ESP ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 305 of 421

Air Conditioning

Vacuum System •^^

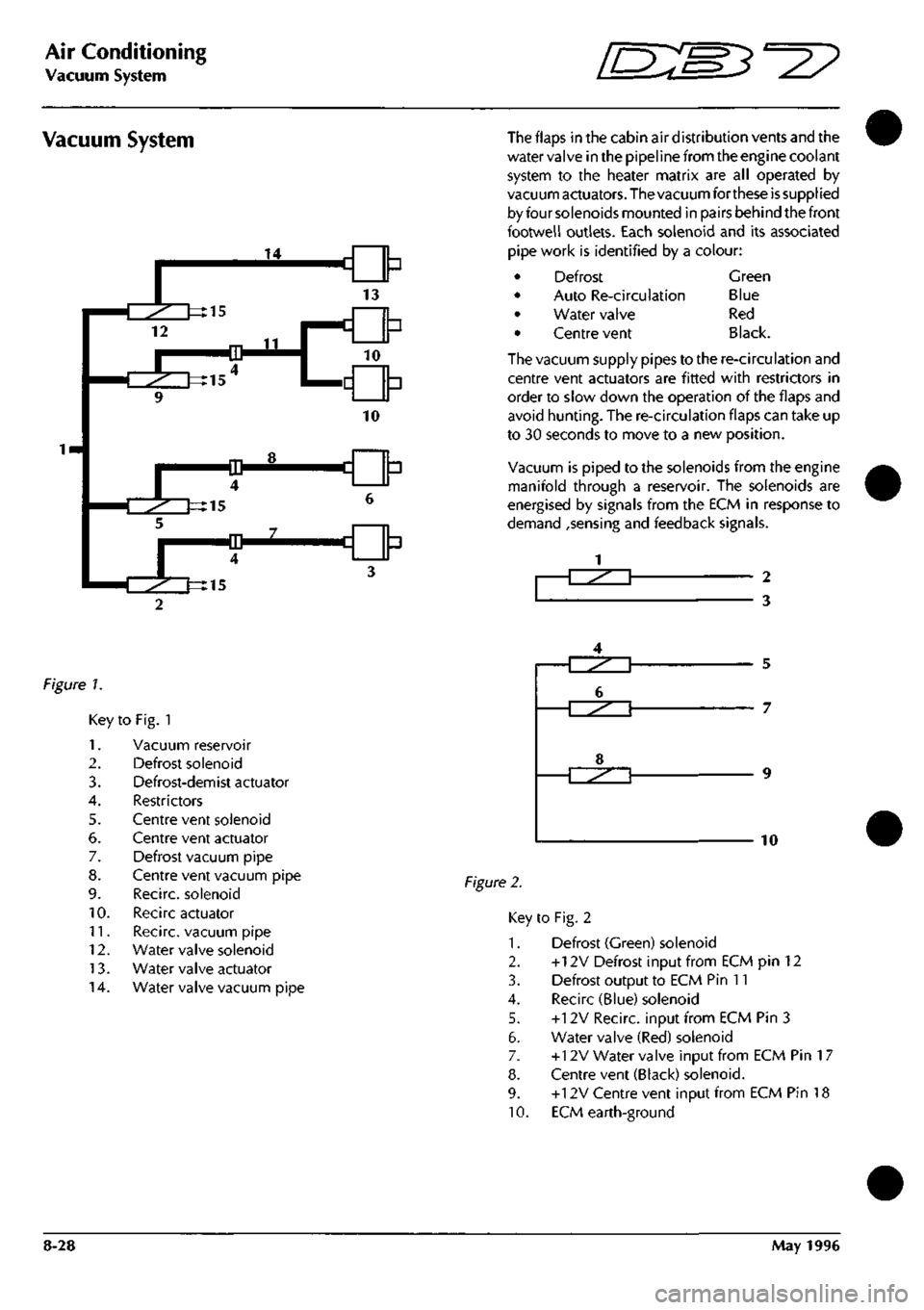

Vacuum System The flaps in the cabin air distribution vents and the

water valve in the pipeline from the engine coolant

system to the heater matrix are all operated by

vacuum actuators. The vacuum forthese

is

supplied

by four solenoids mounted in pairs behind the front

footwell outlets. Each solenoid and its associated

pipe work is identified by a colour:

Defrost

Auto Re-circulation

Water valve

Centre vent

Green

Blue

Red

Black.

The vacuum supply pipes to the re-circulation and

centre vent actuators are fitted with restrictors in

order to slow down the operation of the flaps and

avoid hunting. The re-circulation flaps can take up

to 30 seconds to move to a new position.

Vacuum is piped to the solenoids from the engine

manifold through a reservoir. The solenoids are

energised by signals from the ECM in response to

demand ,sensing and feedback signals.

-T^^^T 2

3

figure 7.

Key

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

to Fig. 1

Vacuum reservoir

Defrost solenoid

Defrost-demist actuator

Restrictors

Centre vent solenoid

Centre vent actuator

Defrost vacuum pipe

Centre vent vacuum pipe

Recirc. solenoid

Recirc actuator

Recirc. vacuum pipe

Water valve solenoid

Water valve actuator

Water valve vacuum pipe

Figure 2.

