differential ACURA TL 1995 Service Owner's Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1108 of 1771

Differential Assembl y

Reassembl y

NOTE:

• I f replacemen t i s required , alway s replac e th e driv e

pinio n an d rin g gea r a s a set .

• I f th e driv e pinio n an d rin g gea r ar e replaced , chec k

th e heigh t adjustmen t (se e pag e 15-25 ).

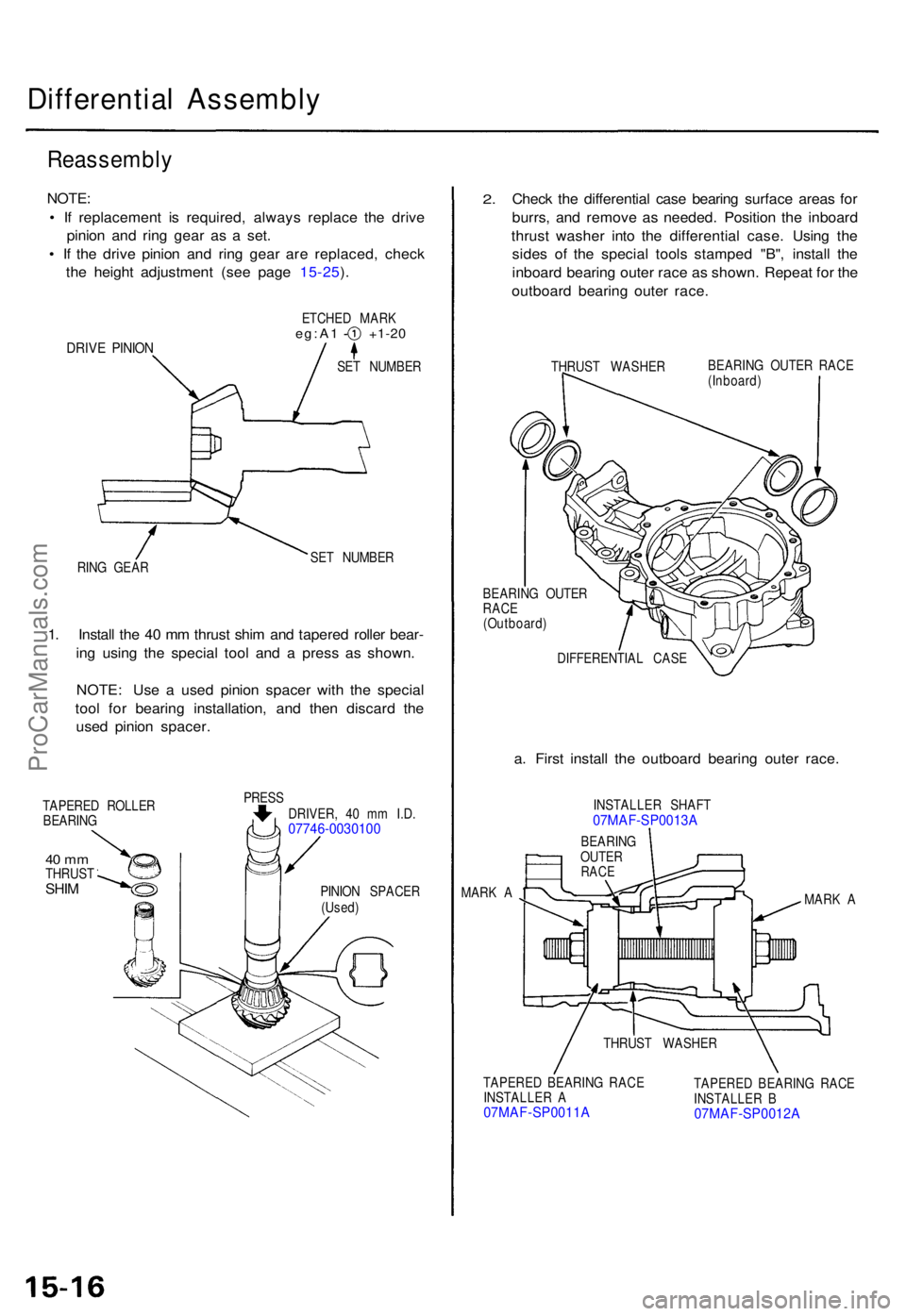

DRIV E PINIO N

ETCHE D MAR Keg:A1 +1-2 0

SET NUMBE R

RIN G GEA R SE

T NUMBE R

1. Instal l th e 4 0 m m thrus t shi m an d tapere d rolle r bear -

in g usin g th e specia l too l an d a pres s a s shown .

NOTE : Us e a use d pinio n space r wit h th e specia l

too l fo r bearin g installation , an d the n discar d th e

use d pinio n spacer .

TAPERE D ROLLE R

BEARIN G

40 m mTHRUS TSHIM

PRES S

DRIVER , 4 0 m m I.D .

07746-0030100

PINIO N SPACE R

(Used )

2.Chec k th e differentia l cas e bearin g surfac e area s fo r

burrs , an d remov e a s needed . Positio n th e inboar d

thrus t washe r int o th e differentia l case . Usin g th e

side s o f th e specia l tool s stampe d "B" , instal l th e

inboar d bearin g oute r rac e a s shown . Repea t fo r th e

outboar d bearin g oute r race .

THRUS T WASHER BEARIN

G OUTE R RAC E

(Inboard )

BEARIN G OUTE R

RAC E

(Outboard )

DIFFERENTIA L CAS E

a. Firs t instal l th e outboar d bearin g oute r race .

