boot ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1210 of 1771

Steering Gearbo x

Reassembl y (cont'd )

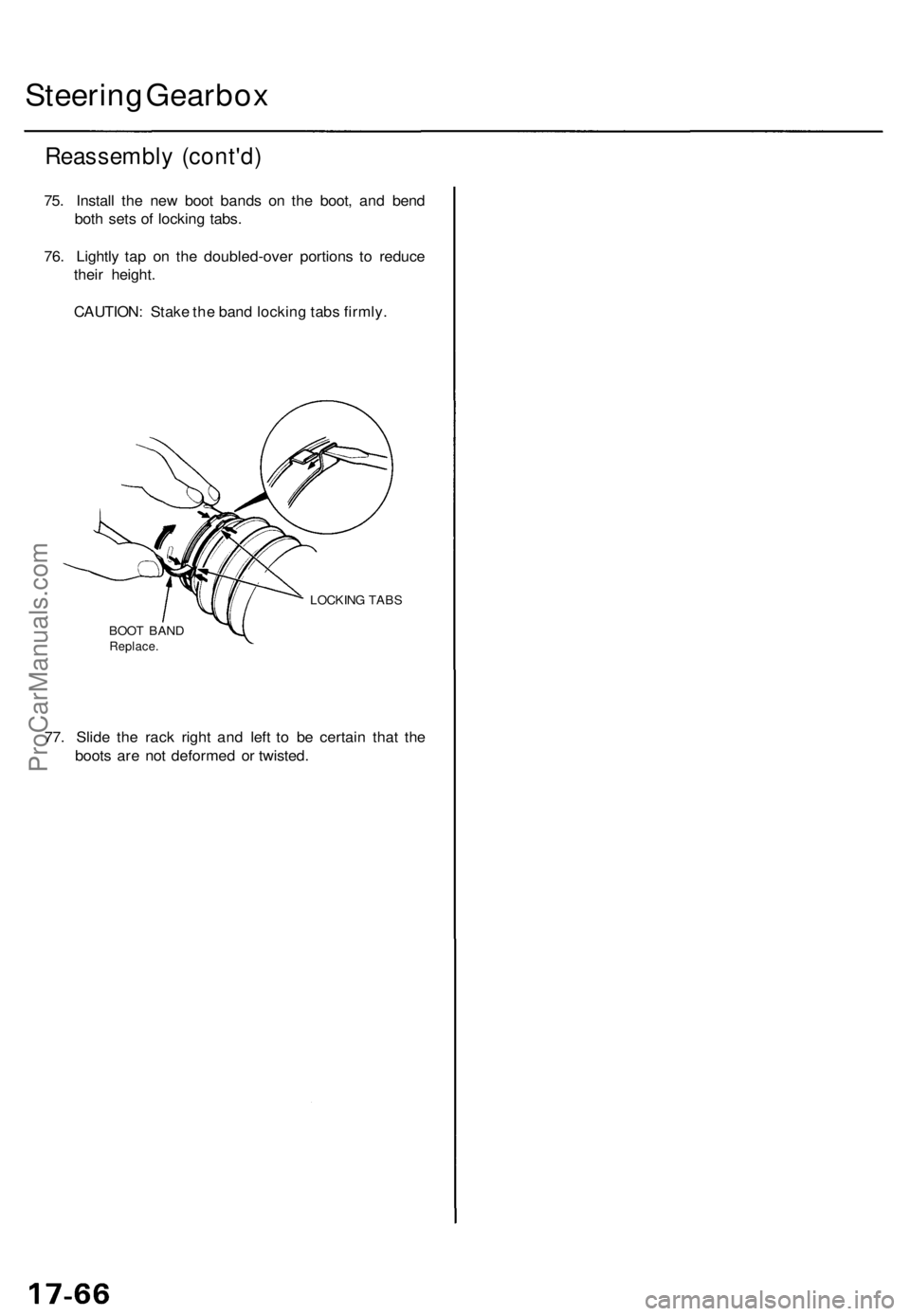

75. Instal l th e ne w boo t band s o n th e boot , an d ben d

bot h set s o f lockin g tabs .

76 . Lightl y ta p o n th e doubled-ove r portion s t o reduc e

thei r height .

CAUTION : Stak e th e ban d lockin g tab s firmly .

LOCKIN G TAB S

BOO T BAN D

Replace .

77. Slid e th e rac k righ t an d lef t t o b e certai n tha t th e

boot s ar e no t deforme d o r twisted .

