parking brake ACURA RL KA9 1996 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 814 of 1954

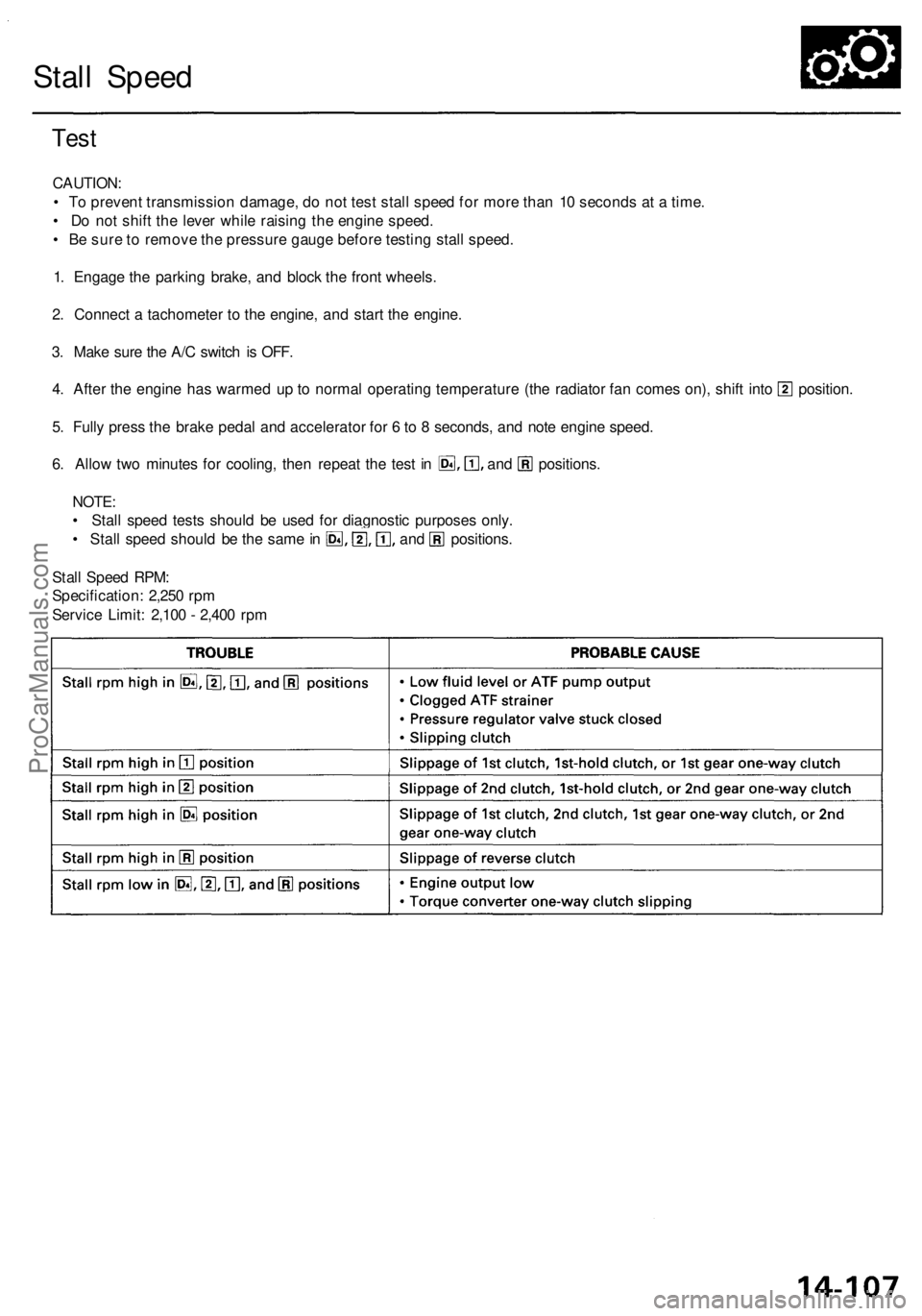

Stall Speed

Test

CAUTION:

• To prevent transmission damage, do not test stall speed for more than 10 seconds at a time.

• Do not shift the lever while raising the engine speed.

• Be sure to remove the pressure gauge before testing stall speed.

1. Engage the parking brake, and block the front wheels.

2. Connect a tachometer to the engine, and start the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into position.

5. Fully press the brake pedal and accelerator for 6 to 8 seconds, and note engine speed.

6. Allow two minutes for cooling, then repeat the test in and positions.

NOTE:

• Stall speed tests should be used for diagnostic purposes only.

• Stall speed should be the same in and positions.

Stall Speed RPM:

Specification: 2,250 rpm

Service Limit: 2,100 - 2,400 rpmProCarManuals.com

Page 1027 of 1954

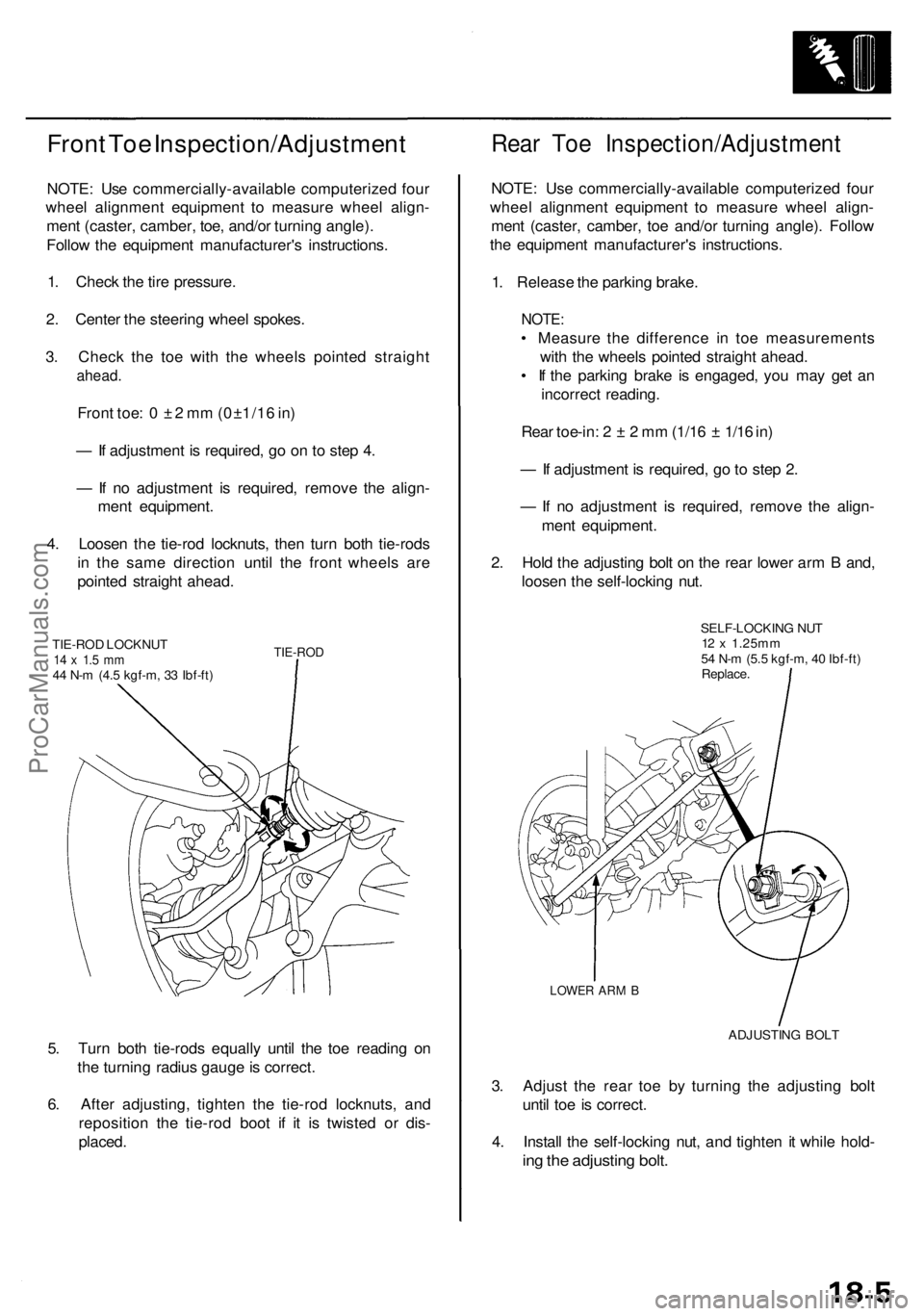

Front Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and/or turning angle).

Follow the equipment manufacturer's instructions.

1. Check the tire pressure.

2. Center the steering wheel spokes.

3. Check the toe with the wheels pointed straight

ahead.

Front toe: 0 ± 2 mm (0±1/16 in)

— If adjustment is required, go on to step 4.

— If no adjustment is required, remove the align-

ment equipment.

4. Loosen the tie-rod locknuts, then turn both tie-rods

in the same direction until the front wheels are

pointed straight ahead.

TIE-ROD LOCKNUT

14 x 1.5 mm

44 N-m (4.5 kgf-m, 33 Ibf-ft)

TIE-ROD

5. Turn both tie-rods equally until the toe reading on

the turning radius gauge is correct.

6. After adjusting, tighten the tie-rod locknuts, and

reposition the tie-rod boot if it is twisted or dis-

placed.

Rear Toe Inspection/Adjustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe and/or turning angle). Follow

the equipment manufacturer's instructions.

1. Release the parking brake.

NOTE:

• Measure the difference in toe measurements

with the wheels pointed straight ahead.

• If the parking brake is engaged, you may get an

incorrect reading.

Rear toe-in: 2 ± 2 mm (1/16 ± 1/16 in)

— If adjustment is required, go to step 2.

— If no adjustment is required, remove the align-

ment equipment.

2. Hold the adjusting bolt on the rear lower arm B and,

loosen the self-locking nut.

SELF-LOCKING NUT

12 x 1.25mm

54 N-m (5.5 kgf-m, 40 Ibf-ft)

Replace.

LOWER ARM B

ADJUSTING BOLT

3. Adjust the rear toe by turning the adjusting bolt

until toe is correct.