INSTALLE R SHAF T07MAF-SP0013A

MARK A

MARK A

TAPERE D BEARIN G RAC E

INSTALLE R A

07MAF-SP0011A

TAPERE D BEARIN G RAC E

INSTALLE R B

07MAF-SP0012A

THRUS T WASHE R

BEARIN

G

OUTE R

RACE

ProCarManuals.com

Page 1110 of 1771

Differential Assembl y

Reassembl y (cont'd )

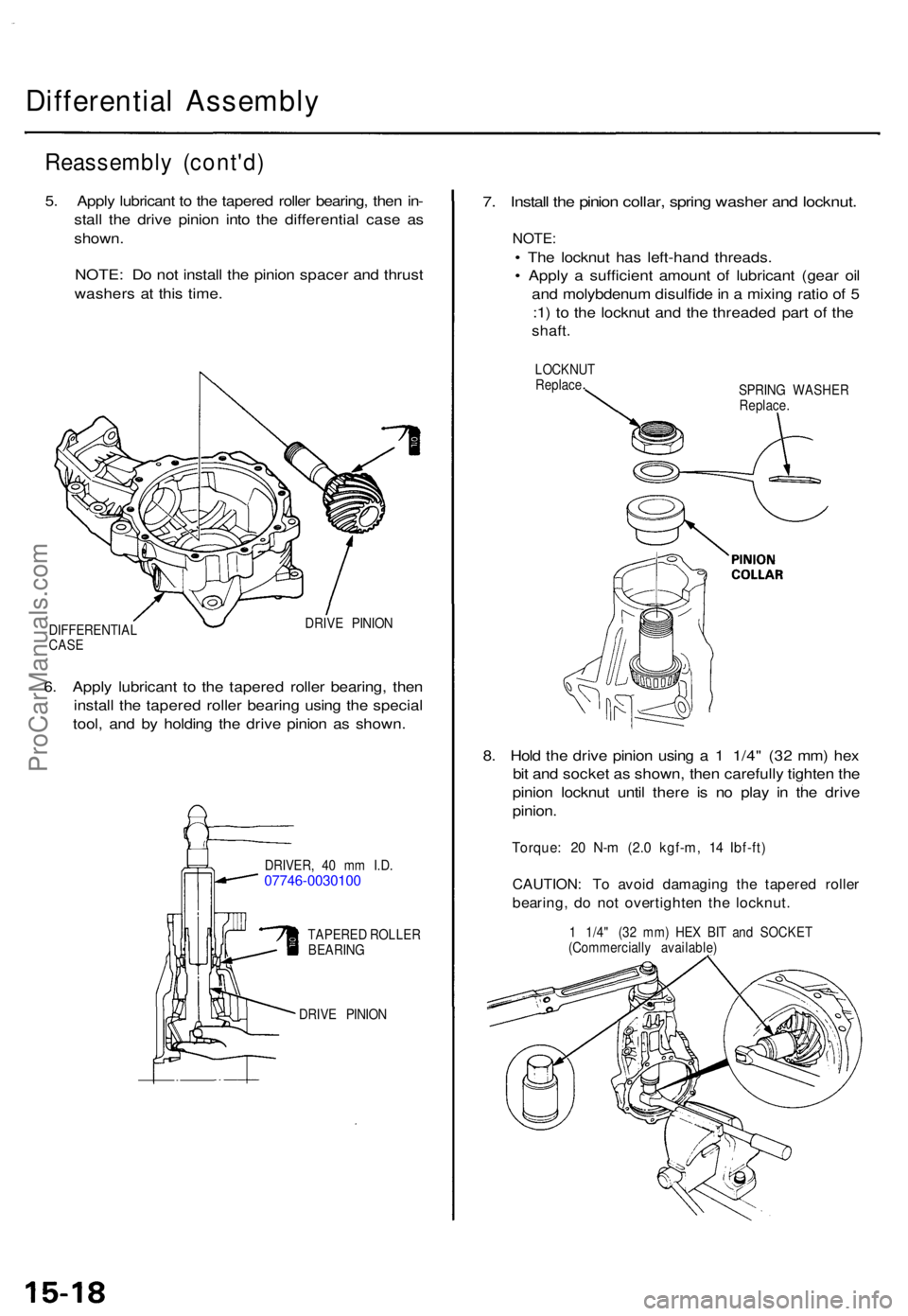

5. Appl y lubrican t t o th e tapere d rolle r bearing , the n in -

stal l th e driv e pinio n int o th e differentia l cas e a s

shown .

NOTE : D o no t instal l th e pinio n space r an d thrus t

washer s a t thi s time .

DIFFERENTIA L

CAS E DRIV

E PINIO N

6. Appl y lubrican t t o th e tapere d rolle r bearing , the n

instal l th e tapere d rolle r bearin g usin g th e specia l

tool , an d b y holdin g th e driv e pinio n a s shown .

DRIVER , 4 0 m m I.D .07746-0030100

TAPERE D ROLLE R

BEARIN G

DRIV E PINIO N

7. Instal l th e pinio n collar , sprin g washe r an d locknut .

NOTE:

• Th e locknu t ha s left-han d threads .

• Appl y a sufficien t amoun t o f lubrican t (gea r oi l

an d molybdenu m disulfid e in a mixin g rati o o f 5

: 1 ) t o th e locknu t an d th e threade d par t o f th e

shaft .

LOCKNU T

Replac e

SPRING WASHE R

Replace .

8. Hol d th e driv e pinio n usin g a 1 1/4 " (3 2 mm ) he x

bi t an d socke t a s shown , the n carefull y tighte n th e

pinio n locknu t unti l ther e i s n o pla y i n th e driv e

pinion .

Torque : 2 0 N- m (2. 0 kgf-m , 1 4 Ibf-ft )

CAUTION : T o avoi d damagin g th e tapere d rolle r

bearing , d o no t overtighte n th e locknut .