ProCarManuals.com

Page 1214 of 1771

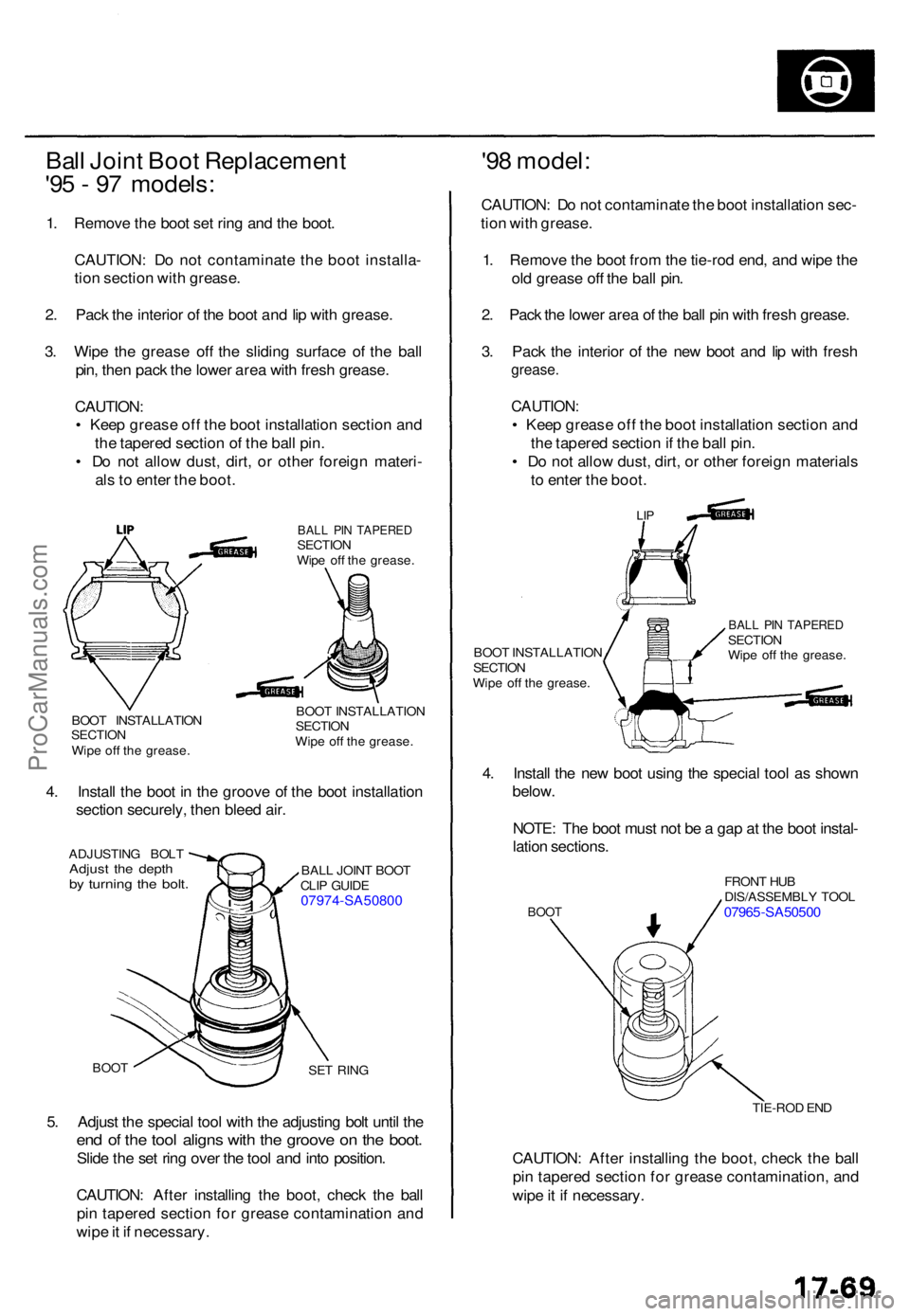

Ball Join t Boo t Replacemen t

'9 5 - 9 7 models :

1. Remov e th e boo t se t rin g an d th e boot .

CAUTION : D o no t contaminat e th e boo t installa -

tio n sectio n wit h grease .

2 . Pac k th e interio r o f th e boo t an d li p wit h grease .

3 . Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pin , the n pac k th e lowe r are a wit h fres h grease .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n materi -

al s to ente r th e boot .

BALL PI N TAPERE DSECTION

Wip e of f th e grease .

BOO T INSTALLATIO N

SECTIO N

Wip e of f th e grease . BOO

T INSTALLATIO N

SECTIO N

Wip e of f th e grease .

4. Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air .

ADJUSTIN G BOL TAdjust th e dept hby turnin g th e bolt .

BOO T

BALL JOIN T BOO T

CLI P GUID E

07974-SA5080 0

SET RIN G

5. Adjus t th e specia l too l wit h th e adjustin g bol t unti l th e

end o f th e too l align s wit h th e groov e o n th e boot .

Slide th e se t rin g ove r th e too l an d int o position .

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r greas e contaminatio n an d

wip e it i f necessary .

'98 model :

CAUTION : D o no t contaminat e th e boo t installatio n sec -

tio n wit h grease .

1 . Remov e th e boo t fro m th e tie-ro d end , an d wip e th e

ol d greas e of f th e bal l pin .

2 . Pac k th e lowe r are a o f th e bal l pi n wit h fres h grease .

3 . Pac k th e interio r o f th e ne w boo t an d li p wit h fres h

grease .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n if th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n material s

t o ente r th e boot .

BALL PI N TAPERE DSECTION

Wip e of f th e grease .

BOO

T INSTALLATIO N

SECTIO N

Wip e of f th e grease .

4. Instal l th e ne w boo t usin g th e specia l too l a s show n

below .

NOTE : Th e boo t mus t no t b e a ga p a t th e boo t instal -

latio n sections .

BOOT

FRON T HU B

DIS/ASSEMBL Y TOO L

07965-SA5050 0

TIE-ROD EN D

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r greas e contamination , an d

wip e it i f necessary .

