boot ACURA TL 1995 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1128 of 1771

Driveshafts

Disassembly (cont'd)

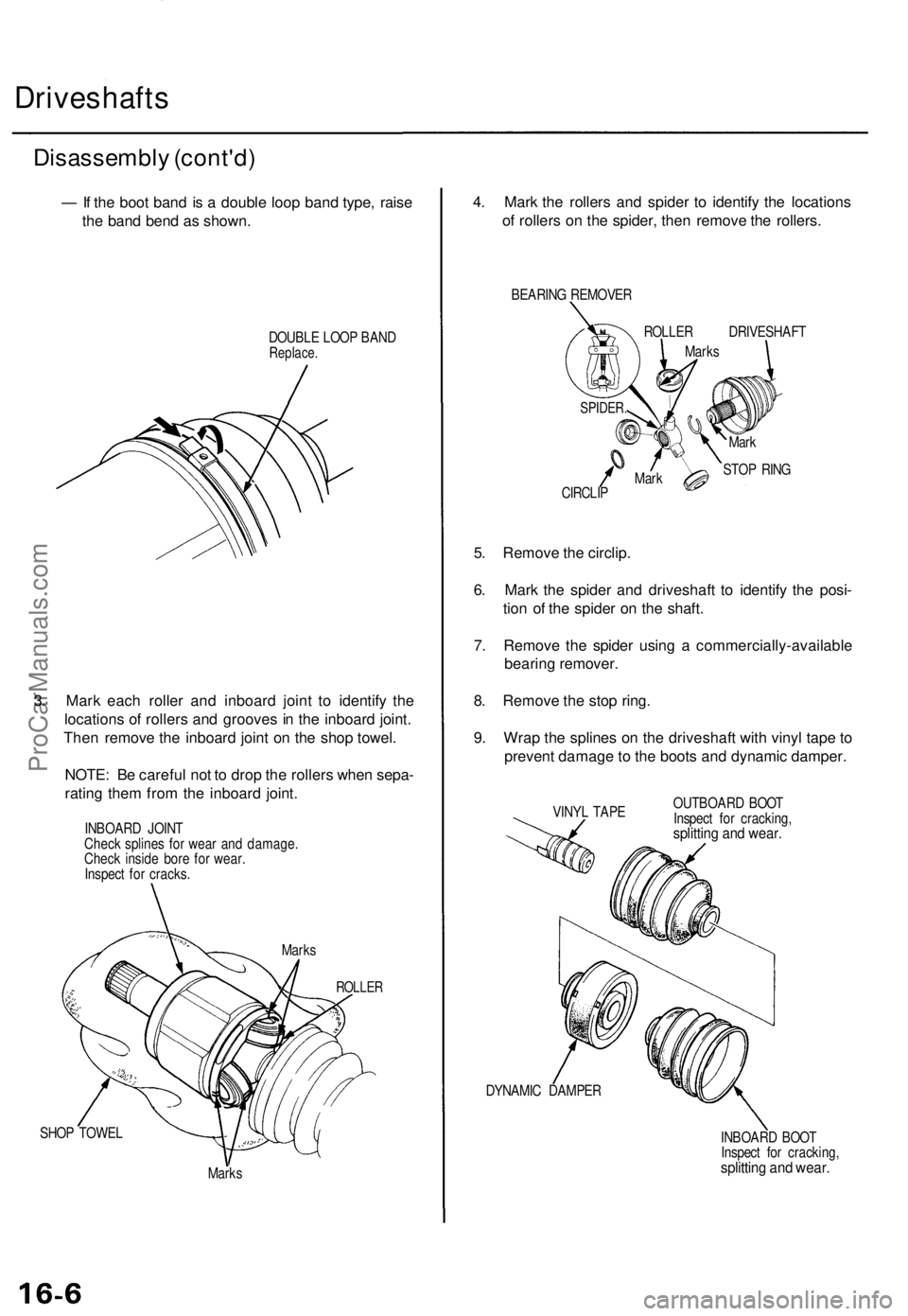

— If the boot band is a double loop band type, raise

the band bend as shown.

DOUBLE LOOP BAND

Replace.

3. Mark each roller and inboard joint to identify the

locations of rollers and grooves in the inboard joint.

Then remove the inboard joint on the shop towel.

NOTE: Be careful not to drop the rollers when sepa-

rating them from the inboard joint.

INBOARD JOINT

Check splines for wear and damage.

Check inside bore for wear.

Inspect for cracks.

SHOP TOWEL

Marks

4. Mark the rollers and spider to identify the locations

of rollers on the spider, then remove the rollers.

BEARING REMOVER

ROLLER DRIVESHAFT

Mark

CIRCLIP

Mark

STOP RING

5. Remove the circlip.

6. Mark the spider and driveshaft to identify the posi-

tion of the spider on the shaft.

7. Remove the spider using a commercially-available

bearing remover.

8. Remove the stop ring.

9. Wrap the splines on the driveshaft with vinyl tape to

prevent damage to the boots and dynamic damper.

VINYL TAPE

OUTBOARD BOOT

Inspect for cracking,

splitting and wear.

DYNAMIC DAMPER

INBOARD BOOT

Inspect for cracking,

splitting and wear.

SPIDER.

