wheel Alfa Romeo 166 2007 Owner handbook (in English)

[x] Cancel search | Manufacturer: ALFA ROMEO, Model Year: 2007, Model line: 166, Model: Alfa Romeo 166 2007Pages: 272, PDF Size: 4.17 MB

Page 162 of 272

161

– Tighten the five fastening bolts (A-

fig. 12).– Lower the car and remove the jack

(fig. 13).– Completely tighten the bolts in the se-

quence shown (fig. 14).

– On cars having the same alloy rims

as the spare wheel ones, wheel cap can

be fitted following the instructions given

in the following paragraph.

IMPORTANTNever fit the wheel cap

to the spare wheel if the spare wheel is

different from the standard one.

After refitting a wheel:

– Stow the spare wheel in the space

provided in the luggage compartment and

fasten it with the ring nut (A-fig. 2).

– Put jack and tools back in the bag and

stow it in the boot.

fig. 7

A0D0041m

fig. 6

A0D0040m

A0D0133m

fig. 8

Page 163 of 272

162

REFITTING A NORMAL WHEEL

Refit the wheel as described below:

– Stop the car in such a position that it

is not dangerous for the traffic where it is

possible to change the wheel safely.

Where possible, park on a level, compact

surface.

– Engage the handbrake

– Engage 1st gear or reverse. For cars

with automatic gearbox set the lever to

positionP.

– Open the boot.

– Fold back the boot mat (A-fig. 1).– Take the tool bag (A-fig. 3) and

the spare wheel and bring them near to

the wheel to be changed.

– Remove the wheel cap (A-fig. 4)

(if present) levering on the edge with the

flat-tipped screwdriver provided in the tool

bag.– Using the L-wrench (B-fig. 5) pro-

vided, loosen the fastening bolts (A) by

about one turn.

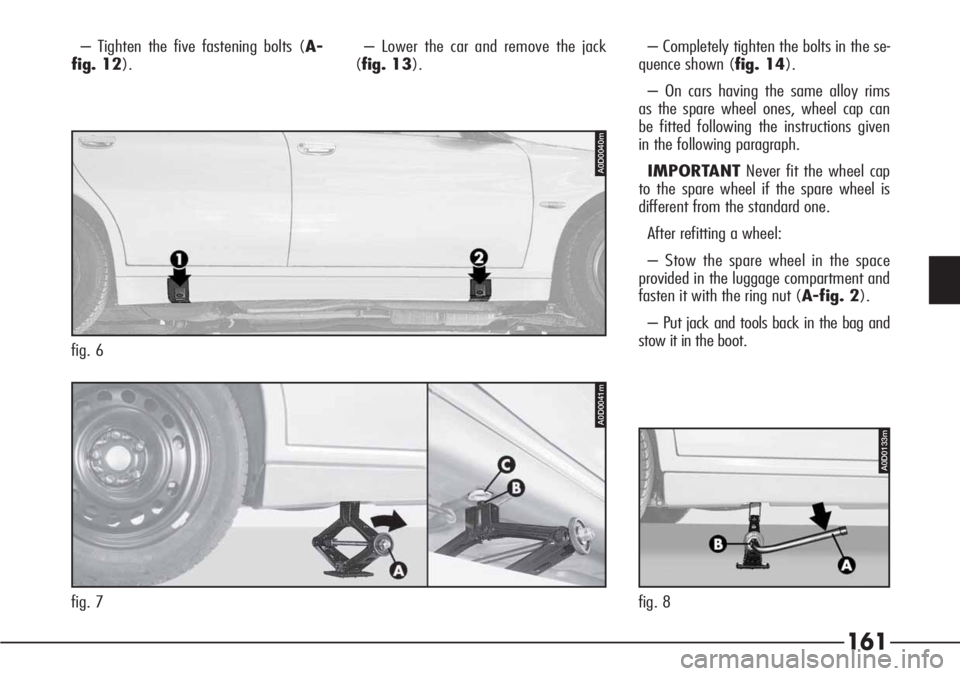

– Position the jack under the car next

to the wheel to be replaced (fig. 6):

Position1: changing a rear wheel;

Position2: changing a front wheel.

