ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 591 of 1771

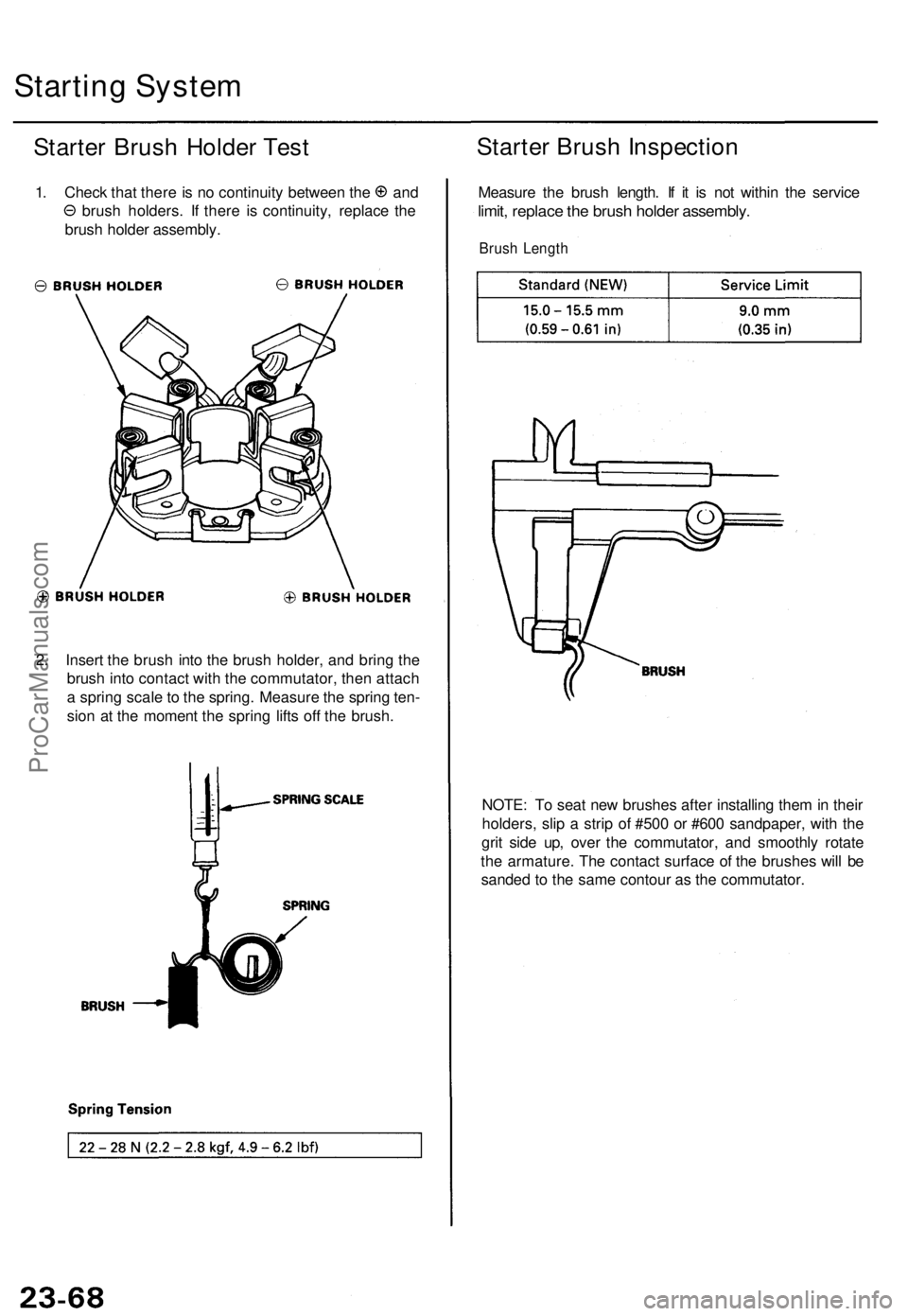

NOTE: T o sea t ne w brushe s afte r installin g the m in thei r

holders , sli p a stri p o f #50 0 o r #60 0 sandpaper , wit h th e

gri t sid e up , ove r th e commutator , an d smoothl y rotat e

th e armature . Th e contac t surfac e o f th e brushe s wil l b e

sande d t o th e sam e contou r a s th e commutator .

2

. Inser t th e brus h int o th e brus h holder , an d brin g th e

brus h int o contac t wit h th e commutator , the n attac h

a sprin g scal e to th e spring . Measur e th e sprin g ten -

sio n a t th e momen t th e sprin g lift s of f th e brush .

Startin g Syste m

Starter Brus h Holde r Tes t

1. Chec k tha t ther e is n o continuit y betwee n th e an d

brush holders . I f ther e i s continuity , replac e th e

brus h holde r assembly .

Starter Brus h Inspectio n

Measure th e brus h length . I f i t i s no t withi n th e servic e

limit, replac e th e brus h holde r assembly .