Marks

ROLLER

MarksProCarManuals.com

Page 1129 of 1771

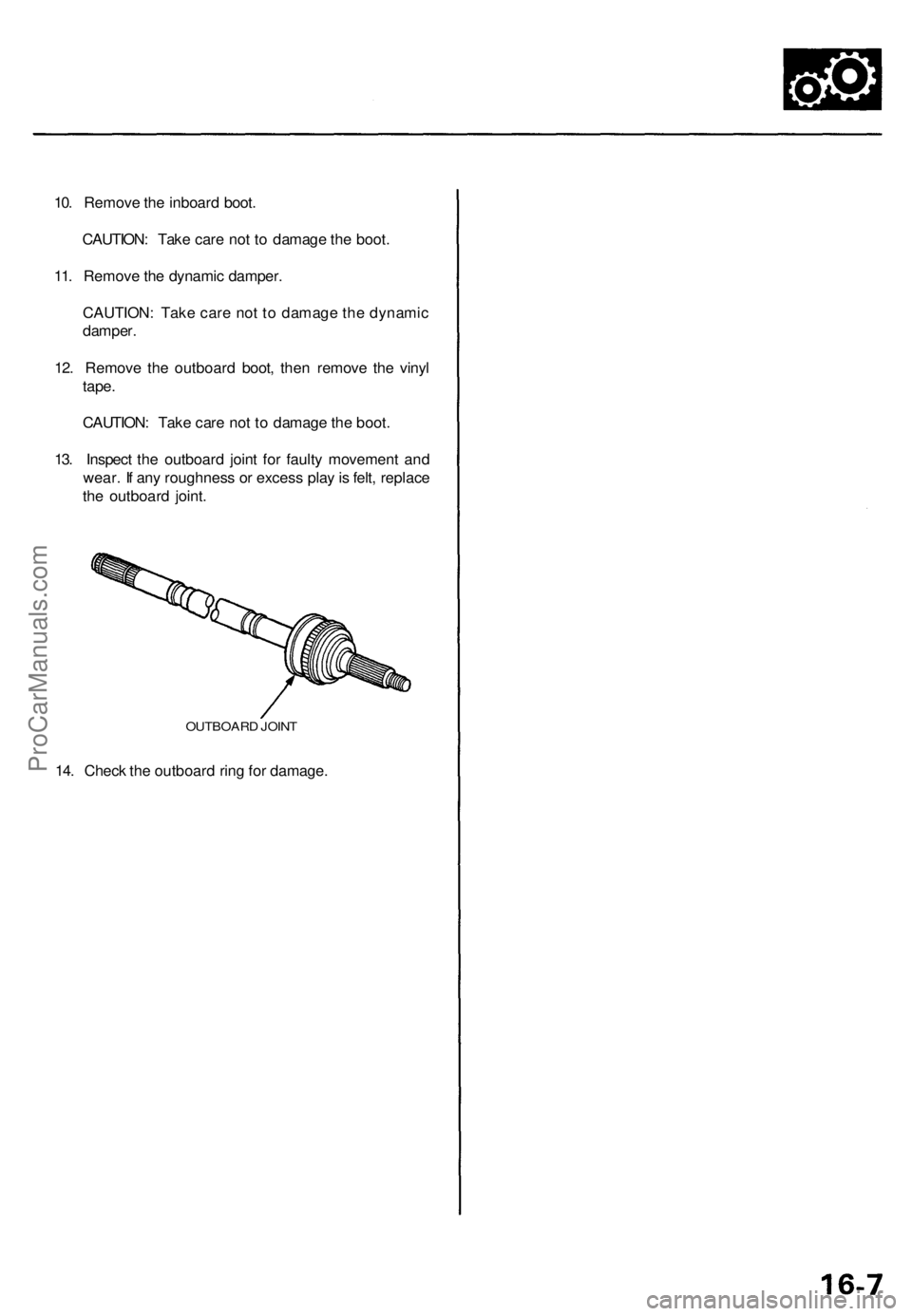

10. Remove the inboard boot.

CAUTION: Take care not to damage the boot.

11. Remove the dynamic damper.

CAUTION: Take care not to damage the dynamic

damper.

12. Remove the outboard boot, then remove the vinyl

tape.

CAUTION: Take care not to damage the boot.

13. Inspect the outboard joint for faulty movement and

wear. If any roughness or excess play is felt, replace

the outboard joint.

