ABS ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 285 of 421

Air Conditioning

Working Practices O" 15-^?

Working Practices

General

Be aware of, and comply

with,

all health and safety

requirements.

Before beginning any repair or service procedure,

disconnect the vehicle battery ground connection

and protect the vehicle from dirt or damage.

Work in a well ventilated, clean and tidy area.

Recovery and chargeequipment must comply

with,

or exceed the standard detailed in the General

Description.

Handling Refrigerant

Wear eye protection at all times.

Use gloves, keep skin that may come into contact

with refrigerant covered. If the refrigerant comes

into contactwith youreyesorskin wash the affected

area immediatelyw'ith cool water and seek medical

advice, do not attempt to treat yourself.

Avoid inhaling refrigerant vapour, it wil

your respiratory system.

irritate

Never use high pressure compressed air to flush out

a system. Under certain circumstances a

combination of HFC 134A and compressed air in

the presenceofa source ofcombustion (for instance,

welding or brazing equipment), results in an

explosion that releases toxic compounds into the

atmosphere.

The refrigerant and CFC 12 must never come into

contact with each other

as

they form an inseparable

mixture that can only be disposed of by incineration.

Do not vent refrigerant directly into the atmosphere,

always use approved recovery equipment.

Refrigerant is costly but it can be recycled. Clean

the refrigerant, using the recovery equipment and

reuse it.

Carry out LeakTestsonly with an electronic analyser

dedicated to Refrigerant El 34A.

Do not attemptto guess the amount of refrigerant in

a system, always recover it and recharge with the

correct charge weight. Do not depress the charge or

discharge port valves to check for the presence of

refrigerant.

Handling Lubricating Oil

Avoid breathinglubricantmist,itwillcauseirritation

to your respiratory system.

Always decant fresh oil from a sealed container. Do

not leave oil exposed to the atmosphere for any

reason other than to fill or empty a system; PAG oil

is hygroscopic (it absorbs water) and iscontaminated

rapidly by atmospheric moisture.

Following the recovery cycle do not reuse the oil

when it has been separated from the refrigerant;

dispose of the oil safely.

System Maintenance

Do not leave the system open to the atmosphere. If

a unit or part of the system is left open for more than

five minutes, it is advisable to renew the receiver-

dryer. There is not a safe period in which work is to

be carried out. Always plug pipes and units

immediately after disconnection and only remove

plugs when re-connecting.

If replacement parts are supplied without transit

plugs and seals do not use the parts. Return them to

your supplier.

Diagnostic equipment for pressure, mass and

volumeshouidbecalibrated regularly and certified

by a third party organisation.

Use extreme care when handling and securing

aluminium fittings, always use a backing spanner

and take special care when handlingtheevaporator.

Use only the correct or recommended tools for the

job and apply the manufacturer's torque

specifications.

Keep the working area, all components and tools

clean.

8-8 May 1996

Page 289 of 421

Air Conditioning //~-->> ^/zz:^^ • ^ ^

General Svstem Procedures ' —"^ ^ '^ General System Procedures

From the condenser the liquid passes into the Receiver-Drier which has three functions:

• Storage vessel for varying system refrigerant demands.

• Filter to remove system contaminants.

• Moisture removal via the desiccant.

With the passage through the receiver-drier completed the, still high pressure liquid refrigerant, enters the Expansion

Valve where it is metered through a controlled orifice which has the effect of reducing the pressure and temperature.

The refrigerant, now in a cold atomised state, flows into the Evaporator and cools the air which is passing through

the matrix.

As heat is absorbed by the refrigerant it once again changes state, into a vapour, and returns to the compressor for

the cycle to be repeated (Fig. 5).

There is an automatic safety valve incorporated in the compressor which operates should the system pressure be

in excess of

41

bar. The valve re-seats when the pressure drops below 35 bar.

Note: The division of HIGH and LOW side is simply the

system pressure

differential created by the

compressor

discharge

(pressure),

suction

(inlet)

ports and

the

relative inlet and outlet

ports

of the

expansion

valve.

This

differential is critical to

system

fault

diagnosis

and efficiency checks.

System Protection

The trinary pressure switch, located in the liquid line, cuts electrical power to the compressor clutch if the system

pressure is outside of the range of 2 Bar

(1

st Function) to 27 Bar (2nd Function). The third function is to switch on

the cooling fans when pressure exceeds 20 bar.