5

7

10

Key to Fig. 2

1.

Defrost (Green) solenoid

2.

+12V Defrost Input from ECM pin 12

3. Defrost output to ECM Pin 11

4.

Recirc (Blue) solenoid

5. +12V Recirc. input from ECM Pin 3

6. Water valve (Red) solenoid

7. +12V Water valve input from ECM Pin

1

7

8. Centre vent (Black) solenoid.

9. +12V Centre vent input from ECM Pin 18

10.

ECM earth-ground

8-28 May 1996

Page 319 of 421

Air Conditioning

System Checking with the Manifold Gauge Set [n::S3^^?

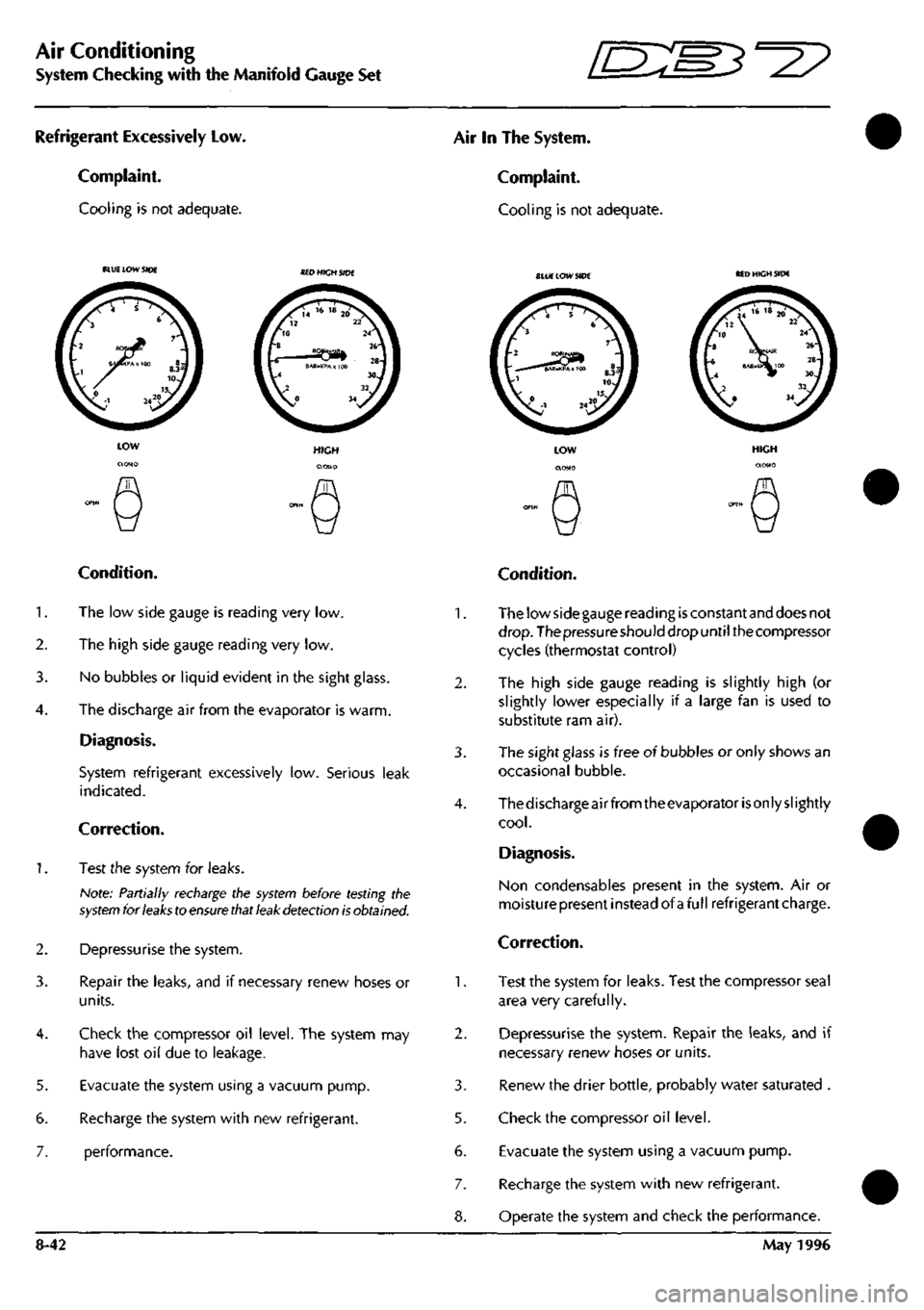

Refrigerant Excessively Low.

Complaint.

Cooling is not adequate.

Air In The System.

Complaint.

Cooling is not adequate.

BLU£ LOW SIDE SlUE LOW SIDE MD HIGH SIDE

5.

6.

7.

Condition.

1.

The low side gauge is reading very low.

2.

