timing belt ACURA TL 1995 Service Repair Manual

[x] Cancel search | Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 61 of 1771

Timing Bel t

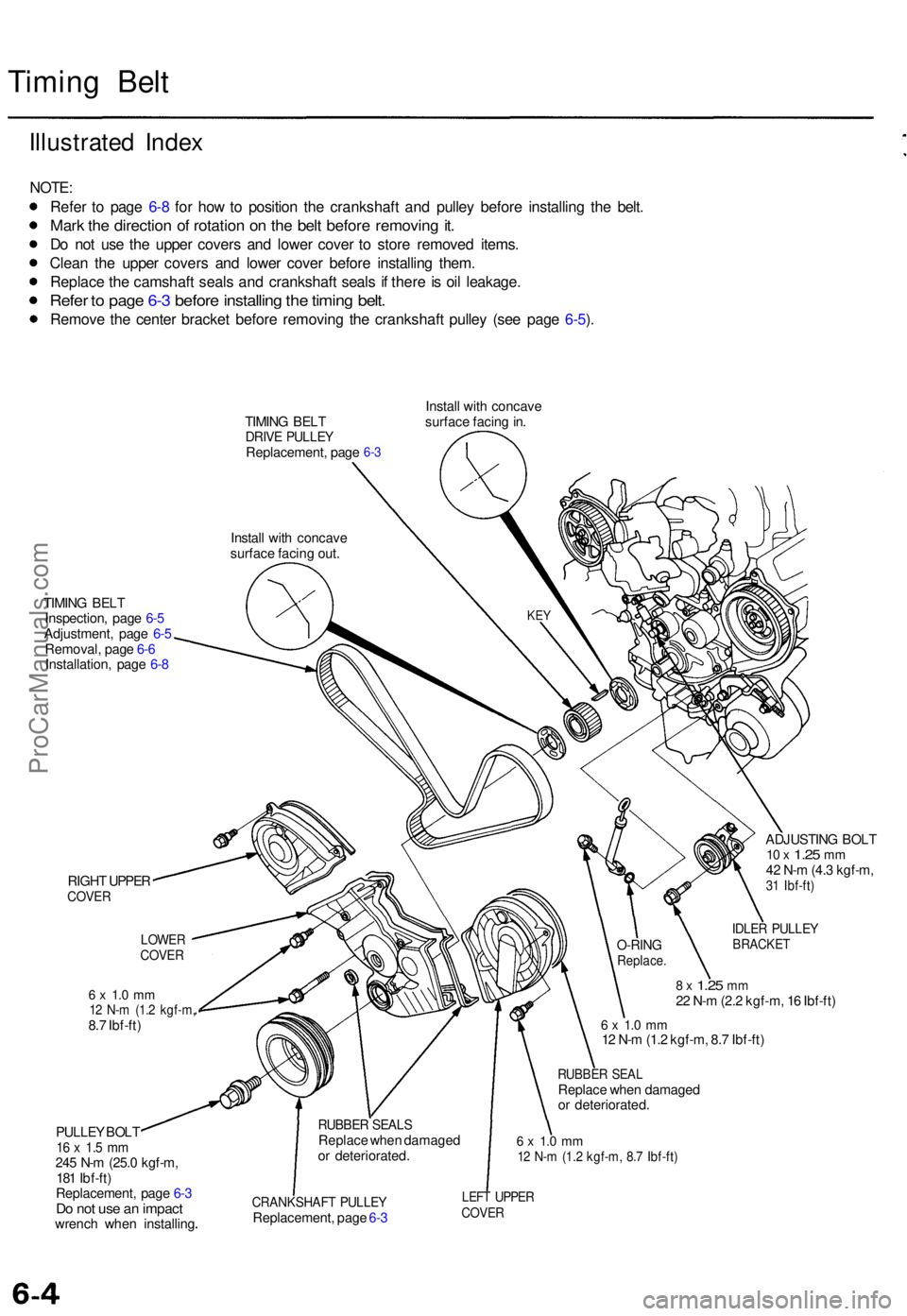

Illustrate d Inde x

NOTE :

Refe r t o pag e 6- 8 fo r ho w to positio n th e crankshaft and pulle y befor e installin g th e belt .

Mark th e directio n o f rotatio n o n th e bel t befor e removin g it .

Do no t us e th e uppe r cover s an d lowe r cove r t o stor e remove d items .

Clea n th e uppe r cover s an d lowe r cove r befor e installin g them .

Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e is oi l leakage .

Refer t o pag e 6- 3 befor e installin g th e timin g belt .

Remov e th e cente r bracke t befor e removin g th e crankshaf t pulle y (se e pag e 6-5 ).

TIMIN G BEL TDRIV E PULLE YReplacement , pag e

Instal l wit h concav e

surfac e facin g out . Instal

l wit h concav e

surfac e facin g in .6-3

TIMIN G BEL T

Inspection , pag e 6- 5

Adjustment , pag e 6-5

Removal , pag e 6- 6

Installation , pag e 6- 8

RIGH T UPPE R

COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft )

PULLE Y BOL T

16 x 1. 5 m m245 N- m (25. 0 kgf-m ,

18 1 Ibf-ft )

Replacement , pag e 6- 3

Do no t us e a n impac twrench whe n installin g ADJUSTIN

G BOL T

10 x 1.2 5 mm42 N- m (4. 3 kgf-m ,31 Ibf-ft )

IDLER PULLE YBRACKE T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

RUBBE R SEA LReplac e whe n damage d

o r deteriorated .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

CRANKSHAF T PULLE YReplacement , pag e 6- 3

LEF T UPPE RCOVER

RUBBE R SEAL SReplac e whe n damage d

o r deteriorated .

O-RINGReplace .