General System Procedures

Leak Test

Faults associated with low refrigerant charge weight and low pressure may be caused by leakage. Leaks traced to

mechanical connections may be caused by torque relaxation or joint face contamination. Evidence of oil around

such areas is an indicator of leakage. When checking for non visible leaks use only a dedicated Refrigerant El 34A

electronic analyser and apply the probe all round the joint connection. Should a leak be traced to a joint, check that

the fixing is secured to the correct tightening torque before any other action is taken.

Do not forget to check the compressor shaft seal and evaporator.

Note: Never

use

a dedicated

CFC 12

or

naiced

flame type

analyser.

Charge Recovery (System Depressurisation)

The process of refrigerant recovery depends on the basic characteristics of your chosen recovery-recycle-recharge

equipment, therefore, follow the manufacturers instructions carefully. Remember that compressor oil may be drawn

out of the system by this process, take note of the quantity recovered so that it may be replaced.

CAUTION: Observe all relevant safety requirements.

• Do not vent refrigerant directly to atmosphere and always use approved recovery-recycle-recharge

equipment.

• Wear suitable eye and skin protection.

• Do not mix the refrigerant with CFC 12.

• Take note of the amount of recovered refrigerant, it indica

tes the

state of the

system

and

thus the

magnitude

of any problem.

8-12 May 1996

Page 290 of 421

^2?

Air Conditioning

General System Procedures

Evacuating the System

This process, the removal of unwanted air and moisture, is critical to the correct operation of the air conditioning

system.

The procedures depends on the characteristics of the recovery-recycle-recharge equipment and must be

carried out exactly in accordance with the manufacturers instructions.

Moisture can be highly destructive and may cause internal blockages due to freezing, but more importantly, water

suspended in the PAG oil will damage the compressor. Once the system has been opened for repairs, or the

refrigerant charge recovered, all traces oi moisture must be removed before recharging with new or recycled

refrigerant.

Adding Compressor Lubricating Oil

Oil can be added by three methods, two of which are direct into the system

• via the recovery-recycle-recharge station

• by proprietary oil injector.

Equipment manufacturer's instructions must be adhered to when using direct oil introduction.

The third method may be required because of rectification work to the existing compressor, or the need to fit a new

compressor. From an existing compressor, drain the oil into a measuring cylinder and record the amount. Flush the

unit out with fresh PAG oil and drain thoroughly. Refill the compressor with the same amount of PAG oil that was

drained out originally and plug all orifices immediately ready for refitting to the vehicle. The transit lubricating oil

must be drained and discarded from a new compressor before it may be fitted. An adjustment should be made to

the system oil level by taking into account:

• the quantity found in the original compressor

• the quantity deposited in the recovery equipment oil separator from the charge recovery operation.

Typically, 80 ml can be drained from the original compressor and 30 ml found in the oil separator; the sum of these

volumes (80 + 30 = 110 ml) is the amount of fresh PAG oil that must be put into the new compressor prior to fitting.

Hote:

The

discrepancy

between

this

figure

and

the

nominal capacity of

135

ml is

caused

by normally not

recoverable

oil being

trapped in

components

such

as

the receiver-drier or

evaporator.

The above statements are only true if there is no evidence of a leak. Where a leak has been detected and rectified,

the compressor must be refilled with the specified quantity.

Caution: Always decant

fresh

oil from a sealed container and do not leave oil exposed to the

atmosphere.

PAG oil is very

hygroscopic

(absorbs

water) and rapidly

attracts

atmospheric moisture.

PAG oil must

NEVER

be mixed with mineral

based

oils.

Do not

reuse

oil following a recovery cycle,

dispose

of it

safely.

Depending on the state of the air conditioning system immediately prior to charge recovery and the rate of recovery,

an amount of oil is drawn out with the refrigerant. The quantity is approximately 30 to 40 mi; this may vary, and

the figure is given only for guidance. It is most important that the oil separator vessel in the recovery equipment is

clean and empty at the start of the process so that the amount drawn out may be accurately measured.

May 1996 8-13

Page 311 of 421

Air Conditioning

Refrigeration /s:s^°27

Refrigeration

Safety Precautions

The air conditioning system is designed to use only

Refrigerant E134A (dichlorodifluoromethane). Extreme

care must betaken NOT to use

a

methylchloride refrigerant.

The chemical reaction between methylchloride and the

aluminium parts ofthe compressor results in the formation

ofproductswhich burn spontaneously on exposure toair,

or decompose with violence in the presence of moisture.

The suitable refrigerant is supplied under the following

names.

El 34A KLEA or equivalent

Warning: Take care when handling refrigerant. Serious

damage will occur if it is allowed to come into

contact with the eyes. Always wear with goggles

and gloves when working with refrigerant

First Aid

If refrigerant should come into contact with the

eyes or

skin,

splash the eyes or affected area with

cold water for several minutes. DO NOT RUB. As

soon as possible thereafter, obtain treatment from a

Doctor or an eye specialist.