The high side gauge reading very low.

3. No bubbles or liquid evident in the sight glass.

4.

The discharge air from the evaporator is warm.

Diagnosis.

System refrigerant excessively low. Serious leak

indicated.

Correction.

1.

Test the system for leaks.

Note: Partially recharge the

system

before testing the

system

for

leaks

to

ensure that leak detection is

obtained.

Depressurise the system.

Repair the leaks, and if necessary renew hoses or

units.

Check the compressor oil level. The system may

have lost oil due to leakage.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

performance.

2.

3.

5.

6.

7.

8-42

Condition.

The low side gauge reading

is

constant and does not

drop.

The pressure should drop until the compressor

cycles (thermostat control)

The high side gauge reading is slightly high (or

slightly lower especially if a large fan is used to

substitute ram air).

The sight glass is free of bubbles or only shows an

occasional bubble.

Thedischarge air from theevaporator

is

only slightly

cool.

Diagnosis.

Non condensables present in the system. Air or

moisturepresent instead of afullrefrigerantcharge.

Correction.

Test the system for leaks. Test the compressor seal

area very carefully.

Depressurise the system. Repair the leaks, and if

necessary renew hoses or units.

Renew the drier bottle, probably water saturated .

Check the compressor oil level.

Evacuate the system using a vacuum pump.

Recharge the system with new refrigerant.

Operate the system and check the performance.

May 1996

Page 342 of 421

Air Conditioning

Air-Conditioning Diagnostics

The Air Conditioning System Diagnostics

The air-conditioning control module (A/CCM) is located at the right end of the air-conditioning unit.

A

digital microprocessor within the

A/CCM

receives

data

signals from

the

operator controlled

switches.

Comparison

of these signals with those returned from the system temperature sensor and feedback devices results in the

appropriate voltage changes necessary to vary: blower motor

speed,

flap positions and system solenoids to respond

to the drivers selected temperature demand.

The air from the two blower motors is passed through the evaporator matrix which, depending on the A/C mode

selected,

removes heat from the incoming air. Depending on the position of

the

two blend

flaps,

the cold air passes

either directly into the vehicle outlet vents, or is passed through the heater matrix to be reheated and then passed

to the vehicle outlet vents.

The amount of air passing through the heater matrix is infinitely variable depending on ambient temperature and

the temperature selected within the vehicle.

