check oil ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 83 of 1771

Camshaft

Inspection (cont'd)

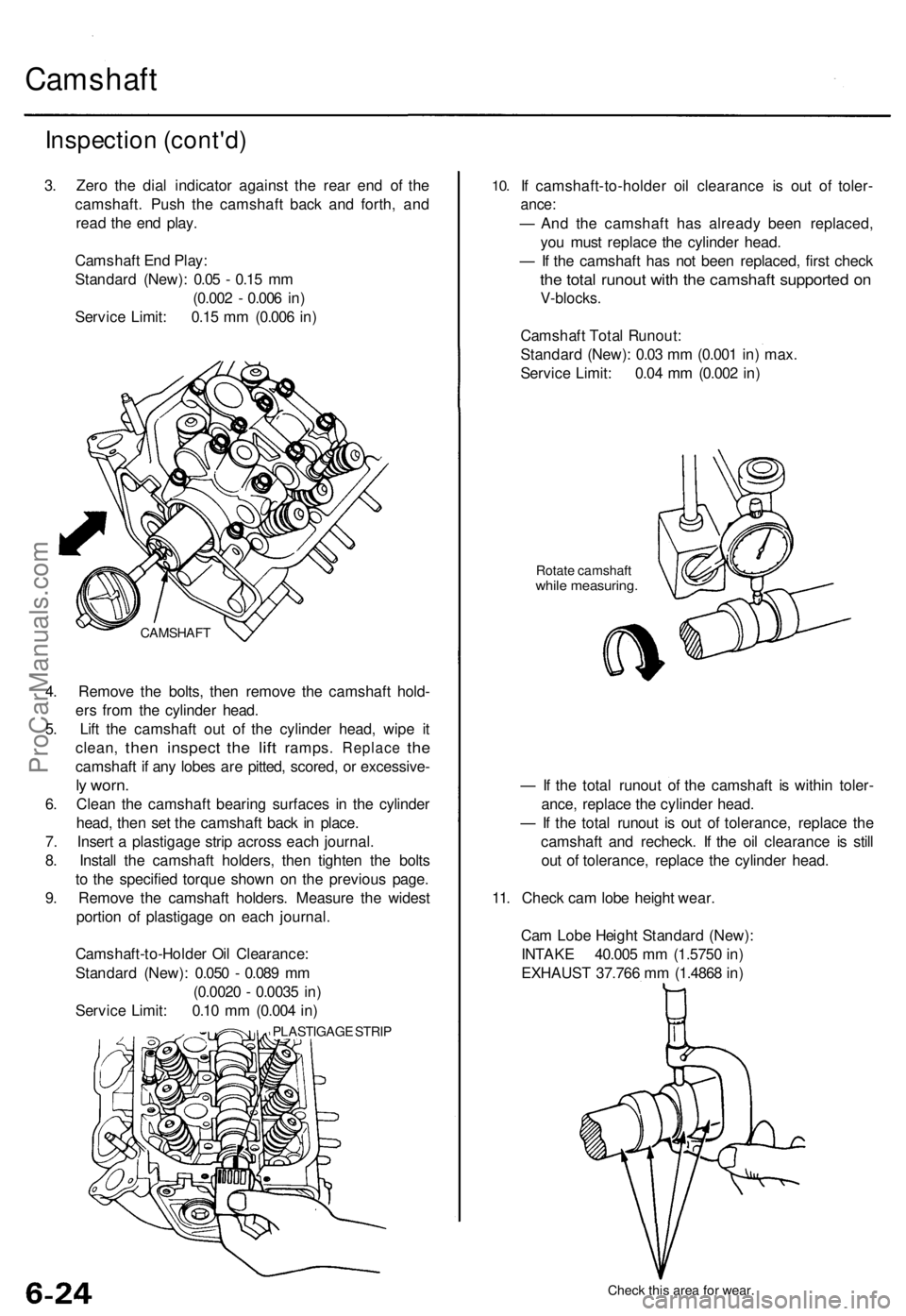

3. Zero the dial indicator against the rear end of the

camshaft. Push the camshaft back and forth, and

read the end play.

Camshaft End Play:

Standard (New): 0.05 - 0.15 mm

(0.002 - 0.006 in)

Service Limit: 0.15 mm (0.006 in)

4. Remove the bolts, then remove the camshaft hold-

ers from the cylinder head.

5. Lift the camshaft out of the cylinder head, wipe it

clean,

then

inspect

the

lift

ramps.

Replace

the

camshaft if any lobes are pitted, scored, or excessive-

ly worn.

6. Clean the camshaft bearing surfaces in the cylinder

head, then set the camshaft back in place.

7. Insert a plastigage strip across each journal.

8. Install the camshaft holders, then tighten the bolts

to the specified torque shown on the previous page.

9. Remove the camshaft holders. Measure the widest

portion of plastigage on each journal.

Camshaft-to-Holder Oil Clearance:

Standard (New): 0.050 - 0.089 mm

(0.0020 - 0.0035 in)

Service Limit: 0.10 mm (0.004 in)

PLASTIGAGE STRIP

10.

If camshaft-to-holder oil clearance is out of toler-

ance:

— And the camshaft has already been replaced,

you must replace the cylinder head.

— If the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Camshaft Total Runout:

Standard (New): 0.03 mm (0.001 in) max.

Service Limit: 0.04 mm (0.002 in)

Rotate camshaft

while measuring.

— If the total runout of the camshaft is within toler-

ance, replace the cylinder head.

— If the total runout is out of tolerance, replace the

camshaft and recheck. If the oil clearance is still

out of tolerance, replace the cylinder head.

11. Check cam lobe height wear.

Cam Lobe Height Standard (New):

INTAKE 40.005 mm (1.5750 in)

EXHAUST 37.766 mm (1.4868 in)

Check this area for wear.

