bolt pattern ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 81 of 1771

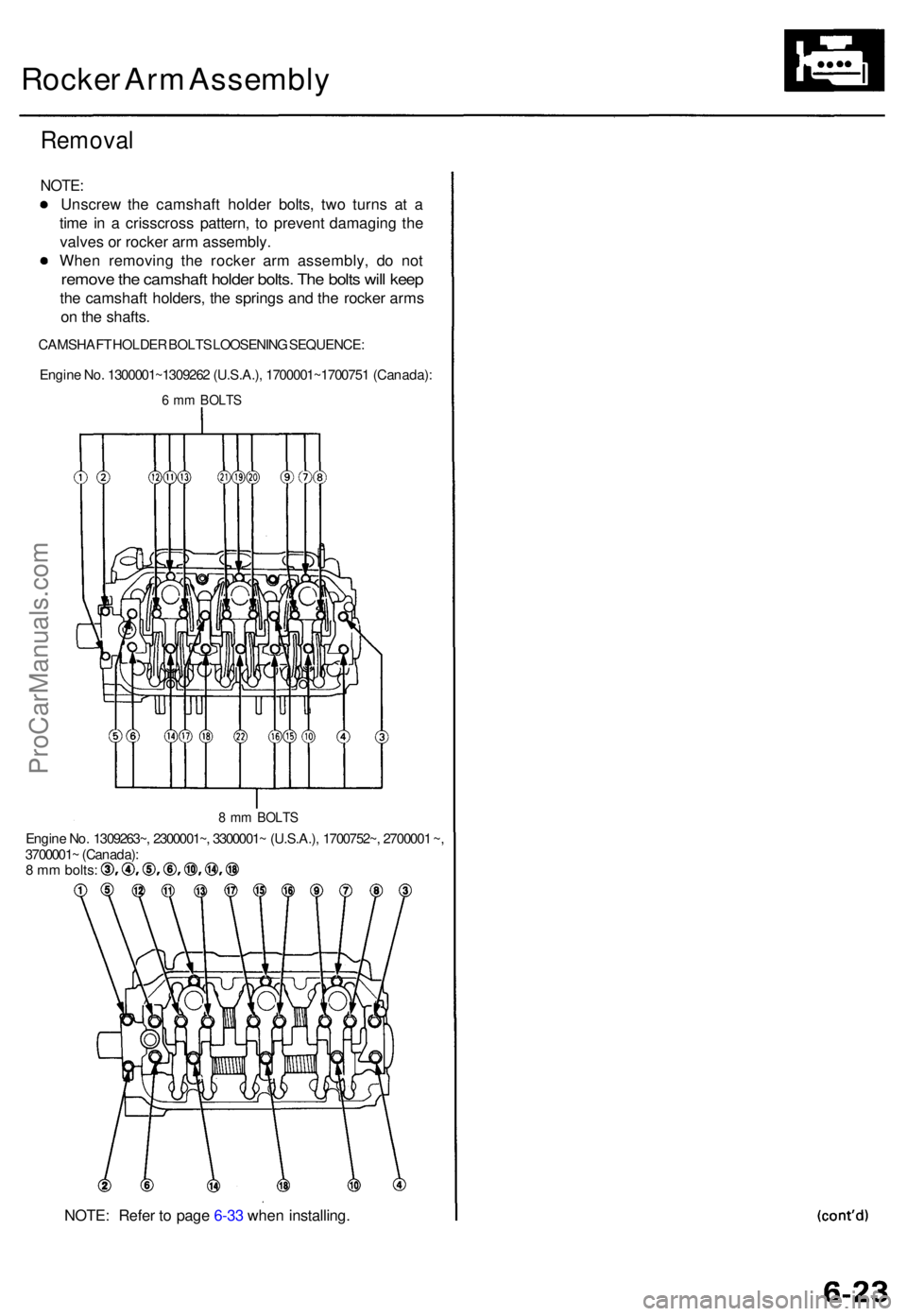

Rocker Ar m Assembl y

Removal

NOTE:

Unscre w th e camshaf t holde r bolts , tw o turn s a t a

tim e i n a crisscros s pattern , t o preven t damagin g th e

valve s o r rocke r ar m assembly .

Whe n removin g th e rocke r ar m assembly , d o no t

remov e th e camshaf t holde r bolts . Th e bolt s wil l kee p

the camshaf t holders , th e spring s an d th e rocke r arm s

o n th e shafts .

CAMSHAF T HOLDE R BOLT S LOOSENIN G SEQUENCE :

Engin e No . 1300001~130926 2 (U.S.A.) , 1700001~170075 1 (Canada) :

6 m m BOLT S

8 m m BOLT S

Engine No . 1309263~ , 2300001~ , 3300001 ~ (U.S.A.) , 1700752~ , 270000 1 ~ ,

3700001 ~ (Canada) :

8 m m bolts :

NOTE : Refe r t o pag e 6-3 3 whe n installing .