Good Practice

1.

Protective sealing plugs must be fitted to all

disconnected pipes and units.

2.

Theprotectivesealingpiugsmustremain inposition

on ail replacement components and pipes until

immediately before assembly.

3. Any part arriving for assembly without sealing

plugs in position must be returned to the supplier as

defective.

4.

It is essential that a second backing spanner is

always used when tightening or loosening all joints.

This minimises distortion or strain on components

or connecting hoses.

5. Components must not be lifted by connecting

pipes,

hoses or capillary tubes.

6. Care must be taken not to damage fins on the

condenser or evaporator matrices. Any damage

must be rectified by the use of fin combs.

7. Before assembly oftube and hosejoints, use

a

small

amount of clean new refrigerant oil on the sealing

seat.

8. Refrigerant oil for any purpose must be kept very

clean and capped at all times. This prevents the oil

absorbing moisture.

9. Before assembly the condition of joints and flares

must be examined. Dirt and even minor damage

will cause leaks at the high pressure points

encountered in the system.

10.

Dirty end fitting can only be cleaned using a cloth

wetted with alcohol.

11.

Afterremovingsealingplugsand immediatelybefore

assembly, visually check the bore of pipes and

components. Where any dirt or moisture is

discovered,

the part must be rejected.

12. Ail components must be allowed to reach room

temperature before sealing plugs are removed.

This prevents condensation should the component

be cold initially.

13.

Before finally tightening hose connections ensure

that the hose lies in the correct position, is not

kinked or twisted and will not be trapped by

subsequent operations, e.g., refitting or closing

bonnet.

14.

Check that hoses are correctly fitted in clips or

straps.

15.

The compressor must be stored horizontally with

the sump down. It must not be rotated before fitting

and charging. Do not remove the shipping plate

until immediately before assembly. Always use

new "O" ring seals in those joints that incorporate

them.

"O" ring seals should be coated with

compressor oil before fitting.

16.

Components or hoses removed must be sealed

immediately after removal.

1 7. Afterthe system has been opened the receiver-drier

must be renewed.

18.

Before

testing,

run the engine until normal running

temperature is reached. This ensures that sufficient

vacuum is available for test. For cooling tests the

engine must be running for the compressor clutch

to operate.

8-34 May 1996

Page 313 of 421

Air Conditioning

Compressors ^?

