brakes ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 1 of 1954

General Info

Specifications

Maintenance

*Engine Electrical

Engine

Cooling

Fuel and Emissions

*TransaxleSteering

Suspension

*Brakes (Including ABS,

TCS and VSA)

*Body

*Heating, Ventilation and Air Conditioning

*Body Electrical

*Restraints

1996±0 4 3.5RL Main Menu

As sections w/ * include SRS components,

special precautions are required when servicing.

ProCarManuals.com

Page 96 of 1954

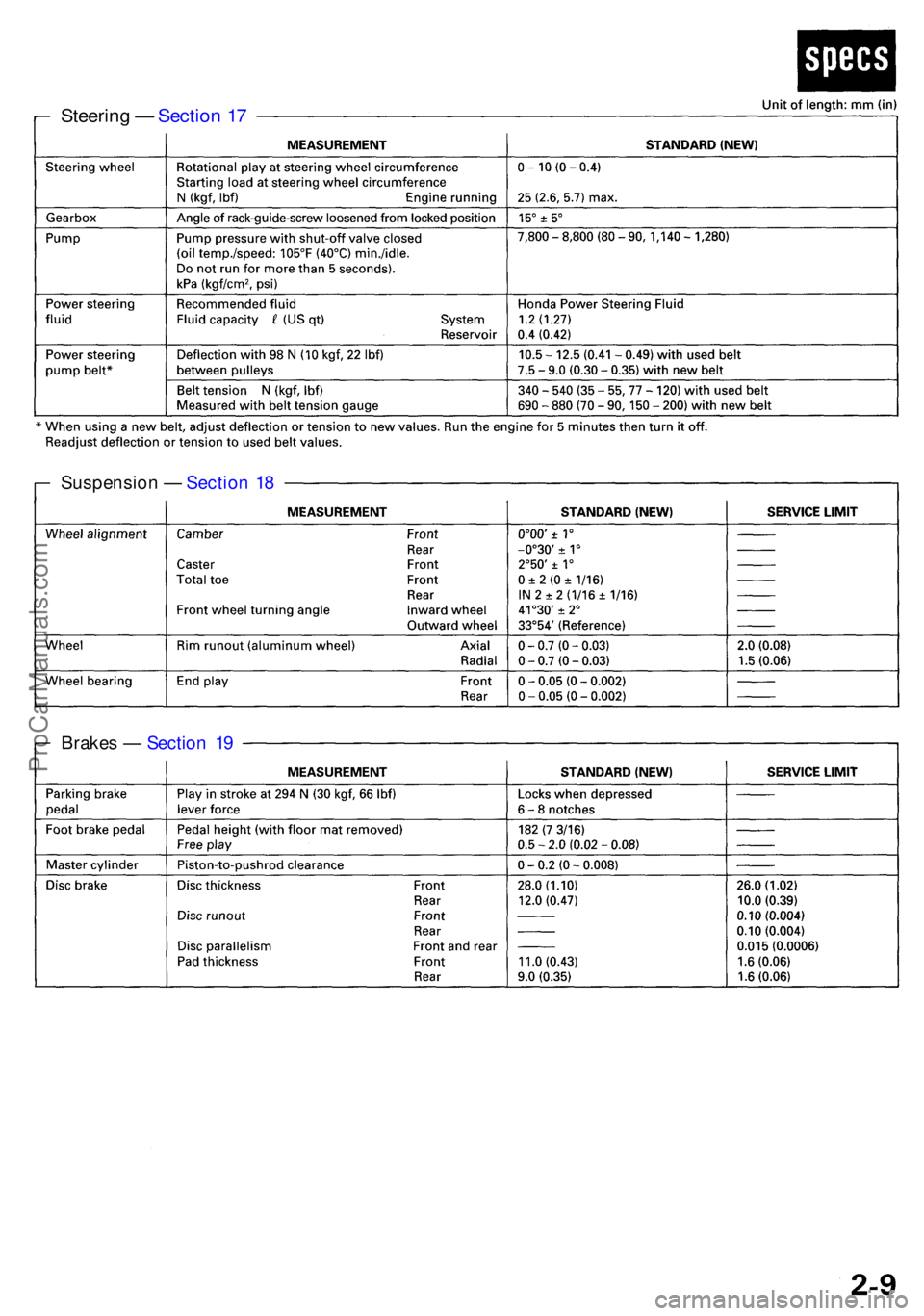

Brakes — Sectio n 1 9

Suspensio

n — Sectio n 1 8

Steerin g — Sectio n 1 7

ProCarManuals.com

Page 731 of 1954

Description

Electronic Control System (cont'd)

