oil ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 28 of 1771

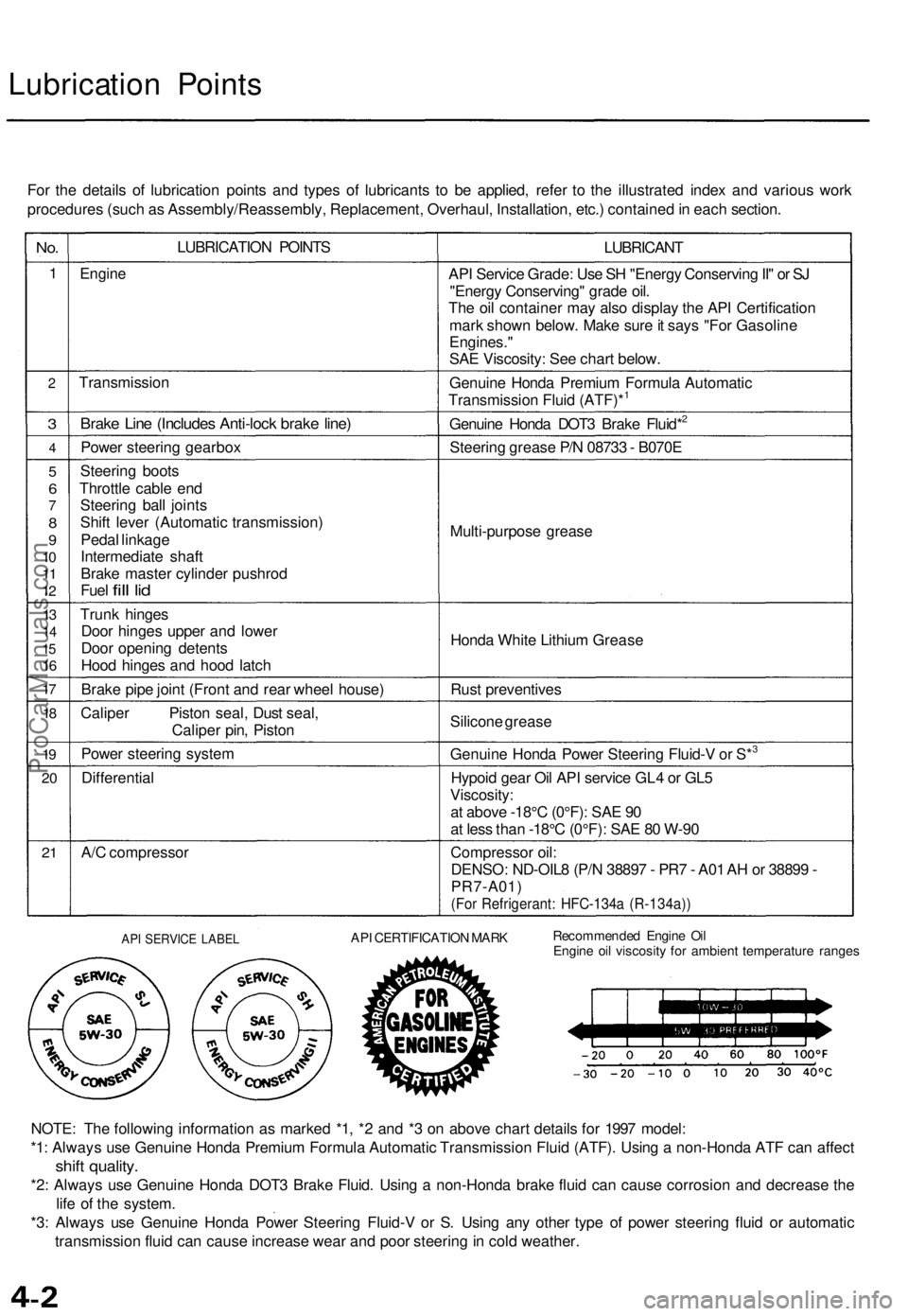

Lubrication Points

For the details of lubrication points and types of lubricants to be applied, refer to the illustrated index and various work

procedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

LUBRICATION POINTS

Engine

Transmission

Brake Line (Includes Anti-lock brake line)

Power steering gearbox

Steering boots

Throttle cable end

Steering ball joints

Shift lever (Automatic transmission)

Pedal linkage

Intermediate shaft

Brake master cylinder pushrod

Fuel

fill

lid

Trunk hinges

Door hinges upper and lower

Door opening detents

Hood hinges and hood latch

Brake pipe joint (Front and rear wheel house)

Caliper Piston seal, Dust seal,

Caliper pin, Piston

Power steering system

Differential

A/C compressor

LUBRICANT

API Service Grade: Use SH "Energy Conserving II" or SJ

"Energy Conserving" grade oil.

The oil container may also display the API Certification

mark shown below. Make sure it says "For Gasoline

Engines."

SAE Viscosity: See chart below.

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF)*1

Genuine Honda DOT3 Brake Fluid*2

Steering grease P/N 08733 - B070E

Multi-purpose grease

Honda White Lithium Grease

Rust preventives

Silicone grease

Genuine Honda Power Steering Fluid-V or S*3

Hypoid gear Oil API service GL4 or GL5

Viscosity:

at above -18°C (0°F): SAE 90

at less than -18°C (0°F): SAE 80 W-90

Compressor oil:

DENSO: ND-OIL8 (P/N 38897 - PR7 - A01 AH or 38899 -

PR7-A01)

(For Refrigerant: HFC-134a (R-134a))

API SERVICE LABEL

API CERTIFICATION MARK

Recommended Engine Oil

Engine oil viscosity for ambient temperature ranges

NOTE: The following information as marked *1, *2 and *3 on above chart details for 1997 model:

*1: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift quality.

