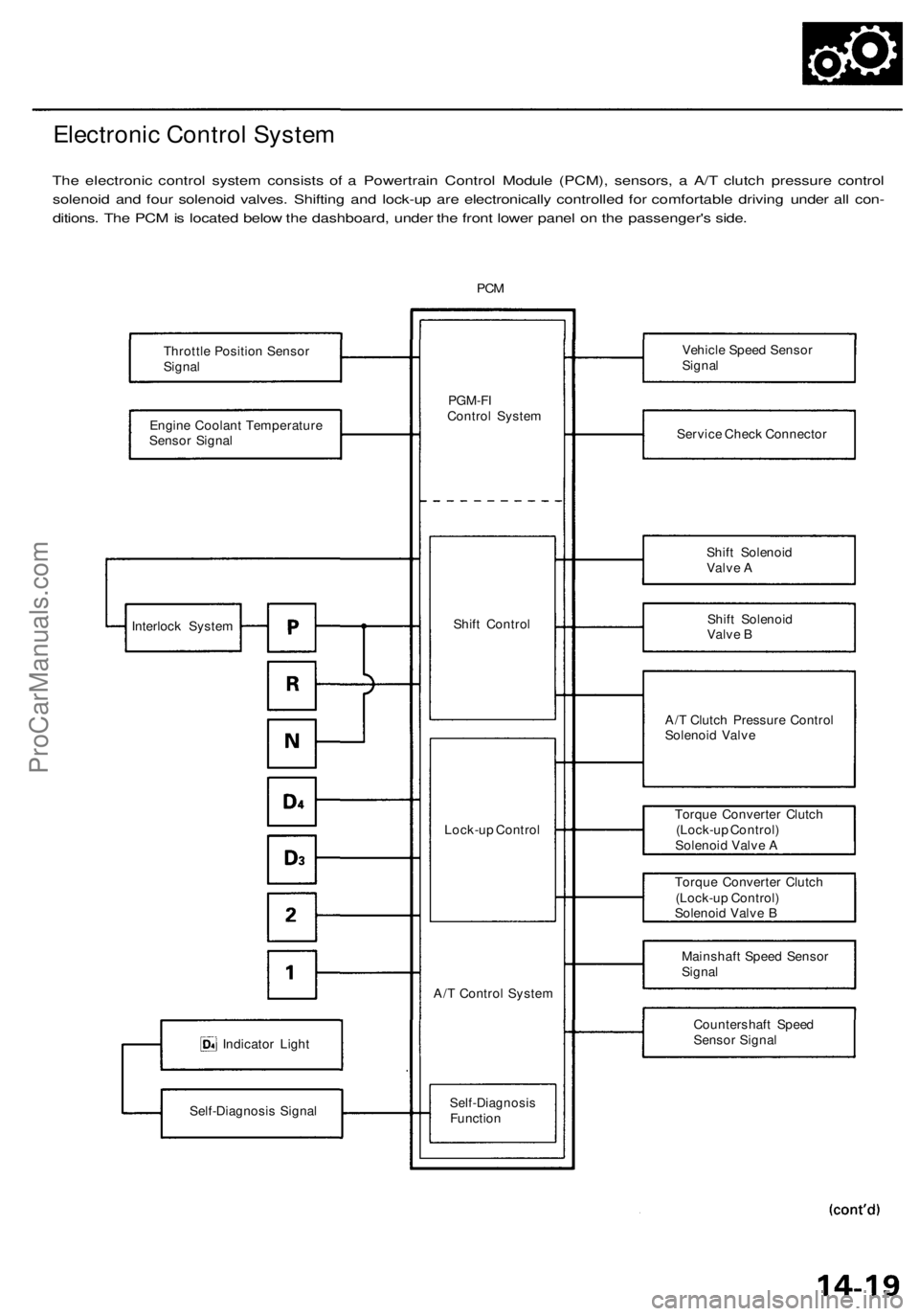

Electronic Control System

The electronic control system consists of a Powertrain Control Module (PCM), sensors, a A/T clutch pressure control

solenoid and four solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all con-

ditions. The PCM is located below the dashboard, under the front lower panel on the passenger's side.

PCM

Throttle Position Sensor

Signal

Engine Coolant Temperature

Sensor Signal

Indicator Light

Self-Diagnosis Signal

PGM-FI

Control System

Shift Control

Lock-up Control

A/T Control System

Self-Diagnosis

Function

Vehicle Speed Sensor

Signal

Service Check Connector

Shift Solenoid

Valve A

Shift Solenoid

Valve B

A/T Clutch Pressure Control

Solenoid Valve

Torque Converter Clutch

(Lock-up Control)

Solenoid Valve A

Torque Converter Clutch

(Lock-up Control)