Brush Lengt h

ProCarManuals.com

Page 592 of 1771

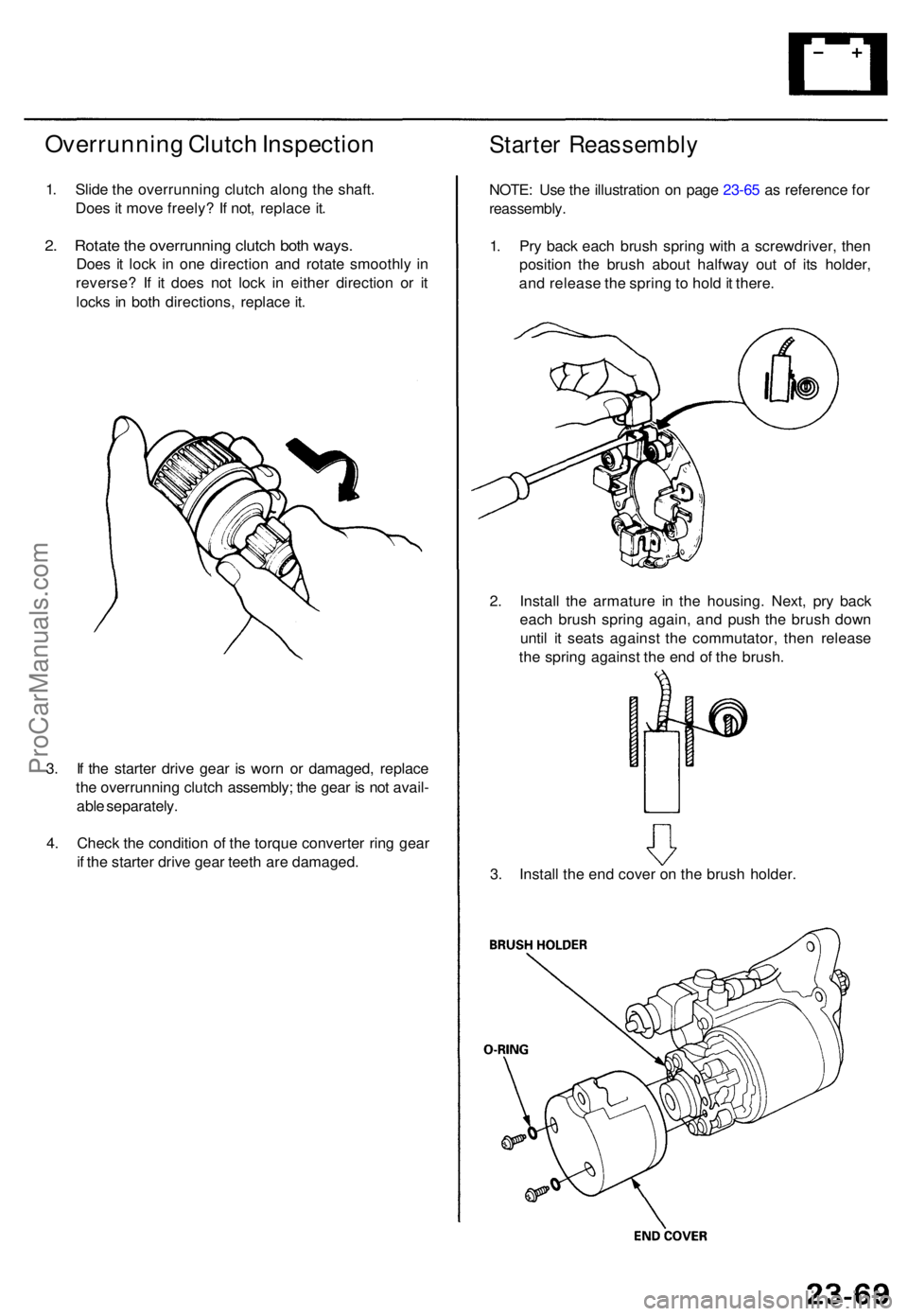

Overrunning Clutc h Inspectio n

1. Slid e th e overrunnin g clutc h alon g th e shaft .

Doe s i t mov e freely ? I f not , replac e it .

2. Rotat e th e overrunnin g clutc h bot h ways .

Does i t loc k i n on e directio n an d rotat e smoothl y i n

reverse ? I f i t doe s no t loc k i n eithe r directio n o r i t

lock s i n bot h directions , replac e it .

Starte r Reassembl y

NOTE: Us e th e illustratio n o n pag e 23-6 5 a s referenc e fo r

reassembly .

1. Pr y bac k eac h brus h sprin g wit h a screwdriver , the n

positio n th e brus h abou t halfwa y ou t o f it s holder ,

an d releas e th e sprin g to hol d it there .

2 . Instal l th e armatur e i n th e housing . Next , pr y bac k

eac h brus h sprin g again , an d pus h th e brus h dow n

unti l i t seat s agains t th e commutator , the n releas e

th e sprin g agains t th e en d o f th e brush .

3 . Instal l th e en d cove r o n th e brus h holder .

3

. I f th e starte r driv e gea r i s wor n o r damaged , replac e

th e overrunnin g clutc h assembly ; th e gea r i s no t avail -

abl e separately .

4 . Chec k th e conditio n o f th e torqu e converte r rin g gea r

i f th e starte r driv e gea r teet h ar e damaged .