LIP

ProCarManuals.com

Page 1224 of 1771

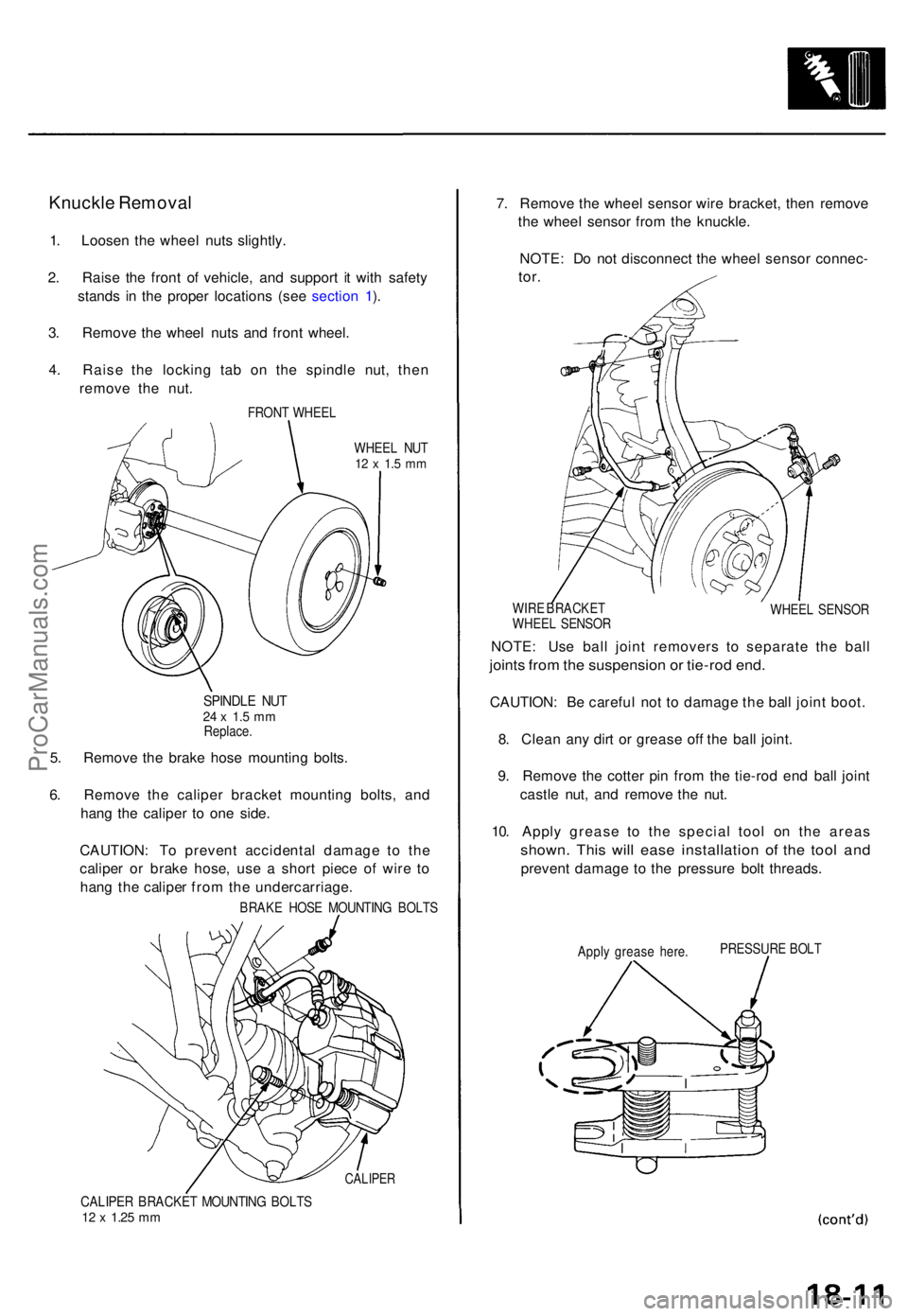

Knuckle Remova l

1. Loose n th e whee l nuts slightly .

2 . Rais e th e fron t o f vehicle , an d suppor t i t wit h safet y

stand s i n th e prope r location s (se e sectio n 1 ).

3 . Remov e th e whee l nuts and fron t wheel .

4 . Rais e th e lockin g ta b o n th e spindl e nut , the n

remov e th e nut .

FRON T WHEE L

WHEE L NU T

12 x 1. 5 m m

SPINDL E NU T24 x 1. 5 m mReplace .

5. Remov e th e brak e hos e mountin g bolts .

6 . Remov e th e calipe r bracke t mountin g bolts , an d

han g th e calipe r t o on e side .

CAUTION : T o preven t accidenta l damag e t o th e

calipe r o r brak e hose , us e a shor t piec e o f wir e t o

han g th e calipe r fro m th e undercarriage .

BRAKE HOS E MOUNTIN G BOLT S

CALIPE R

CALIPER BRACKE T MOUNTIN G BOLT S12 x 1.2 5 mm

7. Remov e th e whee l senso r wir e bracket , the n remov e

th e whee l senso r fro m th e knuckle .

NOTE : D o no t disconnec t th e whee l senso r connec -

tor.

WIR E BRACKE T

WHEE L SENSO R WHEE

L SENSO R

NOTE: Us e bal l join t remover s t o separat e th e bal l

joints fro m th e suspensio n o r tie-ro d end .

CAUTION : B e carefu l no t t o damag e th e bal l join t boot .

8 . Clea n an y dir t o r greas e of f th e bal l joint .

9 . Remov e th e cotte r pi n fro m th e tie-ro d en d bal l join t

castl e nut , an d remov e th e nut .

10 . Appl y greas e t o th e specia l too l o n th e area s

shown . Thi s wil l eas e installatio n of the too l an d

preven t damag e t o th e pressur e bol t threads .

Apply greas e here . PRESSUR

E BOL T

ProCarManuals.com

Page 1225 of 1771

Front Suspensio n

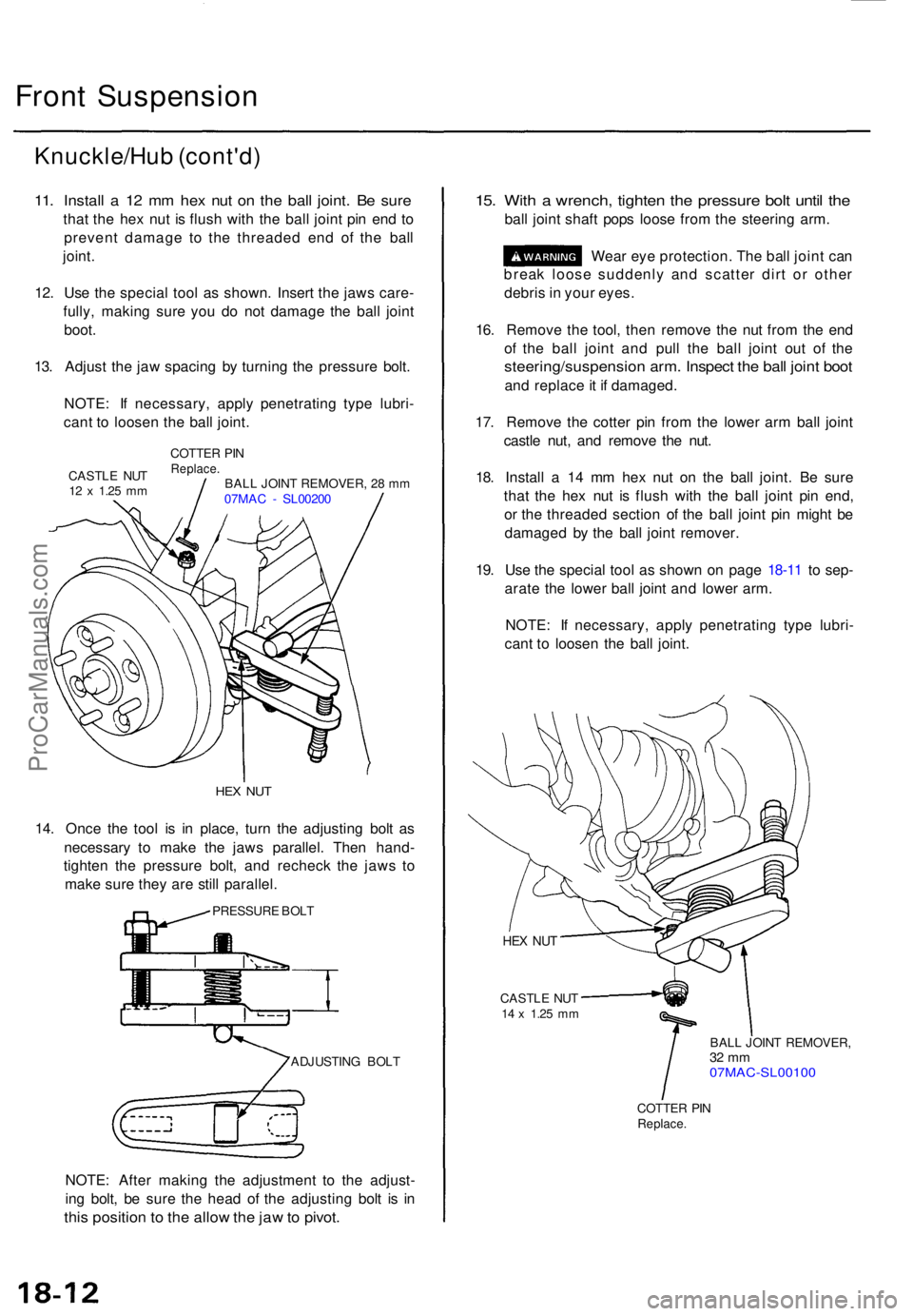

Knuckle/Hu b (cont'd )