1 1/4 " (3 2 mm ) HE X BI T an d SOCKE T

(Commerciall y available )

ProCarManuals.com

Page 1112 of 1771

Differential Assembl y

Reassembl y (cont'd )

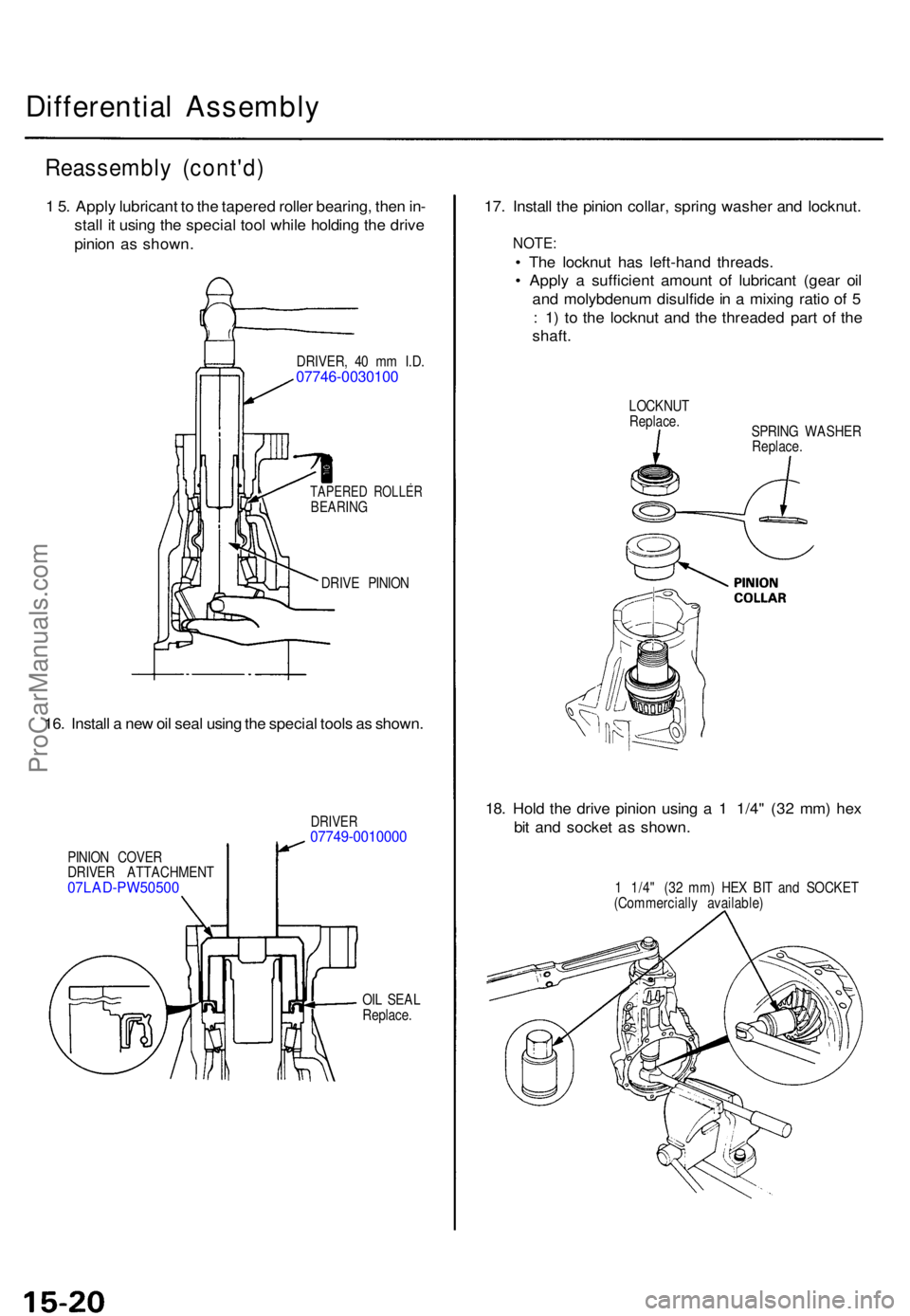

1 5 . Appl y lubrican t t o th e tapere d rolle r bearing , the n in -

stal l i t usin g th e specia l too l whil e holdin g th e driv e

pinio n a s shown .

DRIVER , 4 0 m m I.D .07746-0030100

TAPERE D ROLLE RBEARING

DRIVE PINIO N

16. Instal l a ne w oi l sea l usin g th e specia l tool s a s shown .

PINION COVE R

DRIVE R ATTACHMEN T

07LAD-PW50500

DRIVER07749-0010000

OIL SEA L

Replace .

17. Instal l th e pinio n collar , sprin g washe r an d locknut .

NOTE:

• Th e locknu t ha s left-han d threads .

• Appl y a sufficien t amoun t o f lubrican t (gea r oi l

an d molybdenu m disulfid e in a mixin g rati o o f 5

: 1 ) t o th e locknu t an d th e threade d par t o f th e

shaft .

LOCKNU T

Replace .

SPRING WASHE R

Replace .

18. Hol d th e driv e pinio n usin g a 1 1/4 " (3 2 mm ) he x

bi t an d socke t a s shown.

1 1/4 " (3 2 mm ) HE X BI T an d SOCKE T

(Commerciall y available )

ProCarManuals.com

Page 1114 of 1771

Differential Assembl y

Reassembl y (cont'd )

