differential ACURA TL 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1094 of 1771

Differential

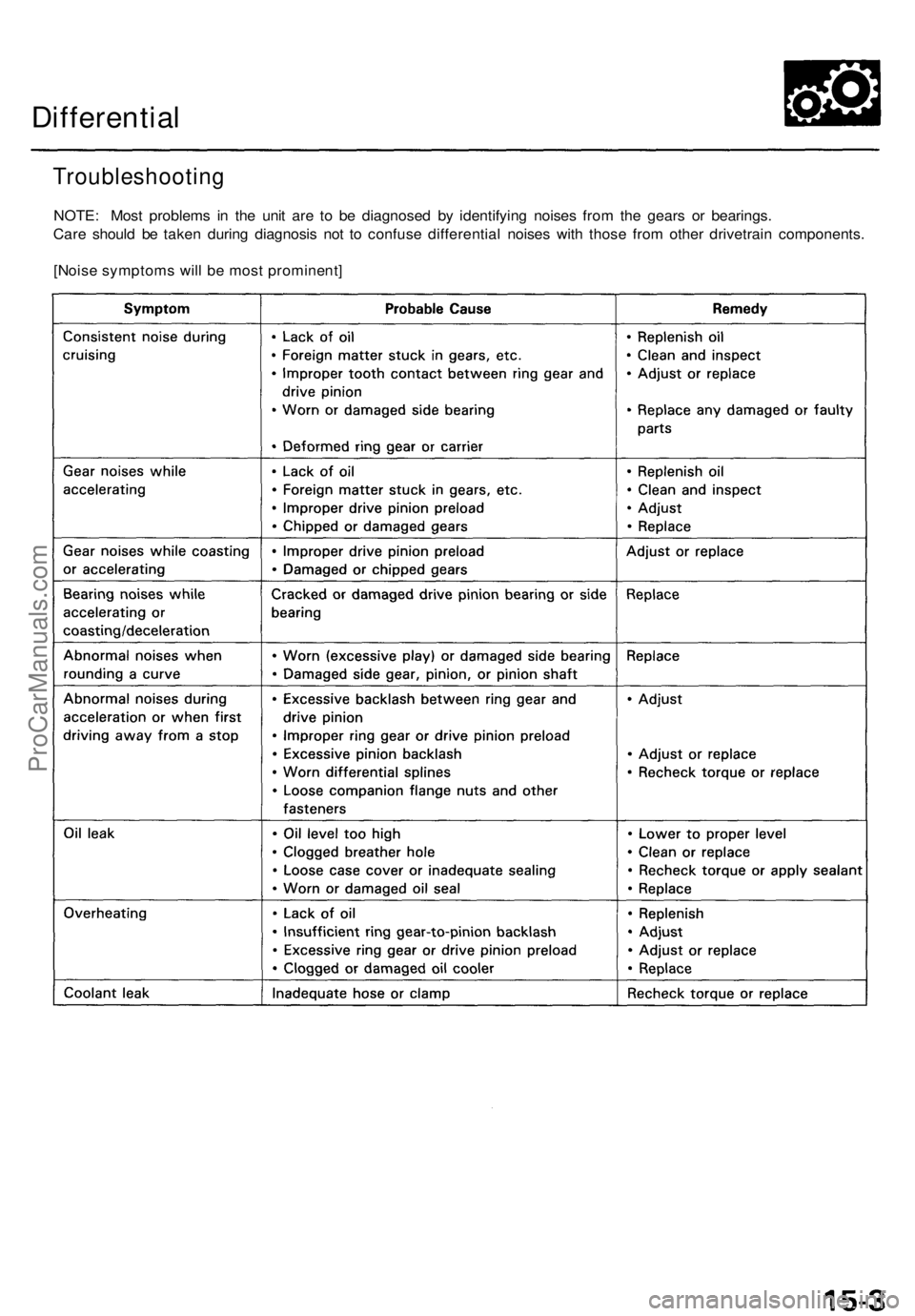

Troubleshootin g

NOTE: Mos t problem s i n th e uni t ar e t o b e diagnose d b y identifyin g noise s fro m th e gear s o r bearings .

Car e shoul d b e take n durin g diagnosi s no t t o confus e differentia l noise s wit h thos e fro m othe r drivetrai n components .

[Nois e symptom s wil l b e mos t prominent ]