Evaporator

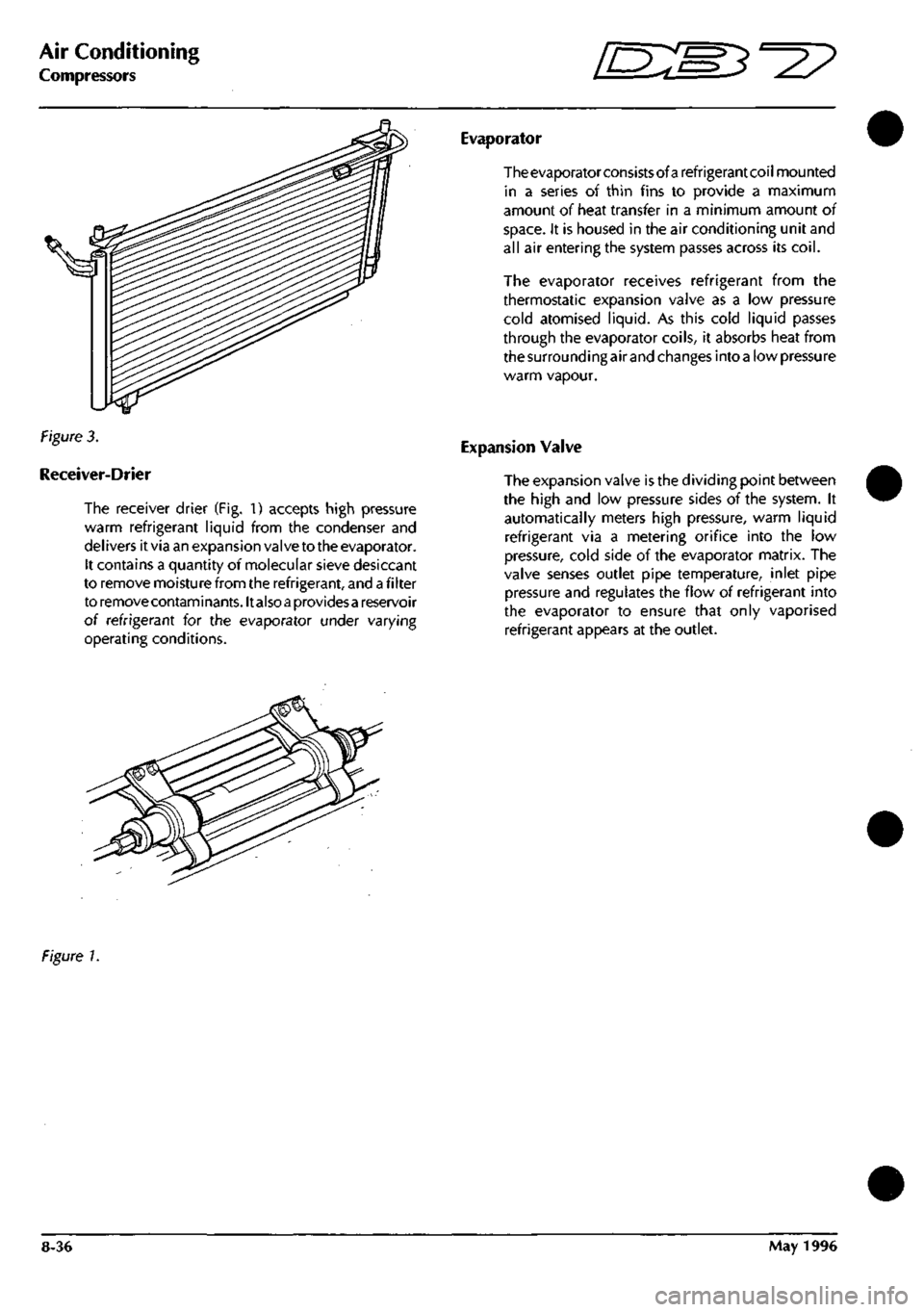

Figure 3.

Receiver-Drier

The receiver drier (Fig. 1) accepts high pressure

warm refrigerant liquid from the condenser and

del ivers it via an expansion valve to the evaporator.

It contains a quantity of molecular sieve desiccant

to remove moisture from the refrigerant, and

a

fi Iter

to removecontaminants.lt also

a

providesa reservoir

of refrigerant for the evaporator under varying

operating conditions.

The evaporator consists of a refrigerant coil mounted

in a series of thin fins to provide a maximum

amount of heat transfer in a minimum amount of

space.

It is housed in the air conditioning unit and

all air entering the system passes across its

coil.

The evaporator receives refrigerant from the

thermostatic expansion valve as a low pressure

cold atomised liquid. As this cold liquid passes

through the evaporator coils, it absorbs heat from

the surrounding air and changes into

a

low pressure

warm vapour.

Expansion Valve

The expansion valve is the dividing point between

the high and low pressure sides of the system. It

automatically meters high pressure, warm liquid

refrigerant via a metering orifice into the low

pressure, cold side of the evaporator matrix. The

valve senses outlet pipe temperature, inlet pipe

pressure and regulates the flow of refrigerant into

the evaporator to ensure that only vaporised

refrigerant appears at the outlet.

Figure 1.

8-36 May 1996

Page 380 of 421

^=2?

The Aston Martin Lagonda Diagnostic System

Users Guide

Software

Software for the PDU system is supplied on CD ROM

discs and supports diagnosis on the following control

units:

Zytek Engine Management System (95 MY)

EEC-V Engine Management System (97 MY)

CM 4L80-E Transmission Controller

PATS - Passive Anti Theft System

Teves Mk II ABS System (95 MY)

Teves Mk IV ABS System (97 MY)

Valeo Air Conditioning System

PMC Airbag System

Megamoss Security System

Autoliv Drivers Seat Belt Pretensioner

(where fitted)

All of these systems are supported in English, French,

Italian,

German and Japanese.

In addition to the specific system software listed above,

thePDU isalsoequipped with general purpose software

to provides multimeter, printing and PDU training

options.

Software for 95 and 97 Model Year Vehicles

Software for both the 95 and 97 model year vehicles is

provided.

The PDU system requires a Vehicle Interface Adaptor

(VIA) to communicate with the control units of 95

model year vehicles.

Communication with 97 model year control units is

principally via an Aston Martin multi-protocol adaptor

to 2 inbuilt diagnostic sockets in the vehicle. Only the

air conditioning unit requires the VIA on 97 model year

vehicles.

If the multimeter function is used, the Vehicle Battery

Adaptor (VBA) will be required to provide the basic

supply and ground levels for the multimeter.