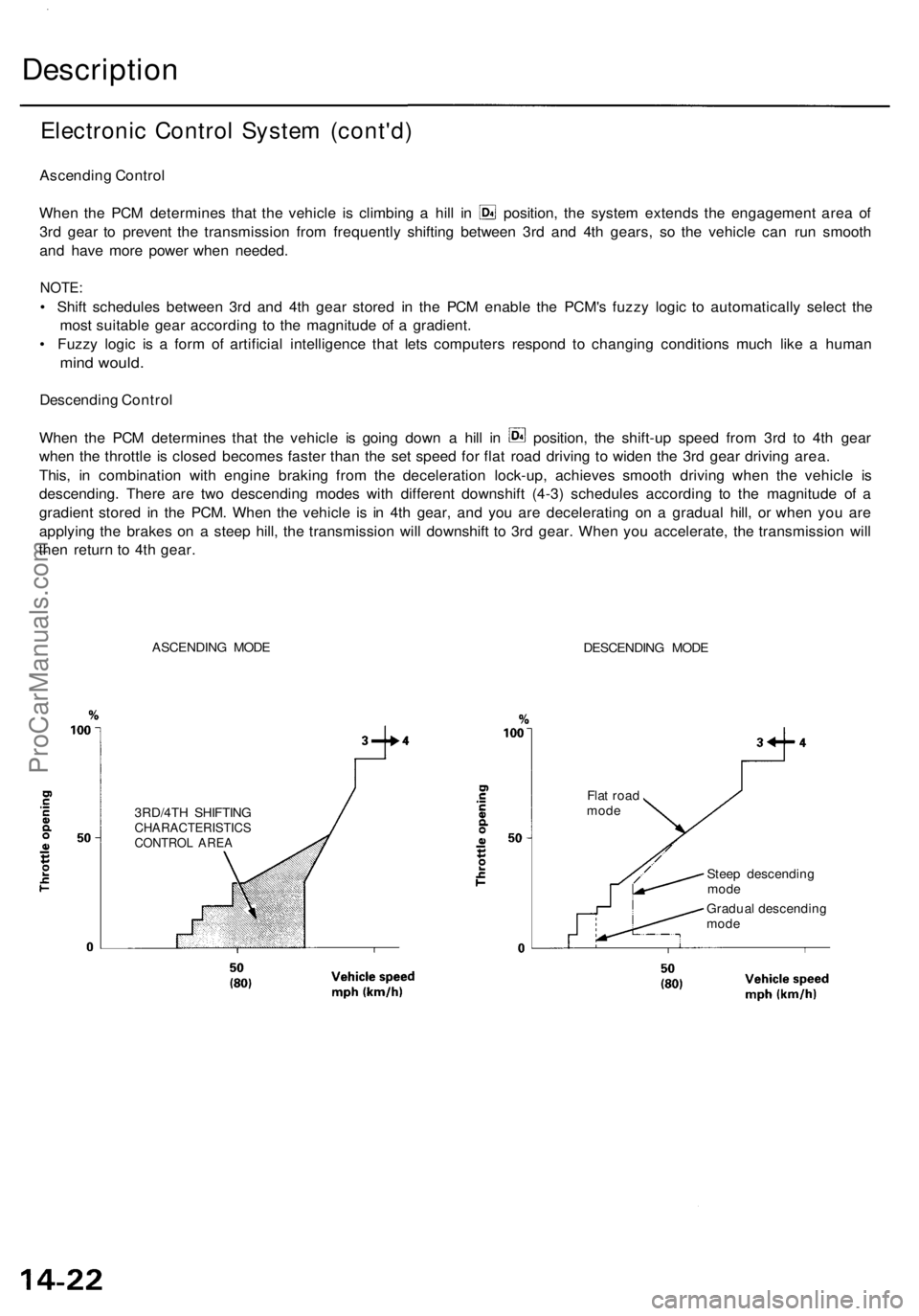

Ascending Control

When the PCM determines that the vehicle is climbing a hill in position, the system extends the engagement area of

3rd gear to prevent the transmission from frequently shifting between 3rd and 4th gears, so the vehicle can run smooth

and have more power when needed.

NOTE:

• Shift schedules between 3rd and 4th gear stored in the PCM enable the PCM's fuzzy logic to automatically select the

most suitable gear according to the magnitude of a gradient.

• Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a human

mind would.

Descending Control

When the PCM determines that the vehicle is going down a hill in position, the shift-up speed from 3rd to 4th gear

when the throttle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.

This, in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle is

descending. There are two descending modes with different downshift (4-3) schedules according to the magnitude of a

gradient stored in the PCM. When the vehicle is in 4th gear, and you are decelerating on a gradual hill, or when you are

applying the brakes on a steep hill, the transmission will downshift to 3rd gear. When you accelerate, the transmission will

then return to 4th gear.