Solenoid Valve B

Mainshaft Speed Sensor

Signal

Countershaft Speed

Sensor Signal

Interlock SystemProCarManuals.com

Page 738 of 1954

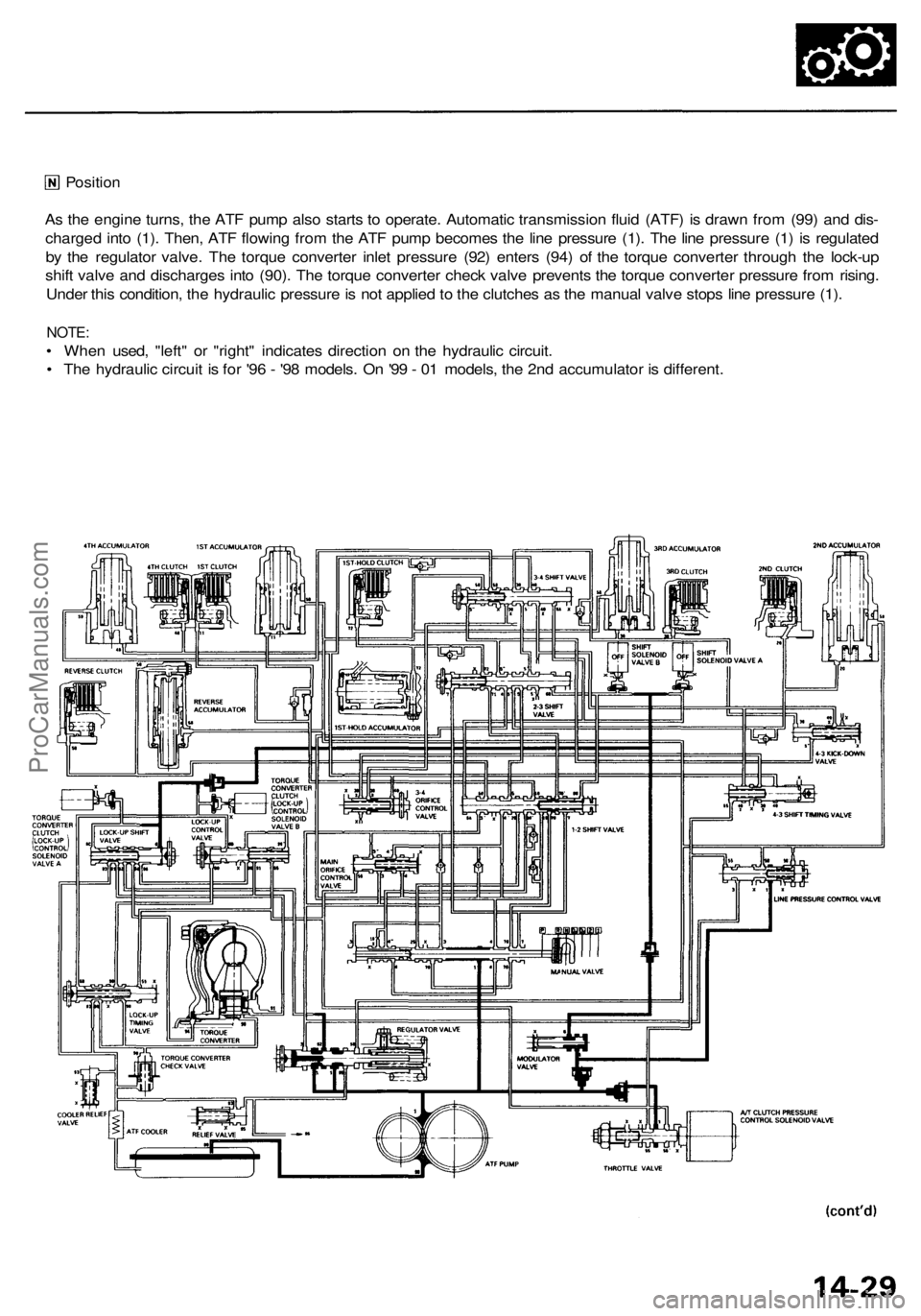

Position

As the engine turns, the ATF pump also starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-

charged into (1). Then, ATF flowing from the ATF pump becomes the line pressure (1). The line pressure (1) is regulated

by the regulator valve. The torque converter inlet pressure (92) enters (94) of the torque converter through the lock-up

shift valve and discharges into (90). The torque converter check valve prevents the torque converter pressure from rising.

Under this condition, the hydraulic pressure is not applied to the clutches as the manual valve stops line pressure (1).

NOTE:

• When used, "left" or "right" indicates direction on the hydraulic circuit.

• The hydraulic circuit is for '96 - '98 models. On '99 - 01 models, the 2nd accumulator is different.ProCarManuals.com