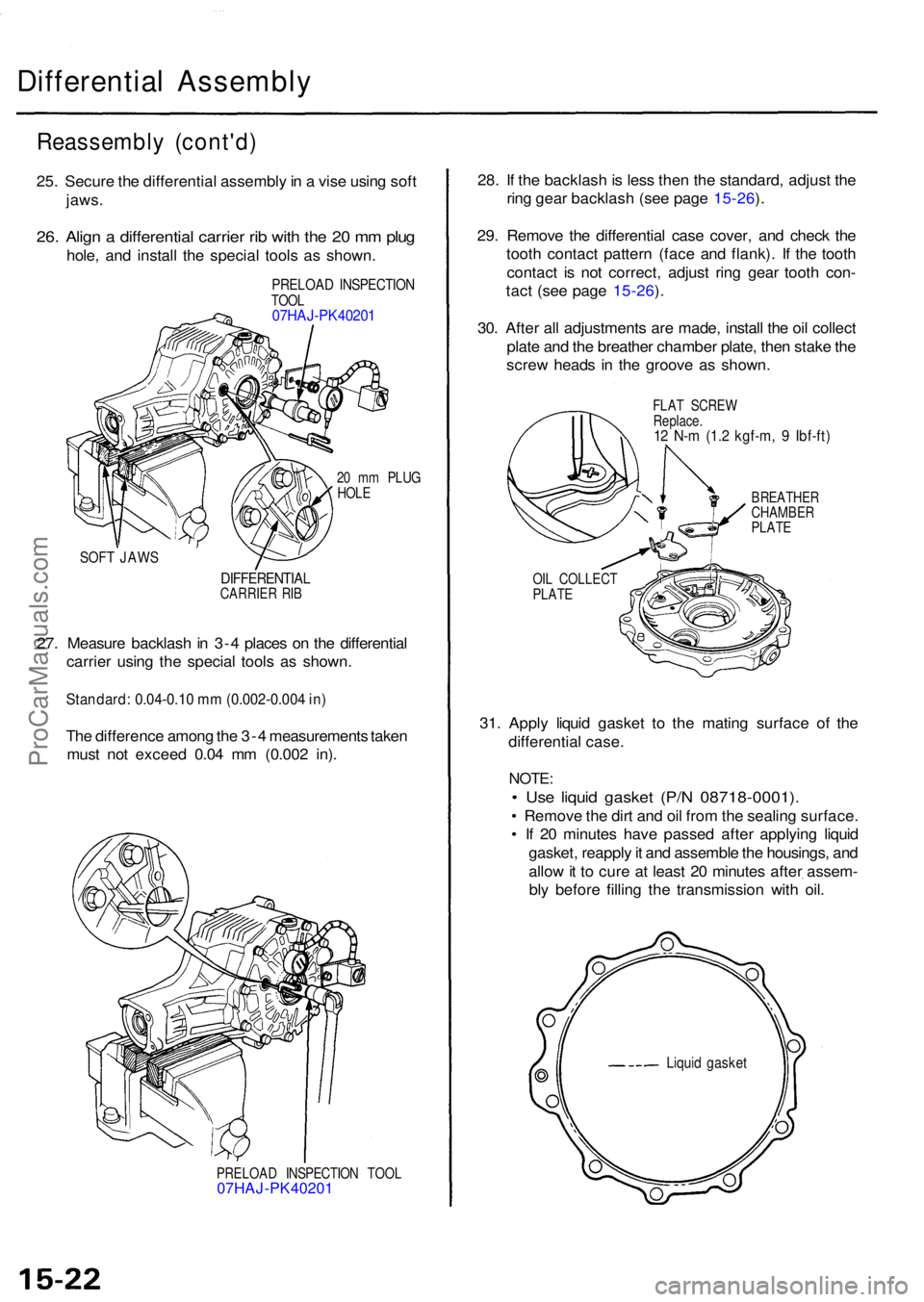

25. Secur e th e differentia l assembl y in a vis e usin g sof t

jaws .

26. Alig n a differentia l carrie r ri b wit h th e 2 0 m m plu g

hole , an d instal l th e specia l tool s a s shown .

PRELOA D INSPECTIO NTOOL07HAJ-PK40201

20 m m PLU G

HOL E

SOF T JAW S

DIFFERENTIA LCARRIER RI B

27. Measur e backlas h in 3- 4 place s o n th e differentia l

carrie r usin g th e specia l tool s a s shown .

Standard: 0.04-0.10 mm (0.002-0.004 in)

The differenc e amon g th e 3- 4 measurement s take n

mus t no t excee d 0.0 4 m m (0.00 2 in) .

PRELOA D INSPECTIO N TOO L07HAJ-PK4020 1

28. I f th e backlas h is les s the n th e standard , adjus t th e

rin g gea r backlas h (se e pag e 15-26 ).

29 . Remov e th e differentia l cas e cover , an d chec k th e

toot h contac t patter n (fac e an d flank) . I f th e toot h

contac t i s no t correct , adjus t rin g gea r toot h con -

tac t (se e pag e 15-26 ).

30 . Afte r al l adjustment s ar e made , instal l th e oi l collec t

plat e an d th e breathe r chambe r plate , the n stak e th e

scre w head s i n th e groov e a s shown .

FLAT SCRE W

Replace .

12 N- m (1. 2 kgf-m , 9 Ibf-ft )

BREATHE RCHAMBER

PLAT E

OI L COLLEC T

PLAT E

31. Appl y liqui d gaske t t o th e matin g surfac e of the

differentia l case .

NOTE :

• Us e liqui d gaske t (P/ N 08718-0001) .

• Remov e th e dir t an d oi l fro m th e sealin g surface .

• I f 2 0 minute s hav e passe d afte r applyin g liqui d

gasket , reappl y it an d assembl e th e housings , an d

allo w it t o cur e a t leas t 2 0 minute s afte r assem -

bl y befor e fillin g th e transmissio n wit h oil .

Liqui d gaske t

ProCarManuals.com

Page 1116 of 1771

Differential Assembl y

Reassembl y (cont'd )