CAMSHAFTProCarManuals.com

Page 94 of 1771

Hydraulic Tappets

Valve Installation

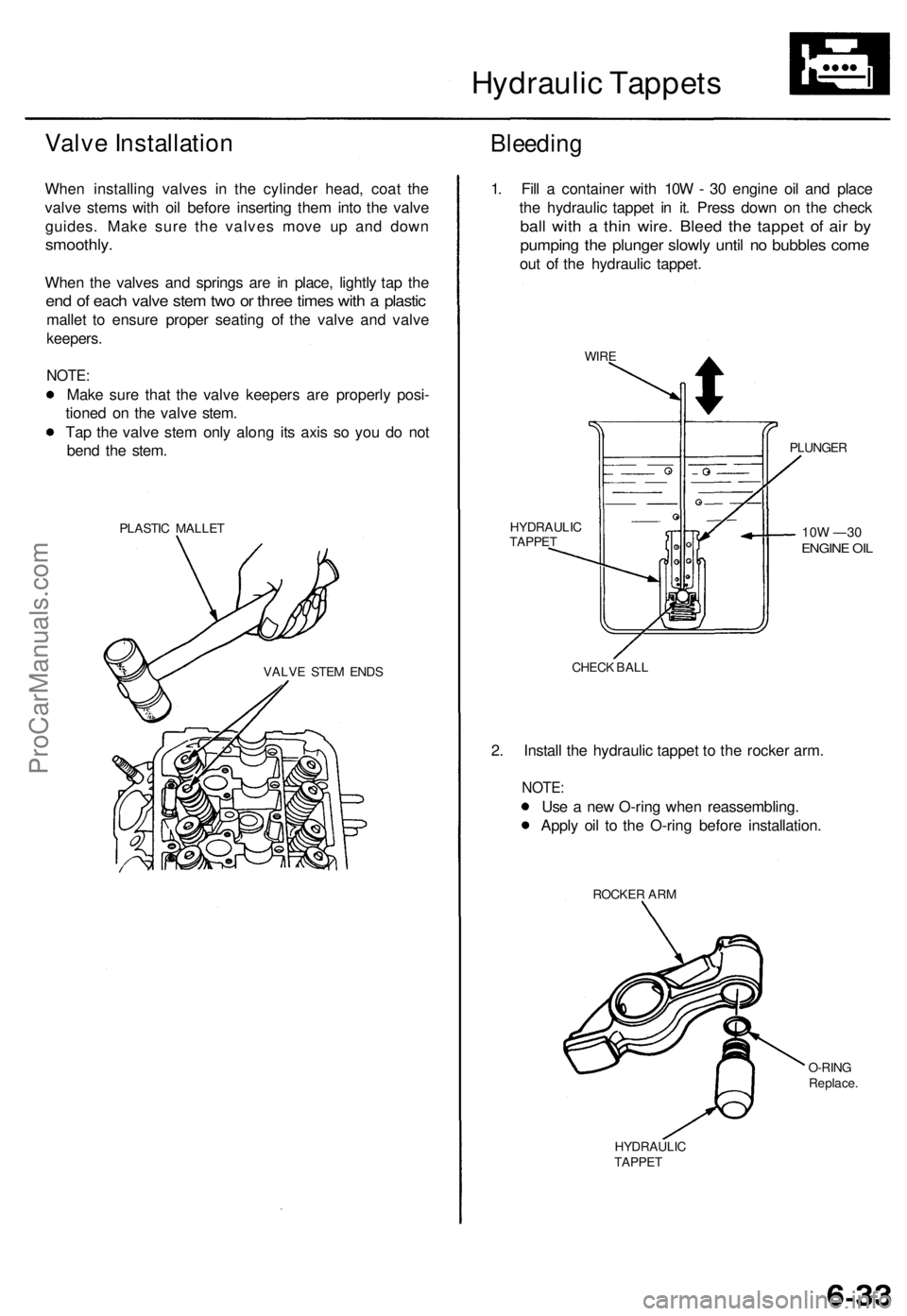

When installing valves in the cylinder head, coat the

valve stems with oil before inserting them into the valve

guides. Make sure the valves move up and down

smoothly.

When the valves and springs are in place, lightly tap the

end of each valve stem two or three times with a plastic

mallet to ensure proper seating of the valve and valve

keepers.

NOTE:

Make sure that the valve keepers are properly posi-

tioned on the valve stem.

Tap the valve stem only along its axis so you do not

bend the stem.

PLASTIC MALLET

Bleeding

VALVE STEM ENDS

1. Fill a container with 10W - 30 engine oil and place

the hydraulic tappet in it. Press down on the check

ball with a thin wire. Bleed the tappet of air by

pumping the plunger slowly until no bubbles come

out of the hydraulic tappet.

WIRE

PLUNGER

10W —30

ENGINE OIL

HYDRAULIC

TAPPET

CHECK BALL

2. Install the hydraulic tappet to the rocker arm.

NOTE:

Use a new O-ring when reassembling.

Apply oil to the O-ring before installation.

ROCKER ARM

O-RING

Replace.

HYDRAULIC

TAPPETProCarManuals.com

Page 97 of 1771

Cylinder Heads

Installation (cont'd)