Page 802 of 1954

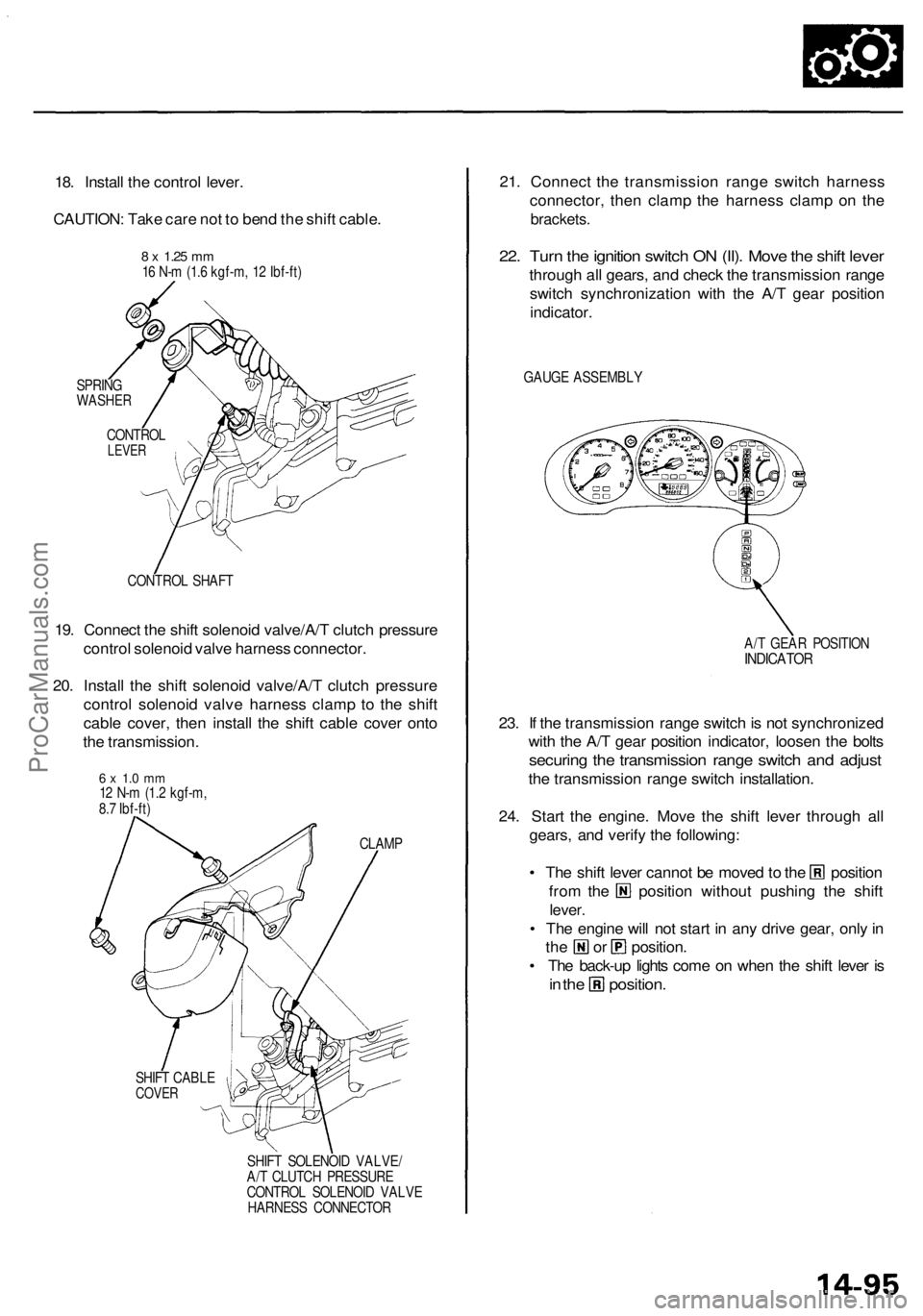

18. Install the control lever.

CAUTION: Take care not to bend the shift cable.

SPRING

WASHER

CONTROL SHAFT

19. Connect the shift solenoid valve/A/T clutch pressure

control solenoid valve harness connector.

20. Install the shift solenoid valve/A/T clutch pressure

control solenoid valve harness clamp to the shift

cable cover, then install the shift cable cover onto

the transmission.

CLAMP

SHIFT CABLE

COVER

SHIFT SOLENOID VALVE/

A/T CLUTCH PRESSURE

CONTROL SOLENOID VALVE

HARNESS CONNECTOR

21. Connect the transmission range switch harness

connector, then clamp the harness clamp on the

brackets.

22. Turn the ignition switch ON (II). Move the shift lever

through all gears, and check the transmission range

switch synchronization with the A/T gear position

indicator.

GAUGE ASSEMBLY

A/T GEAR POSITION

INDICATOR

23. If the transmission range switch is not synchronized

with the A/T gear position indicator, loosen the bolts

securing the transmission range switch and adjust

the transmission range switch installation.

24. Start the engine. Move the shift lever through all

gears, and verify the following:

• The shift lever cannot be moved to the position

from the position without pushing the shift

lever.

• The engine will not start in any drive gear, only in

the or position.

• The back-up lights come on when the shift lever is

in the position.

