light ACURA TL 1995 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 215 of 1771

Idle Contro l Syste m

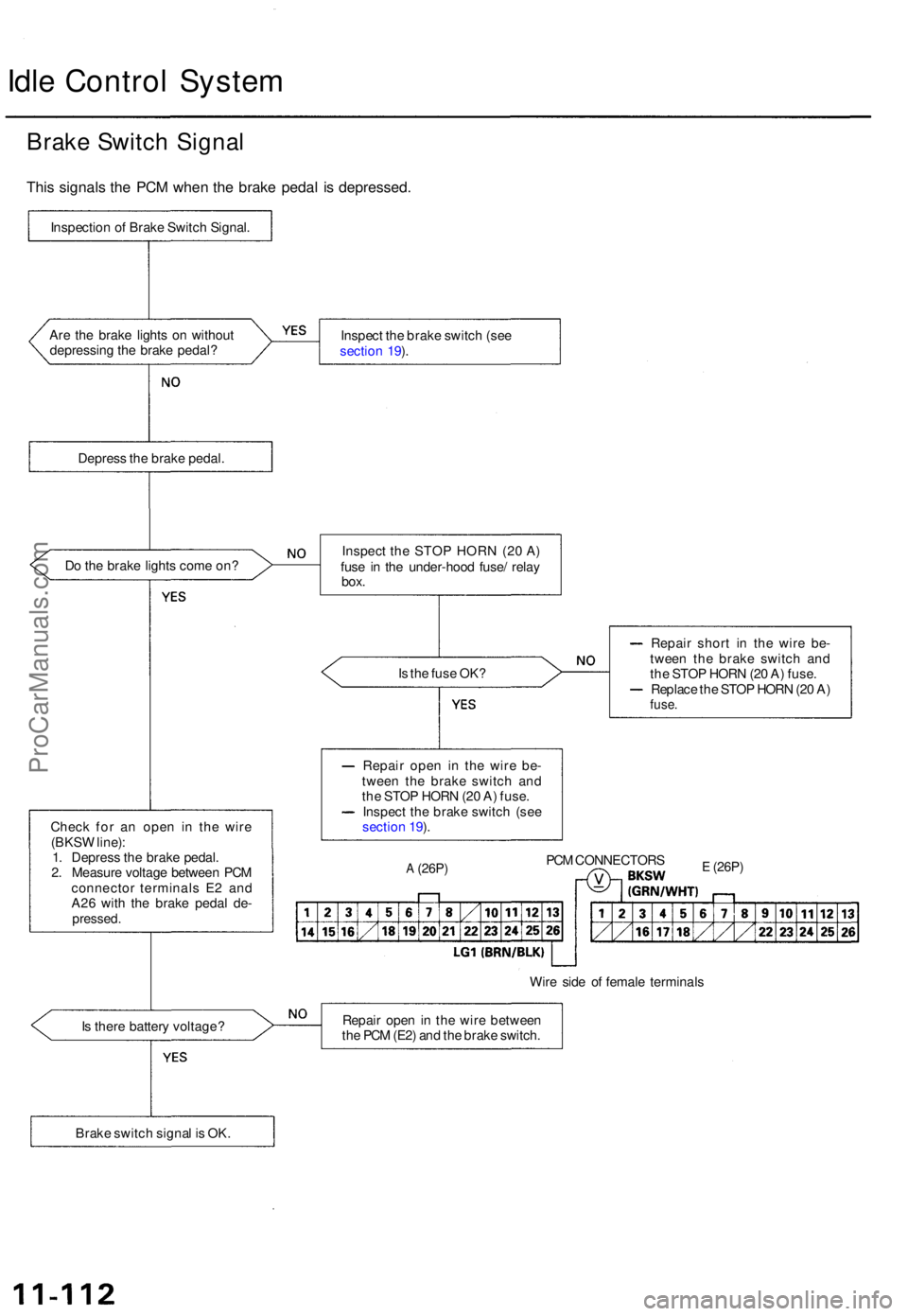

Brake Switc h Signa l

This signal s th e PC M whe n th e brak e peda l i s depressed .

Inspection o f Brak e Switc h Signal .

Ar e th e brak e light s o n withou t

depressin g th e brak e pedal ? Inspec

t th e brak e switc h (se e

sectio n 19 ).

Depres s th e brak e pedal .

D o th e brak e light s com e on ?

Is th e fus e OK ?

Chec k fo r a n ope n i n th e wir e

(BKS W line) :

1 . Depres s th e brak e pedal .

2 . Measur e voltag e betwee n PC M

connecto r terminal s E 2 an d

A2 6 wit h th e brak e peda l de -

pressed .

Repair shor t i n th e wire be-

twee n th e brak e switc h an d

th e STO P HOR N (2 0 A ) fuse .

Replac e th e STO P HOR N (2 0 A )

fuse .

Repai r ope n i n th e wir e be -

twee n th e brak e switc h an d

th e STO P HOR N (2 0 A ) fuse .

Inspec t th e brak e switc h (se e

sectio n 19 ).

A (26P )PCM CONNECTOR SE (26P)

Wire sid e o f femal e terminal s

I s ther e batter y voltage ? Repai

r ope n in th e wir e betwee n

th e PC M (E2 ) an d th e brak e switch .

Brak e switc h signa l i s OK . Inspec

t th e STO P HOR N (2 0 A )

fus e i n th e under-hoo d fuse / rela y

box.