ProCarManuals.com

Page 1095 of 1771

Maintenance

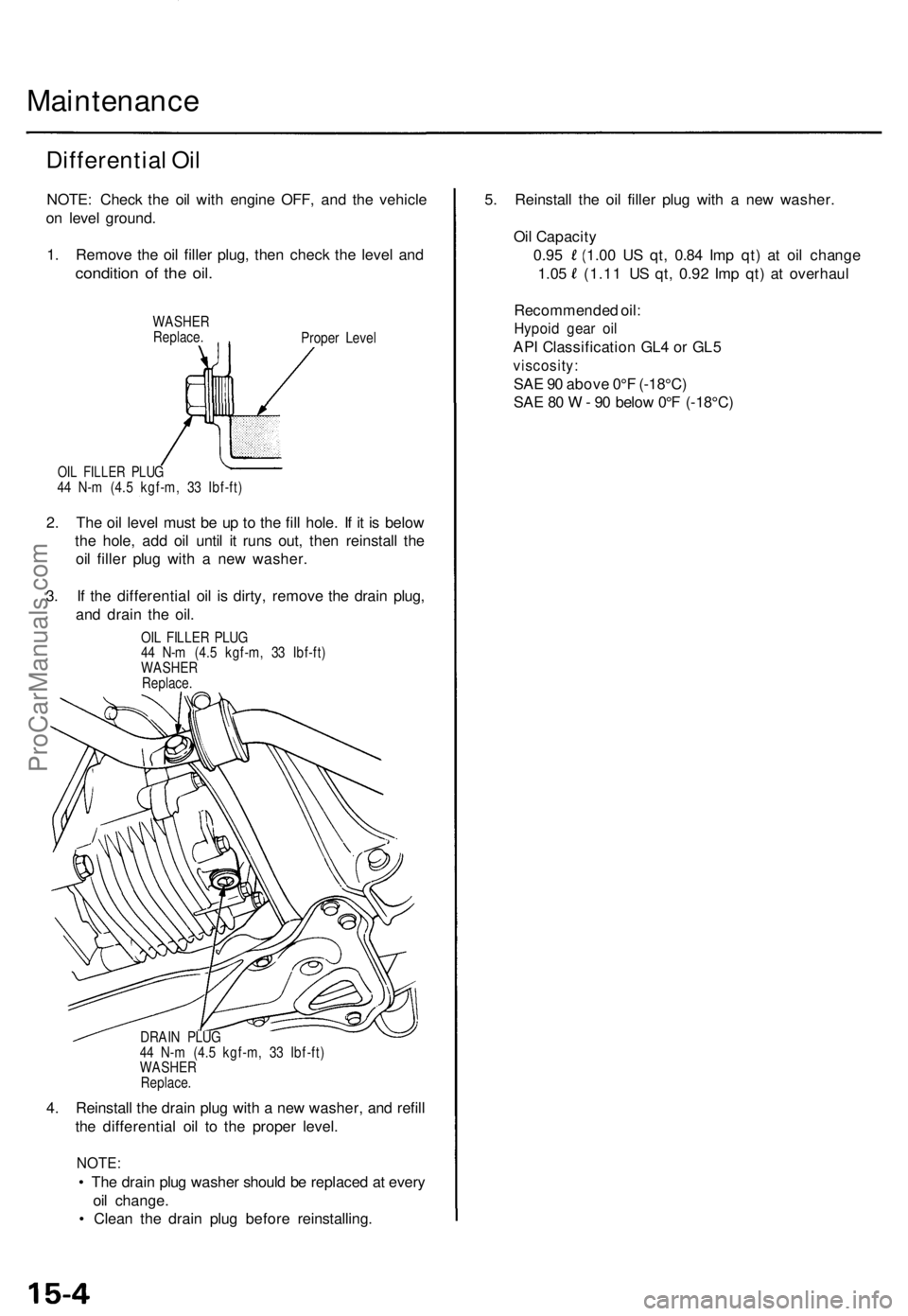

Differential Oi l

NOTE : Chec k th e oi l wit h engin e OFF , an d th e vehicl e

o n leve l ground .

1 . Remov e th e oi l fille r plug , the n chec k th e leve l an d

conditio n o f th e oil .

WASHE R

Replace .

Proper Leve l

OIL FILLE R PLU G44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

2. Th e oi l leve l mus t b e u p t o th e fil l hole . I f i t i s belo w

th e hole , ad d oi l unti l i t run s out , the n reinstal l th e

oi l fille r plu g wit h a ne w washer .

3 . I f th e differentia l oi l i s dirty , remov e th e drai n plug ,

an d drai n th e oil .

OIL FILLE R PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

WASHE R

Replace .

DRAI N PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

WASHE R

Replace .

4. Reinstal l th e drai n plu g wit h a ne w washer , an d refil l

th e differentia l oi l t o th e prope r level .

NOTE :

• Th e drai n plu g washe r shoul d b e replace d a t ever y

oi l change .

• Clea n th e drai n plu g befor e reinstalling . 5

. Reinstal l th e oi l fille r plu g wit h a ne w washer .

Oi l Capacit y

0.9 5 (1.0 0 U S qt , 0.8 4 Im p qt) at oi l chang e

1.05 (1.1 1 U S qt , 0.9 2 Im p qt ) a t overhau l

Recommende d oil :

Hypoi d gea r oi l

AP I Classificatio n GL 4 o r GL 5

viscosity :

SAE 9 0 abov e 0°F (-18°C )

SA E 8 0 W - 9 0 belo w 0° F (-18°C )