8 x

1.25

mm

16 N-m (1.6 kgf-m, 12 Ibf-ft)

CONTROL

LEVER

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)ProCarManuals.com

Page 815 of 1954

Fluid Leve l

Checking/Changin g

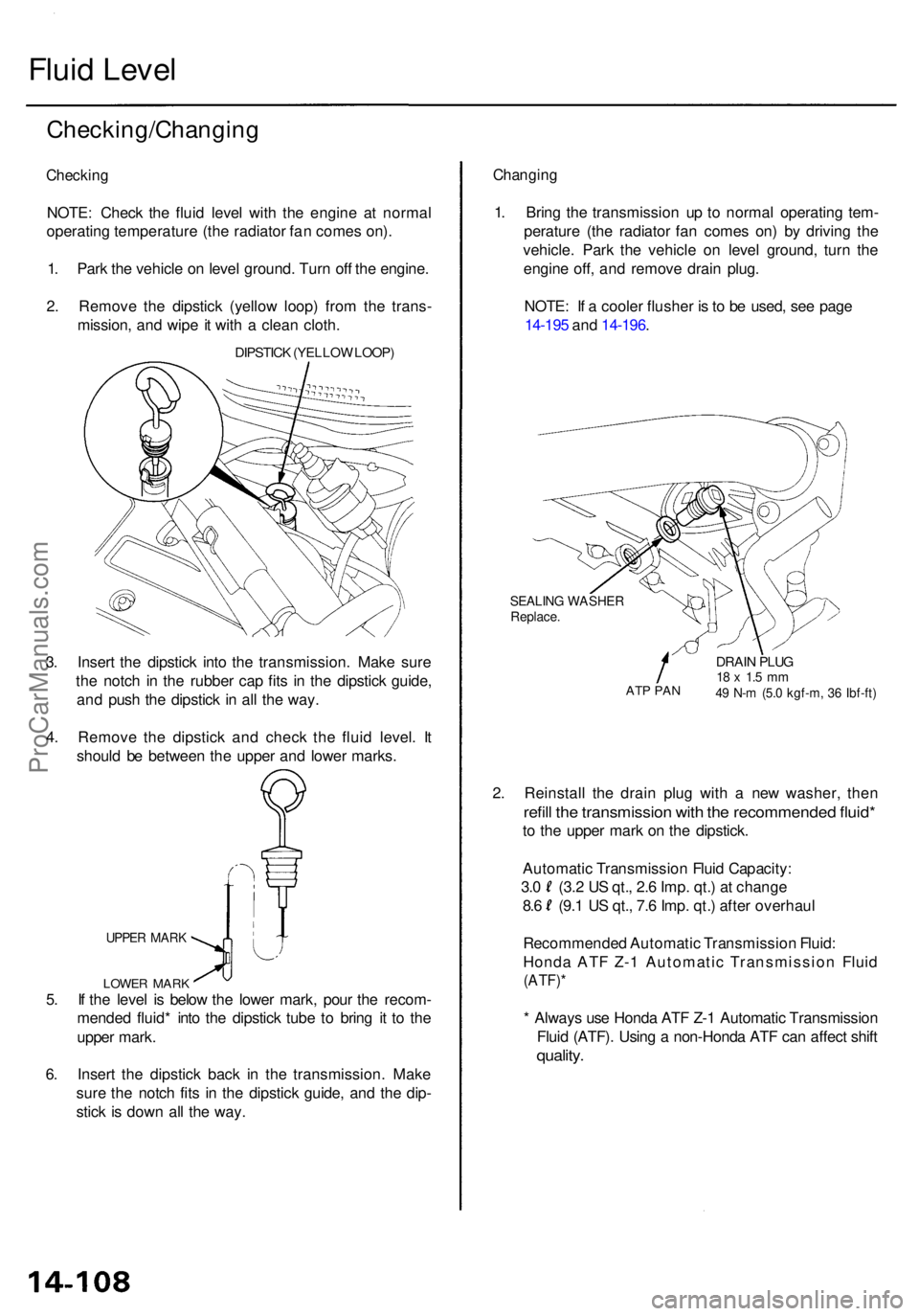

Checking

NOTE: Chec k th e flui d leve l wit h th e engin e a t norma l

operatin g temperatur e (th e radiato r fa n come s on) .

1 . Par k th e vehicl e o n leve l ground . Tur n of f th e engine .

2 . Remov e th e dipstic k (yello w loop ) fro m th e trans -

mission , an d wip e it wit h a clea n cloth .

DIPSTIC K (YELLO W LOOP )

3. Inser t th e dipstic k int o th e transmission . Mak e sur e

th e notc h i n th e rubbe r ca p fit s i n th e dipstic k guide ,

an d pus h th e dipstic k i n al l th e way .

4 . Remov e th e dipstic k an d chec k th e flui d level . I t

shoul d b e betwee n th e uppe r an d lowe r marks .

UPPER MAR K

5. I f th e leve l i s belo w th e lowe r mark , pou r th e recom -

mende d fluid * int o th e dipstic k tub e t o brin g i t t o th e

uppe r mark .

6 . Inser t th e dipstic k bac k i n th e transmission . Mak e

sur e th e notc h fit s i n th e dipstic k guide , an d th e dip -

stic k i s dow n al l th e way .

Changin g

1. Brin g th e transmissio n u p t o norma l operatin g tem -

peratur e (th e radiato r fa n come s on ) b y drivin g th e

vehicle . Par k th e vehicl e o n leve l ground , tur n th e

engin e off , an d remov e drai n plug .

NOTE : I f a coole r flushe r i s to b e used , se e pag e

14-19 5 an d 14-196 .

SEALIN G WASHE RReplace.

ATP PA N

DRAI N PLU G18 x 1. 5 m m49 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

2. Reinstal l th e drai n plu g wit h a ne w washer , the n

refill th e transmissio n wit h th e recommende d fluid *

to th e uppe r mar k o n th e dipstick .

Automati c Transmissio n Flui d Capacity :

3.0 (3. 2 U S qt. , 2. 6 Imp . qt. ) a t chang e

8.6 (9. 1 U S qt. , 7. 6 Imp . qt. ) afte r overhau l

Recommende d Automati c Transmissio n Fluid :

Hond a AT F Z- 1 Automati c Transmissio n Flui d

(ATF) *

* Alway s us e Hond a AT F Z- 1 Automati c Transmissio n

Flui d (ATF) . Usin g a non-Hond a AT F ca n affec t shif t

quality .

