differential ACURA TL 1995 Service User Guide

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 443 of 1771

Differential Carrie r

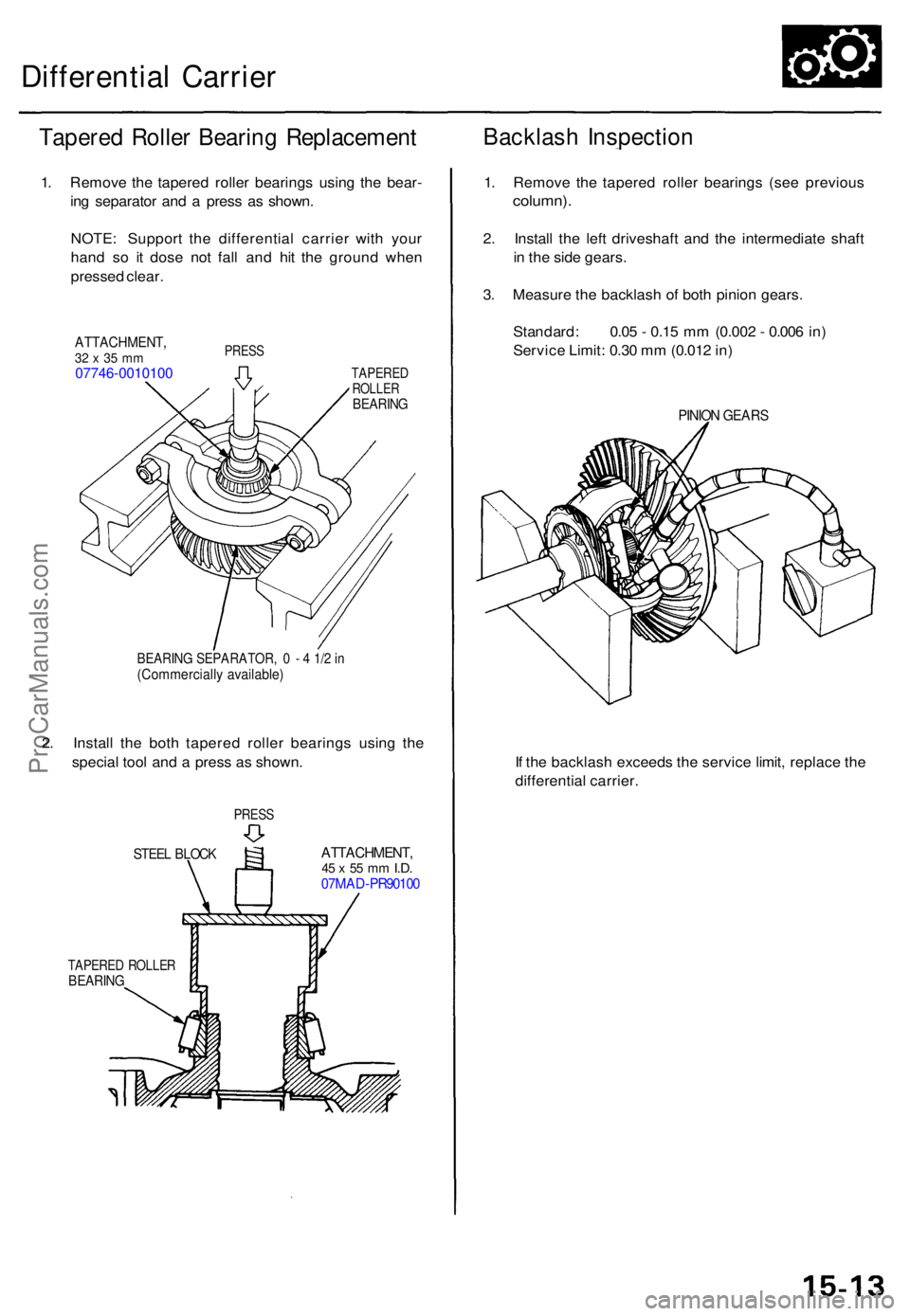

Tapered Rolle r Bearin g Replacemen t

1. Remov e th e tapered roller bearing s usin g th e bear -

in g separato r an d a pres s a s shown .

NOTE : Suppor t th e differentia l carrie r wit h you r

han d s o i t dos e no t fal l an d hi t th e groun d whe n

presse d clear .

ATTACHMENT ,32 x 35 m m07746-001010 0

PRESS

TAPERE DROLLERBEARIN G

BEARIN G SEPARATOR , 0 - 4 1/ 2 in(Commerciall y available )

2. Instal l th e bot h tapere d rolle r bearing s usin g th e

specia l too l an d a pres s a s shown .

STEEL BLOC KATTACHMENT ,45 x 55 m m I.D .07MA D-PR9010 0

TAPERE D ROLLE RBEARIN G

1. Remov e th e tapere d rolle r bearing s (se e previou s

column).

2. Instal l th e lef t driveshaf t an d th e intermediat e shaf t

i n th e sid e gears .

3 . Measur e th e backlas h o f bot h pinio n gears .

Standard : 0.0 5 - 0.1 5 m m (0.00 2 - 0.00 6 in )

Servic e Limit : 0.3 0 m m (0.01 2 in )

PINIO N GEAR S

If th e backlas h exceed s th e servic e limit , replac e th e

differentia l carrier .