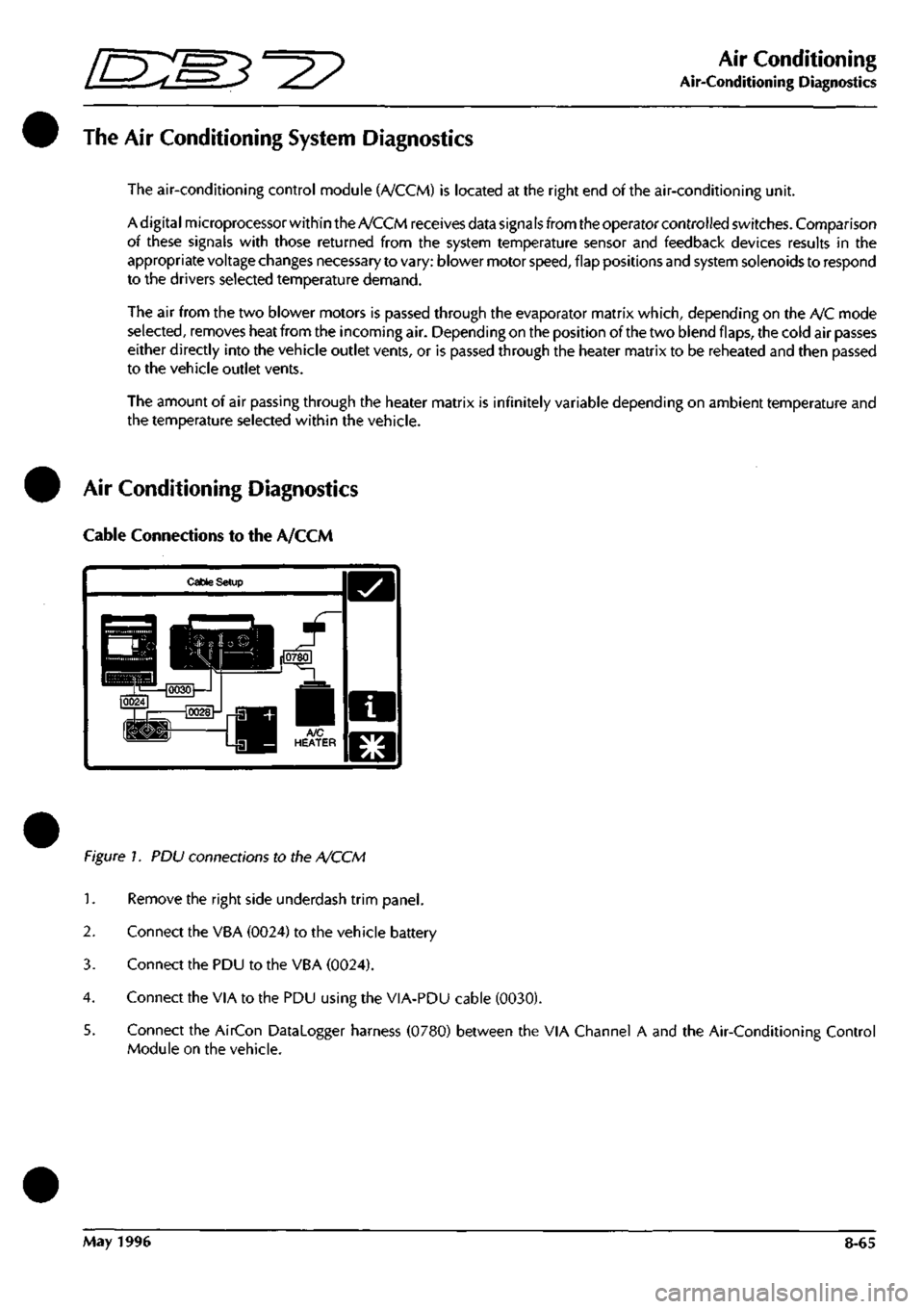

Air Conditioning Diagnostics

Cable Connections to the A/CCM

Cable Setup

Figure 1. PDU connections to the A/CCM

1.

Remove the right side underdash trim panel.

2.

Connect the VBA (0024) to the vehicle battery

3. Connect the PDU to the VBA (0024).

4.

Connect the VIA to the PDU using the VIA-PDU cable (0030).

5. Connect the AirCon Datalogger harness (0780) between the VIA Channel A and the Air-Conditioning Control

Module on the vehicle.

May 1996 8-65

Page 344 of 421

^=2?

Air Conditioning

Portable Diagnostic Unit - Signal Definitions

ThefollowingsignalsaresupportedontheAir-ConditioningControlModule. For each signal. The signal name, mnemonic

and background information are detailed.

Ambient Temperature Sensor

(AMBTEMP)

Auto-Recircuiation Input

(ARECIP)

Auto-Recirculation Output

(ARECOP)

Auxiliary Battery Positive

(AUX+)

Clutch Relay Drive Output

(CLUREL)

A/CCM Pin 34 ref Pin 6

This sensor is located in the right hand blower motor. This signal is used to enable

the A/C system to compensate for changes in ambient air temperature. The output

to pin 34 is 2.732 volts at 0 degrees Celsius and changes by 0.01 volts for each

degree Celsius above or below zero.

A/CCM Pin 9 ref Pin 6

This is effectively an On/Off switch for the A/C system and forms part of the fan

control switch.

Switch Off - Pin 9 should be at ground

Switch On - Pin 9 should be at 10+ volts.

When pin 9 is at ground, pin 3 will be at 10+ volts causing the recirculation flaps

to open.

A/CCM Pin 3 ref Pin 6

This signal will cause the recirculation flaps to close. Operating conditions should

be:

A/C Off - 10+ volts at pin 3, flaps open.

Temp demand minimum - 10+ volts at pin 3, flaps open.

Defrost - 0 volts at pin 3, flaps closed.

Temp demand max - 0 volts at pin 3, flaps closed.

A/CCM Pin 1 ref Vehicle Battery -ve

This signal istheauxiliary supply to the A/CCM. Pin

1

should read battery voltage

if the ignition switch is in the auxiliary or ignition on positions. Pin

1

should read

0 volts when the ignition switch is in the Off position or in position III whilst

cranking the engine. Loss of this supply will cause total failureof the A/C system.

A/CCM Pin 20 ref Pin 6

This signal responds to the input at pin 5 (evaporator sensor). When pin 5 is

between 2.715 and 2.725 volts, pin 20 should read below 1 volt, and the

compressor clutch will be switched off. When pin 5 is between 2.735 and 2.745

volts,

pin 20 will rise to 10+ volts and the compressor will re-engage.

Centre Vent Solenoid

(CVSOL) A/CCM Pin 18 ref Pin 6

The centre vent solenoid controls the operation of the centre vent flap. The centre

vent will open to increase the cooling capabilities of the vehicle when cooling is

selected.

In all other conditions, the centre vent will be closed.

Solenoid energised: pin 18 should read 10+volts and the centre vent will be open.

Solenoid de-energised; pin 18 should read below 0.5 volts and the centre vent

should be closed.

May 1996 8-67

Page 347 of 421

Air Conditioning

Portable Diagnostic Unit - Signal Definitions ^^P

Ground Voltage

(GND2)

Ground Voltage

(GND38)

Ground Voltage

(GND45)

Ground Voltage

(GND6)

High Speed Relay Drive

(HSREL)

In-Car Sensor

(ICSEN)

A/CCMPin2refPin6

A/CCM Pin 38 ref Pin 6

A/CCM Pin 45 ref Pin 6

A/CCM Pin 6 ref Battery -ve

The four ground signals above must be at battery negative voltage at all times.