LOWE R MAR K

ProCarManuals.com

Page 817 of 1954

Pressure Testing

(cont'd)

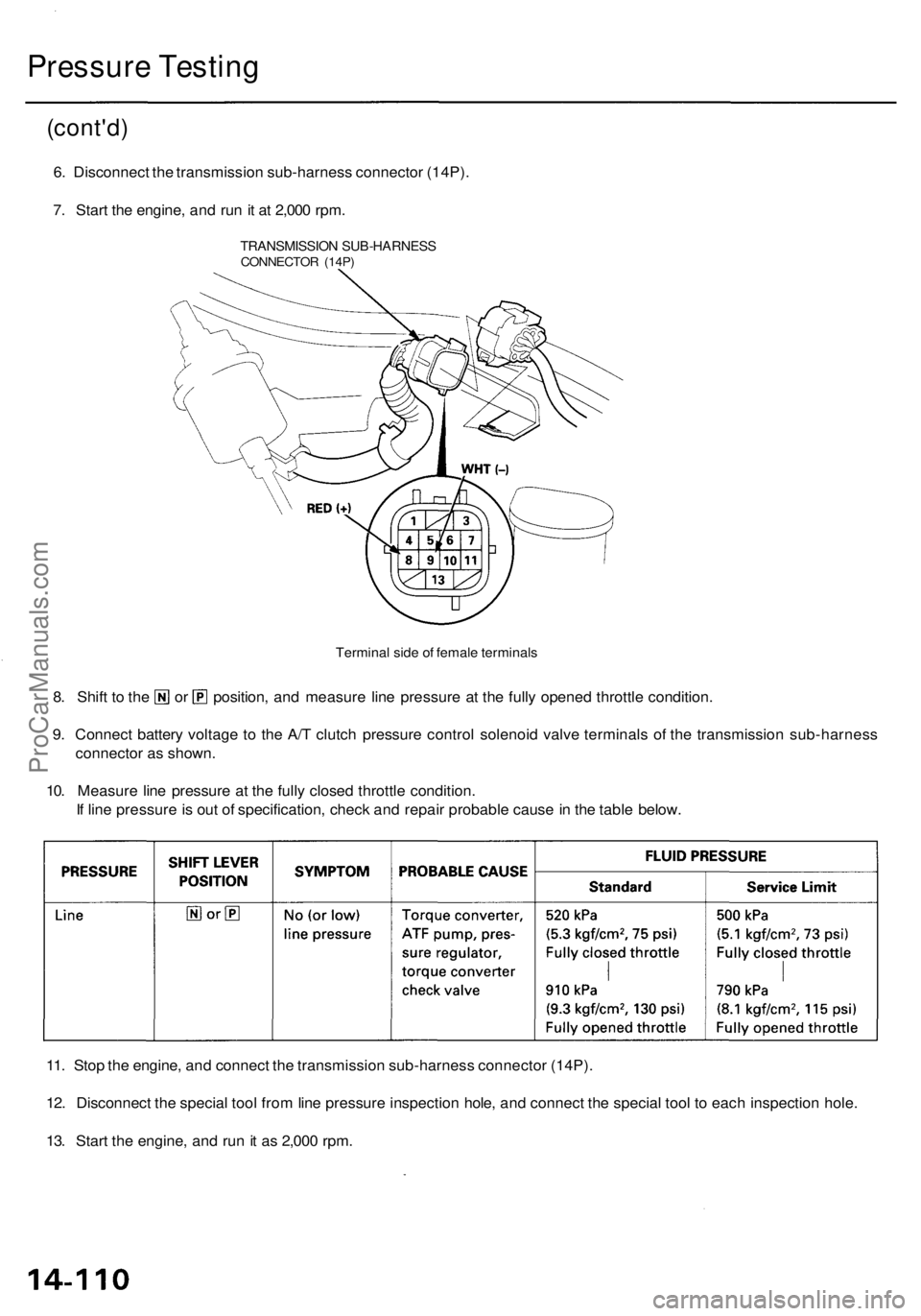

6. Disconnect the transmission sub-harness connector (14P).

7. Start the engine, and run it at 2,000 rpm.

Terminal side of female terminals

8. Shift to the or position, and measure line pressure at the fully opened throttle condition.

9. Connect battery voltage to the A/T clutch pressure control solenoid valve terminals of the transmission sub-harness

connector as shown.

10. Measure line pressure at the fully closed throttle condition.

If line pressure is out of specification, check and repair probable cause in the table below.

11. Stop the engine, and connect the transmission sub-harness connector (14P).

12. Disconnect the special tool from line pressure inspection hole, and connect the special tool to each inspection hole.