ProCarManuals.com

Page 1096 of 1771

Differential Assembl y

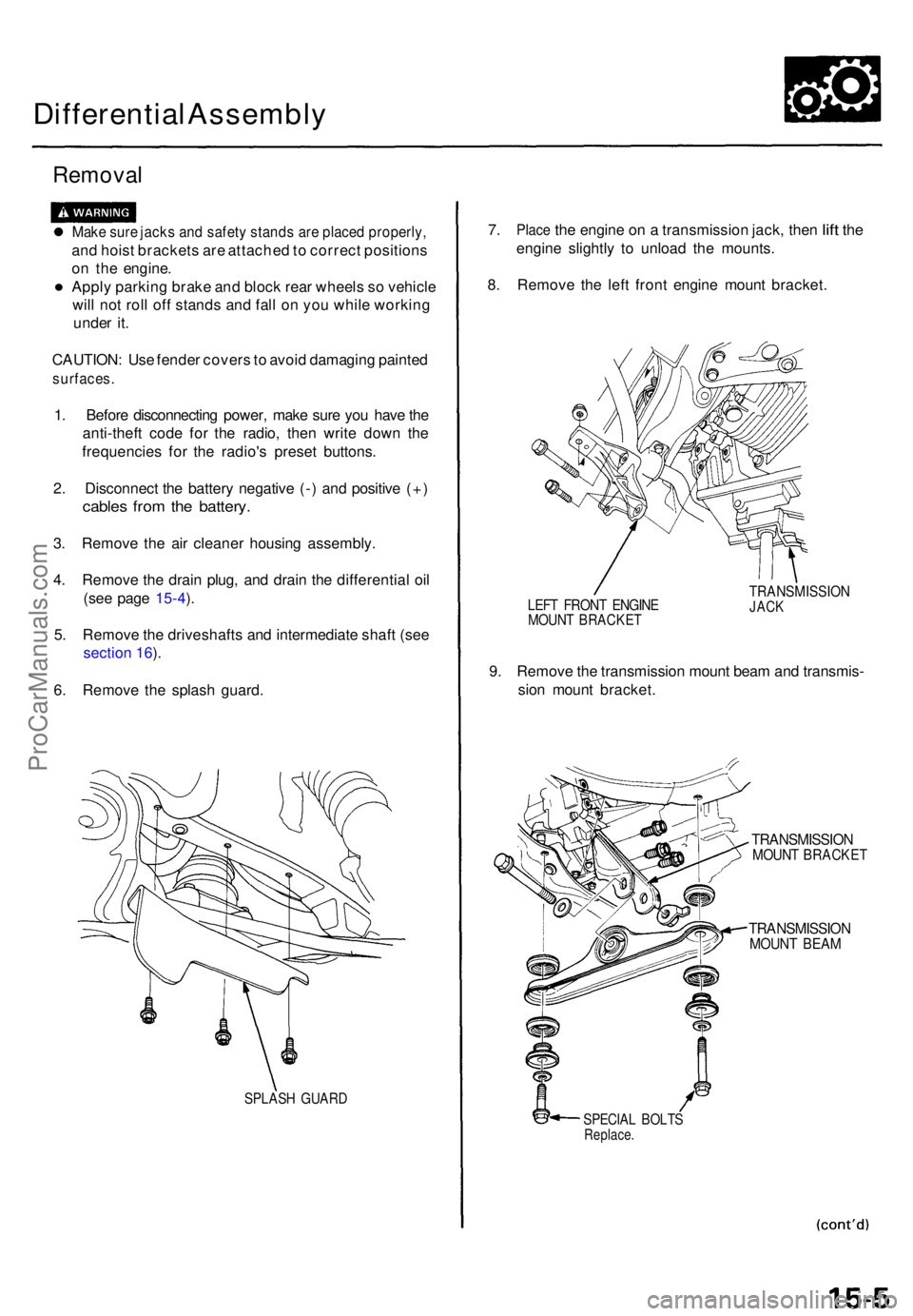

Removal

Make sur e jack s an d safet y stand s ar e place d properly ,

and hois t bracket s ar e attache d to correc t position s

o n th e engine .

• Apply parkin g brak e an d bloc k rea r wheel s s o vehicl e

wil l no t rol l of f stand s an d fal l o n yo u whil e workin g

unde r it .

CAUTION : Us e fende r cover s to avoi d damagin g painte d

surfaces .

1. Befor e disconnectin g power , mak e sur e yo u hav e th e

anti-thef t cod e fo r th e radio , the n writ e dow n th e

frequencie s fo r th e radio' s prese t buttons .

2 . Disconnec t th e batter y negativ e (- ) an d positiv e (+ )

cable s fro m th e battery .

3. Remov e th e ai r cleane r housin g assembly .

4 . Remov e th e drai n plug , an d drai n th e differentia l oi l

(se e pag e 1 5-4 ).

5 . Remov e th e driveshaft s an d intermediat e shaf t (se e

sectio n 16 ).

6 . Remov e th e splas h guard .

SPLAS H GUAR D

7. Plac e the engin e on a transmissio n jack , the n lift th e

engin e slightl y t o unloa d th e mounts .

8 . Remov e th e lef t fron t engin e moun t bracket .

LEFT FRON T ENGIN EMOUNT BRACKE T

TRANSMISSIO NJACK

9. Remov e th e transmissio n moun t bea m an d transmis -

sio n moun t bracket .

TRANSMISSIO NMOUNT BRACKE T

TRANSMISSIO NMOUNT BEA M

SPECIA L BOLT SReplace .

ProCarManuals.com

Page 1097 of 1771

Differential Assembl y

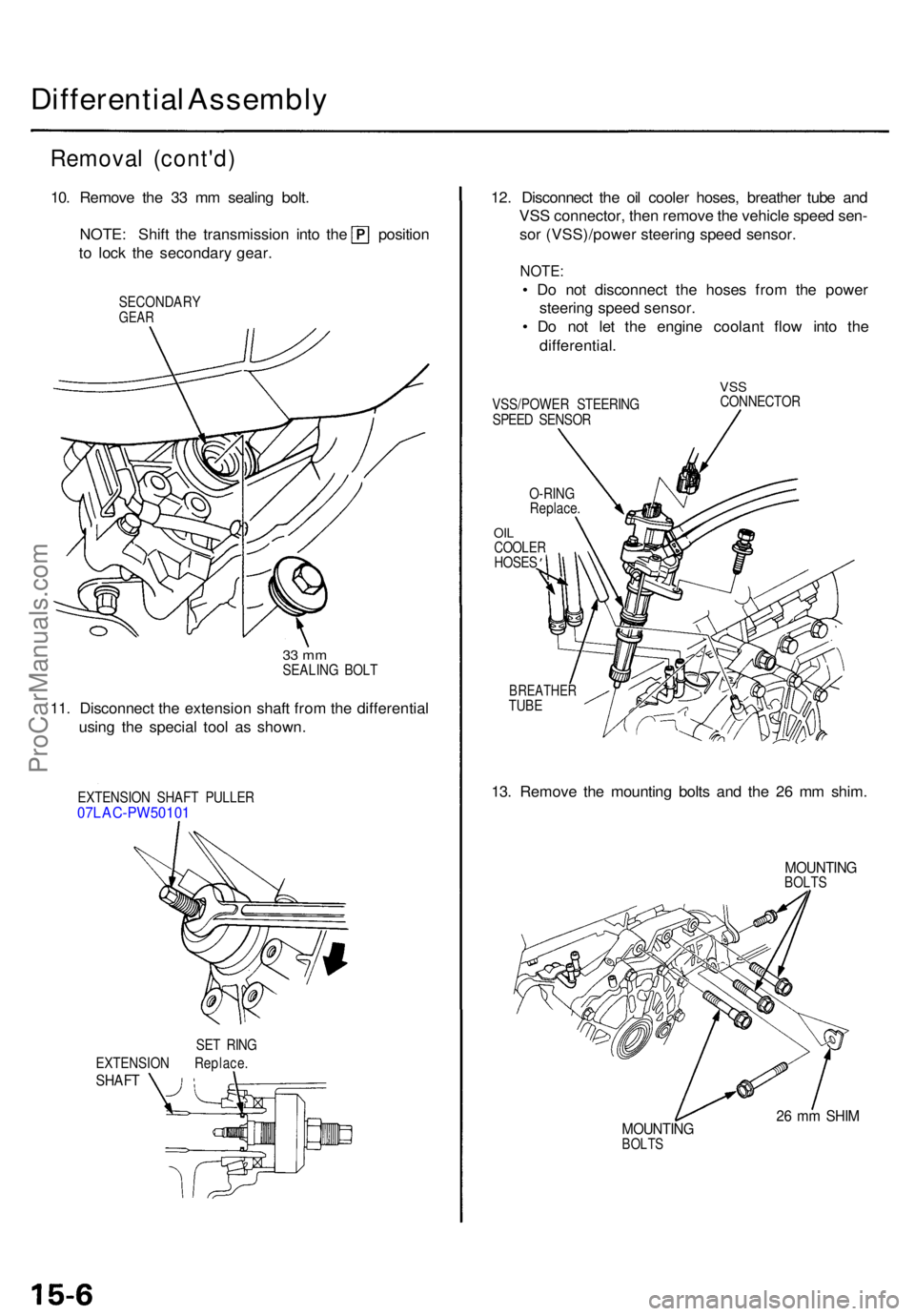

Removal (cont'd )

10. Remov e th e 3 3 m m sealin g bolt .

NOTE : Shif t th e transmissio n int o th e positio n

to loc k th e secondar y gear .