4. Install the self-locking nut, and tighten it while hold-

ing the adjusting bolt.ProCarManuals.com

Page 1041 of 1954

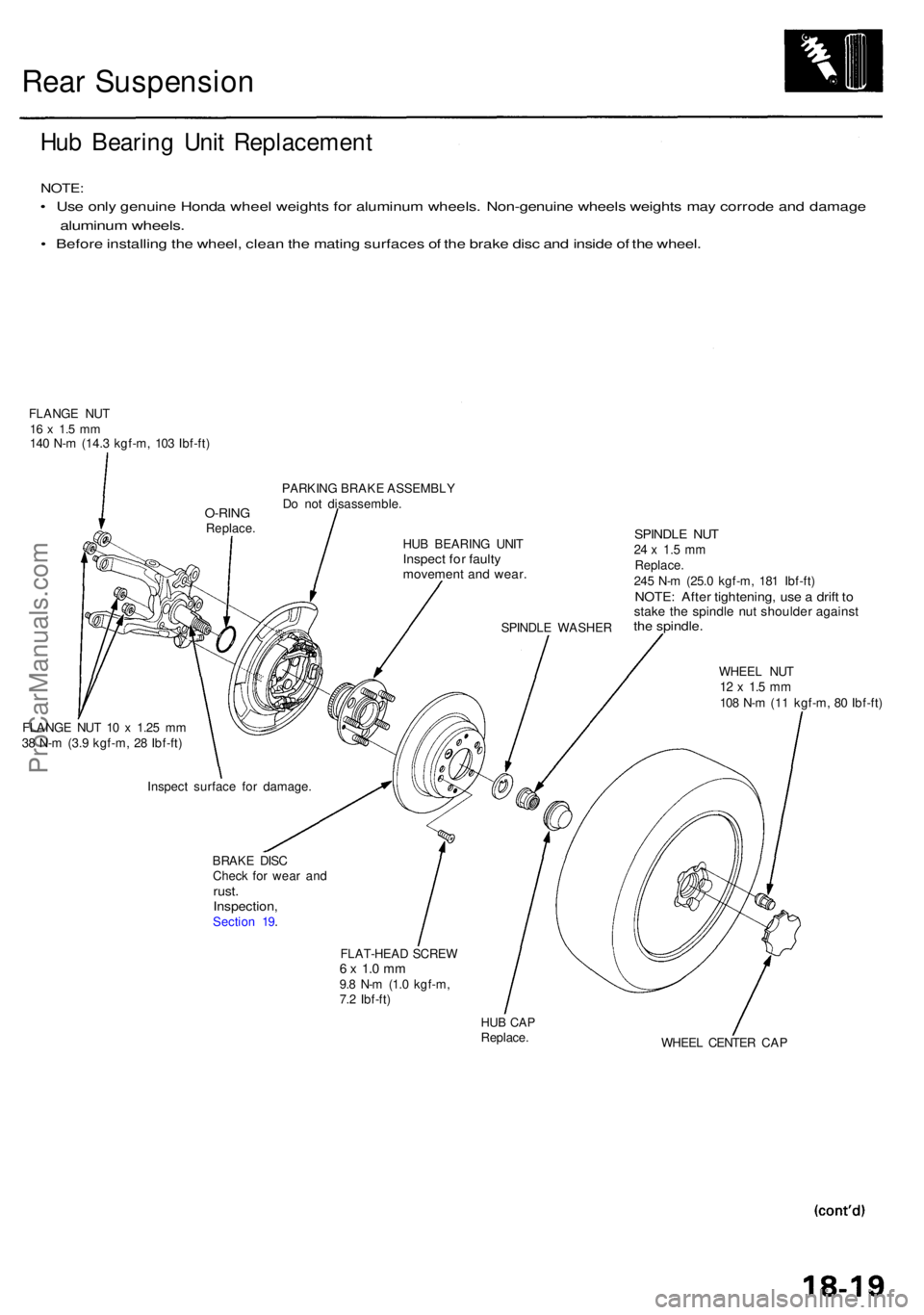

Rear Suspensio n

Hub Bearin g Uni t Replacemen t

NOTE:

• Us e onl y genuin e Hond a whee l weight s fo r aluminu m wheels . Non-genuin e wheel s weight s ma y corrod e an d damag e

aluminum wheels .

• Befor e installin g th e wheel , clea n th e matin g surface s o f th e brak e dis c an d insid e o f th e wheel .

FLANG E NU T16 x 1. 5 m m140 N- m (14. 3 kgf-m , 10 3 Ibf-ft )

PARKING BRAK E ASSEMBL Y

D o no t disassemble .

HU B BEARIN G UNI T

Inspec t fo r fault ymovemen t an d wear .

SPINDL E WASHE R

SPINDLE NU T24 x 1. 5 m mReplace .245 N- m (25. 0 kgf-m , 18 1 Ibf-ft )NOTE : Afte r tightening , us e a drif t t ostak e th e spindl e nu t shoulde r agains tthe spindle .

WHEEL NU T12 x 1. 5 m m108 N- m (1 1 kgf-m , 8 0 Ibf-ft )

FLANG E NU T 1 0 x 1.2 5 m m

3 8 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

BRAKE DIS C

Chec k fo r wea r an d

rust .Inspection ,Section 19 .

FLAT-HEAD SCRE W

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

HUB CA PReplace .

WHEEL CENTE R CA P

Inspec

t surfac e fo r damage .

O-RINGReplace .