*2: Always use Genuine Honda DOT3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

*3: Always use Genuine Honda Power Steering Fluid-V or S. Using any other type of power steering fluid or automatic

transmission fluid can cause increase wear and poor steering in cold weather.ProCarManuals.com

Page 48 of 1771

Engine Removal/Installatio n

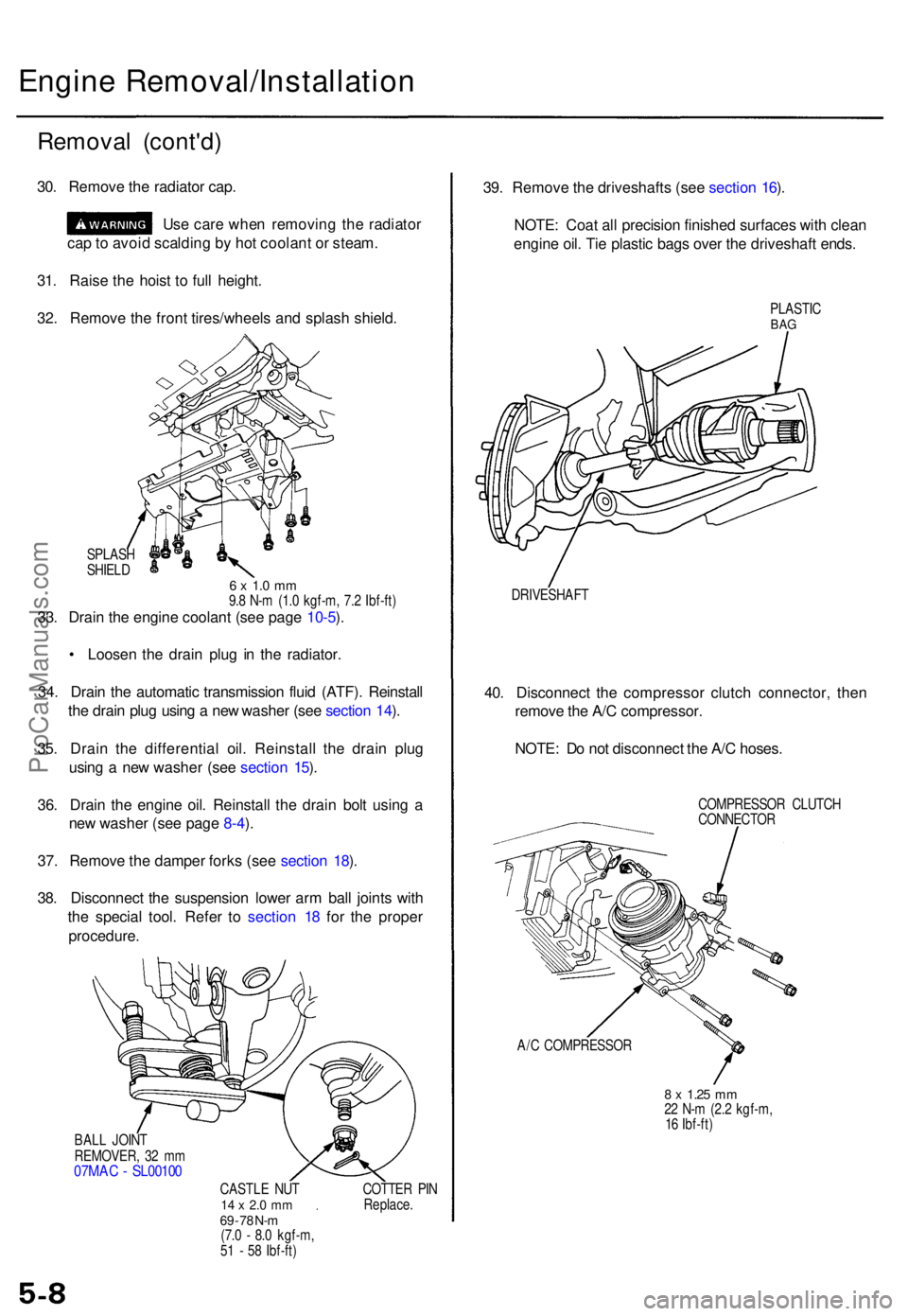

Removal (cont'd )

30. Remov e th e radiato r cap .

Us e car e whe n removin g th e radiato r

ca p to avoi d scaldin g b y ho t coolan t o r steam .

31 . Rais e th e hois t t o ful l height .

32 . Remov e th e fron t tires/wheel s an d splas h shield .

SPLAS H

SHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )33. Drai n th e engin e coolan t (se e pag e 10-5 ).

• Loose n th e drai n plu g i n th e radiator .

34 . Drai n th e automati c transmissio n flui d (ATF) . Reinstal l

th e drai n plu g usin g a ne w washe r (se e sectio n 14 ).

35 . Drai n th e differentia l oil . Reinstal l th e drai n plu g

usin g a ne w washe r (se e sectio n 15 ).

36 . Drai n th e engin e oil . Reinstal l th e drai n bol t usin g a

ne w washe r (se e pag e 8-4 ).

37 . Remov e th e dampe r fork s (se e sectio n 18 ).

38 . Disconnec t th e suspensio n lowe r ar m bal l joint s wit h

th e specia l tool . Refe r t o sectio n 1 8 fo r th e prope r

procedure .

BALL JOIN T

REMOVER , 3 2 m m

07MA C - SL0010 0

CASTLE NU T14 x 2. 0 m m69 - 7 8 N- m(7. 0 - 8. 0 kgf-m ,

5 1 - 5 8 Ibf-ft ) COTTE

R PI N

Replace .

39. Remov e th e driveshaft s (se e sectio n 16 ).

NOTE : Coa t al l precisio n finishe d surface s wit h clea n

engin e oil . Ti e plasti c bag s ove r th e driveshaf t ends .

PLASTI CBAG

DRIVESHAF T

40. Disconnec t th e compresso r clutc h connector , the n

remov e th e A/ C compressor .

NOTE : D o no t disconnec t th e A/ C hoses .