A/CCM Pin 16 ref Pin 6

The high speed relay drive signal is used to energise the high speed relay and to

run the blowers at full speed, bypassing the normal fan control circuit. The high

speed relay will be energised whenever Defrost or High speed Fans is selected.

Relay energised, pin 16 should read 10+ volts

Relay de-energised, pin 16 should read below 0.5 volts.

If the signal at pin 16 is correct but only one fan responds, suspect a fault in the

harness or relay.

A/CCM Pin 4 ref Pin 6

The in-car temperature sensor operates in the range 0-5 volts. Actual output is

2.732 volts at 0 degrees Celsius ±0.01 volts for every degree Celsius above or

below zero. The sensor signal forms a reference point for the whole system.

If the signal on this pin remains at less than

1

volt, suspect either a short to ground

on the signal wire or an open circuit on the 5 volt supply line to the sensor.

If the signal rises to approximately 3 volts, then suspect an open circuit on the

ground supply to the sensor.

8-70 May 1996

Page 353 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions E:MB^^?

Introduction The Aston Martin Diagnostic System

This guide contains instructions for the installation

of the Portable Diagnostic Unit hardware in Aston

Martin Dealer workshops. To achieve maxinnum

benefit from the system, please follow the

instructions carefully. The following System

Diagram shows the principal system components

and panel details.

This introduction briefly describes the system and

its capabilities. This is followed by the Installation

and Power-Up procedures which give detailed

instruaions on how to start the system and access

the self-contained Interactive

Training

Programme.

The subsequent sections detail the fault diagnosis

and maintenance procedures.

WARNING:

The equipment must

only

be used by

trained

personnel.

Care should

be taken to use the

equipment in accordance with the operating

procedures.

Observe

all safety

warnings

in this

guide.

If any part of

the system is damaged do not

use it. Call your local CenRad

Service

Centre

immediately

for a

substitute

part.

Refer to

'Parts

Ordering'.

The Aston Martin Diagnostic System is a new

generation diagnostic

tool

which fulfils

a

number of

functions in aiding the technician to quickly and

accurately locate faults. The heart of the system is

the Portable Diagnostic

Unit,

a

lightweight powerful

computer/measurement system providing a step-

by-step user friendly interface for the technician.

PDU functions include:

Data Logger - The ability to monitor and record

control module signals even whilst the vehicle is

being driven.

On-Line Help-Containing detailed descriptions in

the

operation

ofthevehicleselectroniccomponents.

Vehicle Setup - The ability to setup various

adjustable parameters to their optimum settings.

Diagnostic Trouble Codes - The ability to extract

recorded fault information from the DB7's control

modules.

Each of

these

funaions is described in detail in the

PDU Users Guide.

WARNING: If

the system is used to measure high

voltages,

these voltages can appear on the pins of

other

connectors in

the

system.

Ensure

that socket

covers

are

fitted

on

unused

sockets.

Ensure

that all

connections

are

made

prior to

applying the high

voltage to

the

probes.

Do not

leave the equipment

unattended

in

this

state.

The maximum

voltage

that may be applied

between the

test

probes is 150

volts

AC or DC.

Radio Interference Statements

This digital apparatus does not exceed the Class A

limits for radio noiseemissionsfromdigital apparatus

as set

out

in

the radio interference regulations of the

Canadian Department of Communications.

This equipment has been tested and found to

comply with the limits for Class A digital device

pursuant to part 15 of the Federal Communications

Commission (FCC) rules. However, operation in

close proximity to domestic communication

equipment may cause interference. It is the

responsibility of the user to avoid or correct this

condition.

9-2 May 1996

Page 366 of 421

r^ ' ^ ^ The Aston Martin Lagonda Diagnostic System

Installation Instructions

Finishing the Test

When data analysis is finished, switch off the PDU

and disconnect it from the vehicle. Store the PDU

and cables in the carrying case and refit the case to

the base station.

Connect the PDU to the base station using cable

0064.

The base station will keep the PDU batteries

fully charged at all times (Fig 15).

Figure 15. PDU connected for recharging

Care of the Equipment

CAUTION: With the exception of those parts

referred to in the Servicing and Maintenance

section, there are no user serviceable parts. All

servicing must be carried out by GenRad Service

Centres.

Switch offthe power before cleaningtheequipment.

The Aston Martin Diagnostic System should only

be cleaned using a non-abrasive, mild cleaning

agent. Dust and other particles should be lightly

brushed from the surface before

cleaning.

Cleaning

agent should be applied to a soft lint-free cleaning

cloth and never directly to the unit. Do not soak the

cleaning cloth and take care not to allow cleaning

fluid to enter connectors.

CAUTION: Ifany liquid is spilt on theequipment,

switch off immediately.

Ensure

that the equipment

has

dried out completely before operating it again,

especially in connectors where fluid can lodge.

May 1996 9-15

Page 369 of 421

The Aston Martin Lagonda Diagnostic System

Installation Instructions -=2?

Step 11

Adjust the contrast control. Is the PDU touch screen illuminated?