PRESS

Backlas h Inspectio n

ProCarManuals.com

Page 444 of 1771

Differential Carrier

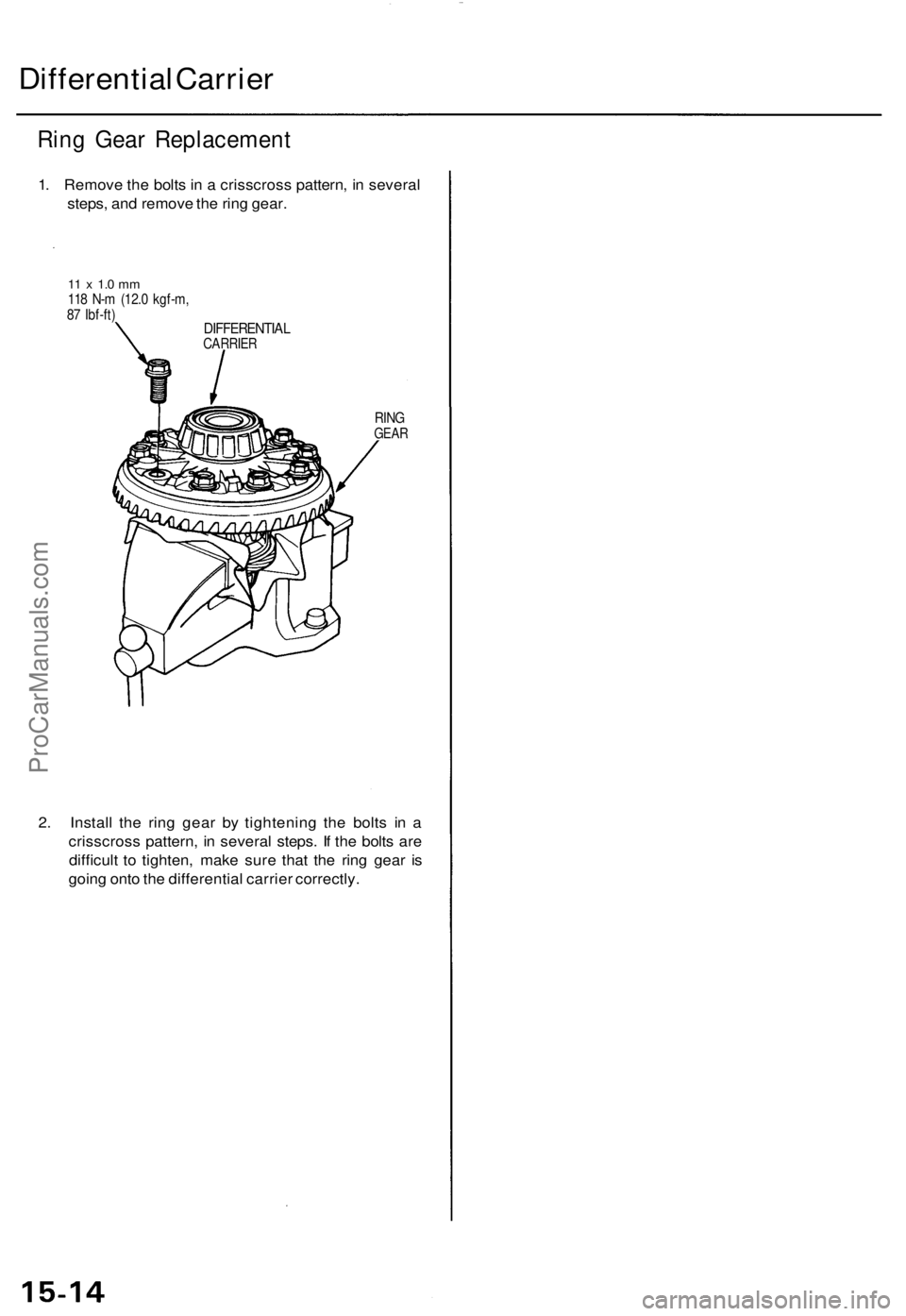

Ring Gear Replacement

1. Remove the bolts in a crisscross pattern, in several

steps, and remove the ring gear.

11 x 1.0 mm

118 N-m (12.0 kgf-m,

87 Ibf-ft)

DIFFERENTIAL

CARRIER

RING

GEAR

2. Install the ring gear by tightening the bolts in a

crisscross pattern, in several steps. If the bolts are

difficult to tighten, make sure that the ring gear is

going onto the differential carrier correctly.ProCarManuals.com

Page 445 of 1771

Differential Assembl y

Reassembl y

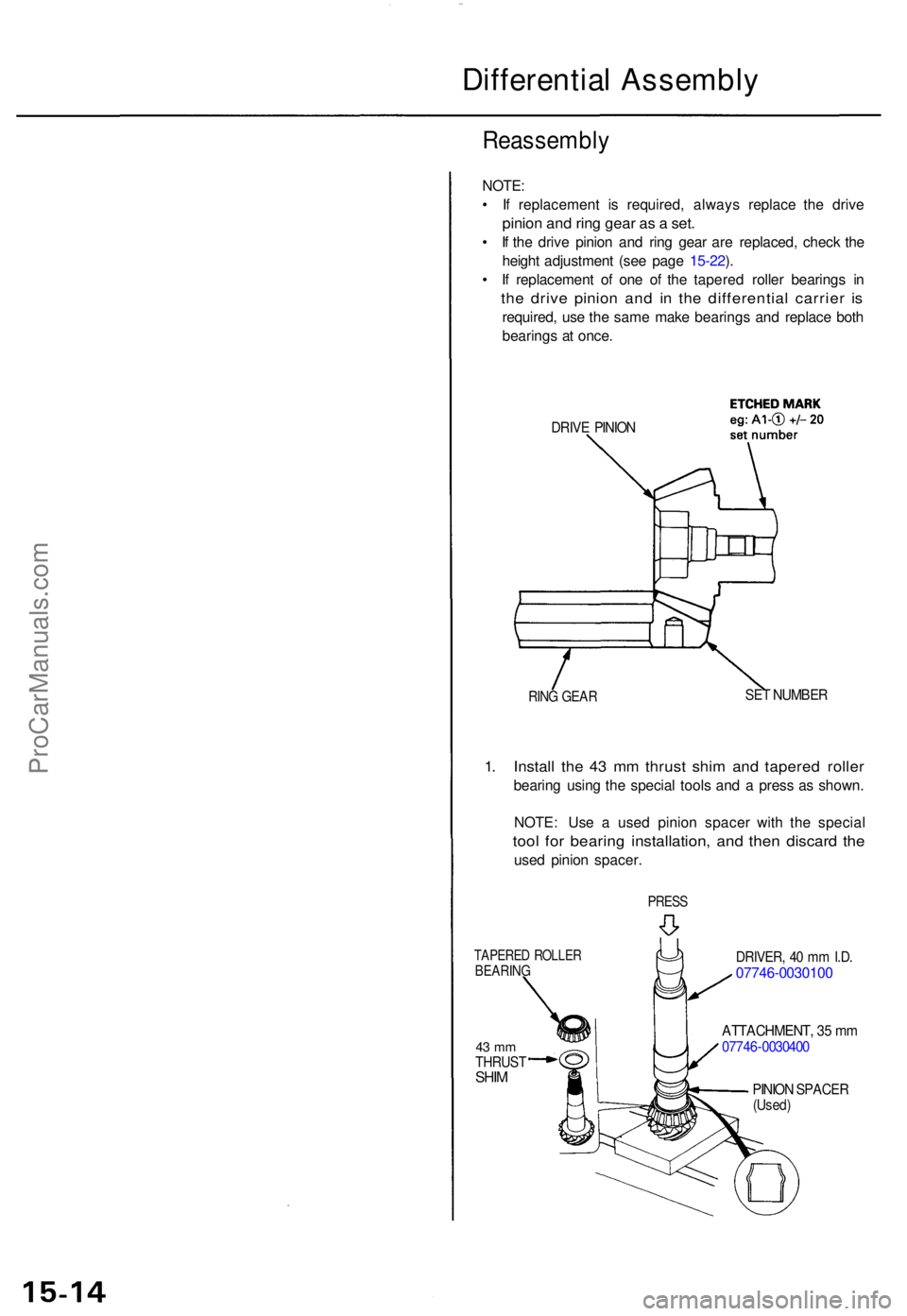

NOTE:

• I f replacemen t i s required , alway s replac e th e driv e

pinion an d rin g gea r a s a set .