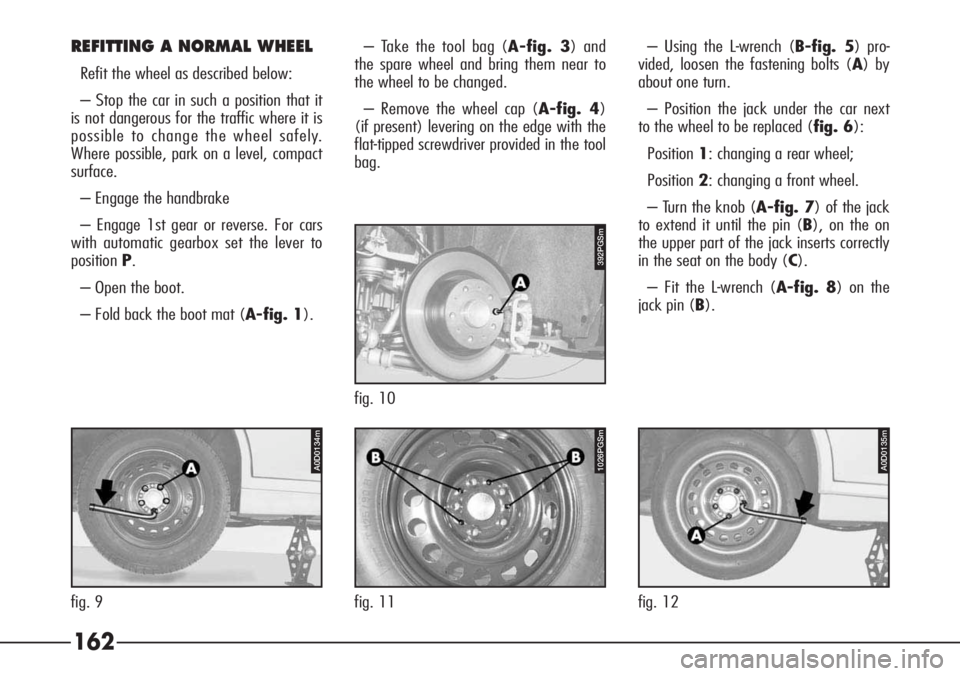

– Turn the knob (A-fig. 7) of the jack

to extend it until the pin (B), on the on

the upper part of the jack inserts correctly

in the seat on the body (C).