ProCarManuals.com

Page 1052 of 1954

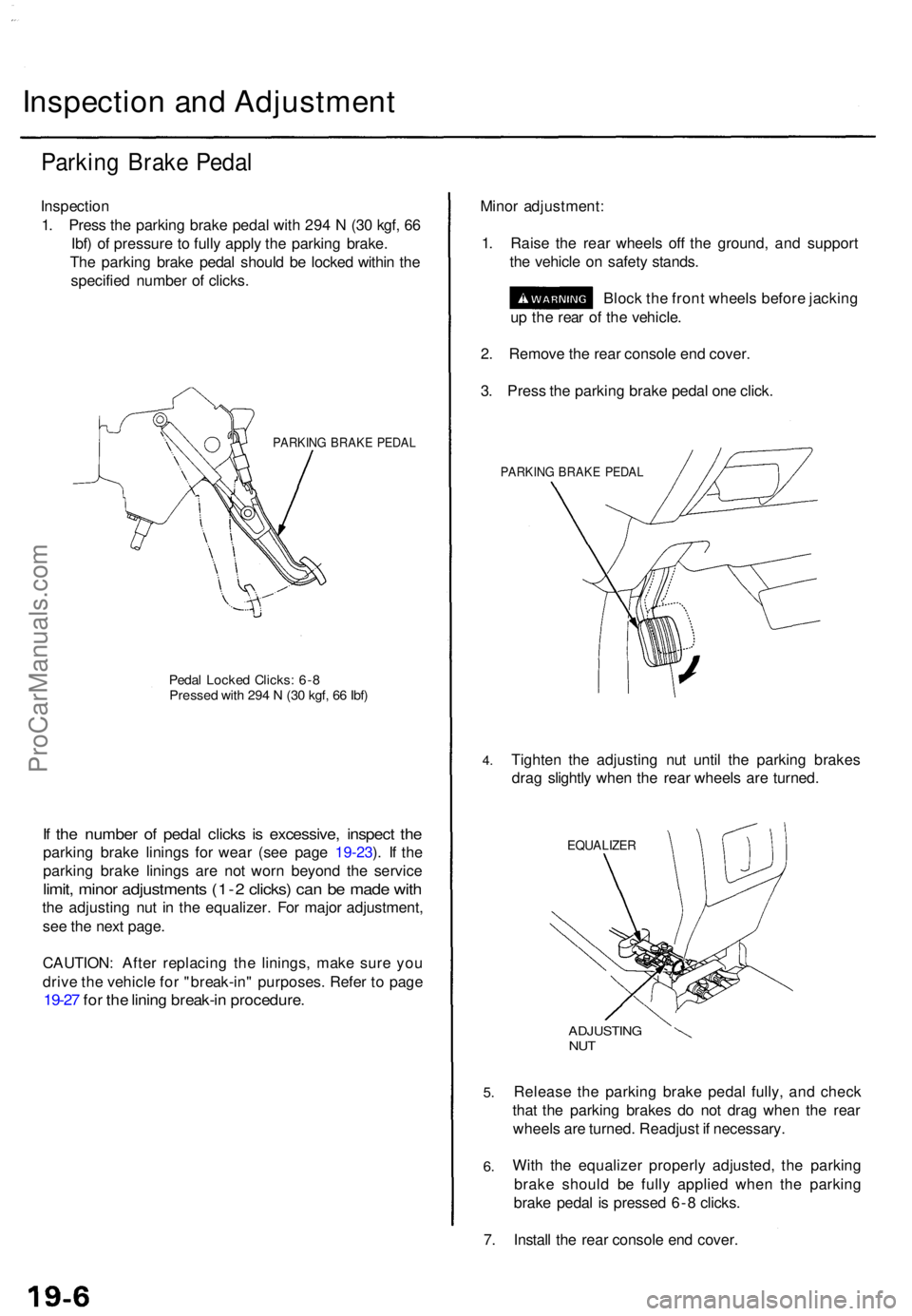

Inspection an d Adjustmen t

Parking Brak e Peda l

Inspectio n

1 . Pres s th e parkin g brak e peda l wit h 29 4 N (3 0 kgf , 6 6

Ibf ) o f pressur e to full y appl y th e parkin g brake .

Th e parkin g brak e peda l shoul d b e locke d withi n th e

specifie d numbe r o f clicks .

PARKIN G BRAK E PEDA L

Pedal Locke d Clicks : 6- 8Presse d wit h 29 4 N (3 0 kgf , 6 6 Ibf )

If th e numbe r o f peda l click s i s excessive , inspec t th e

parkin g brak e lining s fo r wea r (se e pag e 19-23 ). I f th e

parkin g brak e lining s ar e no t wor n beyon d th e servic e

limit, mino r adjustment s (1- 2 clicks ) ca n b e mad e wit h

the adjustin g nu t i n th e equalizer . Fo r majo r adjustment ,

se e th e nex t page .

CAUTION : Afte r replacin g th e linings , mak e sur e yo u

driv e th e vehicl e fo r "break-in " purposes . Refe r t o pag e

19-27 fo r th e linin g break-i n procedure .

Minor adjustment :

1 . Rais e th e rea r wheel s of f th e ground , an d suppor t

th e vehicl e o n safet y stands .

Bloc k th e fron t wheel s befor e jackin g

u p th e rea r o f th e vehicle .

2 . Remov e th e rea r consol e en d cover .

3 . Pres s th e parkin g brak e peda l on e click .

PARKIN G BRAK E PEDA L

4.Tighte n th e adjustin g nu t unti l th e parkin g brake s

dra g slightl y whe n th e rea r wheel s ar e turned .

EQUALIZE R

5.

6.

ADJUSTIN GNUT

Releas e th e parkin g brak e peda l fully , an d chec k

tha t th e parkin g brake s d o no t dra g whe n th e rea r

wheel s ar e turned . Readjus t i f necessary .

Wit h th e equalize r properl y adjusted , th e parkin g

brak e shoul d b e full y applie d whe n th e parkin g

brak e peda l i s presse d 6- 8 clicks .

7 . Instal l th e rea r consol e en d cover .