• I f th e driv e pinio n an d rin g gea r ar e replaced , chec k th e

heigh t adjustmen t (se e pag e 15-22 ).

• I f replacemen t o f on e o f th e tapere d rolle r bearing s i n

th e driv e pinio n an d i n th e differentia l carrie r i s

required , us e th e sam e mak e bearing s an d replac e bot h

bearing s a t once .

DRIVE PINIO N

RING GEA RSET NUMBE R

1. Instal l th e 4 3 m m thrus t shi m an d tapere d rolle r

bearin g usin g th e specia l tool s an d a pres s a s shown .

NOTE : Us e a use d pinio n space r wit h th e specia l

tool fo r bearin g installation , an d the n discar d th e

use d pinio n spacer .

PRESS

DRIVER , 4 0 m m I.D .07746-003010 0

ATTACHMENT , 3 5 m m0774 6-003040 0

TAPERE D ROLLE RBEARIN G

43 m mTHRUS TSHIMPINIO N SPACE R(Used)

ProCarManuals.com

Page 447 of 1771

Differential Assembl y

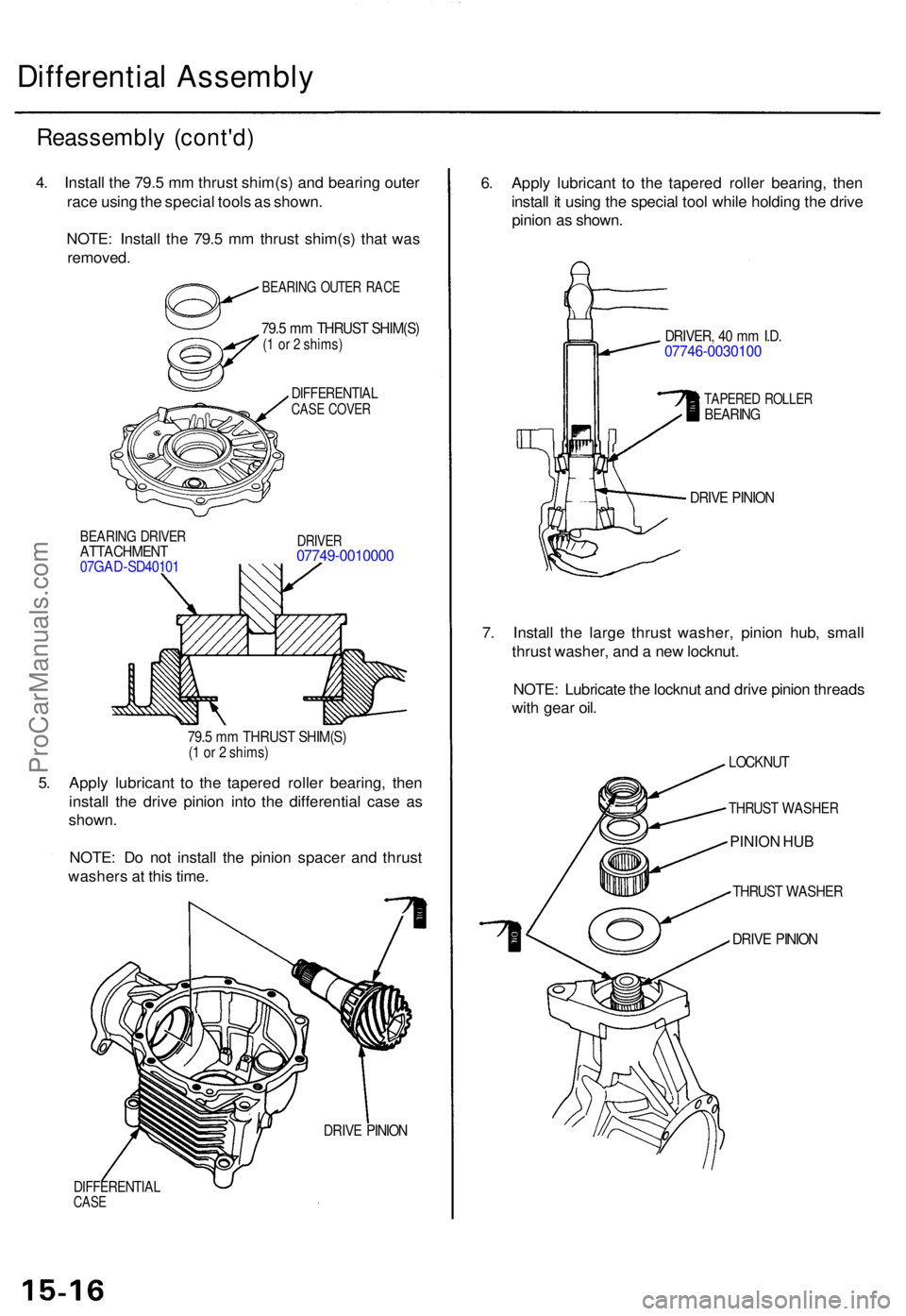

Reassembl y (cont'd )

DIFFERENTIA LCASE COVE R

BEARIN G DRIVE RATTACHMEN T07GAD-SD4010 1

DRIVER07749-001000 0

79.5 m m THRUS T SHIM(S )(1 o r 2 shims )

5. Appl y lubrican t t o th e tapere d rolle r bearing , the n

instal l th e driv e pinio n int o th e differentia l cas e a s

shown .

NOTE : D o no t instal l th e pinio n space r an d thrus t

washer s a t thi s time .

DIFFERENTIA LCASE

DRIV E PINIO N

6. Appl y lubrican t t o th e tapere d rolle r bearing , the n

instal l i t usin g th e specia l too l whil e holdin g th e driv e

pinio n a s shown .

DRIVER , 4 0 m m I.D .07746-003010 0

TAPERED ROLLE RBEARIN G

DRIVE PINIO N

7. Instal l th e larg e thrus t washer , pinio n hub , smal l

thrus t washer , an d a ne w locknut .

NOTE : Lubricat e th e locknu t an d driv e pinio n thread s

wit h gea r oil .

LOCKNU T

THRUST WASHE R

PINION HUB

THRUST WASHE R

DRIVE PINIO N

4. Instal l th e 79. 5 m m thrus t shim(s ) an d bearin g oute r

rac e usin g th e specia l tool s a s shown .

