check engine ACURA RL KA9 1996 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 572 of 1954

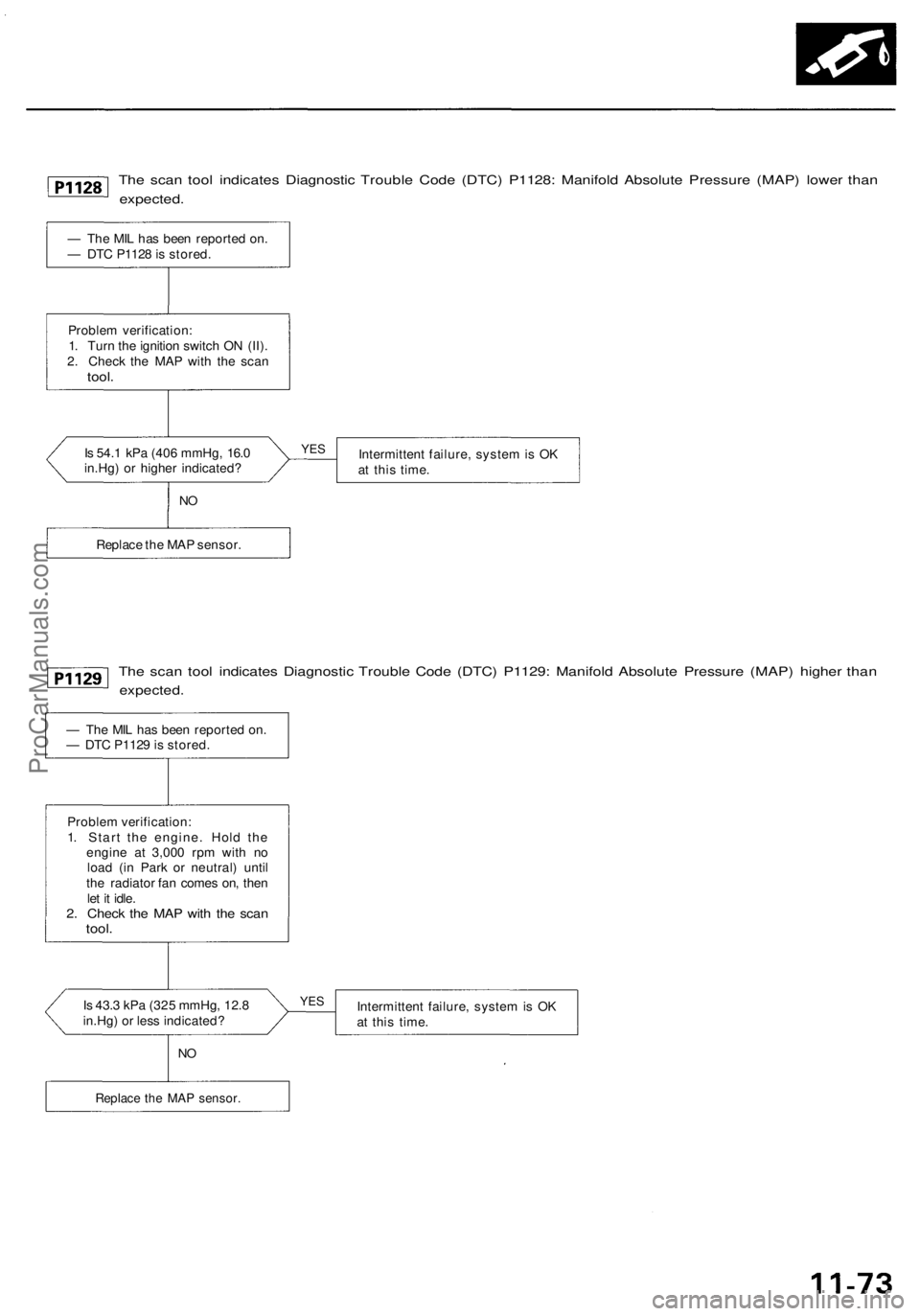

The scan tool indicates Diagnostic Trouble Code (DTC) P1128: Manifold Absolute Pressure (MAP) lower than

expected.

— The MIL has been reported on.

— DTC P1128 is stored.

Problem verification:

1. Turn the ignition switch ON (II).

2. Check the MAP with the scan

tool.

Is 54.1 kPa (406 mmHg, 16.0

in.Hg) or higher indicated?

Intermittent failure, system is OK

at this time.

The scan tool indicates Diagnostic Trouble Code (DTC) P1129: Manifold Absolute Pressure (MAP) higher than

expected.

Is 43.3 kPa (325 mmHg, 12.8

in.Hg) or less indicated?

Intermittent failure, system is OK

at this time.

Replace the MAP sensor.

NO

YES

Problem verification:

1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on, then

let it idle.

2. Check the MAP with the scan

tool.

— The MIL has been reported on.

— DTC P1129 is stored.

Replace the MAP sensor.

NO

YESProCarManuals.com

Page 589 of 1954

PGM-FI System

Secondary Heated Oxygen Sensor (HO2S) (Sensor 2) (cont'd)