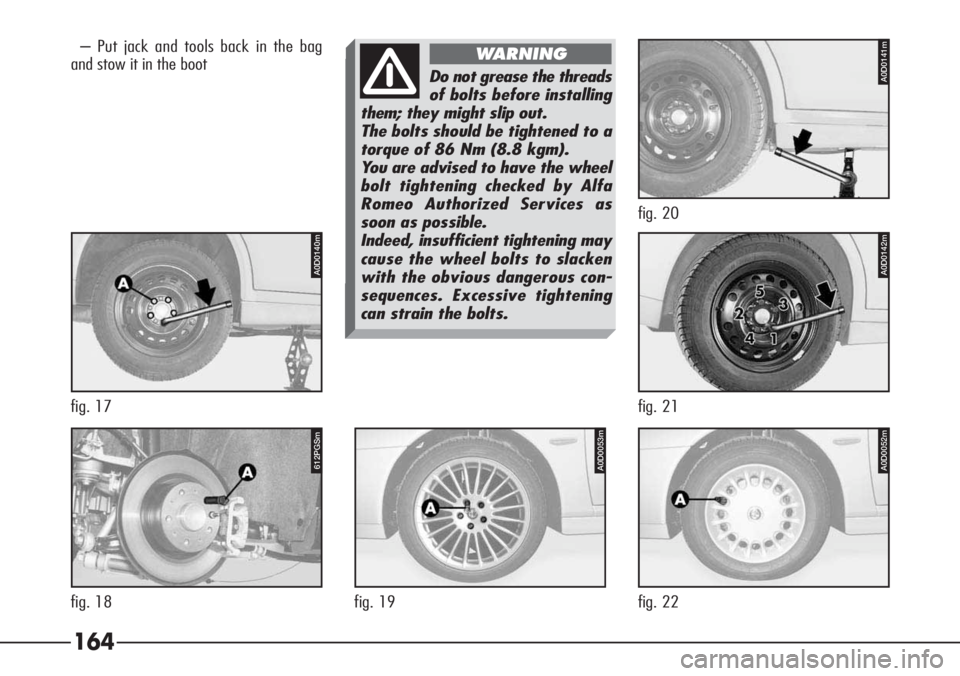

– Fit the L-wrench (A-fig. 8) on the

jack pin (B).

392PGSm

fig. 10

1026PGSm

fig. 11

A0D0134m

fig. 9

A0D0135m

fig. 12

Page 164 of 272

163

– Work the jack and raise the car, until

the wheel is a few centimetres above

ground.

– Completely unscrew the fastening

bolts (A-fig. 16) and remove the

wheel.

– Make sure that the wheel to be in-

stalled is clean and free of impurities on

the hub contact surface which could cause

slackening of the fastening bolts later.

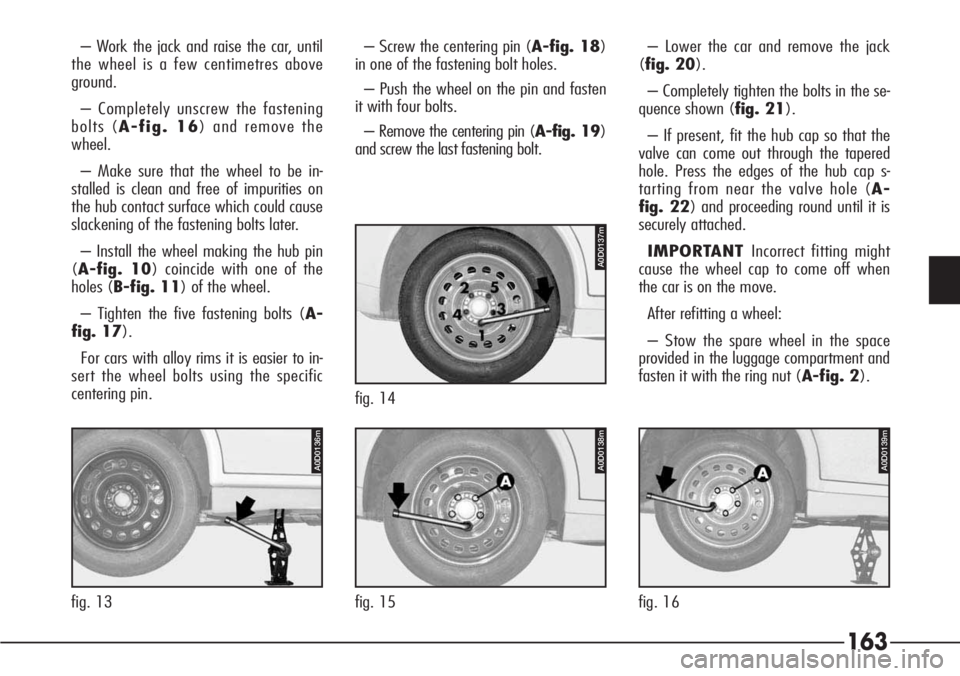

– Install the wheel making the hub pin

(A-fig. 10) coincide with one of the

holes (B-fig. 11) of the wheel.

– Tighten the five fastening bolts (A-

fig. 17).

For cars with alloy rims it is easier to in-

sert the wheel bolts using the specific

centering pin.– Screw the centering pin (A-fig. 18)

in one of the fastening bolt holes.

– Push the wheel on the pin and fasten

it with four bolts.

– Remove the centering pin (A-fig. 19)

and screw the last fastening bolt.– Lower the car and remove the jack

(fig. 20).

– Completely tighten the bolts in the se-

quence shown (fig. 21).

– If present, fit the hub cap so that the

valve can come out through the tapered

hole. Press the edges of the hub cap s-

tarting from near the valve hole (A-

fig. 22) and proceeding round until it is

securely attached.