ProCarManuals.com

Page 103 of 1771

Drive Plat e Connectin

g Ro d an dCrankshaf t

Replacemen t En

d Pla y

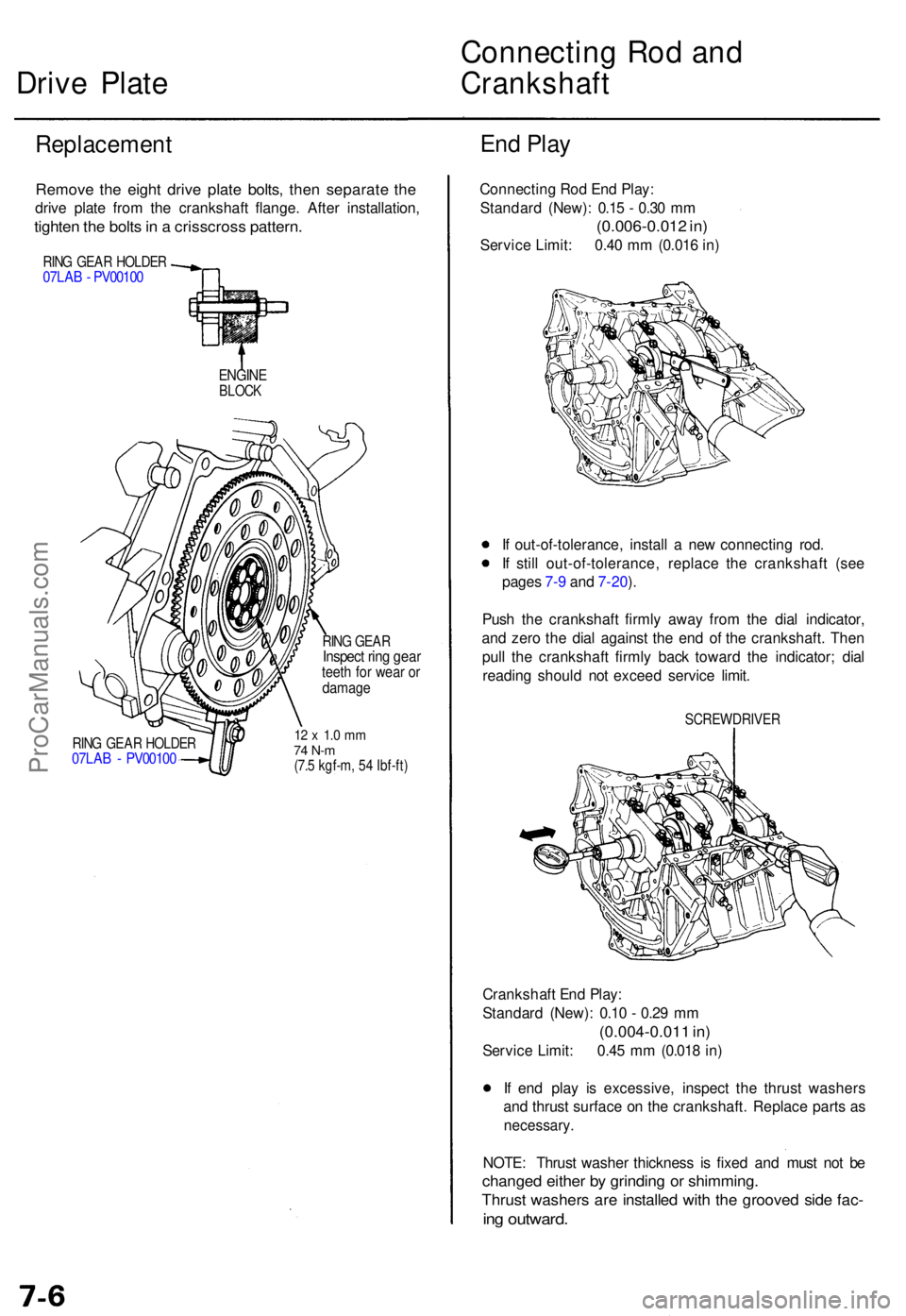

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installation ,

tighten th e bolt s in a crisscros s pattern .

RING GEA R HOLDE R07LAB - PV0010 0

ENGINEBLOCK

RING GEA R HOLDE R07LAB - PV0010 0

RING GEA RInspec t rin g gea rteeth fo r wea r o rdamag e

12 x 1. 0 m m74 N- m(7.5 kgf-m , 5 4 Ibf-ft )

Connectin g Ro d En d Play :

Standar d (New) : 0.1 5 - 0.3 0 m m

(0.006-0.01 2 in )

Servic e Limit : 0.4 0 m m (0.01 6 in )

I f out-of-tolerance , instal l a ne w connectin g rod .

I f stil l out-of-tolerance , replac e th e crankshaf t (se e

page s 7- 9 an d 7-20 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) : 0.1 0 - 0.2 9 m m

(0.004-0.01 1 in )

Servic e Limit : 0.4 5 m m (0.01 8 in )

I f en d pla y i s excessive , inspec t th e thrus t washer s

an d thrus t surfac e o n th e crankshaft . Replac e part s a s

necessary .

NOTE: Thrus t washe r thicknes s i s fixe d an d mus t no t b e

change d eithe r b y grindin g o r shimming .

Thrust washer s ar e installe d wit h th e groove d sid e fac -

ing outward .

ProCarManuals.com

Page 360 of 1771

1. Remove the eight 6 mm bolts and one 8 mm bolt

securing the regulator valve body, then remove the

regulator valve body.

2. Remove the stator shaft, stop shaft, and the regula-

tor separator plate.

3. Remove the three 6 mm bolts and two 8 mm bolts

securing the ATF pump body, then remove the ATF

pump body.

4. Remove the ATF pump driven gear shaft, ATF pump

gears, torque converter check valve, and spring.

5. Remove the four bolts securing the accumulator

cover, then remove the accumulator cover.

NOTE: The accumulator cover is spring loaded. To

prevent stripping the threads in the torque converter

housing, press down on the accumulator cover

while unscrewing the bolts in a crisscross pattern.

6. Remove the eight ATF feed pipes from the accumu-

lator body.

7. Remove the eight 6 mm bolts and seven 6 mm spe-

cial bolts securing the accumulator body, then

remove the accumulator body.