13. Start the engine, and run it as 2,000 rpm.

TRANSMISSION SUB-HARNESS

CONNECTOR (14P)ProCarManuals.com

Page 915 of 1954

Maintenance

Differential Oil

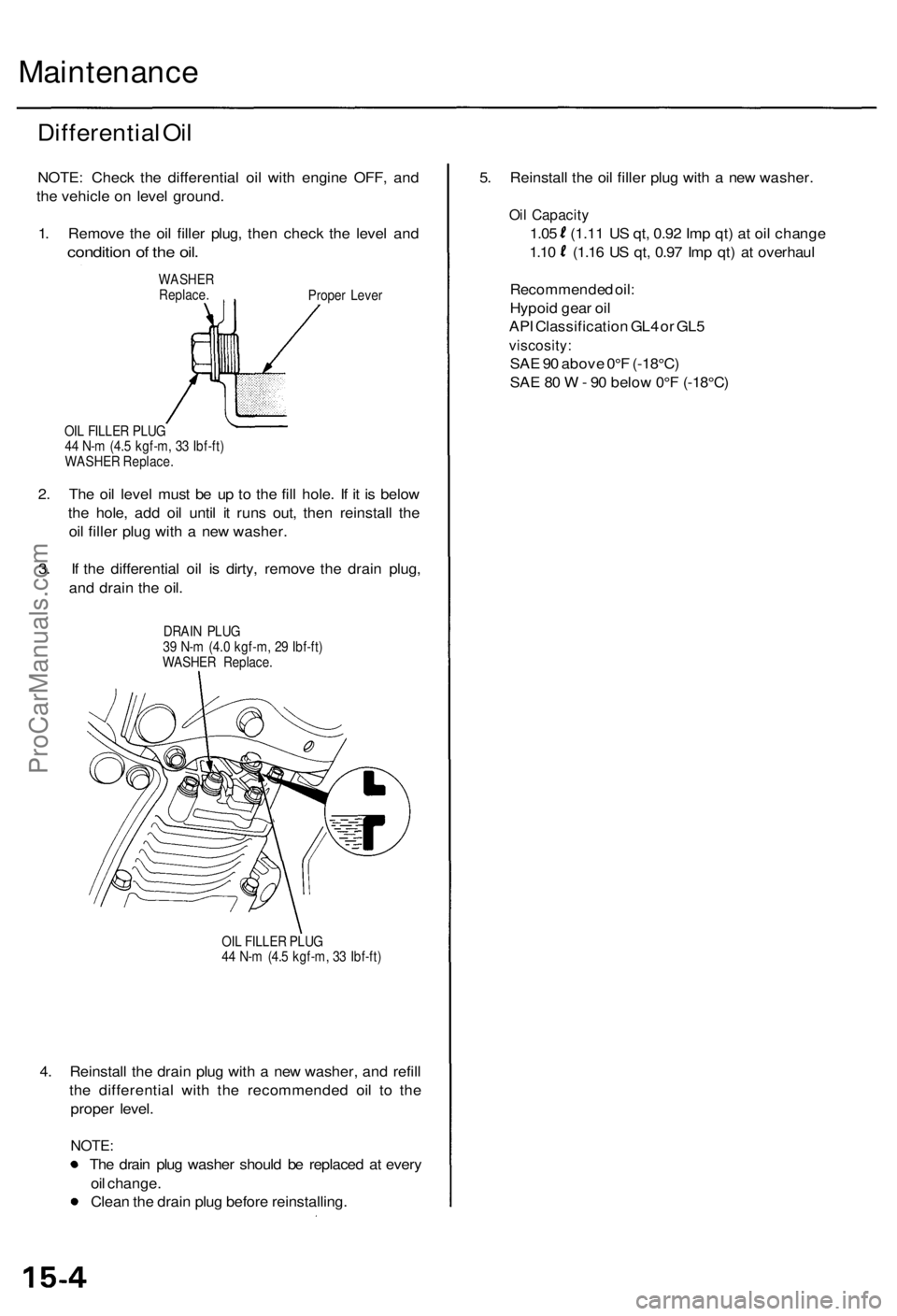

NOTE: Check the differential oil with engine OFF, and

the vehicle on level ground.

1. Remove the oil filler plug, then check the level and

condition of the oil.

WASHER

Replace.

Proper Lever

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

WASHER Replace.

2. The oil level must be up to the fill hole. If it is below

the hole, add oil until it runs out, then reinstall the

oil filler plug with a new washer.

3. If the differential oil is dirty, remove the drain plug,

and drain the oil.

DRAIN PLUG

39 N-m (4.0 kgf-m, 29 Ibf-ft)

WASHER Replace.

OIL FILLER PLUG

44 N-m (4.5 kgf-m, 33 Ibf-ft)

4. Reinstall the drain plug with a new washer, and refill

the differential with the recommended oil to the

proper level.

NOTE:

The drain plug washer should be replaced at every

oil change.

Clean the drain plug before reinstalling.

5. Reinstall the oil filler plug with a new washer.

Oil Capacity

1.05 (1.11 US qt, 0.92 Imp qt) at oil change

1.10 (1.16 US qt, 0.97 Imp qt) at overhaul

Recommended oil:

Hypoid gear oil

API Classification GL4 or GL5

viscosity:

SAE 90 above 0°F (-18°C)