ASCENDING MODE

DESCENDING MODE

3RD/4TH SHIFTING

CHARACTERISTICS

CONTROL AREA

Flat road

mode

Steep descending

mode

Gradual descending

modeProCarManuals.com

Page 1050 of 1954

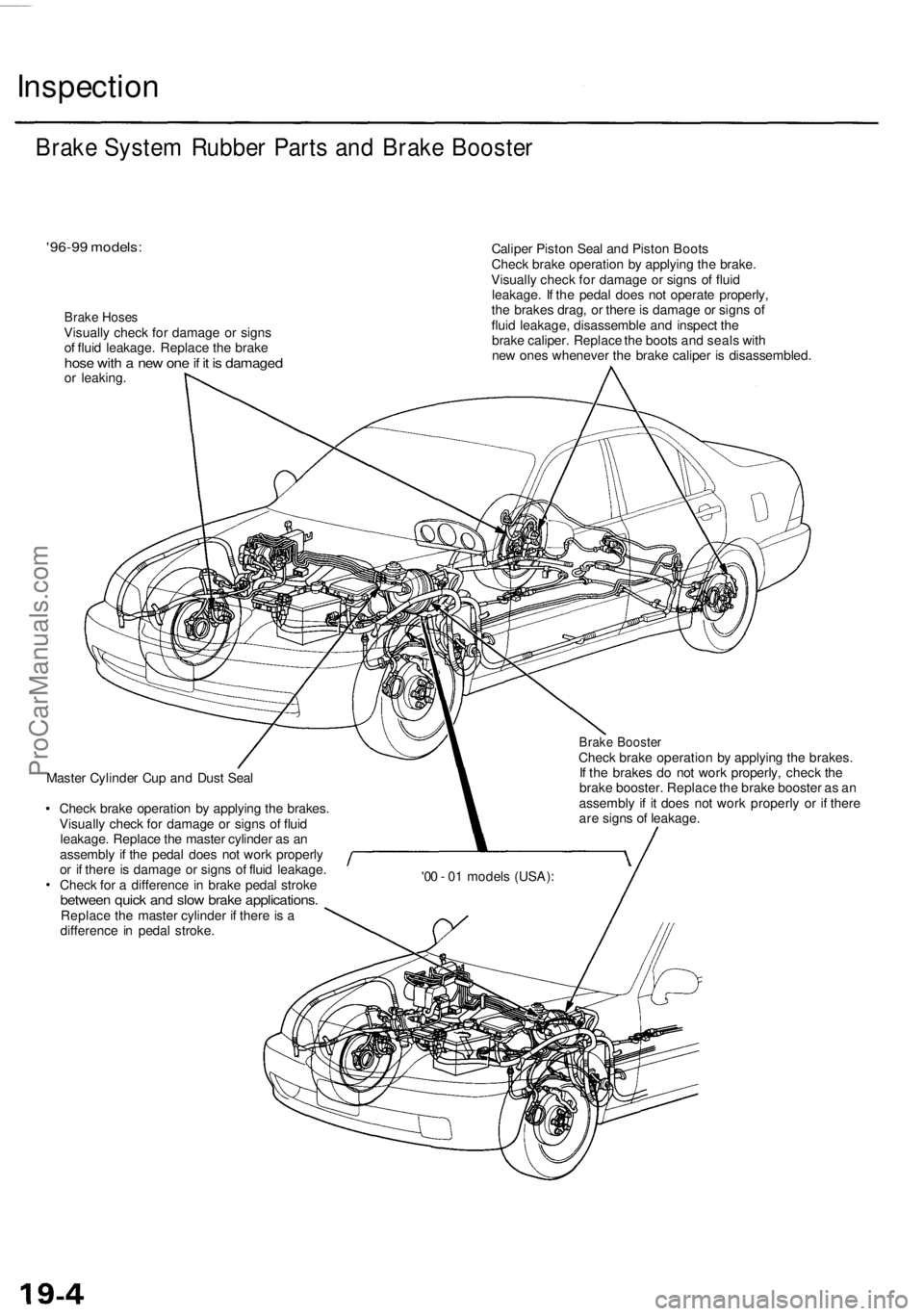

Inspection

'96-99 models:

Brake Hoses

Visually check for damage or signs

of fluid leakage. Replace the brake

hose with a new one if it is damaged

or leaking.

Caliper Piston Seal and Piston Boots

Check brake operation by applying the brake.

Visually check for damage or signs of fluid

leakage. If the pedal does not operate properly,

the brakes drag, or there is damage or signs of

fluid leakage, disassemble and inspect the

brake caliper. Replace the boots and seals with

new ones whenever the brake caliper is disassembled.

Master Cylinder Cup and Dust Seal

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid

leakage. Replace the master cylinder as an

assembly if the pedal does not work properly

or if there is damage or signs of fluid leakage.

Check for a difference in brake pedal stroke

between quick and slow brake applications.

Replace the master cylinder if there is a

difference in pedal stroke.

Brake Booster

Check brake operation by applying the brakes.

If the brakes do not work properly, check the

brake booster. Replace the brake booster as an

assembly if it does not work properly or if there

are signs of leakage.