ProCarManuals.com

Page 217 of 1771

Idle Contro l Syste m

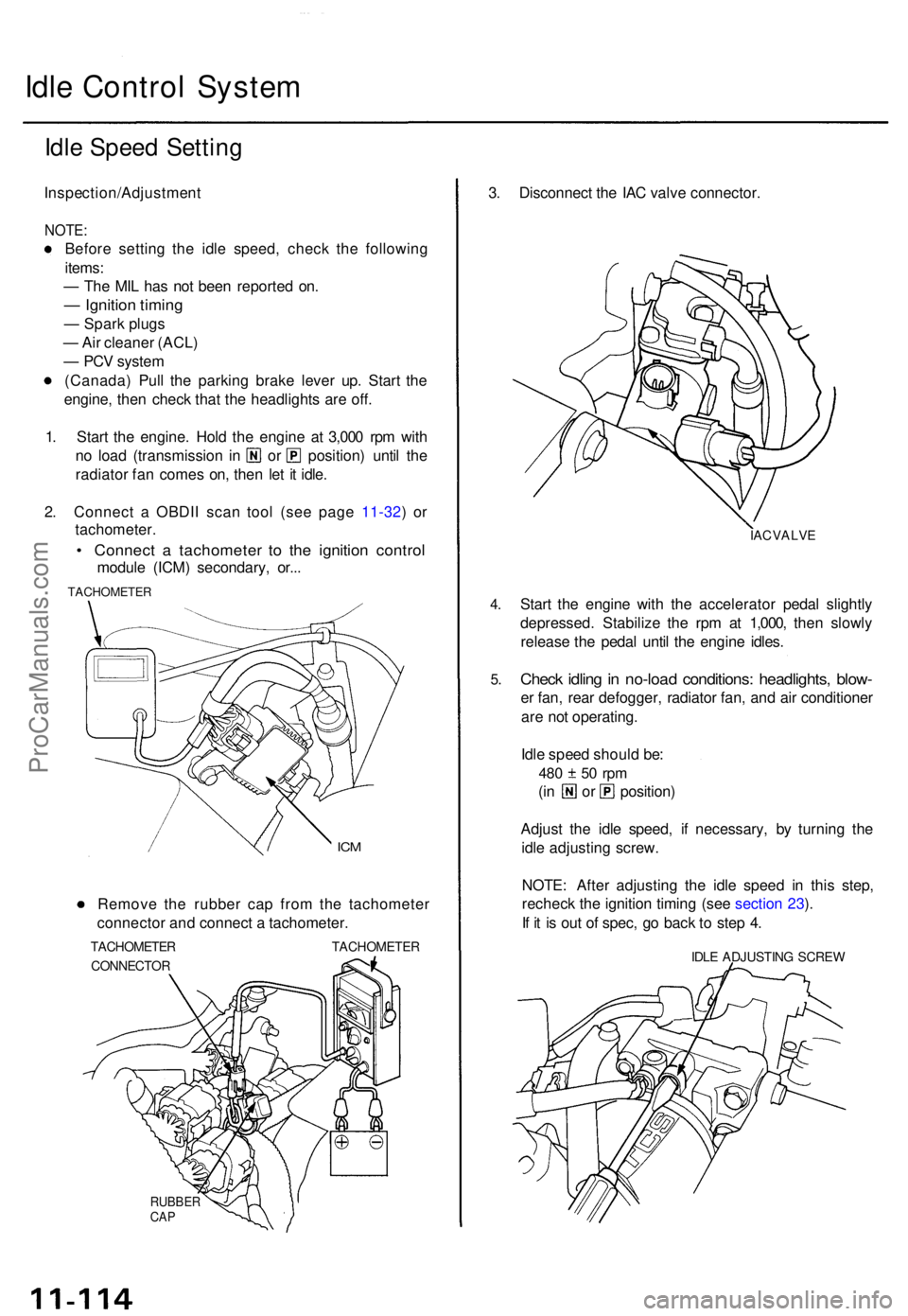

Idle Spee d Settin g

Inspection/Adjustmen t

NOTE:

Before settin g th e idl e speed , chec k th e followin g

items :

— Th e MI L ha s no t bee n reporte d on .

— Ignitio n timin g

— Spar k plug s

— Ai r cleane r (ACL )

— PC V syste m

(Canada ) Pul l th e parkin g brak e leve r up . Star t th e

engine , the n chec k tha t th e headlight s ar e off .

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (transmissio n i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Connec t a OBDI I sca n too l (se e pag e 11-32 ) o r

tachometer .

• Connec t a tachomete r t o th e ignitio n contro l

module (ICM ) secondary , or.. .

TACHOMETE R

ICM

Remov e th e rubbe r ca p fro m th e tachomete r

connecto r an d connec t a tachometer .

TACHOMETE R TACHOMETE R

CONNECTOR

RUBBERCAP

3. Disconnec t th e IA C valv e connector .

4.

5 .

IA C VALV E

Start th e engin e wit h th e accelerato r peda l slightl y

depressed . Stabiliz e th e rp m a t 1,000 , the n slowl y

releas e th e peda l unti l th e engin e idles .

Check idlin g in no-loa d conditions : headlights , blow -

er fan , rea r defogger , radiato r fan , an d ai r conditione r

ar e no t operating .

Idl e spee d shoul d be :

480 5 0 rp m

(in o r position )

Adjus t th e idl e speed , i f necessary , b y turnin g th e

idl e adjustin g screw .

NOTE : Afte r adjustin g th e idl e spee d i n thi s step ,

rechec k th e ignitio n timin g (se e sectio n 23 ).

I f i t i s ou t o f spec , g o bac k t o ste p 4 .

IDL E ADJUSTIN G SCRE W

ProCarManuals.com

Page 218 of 1771

6. Tur n th e ignitio n switc h OFF .

7 . Reconnec t th e 2 P connecto r o n th e IA C valve , the n

d o th e PC M rese t procedure .

8 . Restar t an d idl e th e engin e wit h no-loa d condition s

fo r on e minute , the n chec k th e idl e speed .

NOTE : (Canada ) Pul l th e parkin g brak e leve r up .

Star t th e engine , the n chec k tha t th e headlight s ar e

off.

Idle spee d shoul d be :

640 5 0 rp m

(in o r position )

9 . Idl e th e engin e fo r on e minut e wit h headlight s (Low )

O N an d chec k th e idl e speed .

Idl e spee d shoul d be :

650 5 0 rp m

(in o r position )

10 . Tur n th e headlight s off .

Idle th e engin e fo r on e minut e wit h heate r fa n switc h

at H I an d ai r conditione r on , the n chec k th e idl e speed .

Idl e spee d shoul d be :

650 5 0 rp m

(in o r position )

NOTE : I f th e idl e spee d i s no t withi n specification ,

se e Sympto m Char t o n pag e 11-36 .