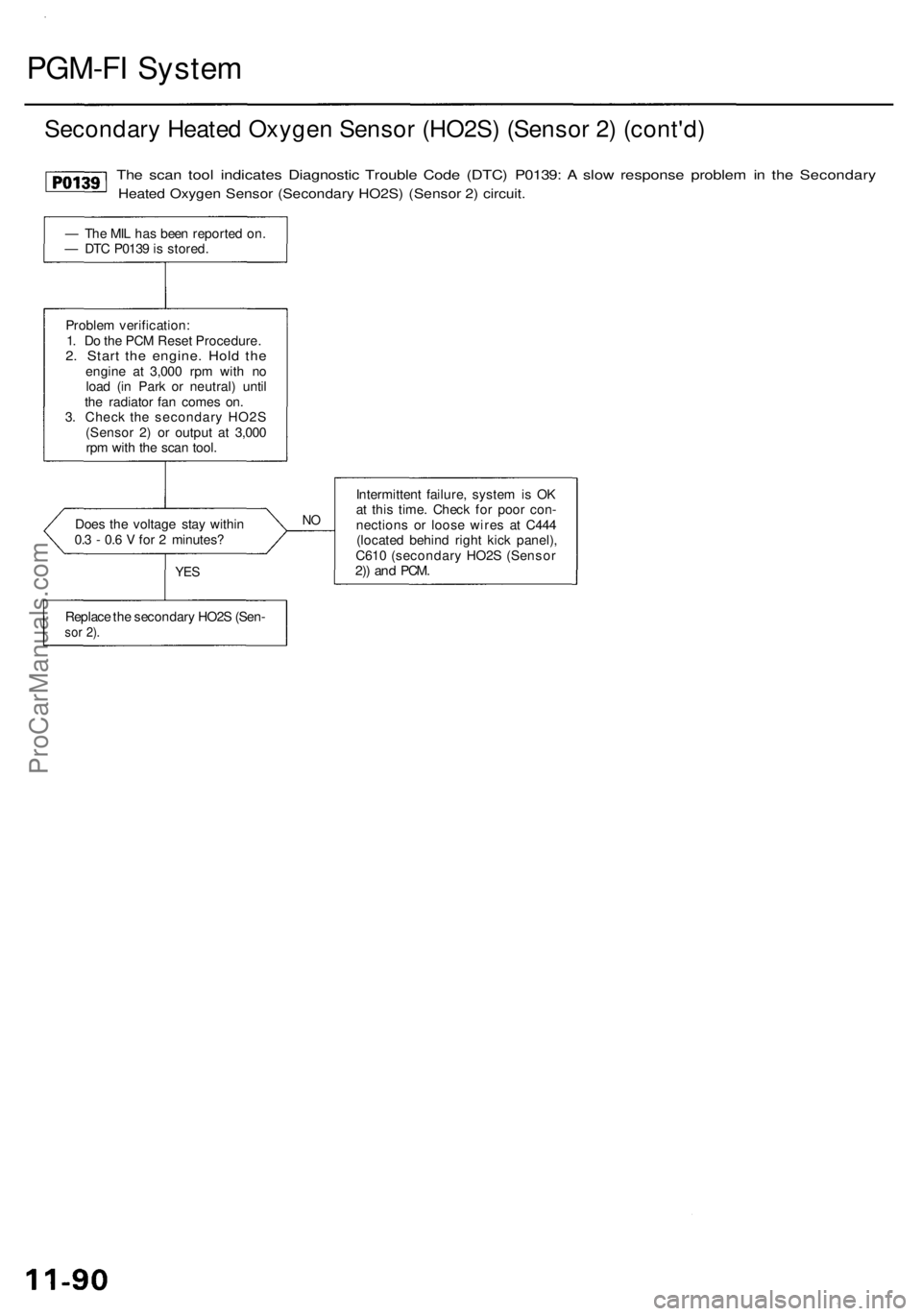

Does the voltage stay within

0.3 - 0.6 V for 2 minutes?

NO

Intermittent failure, system is OK

at this time. Check for poor con-

nections or loose wires at C444

(located behind right kick panel),

C610 (secondary HO2S (Sensor

2)) and

PCM.

The scan tool indicates Diagnostic Trouble Code (DTC) P0139: A slow response problem in the Secondary

Heated Oxygen Sensor (Secondary HO2S) (Sensor 2) circuit.

— The MIL has been reported on.

— DTC P0139 is stored.

Problem verification:

1. Do the PCM Reset Procedure.

2. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on.

3. Check the secondary HO2S

(Sensor 2) or output at 3,000

rpm with the scan tool.

Replace the secondary HO2S (Sen-

sor 2).

YESProCarManuals.com

Page 593 of 1954

PGM-FI System

Fuel Supply System (cont'd)

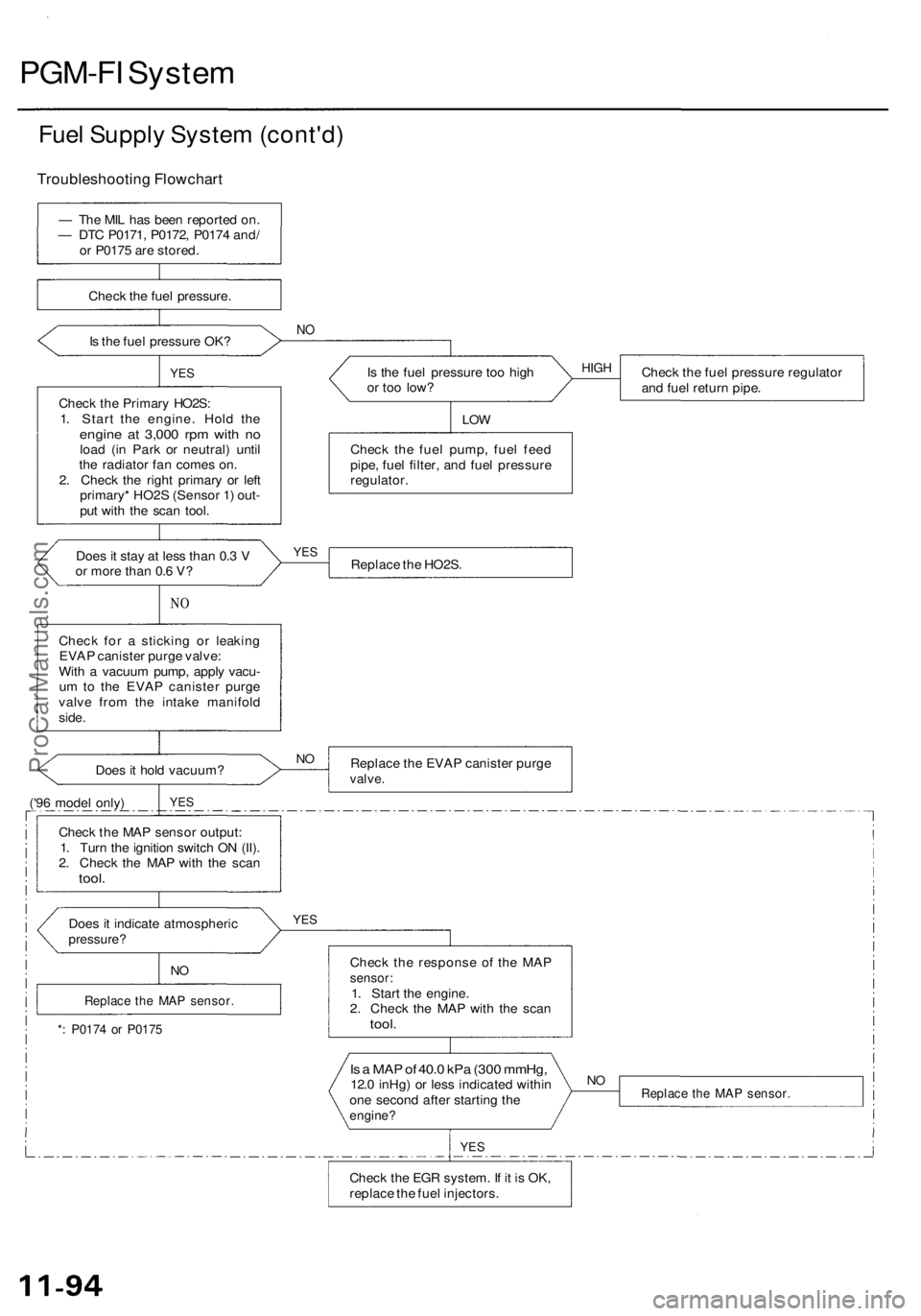

— The MIL has been reported on.

— DTC P0171, P0172, P0174 and/

or P0175 are stored.

Check the fuel pressure.

Is the fuel pressure OK?

NO

YES

Check the Primary HO2S:

1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on.

2. Check the right primary or left

primary* HO2S (Sensor 1) out-

put with the scan tool.

Is the fuel pressure too high

or too low?

Check the fuel pressure regulator

and fuel return pipe.