ProCarManuals.com

Page 1055 of 1954

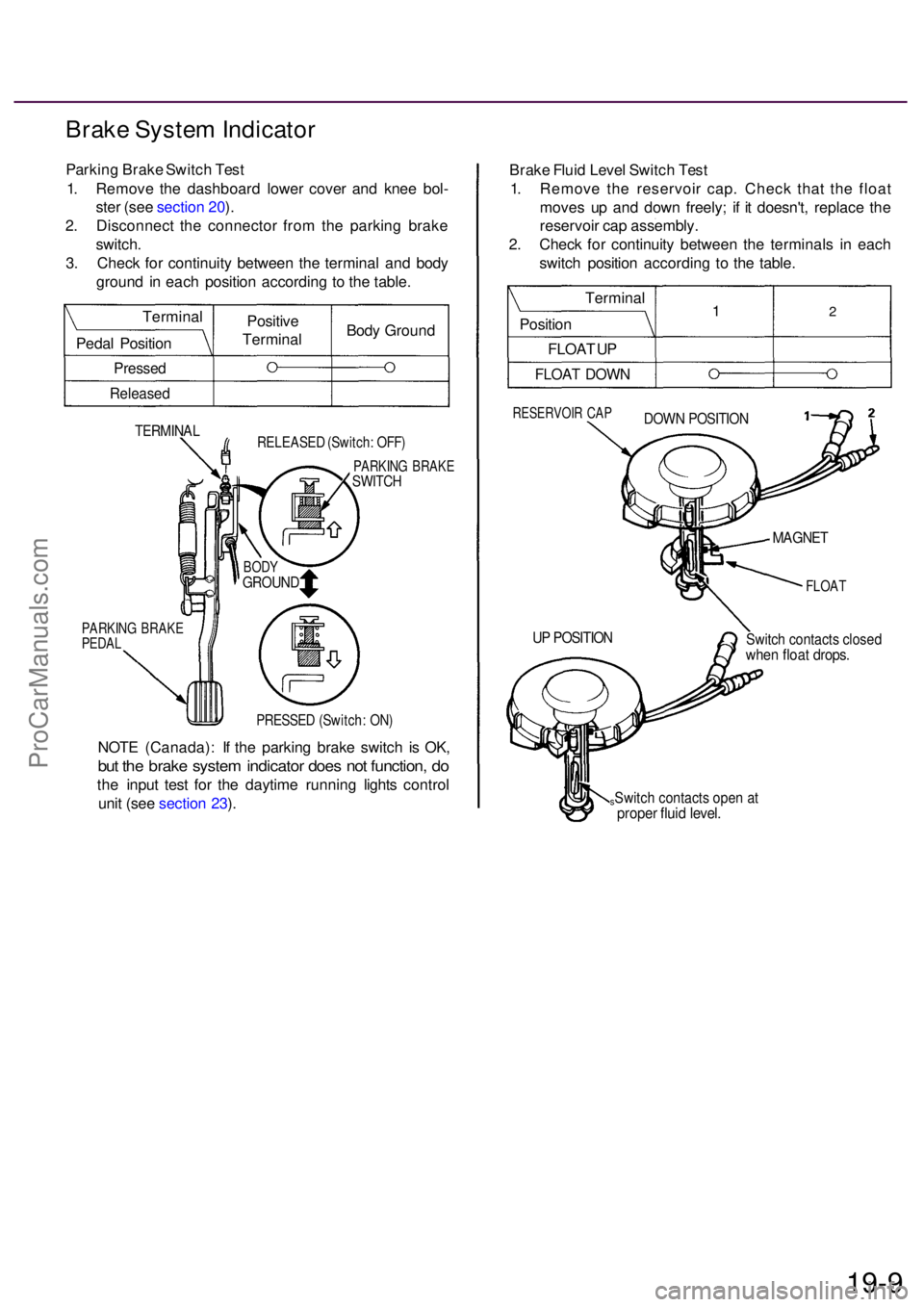

Brake Syste m Indicato r

Parking Brak e Switc h Tes t

1 . Remov e th e dashboar d lowe r cove r an d kne e bol -

ste r (se e sectio n 20 ).

2 . Disconnec t th e connecto r fro m th e parkin g brak e

switch .

3 . Chec k fo r continuit y betwee n th e termina l an d bod y

groun d i n eac h positio n accordin g t o th e table .

TERMINA LRELEASE D (Switch : OFF )

PARKIN G BRAK ESWITCH

PARKIN G BRAK EPEDAL

PRESSE D (Switch : ON )

NOT E (Canada) : I f th e parkin g brak e switc h i s OK ,

but th e brak e syste m indicato r doe s no t function , d o

th e inpu t tes t fo r th e daytim e runnin g light s contro l

uni t (se e sectio n 23 ). Brak

e Flui d Leve l Switc h Tes t

1 . Remov e th e reservoi r cap . Chec k tha t th e floa t

move s u p an d dow n freely ; i f i t doesn't , replac e th e

reservoi r ca p assembly .

2 . Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g t o th e table .

RESERVOI R CA PDOW N POSITIO N

FLOAT

Switch contact s close dwhen floa t drops .

sSwitch contact s ope n a tprope r flui d level .