SECONDAR YGEAR

33 m mSEALIN G BOL T

11. Disconnec t th e extensio n shaf t fro m th e differentia l

usin g th e specia l too l a s shown .

EXTENSIO N SHAF T PULLE R07LAC-PW50101

SET RIN G

EXTENSIO N Replace .

SHAFT

12. Disconnec t th e oi l coole r hoses , breathe r tub e an d

VS S connector , the n remov e th e vehicl e spee d sen -

so r (VSS)/powe r steerin g spee d sensor .

NOTE:

• D o no t disconnec t th e hose s fro m th e powe r

steerin g spee d sensor .

• D o no t le t th e engin e coolan t flo w int o th e

differential .

VSS/POWE R STEERIN G

SPEE D SENSO R

VSSCONNECTO R

OILCOOLE RHOSES

BREATHE RTUBE

13. Remov e th e mountin g bolt s an d th e 2 6 m m shim .

MOUNTIN GBOLTS

MOUNTIN GBOLTS

26 m m SHI M

O-RIN G

Replace .

ProCarManuals.com

Page 1099 of 1771

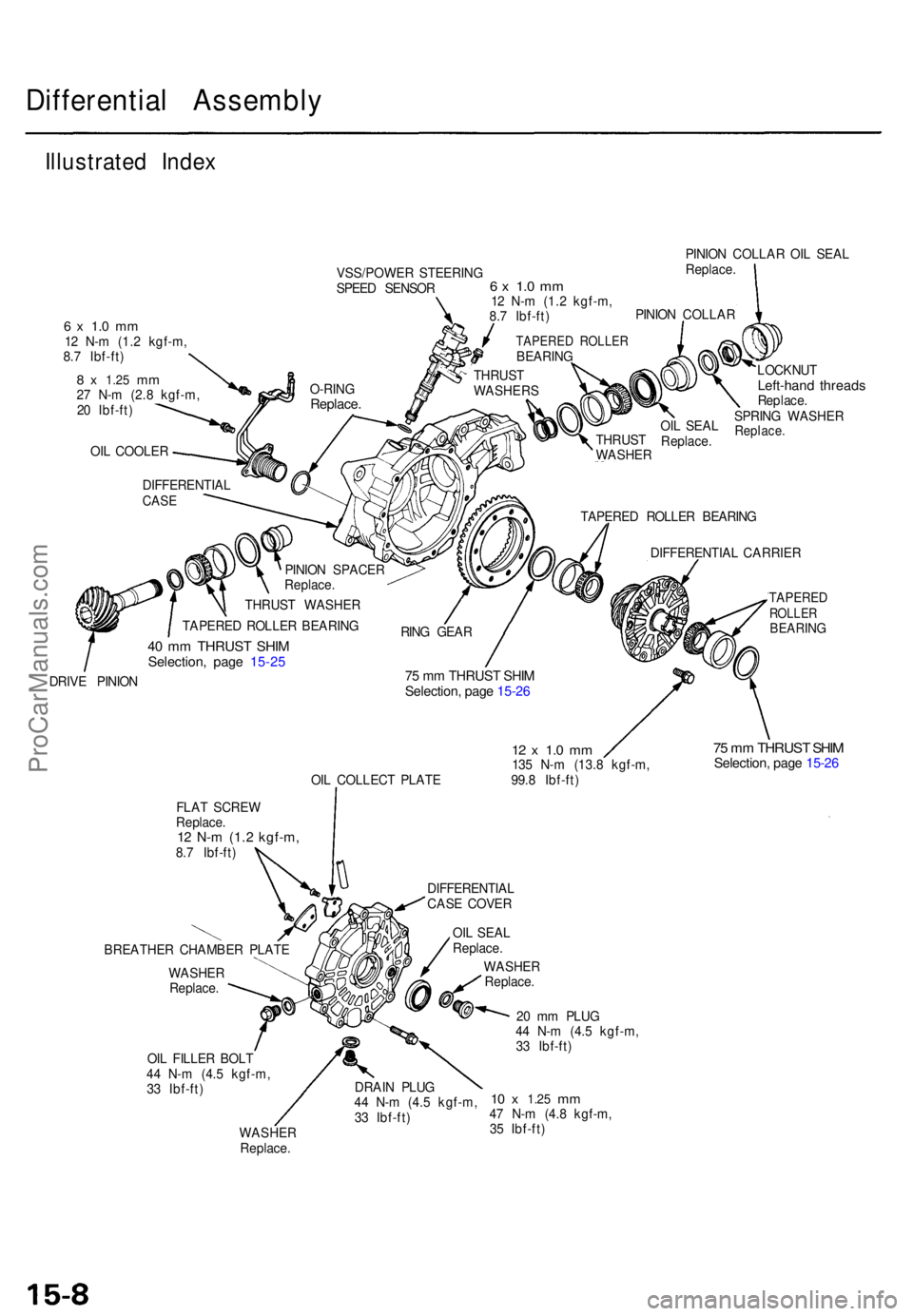

Differential Assembl y

Illustrated Inde x

VSS/POWE R STEERIN G

SPEE D SENSO R PINIO

N COLLA R OI L SEA L

Replace .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

8 x 1.2 5 mm27 N- m (2. 8 kgf-m ,

2 0 Ibf-ft )

OI L COOLE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

LOCKNUT

Left-hand thread sReplace .

SPRIN G WASHE R

Replace.

DIFFERENTIA LCASE

PINIO N SPACE R

Replace .

THRUS T WASHE R

TAPERE D ROLLE R BEARIN G

40 m m THRUS T SHI MSelection , pag e 15-2 5

TAPERE D ROLLE R BEARIN G

DIFFERENTIA L CARRIE R

DRIV E PINIO N

75 m m THRUS T SHI MSelection , pag e 15-2 6

OIL COLLEC T PLAT E

12 x 1. 0 m m135 N- m (13. 8 kgf-m ,

99. 8 Ibf-ft )

TAPERE DROLLERBEARIN G

75 m m THRUS T SHI MSelection , pag e 15-2 6

FLA T SCRE W

Replace .

12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

BREATHE R CHAMBE R PLAT E

WASHE R

Replace .

OI L FILLE R BOL T

4 4 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

WASHE R

Replace . DIFFERENTIA

L

CAS E COVE R

OI L SEA L

Replace .

WASHE R

Replace .