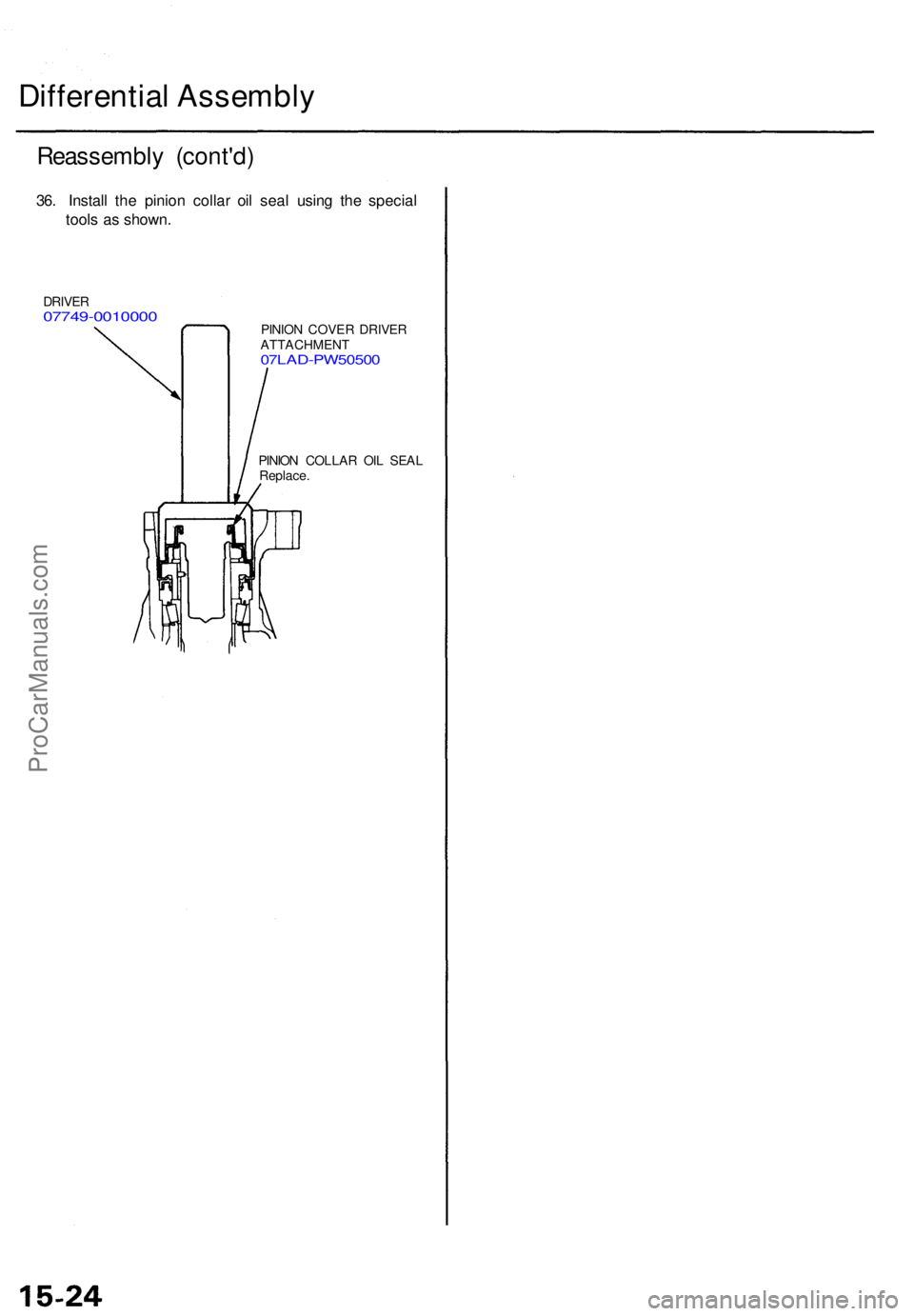

36. Instal l th e pinio n colla r oi l sea l usin g th e specia l

tool s a s shown .

DRIVER07749-001000 0PINION COVE R DRIVE R

ATTACHMEN T

07LAD-PW5050 0

PINION COLLA R OI L SEA L

Replace .

ProCarManuals.com

Page 1119 of 1771

Differential Assembl y

Installation

NOTE: I f th e differentia l case , torqu e converte r housing ,

cylinder bloc k an d oi l pa n ar e replaced , th e 2 6 m m shi m

mus t b e adjusted .

a. Instal l th e differentia l assembly .

b. Measur e th e clearanc e betwee n th e differentia l cas e

and th e torqu e converte r housing .

26 m m SHI M

c. Selec t th e 2 6 m m shi m fro m th e followin g table .

26 m m SHI M

A

B

C

D

E

F

G

H

1

J

K

L

Part Numbe r

41432-PY4-00 0

41433-PY4-00 0

41434-PY4-00 0

41435-PY4-00 0

41436-PY4-000

41437-PY4-00 0

41438-PY4-00 0

41439-PY4-000

41440-PY4-00 0

41441 -PY4-00 0

41442-PY4-00 0

41443-PY4-00 0

Thickness

1.9 m m (0.074 8 in )

2.0 m m (0.078 7 in )

2.1 m m (0.082 7 in )

2.2 m m (0.086 6 in )

2.3 m m (0.090 6 in )

2. 4 m m (0.094 5 in )

2.5 m m (0.098 4 in )

2.6 m m (0.102 4 in )

2.7 m m (0.106 3 in )

2.8 m m (0.110 2 in )

2.9 m m (0.114 2 in )

3.0 m m (0.118 1 in )

Measuremen tValue

1.99—1. 9 m m

2.09-2. 0 mm

2.19-2. 1 mm

2. 29-2 . 2 m m

2.39-2. 3 mm

2.49-2. 4 mm

2.59-2. 5 m m

2.69-2. 6 mm

2.79-2. 7 m m

2.8 9 — 2.8 m m

2.9 9 — 2.9 m m

3.0 9 — 3.0 m m

1. Fil l th e extensio n shaf t an d driv e pinio n wit h Supe r

High Tem p Urea Greas e (P/N 08798-9002).

If th e pinio n colla r oi l sea l i s replaced :

19-20 g (0.67-0.71 oz)

If th e pinio n colla r oi l sea l i s no t replaced :

3.5-4.5 g (0.12-0.1 6 oz )

Fill th e greas e in unti l i t i s flus h wit h extensio n

shaft.