YES - Co to step 12

NO - Renew the PDU (0017)

Step 12

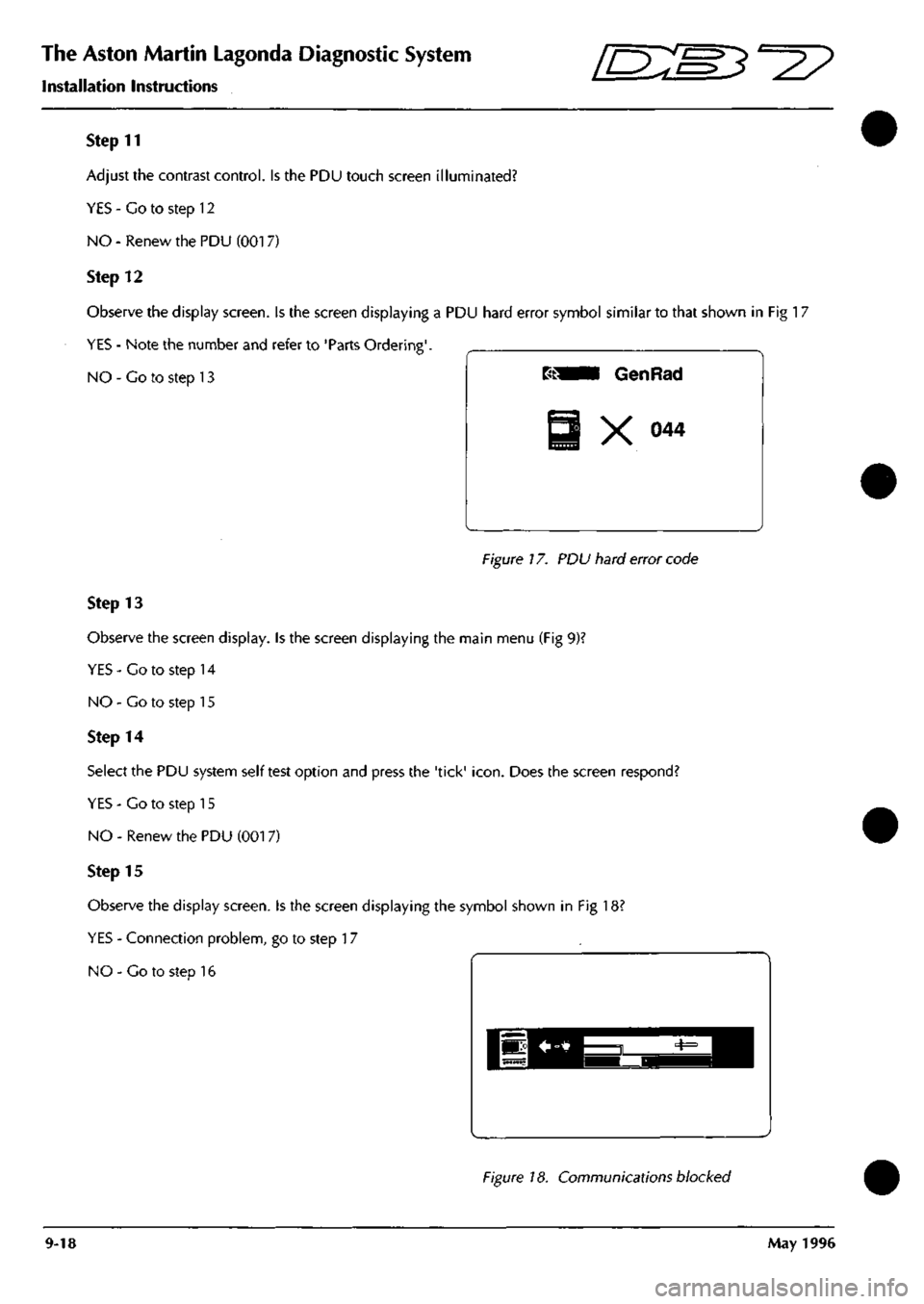

Observe the display screen. Is the screen displaying a PDU hard error symbol similar to that shown in Fig 17

YES - Note the number and refer to 'Parts Ordering'.

NO - Co to step 13

Figure 17. PDU hard error code

Step 13

Observe the screen display. Is the screen displaying the main menu (Fig 9)?

YES-Co to step 14

NO - Go to step 15

Step 14

Select the PDU system self test option and press the 'tick'

icon.

Does the screen respond?

YES - Co to step 15

NO - Renew the PDU (001 7)

Step 15

Observe the display screen. Is the screen displaying the symbol shown in Fig 18?

YES - Connection problem, go to step 17

NO - Co to step 16

Figure 18. Communications blocked

9-18 May 1996

Page 394 of 421

^?