OUTBOARD JOINT

14. Check the outboard ring for damage.ProCarManuals.com

Page 1130 of 1771

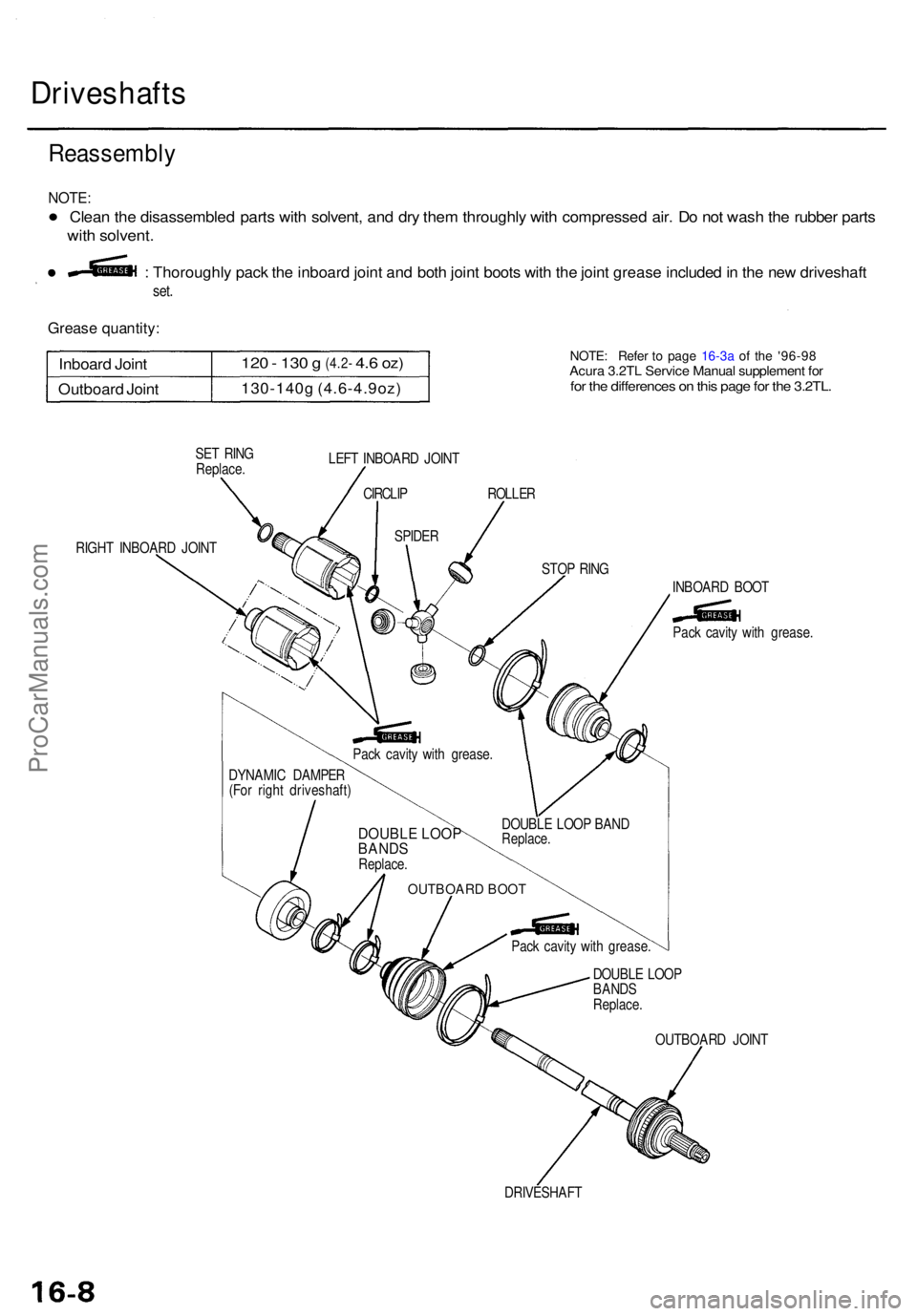

Driveshafts

Reassembl y

NOTE:

• Clean th e disassemble d part s wit h solvent , an d dr y the m throughl y wit h compresse d air . D o no t was h th e rubbe r part s

with solvent .

Grease quantity :

Inboard Join t

Outboar d Join t

120 - 13 0 g (4.2 - 4.6 oz )

130-140 g (4.6-4.9oz )

SET RIN GReplace .

CIRCLIP ROLLE R

RIGH T INBOAR D JOIN T

DYNAMI C DAMPE R

(Fo r righ t driveshaft )

DOUBLE LOO P BAN D

Replace .

INBOAR D BOO T

Pac k cavit y wit h grease .

OUTBOAR D JOIN T

DRIVESHAF T

: Thoroughl y pac k th e inboar d join t an d bot h join t boot s wit h th e join t greas e include d in th e ne w driveshaf t

set.

DOUBL E LOO P

BAND S

Replace .

Pack cavit y wit h grease .

OUTBOARD BOOT

DOUBLE LOOP

BANDS

Replace .

Pack cavit y wit h grease .

SPIDER

LEFT INBOAR D JOIN T

STOP RIN G

NOTE : Refe r t o page 16-3a of the '96-9 8 Acura 3.2TL Servic e Manual supplement forfor the differences on this page for the 3.2TL.