LOWERCOVER

KEY

ProCarManuals.com

Page 63 of 1771

Timing Bel t

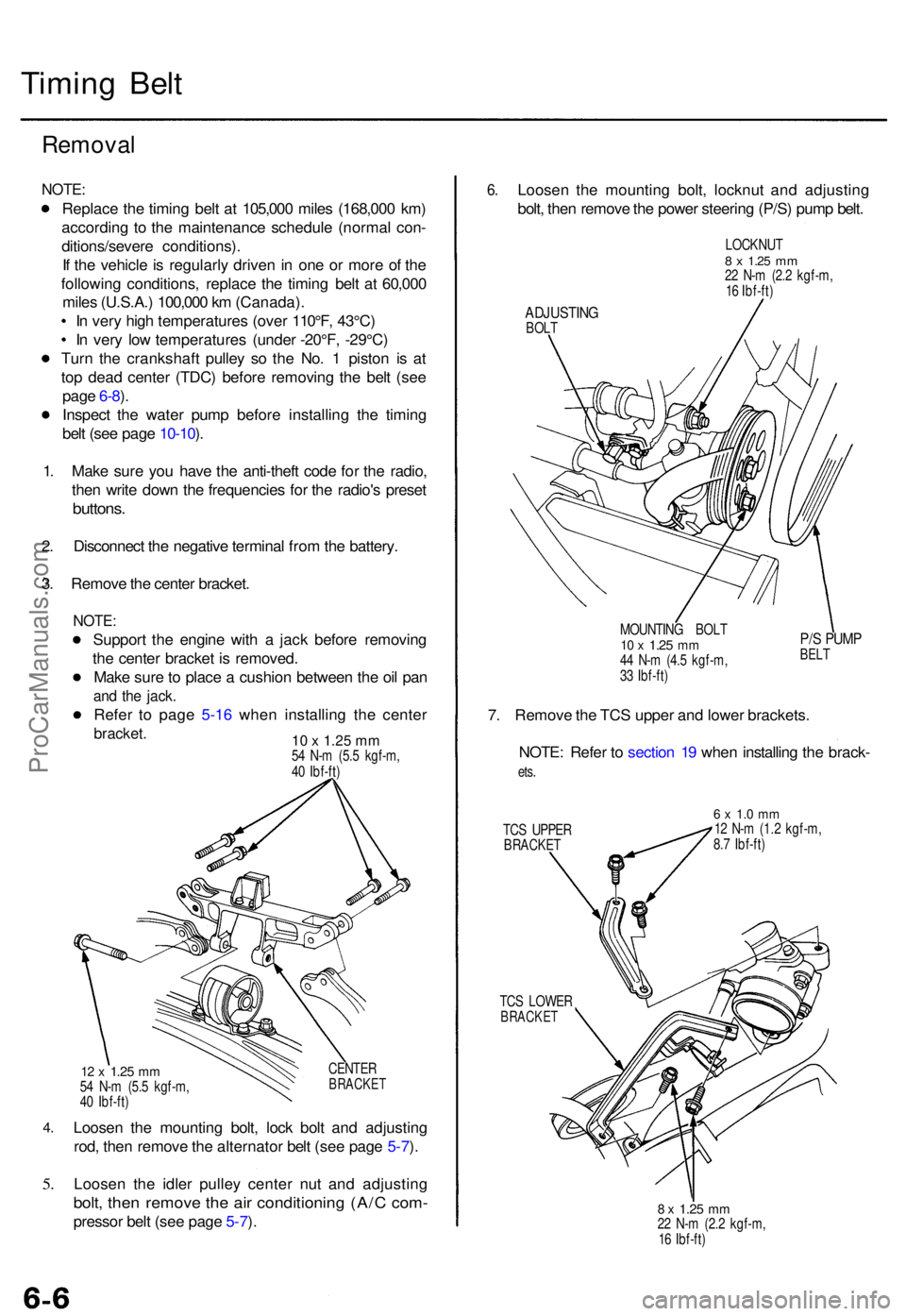

Remova l

NOTE:

Replac e th e timin g bel t a t 105,00 0 mile s (168,00 0 km )

accordin g t o th e maintenanc e schedul e (norma l con -

ditions/sever e conditions) .

I f th e vehicl e is regularl y drive n i n on e o r mor e o f th e

followin g conditions , replac e th e timin g bel t a t 60,00 0

mile s (U.S.A. ) 100,00 0 k m (Canada) .

I n ver y hig h temperature s (ove r 110°F , 43°C )

I n ver y lo w temperature s (unde r -20°F , -29°C )

Tur n th e crankshaf t pulle y s o th e No . 1 pisto n i s a t

to p dea d cente r (TDC ) befor e removin g th e bel t (se e

pag e 6-8 ).

Inspec t th e wate r pum p befor e installin g th e timin g

bel t (se e pag e 10-10 ).

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s prese t

buttons .

2. Disconnec t th e negativ e termina l fro m th e battery .

3 . Remov e th e cente r bracket .

NOTE:

Suppor t th e engin e wit h a jac k befor e removin g

th e cente r bracke t i s removed .

Mak e sur e to plac e a cushio n betwee n th e oi l pa n

and th e jack .

Refer t o pag e 5-1 6 whe n installin g th e cente r

bracket. 10 x 1.25 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

4.

5.

CENTE RBRACKE T12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt, the n remov e th e ai r conditionin g (A/ C com -

presso r bel t (se e pag e 5-7 ).

6 .Loose n th e mountin g bolt , locknu t an d adjustin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p belt .

LOCKNU T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ADJUSTIN GBOLT

MOUNTING BOL T

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

P/S PUM PBELT

7. Remov e th e TC S uppe r an d lowe r brackets .

NOTE : Refe r t o sectio n 1 9 whe n installin g th e brack -

ets.