LOW

Check the fuel pump, fuel feed

pipe, fuel filter, and fuel pressure

regulator.

Does it stay at less than 0.3 V

or more than 0.6 V?

Replace the HO2S.

NO

Check for a sticking or leaking

EVAP canister purge valve:

With a vacuum pump, apply vacu-

um to the EVAP canister purge

valve from the intake manifold

side.

Does it hold vacuum?

('96 model only)

Replace the EVAP canister purge

valve.

YES

Check the MAP sensor output:

1. Turn the ignition switch ON (II).

2. Check the MAP with the scan

tool.

Does it indicate atmospheric

pressure?

YES

*: P0174 or P0175

Check the response of the MAP

sensor:

1. Start the engine.

2. Check the MAP with the scan

tool.

Is a MAP of 40.0 kPa (300 mmHg,

12.0 inHg) or less indicated within

one second after starting the

engine?

Replace the MAP sensor.

YES

Check the EGR system. If it is OK,

replace the fuel injectors.

NO

NO

Replace the MAP sensor.

NO

YES

HIGH

Troubleshooting FlowchartProCarManuals.com

Page 594 of 1954

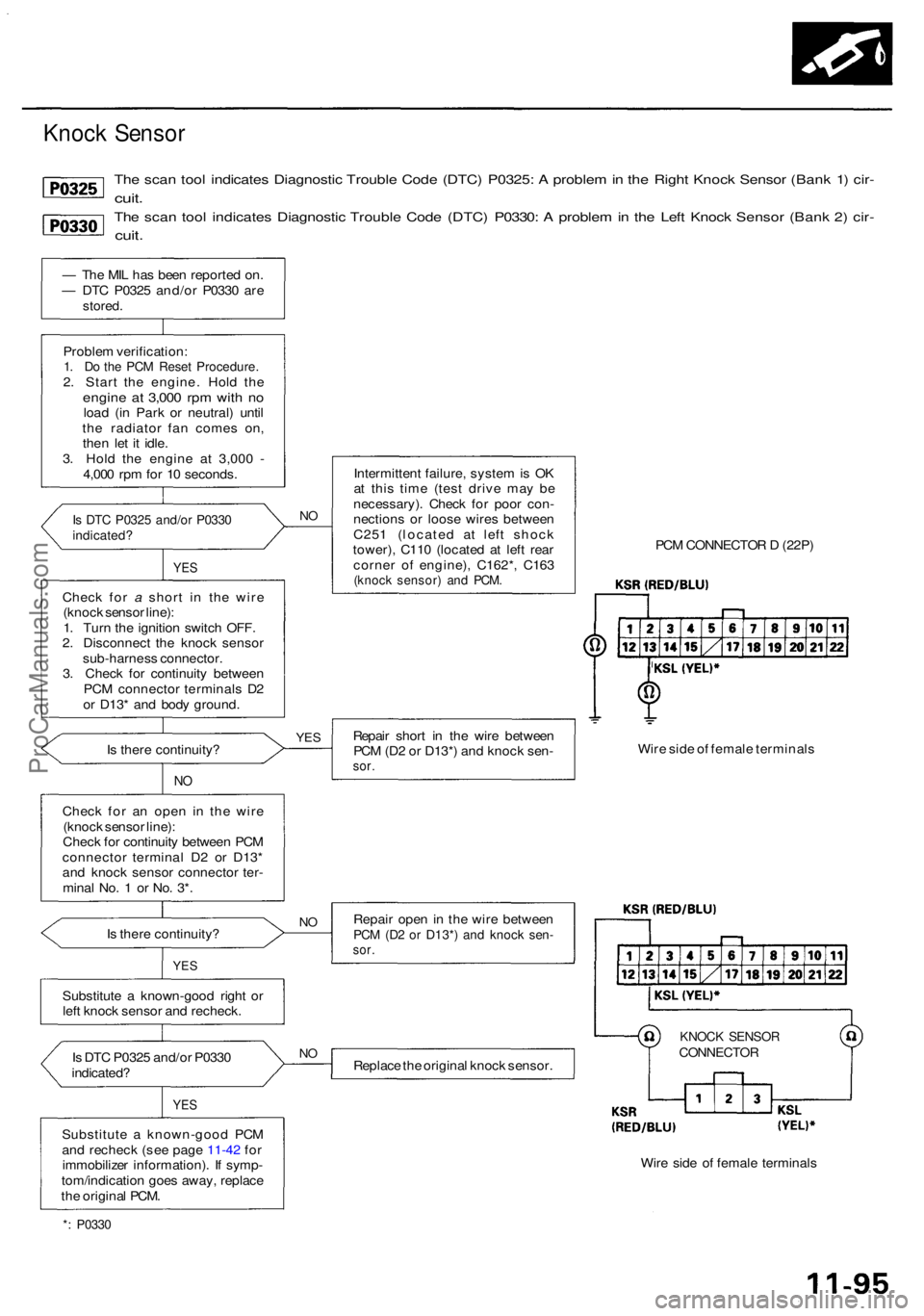

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0325 : A proble m in th e Righ t Knoc k Senso r (Ban k 1 ) cir -

cuit .

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0330 : A proble m in th e Lef t Knoc k Senso r (Ban k 2 ) cir -

cuit .

— Th e MI L ha s bee n reporte d on .

— DT C P032 5 and/o r P033 0 ar e

stored .

Proble m verification :1. D o th e PC M Rese t Procedure .2. Star t th e engine . Hol d th eengin e a t 3,00 0 rp m wit h n oloa d (i n Par k o r neutral ) unti l

th e radiato r fa n come s on ,

the n le t i t idle .

3 . Hol d th e engin e a t 3,00 0 -

4,00 0 rp m fo r 1 0 seconds .

Is DT C P032 5 and/o r P033 0indicated ?

YES

Chec k fo r a shor t i n th e wir e

(knoc k senso r line) :

1 . Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e knoc k senso r

sub-harnes s connector .

3 . Chec k fo r continuit y betwee n

PC M connecto r terminal s D 2

o r D13 * an d bod y ground .

I s ther e continuity ?

NO

Chec k fo r a n ope n i n th e wir e

(knoc k senso r line) :

Chec k fo r continuit y betwee n PC M

connecto r termina l D 2 o r D13 *

an d knoc k senso r connecto r ter -

mina l No . 1 o r No . 3* .

I s ther e continuity ?

YES

Substitut e a known-goo d righ t o r

lef t knoc k senso r an d recheck .

I s DT C P032 5 and/o r P033 0

indicated ?

YES

Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42 fo r

immobilize r information) . I f symp -

tom/indicatio n goe s away , replac e

th e origina l PCM .

NO

Intermitten t failure , syste m is O K

a t thi s tim e (tes t driv e ma y b e

necessary) . Chec k fo r poo r con -

nection s o r loos e wire s betwee n

C25 1 (locate d a t lef t shoc k

tower) , C11 0 (locate d a t lef t rea r

corne r o f engine) , C162* , C16 3

(knoc k sensor ) an d PCM .