ProCarManuals.com

Page 1131 of 1771

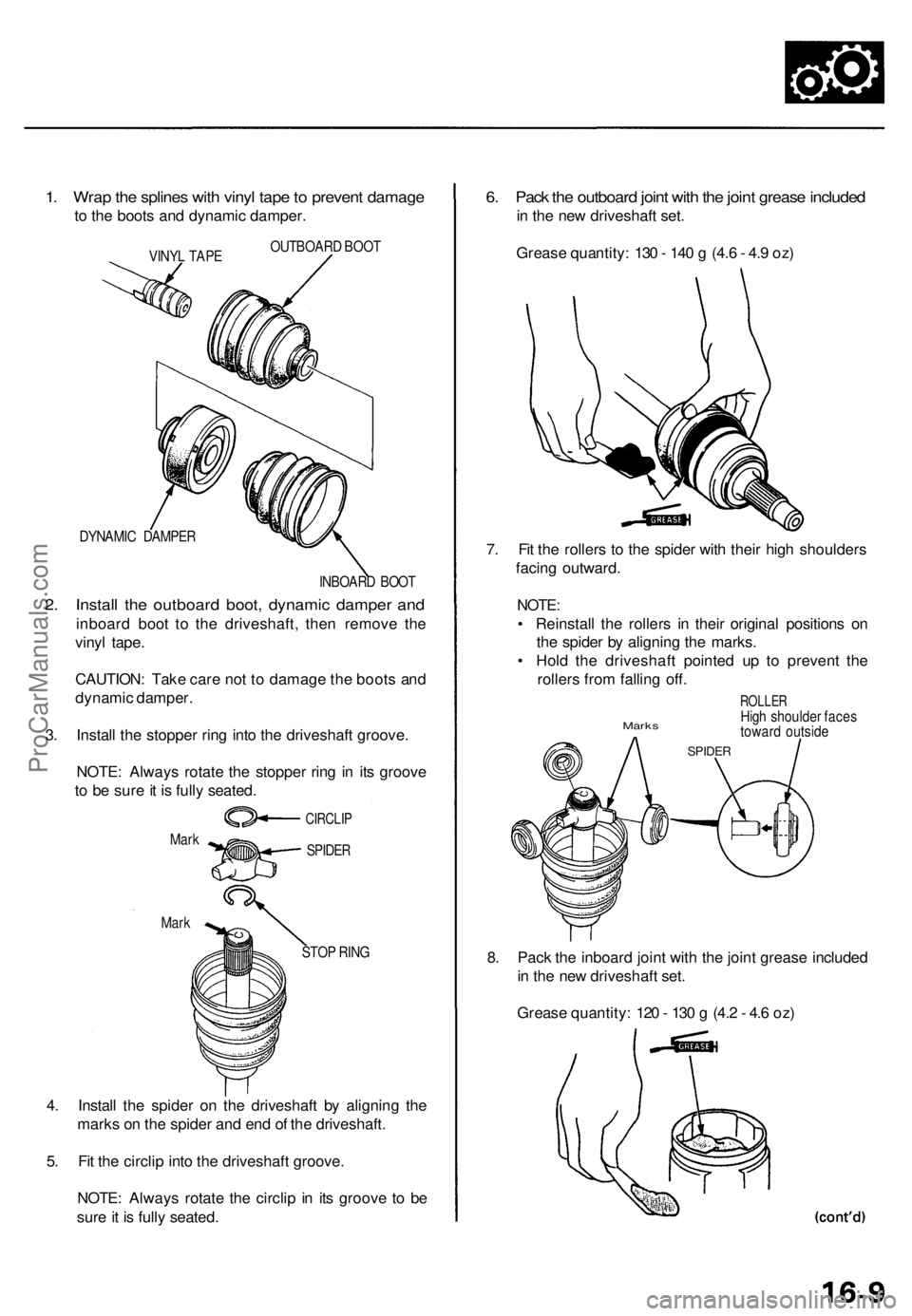

1. Wra p th e spline s wit h viny l tap e to preven t damag e

to th e boot s an d dynami c damper .

VINYL TAP E OUTBOAR

D BOO T

DYNAMI C DAMPE R

INBOARD BOO T

2. Instal l th e outboar d boot , dynami c dampe r an d

inboar d boo t t o th e driveshaft , the n remov e th e

viny l tape .

CAUTION : Tak e car e no t t o damag e th e boot s an d

dynami c damper .

3 . Instal l th e stoppe r rin g int o th e driveshaf t groove .

NOTE : Alway s rotat e th e stoppe r rin g i n it s groov e

t o b e sur e it i s full y seated .

Mark

Mar k

STOP RIN G

4. Instal l th e spide r o n th e driveshaf t b y alignin g th e

mark s o n th e spide r an d en d o f th e driveshaft .

5 . Fi t th e circli p int o th e driveshaf t groove .

NOTE : Alway s rotat e th e circli p in it s groov e t o b e

sur e it i s full y seated .

6. Pac k th e outboar d join t wit h th e join t greas e include d

in th e ne w driveshaf t set .

Greas e quantity : 13 0 - 14 0 g (4. 6 - 4. 9 oz )

7 . Fi t th e roller s t o th e spide r wit h thei r hig h shoulder s

facin g outward .

NOTE:

• Reinstal l th e roller s i n thei r origina l position s o n

th e spide r b y alignin g th e marks .

• Hol d th e driveshaf t pointe d u p t o preven t th e

roller s fro m fallin g off .

ROLLE RHigh shoulde r face sMark s towar d outsid e

SPIDER

8. Pac k th e inboar d join t wit h th e join t greas e include d

i n th e ne w driveshaf t set .

Greas e quantity : 12 0 - 13 0 g (4. 2 - 4. 6 oz )

CIRCLI P

SPIDER

ProCarManuals.com

Page 1132 of 1771

Driveshaft

Reassembl y (cont'd )

9. Fi t th e inboar d join t ont o th e driveshaft .

NOTE:

• Reinstal l th e inboar d join t ont o th e driveshaf t b y

alignin g th e mark s o n th e inboar d join t an d th e

rollers .

• Hol d th e driveshaf t s o th e inboar d join t point s u p

t o preven t i t fro m fallin g off .

INBOAR DJOINT

10. Adjus t th e lengt h of the driveshaft s t o th e figur e

below , the n adjus t th e boot s t o halfwa y betwee n

full compressio n an d ful l extension .

NOTE: Th e end s o f boot s sea t i n th e groov e o f th e

driveshaf t an d joint .

Left: 49 6 - 50 1 m m (19. 5 - 19. 7 in )

Right : 50 3 - 50 8 m m (19. 8 - 20. 0 in )

11. Positio n th e dynami c dampe r a s show n below .

45 2 mm (1. 8 0. 1 in )

DYNAMI C DAMPE R

(Fo r righ t driveshaft )

DYNAMI C DAMPE R BAN D

12. Se t th e doubl e loo p ban d ont o th e boo t an d dynami c

damper wit h th e ban d en d towar d t o fron t o f th e

vehicle .

Front DOUBL

E LOO P BAN D

BOO T

NOTE : Refe r t o page 16-3a of the '96-9 8 Acura 3.2TL Servic e Manual supplement forfor the differences on this page for the 3.2TL.