NOTE : Instal l th e 79. 5 m m thrus t shim(s ) tha t wa s

removed .

IBEARING OUTE R RAC E

79.5 m m THRUS T SHIM(S )(1 o r 2 shims )

ProCarManuals.com

Page 449 of 1771

Differential Assembl y

Reassembl y (cont'd )

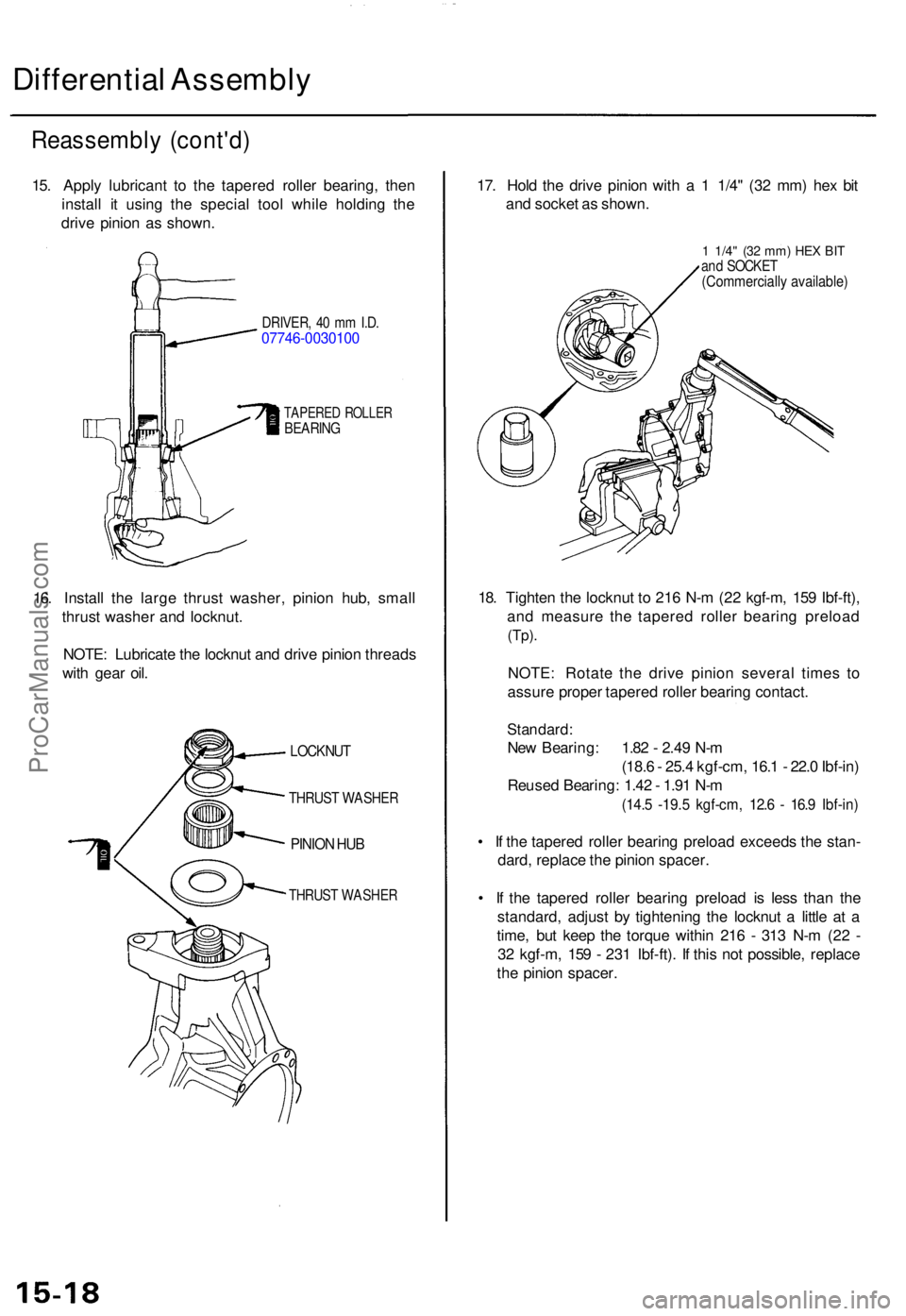

15. Appl y lubrican t t o th e tapere d rolle r bearing , the n

instal l i t usin g th e specia l too l whil e holdin g th e

driv e pinio n a s shown .

DRIVER , 4 0 m m I.D .07746-003010 0

TAPERED ROLLE RBEARIN G

16. Instal l th e larg e thrus t washer , pinio n hub , smal l

thrus t washe r an d locknut .

NOTE : Lubricat e th e locknu t an d driv e pinio n thread s

wit h gea r oil . 17

. Hol d th e driv e pinio n wit h a 1 1/4 " (3 2 mm ) he x bi t

an d socke t a s shown .

1 1/4" (32 mm ) HE X BI Tand SOCKE T(Commerciall y available )

18. Tighte n th e locknu t t o 21 6 N- m (2 2 kgf-m , 15 9 Ibf-ft) ,

an d measur e th e tapere d rolle r bearin g preloa d

(Tp).

NOTE : Rotat e th e driv e pinio n severa l time s t o

assur e prope r tapere d rolle r bearin g contact .

Standard :

New Bearing : 1.8 2 - 2.4 9 N- m

(18. 6 - 25. 4 kgf-cm , 16. 1 - 22. 0 Ibf-in )

Reuse d Bearing : 1.4 2 - 1.9 1 N- m

(14. 5 -19. 5 kgf-cm , 12. 6 - 16. 9 Ibf-in )

• I f th e tapere d rolle r bearin g preloa d exceed s th e stan -

dard , replac e th e pinio n spacer .

• I f th e tapere d rolle r bearin g preloa d i s les s tha n th e

standard , adjus t b y tightenin g th e locknu t a littl e a t a

time , bu t kee p th e torqu e withi n 21 6 - 31 3 N- m (2 2 -

3 2 kgf-m , 15 9 - 23 1 Ibf-ft) . I f thi s no t possible , replac e

th e pinio n spacer .