ProCarManuals.com

Page 593 of 1771

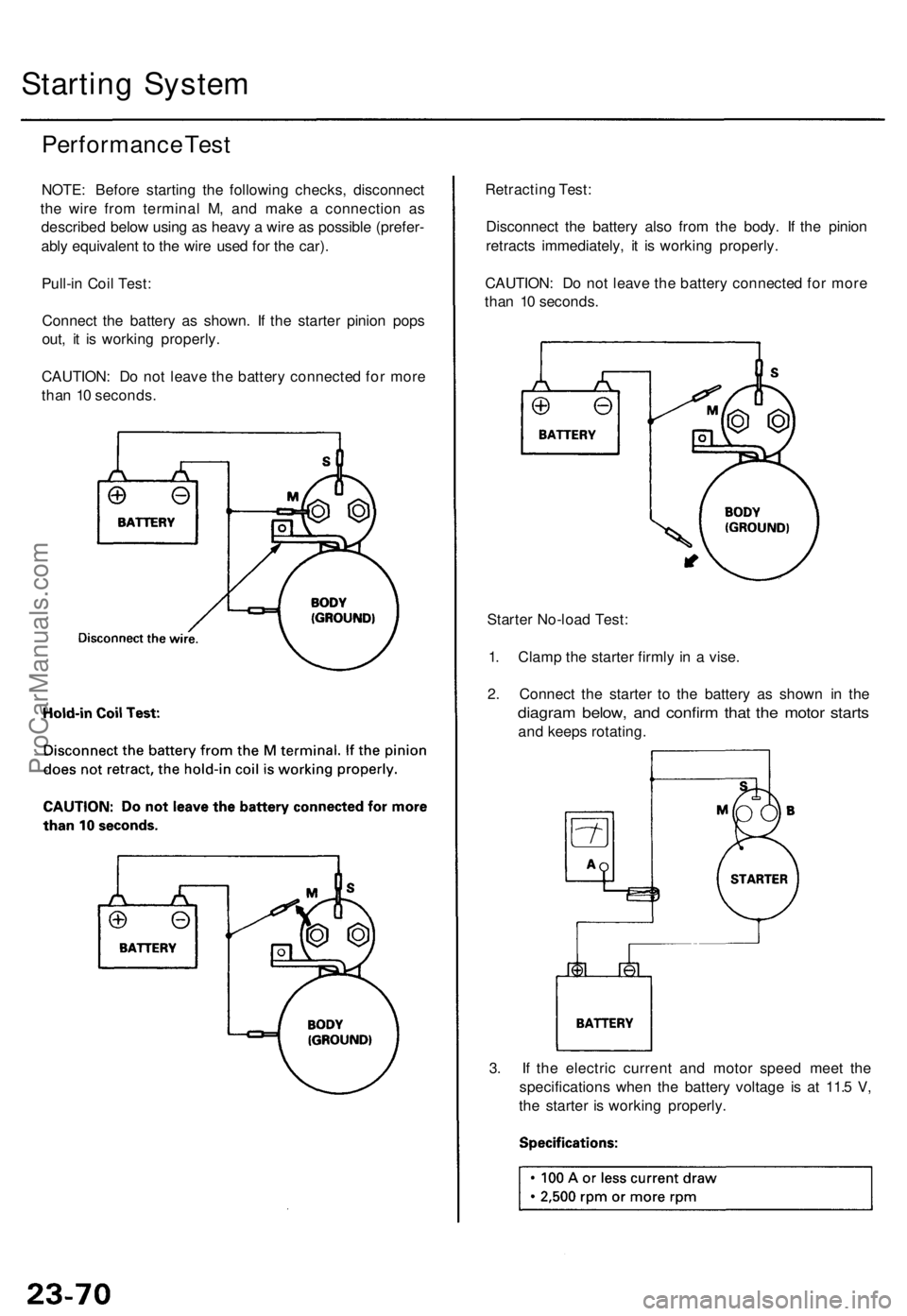

Starting Syste m

Performanc e Tes t

NOTE : Befor e startin g th e followin g checks , disconnec t

th e wir e fro m termina l M , an d mak e a connectio n a s

describe d belo w usin g a s heav y a wir e a s possibl e (prefer -

abl y equivalen t t o th e wir e use d fo r th e car) .

Pull-i n Coi l Test :

Connec t th e batter y a s shown . I f th e starte r pinio n pop s

out , i t i s workin g properly .

CAUTION : D o no t leav e th e batter y connecte d fo r mor e

tha n 1 0 seconds . Retractin

g Test :

Disconnec t th e batter y als o fro m th e body . I f th e pinio n

retract s immediately , i t i s workin g properly .

CAUTION : D o no t leav e th e batter y connecte d fo r mor e

tha n 1 0 seconds .

Starte r No-loa d Test :

1 . Clam p th e starte r firml y i n a vise .

2 . Connec t th e starte r t o th e batter y a s show n i n th e

diagra m below , an d confir m tha t th e moto r start s

and keep s rotating .

3 . I f th e electri c curren t an d moto r spee d mee t th e

specification s whe n th e batter y voltag e i s a t 11. 5 V ,

th e starte r i s workin g properly .