ProCarManuals.com

Page 1160 of 1771

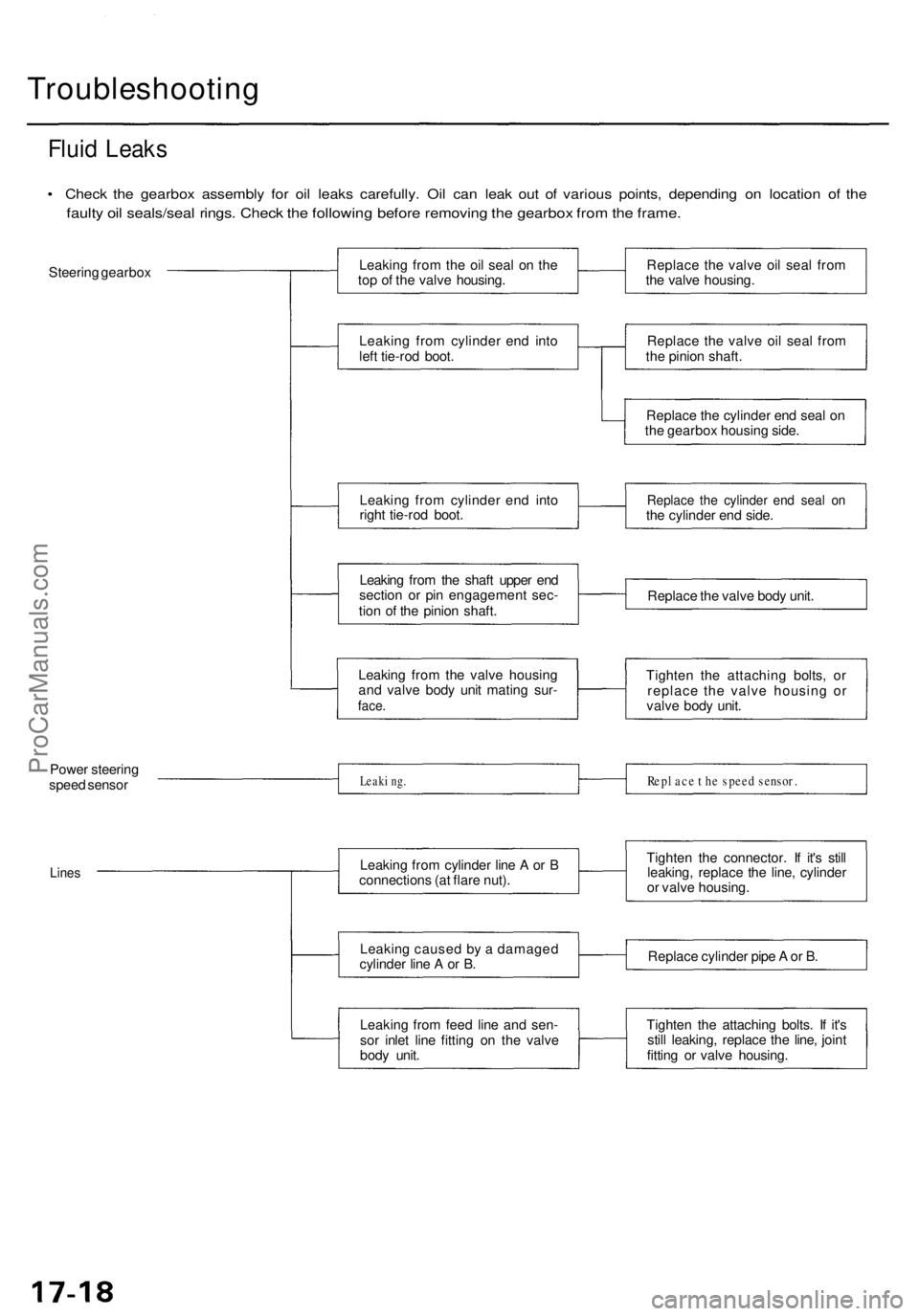

Troubleshooting

Fluid Leak s

• Chec k th e gearbo x assembl y fo r oi l leak s carefully . Oi l ca n lea k ou t o f variou s points , dependin g o n locatio n o f th e

fault y oi l seals/sea l rings . Chec k th e followin g befor e removin g th e gearbo x fro m th e frame .

Steerin g gearbo x Leakin

g fro m th e oi l sea l o n th e

to p o f th e valv e housing .

Leakin g fro m cylinde r en d int o

lef t tie-ro d boot .

Leakin g fro m cylinde r en d int o

righ t tie-ro d boot .

Leakin g fro m th e shaf t uppe r en d

sectio n o r pi n engagemen t sec -

tio n o f th e pinio n shaft .

Leakin g fro m th e valv e housin g

an d valv e bod y uni t matin g sur -

face .

Replac e th e valv e oi l sea l fro m

th e valv e housing .

Replac e th e valv e oi l sea l fro m

th e pinio n shaft .

Replac e th e cylinde r en d sea l o n

th e gearbo x housin g side .

Replac e th e cylinde r en d sea l o nthe cylinde r en d side .

Replac e th e valv e bod y unit .

Tighte n th e attachin g bolts , o r

replac e th e valv e housin g o r

valv e bod y unit .

Powe r steerin g

spee d senso r

Leaking .Replace th e spee d sensor .

LinesLeakin g fro m cylinde r lin e A or B

connection s (a t flar e nut) .

Leakin g cause d b y a damage d

cylinde r lin e A or B .

Leakin g fro m fee d lin e an d sen -

so r inle t lin e fittin g o n th e valv e

bod y unit . Tighte

n th e connector . I f it' s stil l

leaking , replac e th e line , cylinde r

o r valv e housing .

Replac e cylinde r pip e A or B .

Tighte n th e attachin g bolts . I f it' s

stil l leaking , replac e th e line , join t

fittin g o r valv e housing .

ProCarManuals.com

Page 1168 of 1771

Inspection an d Adjustmen t

Fluid Leakag e Inspectio n

POWER STEERIN G SPEE D SENSO R

Chec k fo r leak s a t th e roto r housin g

matin g surfac e an d hos e connections .

GEARBO X an d VALV E BOD Y UNI T an d ASSIS T

CONTRO L VALV E UNI T

Chec k fo r leak s a t th e matin g surface , an d hos e

an d pip e connections .

PUM P ASSEMBL Y

Chec k fo r leak s a t th e pum p

seal, inle t an d outle t fitting s

HOSE S an d LINE S

Inspec t hose s fo r damage , leaks ,

interferenc e o r twisting .Inspect flui d line s fo r damage ,rusting o r leakage .Inspect fo r leak s a t hos e an dline joint s o r connections .

BOOTChec k fo r leaks .