COMPRESSO R CLUTC H

CONNECTO R

A/ C COMPRESSO R

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 60 of 1771

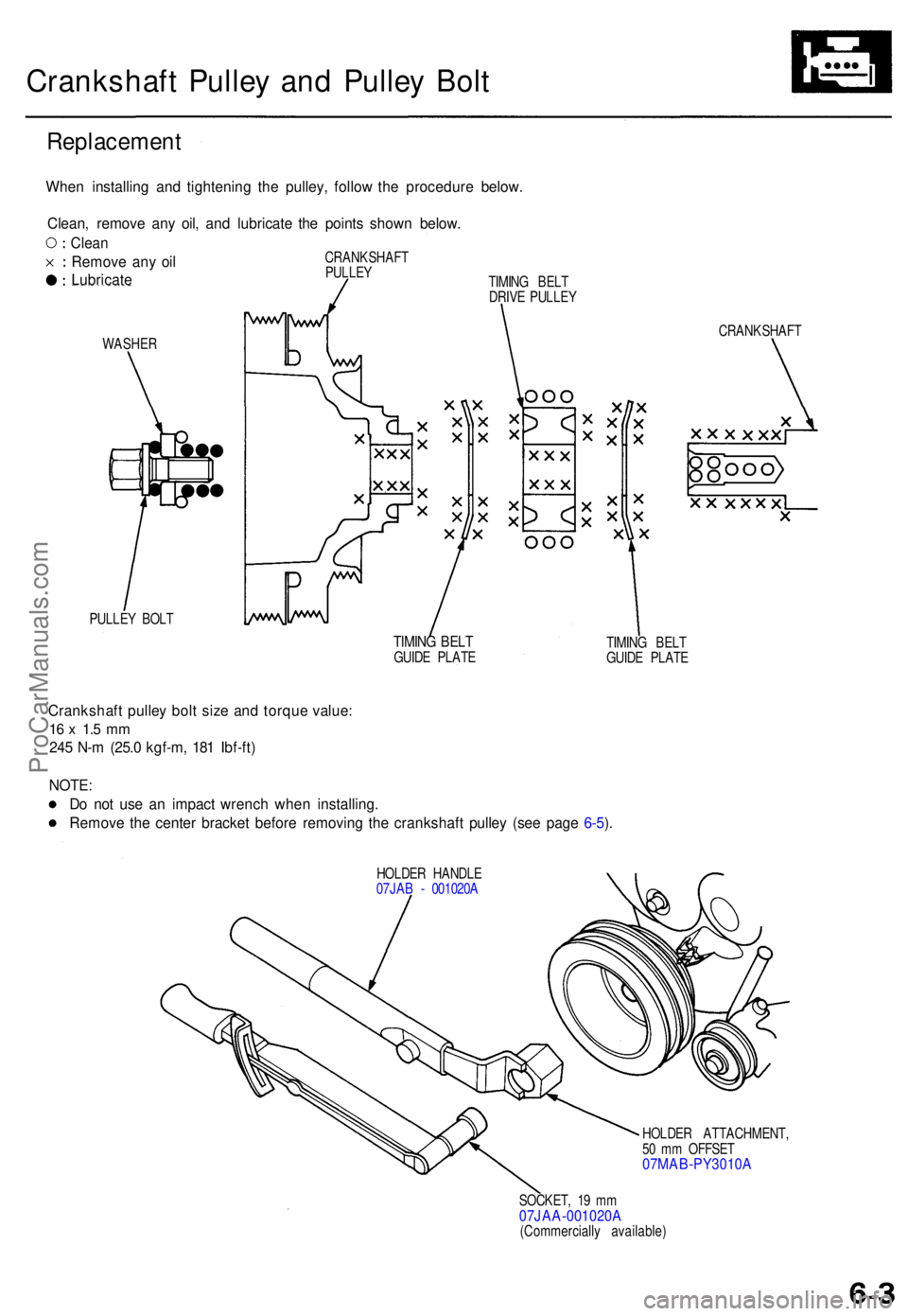

Crankshaft Pulle y an d Pulle y Bol t

Replacemen t

WASHER

PULLE Y BOL T CRANKSHAF

T

TIMING BEL TGUID E PLAT E TIMIN

G BEL T

GUID E PLAT E

Crankshaf t pulle y bol t siz e an d torqu e value :

16 x 1. 5 m m

245 N- m (25. 0 kgf-m , 18 1 Ibf-ft )

NOTE :

D o no t us e a n impac t wrenc h whe n installing .

Remov e th e cente r bracke t befor e removin g th e crankshaf t pulle y (se e pag e 6-5 ).

HOLDE R HANDL E

07JA B - 001020 A

HOLDER ATTACHMENT ,

5 0 m m OFFSE T

07MAB-PY3010 A

SOCKET, 1 9 m m07JAA-001020 A(Commercially available )

When installin g an d tightenin g th e pulley , follo w th e procedur e below .

Clean , remov e an y oil , an d lubricat e th e point s show n below .