Software Loading and Selection

Ensure that the system is powered up and that the PDU is

correctly connected to the base station. Check and if

necessary load the DB7 software CD Revision 002. (see

the installation guide)

Switch 'on' the PDU which will run through two front

screens and then load the following initial PDU software.

Operating System

Main Menu

Selector

Digital Multimeter

Interactive Training

September 1996 9-29

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

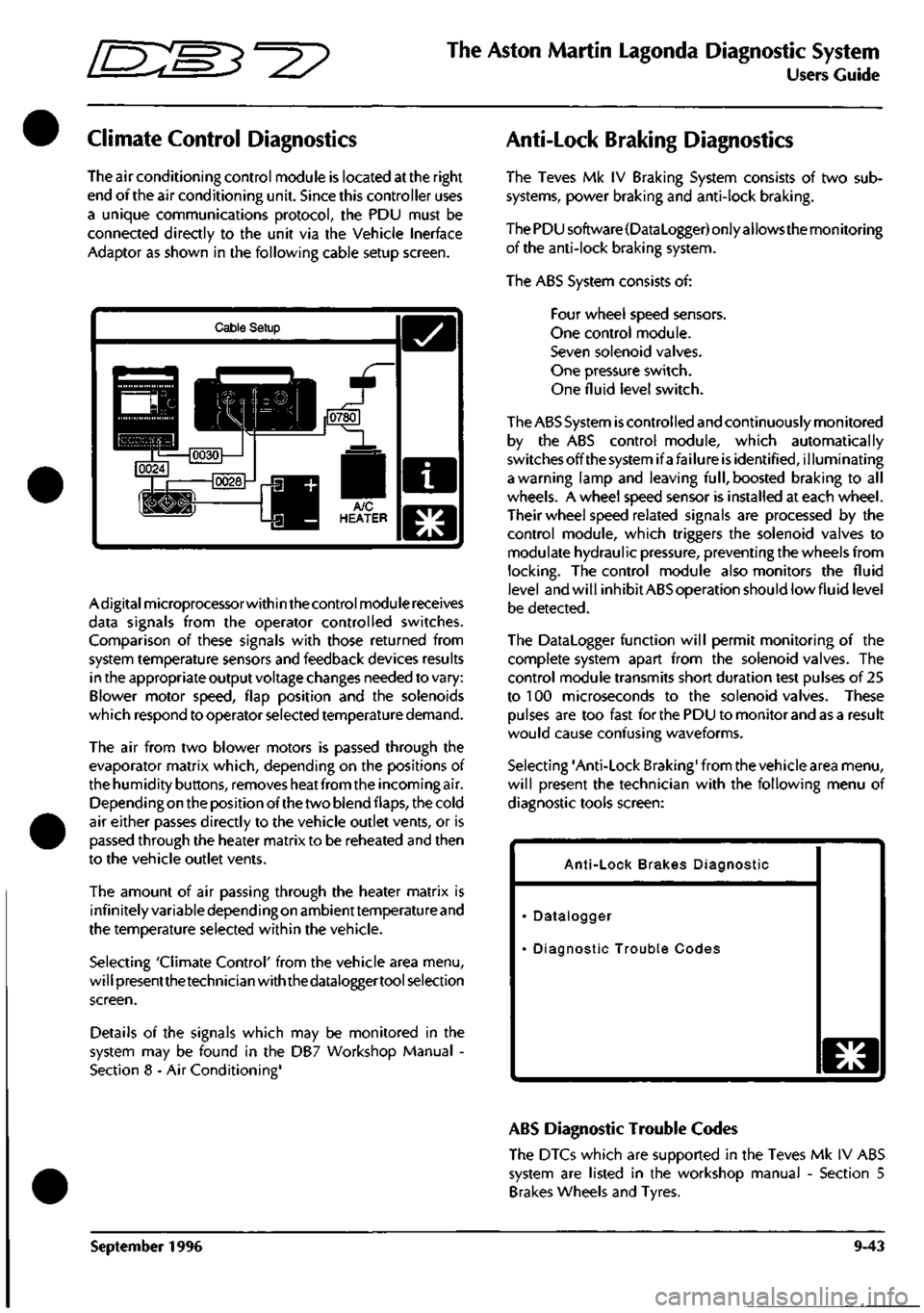

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

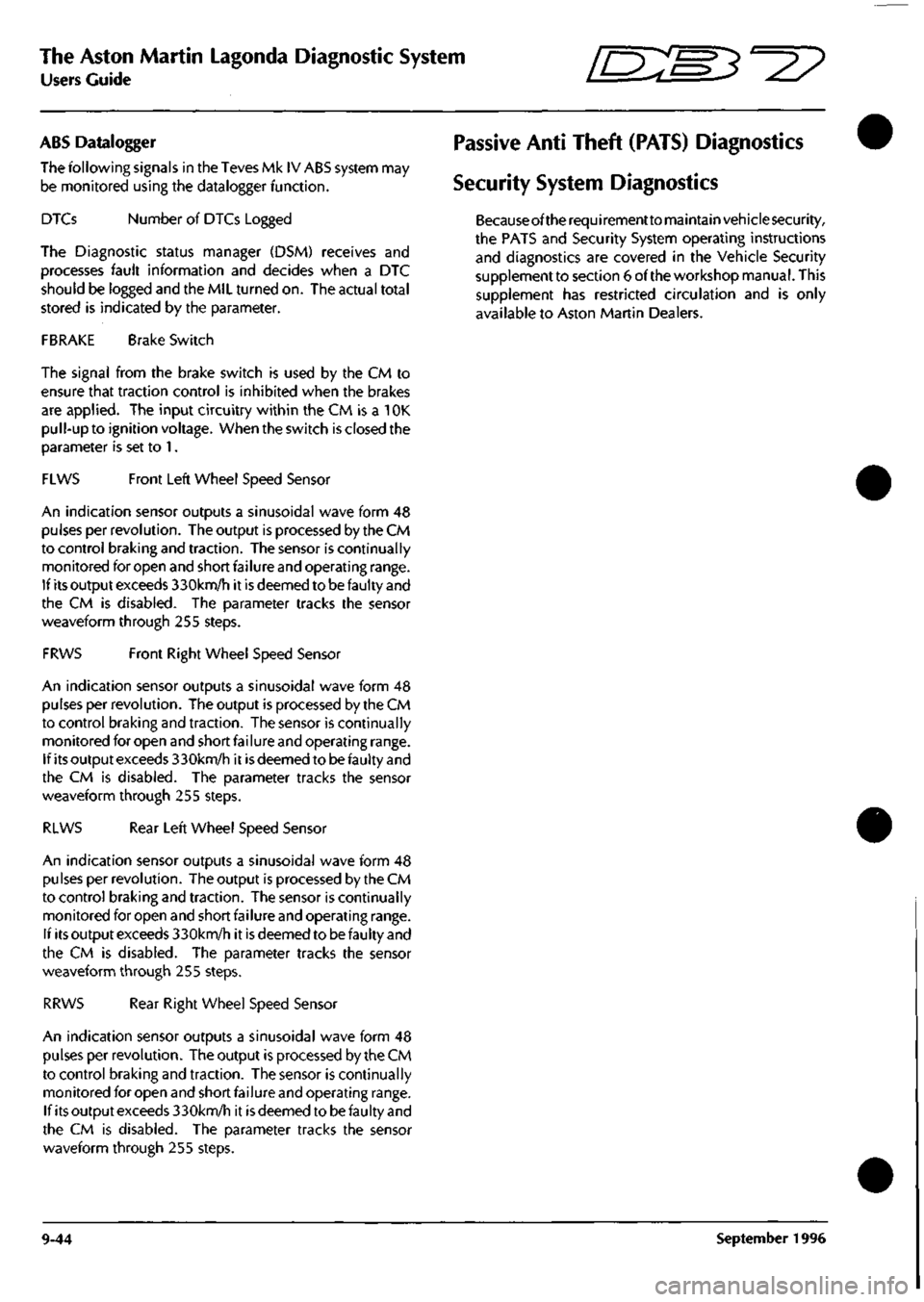

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43

Page 395 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide

Em^'^?

ABS Datalogger

The following signals in the Teves Mk IV ABS system may

be monitored using the datalogger function.

DTCs Number of DTCs Logged

The Diagnostic status manager (DSM) receives and

processes fault information and decides when a DTC

should be logged and the MIL turned on. The actual total

stored is indicated by the parameter.

FBRAKE Brake Switch

The signal from the brake switch is used by the CM to

ensure that traction control is inhibited when the brakes

are applied. The input circuitry within the CM is a

1

OK

pull-up to ignition voltage. When the switch is closed the

parameter is set to 1.

FLWS Front Left Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it is deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

FRWS Front Right Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it

is

deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

RLWS Rear Left Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it

is

deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

weaveform through 255 steps.

RRWS Rear Right Wheel Speed Sensor

An indication sensor outputs a sinusoidal wave form 48

pulses per revolution. The output is processed by the CM

to control braking and traction. The sensor is continually

monitored for open and short failure and operating range.

If its output exceeds 330km/h it is deemed to be faulty and

the CM is disabled. The parameter tracks the sensor

waveform through 255 steps.