ProCarManuals.com

Page 242 of 1771

Intake Ai r Syste m

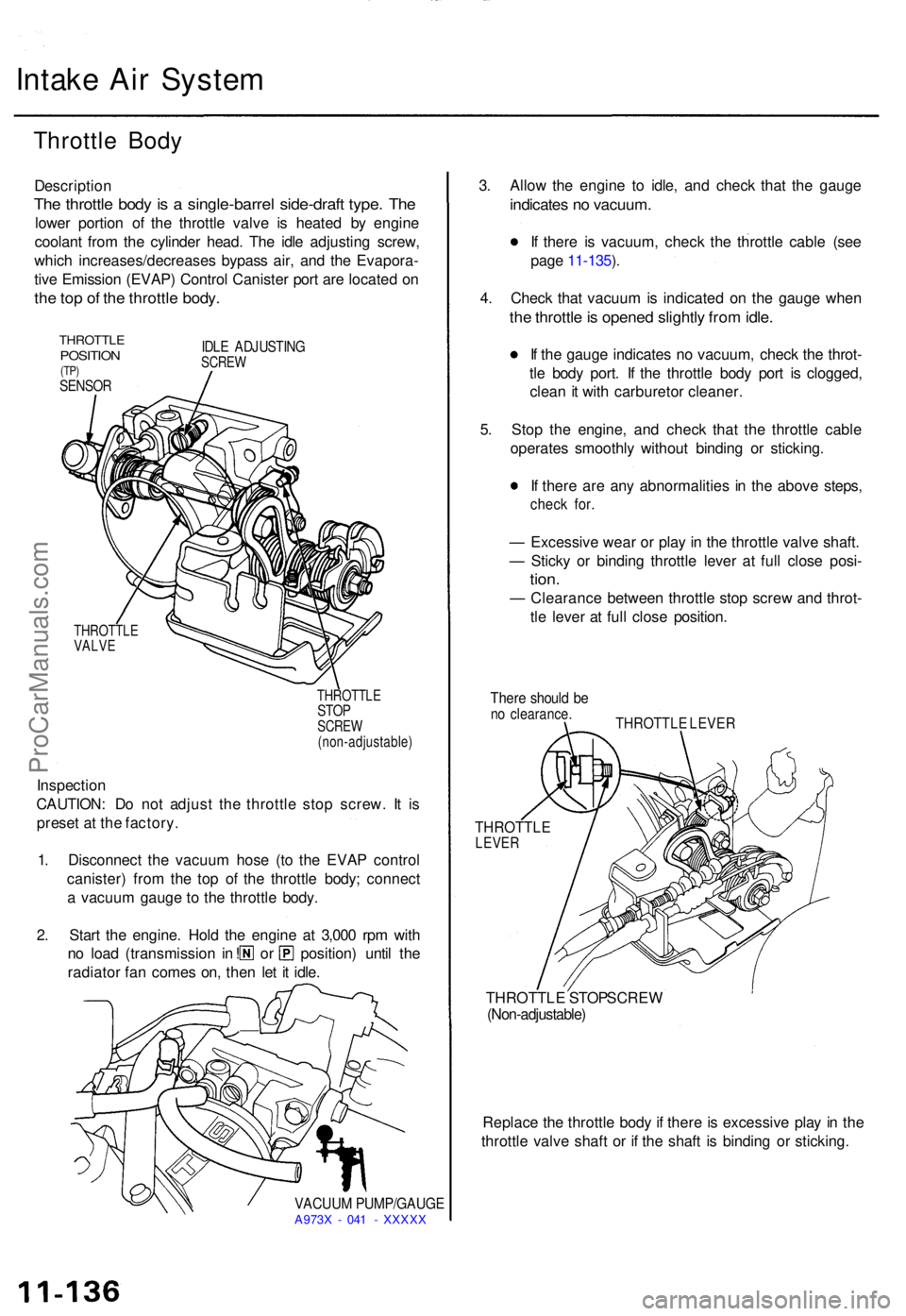

Throttl e Bod y

Descriptio n

The throttl e bod y i s a single-barre l side-draf t type . Th e

lowe r portio n o f th e throttl e valv e i s heate d b y engin e

coolan t fro m th e cylinde r head . Th e idl e adjustin g screw ,

whic h increases/decrease s bypas s air , an d th e Evapora -

tiv e Emissio n (EVAP ) Contro l Caniste r por t ar e locate d o n

the to p o f th e throttl e body .

THROTTL EPOSITION(TP)SENSO R

IDLE ADJUSTIN GSCREW

THROTTL E

VALV E

THROTTLE

STOPSCRE W

(non-adjustable )

Inspection

CAUTION : D o no t adjus t th e throttl e sto p screw . I t i s

prese t a t th e factory .

1 . Disconnec t th e vacuu m hos e (t o th e EVA P contro l

canister ) fro m th e to p o f th e throttl e body ; connec t

a vacuu m gaug e t o th e throttl e body .

2 . Star t th e engine . Hol d th e engine at 3,00 0 rp m wit h

no loa d (transmissio n i n ! o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

VACUU M PUMP/GAUG EA973X - 04 1 - XXXX X

3. Allo w th e engin e t o idle , an d chec k tha t th e gaug e

indicate s n o vacuum .

If ther e i s vacuum , chec k th e throttl e cabl e (se e

pag e 11-135 ).

4 . Chec k tha t vacuu m is indicate d o n th e gaug e whe n

the throttl e is opene d slightl y fro m idle .

If th e gaug e indicate s n o vacuum , chec k th e throt -

tl e bod y port . I f th e throttl e bod y por t i s clogged ,

clea n i t wit h carbureto r cleaner .

5 . Sto p th e engine , an d chec k tha t th e throttl e cabl e

operates smoothly without bindin g o r sticking .

I f ther e ar e an y abnormalitie s i n th e abov e steps ,

check for .

— Excessiv e wea r o r pla y i n th e throttl e valv e shaft .

— Stick y o r bindin g throttl e leve r a t ful l close posi-

tion.

— Clearanc e betwee n throttl e sto p scre w an d throt -

tl e leve r a t ful l clos e position .

There shoul d b eno clearance .THROTTLE LEVE R

THROTTL ELEVER

THROTTL E STO P SCRE W(Non-adjustable )

Replace th e throttl e bod y i f ther e is excessiv e pla y i n th e

throttl e valv e shaf t o r i f th e shaf t i s bindin g o r sticking .