8. Remove the torque converter housing separator

plate with three dowel pins.ProCarManuals.com

Page 424 of 1771

Transmission

Installation

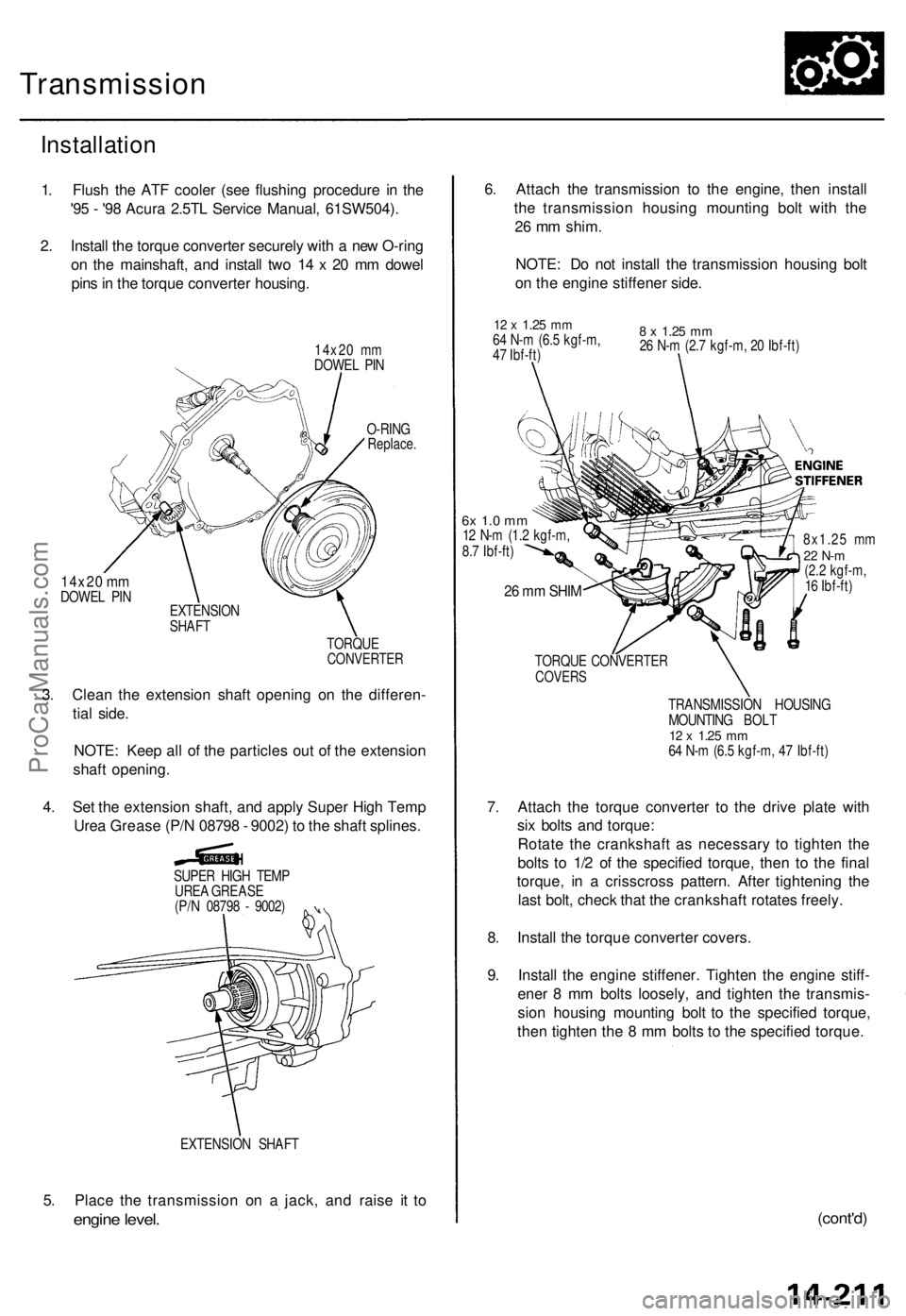

1. Flush the ATF cooler (see flushing procedure in the

'95 - '98 Acura 2.5TL Service Manual, 61SW504).

2. Install the torque converter securely with a new O-ring

on the mainshaft, and install two 14 x 20 mm dowel

pins in the torque converter housing.

14x20 mm

DOWEL PIN

14x20 mm

DOWEL PIN

O-RING

Replace.

EXTENSION

SHAFT

TORQUE

CONVERTER

3. Clean the extension shaft opening on the differen-

tial side.

NOTE: Keep all of the particles out of the extension

shaft opening.

4. Set the extension shaft, and apply Super High Temp

Urea Grease (P/N 08798 - 9002) to the shaft splines.

SUPER HIGH TEMP

UREA GREASE

(P/N 08798 - 9002)

EXTENSION SHAFT

5. Place the transmission on a jack, and raise it to

engine level.

6. Attach the transmission to the engine, then install

the transmission housing mounting bolt with the

26 mm shim.

NOTE: Do not install the transmission housing bolt

on the engine stiffener side.

12 x

1.25

mm

64 N-m (6.5 kgf-m,

47 Ibf-ft)

8 x

1.25

mm

26 N-m (2.7 kgf-m, 20 Ibf-ft)

6x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

26 mm SHIM

8x1.25 mm

22 N-m

(2.2 kgf-m,

16 Ibf-ft)

TORQUE CONVERTER

COVERS

TRANSMISSION HOUSING

MOUNTING BOLT

12 x

1.25

mm

64 N-m (6.5 kgf-m, 47 Ibf-ft)

7. Attach the torque converter to the drive plate with

six bolts and torque:

Rotate the crankshaft as necessary to tighten the

bolts to 1/2 of the specified torque, then to the final

torque, in a crisscross pattern. After tightening the

last bolt, check that the crankshaft rotates freely.

8. Install the torque converter covers.

9. Install the engine stiffener. Tighten the engine stiff-

ener 8 mm bolts loosely, and tighten the transmis-

sion housing mounting bolt to the specified torque,

then tighten the 8 mm bolts to the specified torque.