IMPORTANT Incorrect fitting might

cause the wheel cap to come off when

the car is on the move.

After refitting a wheel:

– Stow the spare wheel in the space

provided in the luggage compartment and

fasten it with the ring nut (A-fig. 2).

A0D0139m

fig. 16

A0D0138m

fig. 15

A0D0136m

fig. 13

A0D0137m

fig. 14

Page 165 of 272

164

– Put jack and tools back in the bag

and stow it in the boot

Do not grease the threads

of bolts before installing

them; they might slip out.

The bolts should be tightened to a

torque of 86 Nm (8.8 kgm).

You are advised to have the wheel

bolt tightening checked by Alfa

Romeo Authorized Services as

soon as possible.

Indeed, insufficient tightening may

cause the wheel bolts to slacken

with the obvious dangerous con-

sequences. Excessive tightening

can strain the bolts.

WARNING

A0D0053m

fig. 19

A0D0052m

fig. 22

612PGSm

fig. 18

A0D0140m

fig. 17

A0D0142m

fig. 21

A0D0141m

fig. 20

Page 194 of 272

193

System/Component Fuse no. Ampere Location

Rearscreen heating 1 30A fig. 93

Relay coil T21, T22, T23 (boot box) 3 5A fig. 86

Relay coil T24 (boot box) 5 10A fig. 86

Remote control receiver 15 10A fig. 93

Sound amplifier 20 25A fig. 93

Sound system 4 15A fig. 86

Sound system controls on steering wheel 5 10Afig. 86

Starter motor 1 30A fig. 89

Trailer presetting 12 10A fig. 93

Windscreen heating 7 15A fig. 93

Windscreen wiper 14 25A fig. 86

System/Component Fuse no. Ampere Location

Navigator 18 5A fig. 86

Parking sensors (control unit) 15 10A fig. 93

Power windows (driver's control

LOCK warning light) 15 10A fig. 93

Powered sunroof 10 20A fig. 93

Presetting 4 – fig. 93

11 – fig. 93

Rain sensor 15 10A fig. 93

Rear current socket 16 20A fig. 93

Rear LH power window (ABI control unit) 14 20Afig. 93

Rear RH power window (ABI control unit) 17 20Afig. 93

Page 198 of 272

197 IF THE VEHICLE

IS TO BE LIFTED

USING THE JACK

See paragraph “In the event of a punc-

ture” of this chapter.

You are informed that.

– the jack mass is 2.100 kg;

– the jack requires no adjustment;

– the jack cannot be repaired and in

case of breakage it must be replaced by

another original one.

– no tool other than its cranking lever

may be installed on the jack.

Before beginning to tow

the car, turn the ignition

key to MAR and then to STOP, do

not remove it. Removing the key

automatically engages the steering

lock resulting in the impossibility

to steer the wheels. When towing

remember that without the help of

the servobrake and power steer-

ing, it is necessary to exert more

effort on the brake pedal and for

steering. Do not use flexible cables

for towing and avoid jerks. During

towing operations make sure that

fastening the joint to the car does

not damage the components in

contact with it. When towing the

car it is compulsory to comply with

the specific traffic regulations con-

cerning both the towing device and

behaviour on the road.

WARNING

The car may fall if the

jack is not positioned cor-

rectly. Never use the jack for

higher capacities than the one

stated on its label.

The purpose of the jack is

only for replacing wheels

on the car with which it is provided

or on cars of the same model. It

must never be used for other pur-

poses such as for example raising

cars of other models. In no case

must it be used for repairs under

the car.

WARNING

WARNING

Page 199 of 272

198IN THE EVENT

OF AN ACCIDENT

– It is important to keep calm.

– If you are not directly involved, stop

at a distance of at least ten metres from

the accident.

– On the motorway stop without ob-

structing the emergency lane.

– Turn off the engine and switch on the

hazard warning lights.

– At night, light the place of the acci-

dent with your headlights.

– Take care not to put yourself in dan-

ger of being run over.