PCM CONNECTO R D (22P )

Repai r shor t i n th e wir e betwee n

PC M (D 2 o r D13* ) an d knoc k sen -

sor.

Wir e sid e o f femal e terminal s

Repai r ope n in th e wir e betwee n

PCM (D 2 o r D13* ) an d knoc k sen -sor.

KNOC K SENSO RCONNECTO RReplace th e origina l knoc k sensor .

Wire sid e o f femal e terminal s

*: P033 0

NO

N

O

YE S

Knoc k Senso r

ProCarManuals.com

Page 605 of 1954

PGM-FI Syste m

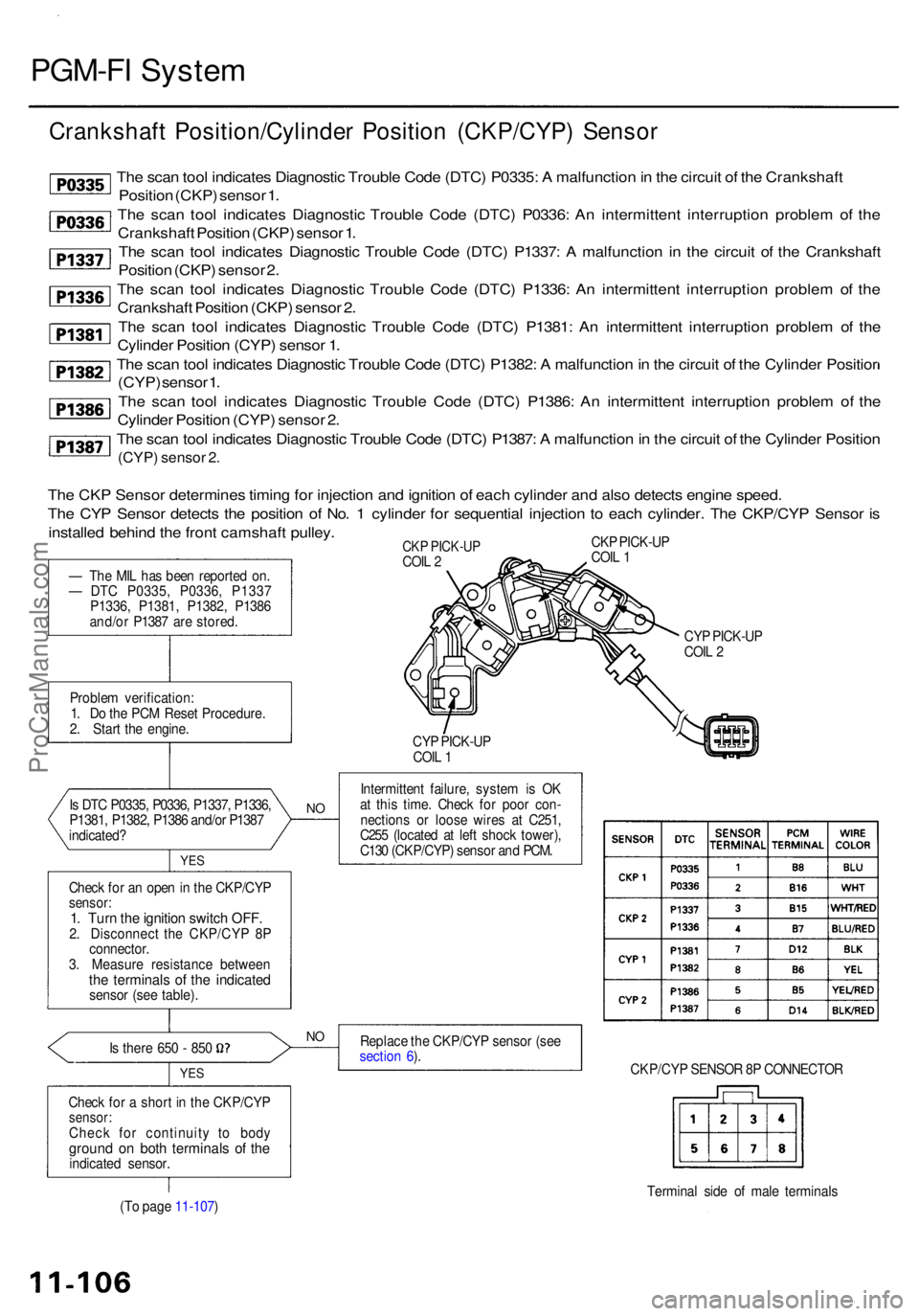

Crankshaf t Position/Cylinde r Positio n (CKP/CYP ) Senso r

The sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0335 : A malfunctio n in th e circui t o f th e Crankshaf t

Positio n (CKP ) senso r 1 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P0336 : A n intermitten t interruptio n proble m of the

Crankshaf t Positio n (CKP ) senso r 1 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1337 : A malfunctio n i n th e circui t o f th e Crankshaf t

Positio n (CKP ) senso r 2 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1336 : A n intermitten t interruptio n proble m o f th e

Crankshaf t Positio n (CKP ) senso r 2 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1381 : A n intermitten t interruptio n proble m o f th e

Cylinde r Positio n (CYP ) senso r 1 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1382 : A malfunctio n in th e circui t o f th e Cylinde r Positio r

(CYP ) senso r 1 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1386 : A n intermitten t interruptio n proble m of the

Cylinde r Positio n (CYP ) senso r 2 .

Th e sca n too l indicate s Diagnosti c Troubl e Cod e (DTC ) P1387 : A malfunctio n in th e circui t o f th e Cylinde r Positio n

(CYP) senso r 2 .

Proble m verification :

1 . D o th e PC M Rese t Procedure .

2 . Star t th e engine .

I s DT C P0335 , P0336 , P1337 , P1336 ,

P1381 , P1382 , P138 6 and/o r P138 7

indicated ?

Chec k fo r a n ope n in th e CKP/CY P

sensor:1. Tur n th e ignitio n switc h OFF .2. Disconnec t th e CKP/CY P 8 P

connector .

3 . Measur e resistanc e betwee n

the terminal s o f th e indicate dsensor (se e table) .

I s ther e 65 0 - 85 0

YES

Chec k fo r a shor t i n th e CKP/CY Psensor:Check fo r continuit y t o bod yground o n bot h terminal s o f th eindicate d sensor . CY

P PICK-U P

COI L 2

CY P PICK-U P

COI L 1

Intermitten t failure , syste m is O K

a t thi s time . Chec k fo r poo r con -

nection s o r loos e wire s a t C251 ,

C25 5 (locate d a t lef t shoc k tower) ,

C13 0 (CKP/CYP ) senso r an d PCM .

Replac e th e CKP/CY P senso r (se e

sectio n 6 ).

CKP/CYP SENSO R 8 P CONNECTO R

Termina l sid e o f mal e terminal s

(T o pag e 11-107 )

NO

YE S

NO

CK P PICK-U P

COI L 1CK P PICK-U PCOIL 2

Th e CK P Senso r determine s timin g fo r injectio n an d ignitio n o f eac h cylinde r an d als o detect s engin e speed .