ProCarManuals.com

Page 252 of 1771

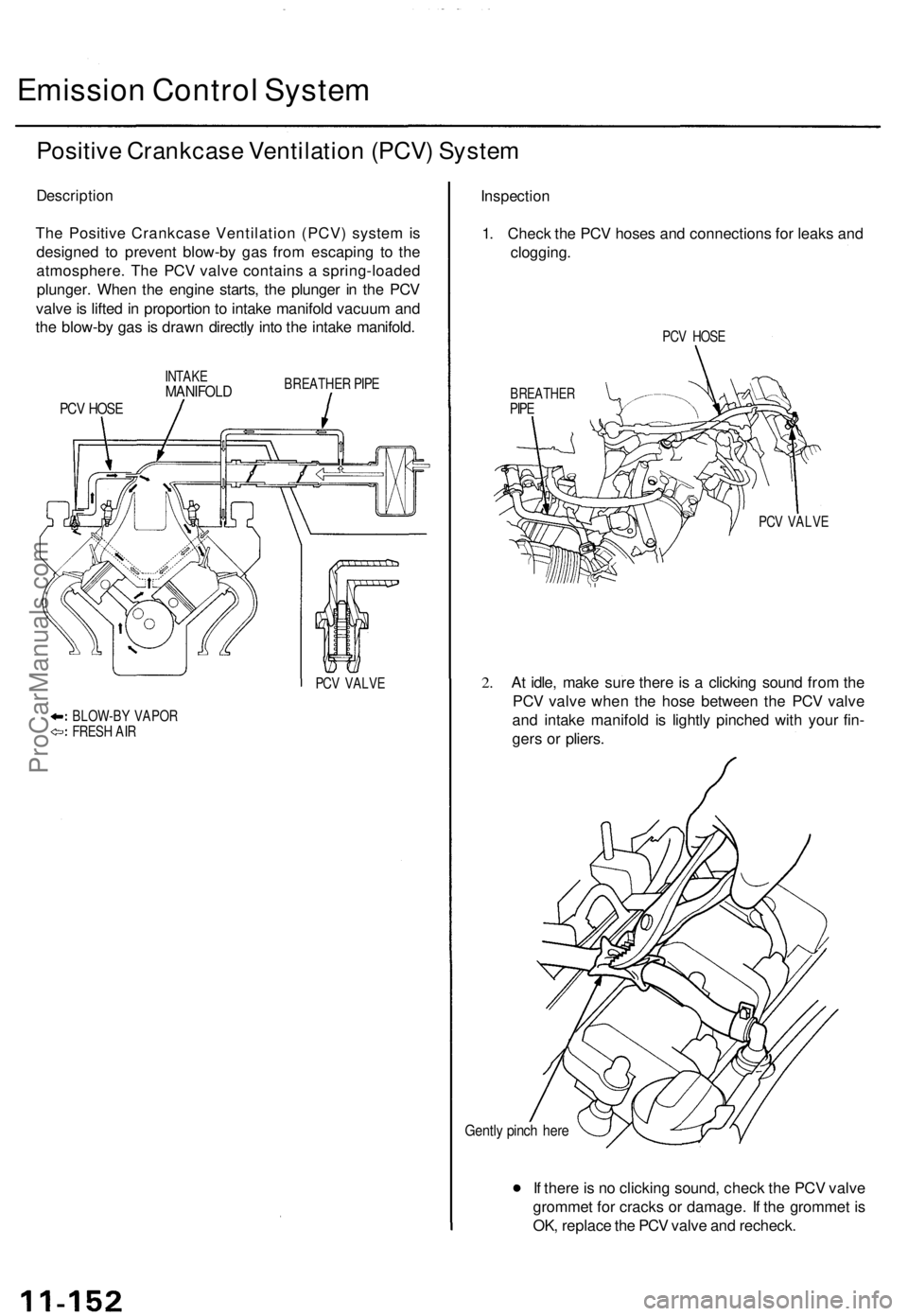

Emission Control System

Positive Crankcase Ventilation (PCV) System

Description

The Positive Crankcase Ventilation (PCV) system is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger. When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manifold vacuum and

the blow-by gas is drawn directly into the intake manifold.

INTAKE

MANIFOLD

BREATHER PIPE

PCV HOSE

PCV VALVE

BLOW-BY VAPOR

FRESH AIR

Inspection

1. Check the PCV hoses and connections for leaks and

clogging.

PCV HOSE

BREATHER

PIPE

PCV VALVE

2.

At idle, make sure there is a clicking sound from the

PCV valve when the hose between the PCV valve

and intake manifold is lightly pinched with your fin-

gers or pliers.