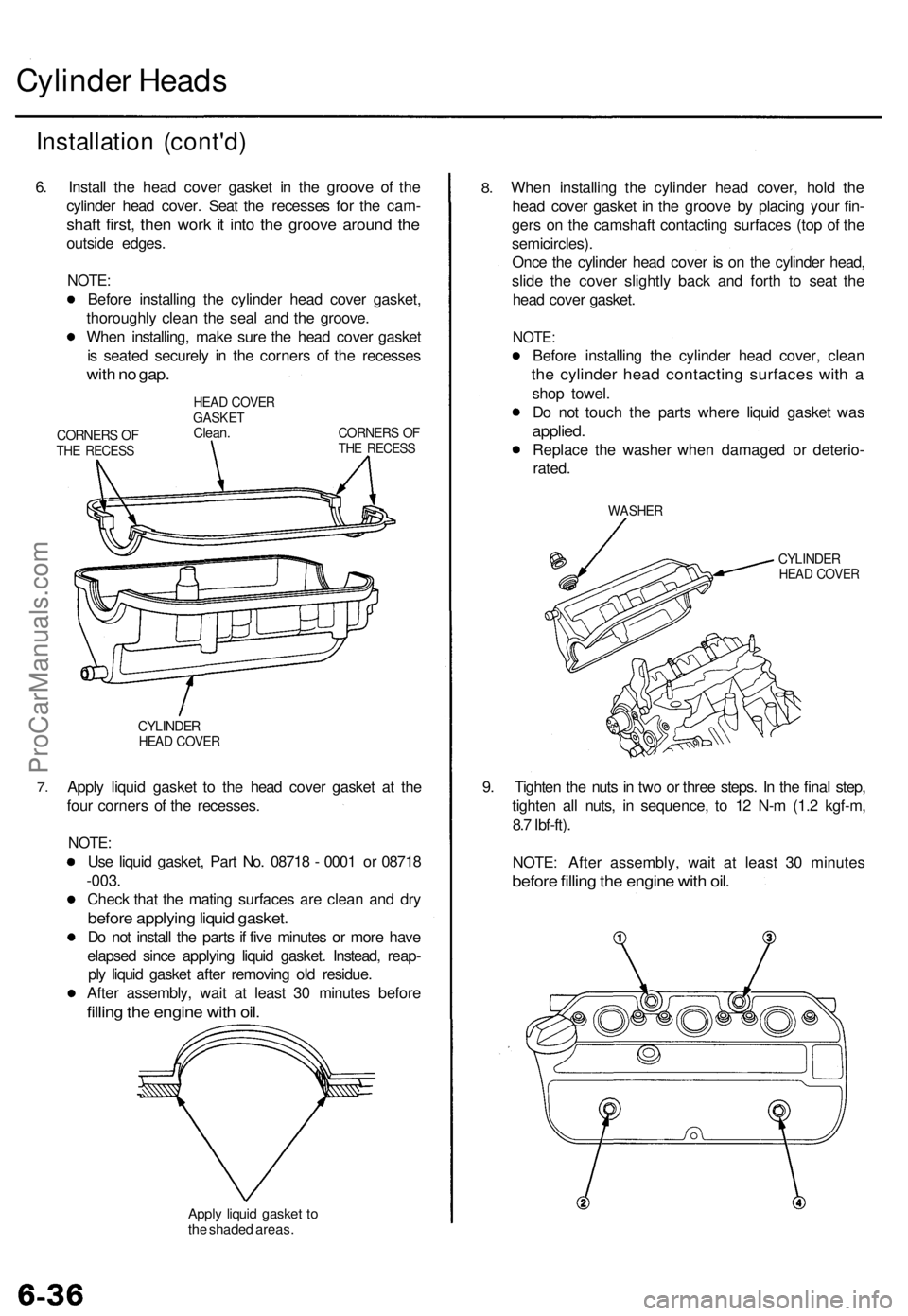

6. Install the head cover gasket in the groove of the

cylinder head cover. Seat the recesses for the cam-

shaft first, then work it into the groove around the

outside edges.

NOTE:

Before installing the cylinder head cover gasket,

thoroughly clean the seal and the groove.

When installing, make sure the head cover gasket

is seated securely in the corners of the recesses

with no gap.

CORNERS OF

THE RECESS

HEAD COVER

GASKET

Clean.

CORNERS OF

THE RECESS

7.

CYLINDER

HEAD COVER

Apply liquid gasket to the head cover gasket at the

four corners of the recesses.

NOTE:

Use liquid gasket, Part No. 08718 - 0001 or 08718

-003.

Check that the mating surfaces are clean and dry

before applying liquid gasket.

Do not install the parts if five minutes or more have

elapsed since applying liquid gasket. Instead, reap-

ply liquid gasket after removing old residue.

After assembly, wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket to

the shaded areas.

8.

When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft contacting surfaces (top of the

semicircles).

Once the cylinder head cover is on the cylinder head,

slide the cover slightly back and forth to seat the

head cover gasket.

NOTE:

Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

Do not touch the parts where liquid gasket was

applied.

Replace the washer when damaged or deterio-

rated.

WASHER

CYLINDER

HEAD COVER

9. Tighten the nuts in two or three steps. In the final step,

tighten all nuts, in sequence, to 12 N-m (1.2 kgf-m,

8.7 Ibf-ft).

NOTE: After assembly, wait at least 30 minutes

before filling the engine with oil.ProCarManuals.com

Page 105 of 1771

Connecting Rod Bearings

Clearance

Selection

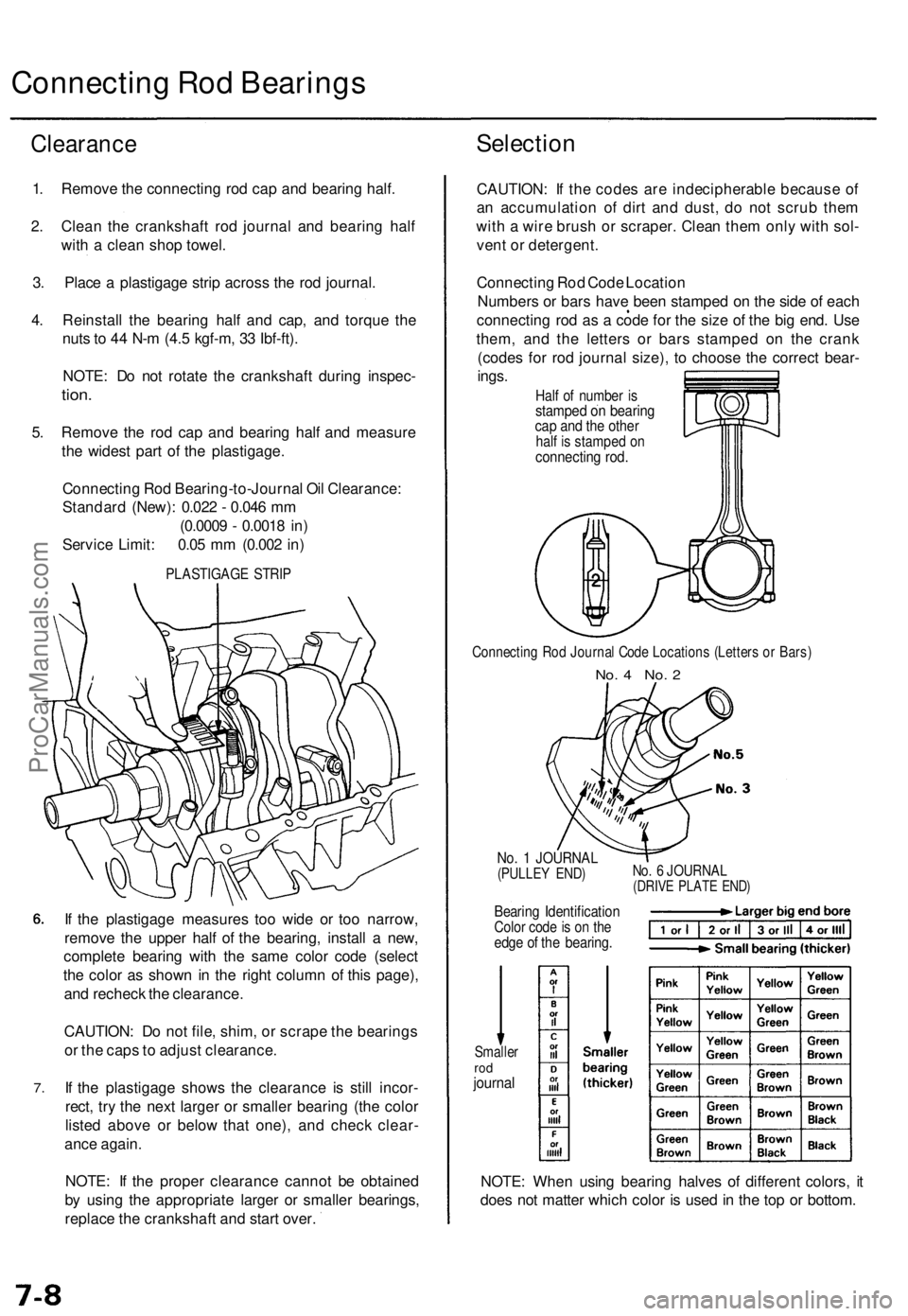

1. Remove the connecting rod cap and bearing half.

2. Clean the crankshaft rod journal and bearing half

with a clean shop towel.