ProCarManuals.com

Page 594 of 1771

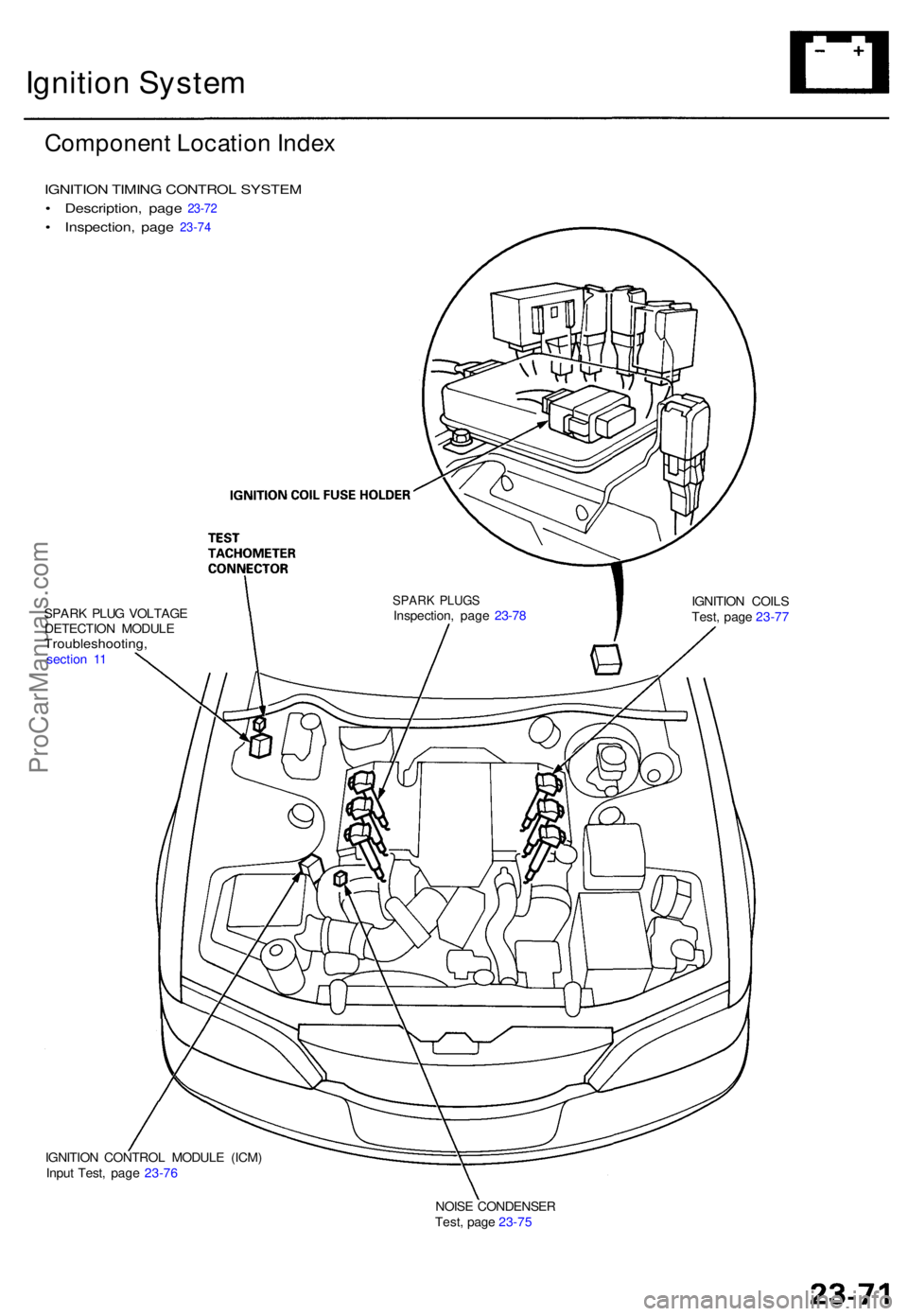

Ignition Syste m

Componen t Locatio n Inde x

IGNITIO N TIMIN G CONTRO L SYSTE M

• Description , pag e 23-7 2

• Inspection , pag e 23-74

SPAR K PLU G VOLTAG E

DETECTIO N MODUL E

Troubleshooting ,section 1 1

SPAR K PLUG SInspection , pag e 23-7 8 IGNITIO

N COIL S

Test , pag e 23-7 7

NOIS E CONDENSE R

Test , pag e 23-75

IGNITIO

N CONTRO L MODUL E (ICM )

Inpu t Test , pag e 23-7 6

ProCarManuals.com

Page 595 of 1771

Ignition Syste m

Descriptio n

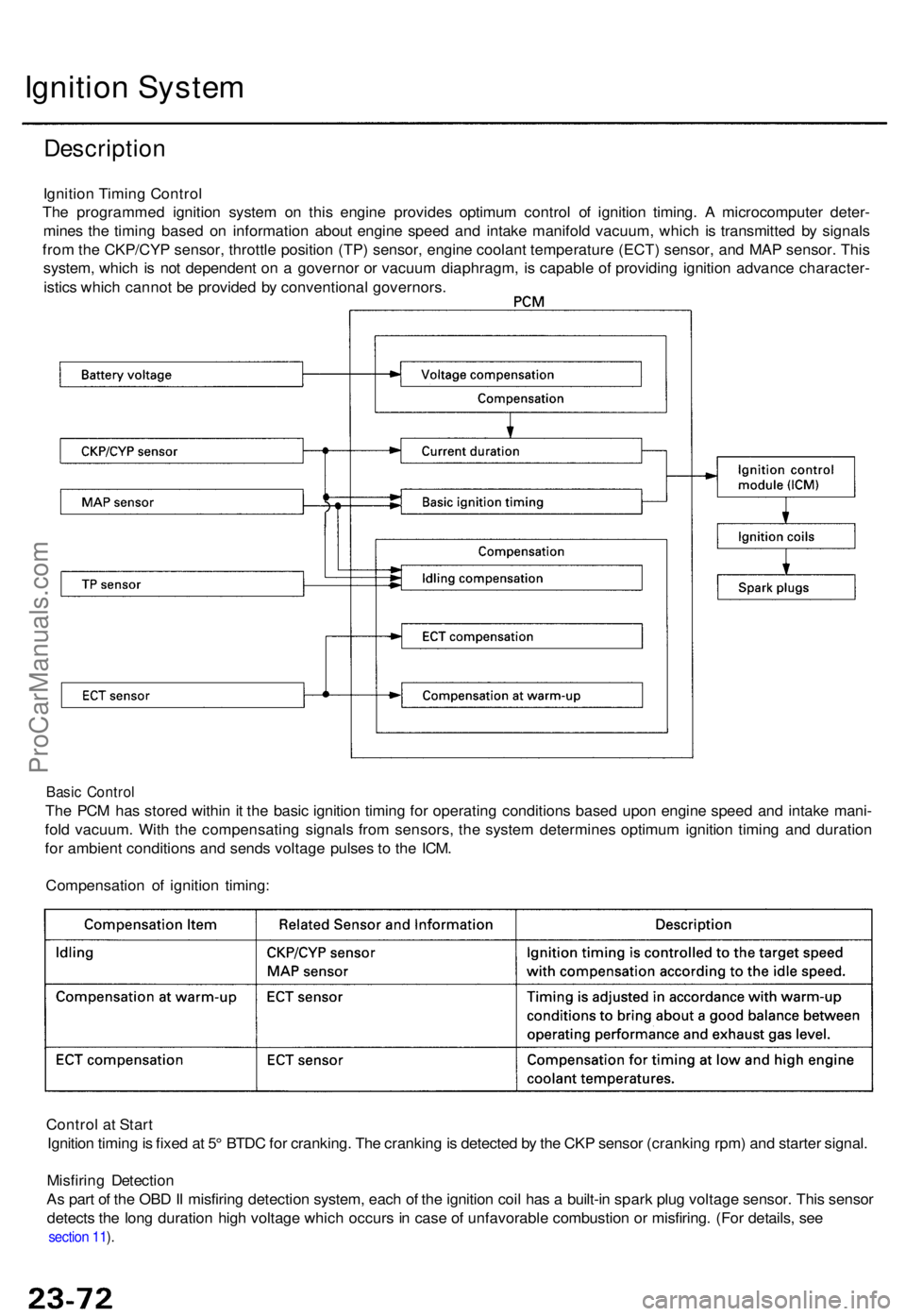

Ignition Timin g Contro l

Th e programme d ignitio n syste m o n thi s engine provide s optimu m contro l o f ignitio n timing . A microcompute r deter -

mine s th e timin g base d o n informatio n abou t engin e spee d an d intak e manifol d vacuum , whic h i s transmitte d b y signal s

fro m th e CKP/CY P sensor , throttl e positio n (TP ) sensor , engin e coolan t temperatur e (ECT ) sensor , an d MA P sensor . Thi s

system , whic h i s no t dependen t o n a governo r o r vacuu m diaphragm , i s capabl e o f providin g ignitio n advanc e character -

istic s whic h canno t b e provide d b y conventiona l governors .

Basic Contro l

The PC M ha s store d withi n it th e basi c ignitio n timin g fo r operatin g condition s base d upo n engin e spee d an d intak e mani -

fol d vacuum . Wit h th e compensatin g signal s fro m sensors , th e syste m determine s optimu m ignitio n timin g an d duratio n

fo r ambien t condition s an d send s voltag e pulse s t o th e ICM .