(cont'd)ProCarManuals.com

Page 438 of 1771

Differential Assembl y

Inspection

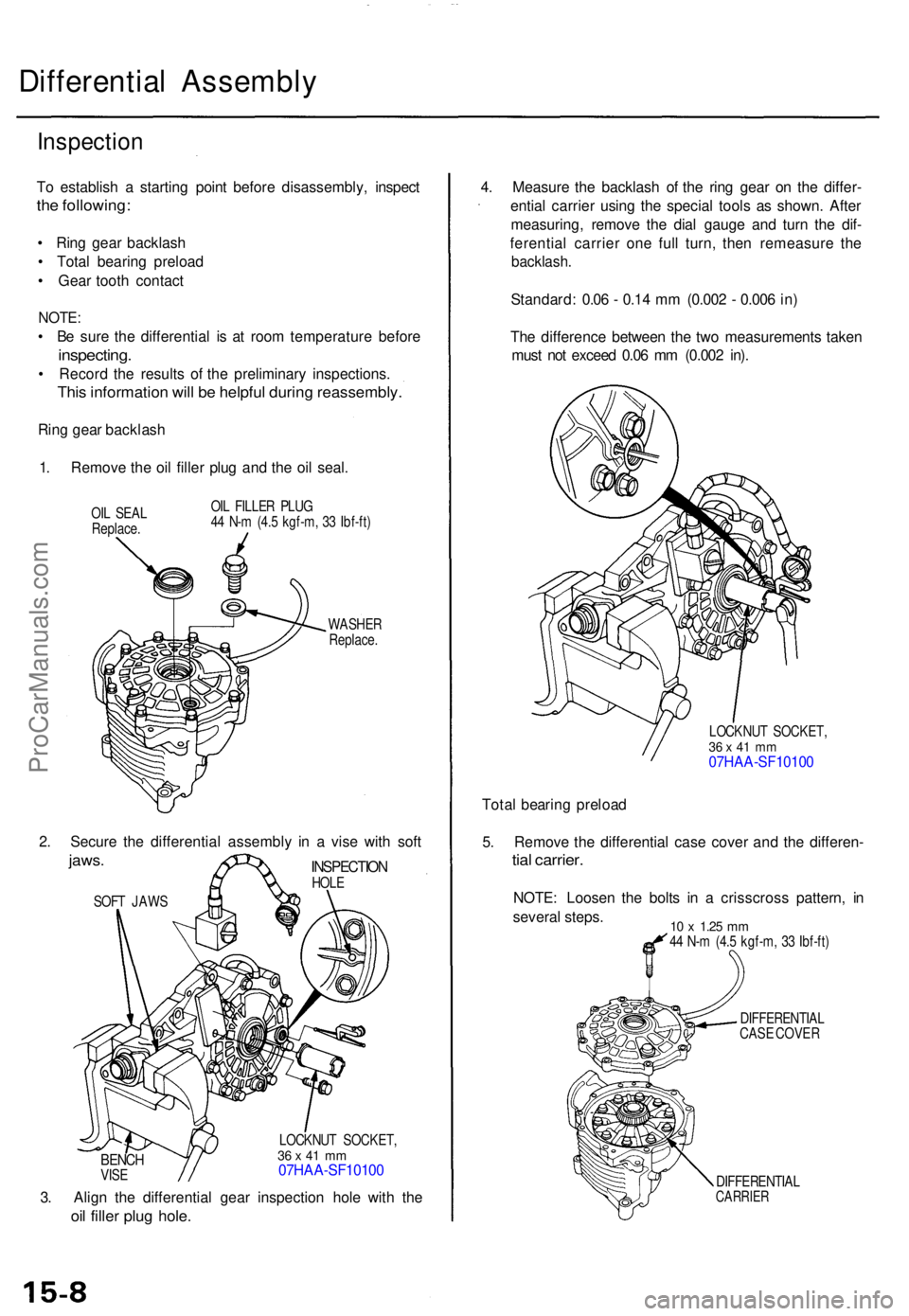

To establis h a startin g poin t befor e disassembly , inspec t

the following :

• Rin g gea r backlas h

• Tota l bearin g preloa d

• Gea r toot h contac t

NOTE:

• B e sur e th e differentia l i s a t roo m temperatur e befor e

inspecting .

• Recor d th e result s o f th e preliminar y inspections .

This informatio n wil l b e helpfu l during reassembly .

Ring gea r backlas h

1 . Remov e th e oi l fille r plu g an d th e oi l seal .

OIL SEA L

Replace . OI

L FILLE R PLU G

4 4 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

WASHE R

Replace .

BENCHVISE LOCKNU

T SOCKET ,

36 x 4 1 m m07HAA-SF1010 0

3. Alig n th e differentia l gea r inspectio n hol e wit h th e

oil fille r plu g hole .

4. Measur e th e backlas h o f th e rin g gea r o n th e differ -

entia l carrie r usin g th e specia l tool s a s shown . Afte r

measuring , remov e th e dia l gaug e an d tur n th e dif -

ferentia l carrie r on e ful l turn , the n remeasur e th e

backlash .

Standard : 0.0 6 - 0.1 4 m m (0.00 2 - 0.00 6 in )

Th e differenc e betwee n th e tw o measurement s take n

mus t no t excee d 0.0 6 m m (0.00 2 in) .

LOCKNU T SOCKET ,36 x 4 1 m m07HAA-SF1010 0

Total bearin g preloa d

5 . Remov e th e differentia l cas e cove r an d th e differen -

tial carrier .

NOTE: Loose n th e bolt s i n a crisscros s pattern , i n

severa l steps .

10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

DIFFERENTIA L

CAS E COVE R

DIFFERENTIA L

CARRIER

SOFT JAW S

INSPECTIO NHOLE

2. Secur e th e differentia l assembl y i n a vis e wit h sof t

jaws .