DRAI N PLU G

4 4 N- m (4. 5 kgf-m ,

3 3 Ibf-ft ) 2

0 m m PLU G

4 4 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

10 x 1.2 5 mm47 N- m (4. 8 kgf-m ,

3 5 Ibf-ft ) OI

L SEA L

Replace .

THRUS

T

WASHE R

PINIO

N COLLA R

TAPERE D ROLLE RBEARING

O-RIN G

Replace .

THRUST

WASHER S

RIN G GEA R

ProCarManuals.com

Page 1101 of 1771

Differential Assembl y

Inspection (cont'd )

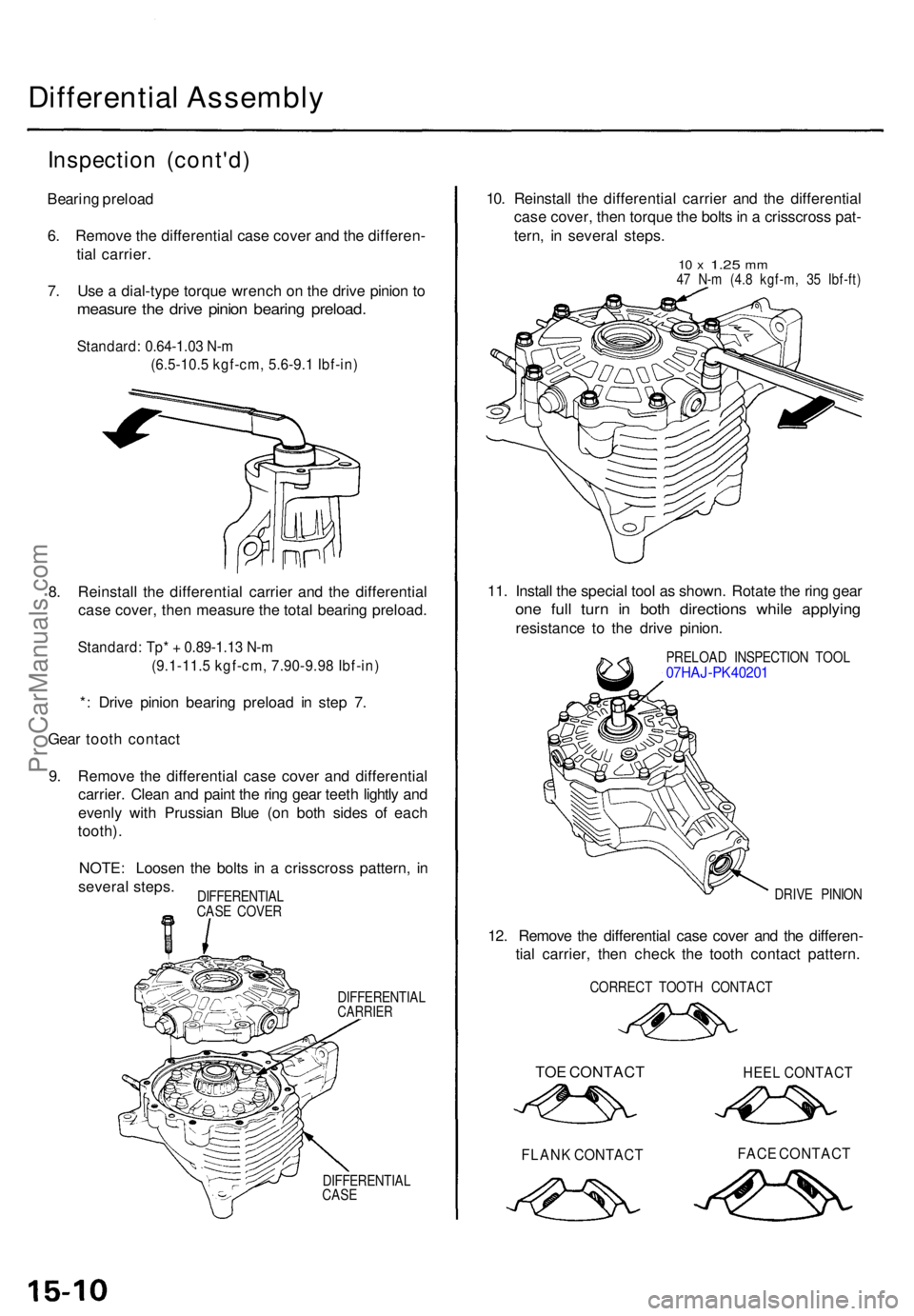

Bearing preloa d

6 . Remov e th e differentia l cas e cove r an d th e differen -

tia l carrier .

7 . Us e a dial-typ e torqu e wrenc h o n th e driv e pinio n t o

measur e th e driv e pinio n bearin g preload .

Standard: 0.64-1.03 N-m

(6.5-10.5 kgf-cm, 5.6-9.1 Ibf-in)

8. Reinstal l th e differentia l carrie r an d th e differentia l

cas e cover , the n measur e th e tota l bearin g preload .

Standard: Tp* + 0.89-1.13 N-m

(9.1-11.5 kgf-cm, 7.90-9.98 Ibf-in)

*: Driv e pinio n bearin g preloa d i n ste p 7 .

Gea r toot h contac t

9 . Remov e th e differentia l cas e cove r an d differentia l

carrier . Clea n an d pain t th e rin g gea r teet h lightl y an d

evenl y with Prussia n Blu e (o n bot h side s o f eac h

tooth) .

NOTE : Loose n th e bolt s i n a crisscros s pattern , i n

severa l steps .

DIFFERENTIA LCARRIER

DIFFERENTIA L

CAS E

10. Reinstal l th e differentia l carrie r an d th e differentia l

cas e cover , the n torqu e th e bolt s in a crisscros s pat -

tern , i n severa l steps .

10 x 1.2 5 mm47 N- m (4. 8 kgf-m , 3 5 Ibf-ft )

11. Instal l th e specia l too l a s shown . Rotat e th e rin g gea r

one ful l tur n i n bot h direction s whil e applyin g

resistanc e t o th e driv e pinion .

PRELOA D INSPECTIO N TOO L07HAJ-PK40201

DRIVE PINIO N

12. Remov e th e differentia l cas e cove r an d th e differen -

tia l carrier , the n chec k th e toot h contac t pattern .