Compensatio n o f ignitio n timing :

Contro l a t Star t

Ignitio n timin g is fixe d a t 5 ° BTD C fo r cranking . Th e crankin g is detecte d b y th e CK P senso r (crankin g rpm ) an d starte r signal .

Misfirin g Detectio n

A s par t o f th e OB D II misfirin g detectio n system , eac h o f th e ignitio n coi l ha s a built-i n spar k plu g voltag e sensor . Thi s senso r

detect s th e lon g duratio n hig h voltag e whic h occur s in cas e o f unfavorabl e combustio n o r misfiring . (Fo r details , se e

section 11 ).

ProCarManuals.com

Page 596 of 1771

Ignition Syste m

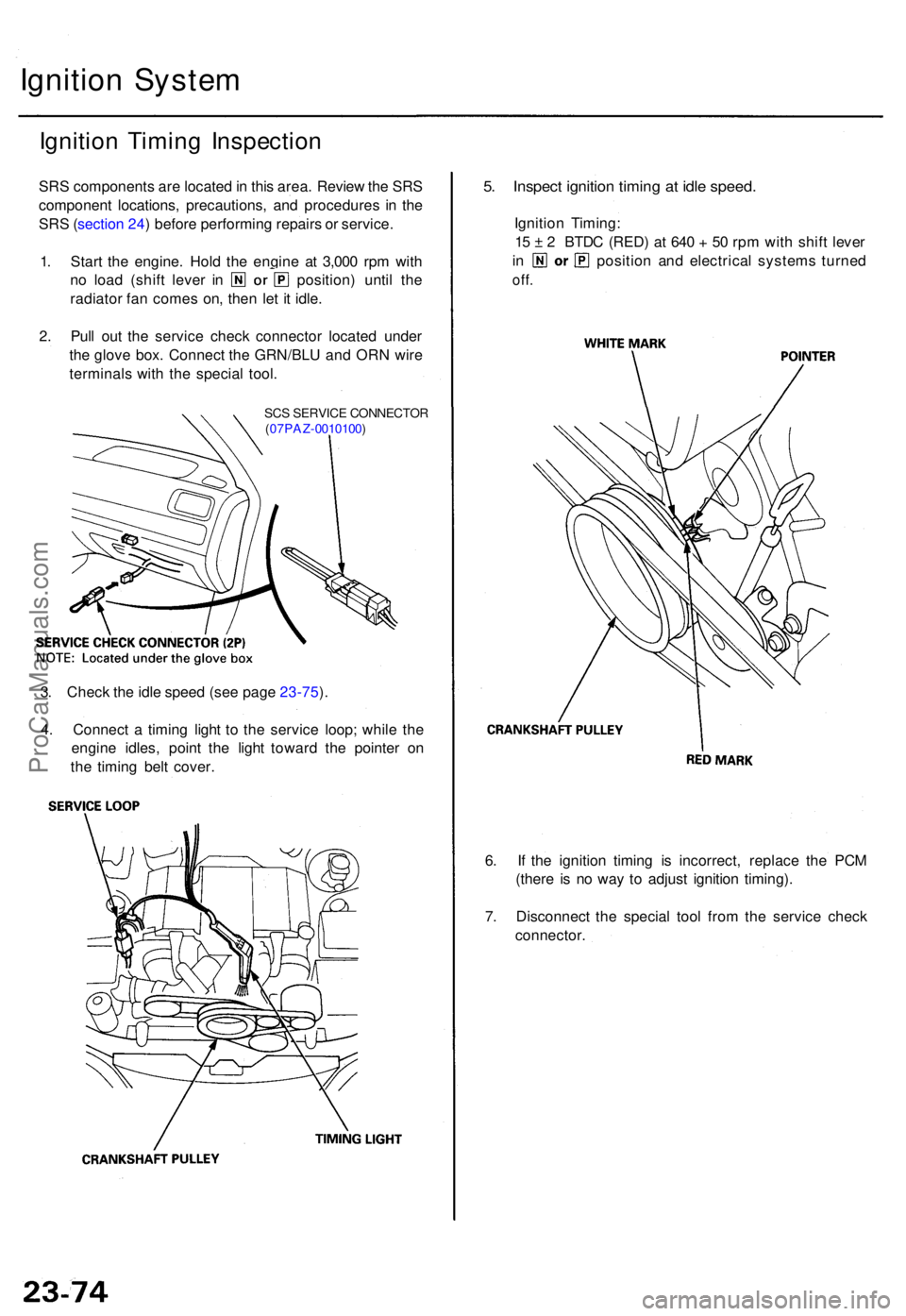

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (shif t leve r i n position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e glov e box . Connec t th e GRN/BL U an d OR N wir e

terminal s wit h th e specia l tool .

SCS SERVIC E CONNECTO R

( 07PAZ -0010100 )

5. Inspec t ignitio n timin g a t idl e speed .

Ignition Timing :

1 5 ± 2 BTD C (RED ) a t 64 0 + 50 rp m wit h shif t leve r

in positio n an d electrica l system s turne d

off.

6. I f th e ignitio n timin g i s incorrect , replac e th e PC M

(ther e i s n o wa y t o adjus t ignitio n timing) .

7 . Disconnec t th e specia l too l fro m th e servic e chec k

connector .

3

. Chec k th e idl e spee d (se e pag e 23-75 ).

4 . Connec t a timin g ligh t t o th e servic e loop ; whil e th e

engin e idles , poin t th e ligh t towar d th e pointe r o n

th e timin g bel t cover .