19-9

UP POSITIO N

MAGNET

BODYGROUN D

Positive

Termina lBod

y Groun d

Termina

l

Peda l Positio n

Pressed

Release d

Termina l

Positio n

FLOA T U P

FLOA T DOW N

12

ProCarManuals.com

Page 1072 of 1954

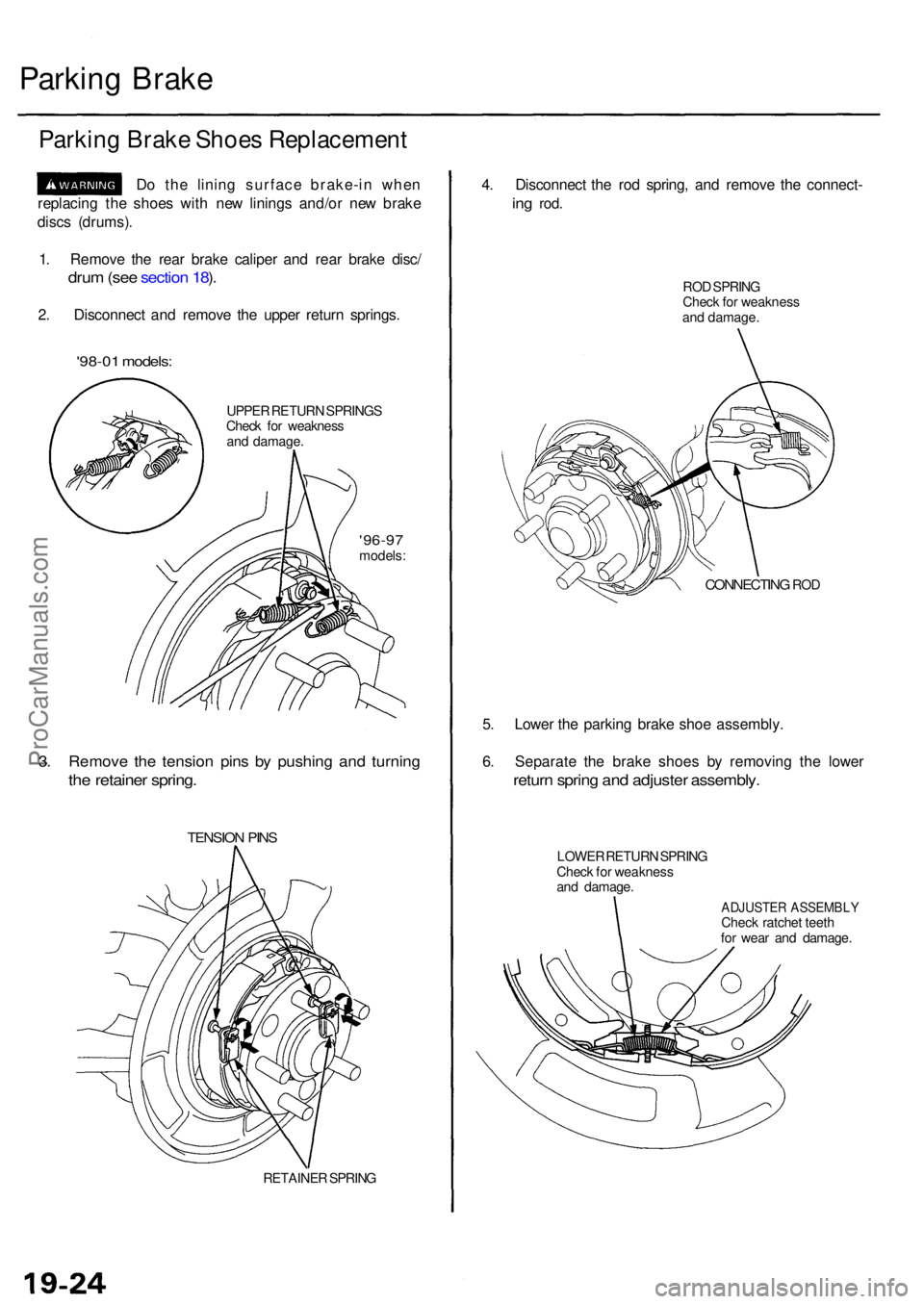

Parking Brak e

Parkin g Brak e Shoe s Replacemen t

Do th e linin g surfac e brake-i n whe n

replacin g th e shoe s wit h ne w lining s and/o r ne w brak e

disc s (drums) .

1 . Remov e th e rea r brak e calipe r an d rea r brak e disc /

drum (se e sectio n 18 ).

2 . Disconnec t an d remov e th e uppe r retur n springs .

'98-01 models :

UPPER RETUR N SPRING S

Chec k fo r weaknes s

an d damage .

'96-97models :

3. Remov e th e tensio n pin s b y pushin g an d turnin g

the retaine r spring .

TENSIO N PIN S

RETAINE R SPRIN G

4. Disconnec t th e ro d spring , an d remov e th e connect -

ing rod .

ROD SPRIN G

Chec k fo r weaknes s

an d damage .

CONNECTIN G ROD

5. Lowe r th e parkin g brak e sho e assembly .

6 . Separat e th e brak e shoe s b y removin g th e lowe r

return sprin g an d adjuste r assembly .

LOWER RETUR N SPRIN G

Chec k fo r weaknes s

an d damage .

ADJUSTE R ASSEMBL YCheck ratche t teet h

fo r wea r an d damage .

ProCarManuals.com

Page 1073 of 1954

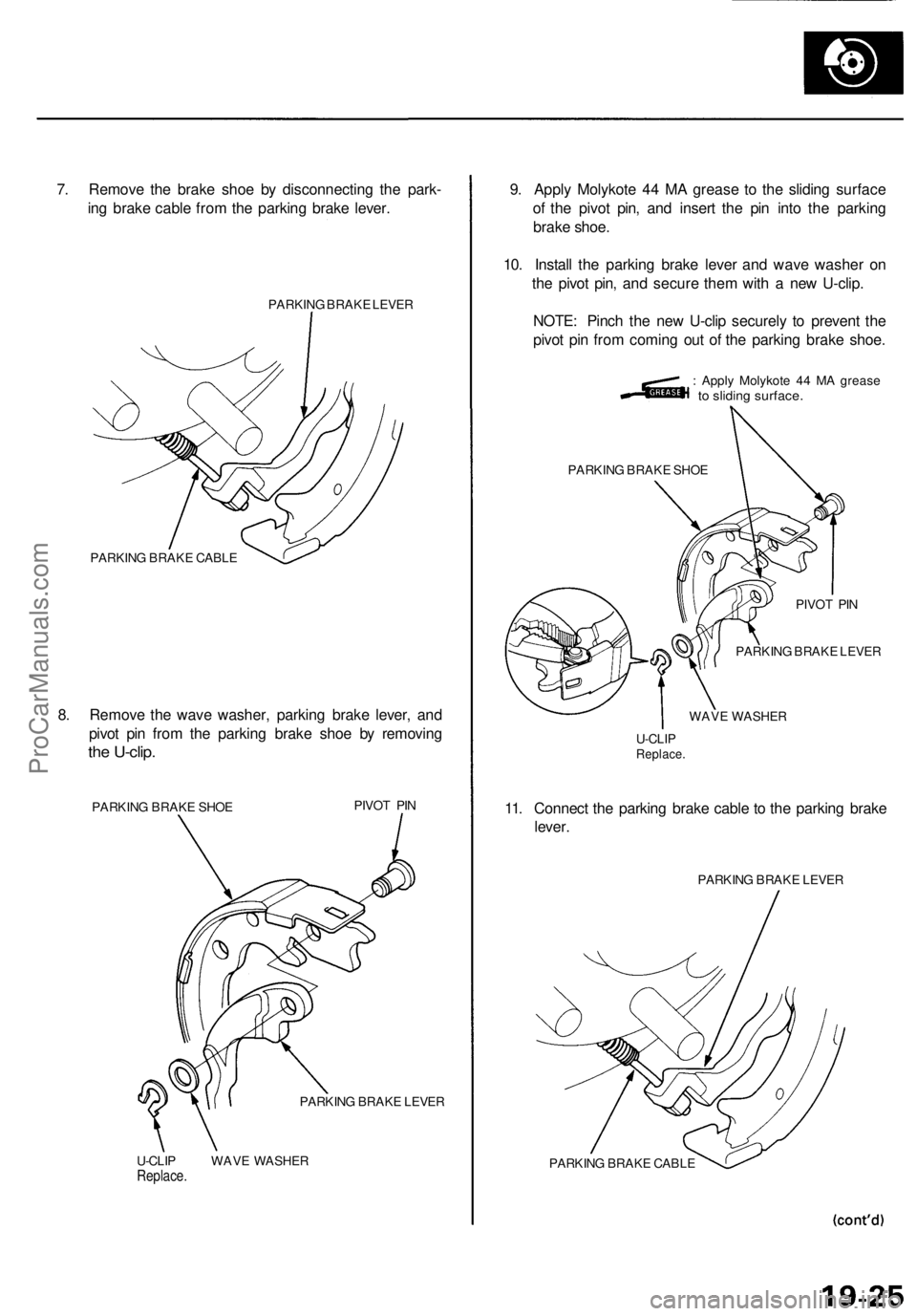

7. Remove the brake shoe by disconnecting the park-

ing brake cable from the parking brake lever.