3. Place a plastigage strip across the rod journal.

4. Reinstall the bearing half and cap, and torque the

nuts to 44 N-m (4.5 kgf-m, 33 Ibf-ft).

NOTE: Do not rotate the crankshaft during inspec-

tion.

5. Remove the rod cap and bearing half and measure

the widest part of the plastigage.

Connecting Rod Bearing-to-Journal Oil Clearance:

Standard (New): 0.022 - 0.046 mm

(0.0009 - 0.0018 in)

Service Limit: 0.05 mm (0.002 in)

PLASTIGAGE STRIP

7.

If the plastigage measures too wide or too narrow,

remove the upper half of the bearing, install a new,

complete bearing with the same color code (select

the color as shown in the right column of this page),

and recheck the clearance.

CAUTION: Do not file, shim, or scrape the bearings

or the caps to adjust clearance.

If the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check clear-

ance again.

NOTE: If the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

CAUTION: If the codes are indecipherable because of

an accumulation of dirt and dust, do not scrub them

with a wire brush or scraper. Clean them only with sol-

vent or detergent.

Connecting Rod Code Location

Numbers or bars have been stamped on the side of each

connecting rod as a code for the size of the big end. Use

them, and the letters or bars stamped on the crank

(codes for rod journal size), to choose the correct bear-

ings.

Half of number is

stamped on bearing

cap and the other

half is stamped on

connecting rod.

Connecting Rod Journal Code Locations (Letters or Bars)

No. 4 No. 2

No. 1 JOURNAL

(PULLEY END)

Bearing Identification

Color code is on the

edge of the bearing.

No. 6 JOURNAL

(DRIVE PLATE END)

Smaller

rod

journal

NOTE: When using bearing halves of different colors, it

does not matter which color is used in the top or bottom.ProCarManuals.com

Page 108 of 1771

Crankshaft

Inspection

Clean the crankshaft oil passages with pipe cleaners

or a suitable brush.

Check the keyway and threads.

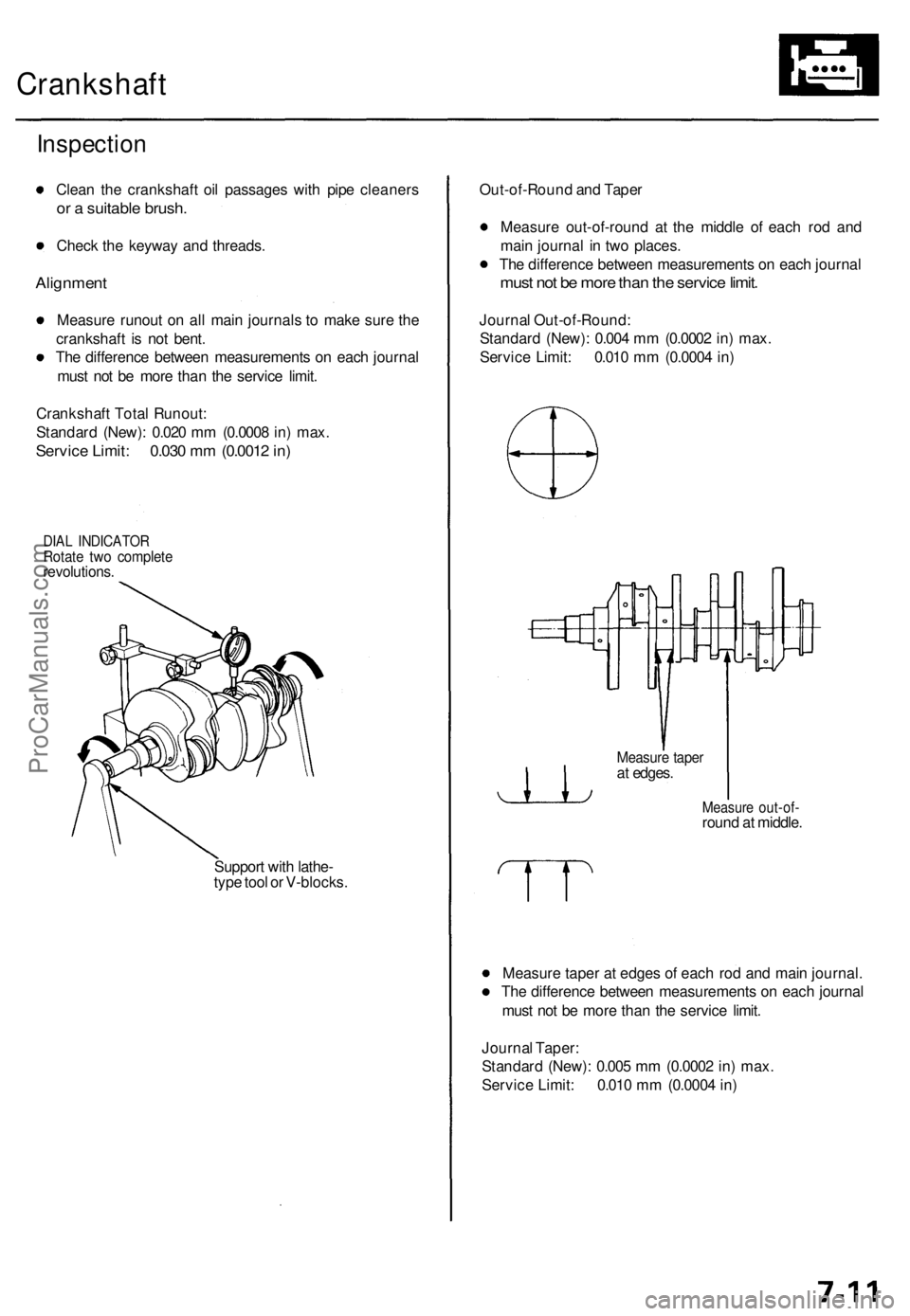

Alignment

Measure runout on all main journals to make sure the

crankshaft is not bent.

The difference between measurements on each journal

must not be more than the service limit.