11. Instal l a 12 m m he x nu t o n th e bal l joint . B e sur e

that th e he x nu t i s flus h wit h th e bal l join t pi n en d t o

preven t damag e t o th e threade d en d o f th e bal l

joint .

12 . Us e th e specia l too l a s shown . Inser t th e jaw s care -

fully , makin g sur e yo u d o no t damag e th e bal l join t

boot .

13 . Adjus t th e ja w spacin g b y turnin g th e pressur e bolt .

NOTE : I f necessary , appl y penetratin g typ e lubri -

can t t o loose n th e bal l joint .

CASTL E NU T12 x 1.2 5 mm

COTTE R PI NReplace .BALL JOIN T REMOVER , 2 8 m m

07MA C - SL0020 0

HEX NU T

14. Onc e th e too l i s i n place , tur n th e adjustin g bol t a s

necessar y t o mak e th e jaw s parallel . The n hand -

tighte n th e pressur e bolt , an d rechec k th e jaw s t o

mak e sur e the y ar e stil l parallel .

PRESSUR E BOL T

ADJUSTIN G BOL T

NOTE : Afte r makin g th e adjustmen t t o th e adjust -

in g bolt , b e sur e th e hea d o f th e adjustin g bol t i s i n

thi s positio n t o th e allo w th e ja w to pivot .

15. Wit h a wrench , tighte n th e pressur e bol t unti l th e

bal l join t shaf t pop s loos e fro m th e steerin g arm .

Wea r ey e protection . Th e bal l join t ca n

brea k loos e suddenl y an d scatte r dir t o r othe r

debri s in you r eyes .

16 . Remov e th e tool , the n remov e th e nu t fro m th e en d

o f th e bal l join t an d pul l th e bal l join t ou t o f th e

steering/suspensio n arm . Inspec t th e bal l join t boo t

and replac e it i f damaged .

17 . Remov e th e cotte r pi n fro m th e lowe r ar m bal l join t

castl e nut , an d remov e th e nut .

18 . Instal l a 1 4 m m he x nu t o n th e bal l joint . B e sur e

tha t th e he x nu t i s flus h wit h th e bal l join t pi n end ,

o r th e threade d sectio n o f th e bal l join t pi n migh t b e

damage d b y th e bal l join t remover .

19 . Us e th e specia l too l a s show n o n pag e 18-1 1 t o sep -

arat e th e lowe r bal l join t an d lowe r arm .

NOTE : I f necessary , appl y penetratin g typ e lubri -

can t t o loose n th e bal l joint .

HEX NU T

CASTL E NU T14 x 1.2 5 mm

BAL L JOIN T REMOVER ,32 m m07MAC-SL0010 0

COTTER PI NReplace .