PARKING BRAKE LEVER

PARKING BRAKE CABLE

8. Remove the wave washer, parking brake lever, and

pivot pin from the parking brake shoe by removing

the U-clip.

PARKING BRAKE SHOE

PIVOT PIN

PARKING BRAKE LEVER

U-CLIP WAVE WASHER

Replace.

9. Apply Molykote 44 MA grease to the sliding surface

of the pivot pin, and insert the pin into the parking

brake shoe.

10. Install the parking brake lever and wave washer on

the pivot pin, and secure them with a new U-clip.

NOTE: Pinch the new U-clip securely to prevent the

pivot pin from coming out of the parking brake shoe.

: Apply Molykote 44 MA grease

to sliding surface.

PARKING BRAKE SHOE

PIVOT PIN

PARKING BRAKE LEVER

WAVE WASHER

U-CLIP

Replace.

11. Connect the parking brake cable to the parking brake

lever.

PARKING BRAKE LEVER

PARKING BRAKE CABLEProCarManuals.com

Page 1074 of 1954

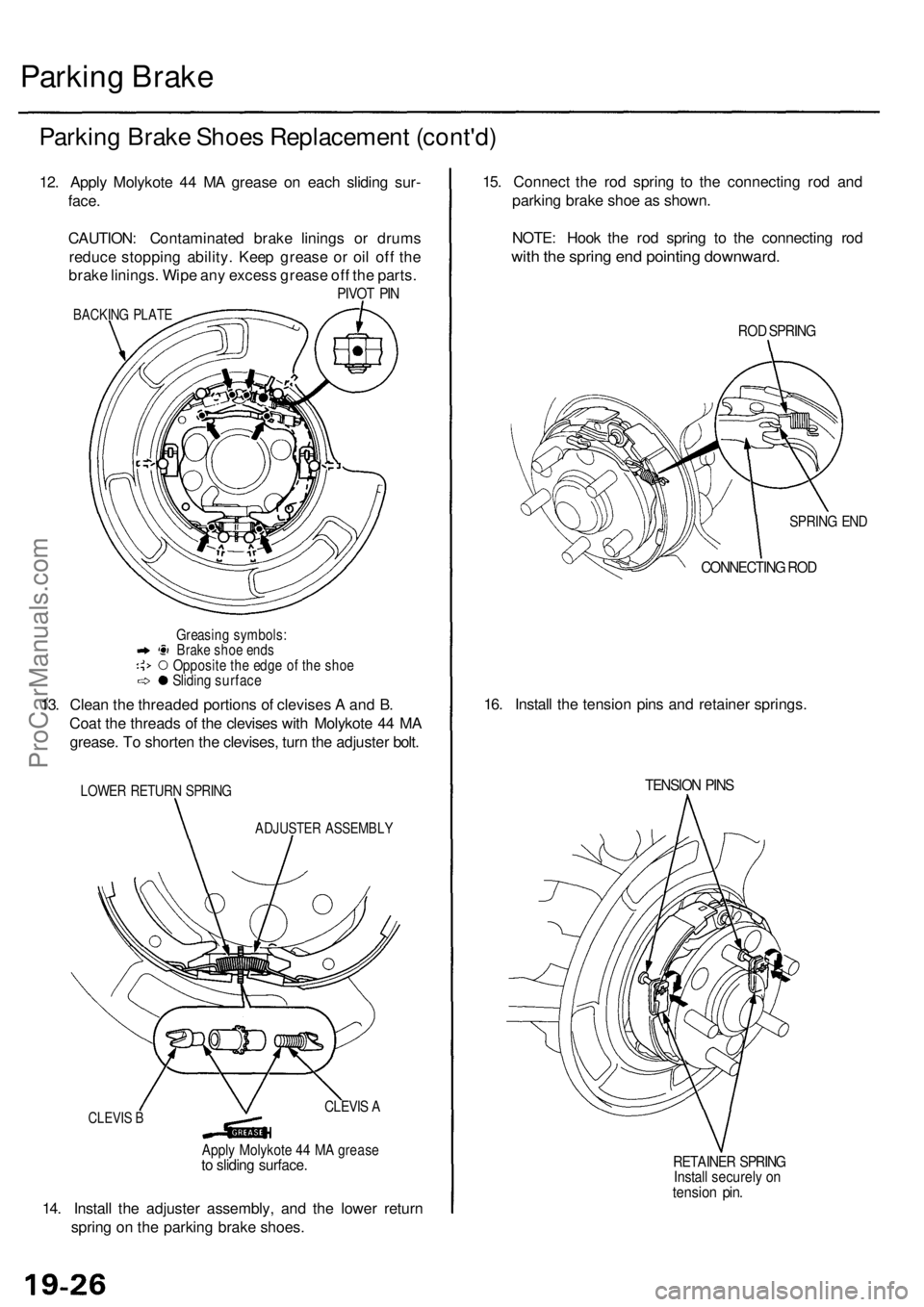

Parking Brake

Parking Brake Shoes Replacement (cont'd)

12. Apply Molykote 44 MA grease on each sliding sur-

face.

CAUTION: Contaminated brake linings or drums

reduce stopping ability. Keep grease or oil off the

brake linings. Wipe any excess grease off the parts.

PIVOT PIN

BACKING PLATE

Greasing symbols:

Brake shoe ends

Opposite the edge of the shoe

Sliding surface

13. Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with Molykote 44 MA

grease. To shorten the clevises, turn the adjuster bolt.