Gently pinch here

If there is no clicking sound, check the PCV valve

grommet for cracks or damage. If the grommet is

OK, replace the PCV valve and recheck.ProCarManuals.com

Page 296 of 1771

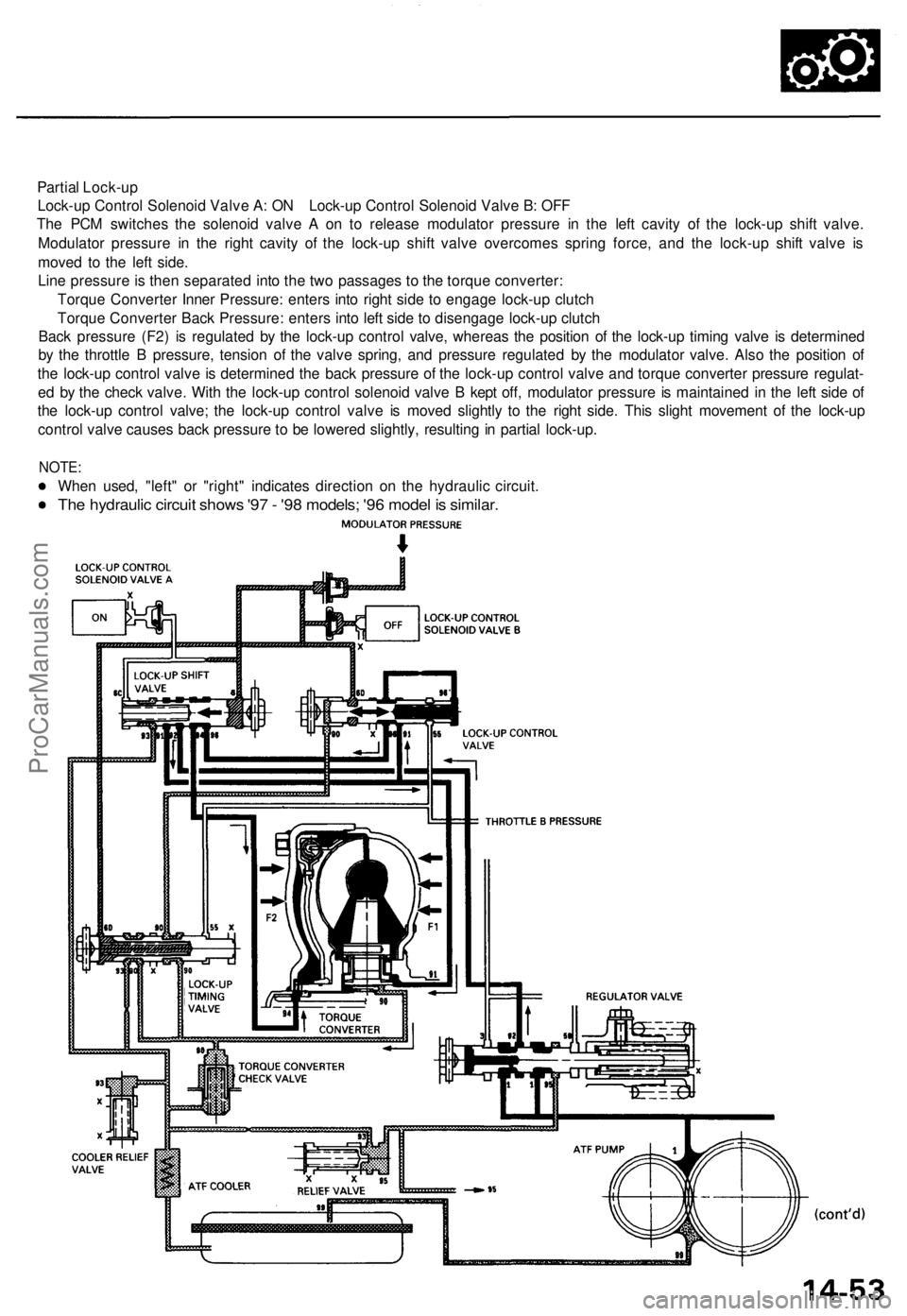

Partial Lock-up

Lock-up Control Solenoid Valve A: ON Lock-up Control Solenoid Valve B: OFF

The PCM switches the solenoid valve A on to release modulator pressure in the left cavity of the lock-up shift valve.

Modulator pressure in the right cavity of the lock-up shift valve overcomes spring force, and the lock-up shift valve is

moved to the left side.

Line pressure is then separated into the two passages to the torque converter:

Torque Converter Inner Pressure: enters into right side to engage lock-up clutch

Torque Converter Back Pressure: enters into left side to disengage lock-up clutch

Back pressure (F2) is regulated by the lock-up control valve, whereas the position of the lock-up timing valve is determined

by the throttle B pressure, tension of the valve spring, and pressure regulated by the modulator valve. Also the position of

the lock-up control valve is determined the back pressure of the lock-up control valve and torque converter pressure regulat-

ed by the check valve. With the lock-up control solenoid valve B kept off, modulator pressure is maintained in the left side of

the lock-up control valve; the lock-up control valve is moved slightly to the right side. This slight movement of the lock-up

control valve causes back pressure to be lowered slightly, resulting in partial lock-up.

NOTE:

When used, "left" or "right" indicates direction on the hydraulic circuit.

The hydraulic circuit shows '97 - '98 models; '96 model is similar.ProCarManuals.com

Page 299 of 1771

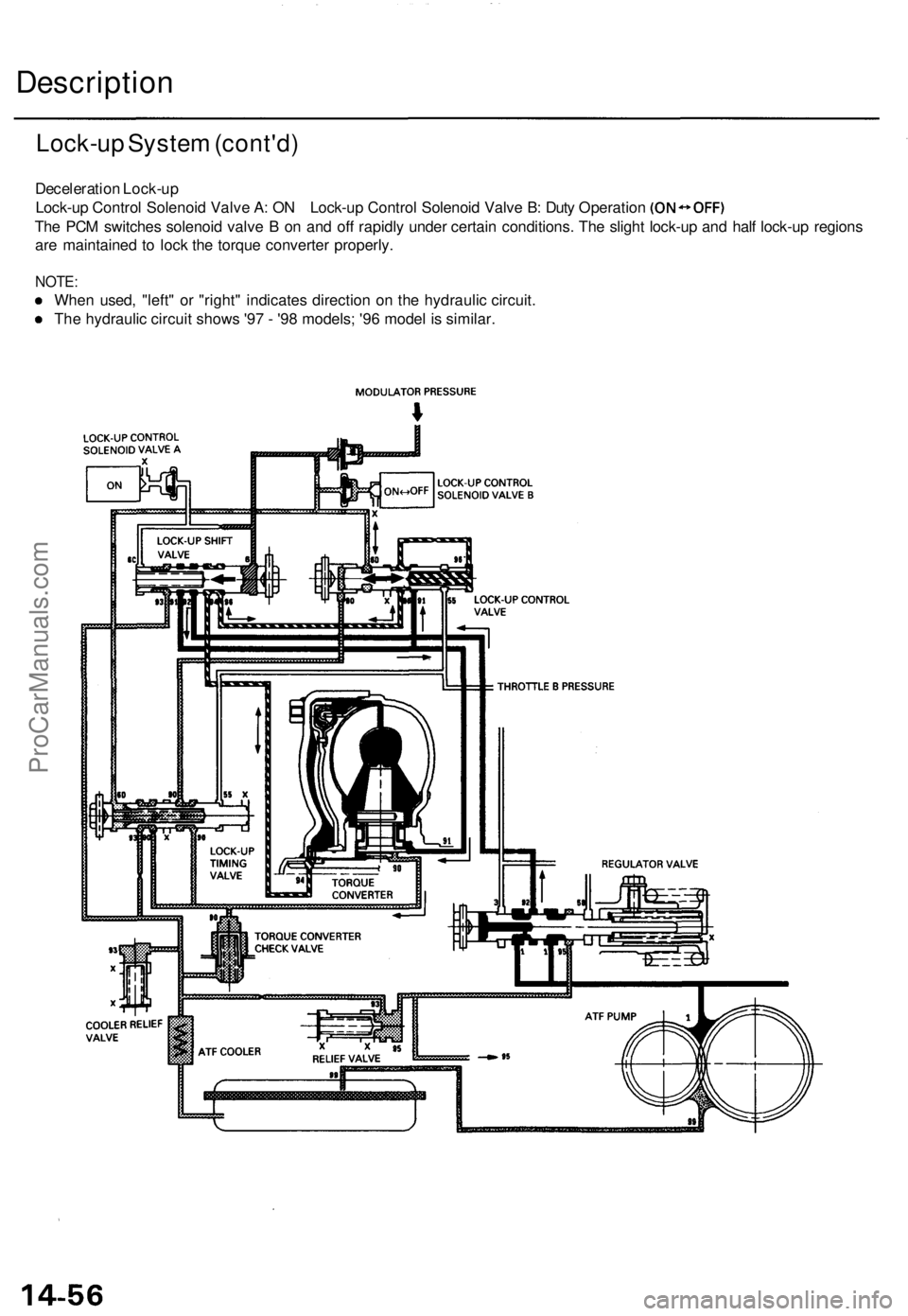

Description

Lock-up System (cont'd)

Deceleration Lock-up

Lock-up Control Solenoid Valve A: ON Lock-up Control Solenoid Valve B: Duty Operation

The PCM switches solenoid valve B on and off rapidly under certain conditions. The slight lock-up and half lock-up regions

are maintained to lock the torque converter properly.

NOTE:

When used, "left" or "right" indicates direction on the hydraulic circuit.