LOCKNU T

THRUST WASHE R

PINION HU B

THRUS T WASHE R

ProCarManuals.com

Page 450 of 1771

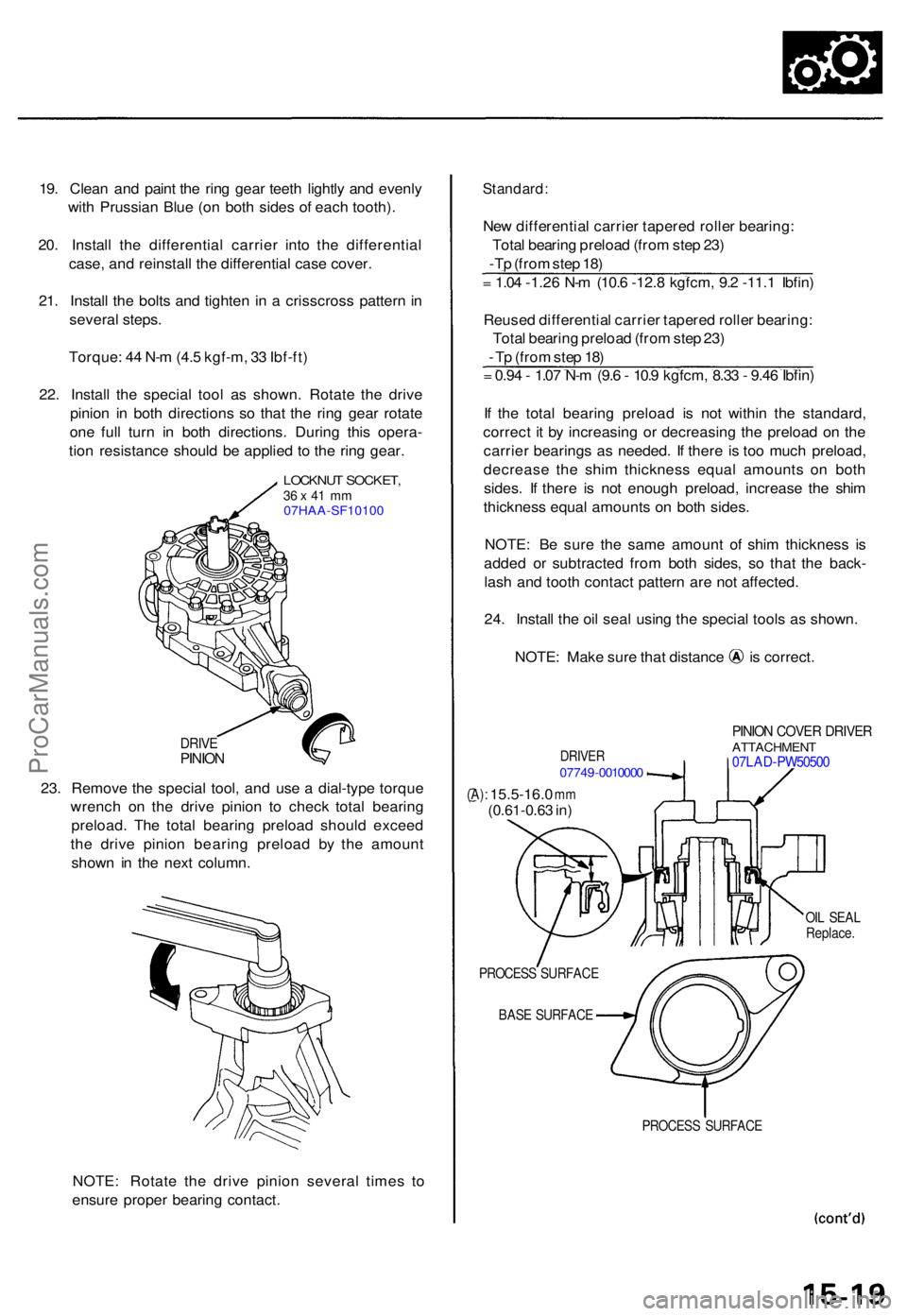

19. Clea n an d pain t th e rin g gea r teet h lightl y an d evenl y

wit h Prussia n Blu e (o n bot h side s o f eac h tooth) .

20 . Instal l th e differentia l carrie r int o th e differentia l

case , an d reinstal l th e differential case cover .

21 . Instal l th e bolt s an d tighte n i n a crisscros s patter n in

severa l steps .

Torque : 4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

22 . Instal l th e specia l too l a s shown . Rotat e th e driv e

pinio n i n bot h direction s s o tha t th e rin g gea r rotat e

on e ful l tur n i n bot h directions . Durin g thi s opera -

tio n resistanc e shoul d b e applie d t o th e rin g gear .

LOCKNU T SOCKET ,36 x 41 m m07HAA-SF10100

DRIV EPINIO N

23. Remov e th e specia l tool , an d us e a dial-typ e torqu e

wrenc h o n th e driv e pinio n t o chec k tota l bearin g

preload . Th e tota l bearin g preloa d shoul d excee d

th e driv e pinio n bearin g preloa d b y th e amoun t

show n i n th e nex t column .

NOTE : Rotat e th e driv e pinio n severa l time s t o

ensur e prope r bearin g contact .

Standard :

New differentia l carrie r tapere d rolle r bearing :

Tota l bearin g preloa d (fro m ste p 23 )

-Tp (fro m ste p 18 )

= 1.0 4 -1.2 6 N- m (10. 6 -12. 8 kgfcm , 9. 2 -11. 1 Ibfin )

Reuse d differentia l carrie r tapere d rolle r bearing :

Tota l bearin g preloa d (fro m ste p 23 )

- T p (fro m ste p 18 )

= 0.9 4 - 1.0 7 N- m (9. 6 - 10. 9 kgfcm , 8.3 3 - 9.4 6 Ibfin )

I f th e tota l bearin g preloa d i s no t withi n th e standard ,

correc t i t b y increasin g o r decreasin g th e preloa d o n th e

carrie r bearing s a s needed . I f ther e i s to o muc h preload ,

decreas e th e shi m thicknes s equa l amount s o n bot h

sides . I f ther e i s no t enoug h preload , increase the shi m

thicknes s equa l amount s o n bot h sides .

NOTE : B e sur e th e sam e amoun t of shi m thicknes s i s

adde d o r subtracte d fro m bot h sides , s o tha t th e back -

las h an d toot h contac t patter n ar e no t affected .

24 . Instal l th e oi l sea l usin g th e specia l tool s a s shown .

NOTE: Mak e sur e tha t distanc e i s correct .

DRIVER07749-001000 0

PINION COVE R DRIVE RATTACHMEN T07LAD-PW5050 0

(A): 15.5-16. 0 mm(0.61-0.6 3 in )

OIL SEA L

Replace .