Passive Anti Theft (PATS) Diagnostics

Security System Diagnostics

Becauseof the requirementto maintain vehicle security,

the PATS and Security System operating instructions

and diagnostics are covered in the Vehicle Security

supplement to section 6 of the workshop manual. This

supplement has restricted circulation and is only

available to Aston Martin Dealers.

9-44 September 1996

Page 404 of 421

^7

The Aston Martin Lagonda Diagnostic System

Users Guide

Diagnostic Trouble Codes

Introduction

The 'Diagnostic trouble codes' application enables the

PDU to monitor the trouble codes logged in selected

control module's and provides the following functions:

• Decode and display any trouble codes logged by

the control module(s) being monitored.

• Decode and display enhanced diagnostic

information, together with any count of the number

of occurrences, when supported by the control

module(s).

• Clearsomeorallofallthesetroublecodes selected

by the user on the PDU screen, when supported by

the control module(s).

Diagnostic Trouble Codes are logged by the Engine

Management and by the Automatic Transmission control

units and can be accessed using the PDU. Logged codes

in the 95 MY Teves Mk II ABS controller can only be

accessed using the brake warning light. The Air

Conditioning control unit does not log trouble codes.

Operation

From the Main Menu make the following selections:

Select Diagnostics

Select Engine or Transmission

The system will then load the appropriate

software

Select Diagnostic Trouble Codes

Connect the PDU to the car as shown on the

screen diagram

Select the / icon to confirm connection

The PDU will then interrogate the chosen control

unit and will display any logged trouble codes.

If no trouble codes have been flagged by the control

module, the PDU will display a screen similar to Fig. 15

The trouble code screen will be headed by a module title

block followed by a list showing all logged trouble codes

for the seleaed module.

Note: There may be more logged diagnostic trouble

codes than displayed on the first

screen.

Use the 'up

arrow' and 'down arrow' icons if

necessary

to scroll

through the total display.

On the Zytek engine management system only, each

trouble code definition will be individually selectable to

invoke the clear trouble codes screen. If one or more

trouble codes are selected, the clear all and clear selected

trouble code icons will be displayed.

On all other systems, only the 'Clear All' function is

available.

'Clear All' and 'Clear Selected Codes' Icons

Freeze Frame Data

m*

As any engine management trouble code is

logged,

the system takes a snapshot (freeze

frame) and records the state of all signals at

that time.

On the Zytek engine management system (95 MY), freeze

frame data can be displayed by selecting a logged trouble

code and touching the 'snowflake'

icon.

On the 97 MY EEC V engine management system, freeze

frame data is accessed using the OBD II scan

tool.

ECC-V EMS DTC'S

No fault codes present

l^

D

a

El

The No Fault Codes screen

September 1996 9-53

Page 406 of 421

"^I?

The Aston Martin Lagonda Diagnostic System

Users Guide

Datalogger

Introduction

Datalogger is software produced to identify permanent or

intermittent faults on vehicle electronics. The objective of

Datalogger is to provide a view of the vehicle's electrical

behaviour, such that intermittent activity can be recorded

and interpreted quickly and accurately. Running on the

Portable Diagnostic Unit (PDU), the Datalogger

appi ication can captu

re

vehicle information in three ways.

• Serial communications direct from the control unit.

• Parallel communications using the Interface Adaptor.

• Direct signal monitoringusingthemeasurementprobes.

Serial Communication

Serial Communication is a two-wire communication link

between the PDU and most vehicle control modules

providingdigital measurements forconnected components.

The serial communication link allows the tester to

determine the current condition of components connected

to the control module, and to identify any history of faults.

On later vehicles, the PDU is connected to the vehicle

diagnostic sockets via the mu

Iti

Protocol Adaptor (MPA) to

gather serial data from the control modules.

Parallel Communication

The Vehicle Interface Adapter (VIA) provides an interface

between the PDU and the vehicle harnesses for the

acquisition of multiple analogue measurements. The VIA

is

connected between the relevantvehicle control module

and it'sharness connector. Thisallows the PDU to captu re

information from a multitude of channels entering the

control module. This vehicle interface is used with control

modules not equipped with a serial communication link

(Teves Mk II braking system and the air conditioning

system).

Measurement Probes

The measurement probes permit readings to be taken

directly from any connector on the vehicle.