TC S UPPE RBRACKE T

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TC S LOWE R

BRACKE T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

ProCarManuals.com

Page 65 of 1771

Timing Belt

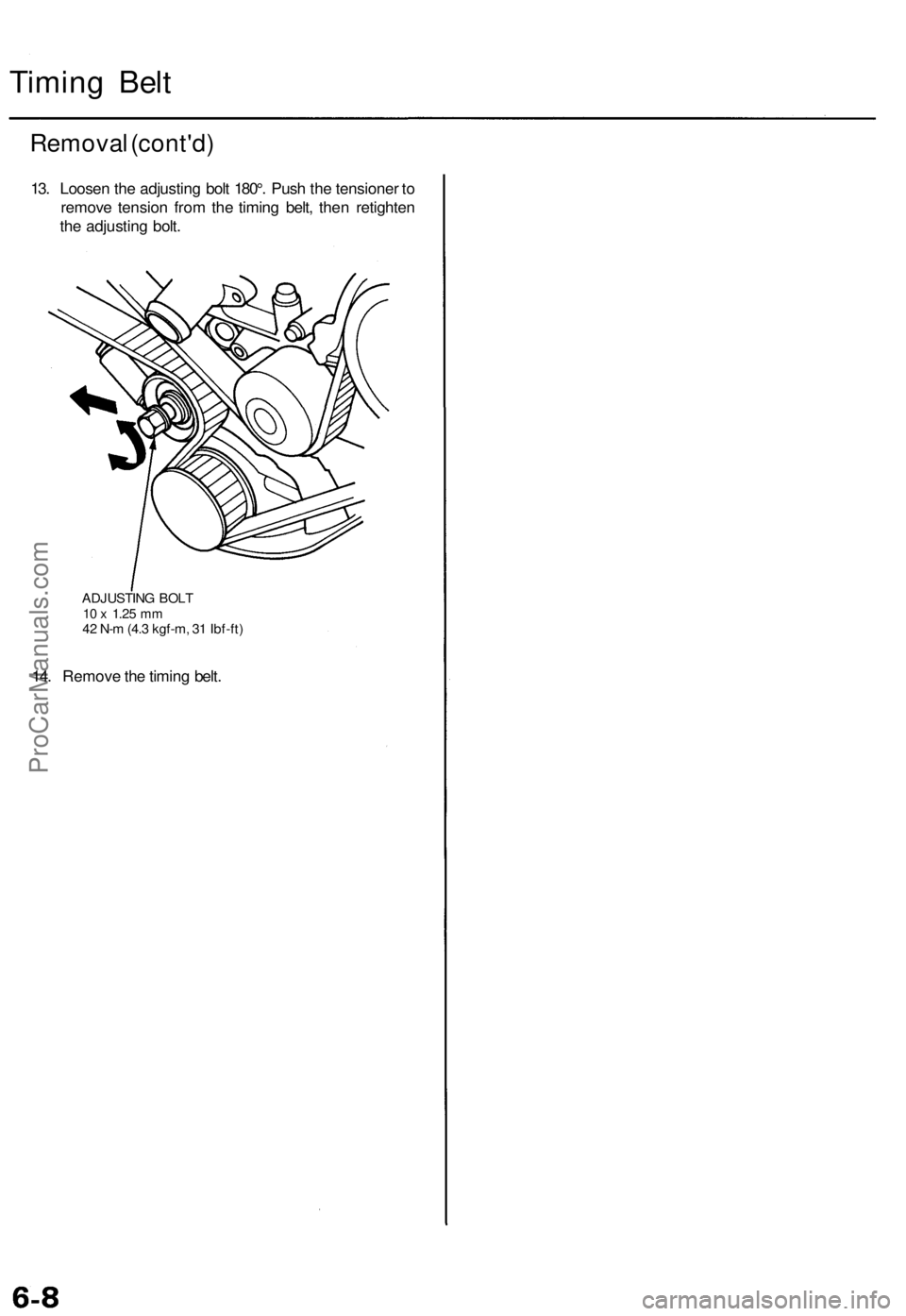

Removal (cont'd)

13. Loosen the adjusting bolt 180°. Push the tensioner to

remove tension from the timing belt, then retighten

the adjusting bolt.