Brake System Rubber Parts and Brake Booster

'00 - 01 models (USA):ProCarManuals.com

Page 1057 of 1954

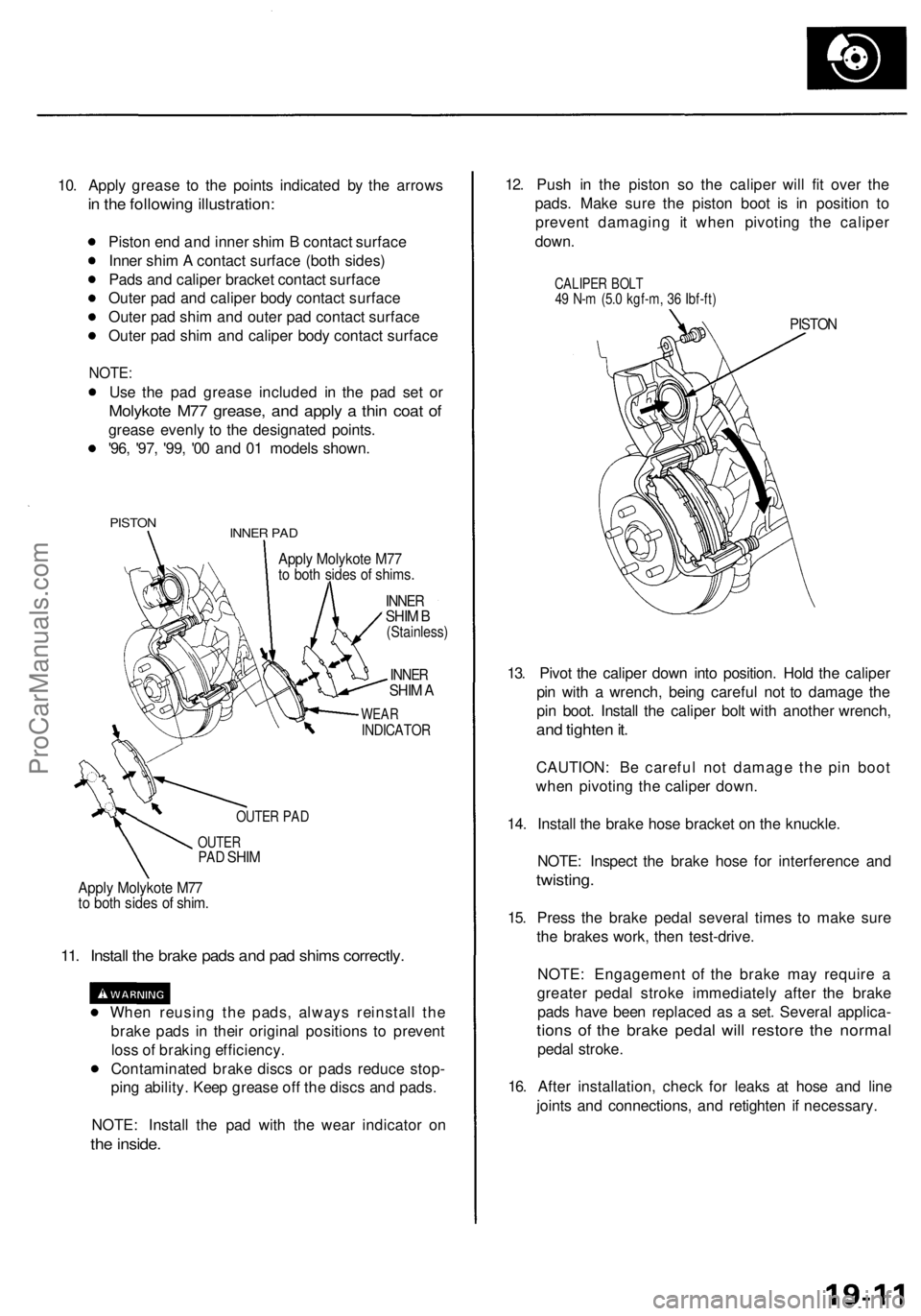

10. Apply grease to the points indicated by the arrows

in the following illustration:

Piston end and inner shim B contact surface

Inner shim A contact surface (both sides)

Pads and caliper bracket contact surface

Outer pad and caliper body contact surface

Outer pad shim and outer pad contact surface

Outer pad shim and caliper body contact surface

NOTE:

Use the pad grease included in the pad set or

Molykote M77 grease, and apply a thin coat of

grease evenly to the designated points.

'96, '97, '99, '00 and 01 models shown.

PISTON

INNER PAD

Apply Molykote M77

to both sides of shims.

INNER

SHIM B

(Stainless)

INNER

SHIM A

WEAR

INDICATOR

OUTER PAD

OUTER

PAD

SHIM

Apply Molykote M77

to both sides of shim.

11. Install the brake pads and pad shims correctly.

When reusing the pads, always reinstall the

brake pads in their original positions to prevent

loss of braking efficiency.