ProCarManuals.com

Page 1191 of 1771

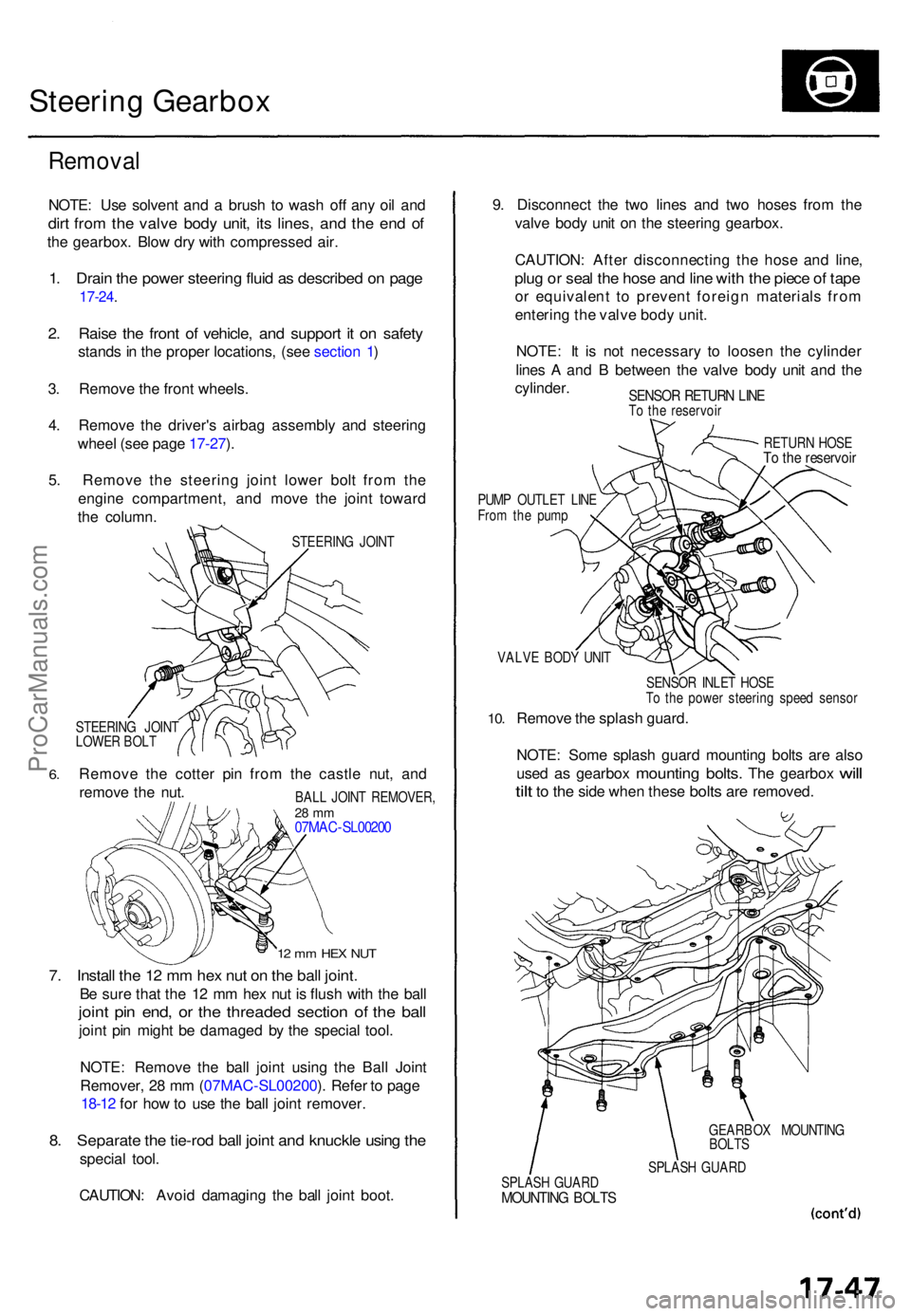

Steering Gearbo x

Remova l

NOTE: Us e solven t an d a brus h t o was h of f an y oi l an d

dirt fro m th e valv e bod y unit , it s lines , an d th e en d o f

the gearbox . Blo w dr y wit h compresse d air .

1. Drai n th e powe r steerin g flui d a s describe d o n pag e

17-24 .

2. Rais e th e fron t o f vehicle , an d suppor t i t o n safet y

stands in th e prope r locations , (se e sectio n 1 )

3 . Remov e th e fron t wheels .

4 . Remov e th e driver' s airba g assembl y an d steerin g

whee l (se e pag e 17-27 ).

5 . Remov e th e steerin g join t lowe r bol t fro m th e

engin e compartment , an d mov e th e join t towar d

th e column .

STEERIN G JOIN T

6.

STEERIN G JOIN T

LOWE R BOL T

Remov e th e cotte r pi n fro m th e castl e nut , an d

remov e th e nut .

12 m m HE X NU T

7. Instal l th e 1 2 m m he x nu t o n th e bal l joint .

Be sur e tha t th e 1 2 m m he x nu t i s flus h wit h th e bal l

joint pi n end , o r th e threade d sectio n o f th e bal l

joint pi n migh t b e damage d b y th e specia l tool .

NOTE : Remov e th e bal l join t usin g th e Bal l Join t

Remover , 2 8 m m (07MA C-SL00200 ). Refe r t o pag e

18-12 for ho w to us e th e bal l join t remover .

8. Separat e th e tie-ro d bal l join t an d knuckl e usin g th e

specia l tool .

CAUTION : Avoi d damagin g th e bal l join t boot . 9

. Disconnec t th e tw o line s an d tw o hose s fro m th e

valv e bod y uni t o n th e steerin g gearbox .

CAUTION : Afte r disconnectin g th e hos e an d line ,

plug o r sea l th e hos e an d lin e wit h th e piec e o f tap e

or equivalen t t o preven t foreig n material s fro m

enterin g th e valv e bod y unit .