ProCarManuals.com

Page 1230 of 1771

Ball Join t Boo t Replacemen t

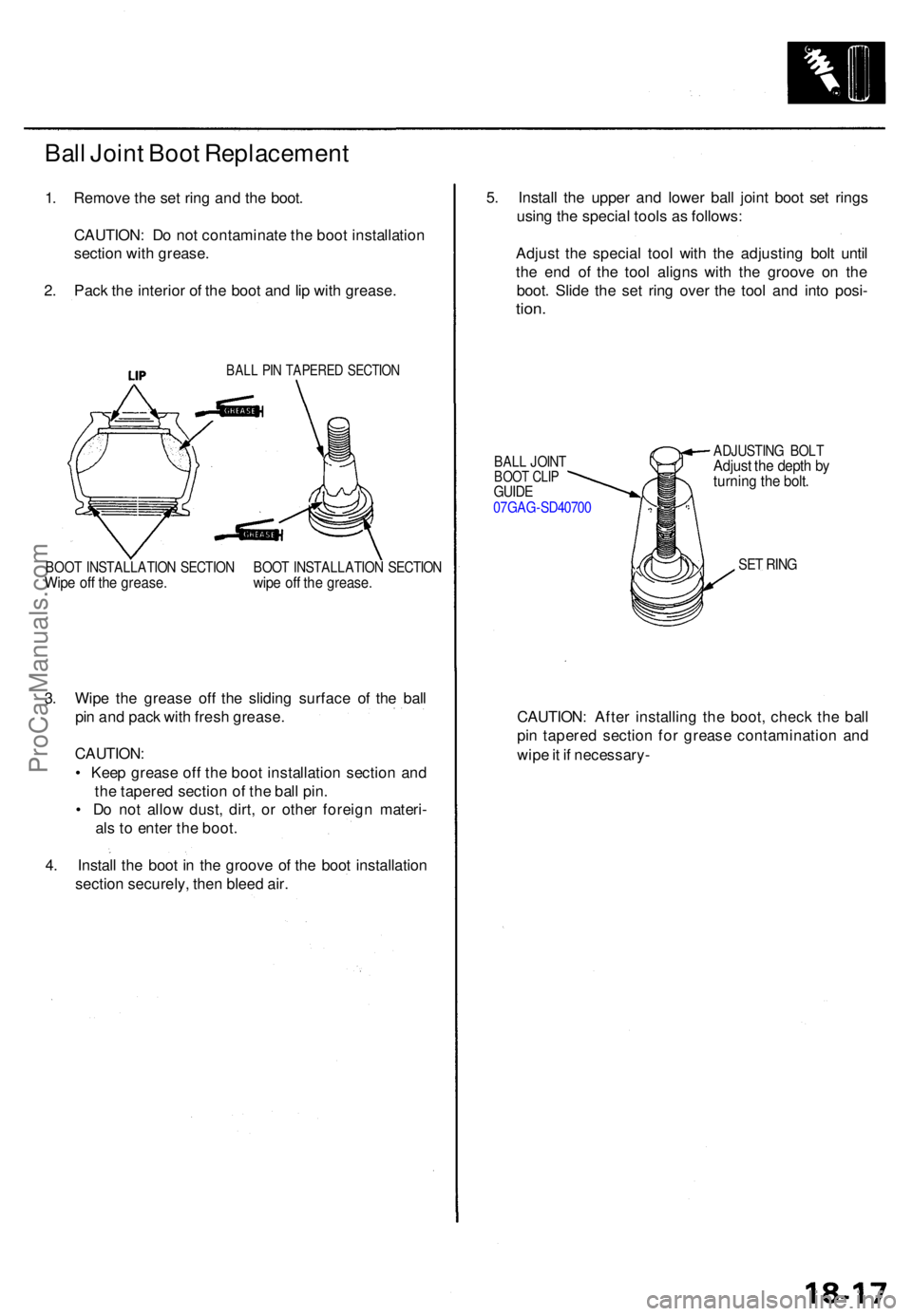

1. Remov e th e se t rin g an d th e boot .

CAUTION : D o no t contaminat e th e boo t installatio n

sectio n wit h grease .

2 . Pac k th e interio r o f th e boo t an d li p wit h grease .

BALL PI N TAPERE D SECTIO N

BOOT INSTALLATIO N SECTIO N BOO T INSTALLATIO N SECTIO NWipe of f th e grease . wip e of f th e grease .

3. Wip e th e greas e of f th e slidin g surfac e o f th e bal l

pi n an d pac k wit h fres h grease .

CAUTION :

• Kee p greas e of f th e boo t installatio n sectio n an d

th e tapere d sectio n o f th e bal l pin .

• D o no t allo w dust , dirt , o r othe r foreig n materi -

al s to ente r th e boot .

4 . Instal l th e boo t i n th e groov e o f th e boo t installatio n

sectio n securely , the n blee d air . 5

. Instal l th e uppe r an d lowe r bal l join t boo t se t ring s

usin g th e specia l tool s a s follows :

Adjus t th e specia l too l wit h th e adjustin g bol t unti l

th e en d o f th e too l align s wit h th e groov e o n th e

boot . Slid e th e se t rin g ove r th e too l an d int o posi -

tion.

BAL L JOIN TBOOT CLI PGUID E07GA G-SD4070 0

ADJUSTIN G BOL TAdjust th e dept h b yturnin g th e bolt .

SET RIN G

CAUTION : Afte r installin g th e boot , chec k th e bal l

pi n tapere d sectio n fo r greas e contaminatio n an d

wip e it i f necessary -

ProCarManuals.com

Page 1241 of 1771

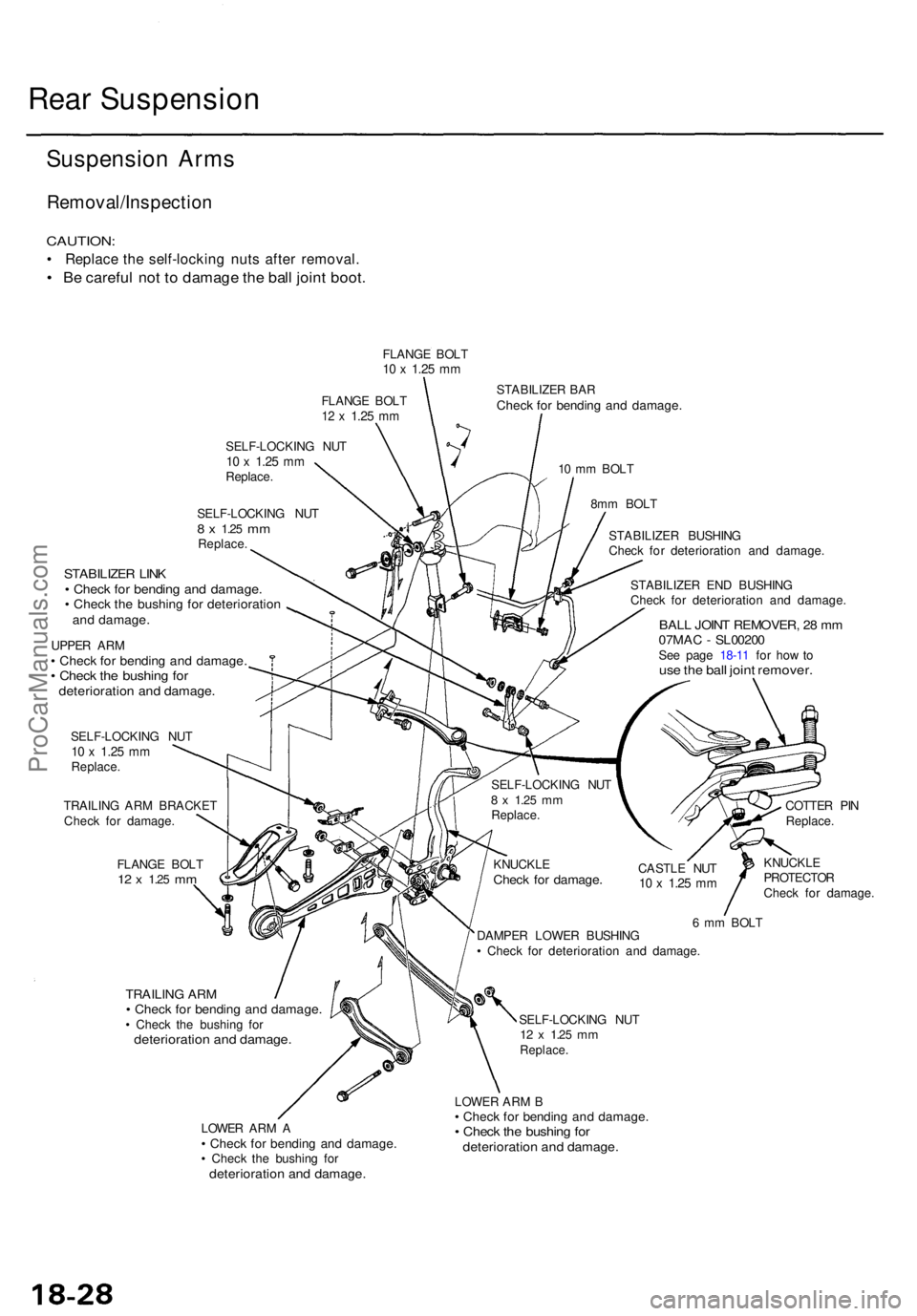

Rear Suspensio n

Suspension Arm s

Removal/Inspectio n

CAUTION:

• Replac e th e self-lockin g nut s afte r removal .