TIMING BEL T

DRIV E PULLE Y

CRANKSHAF

T

PULLE Y

Clean

Remov e an y oi l

Lubricat e

ProCarManuals.com

Page 64 of 1771

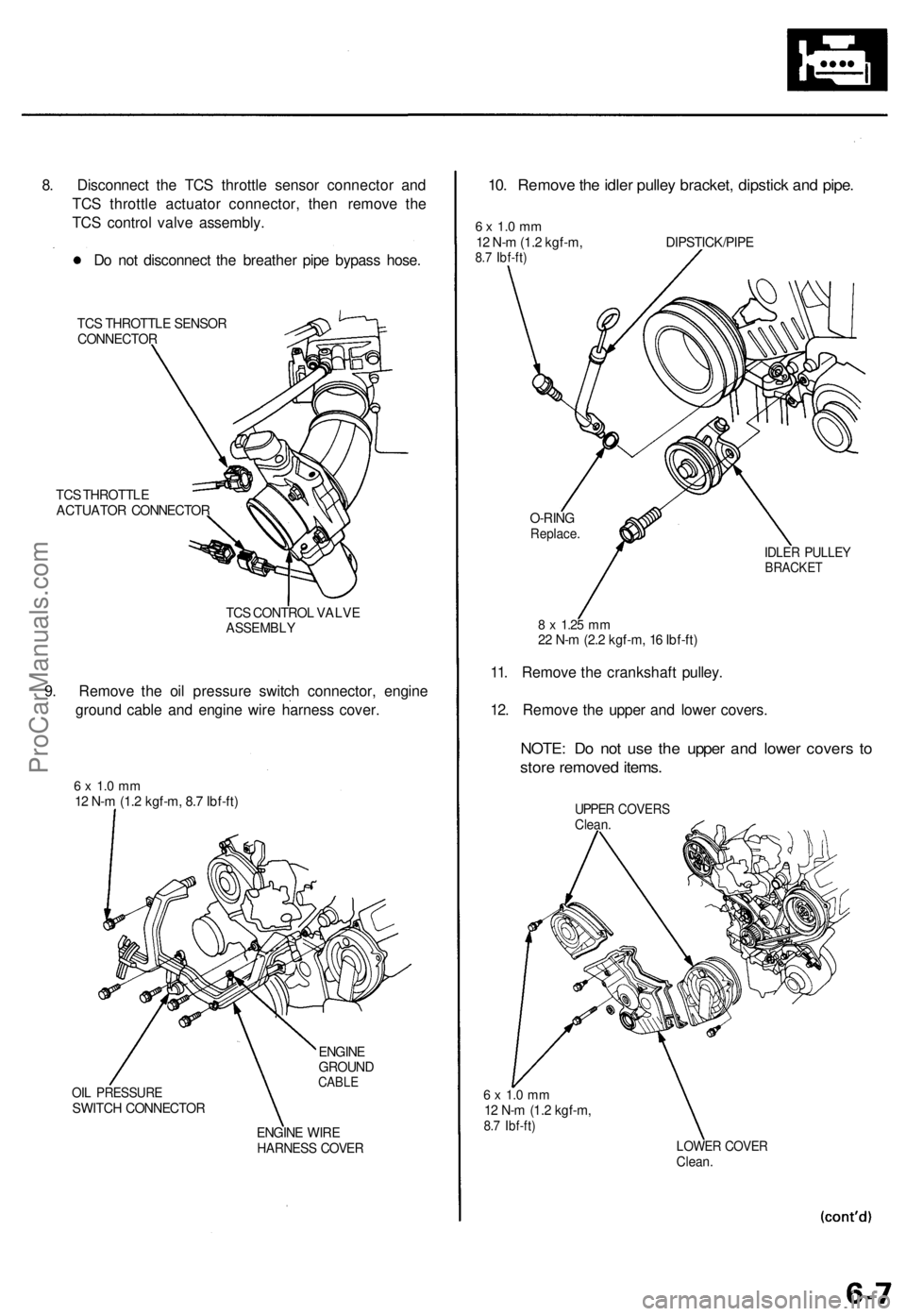

8. Disconnect the TCS throttle sensor connector and

TCS throttle actuator connector, then remove the

TCS control valve assembly.

Do not disconnect the breather pipe bypass hose.

TCS THROTTLE SENSOR

CONNECTOR

TCS THROTTLE

ACTUATOR CONNECTOR

TCS CONTROL VALVE

ASSEMBLY

9. Remove the oil pressure switch connector, engine

ground cable and engine wire harness cover.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

OIL PRESSURE

SWITCH CONNECTOR

ENGINE

GROUND

CABLE

ENGINE WIRE

HARNESS COVER

10. Remove the idler pulley bracket, dipstick and pipe.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

DIPSTICK/PIPE

8 x

1.25

mm

22 N-m (2.2 kgf-m, 16 Ibf-ft)

11. Remove the crankshaft pulley.

12. Remove the upper and lower covers.

NOTE: Do not use the upper and lower covers to

store removed items.

UPPER COVERS

Clean.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

LOWER COVER

Clean.

IDLER PULLEY

BRACKET

O-RING

Replace.ProCarManuals.com

Page 71 of 1771

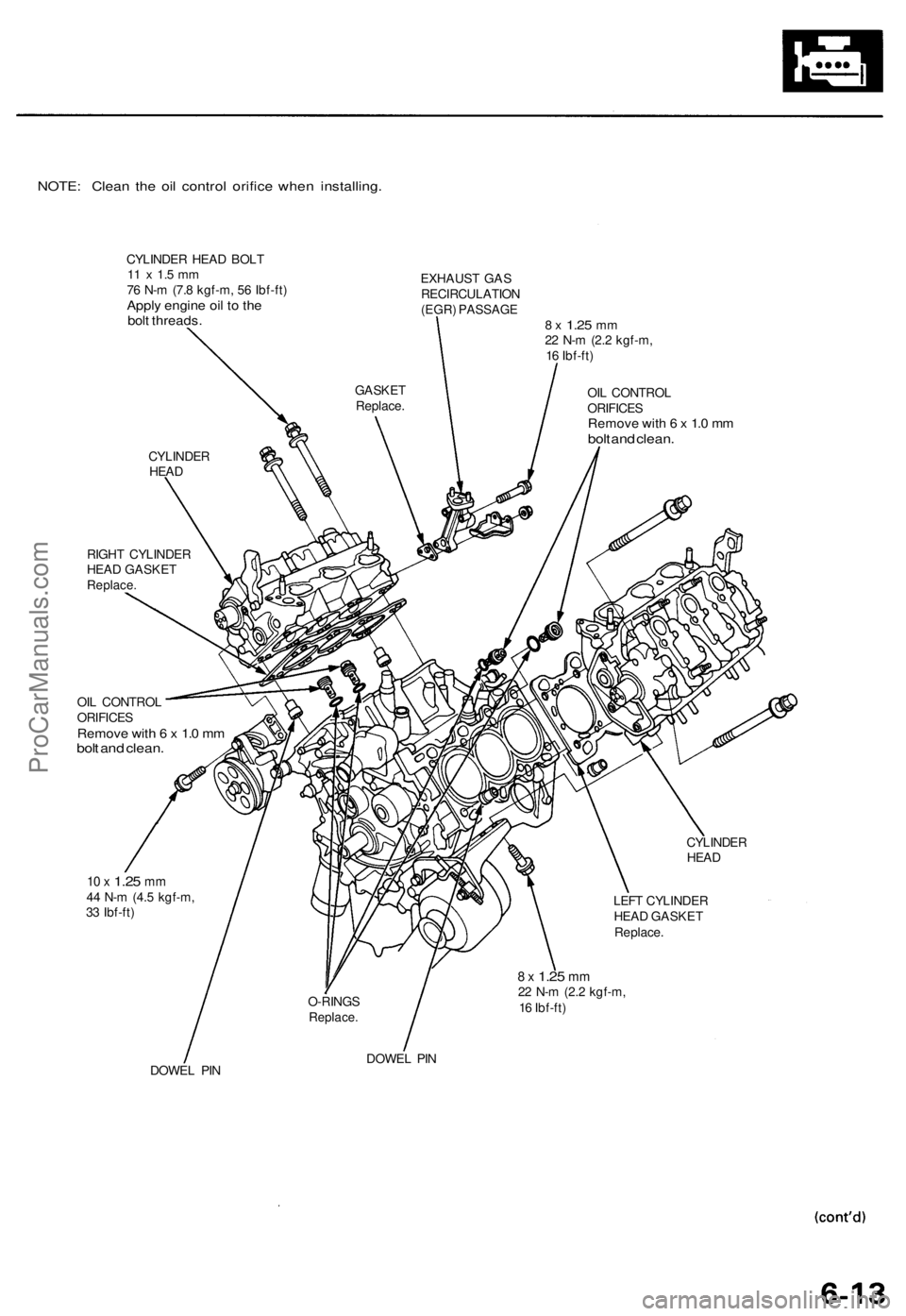

NOTE: Clean the oil control orifice when installing.

CYLINDER HEAD BOLT

11 x 1.5 mm

76 N-m (7.8 kgf-m, 56 Ibf-ft)

Apply engine oil to the

bolt threads.

EXHAUST GAS

RECIRCULATION

(EGR) PASSAGE

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

OIL CONTROL

ORIFICES

Remove with 6 x 1.0 mm

bolt and clean.

RIGHT CYLINDER

HEAD GASKET

Replace.