Th e CY P Senso r detect s th e positio n o f No . 1 cylinde r fo r sequentia l injectio n t o eac h cylinder . Th e CKP/CY P Senso r i s

installe d behin d th e fron t camshaf t pulley .

— Th e MI L ha s bee n reporte d on .

— DT C P0335 , P0336 , P133 7

P1336 , P1381 , P1382 , P138 6

and/o r P138 7 ar e stored .

ProCarManuals.com

Page 616 of 1954

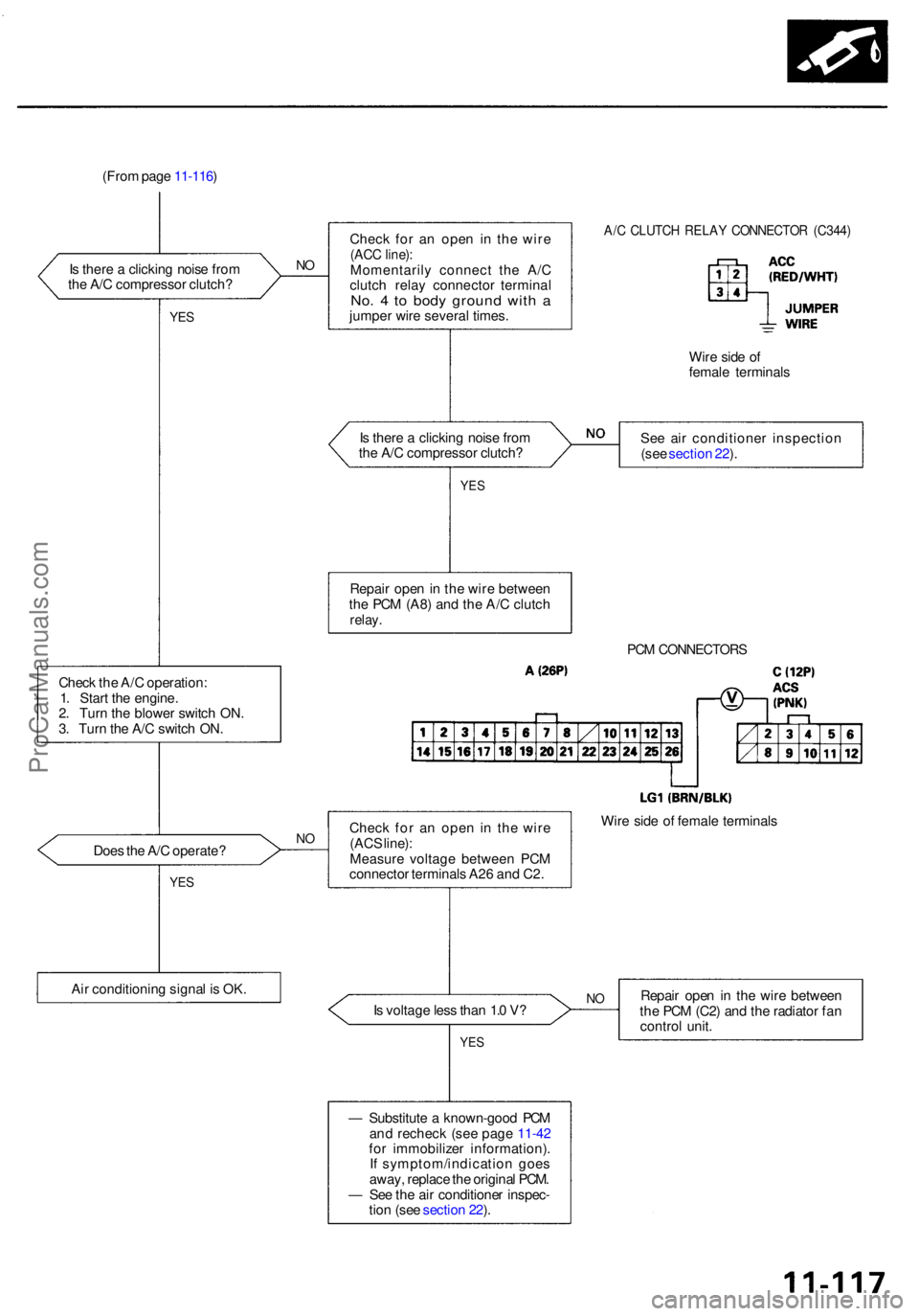

(From pag e 11-116 )

I s ther e a clickin g nois e fro m

th e A/ C compresso r clutch ?

NO

YE S

Chec k fo r a n ope n i n th e wir e(ACC line) :Momentaril y connec t th e A/ C

clutc h rela y connecto r termina l

No. 4 to bod y groun d wit h ajumpe r wir e severa l times .

A/C CLUTC H RELA Y CONNECTO R (C344 )

Wire sid e o f

femal e terminal s

I s ther e a clickin g nois e fro m

th e A/ C compresso r clutch ? Se

e ai r conditione r inspectio n

(se e sectio n 22 ).

YE S

Repai r ope n in th e wir e betwee n

th e PC M (A8 ) an d th e A/ C clutc h

relay.

PCM CONNECTOR S

Check th e A/ C operation :

1 . Star t th e engine .

2 . Tur n th e blowe r switc h ON .

3 . Tur n th e A/ C switc h ON .

Doe s th e A/ C operate ?

YES

Chec k fo r a n ope n i n th e wir e

(AC S line) :

Measur e voltag e betwee n PC M

connecto r terminal s A2 6 an d C2 .

Ai r conditionin g signa l i s OK . Wir

e sid e o f femal e terminal s

I s voltag e les s tha n 1. 0 V ?

YE S

Repai r ope n in th e wir e betwee n

th e PC M (C2 ) an d th e radiato r fa n

contro l unit .

— Substitut e a known-goo d PC M

an d rechec k (se e pag e 11-42

fo r immobilize r information) .

I f symptom/indicatio n goe s

away , replac e th e origina l PCM .