Contaminated brake discs or pads reduce stop-

ping ability. Keep grease off the discs and pads.

NOTE: Install the pad with the wear indicator on

the inside.

12. Push in the piston so the caliper will fit over the

pads. Make sure the piston boot is in position to

prevent damaging it when pivoting the caliper

down.

CALIPER BOLT

49 N-m (5.0 kgf-m, 36 Ibf-ft)

PISTON

13. Pivot the caliper down into position. Hold the caliper

pin with a wrench, being careful not to damage the

pin boot. Install the caliper bolt with another wrench,

and tighten it.

CAUTION: Be careful not damage the pin boot

when pivoting the caliper down.

14. Install the brake hose bracket on the knuckle.

NOTE: Inspect the brake hose for interference and

twisting.

15. Press the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

16. After installation, check for leaks at hose and line

joints and connections, and retighten if necessary.ProCarManuals.com

Page 1066 of 1954

Rear Brake Pads

Inspection and Replacement (cont'd)

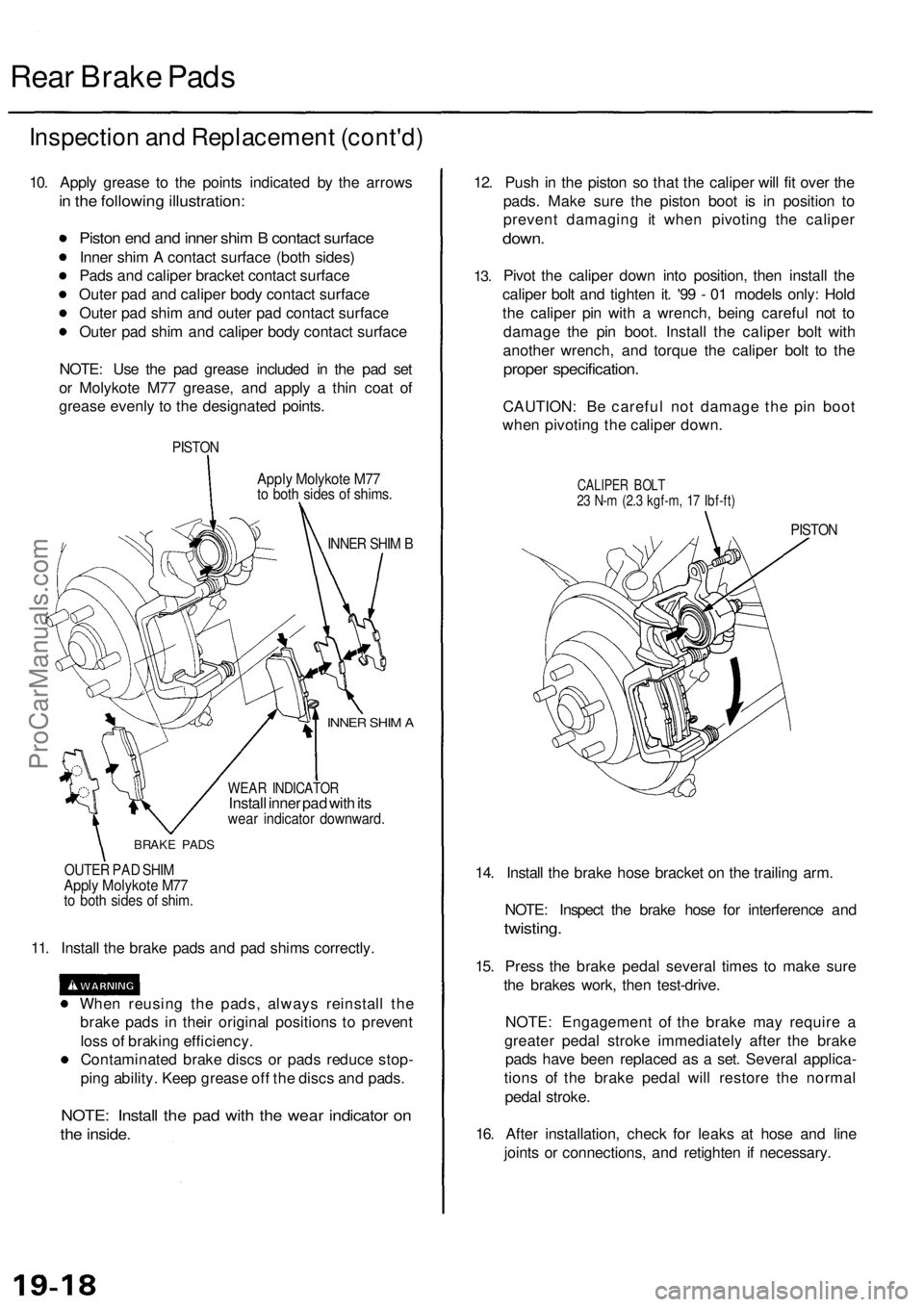

10. Apply grease to the points indicated by the arrows

in the following illustration:

Piston end and inner shim B contact surface

Inner shim A contact surface (both sides)

Pads and caliper bracket contact surface

Outer pad and caliper body contact surface

Outer pad shim and outer pad contact surface

Outer pad shim and caliper body contact surface

NOTE: Use the pad grease included in the pad set

or Molykote M77 grease, and apply a thin coat of

grease evenly to the designated points.

PISTON

Apply Molykote M77

to both sides of shims.

INNER SHIM B

INNER SHIM A

WEAR INDICATOR

Install inner pad with its

wear indicator downward.

BRAKE PADS

OUTER PAD SHIM

Apply Molykote M77

to both sides of shim.

11. Install the brake pads and pad shims correctly.

When reusing the pads, always reinstall the

brake pads in their original positions to prevent

loss of braking efficiency.

Contaminated brake discs or pads reduce stop-