OIL CONTROL

ORIFICES

Remove with 6 x 1.0 mm

bolt and clean.

CYLINDER

HEAD

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

LEFT CYLINDER

HEAD GASKET

Replace.

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

DOWEL PIN

DOWEL PIN

O-RINGS

Replace.

GASKET

Replace.

CYLINDER

HEADProCarManuals.com

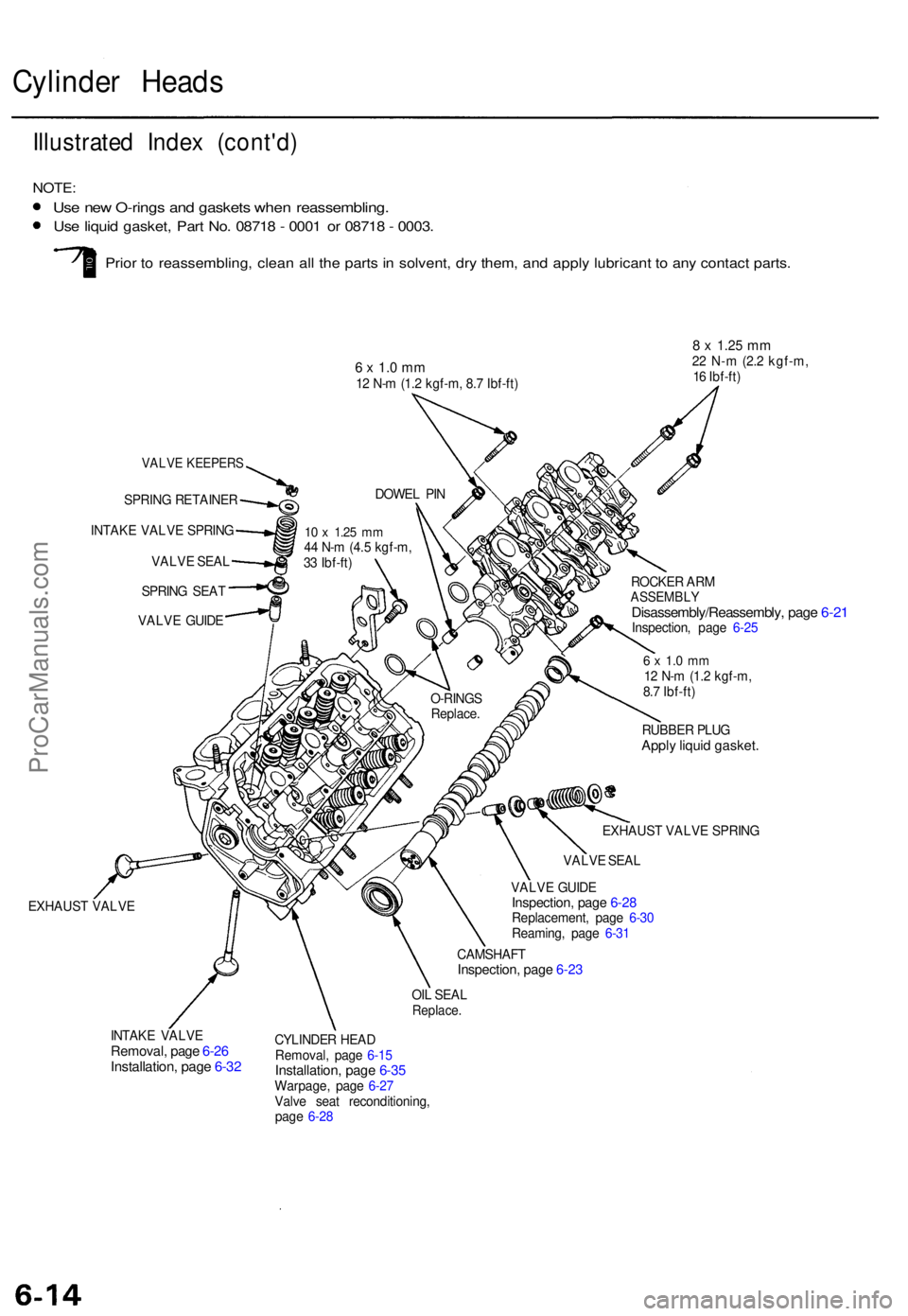

Page 72 of 1771

Cylinder Head s

Illustrate d Inde x (cont'd )

NOTE:

Use ne w O-ring s an d gasket s whe n reassembling .

Use liqui d gasket , Par t No . 0871 8 - 000 1 o r 0871 8 - 0003 .

Prior t o reassembling , clea n al l th e part s in solvent , dr y them , an d appl y lubrican t t o an y contac t parts .

6 x 1.0 mm12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

VALV E KEEPER S

SPRING RETAINE R

INTAK E VALV E SPRIN G

VALV E SEA L

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

SPRIN G SEA T

VALV E GUID E

EXHAUS T VALV E ROCKE

R AR M

ASSEMBL YDisassembly/Reassembly , pag e 6-2 1Inspection , pag e 6-2 5

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

RUBBE R PLU G

Apply liqui d gasket .

VALVE GUID EInspection , pag e 6-2 8Replacement , pag e 6-3 0

Reaming , pag e 6-3 1

CAMSHAF T

Inspection, pag e 6-2 3

OIL SEA LReplace .

INTAKE VALV ERemoval , pag e 6-2 6Installation , pag e 6-3 2

CYLINDE R HEA D

Removal , pag e 6-1 5

Installation , pag e 6-3 5Warpage , pag e 6-2 7

Valv e sea t reconditioning ,

pag e 6-2 8 VALV

E SEA L

EXHAUS

T VALV E SPRIN G

O-RING

S

Replace .