PROCES S SURFAC E

BAS E SURFAC E

PROCESS SURFAC E

ProCarManuals.com

Page 451 of 1771

Differential Assembl y

Reassembl y (cont'd )

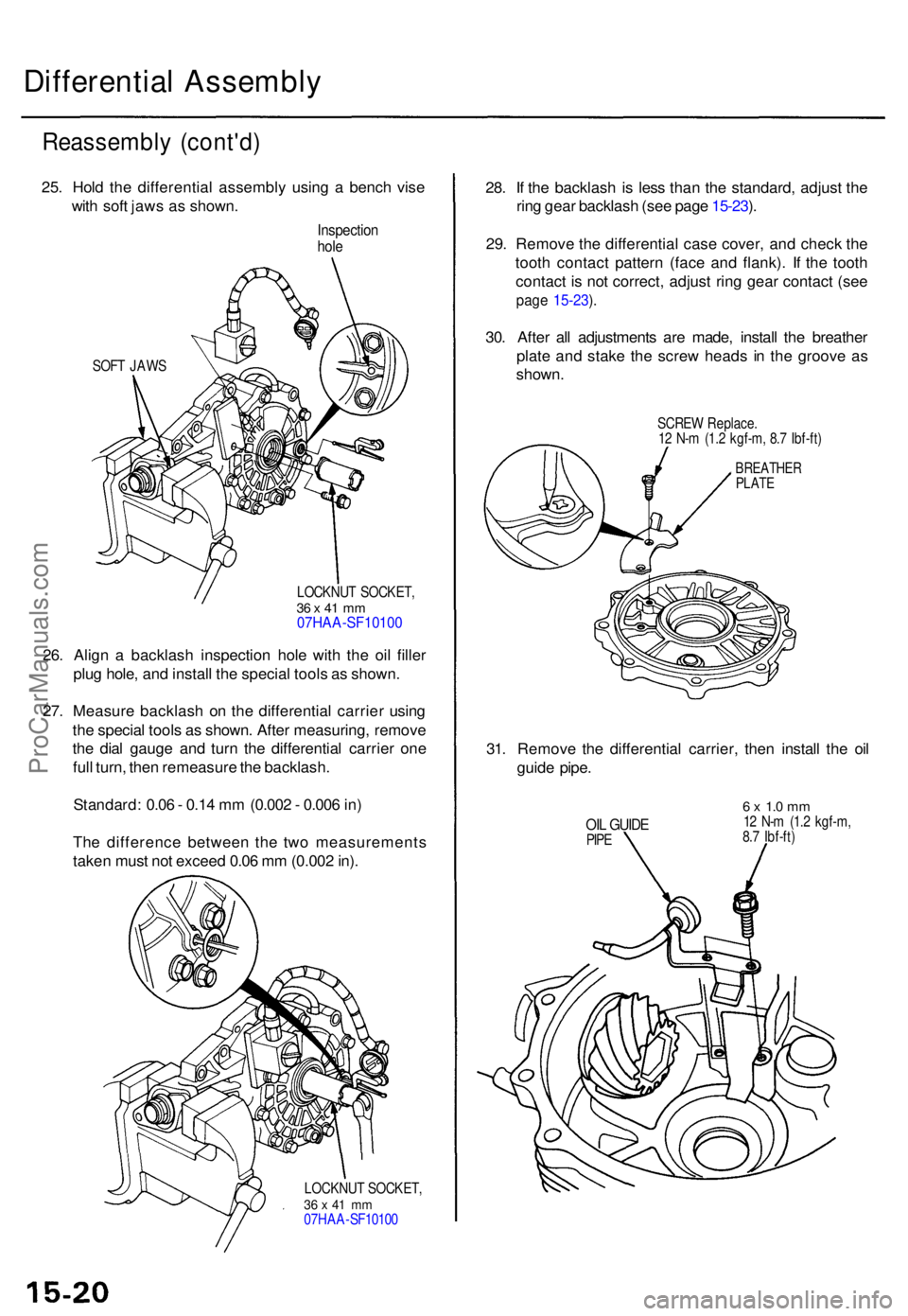

25. Hol d th e differentia l assembl y usin g a benc h vis e

wit h sof t jaw s a s shown .

Inspectio nhole

SOF T JAW S

LOCKNUT SOCKET ,

36 x 41 m m07HAA-SF1010 0

26. Alig n a backlas h inspectio n hol e wit h th e oi l fille r

plu g hole , an d instal l th e specia l tool s a s shown .

27 . Measur e backlas h o n th e differentia l carrie r usin g

th e specia l tool s a s shown . Afte r measuring , remov e

th e dia l gaug e an d tur n th e differentia l carrie r on e

ful l turn , the n remeasur e th e backlash .

Standard : 0.0 6 - 0.1 4 m m (0.00 2 - 0.00 6 in )

Th e differenc e betwee n th e tw o measurement s

take n mus t no t excee d 0.0 6 m m (0.00 2 in) .

LOCKNU T SOCKET ,36 x 41 m m07HA A-SF1010 0

28. I f th e backlas h i s les s tha n th e standard , adjus t th e

rin g gea r backlas h (se e pag e 15-23 ).

29 . Remov e th e differentia l cas e cover , an d chec k th e

toot h contac t patter n (fac e an d flank) . I f th e toot h

contac t i s no t correct , adjus t rin g gea r contac t (se e

page 15-23 ).

30 . Afte r al l adjustment s ar e made , instal l th e breathe r

plat e an d stak e th e scre w head s i n th e groov e a s

shown .

SCREW Replace .

1 2 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

BREATHE RPLATE

31. Remov e th e differentia l carrier , the n instal l th e oi l

guid e pipe .