— Se e th e ai r conditione r inspec -

tio n (se e sectio n 22 ).N O

NO

ProCarManuals.com

Page 622 of 1954

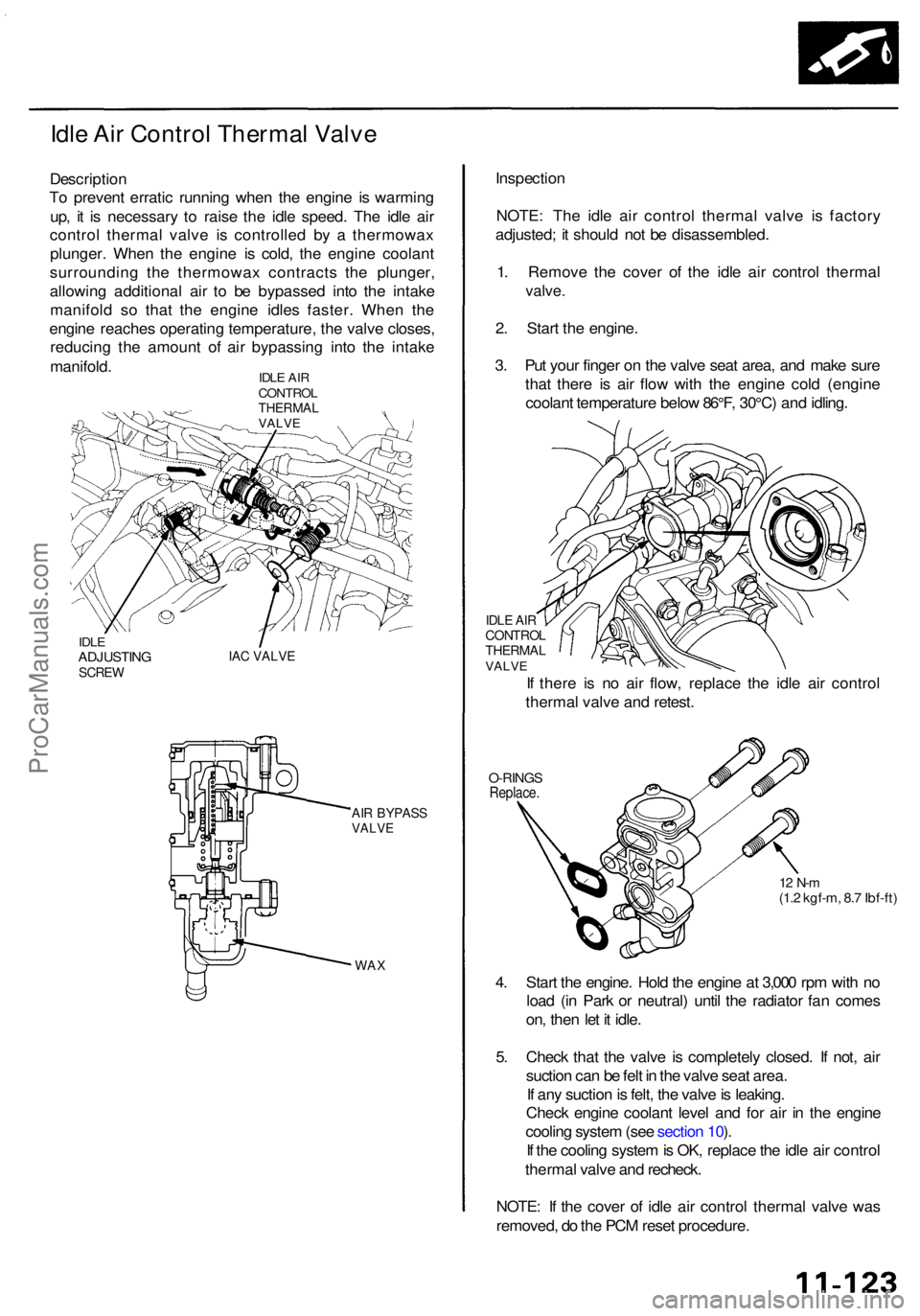

Idle Ai r Contro l Therma l Valv e

Descriptio n

T o preven t errati c runnin g whe n th e engin e i s warmin g

up , i t i s necessar y t o rais e th e idl e speed . Th e idl e ai r

contro l therma l valv e i s controlle d b y a thermowa x

plunger . Whe n th e engin e i s cold , th e engin e coolan t

surroundin g th e thermowa x contract s th e plunger ,

allowin g additiona l ai r t o b e bypasse d int o th e intak e

manifol d s o tha t th e engin e idle s faster . Whe n th e

engin e reache s operatin g temperature , th e valv e closes ,

reducin g th e amoun t o f ai r bypassin g int o th e intak e

manifold .

IDLE AI R

CONTRO L

THERMA LVALVE

IDLEADJUSTIN GSCREWIAC VALV E

AIR BYPAS SVALVE

WAX

Inspectio n

NOTE : Th e idl e ai r contro l therma l valv e i s factor y

adjusted ; i t shoul d no t b e disassembled .

1 . Remov e th e cove r o f th e idl e ai r contro l therma l

valve.

2. Star t th e engine .

3 . Pu t you r finge r o n th e valv e sea t area , an d mak e sur e

tha t ther e i s ai r flo w wit h th e engin e col d (engin e

coolan t temperatur e belo w 86°F , 30°C ) an d idling .

O-RING SReplace .

12 N- m(1.2 kgf-m , 8. 7 Ibf-ft )

4. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h n o

loa d (i n Par k o r neutral ) unti l th e radiato r fa n come s

on , the n le t i t idle .

5 . Chec k tha t th e valv e i s completel y closed . I f not , ai r

suctio n ca n b e fel t i n th e valv e sea t area .

I f an y suctio n is felt , th e valv e is leaking .

Chec k engin e coolan t leve l an d fo r ai r i n th e engin e

coolin g syste m (se e sectio n 10 ).

I f th e coolin g syste m is OK , replac e th e idl e ai r contro l

therma l valv e an d recheck .

NOTE : I f th e cove r o f idl e ai r contro l therma l valv e wa s

removed , d o th e PC M rese t procedure .

IDLE AI RCONTRO LTHERMALVALVE

If ther e i s n o ai r flow , replac e th e idl e ai r contro l

therma l valv e an d retest .