Crankshaft Total Runout:

Standard (New): 0.020 mm (0.0008 in) max.

Service Limit: 0.030 mm (0.0012 in)

DIAL INDICATOR

Rotate two complete

revolutions.

Support with lathe-

type tool or V-blocks.

Out-of-Round and Taper

Measure out-of-round at the middle of each rod and

main journal in two places.

The difference between measurements on each journal

must not be more than the service limit.

Journal Out-of-Round:

Standard (New): 0.004 mm (0.0002 in) max.

Service Limit: 0.010 mm (0.0004 in)

Measure out-of-

round at middle.

Measure taper at edges of each rod and main journal.

The difference between measurements on each journal

must not be more than the service limit.

Journal Taper:

Standard (New): 0.005 mm (0.0002 in) max.

Service Limit: 0.010 mm (0.0004 in)

Measure taper

at edges.ProCarManuals.com

Page 116 of 1771

Pistons

Installation

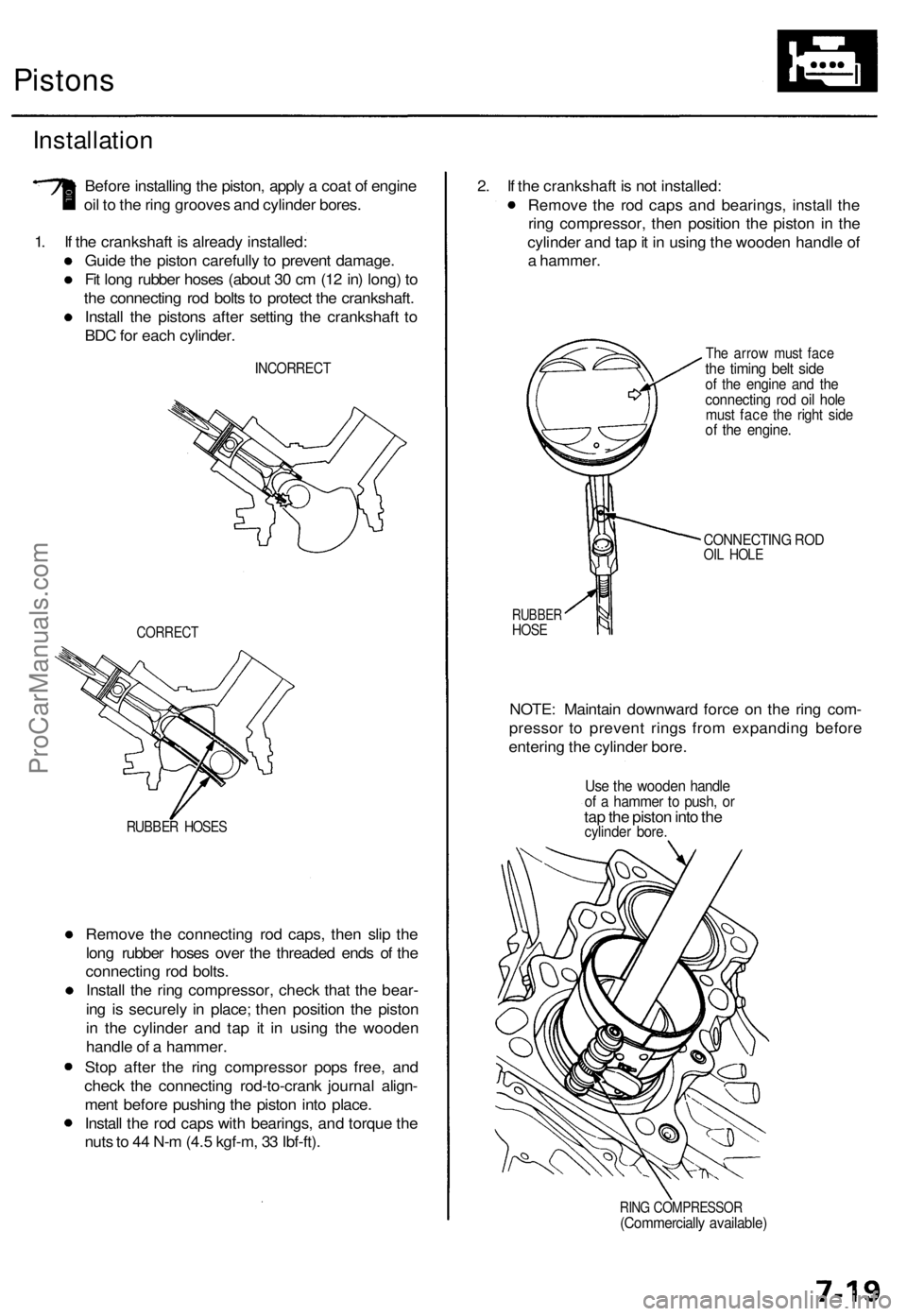

Before installing the piston, apply a coat of engine

oil to the ring grooves and cylinder bores.

1. If the crankshaft is already installed:

Guide the piston carefully to prevent damage.

Fit long rubber hoses (about 30 cm (12 in) long) to

the connecting rod bolts to protect the crankshaft.

Install the pistons after setting the crankshaft to

BDC for each cylinder.

INCORRECT

CORRECT

RUBBER HOSES

Remove the connecting rod caps, then slip the

long rubber hoses over the threaded ends of the

connecting rod bolts.

Install the ring compressor, check that the bear-

ing is securely in place; then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place.

Install the rod caps with bearings, and torque the

nuts to 44 N-m (4.5 kgf-m, 33 Ibf-ft).

2. If the crankshaft is not installed:

Remove the rod caps and bearings, install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a hammer.

The arrow must face

the timing belt side

of the engine and the

connecting rod oil hole

must face the right side

of the engine.

CONNECTING ROD

OIL HOLE

RUBBER

HOSE

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore.

Use the wooden handle

of a hammer to push, or

tap the piston into the

cylinder bore.