• B e carefu l no t t o damag e th e bal l join t boot .

FLANG E BOL T10 x 1.2 5 mm

FLANG E BOL T12 x 1.2 5 mm

SELF-LOCKIN G NU T10 x 1.2 5 mmReplace .

SELF-LOCKIN G NU T

8 x 1.2 5 mmReplace .

STABILIZE R BA RChec k fo r bendin g an d damage .

10 m m BOL T

8m m BOL T

STABILIZE R LIN K• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo r deterioratio nand damage .

UPPER AR M• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo rdeterioratio n an d damage .

SELF-LOCKIN G NU T10 x 1.2 5 mmReplace .

TRAILIN G AR M BRACKE T

Chec k fo r damage .

FLANG E BOL T

12 x 1.2 5 mm

STABILIZE R EN D BUSHIN G

Chec k fo r deterioratio n an d damage .

BALL JOIN T REMOVER , 2 8 m m07MA C - SL0020 0See pag e 18-1 1 fo r ho w tous e th e bal l join t remover .

CASTLE NU T10 x 1.2 5 mm

COTTE R PI N

Replace .

KNUCKL E

PROTECTO R

Chec k fo r damage .

TRAILING AR M• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo rdeterioratio n an d damage .

LOWER AR M A• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo rdeterioratio n an d damage .

6 m m BOL T

DAMPE R LOWE R BUSHIN G

• Chec k fo r deterioratio n an d damage .

SELF-LOCKIN G NU T

12 x 1.2 5 mmReplace .

LOWER AR M B• Chec k fo r bendin g an d damage .• Chec k th e bushin g fo rdeterioratio n an d damage .

KNUCKL ECheck fo r damage .

SELF-LOCKIN G NU T8 x 1.2 5 mmReplace . STABILIZE

R BUSHIN G

Chec k fo r deterioratio n an d damage .

ProCarManuals.com

Page 1250 of 1771

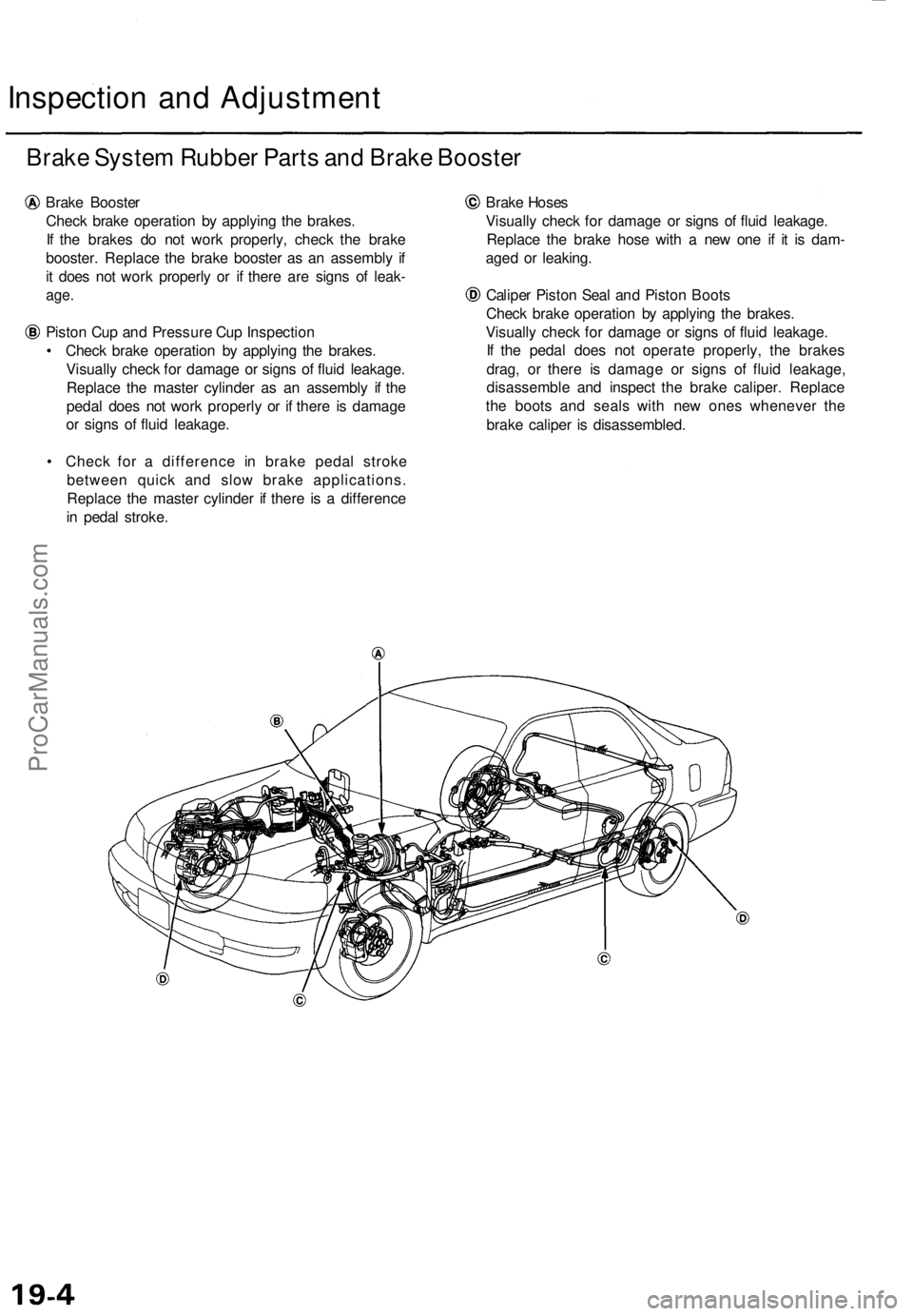

Inspection and Adjustment

Brake System Rubber Parts and Brake Booster

Brake Booster

Check brake operation by applying the brakes.

If the brakes do not work properly, check the brake

booster. Replace the brake booster as an assembly if

it does not work properly or if there are signs of leak-

age.

Piston Cup and Pressure Cup Inspection

• Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

Replace the master cylinder as an assembly if the

pedal does not work properly or if there is damage

or signs of fluid leakage.

• Check for a difference in brake pedal stroke

between quick and slow brake applications.

Replace the master cylinder if there is a difference

in pedal stroke.