The hydraulic circuit shows '97 - '98 models; '96 model is similar.ProCarManuals.com

Page 305 of 1771

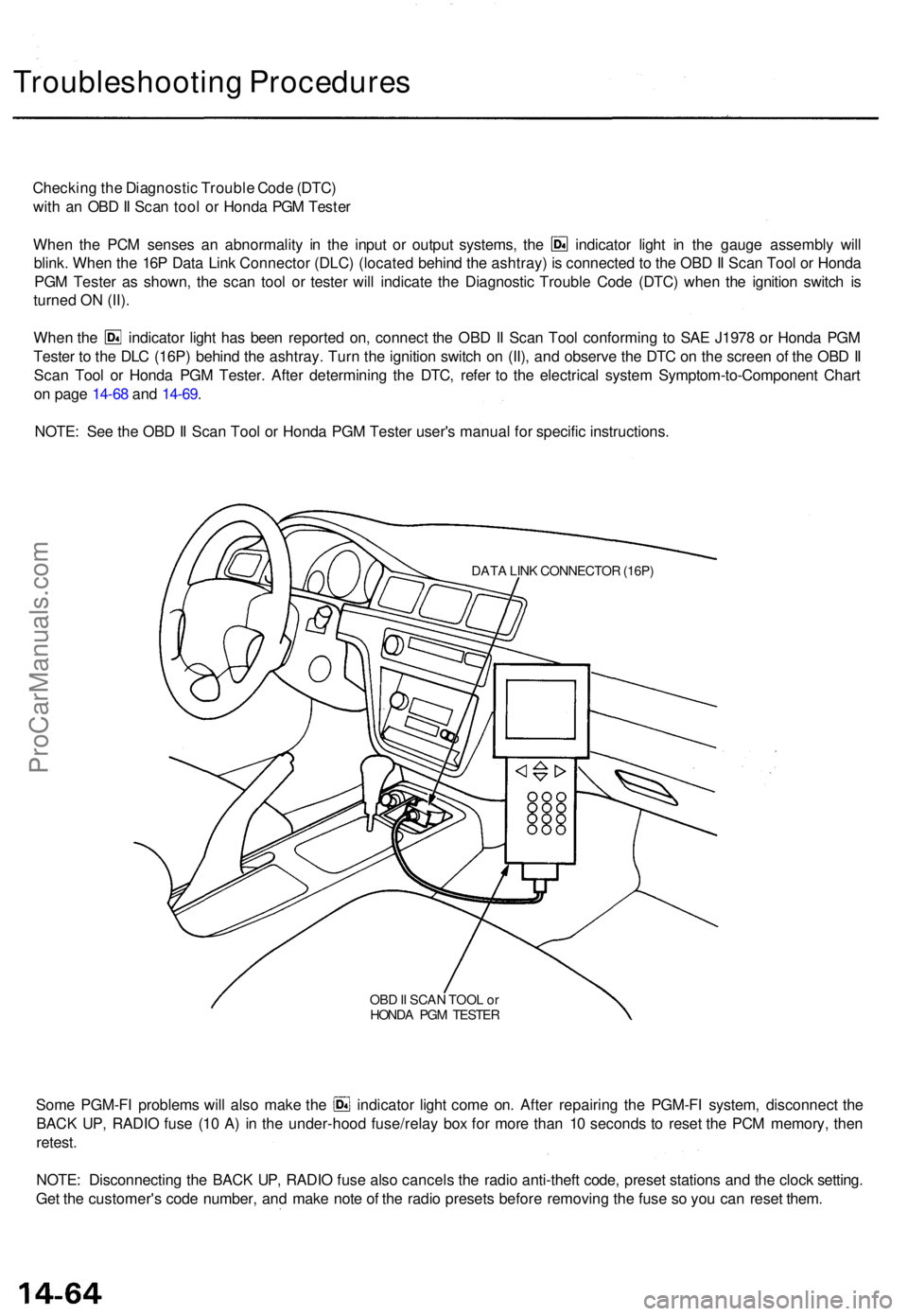

Troubleshooting Procedure s

Checking th e Diagnosti c Troubl e Cod e (DTC )

wit h a n OB D II Sca n too l o r Hond a PG M Teste r

When th e PC M sense s a n abnormalit y i n th e inpu t o r outpu t systems , th e indicato r ligh t i n th e gaug e assembl y wil l

blink . Whe n th e 16 P Dat a Lin k Connecto r (DLC ) (locate d behin d th e ashtray ) i s connecte d to th e OB D II Sca n Too l o r Hond a

PG M Teste r a s shown , th e sca n too l o r teste r wil l indicat e th e Diagnosti c Troubl e Cod e (DTC ) whe n th e ignitio n switc h i s

turne d O N (II) .

Whe n th e indicato r ligh t ha s bee n reporte d on , connec t th e OB D II Sca n Too l conformin g t o SA E J197 8 o r Hond a PG M

Teste r t o th e DL C (16P ) behin d th e ashtray . Tur n th e ignitio n switc h o n (II) , an d observ e th e DT C o n th e scree n o f th e OB D II

Sca n Too l o r Hond a PG M Tester . Afte r determinin g th e DTC , refe r t o th e electrica l syste m Symptom-to-Componen t Char t

o n pag e 14-6 8 an d 14-69 .

NOTE : Se e th e OB D II Sca n Too l o r Hond a PG M Teste r user' s manua l fo r specifi c instructions .

DATA LIN K CONNECTO R (16P )

OBD II SCA N TOO L o r

HOND A PG M TESTE R

Some PGM-F I problem s wil l als o mak e th e indicator light com e on . Afte r repairin g th e PGM-F I system , disconnec t th e

BAC K UP , RADI O fus e (1 0 A ) i n th e under-hoo d fuse/rela y bo x fo r mor e tha n 1 0 second s t o rese t th e PC M memory , the n

retest .

NOTE : Disconnectin g th e BAC K UP , RADI O fus e als o cancel s th e radi o anti-thef t code , prese t station s an d th e cloc k setting .