DOWE

L PI N

ProCarManuals.com

Page 75 of 1771

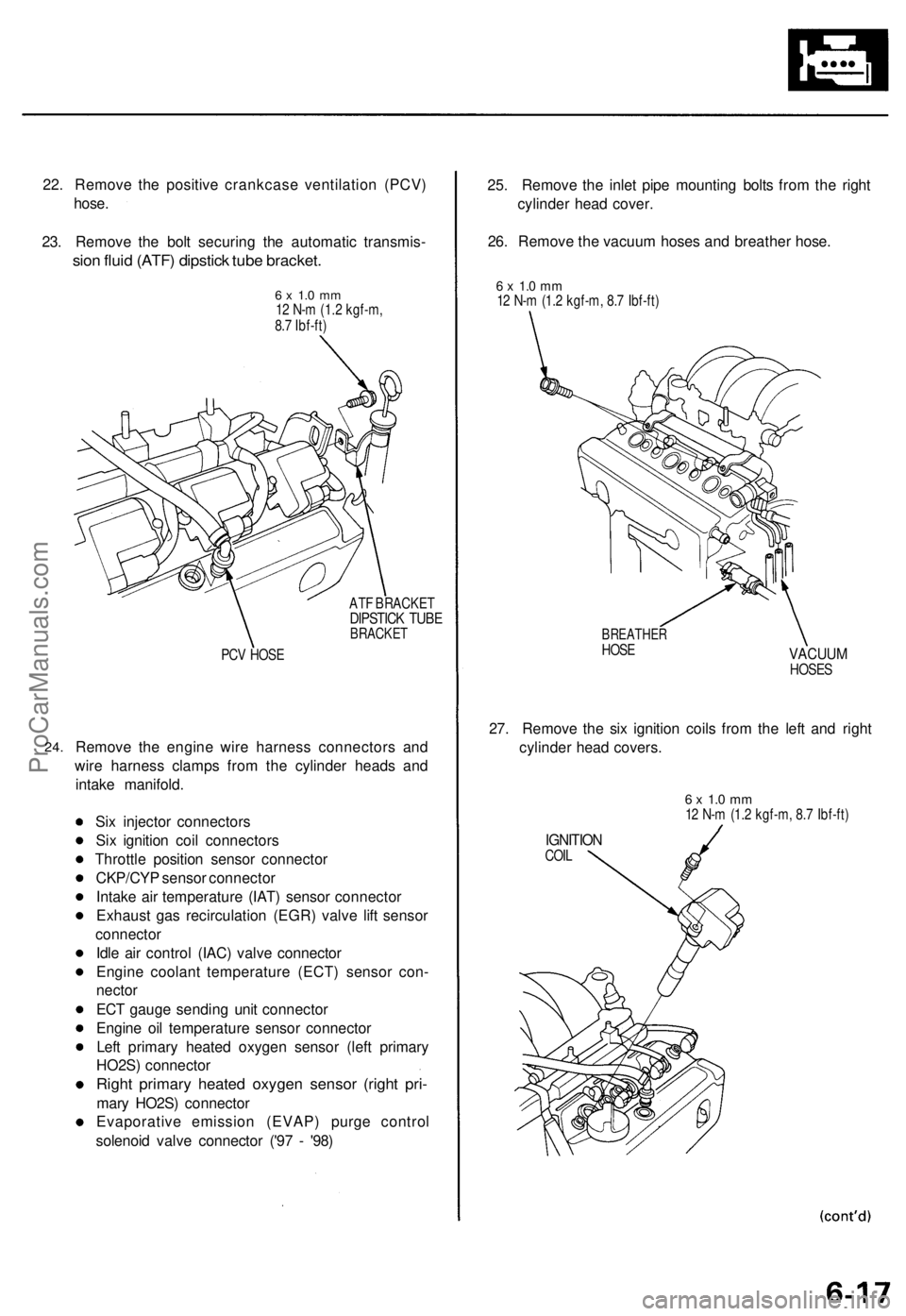

22. Remove the positive crankcase ventilation (PCV)

hose.

23. Remove the bolt securing the automatic transmis-

sion fluid (ATF) dipstick tube bracket.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

ATF BRACKET

DIPSTICK TUBE

BRACKET

PCV HOSE

24.

Remove the engine wire harness connectors and

wire harness clamps from the cylinder heads and

intake manifold.

Six injector connectors

Six ignition coil connectors

Throttle position sensor connector

CKP/CYP sensor connector

Intake air temperature (IAT) sensor connector

Exhaust gas recirculation (EGR) valve lift sensor

connector

Idle air control (IAC) valve connector

Engine coolant temperature (ECT) sensor con-

nector

ECT gauge sending unit connector

Engine oil temperature sensor connector

Left primary heated oxygen sensor (left primary

HO2S) connector

Right primary heated oxygen sensor (right pri-

mary HO2S) connector

Evaporative emission (EVAP) purge control

solenoid valve connector ('97 - '98)

25. Remove the inlet pipe mounting bolts from the right

cylinder head cover.

26. Remove the vacuum hoses and breather hose.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

BREATHER

HOSE

VACUUM

HOSES

27. Remove the six ignition coils from the left and right

cylinder head covers.