ProCarManuals.com

Page 439 of 1771

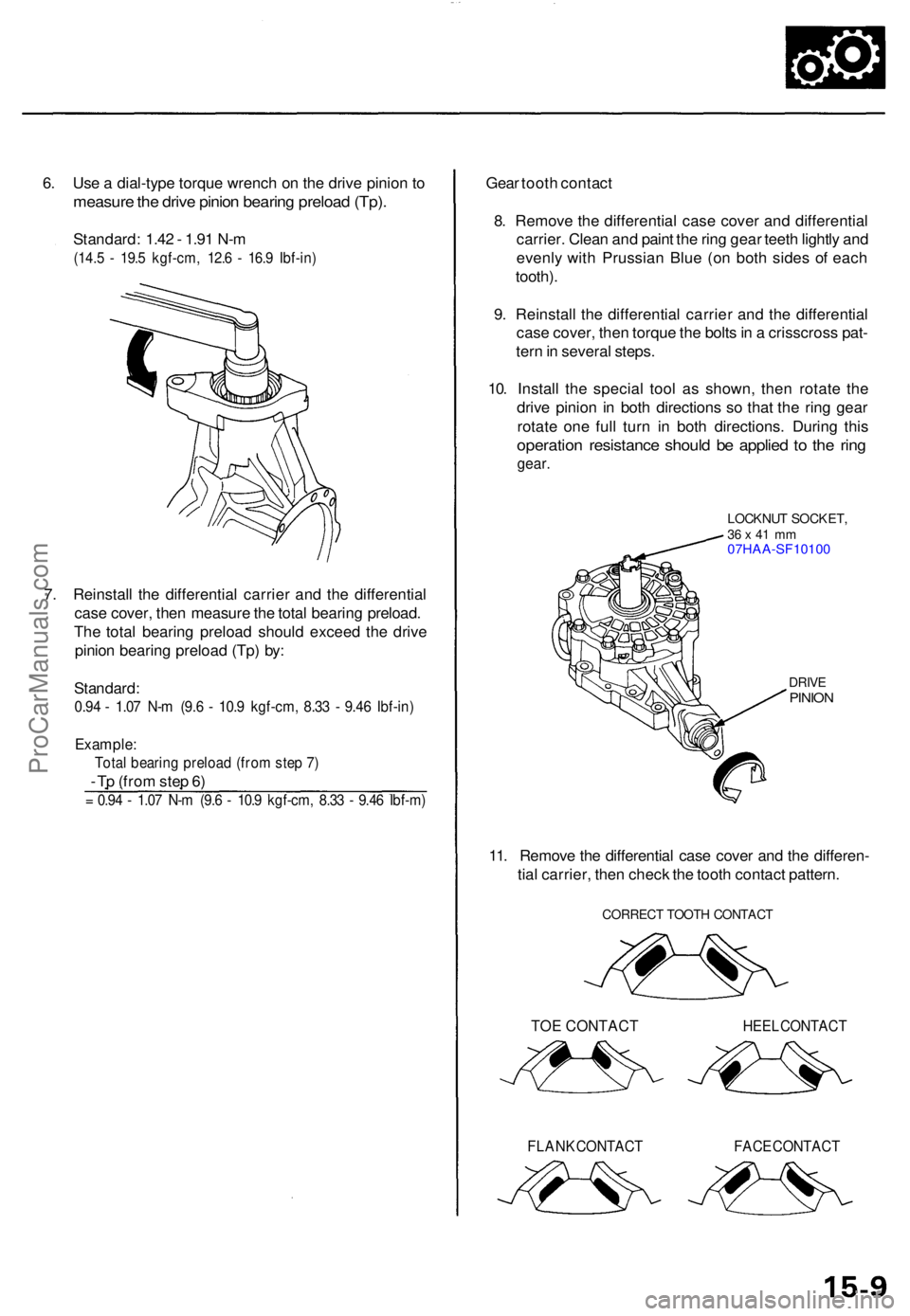

6. Us e a dial-typ e torqu e wrenc h o n th e driv e pinio n t o

measur e th e driv e pinio n bearin g preloa d (Tp) .

Standard : 1.4 2 - 1.9 1 N- m

(14. 5 - 19. 5 kgf-cm , 12. 6 - 16. 9 Ibf-in )

7. Reinstal l th e differentia l carrie r an d th e differentia l

cas e cover , the n measur e th e tota l bearin g preload .

Th e tota l bearin g preloa d shoul d excee d th e driv e

pinio n bearin g preloa d (Tp ) by :

Standard :

0.94 - 1.0 7 N- m (9. 6 - 10. 9 kgf-cm , 8.3 3 - 9.4 6 Ibf-in )

Example :

Total bearin g preloa d (fro m ste p 7 )

- T p (fro m ste p 6 )

= 0.9 4 - 1.0 7 N- m (9. 6 - 10. 9 kgf-cm , 8.3 3 - 9.4 6 Ibf-m )

Gear toot h contac t

8 . Remov e th e differentia l cas e cove r an d differentia l

carrier . Clea n an d pain t th e rin g gea r teet h lightl y an d

evenl y wit h Prussia n Blu e (o n bot h side s o f eac h

tooth) .

9 . Reinstal l th e differentia l carrie r an d th e differentia l

cas e cover , the n torqu e th e bolt s in a crisscros s pat -

ter n in severa l steps .

10 . Instal l th e specia l too l a s shown , the n rotat e th e

driv e pinio n i n bot h direction s s o tha t th e rin g gea r

rotat e on e ful l tur n i n bot h directions . Durin g thi s

operatio n resistanc e shoul d b e applie d t o th e rin g

gear .

LOCKNU T SOCKET ,36 x 41 m m07HAA-SF1010 0

DRIVEPINIO N

11. Remov e th e differentia l cas e cove r an d th e differen -

tia l carrier , the n chec k th e toot h contac t pattern .