The Aston Martin Lagonda Diagnostic System

Users Guide

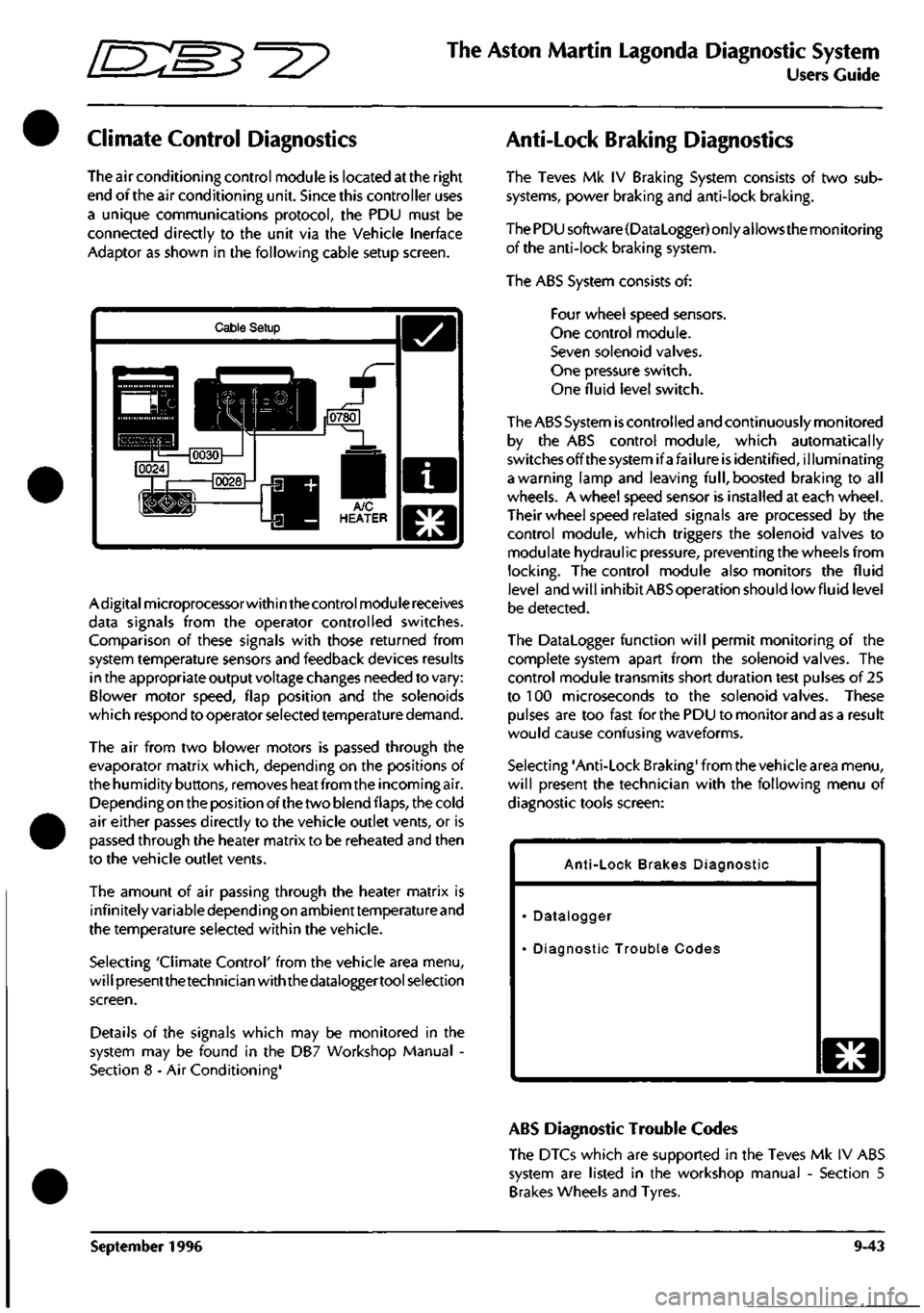

Climate Control Diagnostics

The air conditioning control module is located at the right

end of the air conditioning unit. Since this controller uses

a unique communications protocol, the PDU must be

connected directly to the unit via the Vehicle Inerface

Adaptor as shown in the following cable setup screen.

Cable Setup

Adigitalmicroprocessorwithin the control module receives

data signals from the operator controlled switches.

Comparison of these signals with those returned from

system temperature sensors and feedback devices results

in the appropriate output voltage changes needed to vary:

Blower motor speed, flap position and the solenoids

which respond to operator selected temperature demand.

The air from two blower motors is passed through the

evaporator matrix which, depending on the positions of

the humidity buttons, removes heat from the incoming air.

Dependingon the position of the two blend flaps, the cold

air either passes directly to the vehicle outlet vents, or is

passed through the heater matrix to be reheated and then

to the vehicle outlet vents.

The amount of air passing through the heater matrix is

infinitely variable depending on ambienttemperature and

the temperature selected within the vehicle.

Selecting 'Climate Control' from the vehicle area menu,

will presentthetechnician with the dataloggertool selection

screen.

Details of the signals which may be monitored in the

system may be found in the DB7 Workshop Manual -

Section 8 - Air Conditioning'

Anti-Lock Braking Diagnostics

The Teves Mk IV Braking System consists of two sub

systems, power braking and anti-lock braking.