OIL GUID EPIPE

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com

Page 455 of 1771

Differential Assembly

Installation

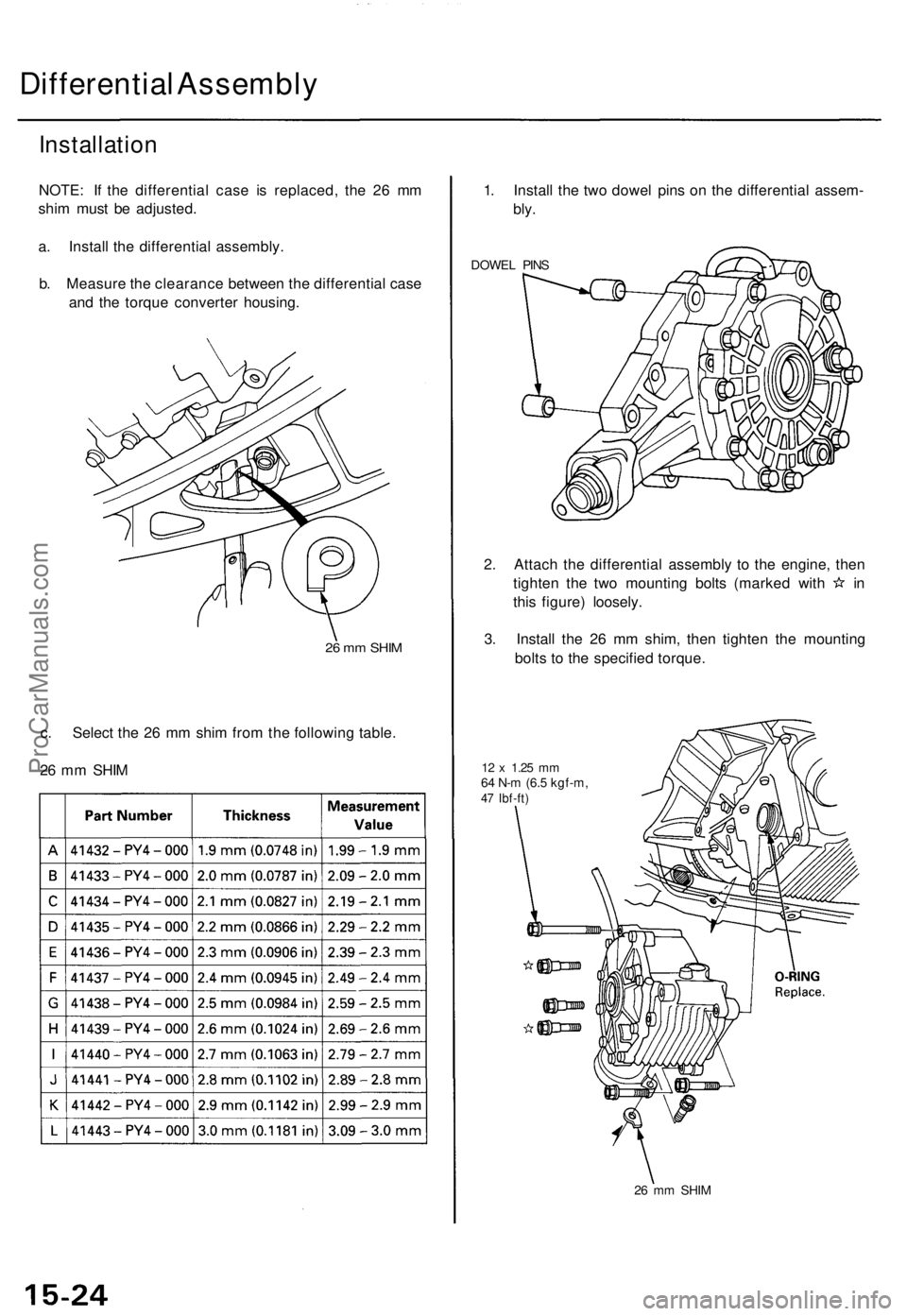

NOTE: If the differential case is replaced, the 26 mm

shim must be adjusted.

a. Install the differential assembly.

b. Measure the clearance between the differential case

and the torque converter housing.

26 mm SHIM

c. Select the 26 mm shim from the following table.

26 mm SHIM

1. Install the two dowel pins on the differential assem-

bly.

DOWEL PINS

2. Attach the differential assembly to the engine, then

tighten the two mounting bolts (marked with in

this figure) loosely.

3. Install the 26 mm shim, then tighten the mounting

bolts to the specified torque.

12 x

1.25

mm

64 N-m (6.5 kgf-m,

47 Ibf-ft)

26 mm SHIMProCarManuals.com

Page 457 of 1771

Differential Assembl y

Installatio n (cont'd )

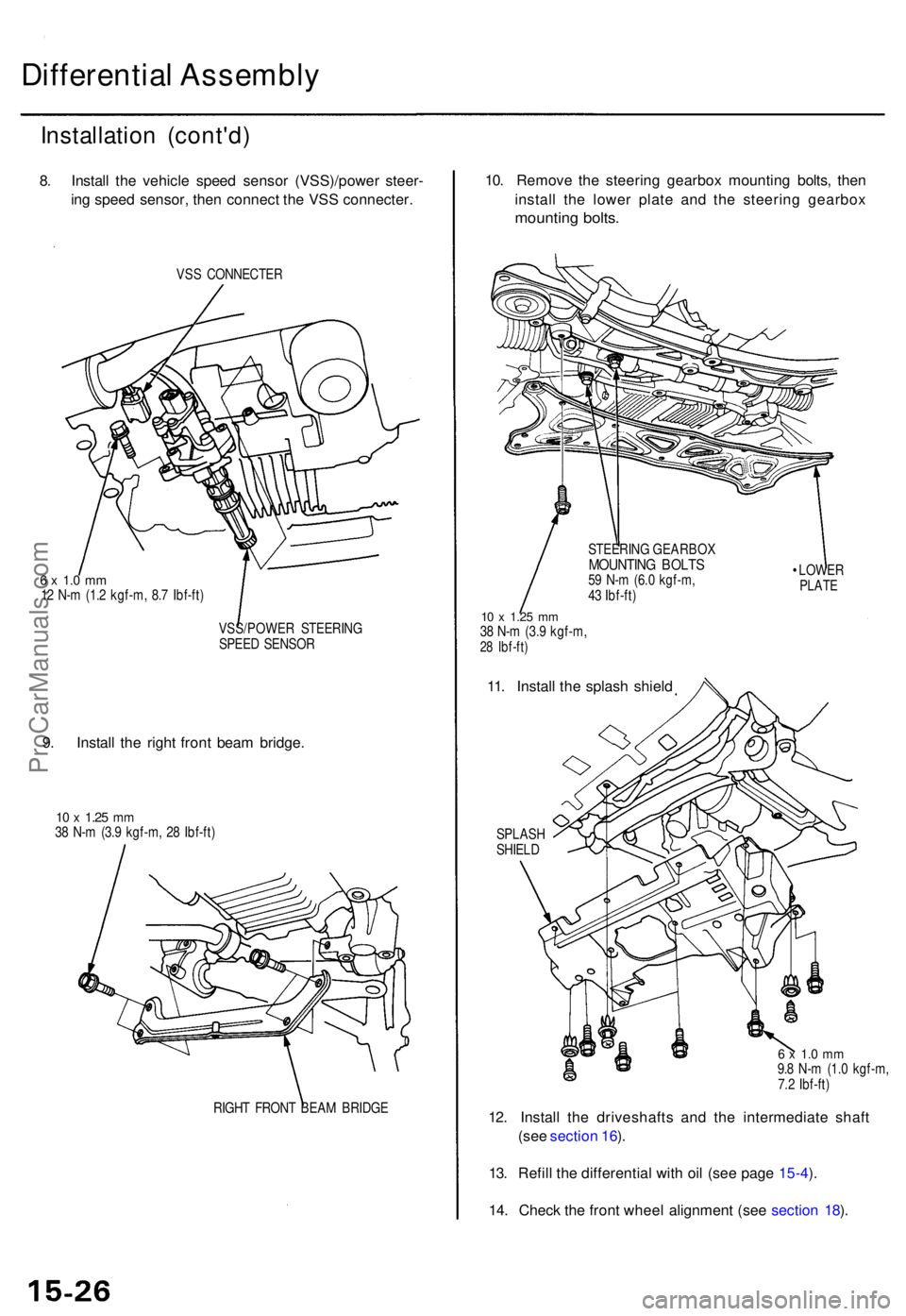

8. Instal l th e vehicl e spee d senso r (VSS)/powe r steer -

in g spee d sensor , the n connec t th e VS S connecter .