ProCarManuals.com

Page 634 of 1954

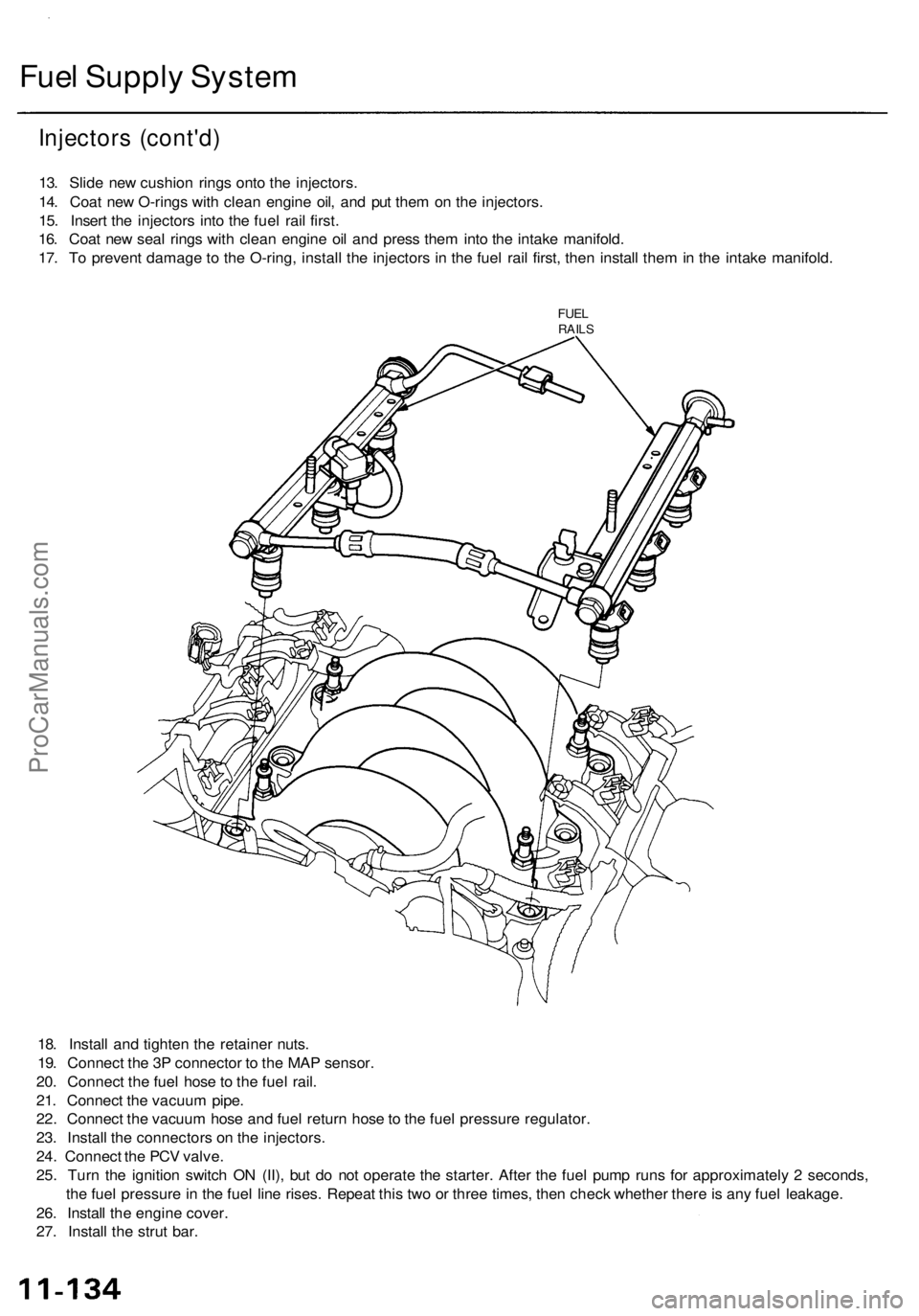

Fuel Supply System

Injectors (cont'd)

13. Slide new cushion rings onto the injectors.

14. Coat new O-rings with clean engine oil, and put them on the injectors.

15. Insert the injectors into the fuel rail first.

16. Coat new seal rings with clean engine oil and press them into the intake manifold.

17. To prevent damage to the O-ring, install the injectors in the fuel rail first, then install them in the intake manifold.

FUEL

RAILS

18. Install and tighten the retainer nuts.

19. Connect the 3P connector to the MAP sensor.

20. Connect the fuel hose to the fuel rail.

21. Connect the vacuum pipe.

22. Connect the vacuum hose and fuel return hose to the fuel pressure regulator.

23. Install the connectors on the injectors.

24. Connect the PCV valve.

25. Turn the ignition switch ON (II), but do not operate the starter. After the fuel pump runs for approximately 2 seconds,

the fuel pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

26. Install the engine cover.

27. Install the strut bar.ProCarManuals.com

Page 651 of 1954

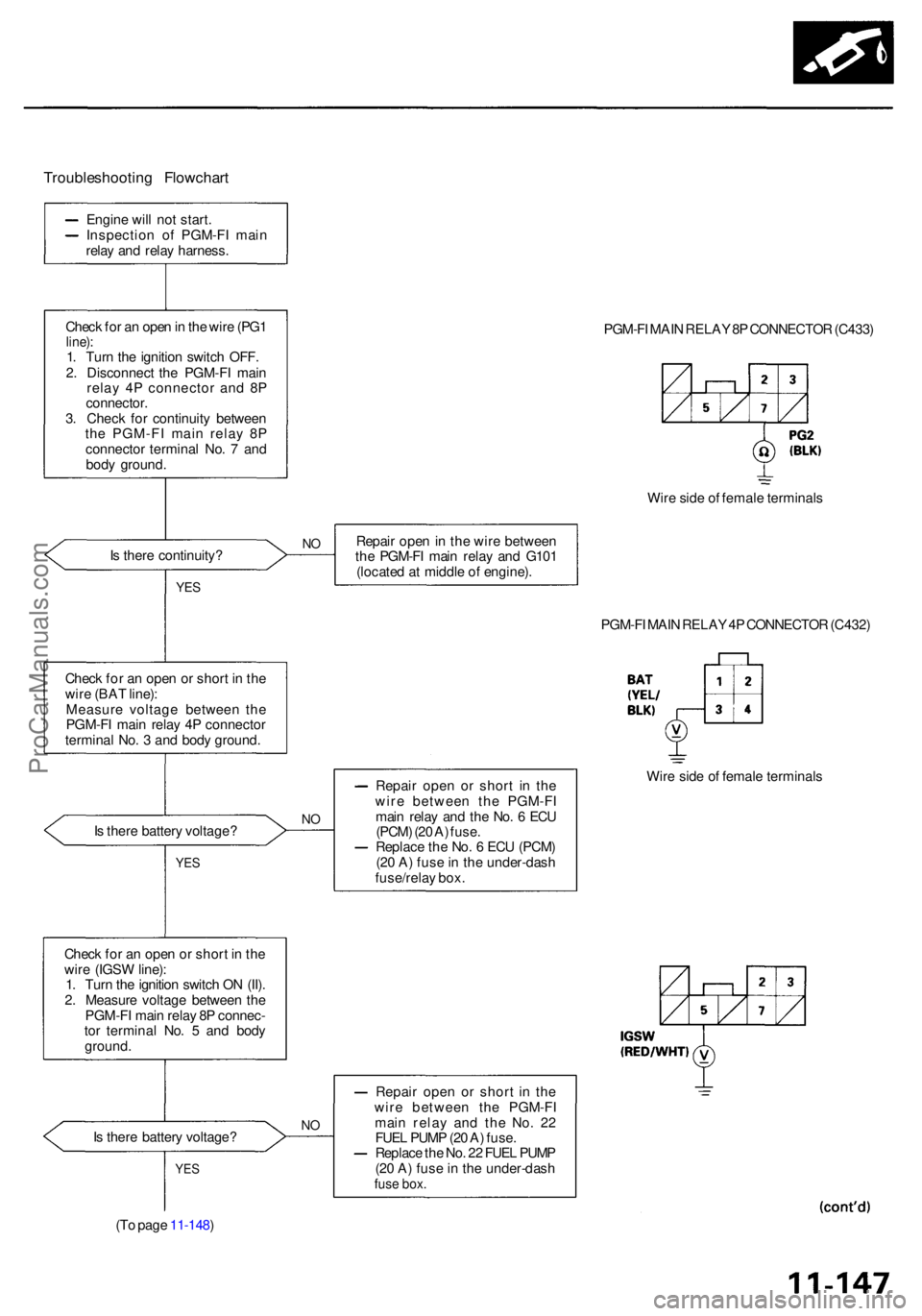

Troubleshooting Flowchar t

Check fo r a n ope n o r shor t i n th e

wir e (BA T line) :

Measur e voltag e betwee n th e

PGM-F I mai n rela y 4 P connecto r

termina l No . 3 an d bod y ground .