CORREC T TOOT H CONTAC T

TOE CONTACT HEEL CONTAC T

FLANK CONTAC T FACE CONTAC T

ProCarManuals.com

Page 440 of 1771

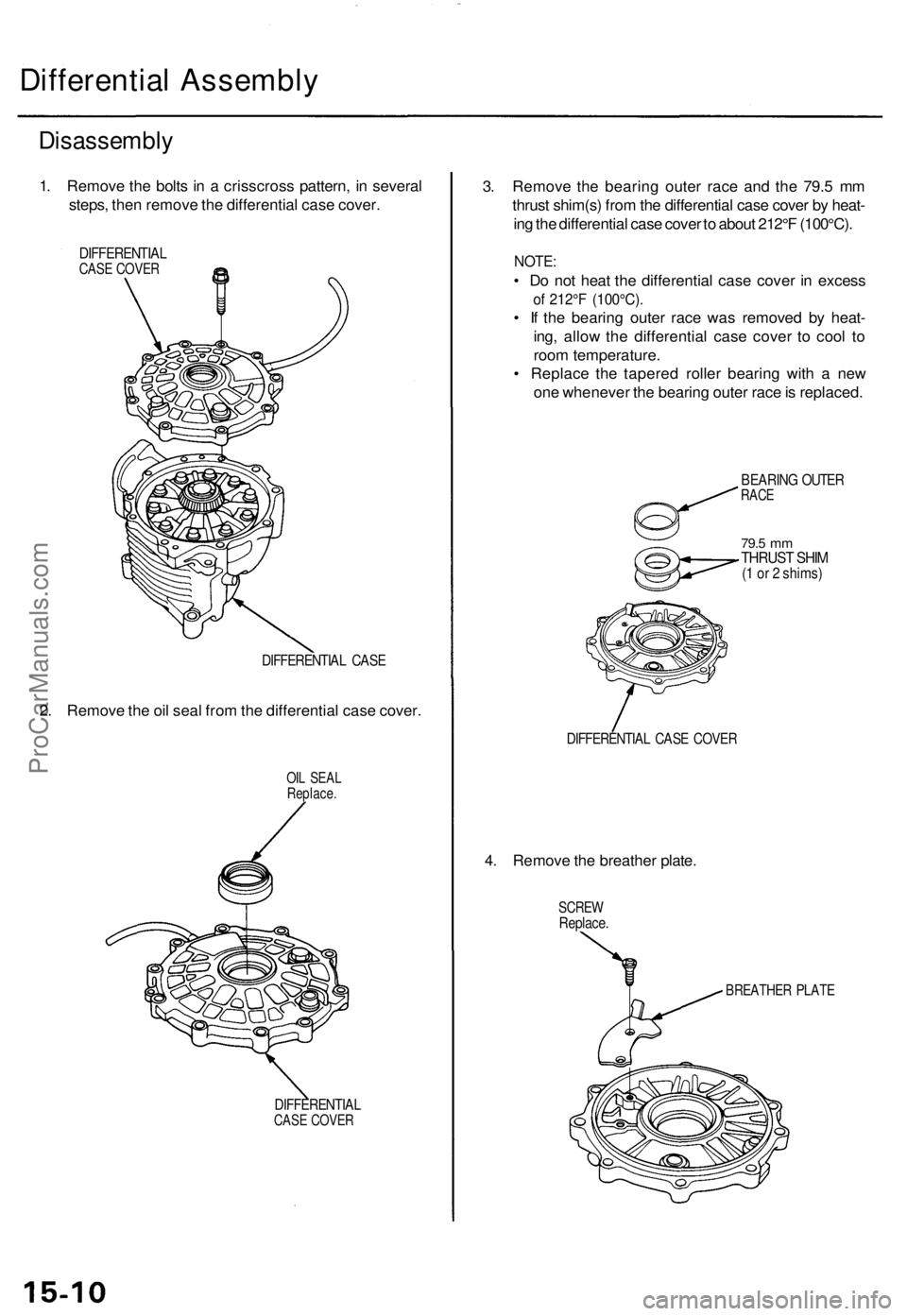

Differential Assembly

Disassembly

1. Remove the bolts in a crisscross pattern, in several

steps, then remove the differential case cover.

DIFFERENTIAL

CASE COVER

DIFFERENTIAL CASE

2. Remove the oil seal from the differential case cover.

OIL SEAL

Replace.

DIFFERENTIAL

CASE COVER

3. Remove the bearing outer race and the 79.5 mm

thrust shim(s) from the differential case cover by heat-

ing the differential case cover to about 212°F (100°C).

NOTE:

• Do not heat the differential case cover in excess

of 212°F (100°C).

• If the bearing outer race was removed by heat-

ing, allow the differential case cover to cool to

room temperature.

• Replace the tapered roller bearing with a new

one whenever the bearing outer race is replaced.

BEARING OUTER

RACE

79.5

mm

THRUST SHIM

(1 or 2 shims)

DIFFERENTIAL CASE COVER

4. Remove the breather plate.

SCREW

Replace.