CORREC T TOOT H CONTAC T

TOE CONTAC T HEE L CONTAC T

FLANK CONTAC T FAC E CONTAC T

DIFFERENTIA L

CAS E COVE R

ProCarManuals.com

Page 1103 of 1771

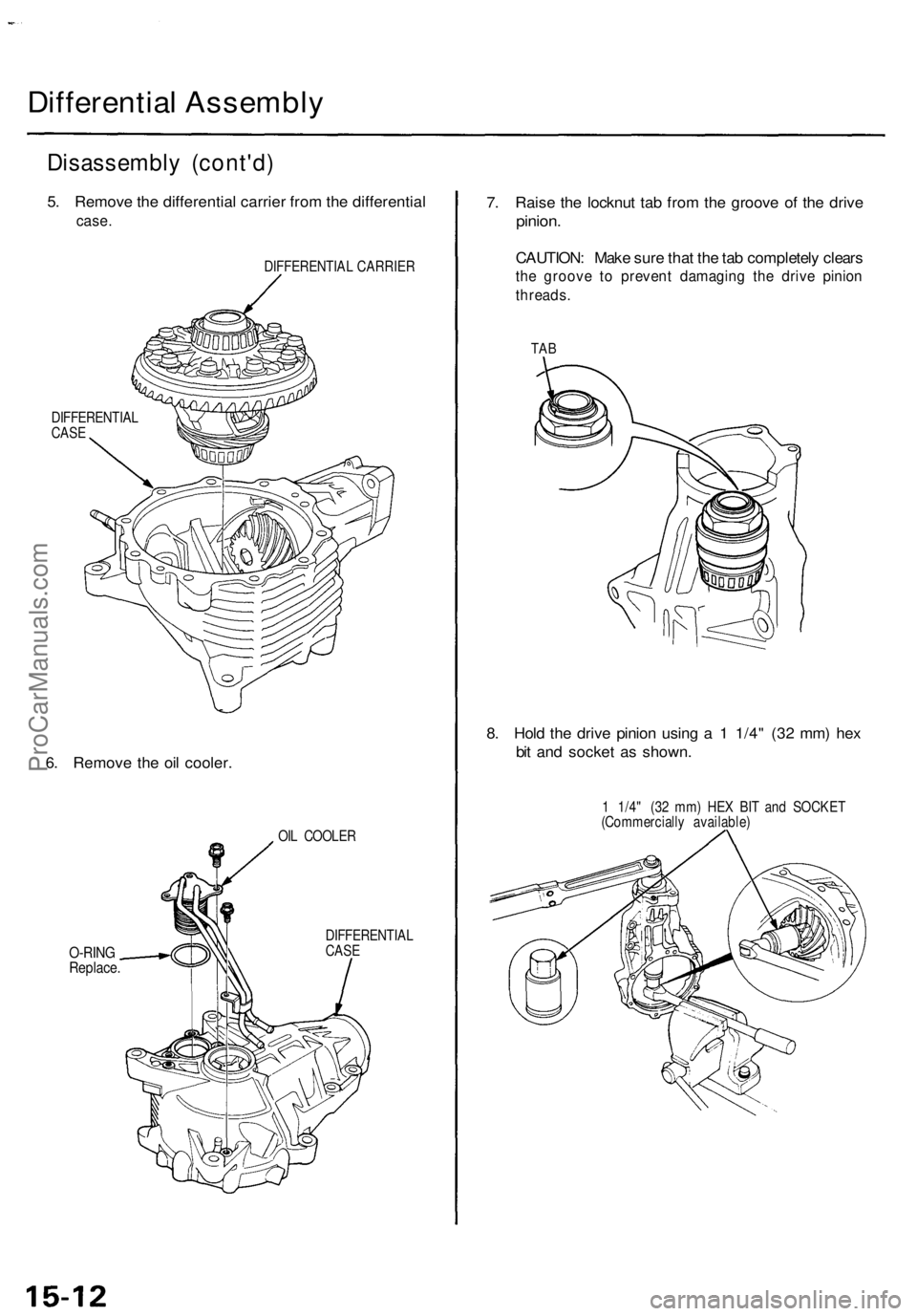

Differential Assembl y

Disassembl y (cont'd )

5. Remov e th e differentia l carrie r fro m th e differentia l

case.

DIFFERENTIA L CARRIE R

DIFFERENTIA L

CAS E

6. Remov e th e oi l cooler .

OIL COOLE R

O-RINGReplace .

DIFFERENTIA L

CAS E

7. Rais e th e locknu t ta b fro m th e groov e of the driv e

pinion .

CAUTION : Mak e sur e tha t th e ta b completel y clear s

the groov e t o preven t damagin g th e driv e pinio n

threads .

TAB

8. Hol d th e driv e pinio n usin g a 1 1/4 " (3 2 mm ) he x

bi t an d socke t a s shown .

1 1/4 " (3 2 mm ) HE X BI T an d SOCKE T

(Commerciall y available )