Brake Hoses

Visually check for damage or signs of fluid leakage.

Replace the brake hose with a new one if it is dam-

aged or leaking.

Caliper Piston Seal and Piston Boots

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

If the pedal does not operate properly, the brakes

drag, or there is damage or signs of fluid leakage,

disassemble and inspect the brake caliper. Replace

the boots and seals with new ones whenever the

brake caliper is disassembled.ProCarManuals.com

Page 1254 of 1771

Front Brak e Pad s

Inspectio n an d Replacemen t

• Neve r us e a n ai r hos e o r dr y brus h t o clea n brak e

assemblies .

• Us e a n OSHA-approve d vacuu m cleane r t o avoi d

breathin g brak e dust .

1 . Loose n th e fron t whee l nut s slightly , the n rais e th e

vehicle , an d suppor t i t o n safet y stands . Remov e

the fron t wheels .

2. Remov e th e calipe r bolt , an d pivo t th e calipe r u p

ou t o f th e way .

CALIPE R BOL T CALIPE

R BOD Y

NOTE : Chec k th e hose s an d pi n boot s fo r damag e

and deterioration .

3. Remov e th e pa d shims , pa d retainer s an d pads .

INNER PA D SHIM SCheck fo r weakness .

INNE R PA D

('9 7 -9 8 models )

Chec k fo r wear . OUTE

R PA D

Chec k fo r wear .

('95 , '9 6 models )

OUTER PA D SHI M

Chec k fo r weakness .

4. Usin g vernie r calipers , measur e th e thicknes s o f

eac h brak e pa d lining .

Brak e Pa d Thickness :

Standard: 10.5-11. 5 m m (0.41-0.4 5 in )

Servic e Limit : 1. 6 m m (0.0 6 in )

'95 - 9 6 models : '9 7 - 9 8 models :

BACKIN G PLAT E

NOTE : Measuremen t doe s no t includ e pa d backin g

plat e thickness .

5 . I f th e brak e pa d thicknes s i s les s tha n servic e limit ,

replac e th e fron t pad s a s a set .

6 . Clea n th e calipe r thoroughly ; remov e an y rust , an d

chec k fo r groove s an d cracks .

7 . Chec k th e brak e dis c fo r damag e an d cracks .

8 . Instal l th e pa d retainers .

PAD RETAINER S

PAD RETAINER S

ProCarManuals.com

Page 1255 of 1771

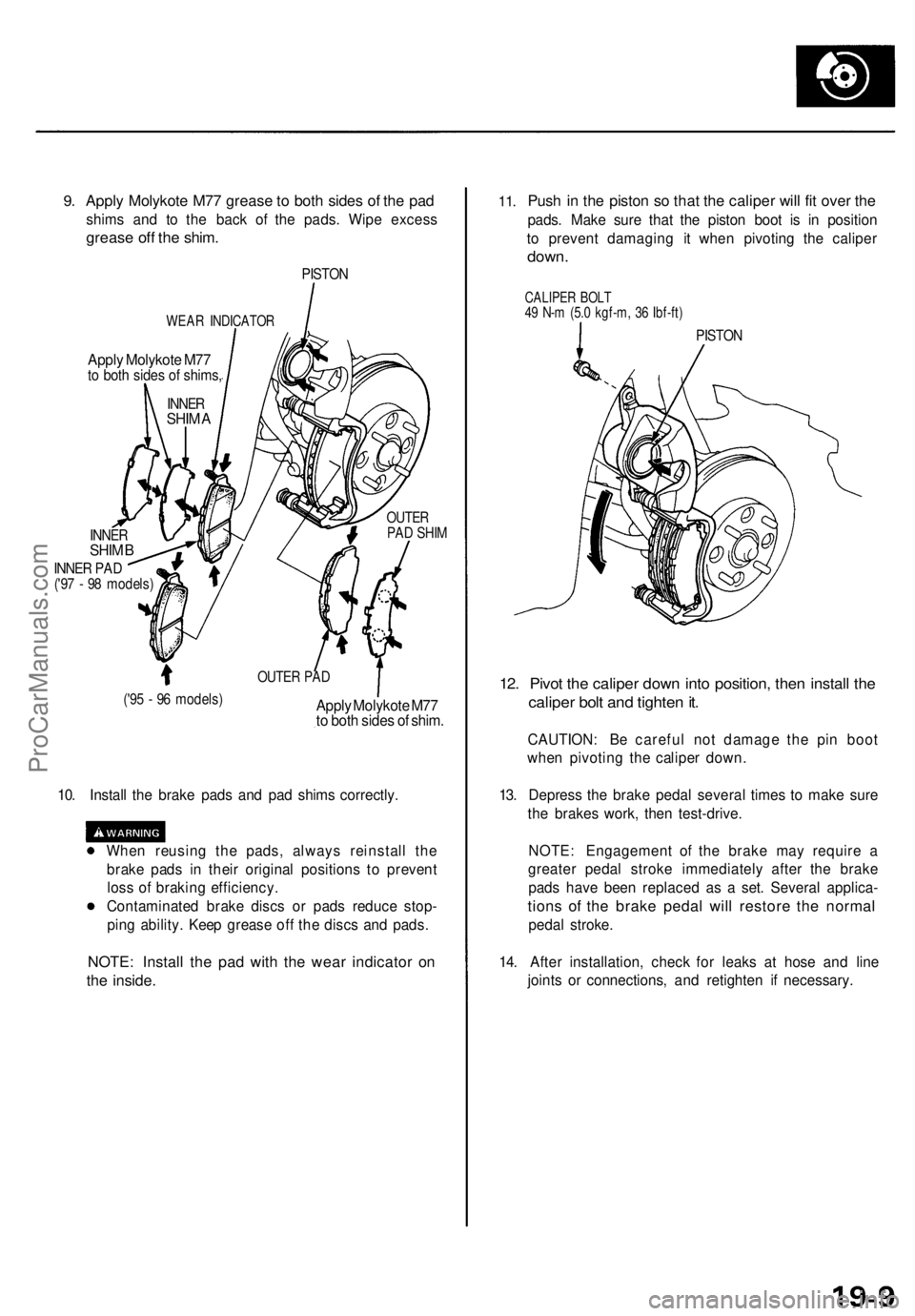

9.

Apply Molykote M77 grease to both sides of the pad

shims and to the back of the pads. Wipe excess

grease off the shim.

PISTON

WEAR INDICATOR

Apply Molykote M77

to both sides of shims,

INNER

SHIM B

INNER PAD

('97 - 98 models)

OUTER

PAD SHIM

('95 - 96 models)

Apply Molykote M77

to both sides of shim.