ProCarManuals.com

Page 597 of 1771

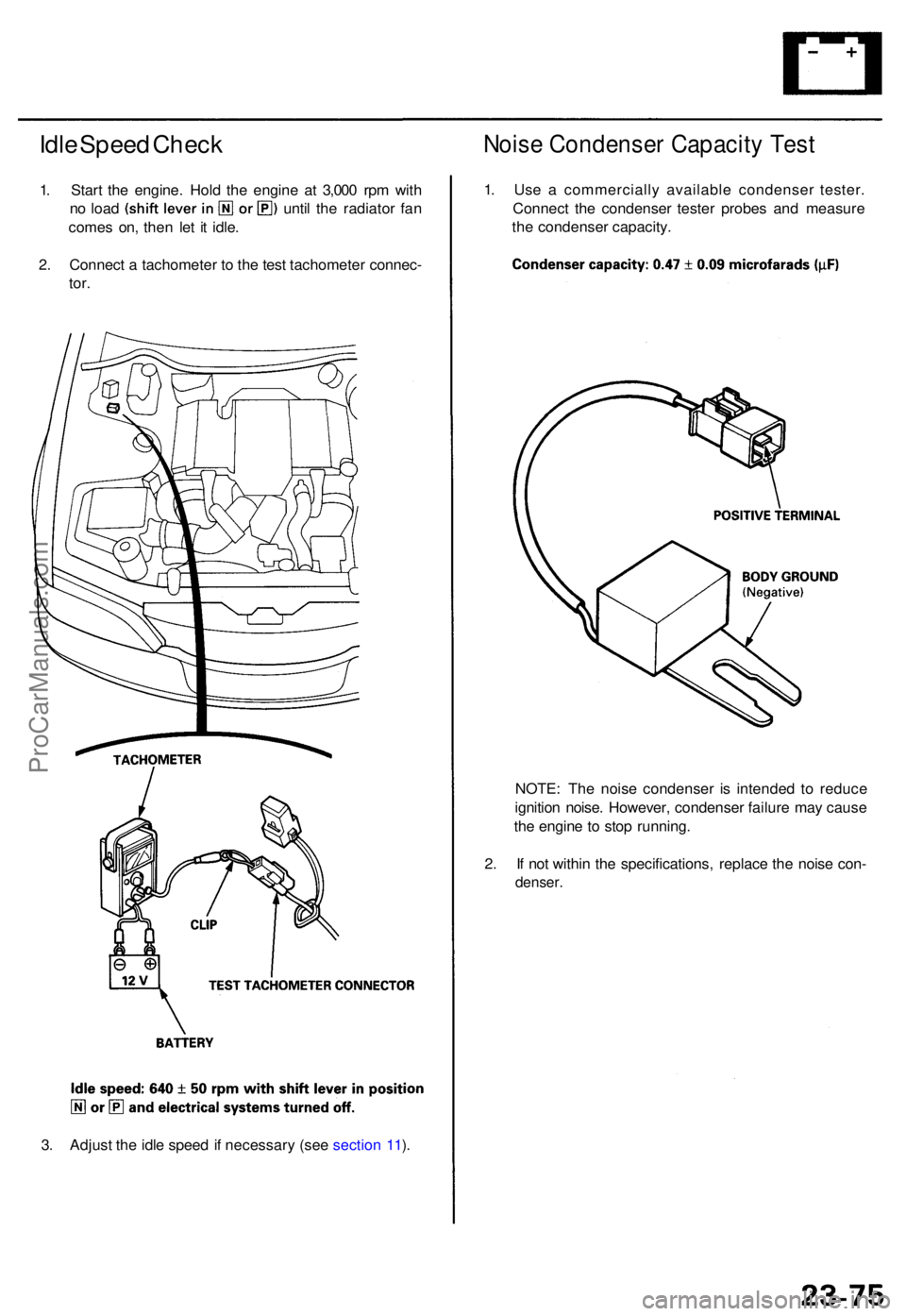

Idle Spee d Chec k

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d unti l th e radiato r fa n

come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r connec -

tor.

Nois e Condense r Capacit y Tes t

1. Us e a commerciall y availabl e condense r tester .

Connec t th e condense r teste r probe s an d measur e

th e condense r capacity .

NOTE : Th e nois e condense r i s intende d t o reduc e

ignitio n noise . However , condense r failur e ma y caus e

th e engin e t o sto p running .

2 . I f no t withi n th e specifications , replac e th e nois e con -

denser .