ProCarManuals.com

Page 1105 of 1771

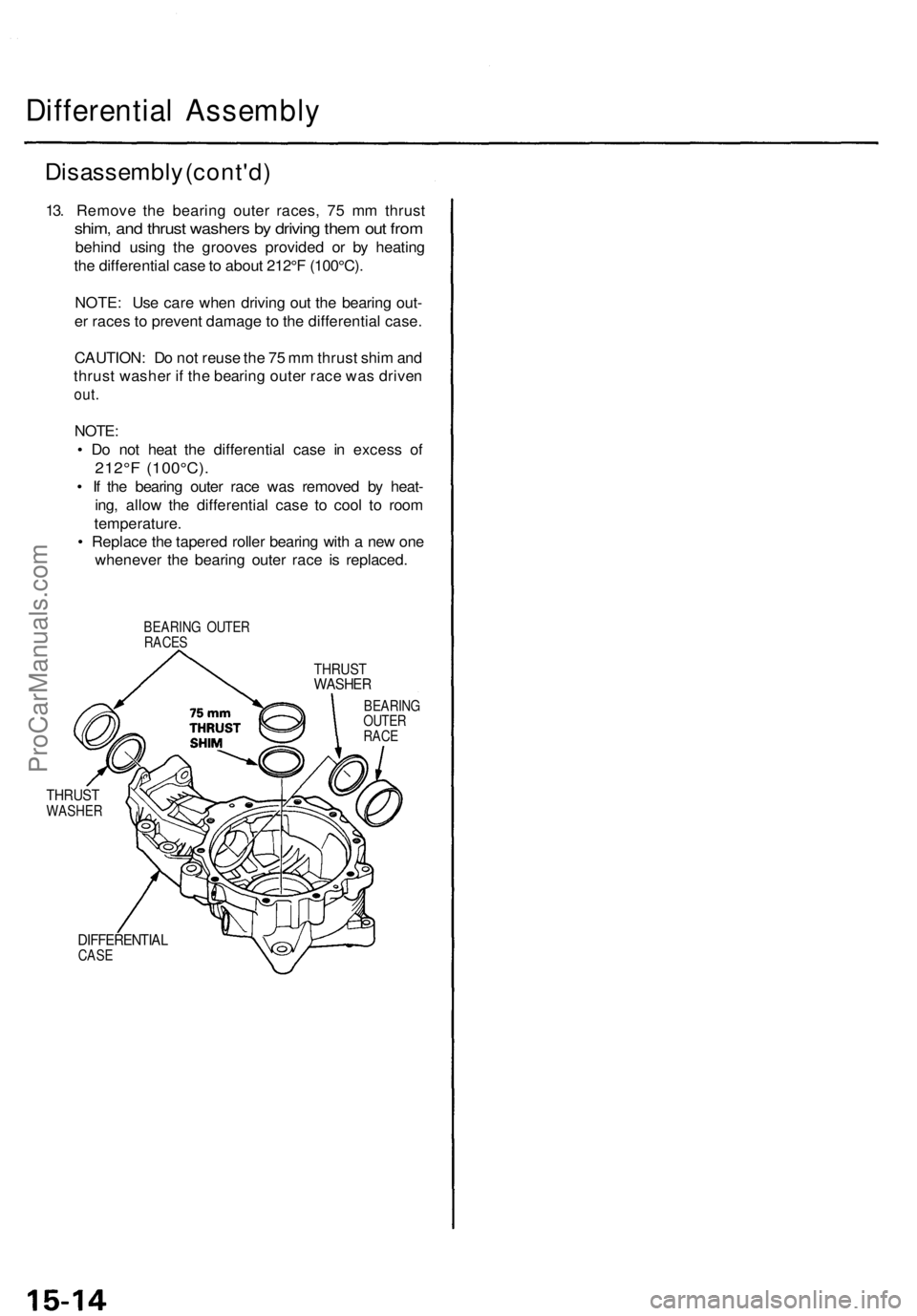

Differential Assembl y

Disassembl y (cont'd )

13. Remov e th e bearin g oute r races , 7 5 m m thrus t

shim, an d thrus t washer s b y drivin g the m ou t fro m

behin d usin g th e groove s provide d o r b y heatin g

th e differentia l cas e to abou t 212° F (100°C) .

NOTE : Us e car e whe n drivin g ou t th e bearin g out -

e r race s t o preven t damag e to th e differentia l case .

CAUTION : D o no t reus e th e 7 5 m m thrus t shi m an d

thrus t washe r i f th e bearin g oute r rac e wa s drive n

out.

NOTE :

• D o no t hea t th e differentia l cas e i n exces s o f

212° F (100°C) .

• I f th e bearin g oute r rac e wa s remove d b y heat -

ing , allo w th e differentia l cas e t o coo l t o roo m

temperature .

• Replac e th e tapere d rolle r bearin g wit h a ne w on e

wheneve r th e bearin g oute r rac e i s replaced .