Datalogger Applications

Datalogger may be used to interrogate the following DB7

systems:

• ABS braking system controller

• Engine Management Controller

• Air Conditioning Controller

• Automatic Transmission Controller

• Passive Anti Theft (97 MY)

• Security System (97 MY)

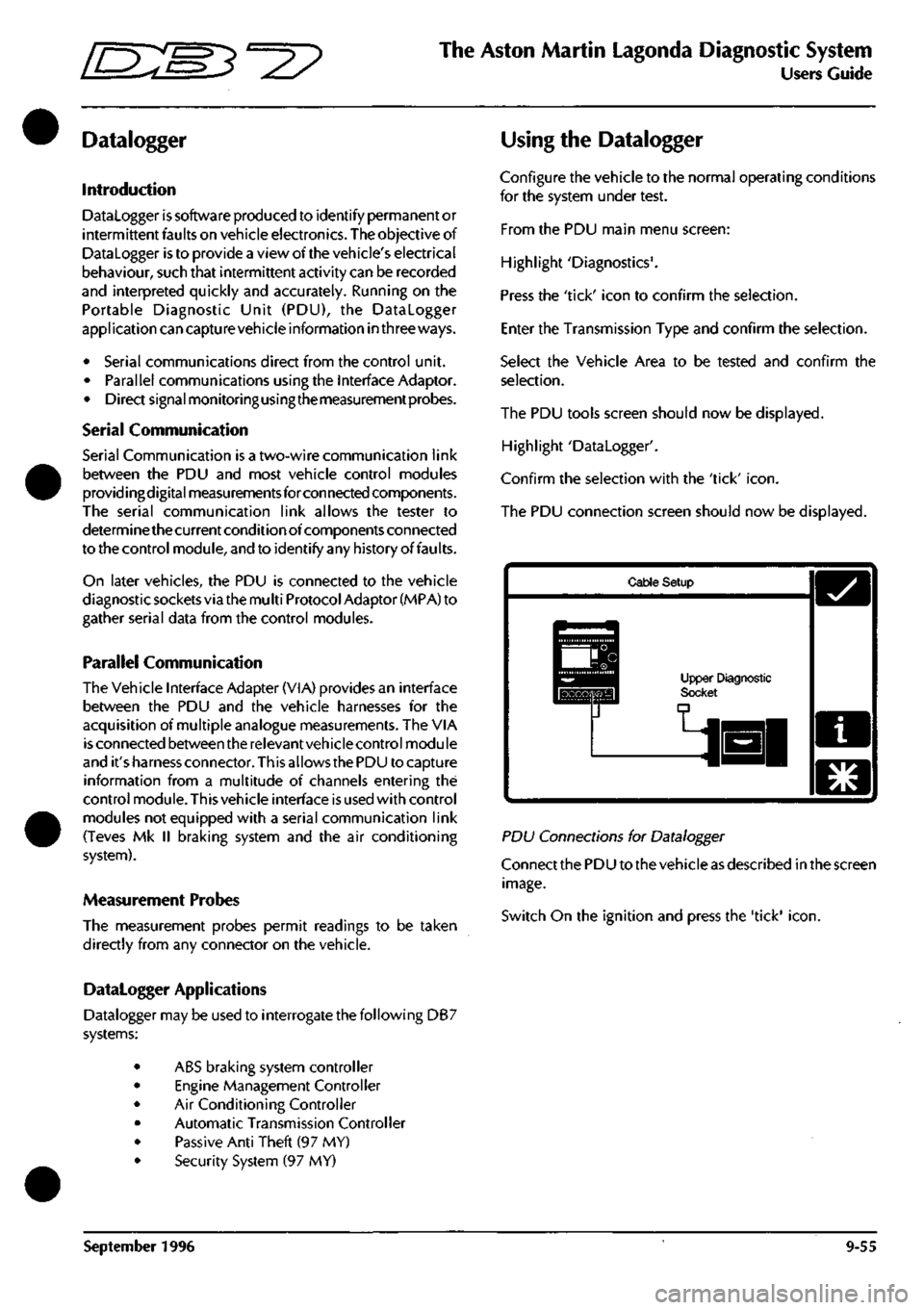

Using the Datalogger

Configure the vehicle to the normal operating conditions

for the system under test.

From the PDU main menu screen:

Highlight 'Diagnostics'.

Press the 'tick' icon to confirm the selection.

Enter the Transmission Type and confirm the selection.

Select the Vehicle Area to be tested and confirm the

selection.

The PDU tools screen should now be displayed.

Highlight 'Datalogger'.

Confirm the selection with the 'tick'

icon.

The PDU connection screen should now be displayed.

Cable Setup

Upper Diagnostic Socl

PD\J Connections for Datalogger

Connect the PDU to the vehicle as described in the screen

image.

Switch On the ignition and press the 'tick'

icon.

September 1996 9-55