VSS CONNECTE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

VSS/POWE R STEERIN G

SPEE D SENSO R

9. Instal l th e righ t fron t bea m bridge .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m , 2 8 Ibf-ft )

RIGH T FRON T BEA M BRIDG E

10. Remov e th e steerin g gearbo x mountin g bolts , the n

instal l th e lowe r plat e an d th e steerin g gearbo x

mounting bolts .

STEERIN G GEARBO XMOUNTING BOLT S59 N- m (6. 0 kgf-m ,

4 3 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,28 Ibf-ft )

11. Instal l th e splas h shiel d

SPLAS HSHIELD •

LOWE R

PLATE

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

12. Instal l th e driveshaft s an d th e intermediat e shaf t

(se e sectio n 16 ).

13 . Refil l th e differentia l wit h oi l (se e pag e 15-4 ).

14 . Chec k th e fron t whee l alignmen t (se e sectio n 18 ).

ProCarManuals.com

Page 1010 of 1771

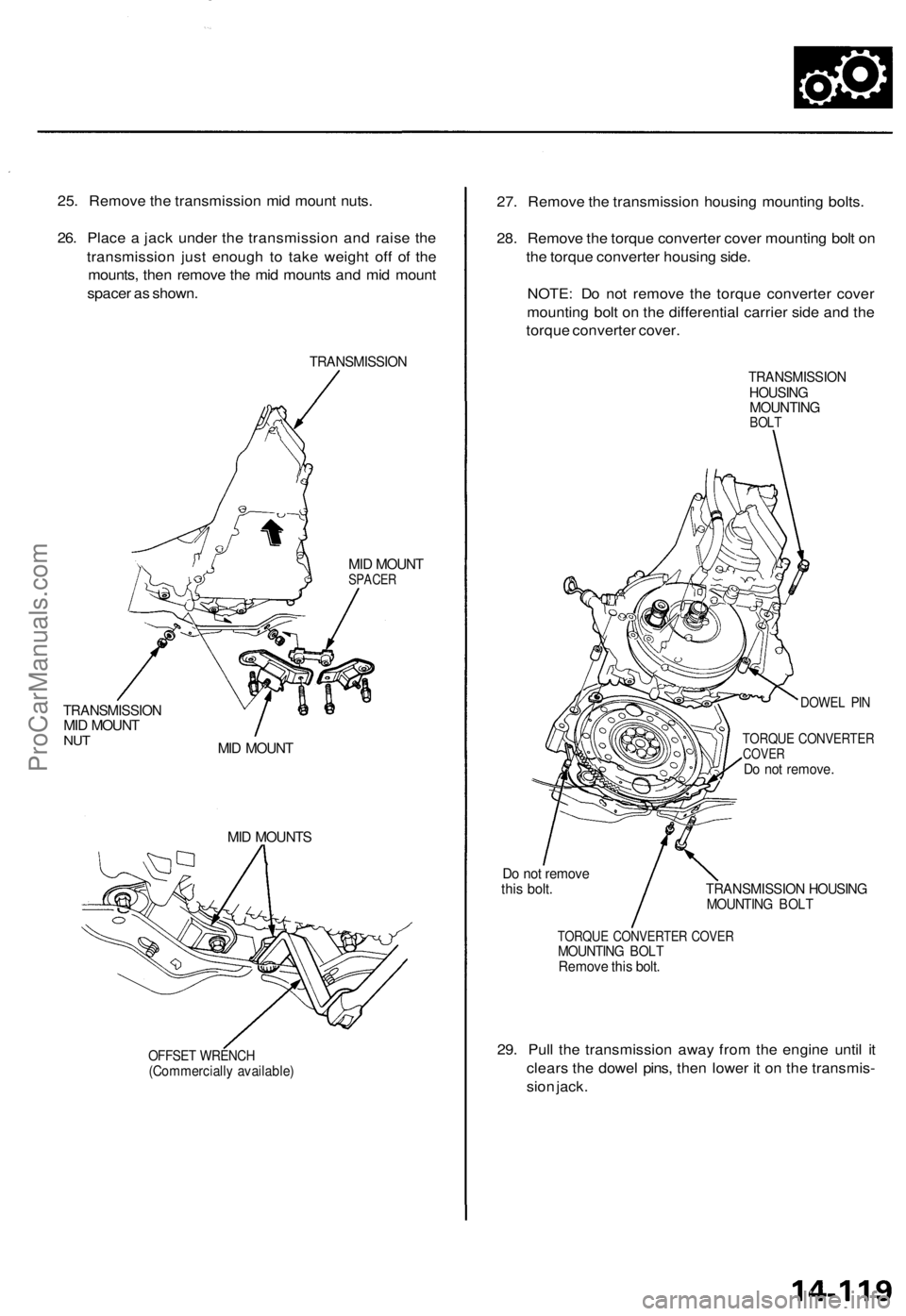

25. Remove the transmission mid mount nuts.

26. Place a jack under the transmission and raise the

transmission just enough to take weight off of the

mounts, then remove the mid mounts and mid mount

spacer as shown.

TRANSMISSION

TRANSMISSION

MID MOUNT

NUT

MID MOUNT

SPACER

MID MOUNT

MID MOUNTS

OFFSET WRENCH

(Commercially available)

27. Remove the transmission housing mounting bolts.

28. Remove the torque converter cover mounting bolt on

the torque converter housing side.

NOTE: Do not remove the torque converter cover

mounting bolt on the differential carrier side and the

torque converter cover.

TRANSMISSION

HOUSING

MOUNTING

BOLT

DOWEL PIN

TORQUE CONVERTER

COVER

Do not remove.

Do not remove

this bolt.

TRANSMISSION HOUSING

MOUNTING BOLT

TORQUE CONVERTER COVER

MOUNTING BOLT

Remove this bolt.

29. Pull the transmission away from the engine until it

clears the dowel pins, then lower it on the transmis-

sion jack.ProCarManuals.com