BEARING OUTE RRACES

THRUS TWASHE R

BEARIN G

OUTE R

RAC E

THRUS TWASHE R

DIFFERENTIA LCASE

ProCarManuals.com

Page 1106 of 1771

Differential Carrie r

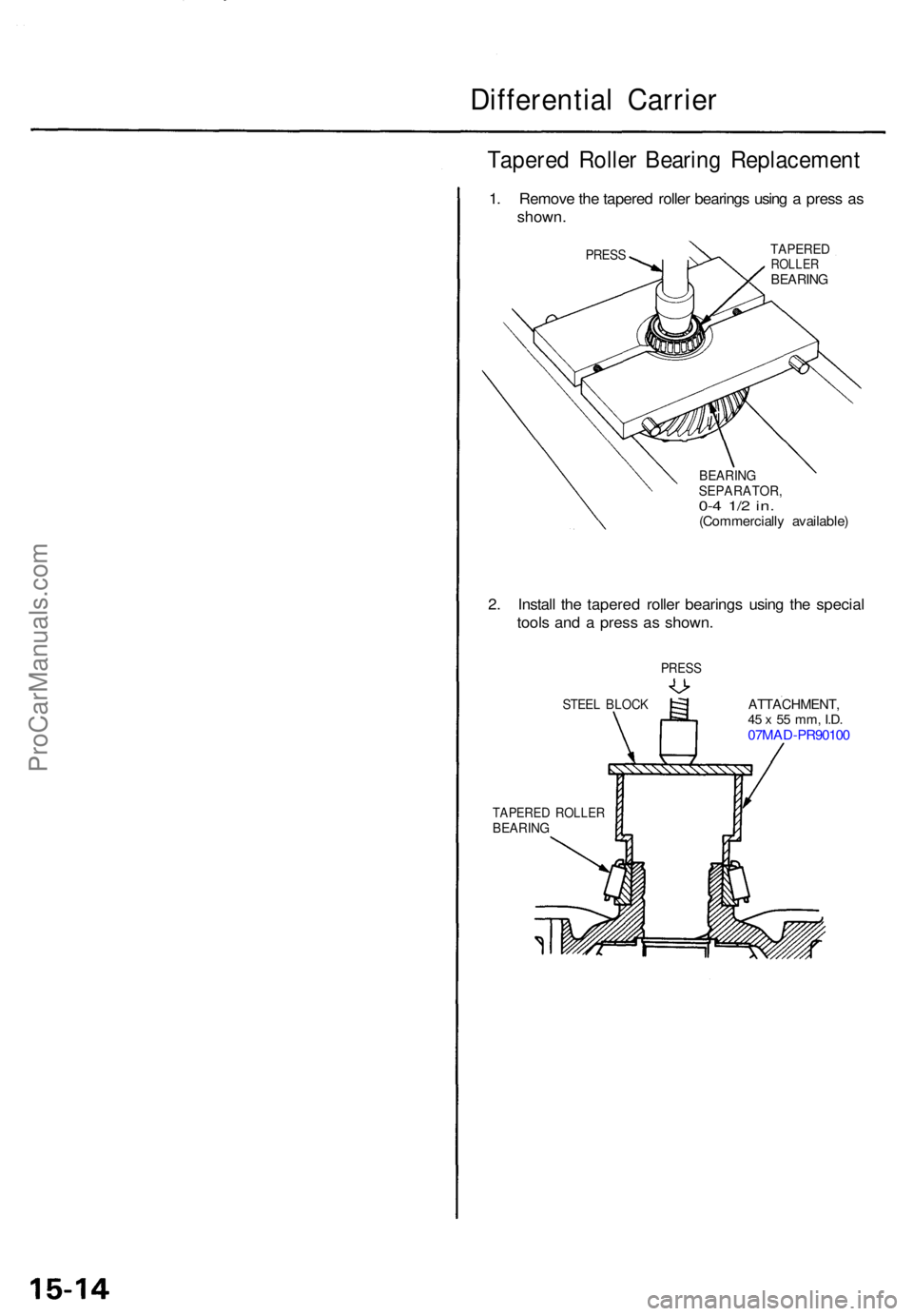

Tapered Rolle r Bearin g Replacemen t

1. Remov e th e tapere d rolle r bearing s usin g a pres s a s

shown .

PRESSTAPERE DROLLERBEARIN G

BEARIN GSEPARATOR ,0-4 1/ 2 in .(Commerciall y available )

2. Instal l th e tapere d rolle r bearing s usin g th e specia l

tool s an d a pres s a s shown .

PRESS

STEEL BLOC KATTACHMENT ,45 x 55 mm , I.D.07MA D-PR9010 0

TAPERE D ROLLE RBEARING

ProCarManuals.com

Page 1107 of 1771

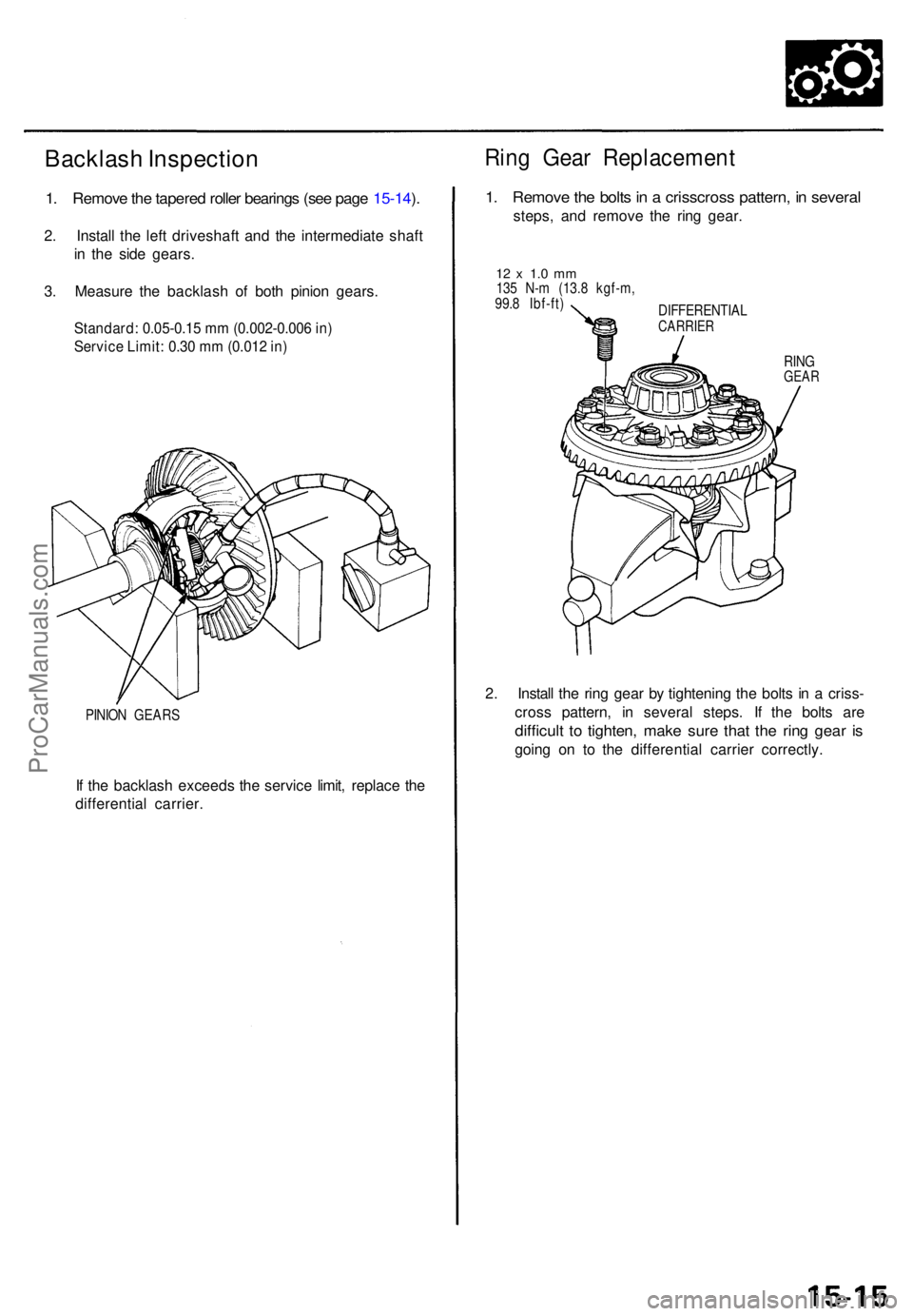

Backlash Inspectio n

1. Remov e th e tapere d rolle r bearing s (se e pag e 15-14 ).

2 . Instal l th e lef t driveshaf t an d th e intermediat e shaf t

i n th e sid e gears .

3 . Measur e th e backlas h o f bot h pinio n gears .

Standard: 0.05-0.15 mm (0.002-0.006 in)

Service Limit: 0.30 mm (0.012 in)

PINION GEAR S

If th e backlas h exceed s th e servic e limit , replac e th e

differentia l carrier .

Ring Gea r Replacemen t

1. Remov e th e bolt s in a crisscros s pattern , i n severa l

steps, an d remov e th e rin g gear .

12 x 1. 0 m m135 N- m (13. 8 kgf-m ,

99. 8 Ibf-ft )

DIFFERENTIAL

CARRIER

RINGGEA R

2. Instal l th e rin g gea r b y tightenin g th e bolt s i n a criss -

cros s pattern , i n severa l steps . I f th e bolt s ar e

difficul t t o tighten , mak e sur e tha t th e rin g gea r i s

goin g o n t o th e differentia l carrie r correctly .

ProCarManuals.com