LOWER RETURN SPRING

ADJUSTER ASSEMBLY

14. Install the adjuster assembly, and the lower return

spring on the parking brake shoes.

15. Connect the rod spring to the connecting rod and

parking brake shoe as shown.

NOTE: Hook the rod spring to the connecting rod

with the spring end pointing downward.

ROD SPRING

SPRING END

CONNECTING ROD

16. Install the tension pins and retainer springs.

TENSION PINS

RETAINER SPRING

Install securely on

tension pin.

CLEVIS B

CLEVIS A

Apply Molykote 44 MA grease

to sliding surface.ProCarManuals.com

Page 1084 of 1954

Troubleshooting Precautions

ABS Indicator Light:

The ABS indicator light comes on for 3 seconds and then goes off when the control unit detects no problem during the ini-

tial diagnosis right after the engine starts. However, the ABS indicator light can stay on for up to 40 seconds when the

control unit starts to check for pump overrun, etc. during the initial diagnosis. The ABS indicator light comes on, and the

ABS control unit memorizes the diagnostic trouble code (DTC) under certain conditions.

The parking brake is applied for more than 30 seconds while the vehicle is being driven. (DTC 2-1)

The transmission downshifted excessively. (DTC 4-1, 4-2)

The vehicle loses traction, and the front wheels spin for more than 1 minute when starting from a stuck condition on a

muddy, snowy, or sandy road. (DTC 4-8)

Tire adhesion is lost due to excessive cornering speed. (DTC 5, 5-4, 5-8)

The vehicle is driven on an extremely rough road. (DTC 8-1)

The vehicle is interfered by strong radio waves (noise), for example, illegal radio, etc. (DTC 8-2)

NOTE: If there is any trouble in the system, the ABS indicator light comes on during driving.

Diagnostic Trouble Code (DTC):

When the control unit detects a problem and the ABS indicator light comes on, the control unit memorizes the DTC.

The control unit has three memory registers. When a problem occurs, the control unit stores the DTC in the first memory

register. If another problem occurs, or the same problem occurs again, the control unit moves the first DTC to the next

memory register, and stores the second DTC in the first register. If there's a third problem occurrence, the two existing

DTCs are moved up one register, and the third DTC is stored in the first register. If problems continue to occur, the oldest

problem is moved out of the last register and lost, and the most recent problem is stored in the first register. When the

same problem occurs three times, the same DTC is stored in all memory registers. (Refer to the Symptom-to-System

Chart for diagnostic period.)

The most recent DTC is indicated first, and the oldest DTC is indicated last.

The DTCs are erased from the control unit when the ABS control unit +B2 power supply or connector is disconnected.

The control unit's memory can be erased by disconnecting the ABS B2 fuse for more than 3 seconds.

Self-diagnosis:

There are three self-diagnoses described below.

Initial diagnosis: Performed right after the engine starts until the ABS indicator light goes off.

Regular diagnosis: Continuously performed (under some conditions) after the ABS indicator light goes off until the

engine stops.

Individual part/system diagnosis: Diagnosis about a specific part/system under its operating conditions.

The CPU (central processing unit) controls the following when it detects a problem during self-diagnosis:

Turns the ABS indicator light ON.

Turns the front and rear fail-safe relays off.

Stops the ABS control.

Stops the ABS pump. (The pump may work under some conditions.)

After the DTC is stored in the control unit, the CPU stops self-diagnosis.ProCarManuals.com

Page 1114 of 1954

Troubleshooting

DTC 5 , 5-4 , 5-8 : Rea r Whee l Loc k

The AB S contro l uni t monitor s th e rea r whee l senso r signal s durin g th e regula r diagnosi s (durin g driving) . Thi s diagnosi s

is no t performe d whe n th e parkin g brak e signa l i s ON . Th e AB S contro l uni t turn s th e AB S indicato r ligh t o n if i t detect s n o

signal(s ) fro m th e rea r whee l sensor(s ) du e to , fo r example , rea r whee l lock .

Possibl e causes :

Wheel spi n durin g cornerin g

Open circuit , interna l shor t o r shor t t o th e bod y groun d in th e whee l senso r syste m

Rear brak e dra g

Modulato r doe s no t decreas e pressur e properl y

Faulty AB S contro l uni t

— Whe n vehicl e i s driven , ABSindicato r ligh t i s ON .— Wit h th e SC S servic e connec -tor connecte d (se e pag e 19-40 ),DTC s 5 , 5- 4 and/o r 5- 8 ar e indi -

cated .

Chec k th e PAR K circuit :

1. Tur n th e ignitio n switc h O N (II) .2. Pres s th e parking brake pedal .

Doe s th e brak e syste m ligh t

com e on ? Parkin

g brak e switc h stuc k OFF .

Repai r ope n circui t betwee n th e

under-das h fuse/rela y bo x an d

parkin g brak e switch .

NOTE:The self-diagnosi s o f th e whee l senso r i s per -forme d i n thi s step .

Test-driv e wit h th e parkin g brak e released .

Does th e AB S indicato r ligh tcom e on ?

Chec k fo r rea r brak e drag :

1 . Rais e th e rea r o f th e vehicle ,

and suppor t i t wit h safet ystands (se e sectio n 1 ).2 . Spi n th e lef t and/o r righ t rea rwhee l an d chec k fo r brak e

drag . I

s cod e 4- 4 o r 4- 8 indicated ?

Perform th e troubleshootin g fo rthe rea r whee l sensor .

Perfor m th e appropriat e trouble -

shootin g fo r th e code .

Doe s th e brak e drag ?

Repair th e rea r brak e drag .

Check th e AB S functio n (se epage 19-95 ).

Th e probabl e caus e wa s tha t

tractio n wa s los t du e t o exces -

siv e cornerin g speed , etc .

Chec

k th e self-diagnosis :

Test-driv e th e vehicl e a t speed s

of 6 mp h (1 0 km/h ) o r more .

Confir m th e DT C (se e pag e 19-40 ).

ProCarManuals.com