RING COMPRESSOR

(Commercially available)ProCarManuals.com

Page 120 of 1771

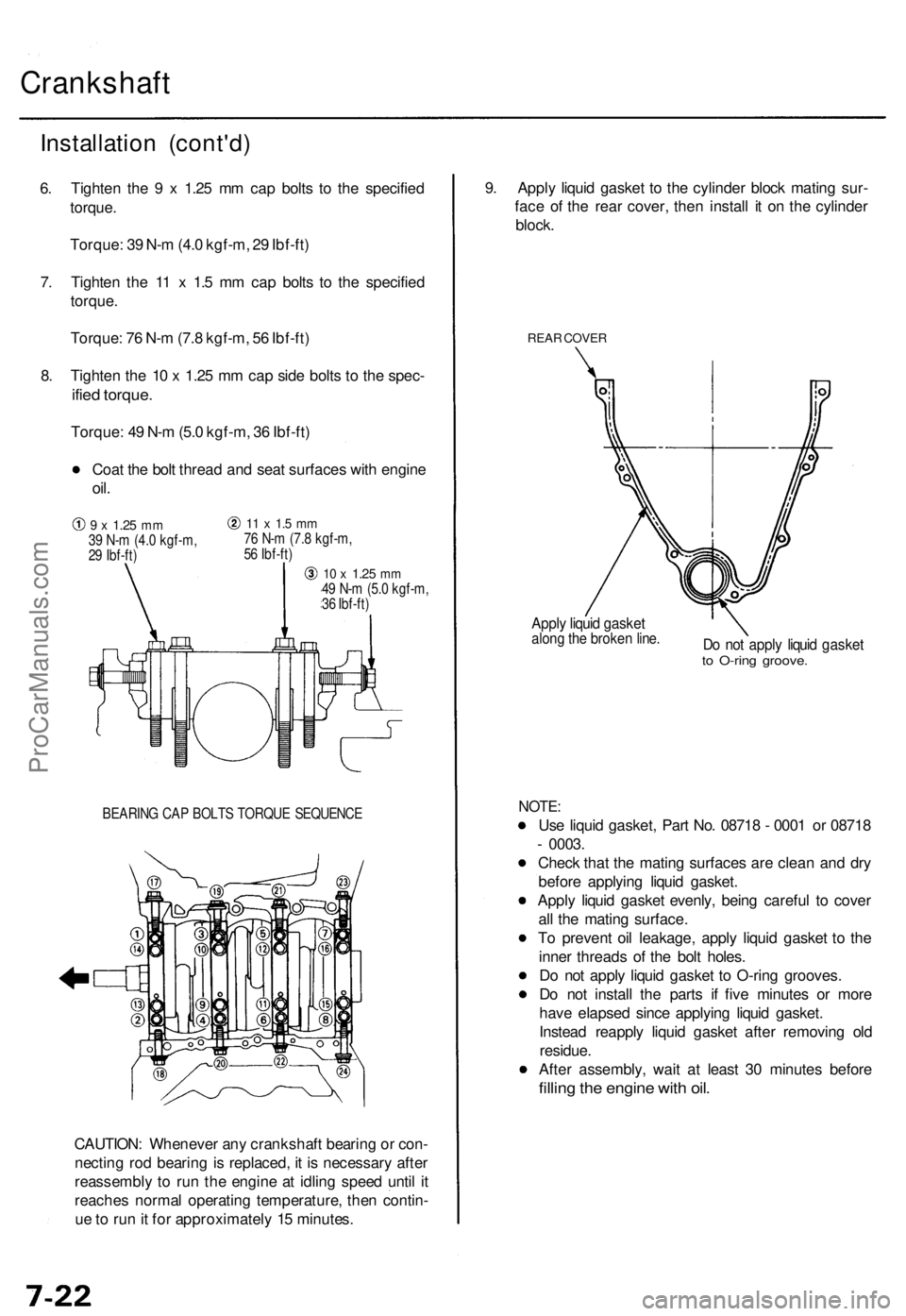

Crankshaft

BEARING CAP BOLTS TORQUE SEQUENCE

CAUTION: Whenever any crankshaft bearing or con-

necting rod bearing is replaced, it is necessary after

reassembly to run the engine at idling speed until it

reaches normal operating temperature, then contin-

ue to run it for approximately 15 minutes.

9. Apply liquid gasket to the cylinder block mating sur-

face of the rear cover, then install it on the cylinder

block.

REAR COVER

Apply liquid gasket

along the broken line.

Do not apply liquid gasket

to O-ring groove.

NOTE:

Use liquid gasket, Part No. 08718 - 0001 or 08718

- 0003.

Check that the mating surfaces are clean and dry

before applying liquid gasket.

Apply liquid gasket evenly, being careful to cover

all the mating surface.

To prevent oil leakage, apply liquid gasket to the

inner threads of the bolt holes.

Do not apply liquid gasket to O-ring grooves.

Do not install the parts if five minutes or more

have elapsed since applying liquid gasket.

Instead reapply liquid gasket after removing old

residue.

After assembly, wait at least 30 minutes before

filling the engine with oil.

Installation (cont'd)

6. Tighten the 9 x 1.25 mm cap bolts to the specified

torque.

Torque: 39 N-m (4.0 kgf-m, 29 Ibf-ft)

7. Tighten the 11 x 1.5 mm cap bolts to the specified

torque.

Torque: 76 N-m (7.8 kgf-m, 56 Ibf-ft)

8. Tighten the 10 x 1.25 mm cap side bolts to the spec-

ified torque.

Torque: 49 N-m (5.0 kgf-m, 36 Ibf-ft)

Coat the bolt thread and seat surfaces with engine

oil.