SAE 80 W - 90 below 0°F (-18°C)ProCarManuals.com

Page 981 of 1954

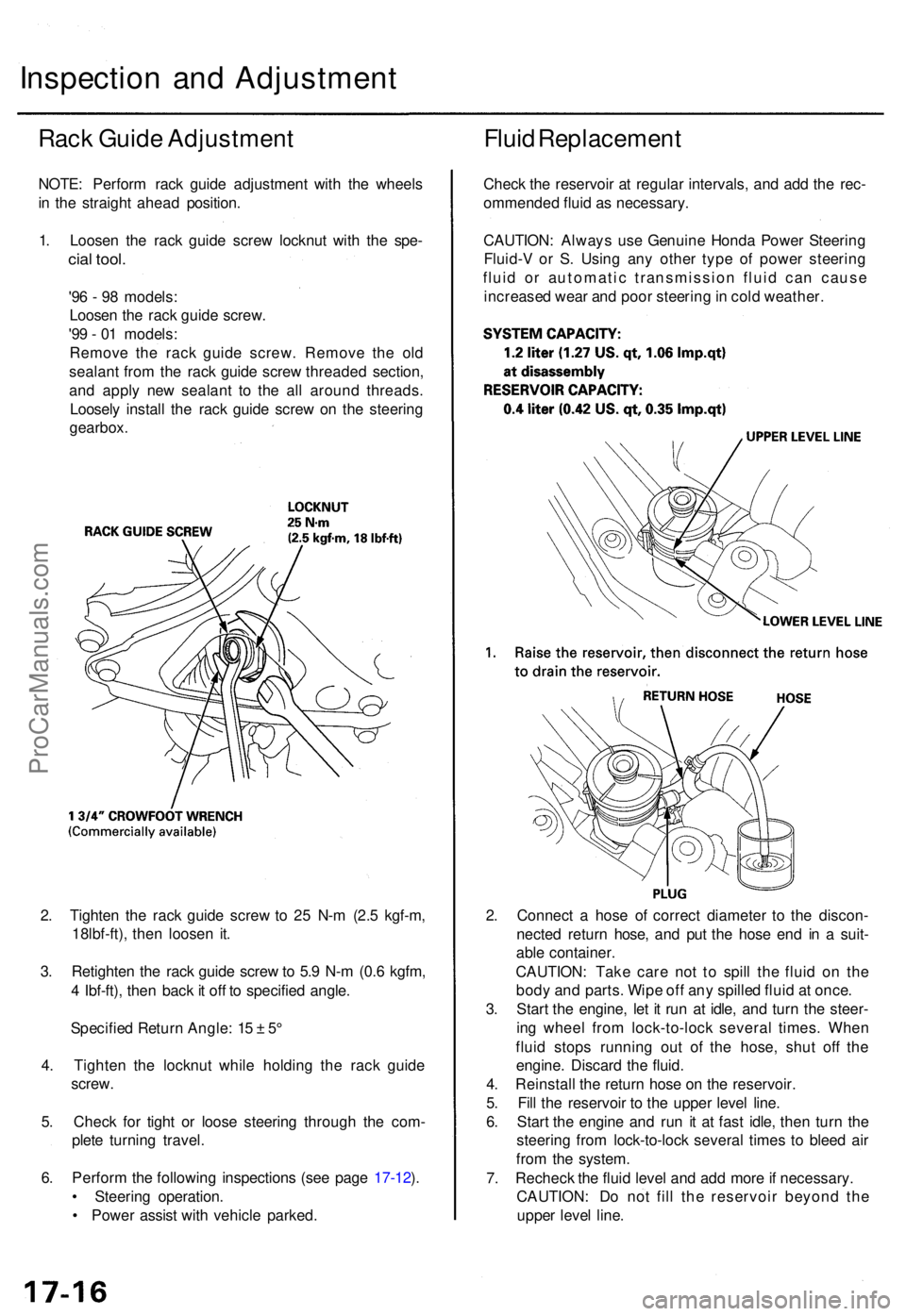

2. Tighte n th e rac k guid e scre w to 2 5 N- m (2. 5 kgf-m ,

18lbf-ft) , the n loose n it .

3 . Retighte n th e rac k guid e scre w to 5. 9 N- m (0. 6 kgfm ,

4 Ibf-ft) , the n bac k it of f t o specifie d angle .

Specifie d Retur n Angle : 1 5 ± 5°

4 . Tighte n th e locknu t whil e holdin g th e rac k guid e

screw .

5 . Chec k fo r tigh t o r loos e steerin g throug h th e com -

plet e turnin g travel .

6 . Perfor m th e followin g inspection s (se e pag e 17-12 ).

• Steerin g operation .

• Powe r assis t wit h vehicl e parked . 2

. Connec t a hos e o f correc t diamete r t o th e discon -

necte d retur n hose , an d pu t th e hos e en d i n a suit -

abl e container .

CAUTION : Tak e car e no t t o spil l th e flui d o n th e

bod y an d parts . Wip e of f an y spille d flui d a t once .

3 . Star t th e engine , le t i t ru n a t idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l times . Whe n

flui d stop s runnin g ou t of the hose , shu t of f th e

engine . Discar d th e fluid .

4 . Reinstal l th e retur n hos e o n th e reservoir .

5 . Fil l th e reservoi r t o th e uppe r leve l line .

6 . Star t th e engin e an d ru n i t a t fas t idle , the n tur n th e

steerin g fro m lock-to-loc k severa l time s t o blee d ai r

fro m th e system .

7 . Rechec k th e flui d leve l an d ad d mor e if necessary .

CAUTION : D o no t fil l th e reservoi r beyon d th e

uppe r leve l line .

Inspectio n an d Adjustmen t

Rack Guid e Adjustmen t

NOTE: Perfor m rac k guid e adjustmen t wit h th e wheel s

i n th e straigh t ahea d position .

1 . Loose n th e rac k guid e scre w locknu t wit h th e spe -

cial tool .

'96 - 9 8 models :

Loose n th e rac k guid e screw .

'9 9 - 0 1 models :

Remov e th e rac k guid e screw . Remov e th e ol d

sealan t fro m th e rac k guid e scre w threade d section ,

an d appl y ne w sealan t t o th e al l aroun d threads .

Loosel y instal l th e rac k guid e scre w o n th e steerin g

gearbox .

Fluid Replacemen t

Check th e reservoi r a t regula r intervals , an d ad d th e rec -

ommende d flui d a s necessary .

CAUTION : Alway s us e Genuin e Hond a Powe r Steerin g

Fluid- V o r S . Usin g an y othe r typ e o f powe r steerin g

flui d o r automati c transmissio n flui d ca n caus e

increase d wea r an d poo r steerin g in col d weather .