BREATHER PLATEProCarManuals.com

Page 444 of 1771

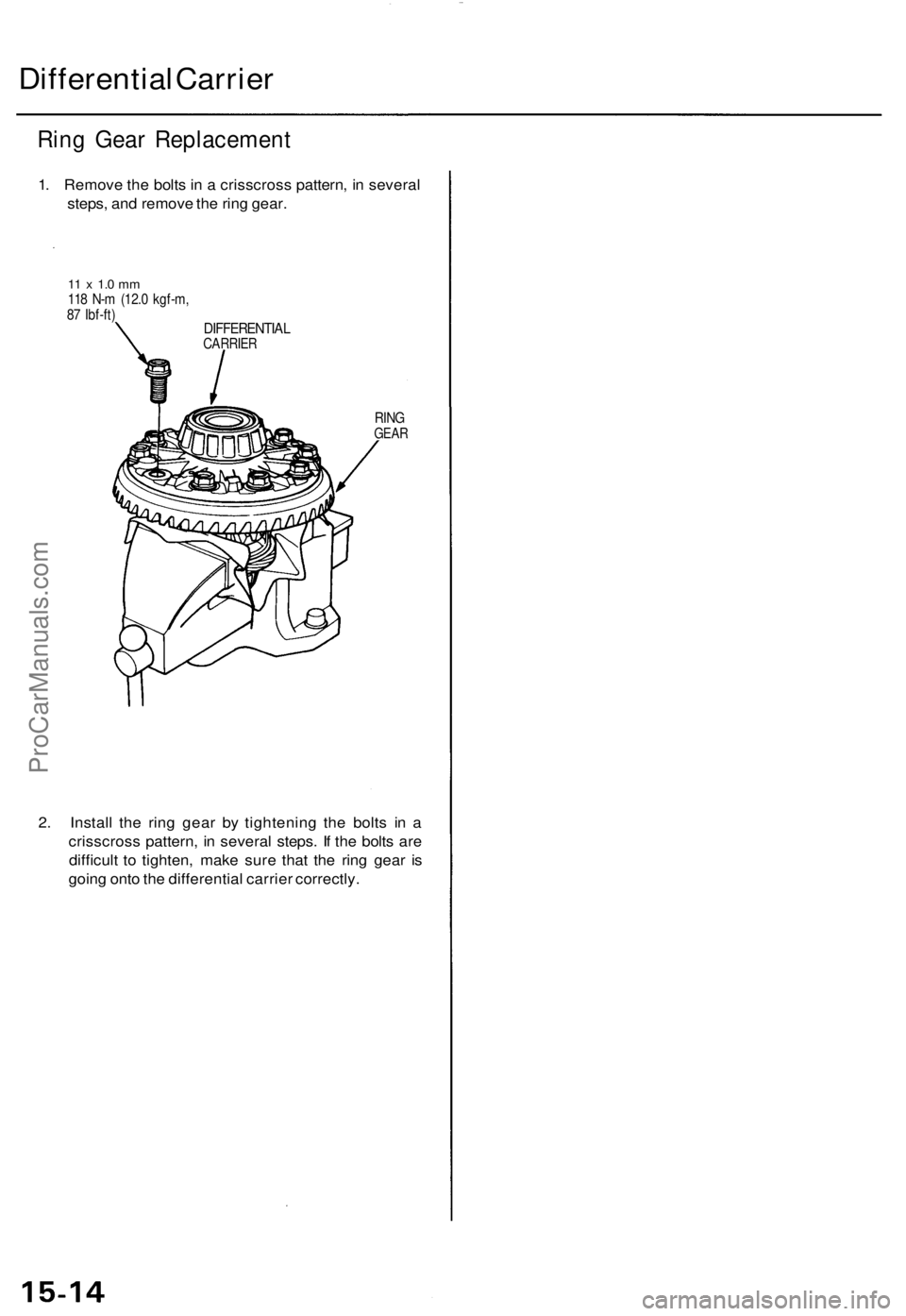

Differential Carrier

Ring Gear Replacement

1. Remove the bolts in a crisscross pattern, in several

steps, and remove the ring gear.

11 x 1.0 mm

118 N-m (12.0 kgf-m,

87 Ibf-ft)

DIFFERENTIAL

CARRIER

RING

GEAR

2. Install the ring gear by tightening the bolts in a

crisscross pattern, in several steps. If the bolts are

difficult to tighten, make sure that the ring gear is

going onto the differential carrier correctly.ProCarManuals.com

Page 755 of 1771

Rocker Arm Assembly

Removal

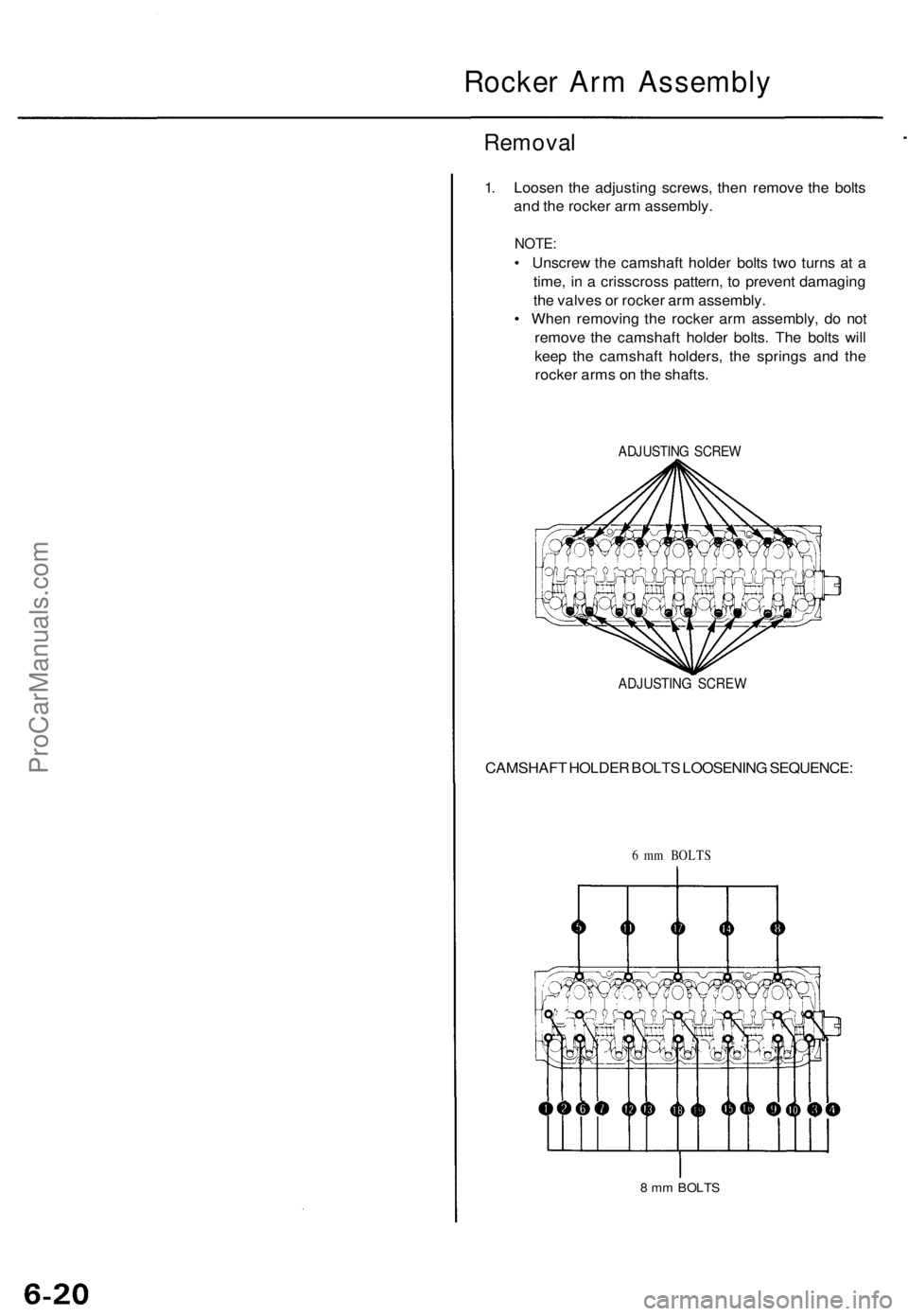

1. Loosen the adjusting screws, then remove the bolts

and the rocker arm assembly.

NOTE:

• Unscrew the camshaft holder bolts two turns at a

time, in a crisscross pattern, to prevent damaging

the valves or rocker arm assembly.

• When removing the rocker arm assembly, do not

remove the camshaft holder bolts. The bolts will

keep the camshaft holders, the springs and the

rocker arms on the shafts.