PINIO N COLLA R OI L SEA L

EXTENSIO NSHAFT

DRIVE PINIO N

2. Instal l th e dowe l pin s an d th e differentia l assembly .

12 x 1.2 5 mm64 N- m (6. 5 kgf- m47 Ibf-ft )

DOWE LPINS

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,47 Ibf-ft )

DIFFERENTIA LASSEMBLY

ProCarManuals.com

Page 1120 of 1771

Differential Assembl y

Installation (cont'd )

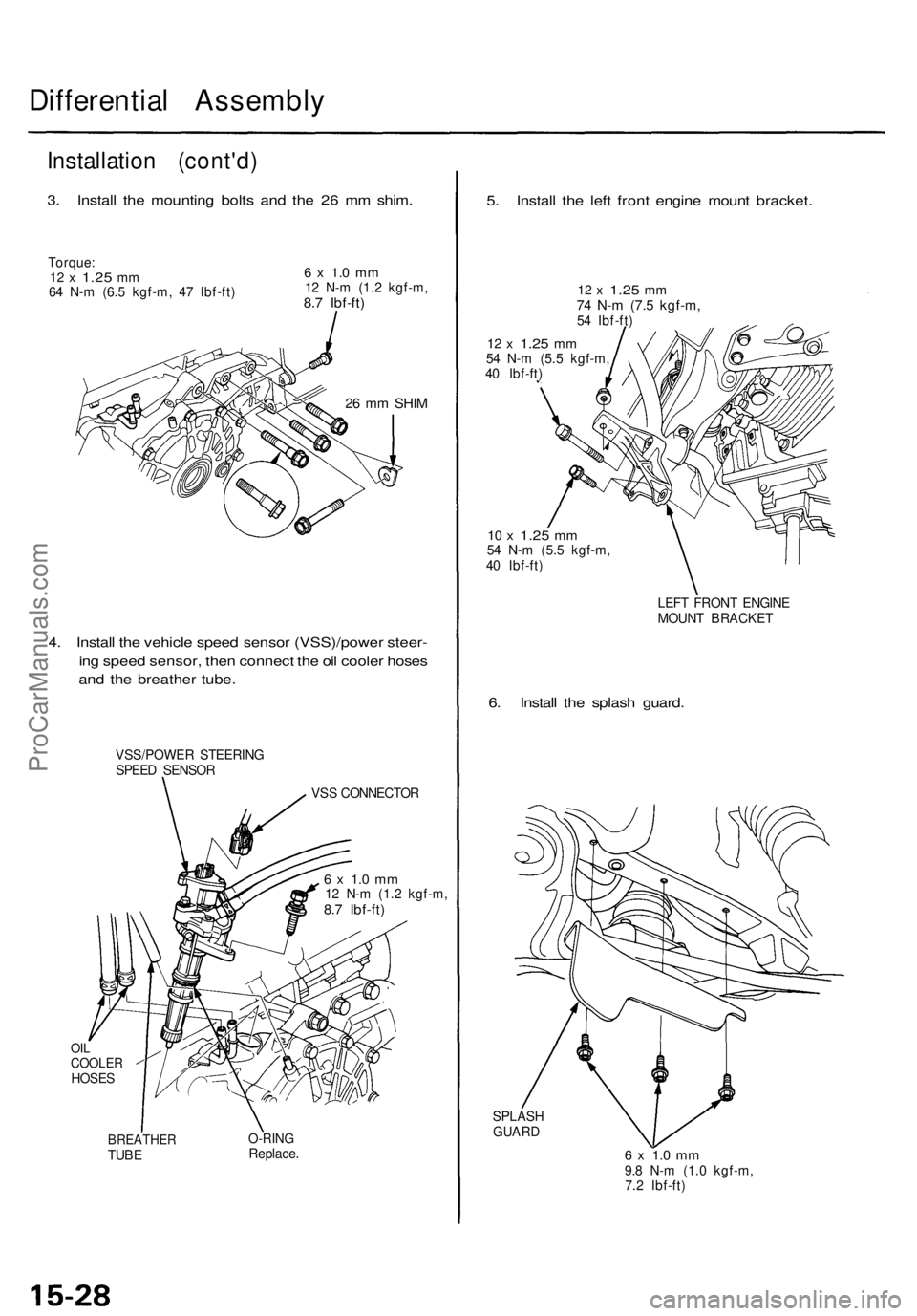

3. Instal l th e mountin g bolt s an d th e 2 6 m m shim .

Torque :12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

26 m m SHI M

4. Instal l th e vehicl e spee d senso r (VSS)/powe r steer -

in g spee d sensor , the n connec t th e oi l coole r hose s

an d th e breathe r tube .

VSS/POWE R STEERIN G

SPEE D SENSO R

VSS CONNECTO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

OILCOOLE RHOSES

BREATHE RTUBEO-RIN GReplace .

5. Instal l th e lef t fron t engin e moun t bracket .

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,54 Ibf-ft )