NOTE : I t i s no t necessar y t o loose n th e cylinde r

line s A an d B betwee n th e valv e bod y uni t an d th e

cylinder .

SENSOR RETUR N LIN ETo th e reservoi r

RETURN HOS E

To th e reservoi r

PUMP OUTLE T LIN E

Fro m th e pum p

VALV E BOD Y UNI T

10.

SENSO R INLE T HOS E

T o th e powe r steerin g spee d senso r

Remove th e splas h guard .

NOTE : Som e splas h guar d mountin g bolt s ar e als o

use d

as gearbo x mountin g bolts. The gearbo x will

til t

to th e sid e whe n thes e bolts are removed .

GEARBO X MOUNTIN G

BOLT S

SPLAS H GUAR D

SPLAS H GUAR D

MOUNTIN G BOLT S

BALL JOIN T REMOVER ,28 m m07MA C-SL0020 0

ProCarManuals.com

Page 1193 of 1771

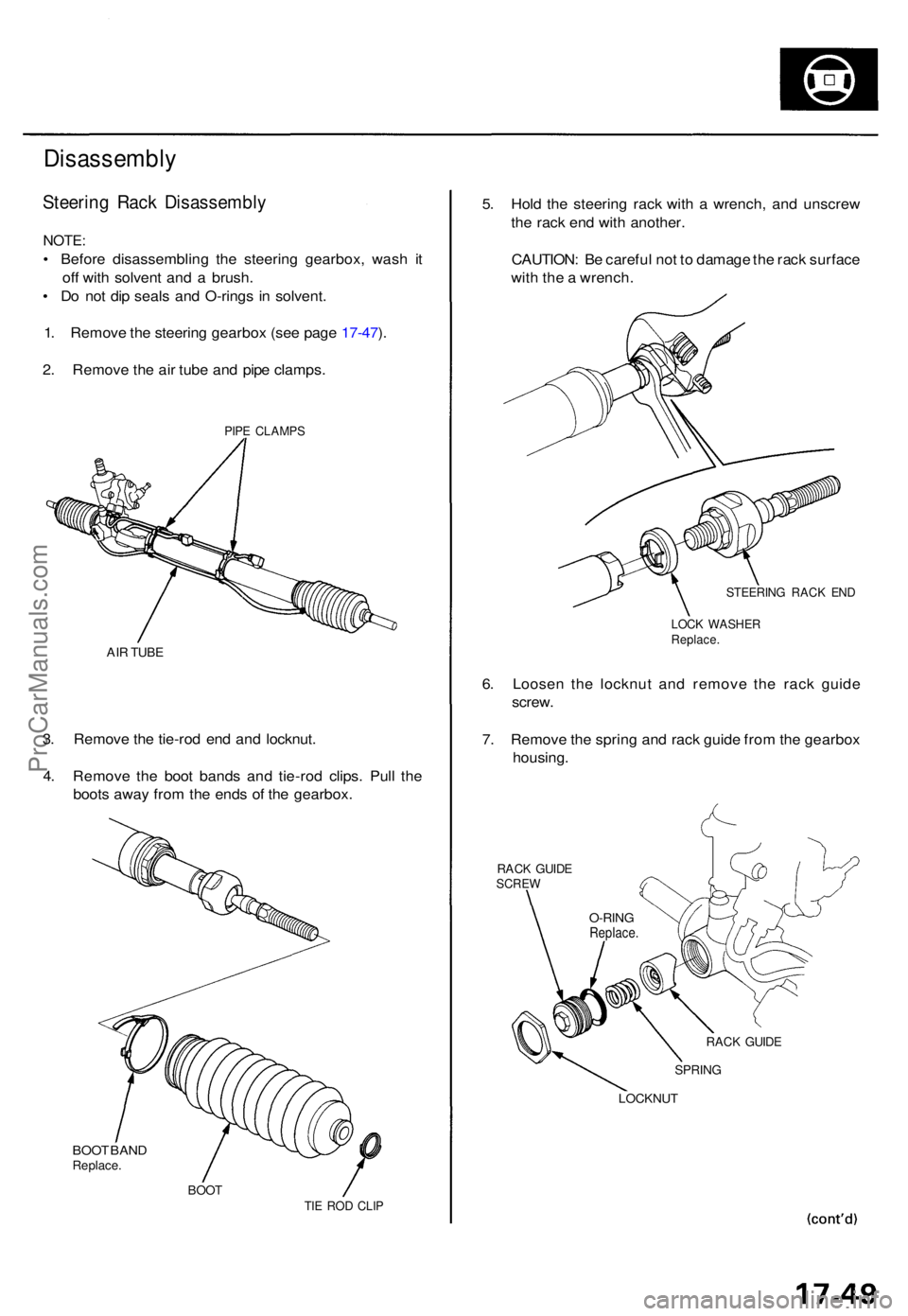

Disassembly

Steering Rac k Disassembl y

NOTE:

• Befor e disassemblin g th e steerin g gearbox , was h i t

of f wit h solven t an d a brush .

• D o no t di p seal s an d O-ring s i n solvent .

1 . Remov e th e steerin g gearbo x (se e pag e 17-47 ).

2 . Remov e th e ai r tub e an d pip e clamps .

PIPE CLAMP S

AIR TUB E

3. Remov e th e tie-ro d en d an d locknut .

4 . Remov e th e boo t band s an d tie-ro d clips . Pul l th e

boot s awa y fro m th e end s o f th e gearbox.

BOO T BAN DReplace .

BOOTTIE RO D CLI P

5. Hol d th e steerin g rac k wit h a wrench , an d unscre w

th e rac k en d wit h another .

CAUTION : B e carefu l no t t o damag e th e rac k surfac e

wit h th e a wrench .