9 x

1.25

mm

39 N-m (4.0 kgf-m,

29 Ibf-ft)

11 x 1.5 mm

76 N-m (7.8 kgf-m,

56 Ibf-ft)

10 x

1.25

mm

49 N-m (5.0 kgf-m,

36 Ibf-ft)ProCarManuals.com

Page 126 of 1771

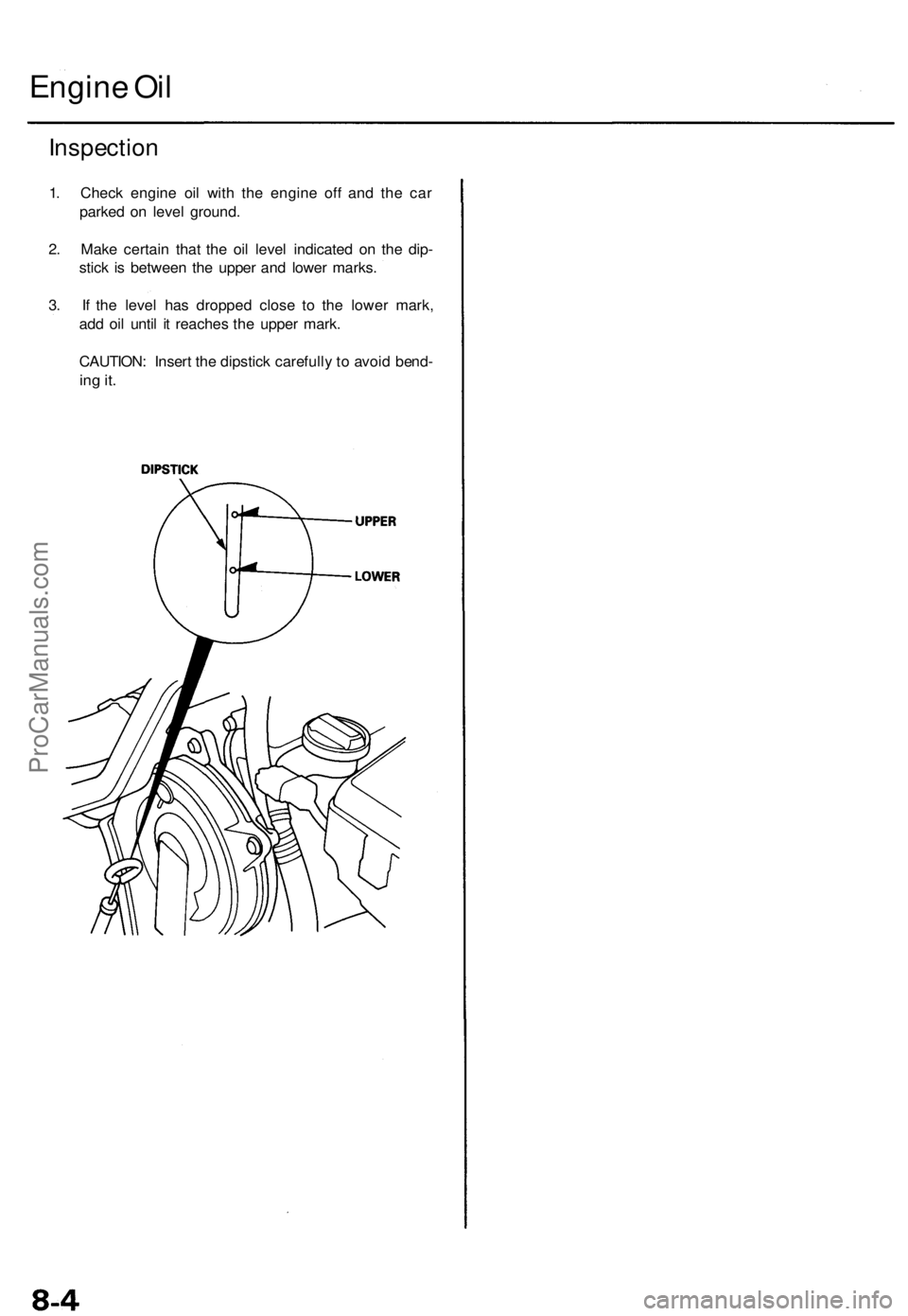

Inspection

1. Check engine oil with the engine off and the car

parked on level ground.

2. Make certain that the oil level indicated on the dip-

stick is between the upper and lower marks.

3. If the level has dropped close to the lower mark,

add oil until it reaches the upper mark.

CAUTION: Insert the dipstick carefully to avoid bend-

ing it.

Engine OilProCarManuals.com

Page 128 of 1771

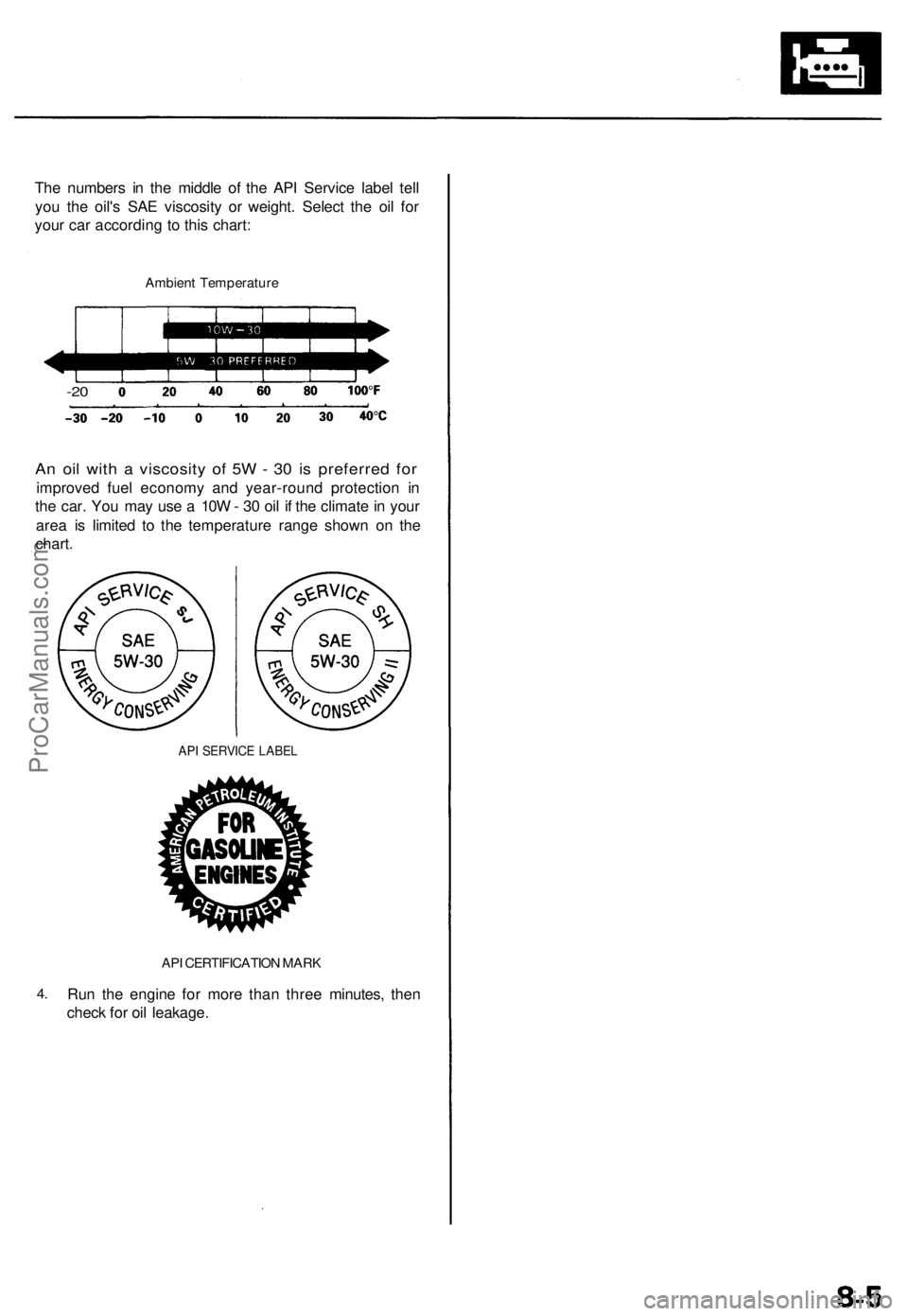

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight. Select the oil for

your car according to this chart:

Ambient Temperature

-20

An oil with a viscosity of 5W - 30 is preferred for

improved fuel economy and year-round protection in

the car. You may use a 10W - 30 oil if the climate in your

area is limited to the temperature range shown on the

chart.