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

10 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

LEFT FRON T ENGIN E

MOUN T BRACKE T

6. Instal l th e splas h guard .

SPLAS HGUARD

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

ProCarManuals.com

Page 1124 of 1771

Driveshafts

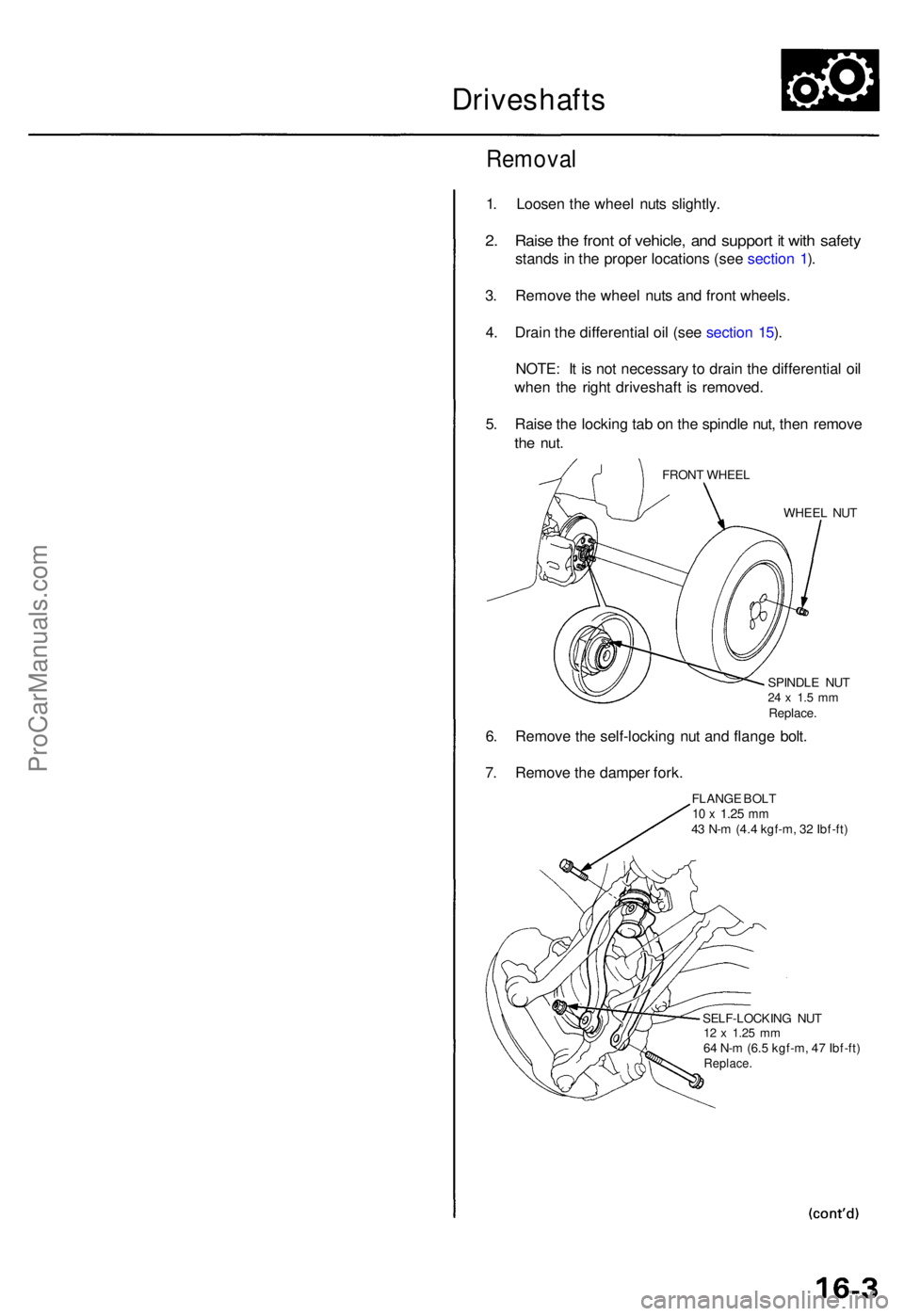

Removal

1. Loose n th e whee l nut s slightly .

2. Rais e th e fron t o f vehicle , an d suppor t i t wit h safet y

stand s in th e prope r location s (se e sectio n 1 ).

3 . Remov e th e whee l nut s an d fron t wheels .

4 . Drai n th e differential oil (se e sectio n 15 ).

NOTE : I t i s no t necessar y t o drai n th e differential oil

whe n th e righ t driveshaf t i s removed .

5 . Rais e th e lockin g ta b o n th e spindl e nut , the n remov e

the nut .

FRON T WHEE L

WHEEL NU T

SPINDL E NU T

24 x 1. 5 m mReplace .

6. Remov e th e self-lockin g nu t an d flang e bolt .

7 . Remov e th e dampe r fork .

FLANG E BOL T10 x 1.2 5 mm43 N- m (4. 4 kgf-m , 3 2 Ibf-ft )

SELF-LOCKIN G NU T

12 x 1.2 5 m m64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Replace .

ProCarManuals.com

Page 1125 of 1771

Driveshafts

Removal (cont'd )