ADJUSTING SCREW

ADJUSTING SCREW

CAMSHAFT HOLDER BOLTS LOOSENING SEQUENCE:

6 mm BOLTS

8 mm BOLTSProCarManuals.com

Page 780 of 1771

Drive Plat e Connectin

g Ro d an dCrankshaf t

Replacemen tEnd Pla y

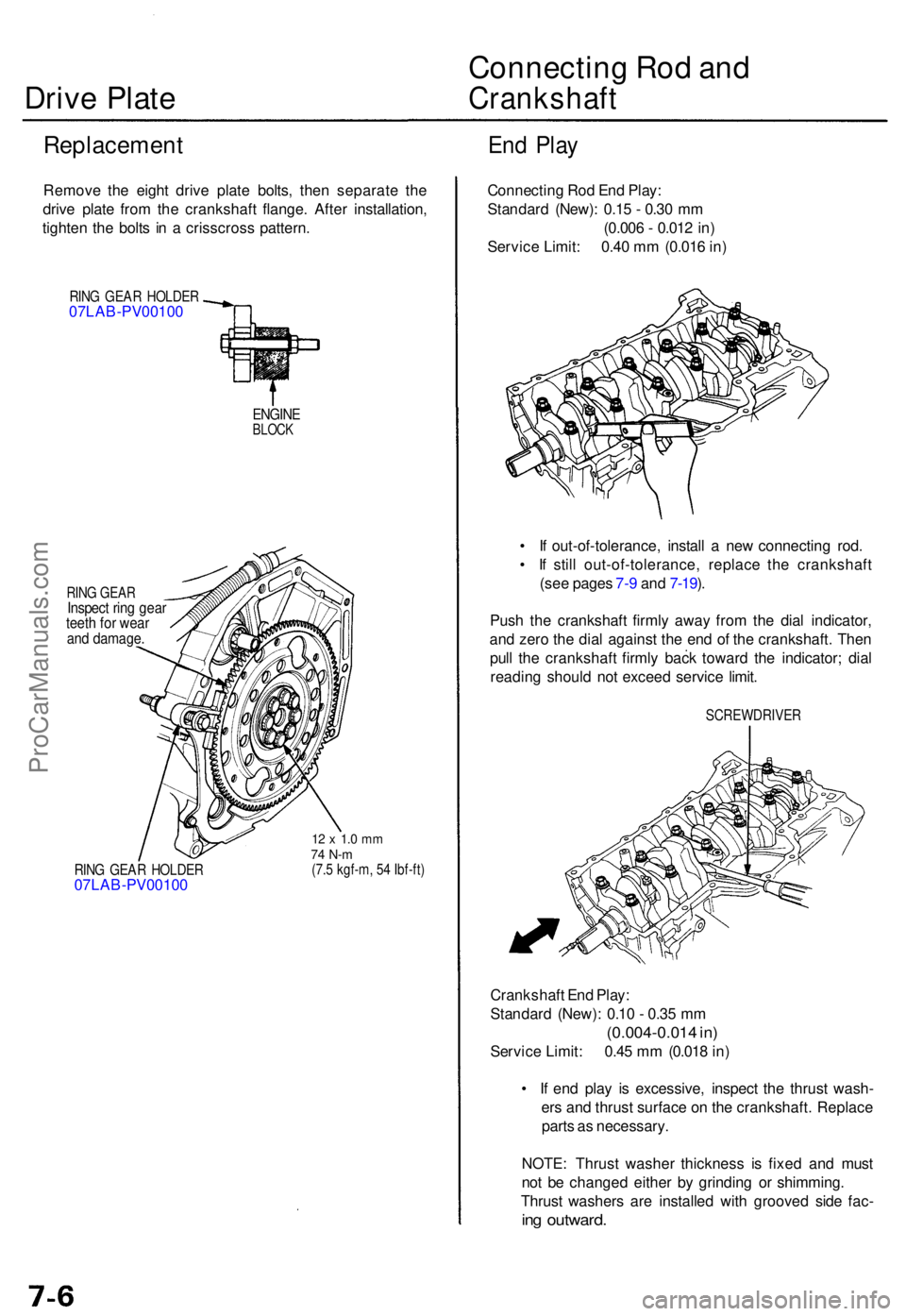

Remov e th e eigh t driv e plat e bolts , the n separat e th e

driv e plat e fro m th e crankshaf t flange . Afte r installation ,

tighte n th e bolt s i n a crisscros s pattern .

RING GEA R HOLDE R07LAB-PV00100

ENGINEBLOCK

RING GEA RInspec t rin g gea rteeth fo r wea rand damage .

RING GEA R HOLDE R07LAB-PV0010 0

12 x 1. 0 m m74 N- m(7.5 kgf-m , 5 4 Ibf-ft )

Connectin g Ro d En d Play :

Standar d (New) : 0.1 5 - 0.3 0 m m

(0.00 6 - 0.01 2 in )

Servic e Limit : 0.4 0 m m (0.01 6 in )

• I f out-of-tolerance , instal l a ne w connectin g rod .

• I f stil l out-of-tolerance , replac e th e crankshaf t

(se e page s 7- 9 an d 7-19 ).

Pus h th e crankshaf t firml y awa y fro m th e dia l indicator ,

an d zer o th e dia l agains t th e en d o f th e crankshaft . The n

pul l th e crankshaf t firml y bac k towar d th e indicator ; dia l

readin g shoul d no t excee d servic e limit .

SCREWDRIVE R

Crankshaft En d Play :

Standar d (New) : 0.1 0 - 0.3 5 m m

(0.004-0.01 4 in )

Servic e Limit : 0.4 5 m m (0.01 8 in )

• I f en d pla y i s excessive , inspec t th e thrus t wash -

er s an d thrus t surfac e o n th e crankshaft . Replac e

part s a s necessary .

NOTE : Thrus t washe r thicknes s i s fixe d an d mus t

no t b e change d eithe r b y grindin g o r shimming .

Thrus t washer s ar e installe d wit h groove d sid e fac -

ing outward .

ProCarManuals.com