API SERVICE LABEL

4.

API CERTIFICATION MARK

Run the engine for more than three minutes, then

check for oil leakage.ProCarManuals.com

Page 130 of 1771

Oil Pressur e Engin

e Oi l Temperatur e Switc h

Testin gTestin g

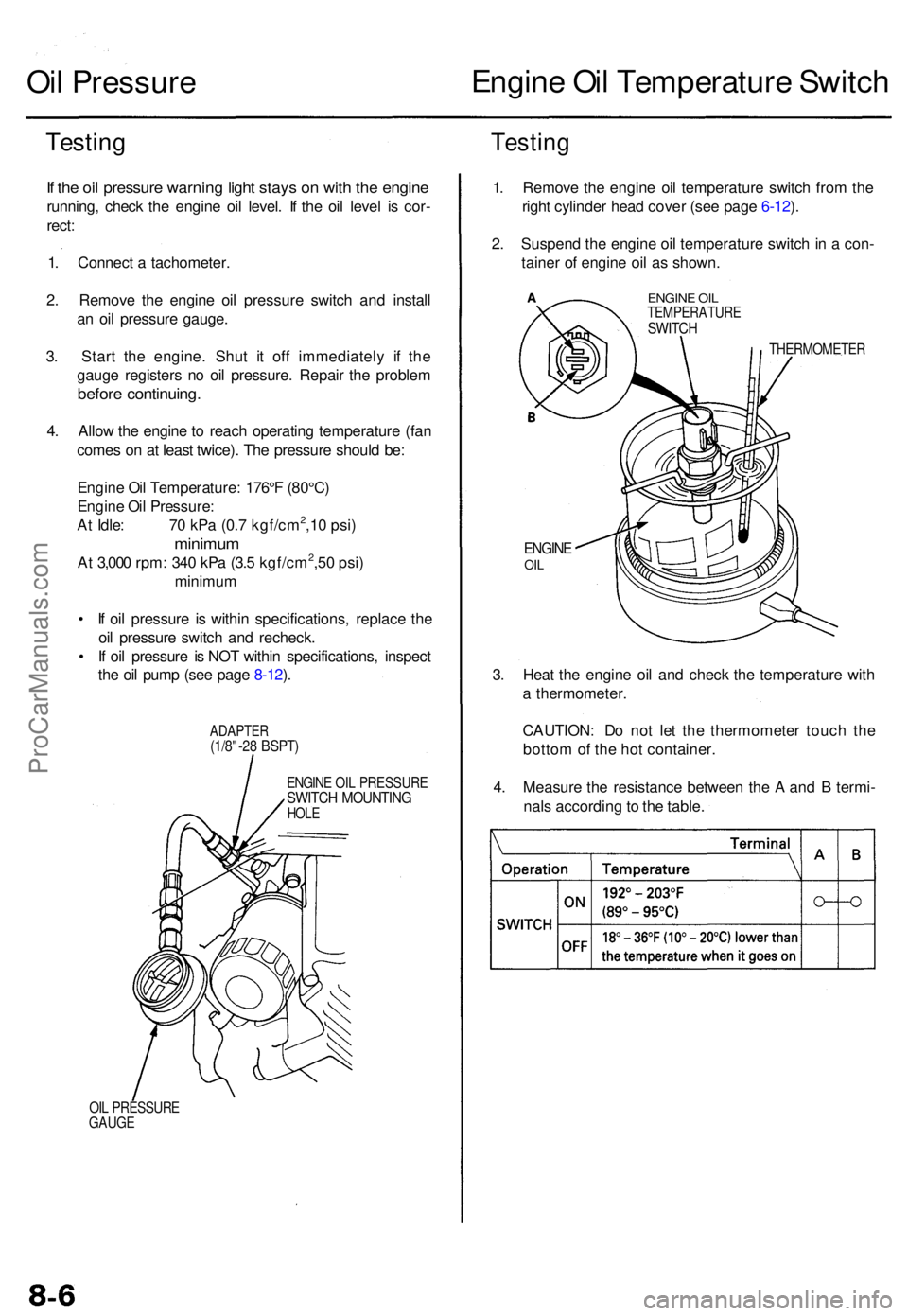

If th e oi l pressur e warnin g ligh t stay s o n wit h th e engin e

running , chec k th e engin e oi l level . I f th e oi l leve l i s cor -

rect :

1 . Connec t a tachometer .

2 . Remov e th e engin e oi l pressur e switc h an d instal l

a n oi l pressur e gauge .

3 . Star t th e engine . Shu t i t of f immediatel y i f th e

gaug e register s n o oi l pressure . Repai r th e proble m

before continuing .

4. Allo w th e engin e to reac h operatin g temperatur e (fa n

come s o n a t leas t twice) . Th e pressur e shoul d be :

Engin e Oi l Temperature : 176° F (80°C )

Engin e Oi l Pressure :

A t Idle : 7 0 kP a (0. 7 kgf/cm

2,1 0 psi )

minimu m

At 3,00 0 rpm : 34 0 kP a (3. 5 kgf/cm2,5 0 psi )

minimu m

• I f oi l pressur e i s withi n specifications , replac e th e

oi l pressur e switc h an d recheck .

• I f oi l pressur e i s NO T withi n specifications , inspec t

th e oi l pum p (se e pag e 8-12 ).

ADAPTE R(1/8"-28 BSPT )

ENGIN E OI L PRESSUR ESWITCH MOUNTIN GHOLE

OIL PRESSUR E

GAUG E

1. Remov e th e engin e oi l temperatur e switc h fro m th e

righ t cylinde r hea d cove r (se e pag e 6-12 ).

2 . Suspen d th e engin e oi l temperatur e switc h in a con -

taine r o f engin e oi l a s shown .

ENGINE OI LTEMPERATUR ESWITCH

THERMOMETE R

ENGINEOIL

3. Hea t th e engin e oi l an d chec k th e temperatur e wit h

a thermometer .

CAUTION : D o no t le t th e thermomete r touc h th e

botto m of th e ho t container .

4 . Measur e th e resistanc e betwee n th e A an d B termi -

nal s accordin g to th e table .

ProCarManuals.com