ADJUSTING BOLT

10 x

1.25

mm

42 N-m (4.3 kgf-m, 31 Ibf-ft)

14. Remove the timing belt.ProCarManuals.com

Page 68 of 1771

Timing Bel t

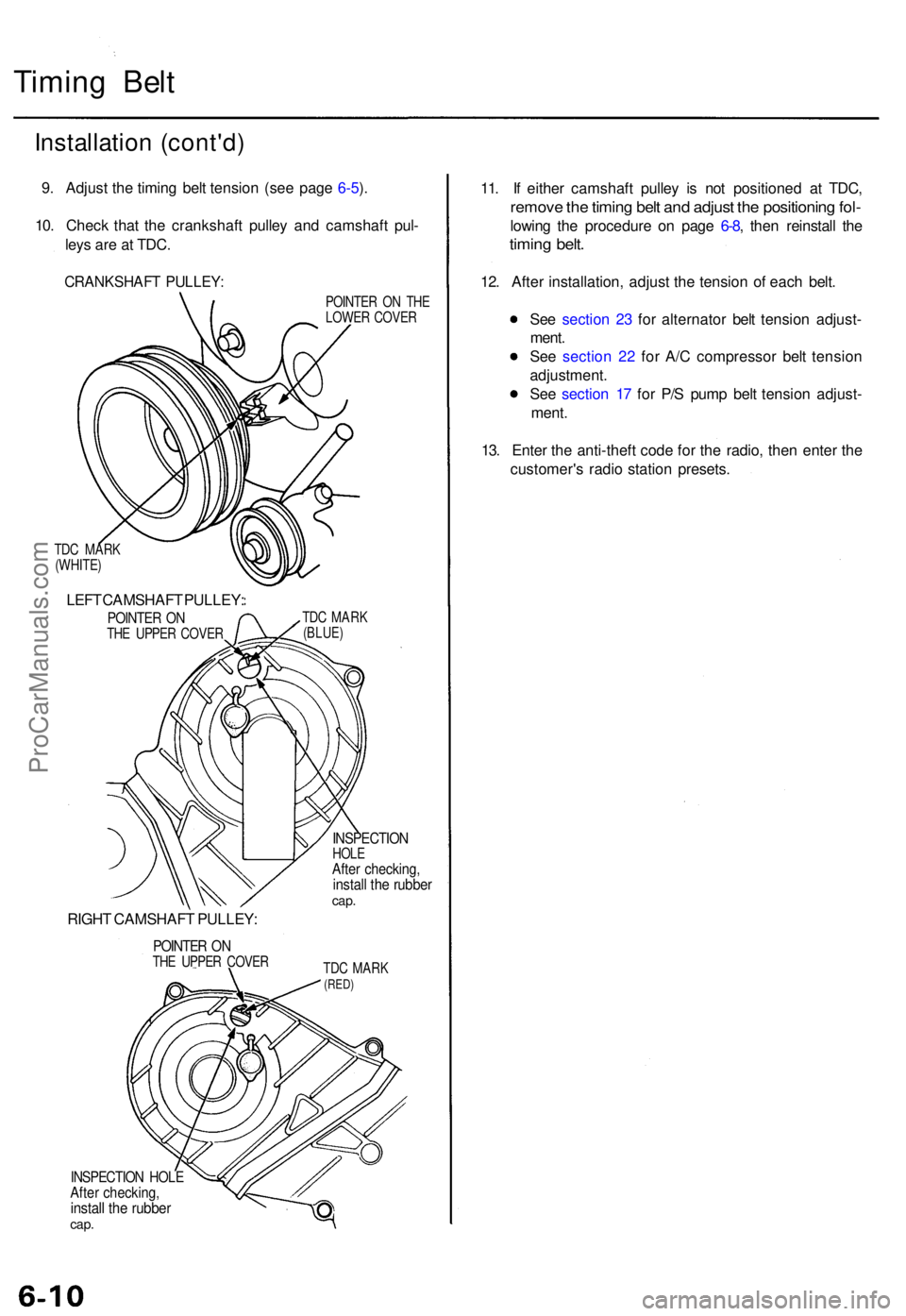

Installatio n (cont'd )

9. Adjus t th e timin g bel t tensio n (se e pag e 6-5 ).

10 . Chec k tha t th e crankshaf t pulle y an d camshaf t pul -

ley s ar e a t TDC .

CRANKSHAF T PULLEY :

TDC MAR K

(WHITE )

LEFT CAMSHAF T PULLEY :

POINTER O NTH E UPPE R COVE R

RIGHT CAMSHAF T PULLEY :

POINTER O NTH E UPPE R COVE R POINTE

R O N TH E

LOWE R COVE R

TD C MAR K

(BLUE )

INSPECTIO NHOLEAfter checking ,install th e rubbe rcap.

TDC MAR K(RED)

INSPECTIO N HOL EAfter checking ,install th e rubbe rcap.

11. I f eithe r camshaf t pulle y i s no t positione d a t TDC ,

remov e th e timin g bel t an d adjus t th e positionin g fol -

lowin g th e procedur e o n pag e 6-8 , the n reinstal l th e

timin g belt .

12. Afte r installation , adjus t th e tensio n o f eac h belt .

Se e sectio n 2 3 fo r alternato r bel t tensio n adjust -

ment .

Se e sectio n 2 2 fo r A/ C compresso r bel t tensio n

adjustment .

Se e sectio n 1 7 fo r P/ S pum p bel t tensio n adjust -

ment .

13 . Ente r th e anti-theft code fo r th e radio , the n ente r th e

customer' s radi o statio n presets .