– Signal the accident placing the reflect-

ing triangle plainly in view at the regula-

tion distance.

– Call the rescue organisation giving in-

formation as exact as possible. On motor-

ways use the special call boxes.

– In motorway pileups, especially with

poor visibility, the risk exists of being in-

volved in other crashes. Leave the vehi-

cle immediately and go over the guard

rail. The car is to be lifted

positioning the jack or

the workshop lift arm

plate only in the points shown

(1-2 fig. 100).

Between the lift plate and the

body interpose a rubber pad

with a maximum size of 60x60

mm and maximum thickness of

30 mm. The pad should insert in

the special recess on the under

door panel, without interfering

with it.

USING AN ARM LIFT OR

WORKSHOP LIFT

The vehicle must only be lifted laterally

positioning the ends of the arms or the

workshop lift in the areas (1-2) illustrat-

ed, approx. 30 cm from the profile of the

wheelhouse (fig. 100).

A0D0040m

fig. 100

Page 203 of 272

202 PROGRAMMED

MAINTENANCE

PRECAUTIONS

Many moving parts, high voltage cables

and parts that reach high temperatures

which may cause serious injury to unquali-

fied persons are located in the engine

compartment.

The following precautions should there-

fore be taken:

– Switch off the engine and wait until

it cools.

– Be particularly cautious when work-

ing near the engine cooling fan as this

may cut in unexpectedly on the basis of

the engine coolant temperature.

– Do not smoke or use naked flame.

– Always keep a fire extinguisher to

hand.

– Do not use the jack supplied with the

car for checking underneath it.Vehicle maintenance

should be entrusted to

an Alfa Romeo Author-

ized Service. For interventions of

routine maintenance and small

repairs you wish to carry out

your-self, make sure you always

have the proper equipment, gen-

uine Alfa Romeo spare parts and

the necessary liquids; do not,

however, carry out these opera-

tions if you have no experience.

The jack with which the

vehicle is fitted must on-

ly be used when changing a wheel.

All other operations where the ve-

hicle must be lifted require the use

of specific procedures and should

be carried out by Alfa Romeo Au-

thorized Services.

WARNING

Ensure that scarves, ties

and loose clothing cannot

get caught by moving parts.

WARNING

DANGER-SERIOUS INJU-

RY. When carrying out

checks or maintenance operations

in the engine compartment, take

special care not to bump the head

on the raised bonnet.

WARNING

Never smoke when

working in the engine

compartment: inflammable gas and

vapours may be present which con-

stitute a fire hazard.

WARNING

Page 207 of 272

206 ANNUAL INSPECTION

PLAN

An annual inspection plan has

been established for cars that cov-

er less than 20,000 km a year

(e.g. 10,000 km). It consists of

the following:

– Checking the condition/wear of tyres,

and adjusting pressure (including the com-

pact spare wheel, where applicable).

– Checking the lighting system (head-

lights, turn indicators, hazard warning

lights, boot light, passenger compart-

ment, warning lights of instrument panel,

etc.).

– Checking the working order of the

windscreen wiper-washer and adjusting

the nozzles.

– Checking the positioning/wear of the

windscreen wipers.

– Checking the condition and wear of

the front brake pad.– Sight inspect the conditions of: en-

gine, gearbox, transmission, pipes and

hoses (exhaust - fuel - brakes), rubber

parts (boots, sleeves, bushes, etc.).

– Check for bonnet and boot lock clean-

ness, lever cleanness and lubrication.

– Check battery charge and fluid level

(electrolyte).

– Visually checking the condition of the

belts and various controls.

– Checking and topping up, if neces-

sary, the level of liquids (coolant, brake

fluid, windscreen washer fluid, battery

etc.).

– Change engine oil and oil filter, if re-

quired.

– Check and replace pollen filter, if re-

quired.

– Check and replace air cleaner, if re-

quired.

ADDITIONAL OPERATIONS

Every 1000 kmor before long jour-

neys check and if necessary top up:

– the engine coolant fluid level

– brake fluid/hydraulic clutch control

fluid level

– power steering fluid level

– windscreen washer and headlamp

washer fluid level

– tyre pressure and conditions.