10. Install the brake pads and pad shims correctly.

When reusing the pads, always reinstall the

brake pads in their original positions to prevent

loss of braking efficiency.

Contaminated brake discs or pads reduce stop-

ping ability. Keep grease off the discs and pads.

NOTE: Install the pad with the wear indicator on

the inside.

11.

Push in the piston so that the caliper will fit over the

pads. Make sure that the piston boot is in position

to prevent damaging it when pivoting the caliper

down.

CALIPER BOLT

49 N-m (5.0 kgf-m, 36 Ibf-ft)

PISTON

12. Pivot the caliper down into position, then install the

caliper bolt and tighten it.

CAUTION: Be careful not damage the pin boot

when pivoting the caliper down.

13. Depress the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

pedal stroke.

14. After installation, check for leaks at hose and line

joints or connections, and retighten if necessary.

INNER

SHIM A

OUTER PADProCarManuals.com

Page 1257 of 1771

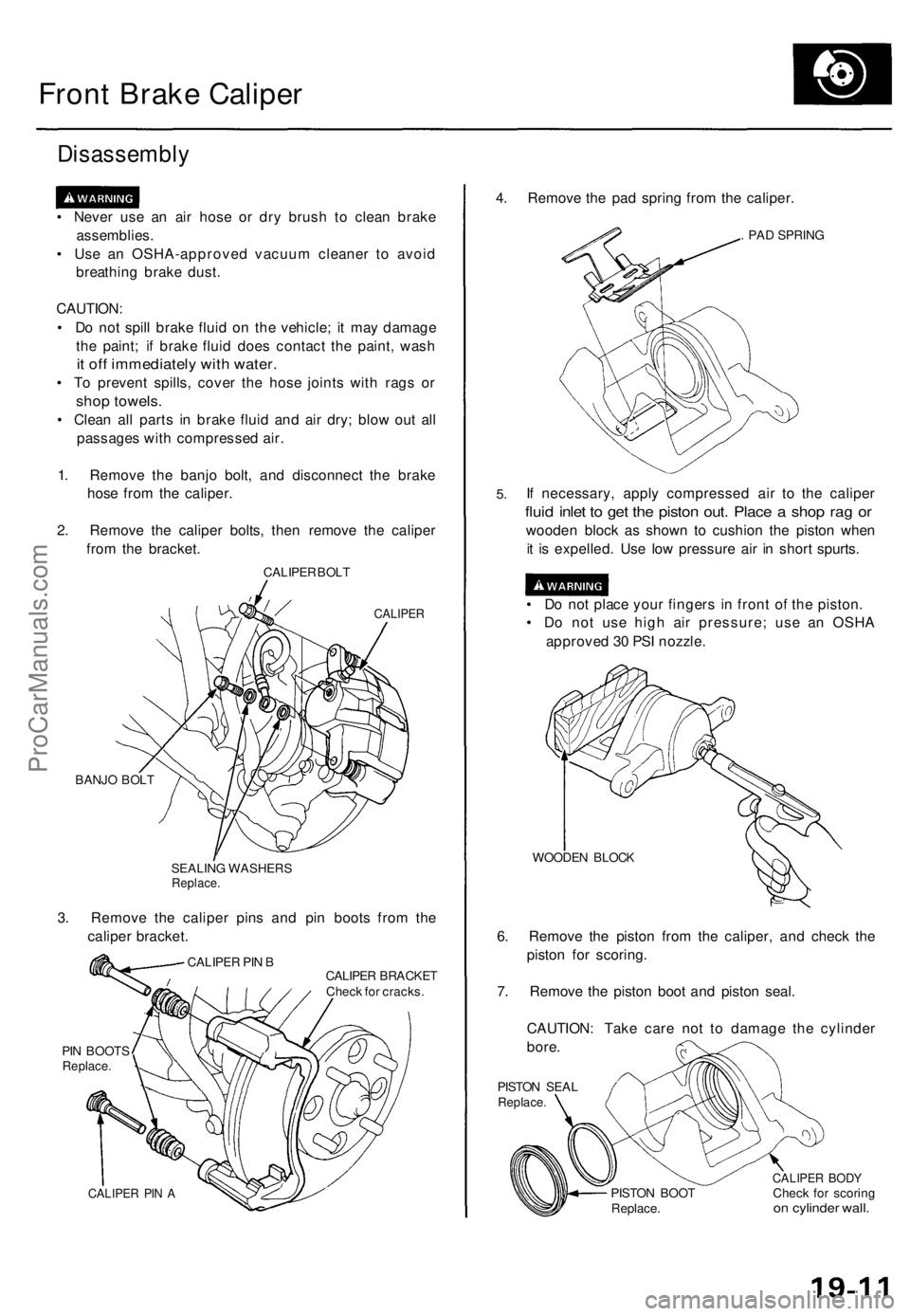

Front Brake Caliper

Disassembly

• Never use an air hose or dry brush to clean brake

assemblies.

• Use an OSHA-approved vacuum cleaner to avoid

breathing brake dust.

CAUTION:

• Do not spill brake fluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wash

it off immediately with water.

• To prevent spills, cover the hose joints with rags or

shop towels.

• Clean all parts in brake fluid and air dry; blow out all

passages with compressed air.

1. Remove the banjo bolt, and disconnect the brake

hose from the caliper.

2. Remove the caliper bolts, then remove the caliper

from the bracket.

CALIPER BOLT

CALIPER

BANJO BOLT

SEALING WASHERS

Replace.

3. Remove the caliper pins and pin boots from the

caliper bracket.

CALIPER BRACKET

Check for cracks.

PIN BOOTS

Replace.

CALIPER PIN A

4. Remove the pad spring from the caliper.

. PAD SPRING

5.

If necessary, apply compressed air to the caliper

fluid inlet to get the piston out. Place a shop rag or

wooden block as shown to cushion the piston when

it is expelled. Use low pressure air in short spurts.

• Do not place your fingers in front of the piston.

• Do not use high air pressure; use an OSHA

approved 30 PSI nozzle.

WOODEN BLOCK

6. Remove the piston from the caliper, and check the

piston for scoring.

7. Remove the piston boot and piston seal.

CAUTION: Take care not to damage the cylinder

bore.

PISTON SEAL

Replace.

PISTON BOOT

Replace.

CALIPER BODY

Check for scoring

on cylinder wall.

CALIPER PIN BProCarManuals.com