6 x 1.0 mm

12 N-m (1.2 kgf-m, 8.7 Ibf-ft)

IGNITION

COILProCarManuals.com

Page 83 of 1771

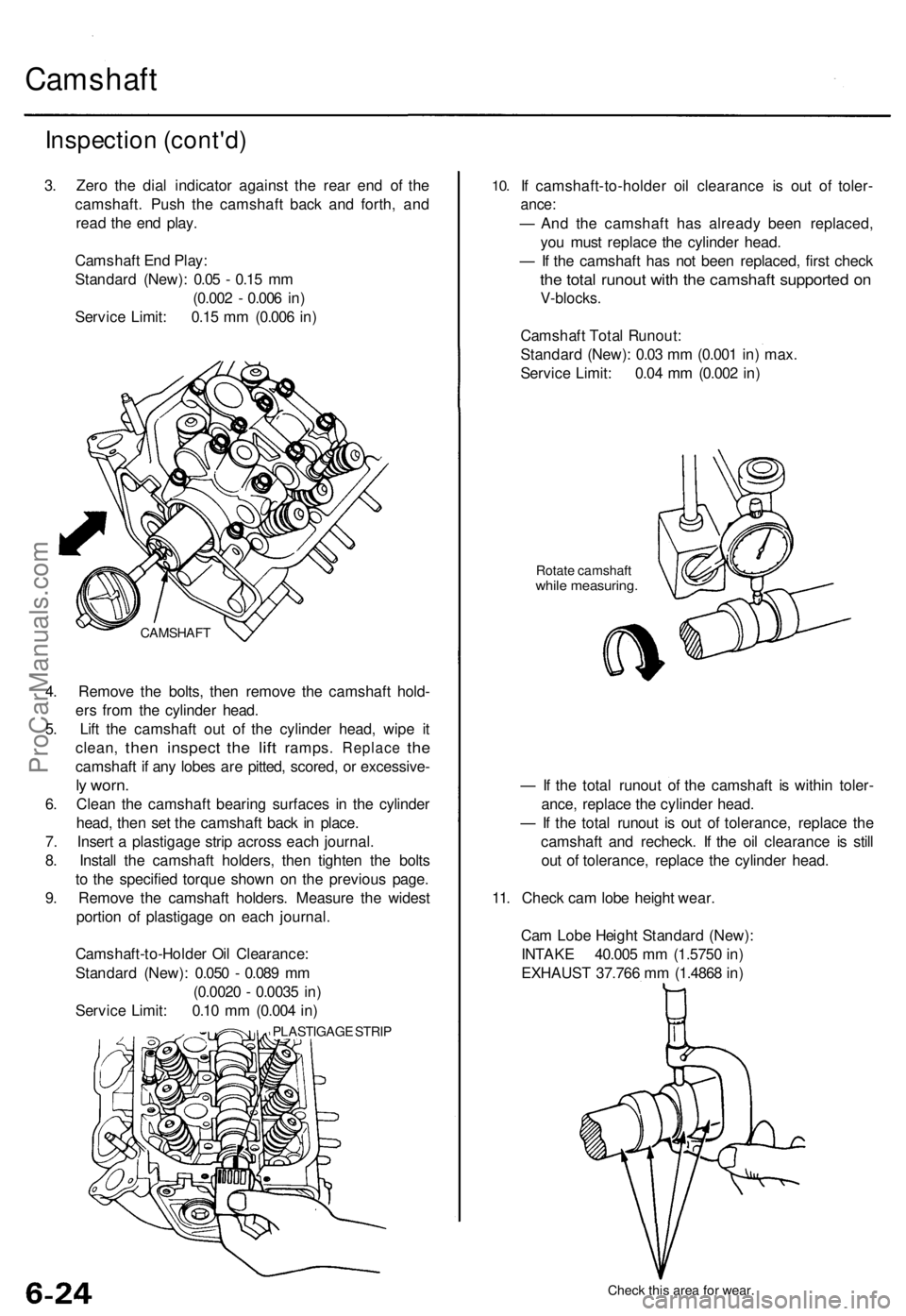

Camshaft

Inspection (cont'd)

3. Zero the dial indicator against the rear end of the

camshaft. Push the camshaft back and forth, and

read the end play.

Camshaft End Play:

Standard (New): 0.05 - 0.15 mm

(0.002 - 0.006 in)

Service Limit: 0.15 mm (0.006 in)

4. Remove the bolts, then remove the camshaft hold-

ers from the cylinder head.

5. Lift the camshaft out of the cylinder head, wipe it

clean,

then

inspect

the

lift

ramps.

Replace

the

camshaft if any lobes are pitted, scored, or excessive-

ly worn.

6. Clean the camshaft bearing surfaces in the cylinder

head, then set the camshaft back in place.

7. Insert a plastigage strip across each journal.

8. Install the camshaft holders, then tighten the bolts

to the specified torque shown on the previous page.

9. Remove the camshaft holders. Measure the widest

portion of plastigage on each journal.

Camshaft-to-Holder Oil Clearance:

Standard (New): 0.050 - 0.089 mm

(0.0020 - 0.0035 in)

Service Limit: 0.10 mm (0.004 in)

PLASTIGAGE STRIP

10.

If camshaft-to-holder oil clearance is out of toler-

ance:

— And the camshaft has already been replaced,

you must replace the cylinder head.

— If the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Camshaft Total Runout:

Standard (New): 0.03 mm (0.001 in) max.

Service Limit: 0.04 mm (0.002 in)

Rotate camshaft

while measuring.

— If the total runout of the camshaft is within toler-

ance, replace the cylinder head.

— If the total runout is out of tolerance, replace the

camshaft and recheck. If the oil clearance is still

out of tolerance, replace the cylinder head.

11. Check cam lobe height wear.

Cam Lobe Height Standard (New):

INTAKE 40.005 mm (1.5750 in)

EXHAUST 37.766 mm (1.4868 in)

Check this area for wear.