ProCarManuals.com

Page 116 of 1771

Pistons

Installation

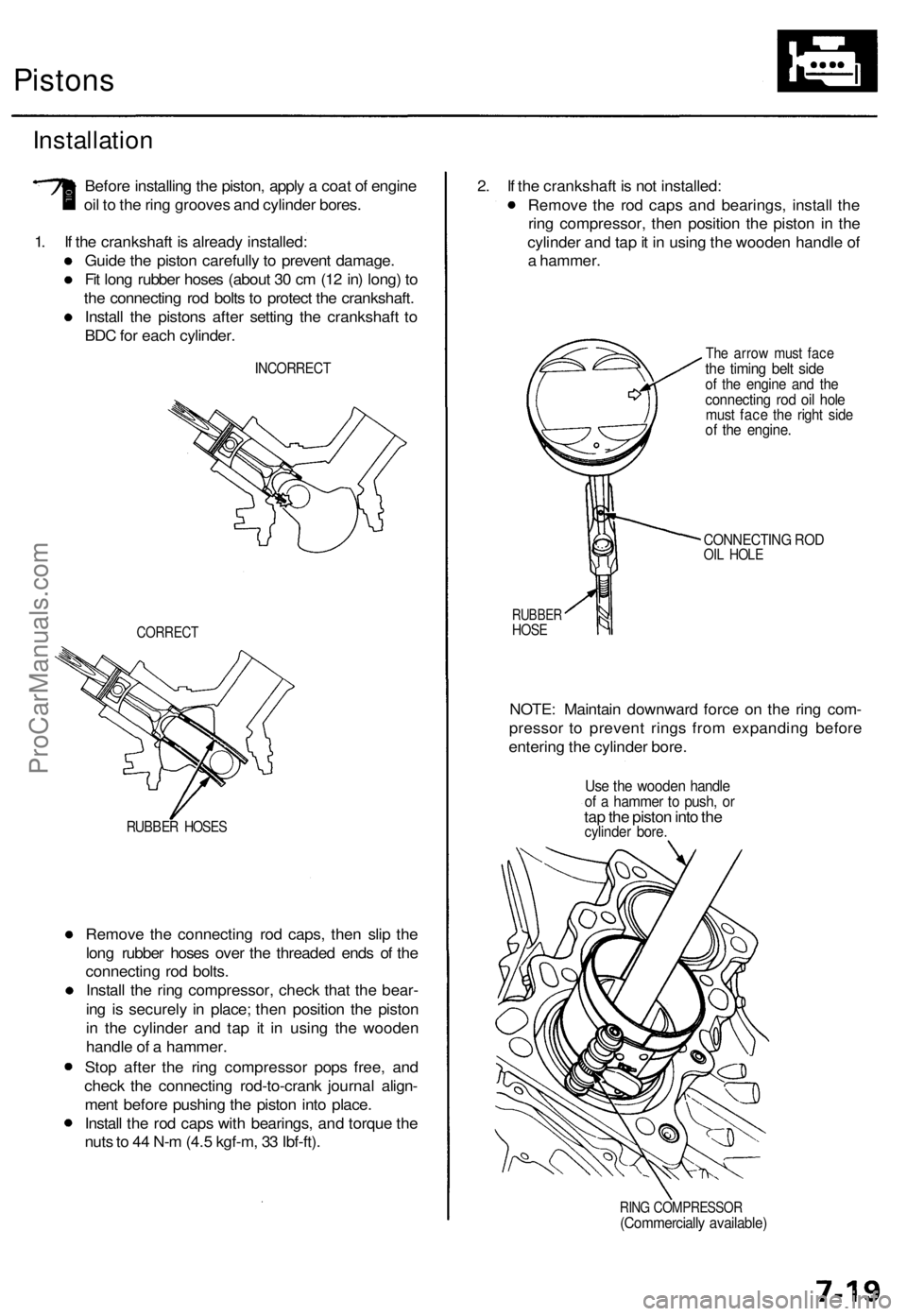

Before installing the piston, apply a coat of engine

oil to the ring grooves and cylinder bores.

1. If the crankshaft is already installed:

Guide the piston carefully to prevent damage.

Fit long rubber hoses (about 30 cm (12 in) long) to

the connecting rod bolts to protect the crankshaft.

Install the pistons after setting the crankshaft to

BDC for each cylinder.

INCORRECT

CORRECT

RUBBER HOSES

Remove the connecting rod caps, then slip the

long rubber hoses over the threaded ends of the

connecting rod bolts.

Install the ring compressor, check that the bear-

ing is securely in place; then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place.

Install the rod caps with bearings, and torque the

nuts to 44 N-m (4.5 kgf-m, 33 Ibf-ft).

2. If the crankshaft is not installed:

Remove the rod caps and bearings, install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a hammer.

The arrow must face

the timing belt side

of the engine and the

connecting rod oil hole

must face the right side

of the engine.

CONNECTING ROD

OIL HOLE

RUBBER

HOSE

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore.

Use the wooden handle

of a hammer to push, or

tap the piston into the

cylinder bore.

RING COMPRESSOR

(Commercially available)ProCarManuals.com

Page 742 of 1771

Timing Bel t

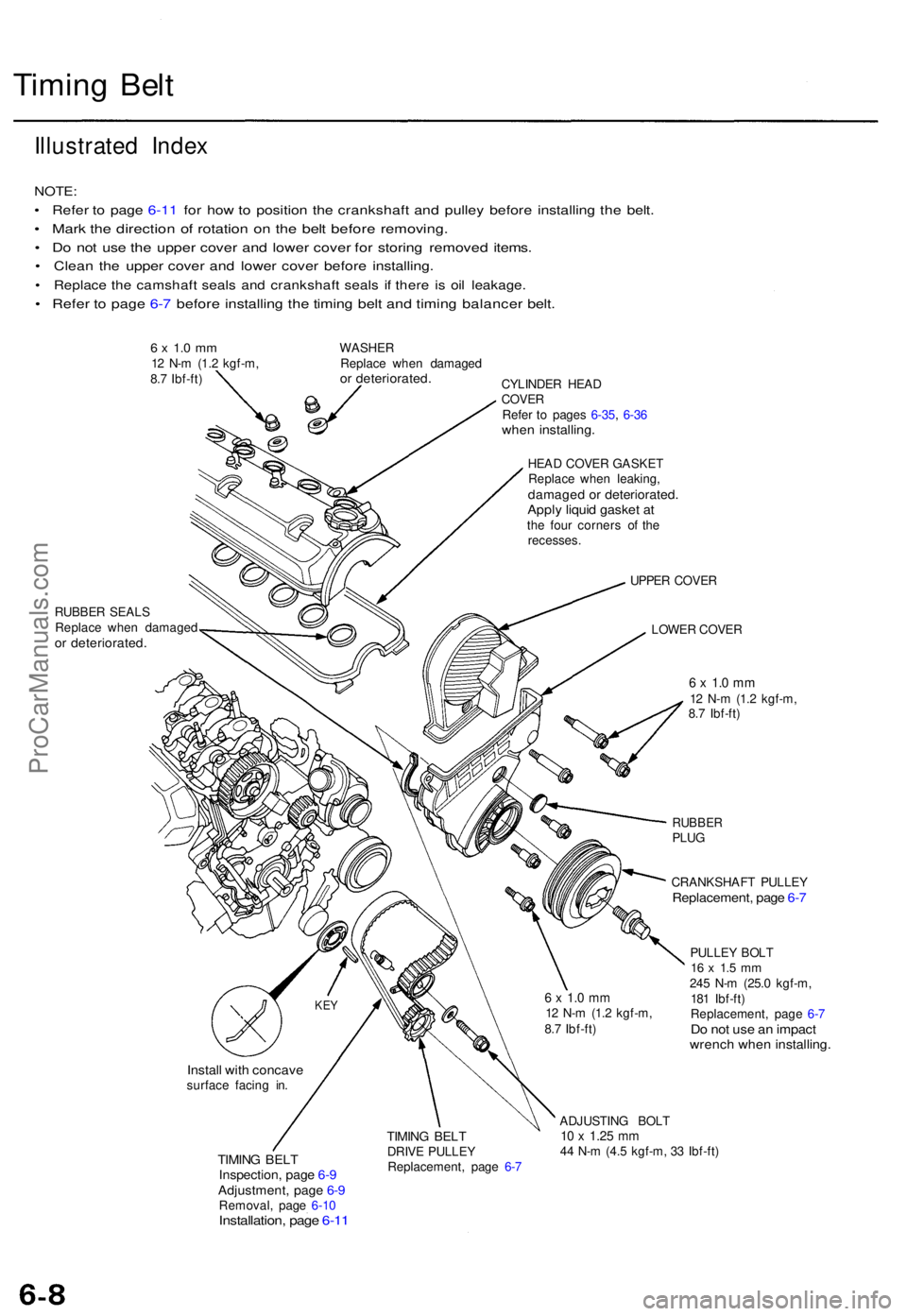

Illustrate d Inde x

NOTE :

• Refe r t o pag e 6-1 1 fo r ho w to positio n th e crankshaf t an d pulle y befor e installin g th e belt .