– check light system operation (head-

lights, direction indicators, hazard lights,

etc.).

– check windscreen wiper/washer op-

eration and windscreen/rear window

blade position/wear.

Every 3000 kmcheck the level of

the engine oil and top up if necessary.

Every 5000 km(only for fuel oil en-

gines): drain the condensation water

from the filter. You are recommended to

use products of the FL Selenia, de-

signed and developed expressly for Alfa

Romeo cars (see the table “Fluids and lu-

bricants” in the Technical specifications”

chapter).

Page 216 of 272

215

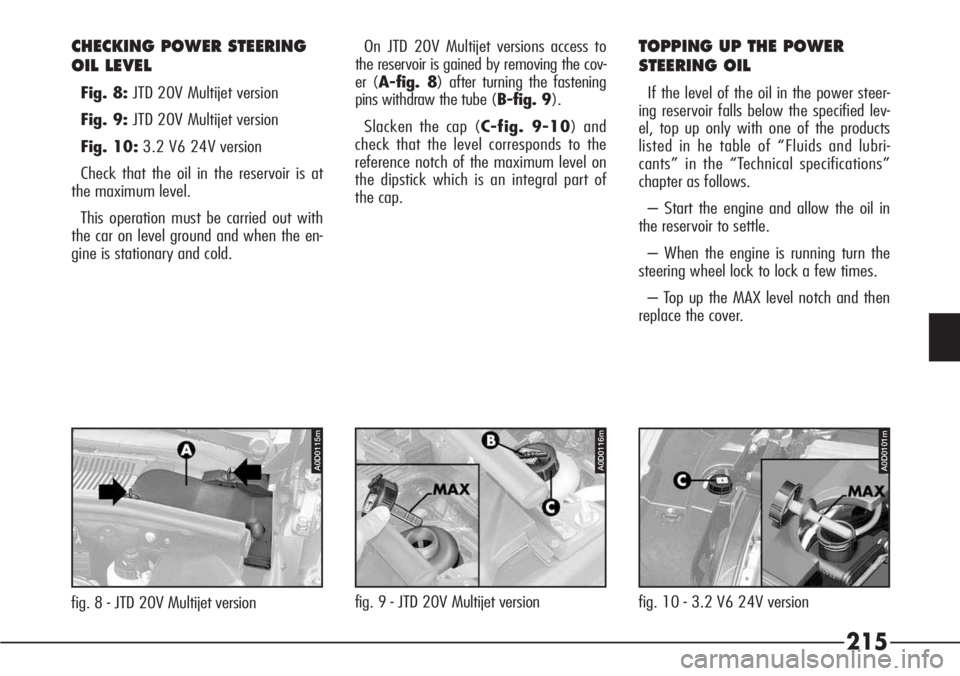

CHECKING POWER STEERING

OIL LEVEL

Fig. 8:JTD 20V Multijet version

Fig. 9:JTD 20V Multijet version

Fig. 10:3.2 V6 24V version

Check that the oil in the reservoir is at

the maximum level.

This operation must be carried out with

the car on level ground and when the en-

gine is stationary and cold.

fig. 8 - JTD 20V Multijet versionfig. 9 - JTD 20V Multijet versionfig. 10 - 3.2 V6 24V version On JTD 20V Multijet versions access to

the reservoir is gained by removing the cov-

er (A-fig. 8) after turning the fastening

pins withdraw the tube (B-fig. 9).

Slacken the cap (C-fig. 9-10) and

check that the level corresponds to the

reference notch of the maximum level on

the dipstick which is an integral part of

the cap.

TOPPING UP THE POWER

STEERING OIL

If the level of the oil in the power steer-

ing reservoir falls below the specified lev-

el, top up only with one of the products

listed in he table of “Fluids and lubri-

cants” in the “Technical specifications”

chapter as follows.

– Start the engine and allow the oil in

the reservoir to settle.

– When the engine is running turn the

steering wheel lock to lock a few times.

– Top up the MAX level notch and then

replace the cover.

A0D0115mA0D0101mA0D0116m