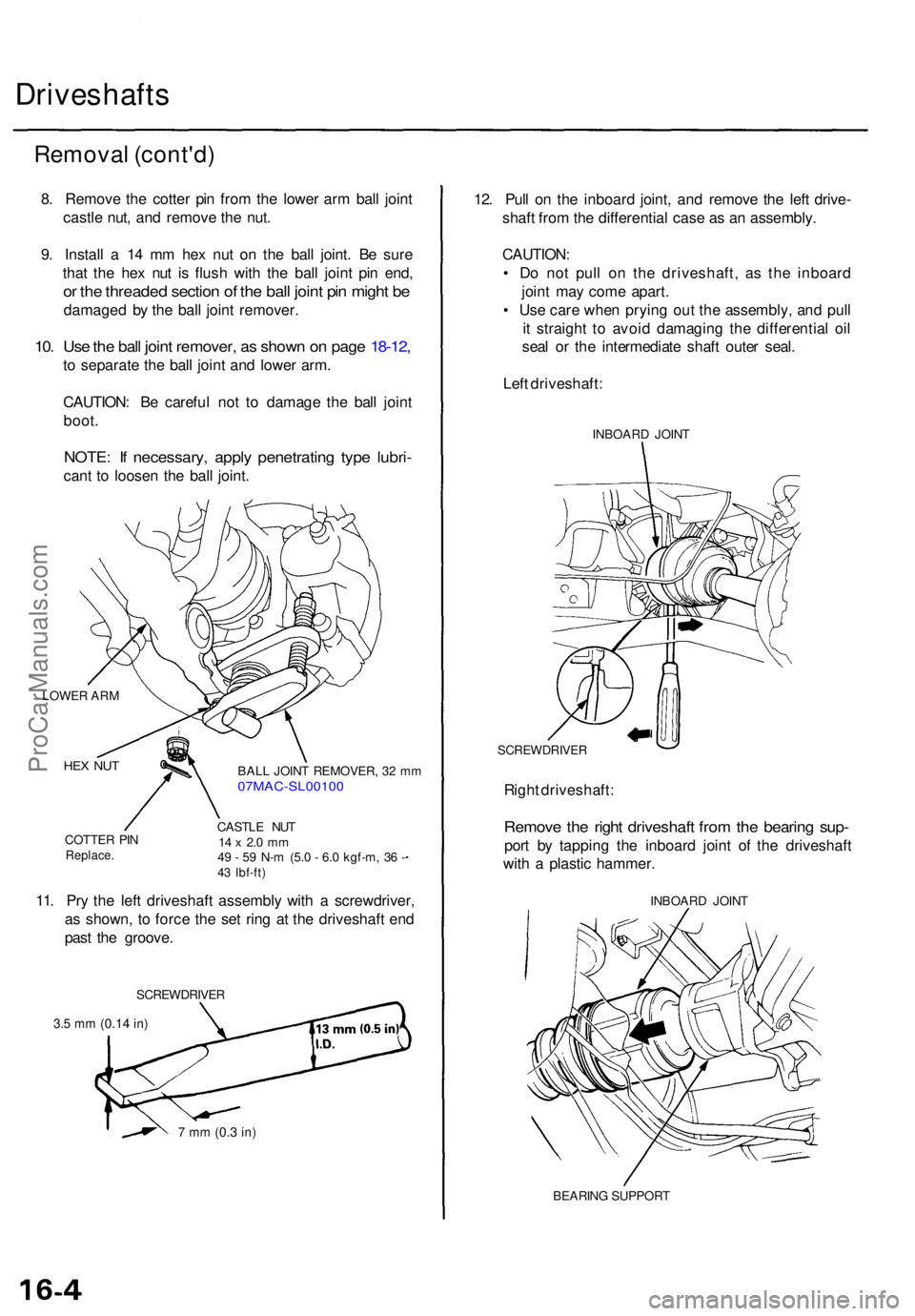

8. Remov e th e cotte r pi n fro m th e lowe r ar m bal l join t

castl e nut , an d remov e th e nut .

9 . Instal l a 1 4 m m he x nu t o n th e bal l joint . B e sur e

tha t th e he x nu t i s flus h wit h th e bal l join t pi n end ,

or th e threade d sectio n o f th e bal l join t pi n migh t b e

damage d b y th e bal l join t remover .

10. Us e th e bal l join t remover , a s show n o n pag e 18-12 ,

to separat e th e bal l join t an d lowe r arm .

CAUTION : B e carefu l no t t o damag e th e bal l join t

boot .

NOTE : I f necessary , appl y penetratin g typ e lubri -

cant t o loose n th e bal l joint .

LOWE R AR M

HEX NU T

COTTE R PI NReplace .

BALL JOIN T REMOVER , 3 2 m m07MAC-SL0010 0

CASTLE NU T14 x 2. 0 m m49 - 5 9 N- m (5. 0 - 6. 0 kgf-m , 3 6 -43 Ibf-ft )

11. Pr y th e lef t driveshaf t assembl y wit h a screwdriver ,

a s shown , t o forc e th e se t rin g a t th e driveshaf t en d

pas t th e groove .

SCREWDRIVE R

3.5 m m (0.1 4 in)

7 m m (0. 3 in)

12. Pul l o n th e inboar d joint , an d remov e th e lef t drive -

shaf t fro m th e differential case a s a n assembly .

CAUTION :

• D o no t pul l o n th e driveshaft , a s th e inboar d

join t ma y com e apart .

• Us e car e whe n pryin g ou t th e assembly , an d pul l

i t straigh t t o avoi d damagin g th e differentia l oi l

sea l o r th e intermediat e shaf t oute r seal .

Lef t driveshaft :

INBOARD JOIN T

SCREWDRIVE R

Right driveshaft :

Remove th e righ t driveshaf t fro m th e bearin g sup -

port b y tappin g th e inboar d join t o f th e driveshaf t

wit h a plasti c hammer .

INBOARD JOIN T

BEARIN G SUPPOR T

ProCarManuals.com

Page 1136 of 1771

4. Instal l th e inboar d en d o f th e driveshaf t int o th e dif -

ferentia l o r th e intermediat e shaft .

SET RIN GReplace .Make sur e th e lef t driveshaf t lock s in th e differen -

tia l sid e gea r groove , an d th e inboar d join t sub-axl e

bottom s i n th e differential .

Lef t Driveshaf t

SE T RIN G GROOV E SE

T RIN G

Replace .

Right Driveshaf t

Inser t th e righ t driveshaf t inboar d join t sub-axl e int o

the intermediat e shaf t unti l th e intermediat e shaf tset rin g lock s in th e groov e in th e righ t driveshaft .

5. Instal l th e knuckl e o n th e lowe r arm , the n tighte n

the castl e nu t an d instal l a ne w cotte r pin .

FLANG E BOL T10 x 1.2 5 mm43 N- m (4. 4 kgf-m , 3 2 Ibf-ft )

SELF-LOCKIN G NU T

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Replace .

CASTL E NU T

14 x 2. 0 m m49-5 9 N- m (5. 0 - 6. 0 kgf-m ,

36-4 3 Ibf-ft )

6. Instal l th e dampe r for k ove r th e driveshaf t an d ont o

th e lowe r arm . Instal l th e dampe r i n th e dampe r

fork s o th e alignin g ta b i s aligne d wit h th e slo t i n

th e dampe r for k (se e sectio n 18 ).

Loosel y instal l th e flang e bolt s an d th e ne w self -

lockin g nut .

NOTE : Th e bolt s an d nu t shoul d b e tightene d wit h

the vehicle' s weigh t o n th e damper .

Install a ne w spindl e nut , the n tighte n th e nut .

7.

8.

FRON T WHEE L

WHEE L NU T

SPINDL E NU T24 x 1. 5 m mReplace .

9. Instal l th e fron t whee l wit h th e whee l nuts .

NOTE : Befor e installin g th e wheel , clea n th e matin g

surface s o f th e brak e dis c an d th e wheel .

10 . Tighte n th e flang e bolt s an d th e ne w self-lockin g

nu t wit h th e vehicle' s weigh t o n th e damper .

11. Refil l th e transmissio n wit h recommende d flui d (se e

sectio n 14 ).

12 . Chec k th e fron t whee l alignmen t an d adjus t i f nec -

essar y (se e sectio n 18 ).

COTTE R PI N'Replace .On reassembly , ben d th ecotte r pi n a s shown .

SET RIN G GROOV ESIDE GEA R

ProCarManuals.com