3. Adjus t th e idl e spee d if necessar y (se e sectio n 11 ).

ProCarManuals.com

Page 598 of 1771

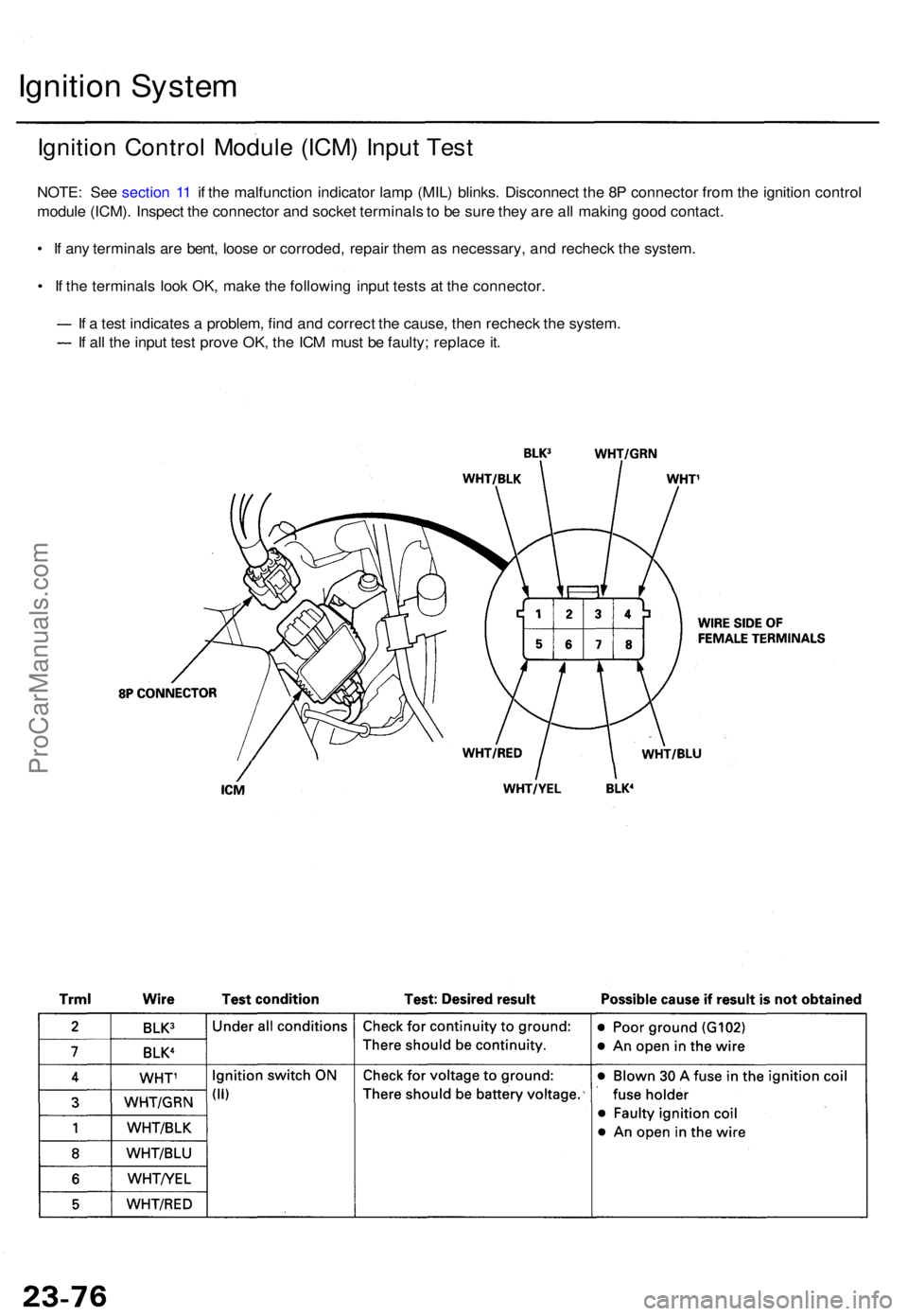

Ignition Syste m

Ignition Contro l Modul e (ICM ) Inpu t Tes t

NOTE : Se e sectio n 1 1 i f th e malfunctio n indicator lamp (MIL ) blinks . Disconnec t th e 8 P connecto r fro m th e ignitio n contro l

modul e (ICM) . Inspec t th e connecto r an d socke t terminal s to b e sur e the y ar e al l makin g goo d contact .

• I f an y terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

• I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

I f a tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

I f al l th e inpu t tes t prov e OK , th e IC M mus t b e faulty ; replac e it .

ProCarManuals.com

Page 599 of 1771

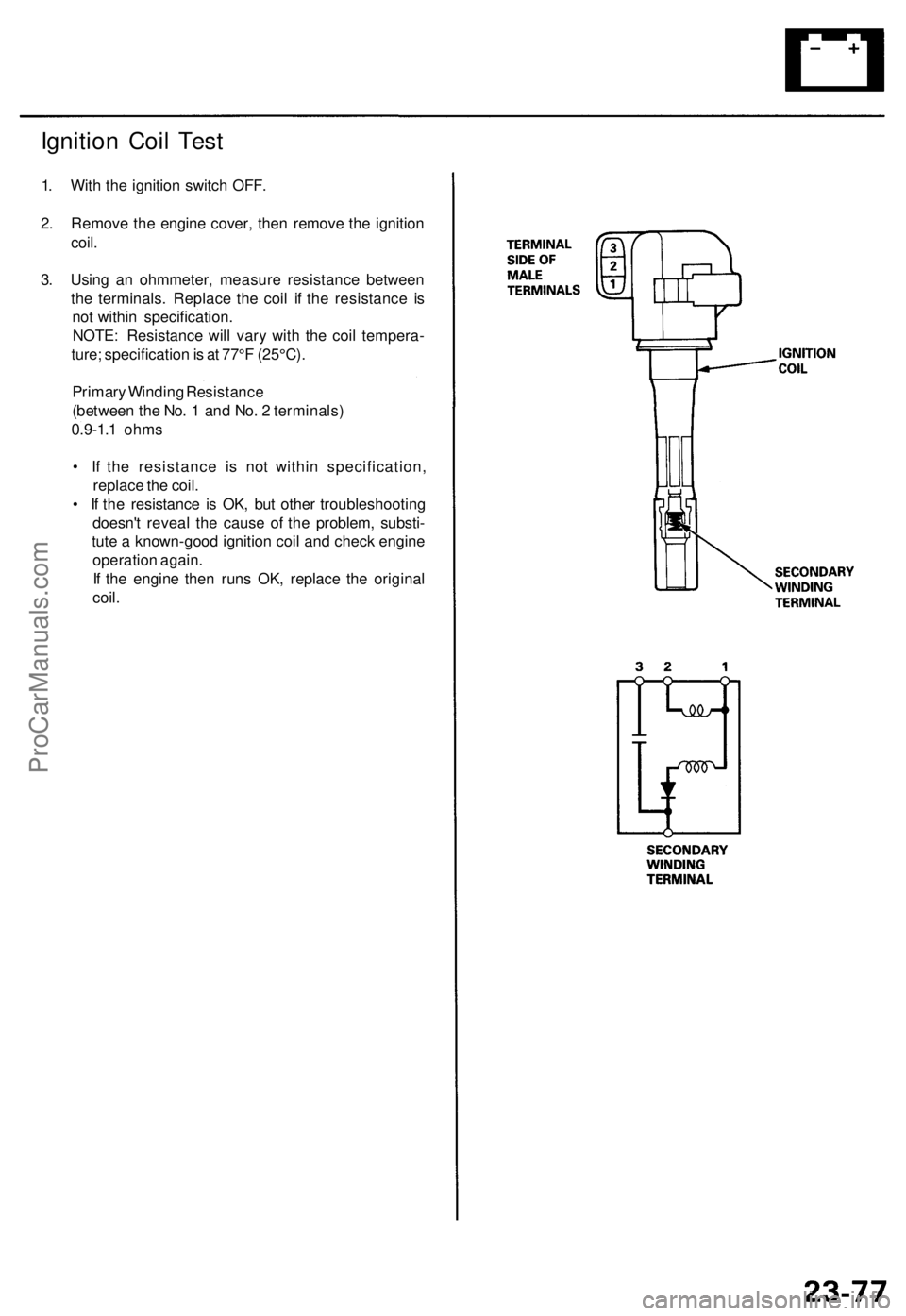

Ignition Coi l Tes t

1. Wit h th e ignitio n switc h OFF .

2 . Remov e th e engin e cover , the n remov e th e ignitio n

coil .