ProCarManuals.com

Page 1022 of 1954

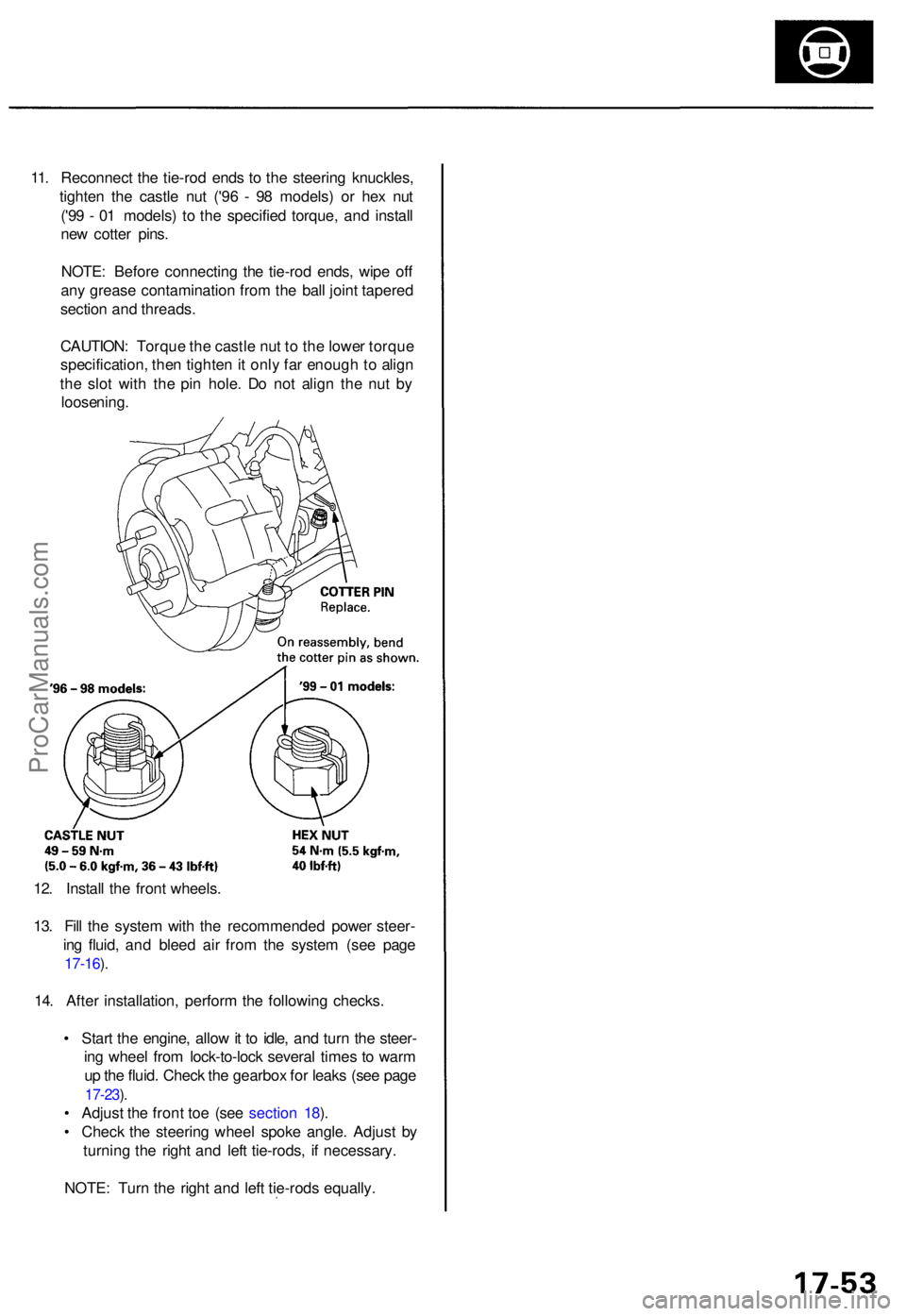

12. Instal l th e fron t wheels .

13 . Fil l th e syste m wit h th e recommende d powe r steer -

in g fluid , an d blee d ai r fro m th e syste m (se e pag e

17-16 ).

14 . Afte r installation , perfor m th e followin g checks .

• Star t th e engine , allo w it t o idle , an d tur n th e steer -

in g whee l fro m lock-to-loc k severa l time s t o war m

u p th e fluid . Chec k th e gearbo x fo r leak s (se e pag e

17-23 ).

• Adjus t th e fron t to e (se e sectio n 18 ).

• Chec k th e steerin g whee l spok e angle . Adjus t b y

turnin g th e righ t an d lef t tie-rods , i f necessary .

NOTE : Tur n th e righ t an d lef t tie-rod s equally .

11

. Reconnec t th e tie-ro d end s t o th e steerin g knuckles ,

tighte n th e castl e nu t ('9 6 - 9 8 models ) o r he x nu t

('9 9 - 0 1 models ) t o th e specifie d torque , an d instal l

ne w cotte r pins .

NOTE : Befor e connectin g th e tie-ro d ends , wip e of f

an y greas e contaminatio n fro m th e bal l join t tapere d

sectio n an d threads .

CAUTION : Torqu e th e castl e nu t t o th e lowe r torqu e

specification , the n tighte n it onl y fa r enoug h to alig n

th e slo t wit h th e pi n hole . D o no t alig n th e nu t b y

loosening .

ProCarManuals.com