• Mar k th e directio n o f rotatio n o n th e bel t befor e removing .

• D o no t us e th e uppe r cove r an d lowe r cove r fo r storin g remove d items .

• Clea n th e uppe r cove r an d lowe r cove r befor e installing .

• Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e i s oi l leakage .

• Refe r t o pag e 6- 7 befor e installin g th e timin g bel t an d timin g balance r belt .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) WASHE

R

Replac e whe n damage dor deteriorated .CYLINDER HEA DCOVE RRefer t o page s 6-35 , 6-3 6whe n installing .

HEAD COVE R GASKE T

Replac e whe n leaking ,

damage d o r deteriorated .Apply liqui d gaske t a tth e fou r corner s o f th e

recesses .

RUBBE R SEAL S

Replac e whe n damage d

or deteriorated .

UPPER COVE R

LOWE R COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

RUBBE RPLUG

CRANKSHAF T PULLE Y

Replacement , pag e 6- 7

PULLE Y BOL T16 x 1. 5 m m245 N- m (25. 0 kgf-m ,

18 1 Ibf-ft )

Replacement , pag e 6- 7

Do no t us e a n impac twrench whe n installing .

Install wit h concav esurface facin g in .

TIMIN G BEL TInspection , pag e 6- 9Adjustment , pag e 6- 9Removal , pag e 6-1 0Installation , pag e 6-1 1

TIMIN G BEL TDRIV E PULLE Y

Replacement , pag e 6- 7 ADJUSTIN

G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

KEY6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com

Page 745 of 1771

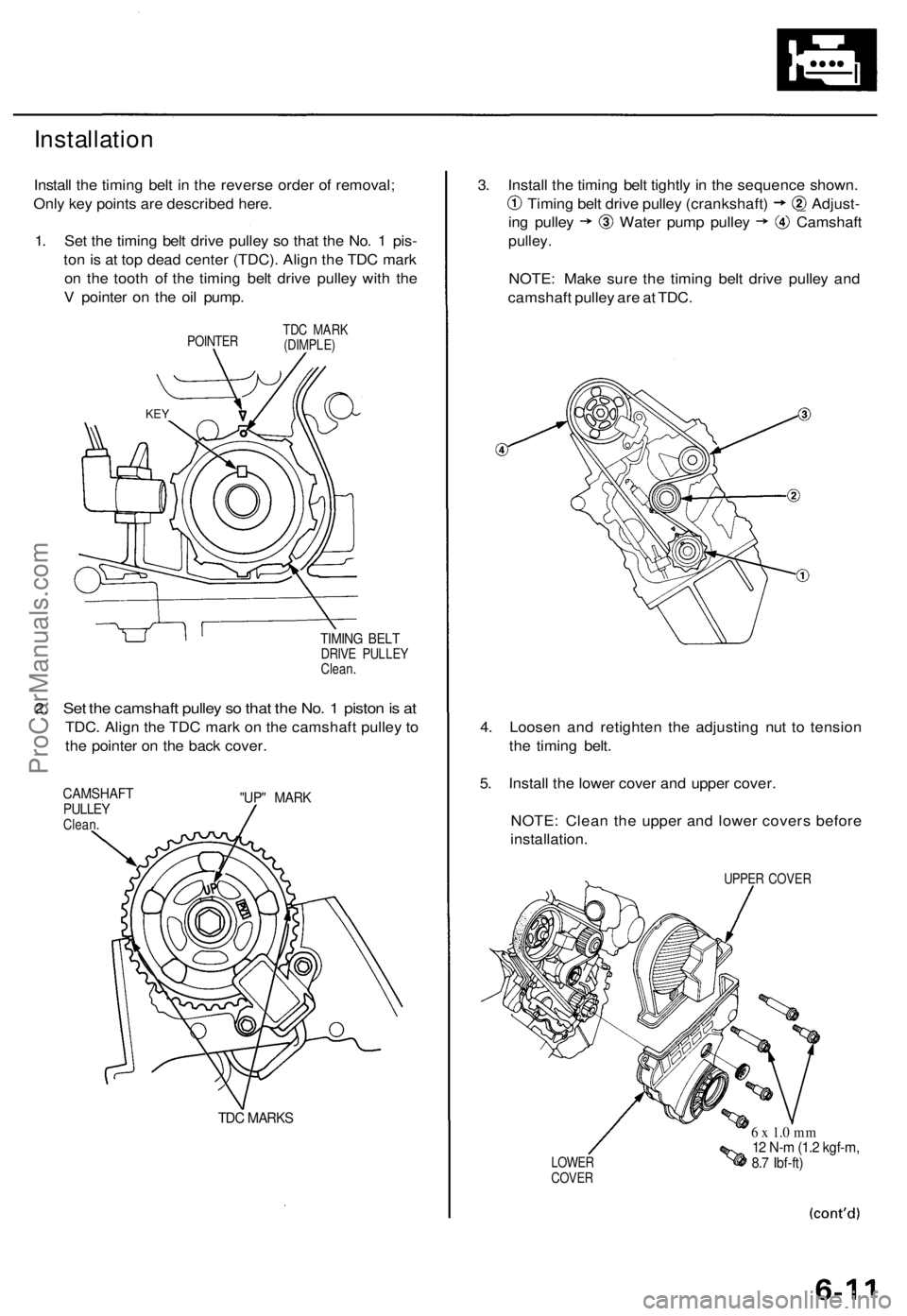

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here.