Ge t th e customer' s cod e number , an d mak e not e o f th e radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

ProCarManuals.com

Page 306 of 1771

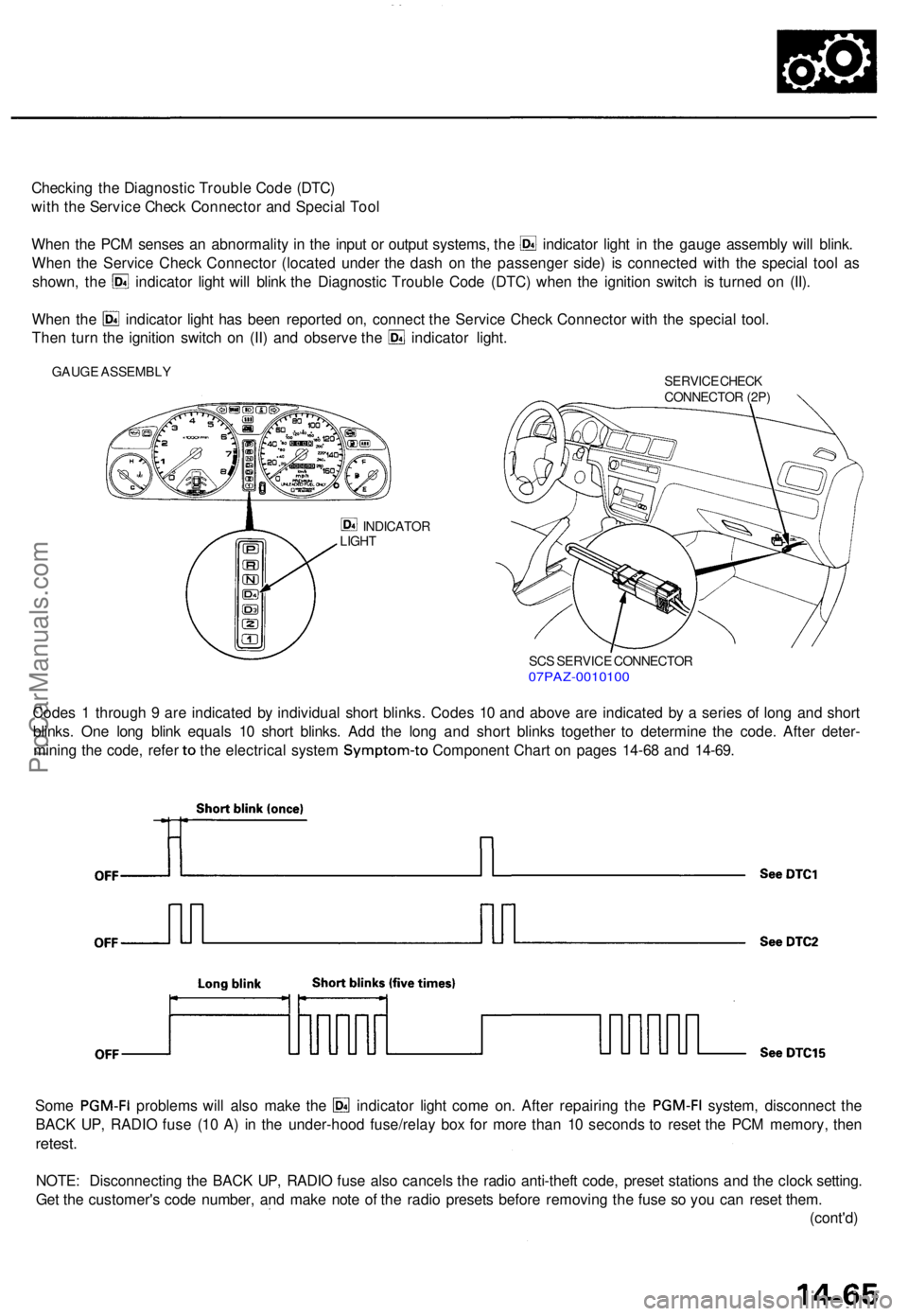

Checking th e Diagnosti c Troubl e Cod e (DTC )

wit h th e Servic e Chec k Connecto r an d Specia l Too l

Whe n th e PC M sense s a n abnormalit y i n th e inpu t o r outpu t systems , th e indicato r ligh t i n th e gaug e assembl y wil l blink .

Whe n th e Servic e Chec k Connecto r (locate d unde r th e das h o n th e passenge r side ) i s connecte d wit h th e specia l too l a s

shown , th e indicato r ligh t wil l blin k th e Diagnosti c Troubl e Cod e (DTC ) whe n th e ignitio n switc h i s turne d o n (II) .

Whe n th e indicato r ligh t ha s bee n reporte d on , connec t th e Servic e Chec k Connecto r wit h th e specia l tool .

Then tur n th e ignitio n switc h o n (II ) an d observ e th e indicato r light .

GAUG E ASSEMBL Y

SERVICE CHEC K

CONNECTO R (2P )

INDICATO R

LIGH T

SCS SERVIC E CONNECTO R07PAZ-001010 0

Codes 1 throug h 9 ar e indicate d b y individua l shor t blinks . Code s 1 0 an d abov e ar e indicate d b y a serie s o f lon g an d shor t

blinks . On e lon g blin k equal s 1 0 shor t blinks . Ad d th e lon g an d shor t blink s togethe r t o determin e th e code . Afte r deter -

mining th e code , refe r to th e electrica l syste m Symptom-t o Component Char t o n page s 14-6 8 an d 14-69 .

Some PGM-F I problem s wil l als o mak e th e indicato r ligh t com e on . Afte r repairin g th e PGM-F I system, disconnec t th e

BAC K UP , RADI O fus e (1 0 A ) i n th e under-hoo d fuse/rela y bo x fo r mor e tha n 1 0 second s t o rese t th e PC M memory , the n

retest .

NOTE : Disconnectin g th e BAC K UP , RADI O fus e als o cancel s th e radi o anti-thef t code , prese t station s an d th e cloc k setting .

Ge t th e customer' s cod e number , an d mak e not e o f th e radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

(cont'd )