The PDU software(DataLogger) only allows the monitoring

of the anti-lock braking system.

The ABS System consists of:

Four wheel speed sensors.

One control module.

Seven solenoid valves.

One pressure switch.

One fluid level switch.

The ABS System

is

controlled and continuously monitored

by the ABS control module, which automatically

switchesoffthesystemifafailure is identified, illuminating

a warning lamp and leaving

full,

boosted braking to all

wheels. A wheel speed sensor is installed at each wheel.

Their wheel speed related signals are processed by the

control module, which triggers the solenoid valves to

modulate hydraulic pressure, preventing the wheels from

locking.

The control module also monitors the fluid

level and will inhibit ABS operation should lowfluid level

be detected.

The Datalogger function will permit monitoring of the

complete system apart from the solenoid valves. The

control module transmits short duration test pulses of 25

to 100 microseconds to the solenoid valves. These

pulses are too fast for the PDU to monitor and as a result

would cause confusing waveforms.

Selecting 'Anti-Lock Braking' from the vehicle area menu,

will present the technician with the following menu of

diagnostic tools screen:

Anti-Lock Brakes Diagnostic

Datalogger

Diagnostic Trouble Codes

o

ABS Diagnostic Trouble Codes

The DTCs which are supported in the Teves Mk IV ABS

system are listed in the workshop manual - Section 5

Brakes Wheels and Tyres.

September 1996 9-43

Page 398 of 421

^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

Seat Belt Pretensioner Diagnostics

(where fitted)

Description

The DB7 seat belt pretensioner system operates the

drivers seat belt pretensioner in conjunction with the

Airbag system. The seat belt pretensioner control

module is located underthe right hand seat, beside the

seat control module.

The pretensioner control module calculates changes

in vehicle speed using an input signal from an

accelerometer. When a collision is detected (Rapid

reduction in vehicle speed) the pretensioner charge is

fired using electrical energy stored in a capacitor

within the pretensioner control module. Firing of the

pretensioner charge applies additional tension to the

drivers seat belt.

The airbag and seat belt pretensioner systems share the

SRS (Airbag) warning lamp. Any fault detected by the

pretensioner control module is indicated by constant

illumination ofthe

SRS

(Airbag) warning

lamp.

Flashing

of the SRS warning lamp indicates a fault in the airbag

system.

Should both systems develop faults, the pretensioner

system will permanently illuminate the warning lamp.

This would mask the airbag system warning indication.

Therefore, rectify the pretensioner fault and then retest

for faults in the airbag system

The pretensioner control module can log up to 10

diagnostic trouble codes together with a time since

each fault was alerted to the driver. Each fault will be

identified as 'Permanent' or 'Intermittent' on the PDU

diagnostic trouble codes screen.

System Connections

The Autoliv RC5 Pretensioner Control Module has an

18 pin connector featuring six shorting bridges. The

mating halves ofthe connector may be securely locked

using a double mechanical locking system.

The following pins on the control module connector

are used in the Aston Martin seat belt pretensioner

system:

Pin 1

Pin 2

Pin n

Pin 12

Pin 14

Pin 15

Case

September 1996

Ground

SRS/Airbag Warning Lamp

Drivers airbag positive

Drivers airbag negative

Serial communications

12 volt positive feed

Ground

System Fault Strategy

No single fault may cause an unexpected deployment.

The controller will supervise the airbag/pretensioner

electrical system in order to warn the driver should a

fault occur. Any fault detected by the self diagnostics

shall cause the airbag warning lamp to be activated,

and in some cases the pretensioner control module to

enter shutdown mode. In shutdown mode, the energy

ofthe reserve capacitors shall be discharged to avoid

unintended deployment.

As the ignition is switched on, the pretensioner

controller will directly discharge theenergy capacitors.

When the start up procedure is completed without

detecting any faults, the converter will be activated

allowing the capacitors to be

charged.

The system shall

be fully active within 11 seconds after switching the

ignition on providing that no faults are detected.

All system faults monitored by the controller are filtered

in software to avoid fault warnings due to transient

electrical disturbances.

If a fault which could lead to inadvertent deployment

bedetectedbythemicroprocessor,asoftwareshutdown

will be generated. However, a leakage to an earth or

positive potential in the pretensioner output circuit

shall not cause the controller to enter shutdown mode.

If

a

permanent short of the ignition transistor occurs, a

shutdown shall be generated by the hardware circuit.

If a shutdown occurs, the system shall be unable to

deploy the pretensioner after a period of

3

seconds (i.e.

capacitors discharged to under minimum deployment

voltage).

WARNING: To avoid the possibility of personal

injury caused by accidental deployment of the

pretensioner, disconnect the vehicle battery and

wait at least 10 minutes for all voltages to fully

discharge before working on the pretensioner

system. This covers the possibility of the normal

capacitor discharge circuits being inopera tive and

failing to discharge the capacitor when instructed

to do so.

If the module enters shutdown mode, all diagnostic

functions are stopped, but the communications link

remains active. A fault code corresponding to the

cause of the problem may be read by the PDU.

9-47