CAMSHAFTProCarManuals.com

Page 92 of 1771

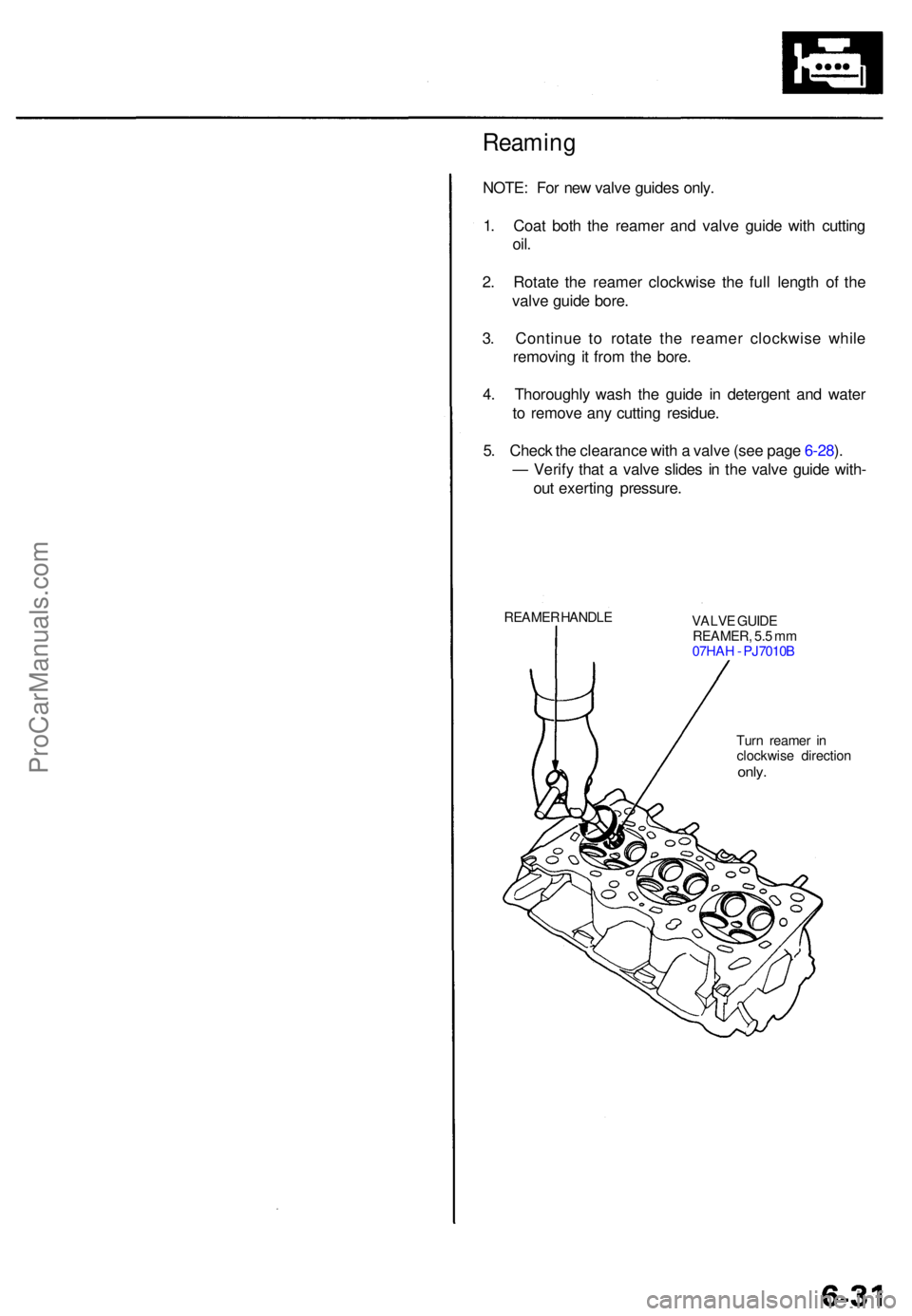

Reaming

NOTE: Fo r ne w valv e guide s only .

1 . Coa t bot h th e reame r an d valv e guid e wit h cuttin g

oil.

2. Rotat e th e reame r clockwis e th e ful l lengt h o f th e

valv e guid e bore .

3 . Continu e t o rotat e th e reame r clockwis e whil e

removin g i t fro m th e bore .

4 . Thoroughl y was h th e guid e i n detergen t an d wate r

t o remov e an y cuttin g residue .

5 . Chec k th e clearanc e wit h a valv e (se e pag e 6-28 ).

— Verif y tha t a valv e slide s i n th e valv e guid e with -

ou t exertin g pressure .

REAMER HANDL E

VALVE GUID E

REAMER , 5. 5 m m

07HA H - PJ7010 B

Tur n reame r i n

clockwis e directio n

only.

ProCarManuals.com

Page 93 of 1771

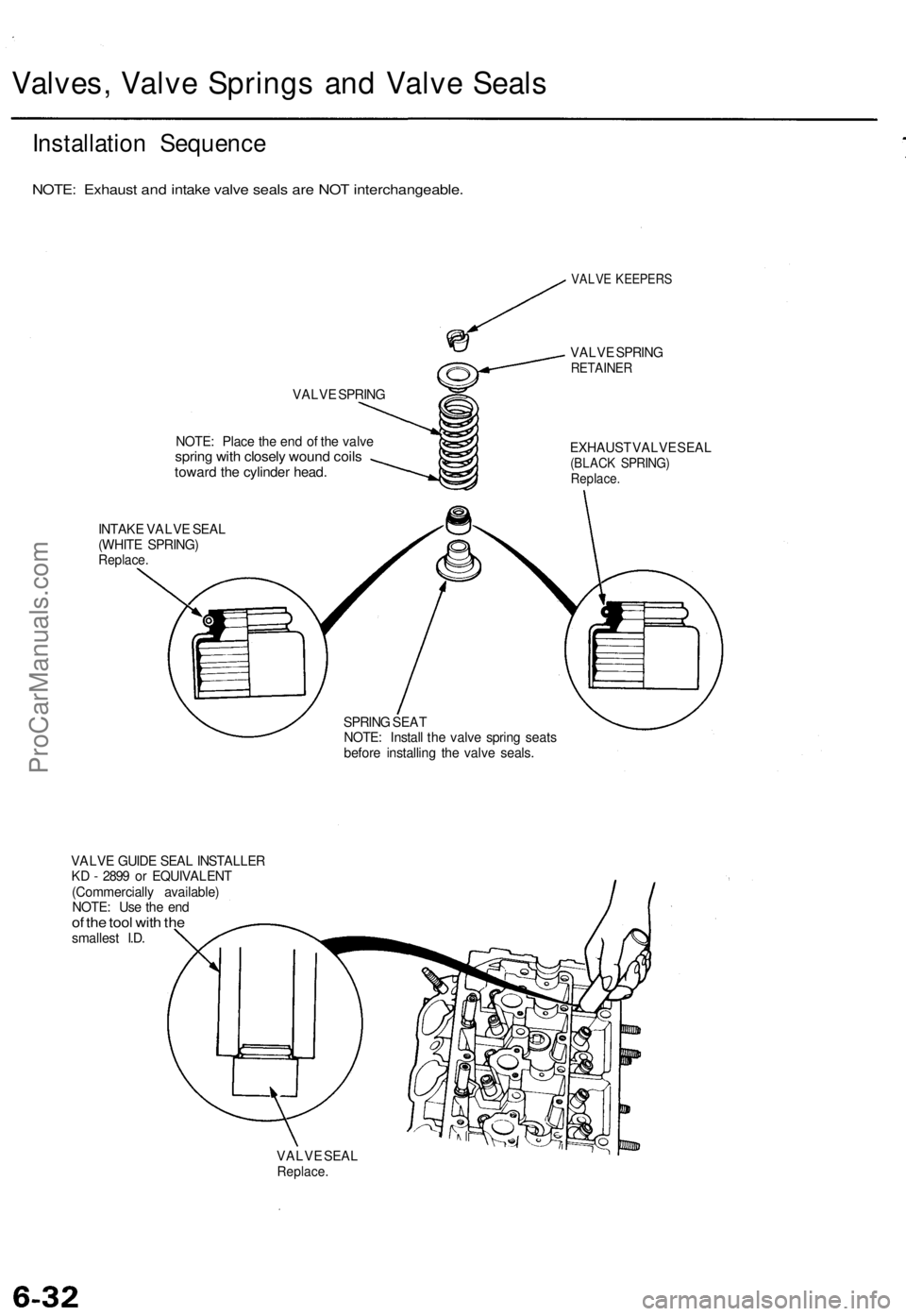

Valves, Valve Springs and Valve Seals

Installation Sequence

NOTE: Exhaust and intake valve seals are NOT interchangeable.

VALVE SPRING

NOTE: Place the end of the valve

spring with closely wound coils

toward the cylinder head.

INTAKE VALVE SEAL

(WHITE SPRING)

Replace.

VALVE KEEPERS

VALVE SPRING

RETAINER

EXHAUST VALVE SEAL

(BLACK SPRING)

Replace.

SPRING SEAT

NOTE: Install the valve spring seats

before installing the valve seals.

VALVE GUIDE SEAL INSTALLER

KD - 2899 or EQUIVALENT

(Commercially available)

NOTE: Use the end

of the tool with the

smallest I.D.

VALVE SEAL

Replace.ProCarManuals.com