3 . Usin g a n ohmmeter , measur e resistanc e betwee n

th e terminals . Replac e th e coi l i f th e resistanc e i s

no t withi n specification .

NOTE : Resistanc e wil l var y wit h th e coi l tempera -

ture ; specificatio n is a t 77° F (25°C) .

Primar y Windin g Resistanc e

(betwee n th e No . 1 an d No . 2 terminals )

0.9 -1. 1 ohm s

• I f th e resistanc e i s no t withi n specification ,

replac e th e coil .

• I f th e resistanc e i s OK , bu t othe r troubleshootin g

doesn' t revea l th e caus e o f th e problem , substi -

tut e a known-goo d ignitio n coi l an d chec k engin e

operatio n again .

I f th e engin e the n run s OK , replac e th e origina l

coil .

ProCarManuals.com

Page 600 of 1771

Ignition Syste m

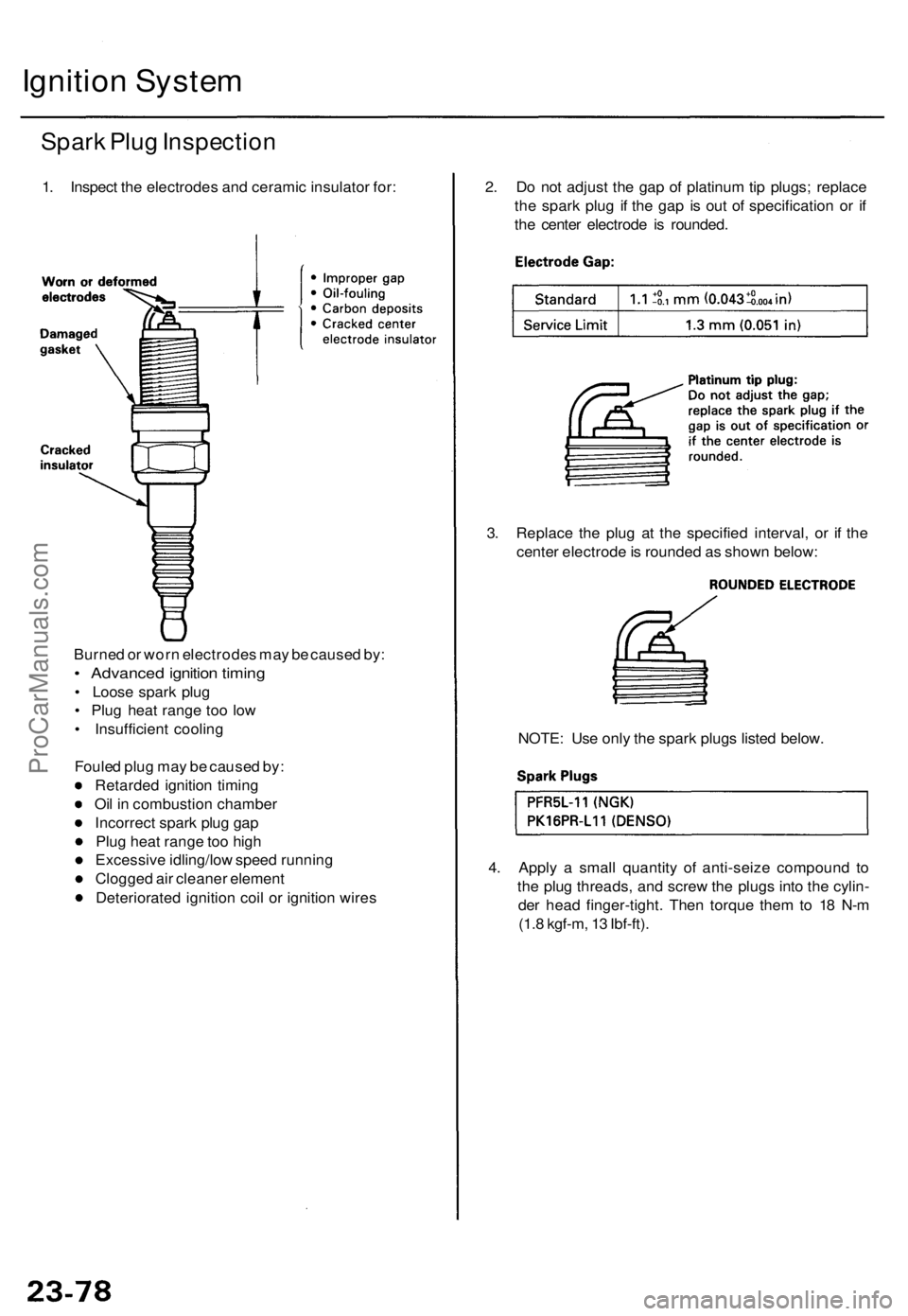

Spark Plu g Inspectio n

1. Inspec t th e electrode s an d cerami c insulato r for : 2. D o no t adjus t th e ga p o f platinu m tip plugs ; replac e

th e spar k plu g i f th e ga p i s ou t o f specificatio n o r i f

th e cente r electrod e i s rounded .

3 . Replac e th e plu g a t th e specifie d interval , o r i f th e

cente r electrod e is rounde d a s show n below :

4 . Appl y a smal l quantit y o f anti-seiz e compoun d t o

th e plu g threads , an d scre w th e plug s int o th e cylin -

de r hea d finger-tight . The n torqu e the m to 1 8 N- m

(1. 8 kgf-m , 1 3 Ibf-ft) .

NOTE

: Us e onl y th e spar k plug s liste d below .

Burne

d o r wor n electrode s ma y b e cause d by :

• Advance d ignitio n timin g

• Loos e spar k plu g

• Plu g hea t rang e to o lo w

• Insufficien t coolin g

Foule d plu g ma y b e cause d by :

Retarde d ignitio n timin g

Oi l i n combustio n chambe r

Incorrec t spar k plu g ga p

Plu g hea t rang e to o hig h

Excessiv e idling/lo w spee d runnin g

Clogge d ai r cleane r elemen t

Deteriorate d ignitio n coi l o r ignitio n wire s

ProCarManuals.com