ping ability. Keep grease off the discs and pads.

NOTE: Install the pad with the wear indicator on

the inside.

12. Push in the piston so that the caliper will fit over the

pads. Make sure the piston boot is in position to

prevent damaging it when pivoting the caliper

down.

13.

Pivot the caliper down into position, then install the

caliper bolt and tighten it. '99 - 01 models only: Hold

the caliper pin with a wrench, being careful not to

damage the pin boot. Install the caliper bolt with

another wrench, and torque the caliper bolt to the

proper specification.

CAUTION: Be careful not damage the pin boot

when pivoting the caliper down.

CALIPER BOLT

23 N-m (2.3 kgf-m, 17 Ibf-ft)

PISTON

14. Install the brake hose bracket on the trailing arm.

NOTE: Inspect the brake hose for interference and

twisting.

15. Press the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

16. After installation, check for leaks at hose and line

joints or connections, and retighten if necessary.ProCarManuals.com

Page 1279 of 1954

Troubleshooting

DTC 71: Abnormal Wheel Speed Signal

Are any DTCs except 71 indicated?

Check the tires.

Are tires with specified size and

inflated to specification?

Check for brake drag.

Do the brakes drag?

Visually check for appropriate

wheel sensor and pulser installa-

tion (see table).

Are they installed correctly?

Check the four pulser gears for a

chipped tooth (see table).

Is the pulser OK?

Problem Verification:

1. Clear the DTC.

2. Test-drive the vehicle at 19

mph (30 km/h) or more.

3. Verify the DTC.

Is DTC 71 indicated?

YES

Check for loose terminals in the

VSA control unit 42P connector.

If necessary, substitute a known-

good VSA modulator-control

unit, and recheck.

Preform the appropriate trou-

bleshooting for the DTC.

Replace the tire(s) with the spec-

ified size.

Repair the brake drag.

Reinstall or replace the wheel

sensor or pulser.

Replace the driveshaft or hub

unit. (Chipped pulser gear.)

The system is OK at this time.

Verify the DTC.ProCarManuals.com