1. Set the timing belt drive pulley so that the No. 1 pis-

ton is at top dead center (TDC). Align the TDC mark

on the tooth of the timing belt drive pulley with the

V pointer on the oil pump.

POINTER

TDC MARK

(DIMPLE)

TIMING BELT

DRIVE PULLEY

Clean.

2. Set the camshaft pulley so that the No. 1 piston is at

TDC. Align the TDC mark on the camshaft pulley to

the pointer on the back cover.

CAMSHAFT

PULLEY

Clean.

"UP" MARK

TDC MARKS

3. Install the timing belt tightly in the sequence shown.

Timing belt drive pulley (crankshaft) _ Adjust-

ing pulley Water pump pulley Camshaft

pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulley are at TDC.

4. Loosen and retighten the adjusting nut to tension

the timing belt.

5. Install the lower cover and upper cover.

NOTE: Clean the upper and lower covers before

installation.

UPPER COVER

LOWER

COVER

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

KEYProCarManuals.com

Page 746 of 1771

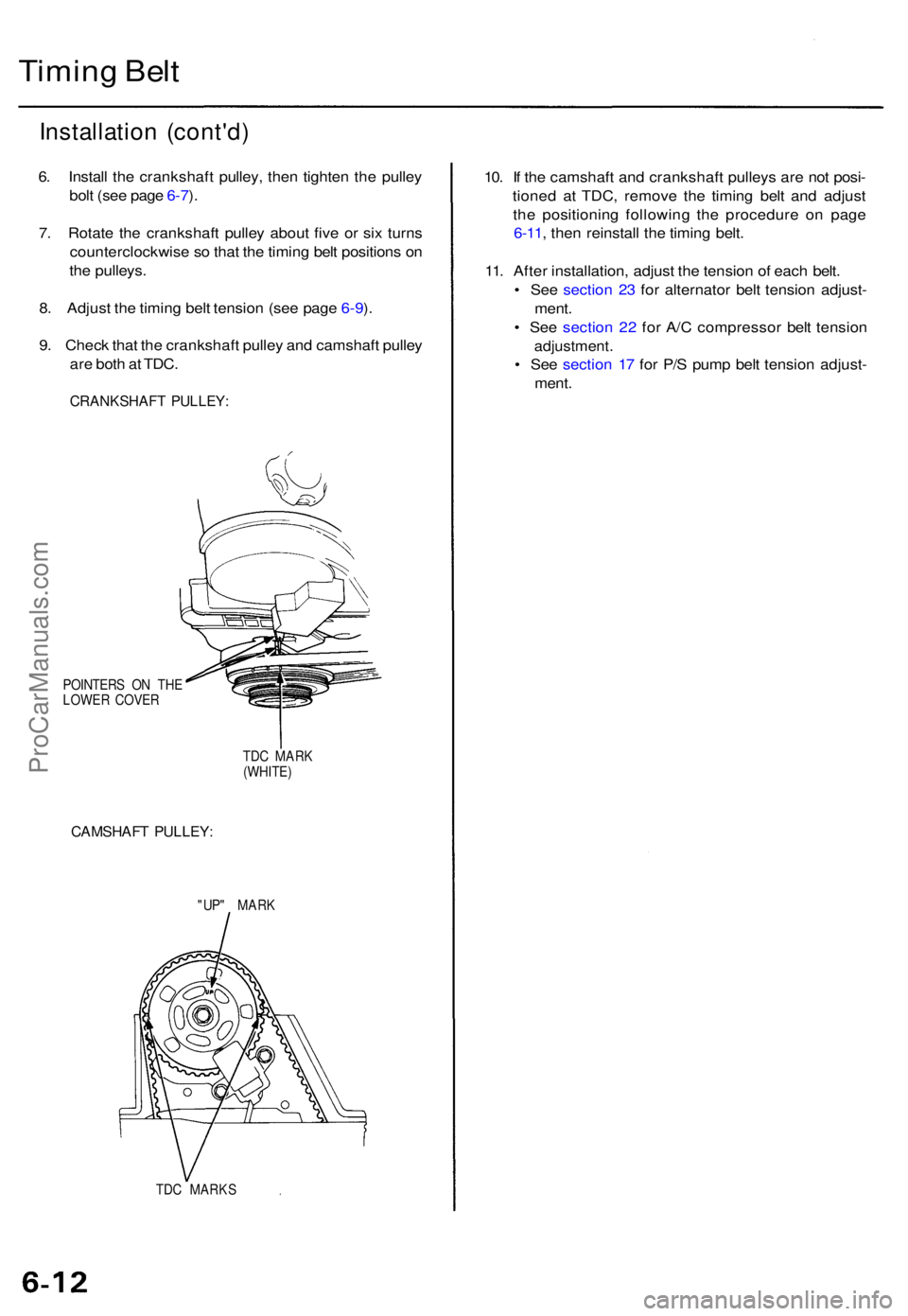

Timing Bel t

Installatio n (cont'd )

6. Instal l th e crankshaf t pulley , the n tighte n th e pulle y

bol t (se e pag e 6-7 ).

7 . Rotat e th e crankshaf t pulle y abou t fiv e o r si x turn s

counterclockwis e s o tha t th e timin g bel t position s o n

th e pulleys .

8 . Adjus t th e timin g bel t tensio n (se e pag e 6-9 ).

9 . Chec k tha t th e crankshaf t pulle y an d camshaf t pulle y

ar e bot h a t TDC .