ProCarManuals.com

Page 309 of 1771

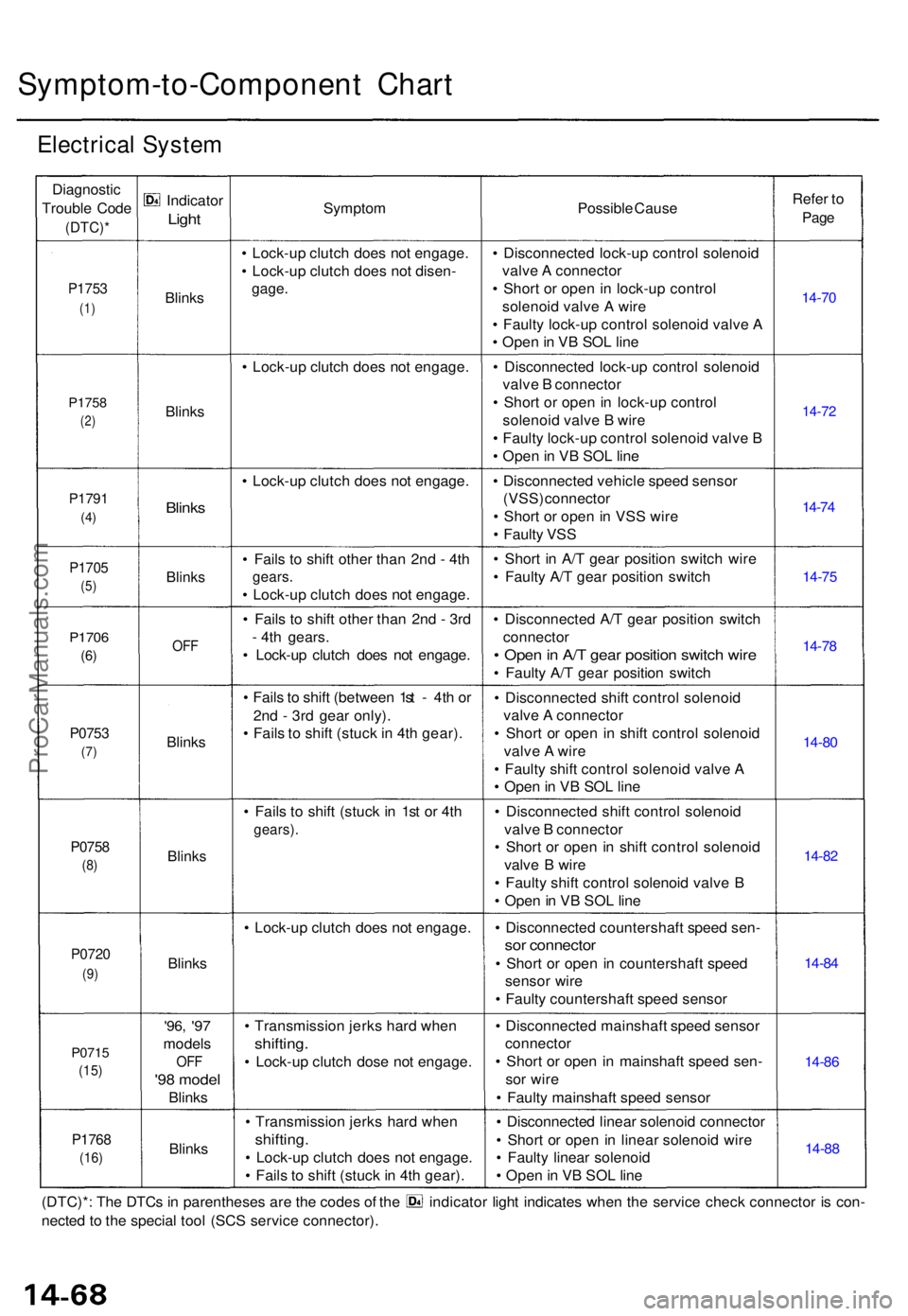

Symptom-to-Component Char t

Electrica l Syste m

Diagnosti c

Troubl e Cod e

(DTC) *

P1753

(1)

P175 8

(2)

P179 1

(4)

P170 5

(5)

P170 6

(6)

P075 3

(7)

P075 8

(8)

P072 0

(9)

P071 5

(15)

P176 8

(16)

Indicato r

Light

Blink s

Blink s

Blinks

Blink s

OFF

Blink s

Blink s

Blinks

'96, '97

model s

OFF

'98 mode l

Blinks

Blink s

Sympto m

• Lock-u p clutc h doe s no t engage .

• Lock-u p clutc h doe s no t disen -

gage.

• Lock-u p clutc h doe s no t engage .

• Lock-u p clutc h doe s no t engage .

• Fail s t o shif t othe r tha n 2n d - 4t h

gears .

• Lock-u p clutc h doe s no t engage .

• Fail s t o shif t othe r tha n 2n d - 3r d

- 4t h gears .

• Lock-u p clutc h doe s no t engage .

• Fail s to shif t (betwee n 1s t - 4t h o r

2n d - 3r d gea r only) .

• Fail s t o shif t (stuc k in 4t h gear) .

• Fail s t o shif t (stuc k i n 1s t o r 4t h

gears) .

• Lock-u p clutc h doe s no t engage .

• Transmissio n jerk s har d whe n

shifting .

• Lock-u p clutc h dos e no t engage .

• Transmissio n jerk s har d whe n

shifting .

• Lock-u p clutc h doe s no t engage .

• Fail s t o shif t (stuc k in 4t h gear) . Possibl

e Caus e

• Disconnecte d lock-u p contro l solenoi d

valv e A connecto r

• Shor t o r ope n i n lock-u p contro l

solenoi d valv e A wir e

• Fault y lock-u p contro l solenoi d valv e A

• Ope n in V B SO L lin e

• Disconnecte d lock-u p contro l solenoi d

valv e B connecto r

• Shor t o r ope n in lock-u p contro l

solenoi d valv e B wir e

• Fault y lock-u p contro l solenoi d valv e B

• Ope n in V B SO L lin e

• Disconnecte d vehicl e spee d senso r

(VSS) connecto r

• Shor t o r ope n in VS S wir e

• Fault y VS S

• Shor t i n A/ T gea r positio n switc h wir e

• Fault y A/ T gea r positio n switc h

• Disconnecte d A/ T gea r positio n switc h

connecto r

• Ope n in A/ T gea r positio n switc h wir e

• Fault y A/ T gea r positio n switc h

• Disconnecte d shif t contro l solenoi d

valv e A connecto r

• Shor t o r ope n i n shif t contro l solenoi d

valv e A wir e

• Fault y shif t contro l solenoi d valv e A

• Ope n in V B SO L lin e

• Disconnecte d shif t contro l solenoi d

valv e B connecto r

• Shor t o r ope n i n shif t contro l solenoi d

valv e B wir e

• Fault y shif t contro l solenoi d valv e B

• Ope n in V B SOL line

• Disconnecte d countershaf t spee d sen -

sor connecto r

• Shor t o r ope n i n countershaf t spee d

senso r wir e

• Fault y countershaf t spee d senso r

• Disconnecte d mainshaf t spee d senso r

connecto r

• Shor t o r ope n i n mainshaf t spee d sen -

so r wir e

• Fault y mainshaf t spee d senso r

• Disconnecte d linea r solenoi d connecto r

• Shor t o r ope n i n linea r solenoi d wir e

• Fault y linea r solenoi d

• Ope n in V B SOL line Refe

r t o

Pag e

14-7 0

14-72

14-74

14-7 5

14-78

14-8 0

14-82

14-84

14-8 6

14-8 8

(DTC)* : Th e DTC s in parenthese s ar e th e code s o f th e indicato r ligh t indicate s whe n th e servic e chec k connecto r i s con -

necte d to th e specia l too l (SC S servic e connector) .

ProCarManuals.com