I s ther e batter y voltage ?

YES

Chec k fo r a n ope n o r shor t i n th e

wir e (IGS W line) :

1 . Tur n th e ignitio n switc h O N (II) .

2 . Measur e voltag e betwee n th e

PGM-F I mai n rela y 8 P connec -

to r termina l No . 5 an d bod y

ground .

I s ther e batter y voltage ?

YES

(To pag e 11-148 ) PGM-F

I MAI N RELA Y 8P CONNECTO R (C433 )

Wir e sid e o f femal e terminal s

NORepai r ope n in th e wir e betwee n

th e PGM-F I mai n rela y an d G10 1

(locate d a t middl e o f engine) .

NO

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 6 EC U

(PCM ) (2 0 A ) fuse .

Replac e th e No . 6 EC U (PCM )

(2 0 A ) fus e in th e under-das h

fuse/rela y box . PGM-F

I MAI N RELA Y 4P CONNECTO R (C432 )

Wir e sid e o f femal e terminal s

NO

Repai r ope n o r shor t i n th e

wir e betwee n th e PGM-F I

mai n rela y an d th e No . 2 2

FUE L PUM P (2 0 A ) fuse .

Replac e th e No . 2 2 FUE L PUM P

(2 0 A ) fus e in th e under-das h

fuse box .

YES

Is ther e continuity ?

Engin

e wil l no t start .

Inspectio n o f PGM-F I mai n

rela y an d rela y harness .

Chec k fo r a n ope n in th e wir e (PG 1

line) :1. Tur n th e ignitio n switc h OFF .

2 . Disconnec t th e PGM-F I mai n

rela y 4 P connecto r an d 8 P

connector .

3 . Chec k fo r continuit y betwee n

th e PGM-F I mai n rela y 8 P

connecto r termina l No . 7 an d

bod y ground .

ProCarManuals.com

Page 656 of 1954

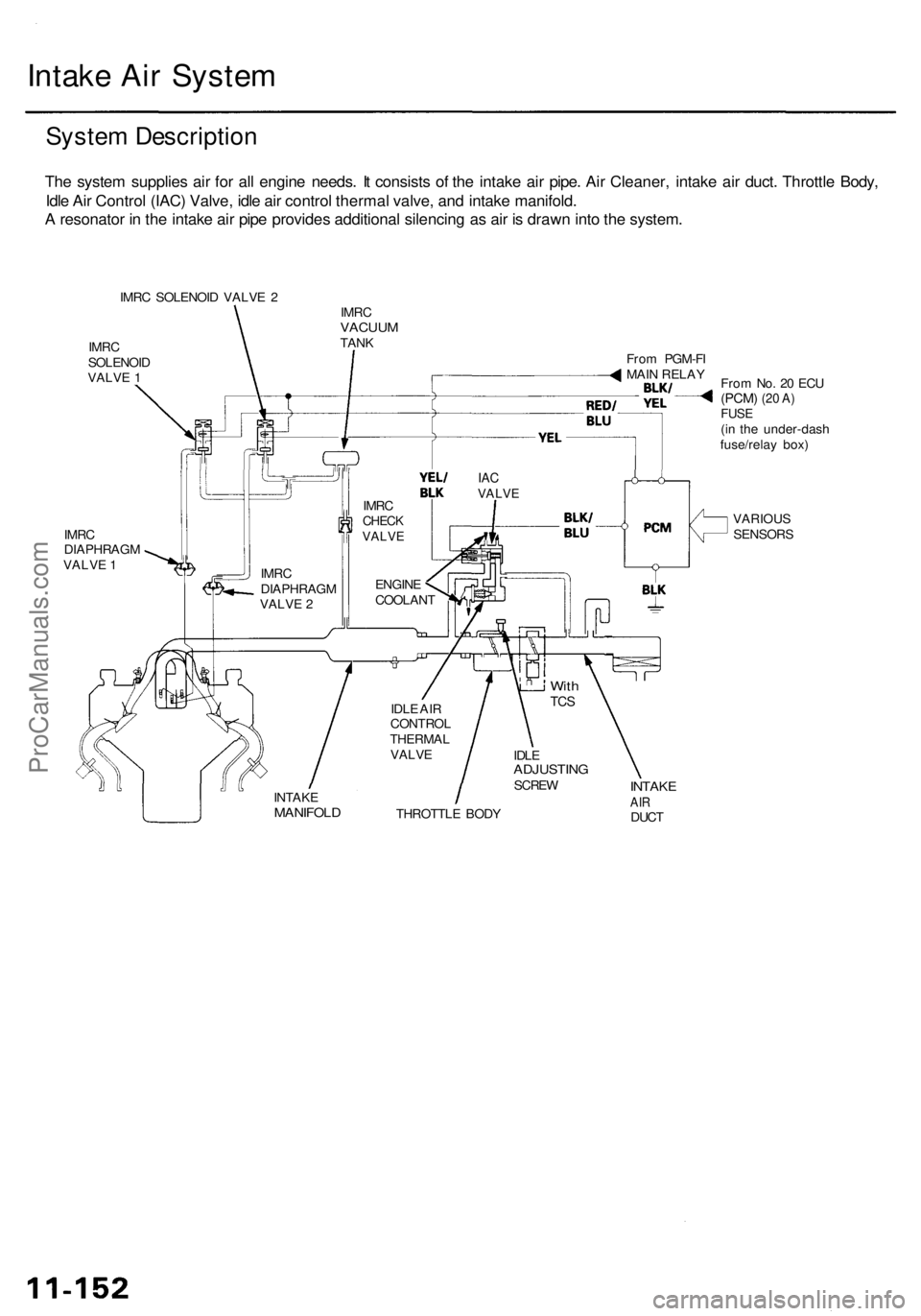

Intake Air System

System Description

The system supplies air for all engine needs. It consists of the intake air pipe. Air Cleaner, intake air duct. Throttle Body,

Idle Air Control (IAC) Valve, idle air control thermal valve, and intake manifold.

A resonator in the intake air pipe provides additional silencing as air is drawn into the system.

IMRC SOLENOID VALVE 2

IMRC

SOLENOID

VALVE 1

IMRC

VACUUM

TANK

From No. 20 ECU

(PCM)

(20 A)

FUSE

(in the under-dash

fuse/relay box)

IMRC

DIAPHRAGM

VALVE 1

VARIOUS

SENSORS

THROTTLE BODY

INTAKE

AIR

DUCT

INTAKE

MANIFOLD

IDLE

ADJUSTING

SCREW

With

TCS

IDLE AIR

CONTROL

THERMAL

VALVE

IAC

VALVE

From PGM-FI

MAIN RELAY

IMRC

DIAPHRAGM

VALVE 2

IMRC

CHECK

VALVE

ENGINE

COOLANTProCarManuals.com