STEERIN G RAC K EN D

LOC K WASHE RReplace.

6. Loose n th e locknu t an d remov e th e rac k guid e

screw .

7 . Remov e th e sprin g an d rac k guid e fro m th e gearbo x

housing .

RACK GUID ESCRE W

RACK GUID E

SPRIN G

LOCKNU T

O-RINGReplace .

ProCarManuals.com

Page 1209 of 1771

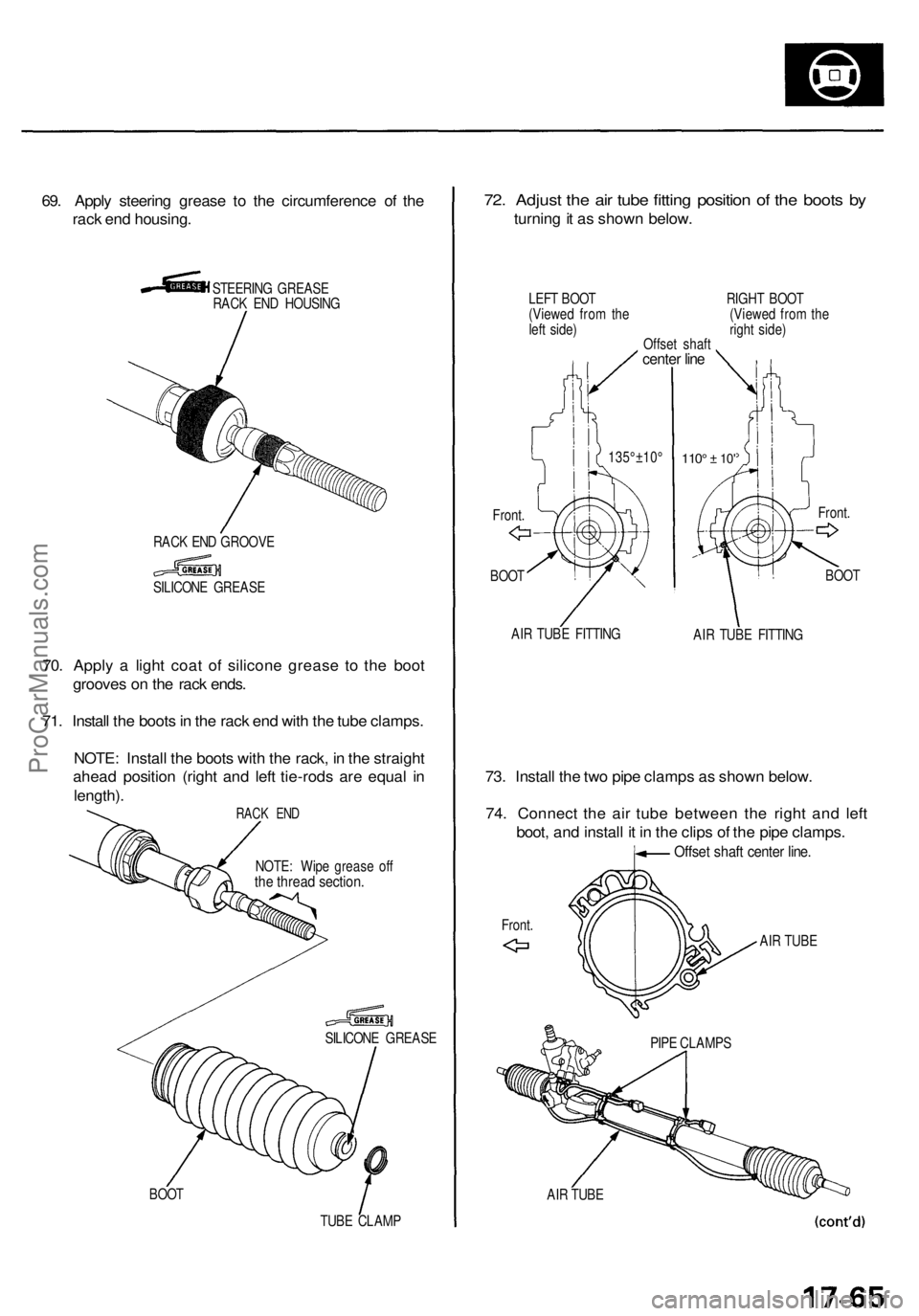

69. Appl y steerin g greas e t o th e circumferenc e o f th e

rac k en d housing .

STEERIN G GREAS E

RAC K EN D HOUSIN G

RAC K EN D GROOV E

SILICON E GREAS E

70. Appl y a ligh t coa t of silicon e greas e t o th e boo t

groove s o n th e rac k ends .

71 . Instal l th e boot s in th e rac k en d wit h th e tub e clamps .

NOTE : Instal l th e boot s wit h th e rack , i n th e straigh t

ahea d positio n (righ t an d lef t tie-rod s ar e equa l i n

length) .

NOTE: Wip e greas e of fthe threa d section .

SILICON E GREAS E

BOO T

TUBE CLAM P

72. Adjus t th e ai r tub e fittin g positio n o f th e boot s b y

turnin g it a s show n below .

LEFT BOO T RIGH T BOO T

(Viewe d fro m th e (Viewe d fro m th e

lef t side ) righ t side )

Offse t shaf t

center lin e

135°±10 °

BOO T110° ± 10 '

BOO T

AI R TUB E FITTIN G

AIR TUB E FITTIN G

73. Instal l th e tw o pip e clamp s a s show n below .

74 . Connec t th e ai r tub e betwee n th e righ t an d lef t

boot , an d instal l i t i n th e clip s o f th e pip e clamps .

Offset shaf t cente r line .

AIR TUB E

AI R TUB E PIP

E CLAMP S

Front

. Front

.

Front .

RACK EN D

ProCarManuals.com