CRANKSHAF T PULLEY :

POINTER S O N TH E

LOWE R COVE R

TDC MAR K

(WHITE )

CAMSHAF T PULLEY :

"UP" MAR K

TD C MARK S

10. I f th e camshaf t an d crankshaf t pulley s ar e no t posi -

tione d a t TDC , remov e th e timin g bel t an d adjus t

th e positionin g followin g th e procedur e o n pag e

6-11 , the n reinstal l th e timin g belt .

11 . Afte r installation , adjus t th e tensio n o f eac h belt .

• Se e sectio n 2 3 fo r alternato r bel t tensio n adjust -

ment .

• Se e sectio n 2 2 fo r A/ C compresso r bel t tensio n

adjustment .

• Se e sectio n 1 7 fo r P/ S pum p bel t tensio n adjust -

ment .

ProCarManuals.com

Page 798 of 1771

Pistons

Installation

Before installing the piston, apply a coat of

engine oil to the ring grooves and cylinder

bores.

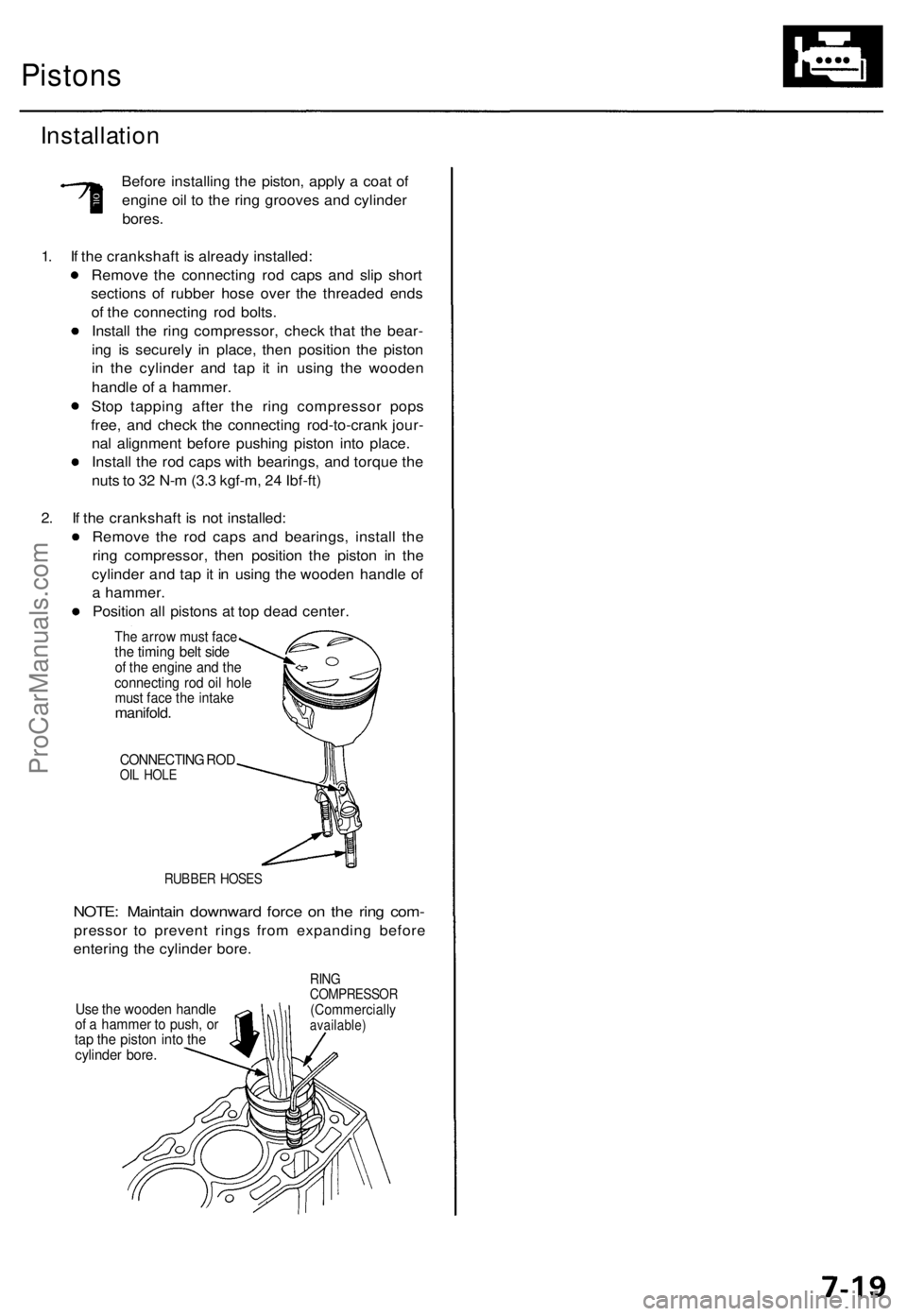

1. If the crankshaft is already installed:

Remove the connecting rod caps and slip short

sections of rubber hose over the threaded ends

of the connecting rod bolts.

Install the ring compressor, check that the bear-

ing is securely in place, then position the piston

in the cylinder and tap it in using the wooden

handle of a hammer.

Stop tapping after the ring compressor pops

free, and check the connecting rod-to-crank jour-

nal alignment before pushing piston into place.

Install the rod caps with bearings, and torque the

nuts to 32 N-m (3.3 kgf-m, 24 Ibf-ft)

2. If the crankshaft is not installed:

Remove the rod caps and bearings, install the

ring compressor, then position the piston in the

cylinder and tap it in using the wooden handle of

a hammer.

Position all pistons at top dead center.

The arrow must face

the timing belt side

of the engine and the

connecting rod oil hole

must face the intake

manifold.

CONNECTING ROD

OIL HOLE

RUBBER HOSES

NOTE: Maintain downward force on the ring com-

pressor to prevent rings from expanding before

entering the cylinder bore.

Use the wooden handle

of a hammer to push, or

tap the piston into the

cylinder bore.

RING

COMPRESSOR

(Commercially

available)ProCarManuals.com