ESP ASTON MARTIN DB7 1997 Owner's Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 400 of 421

^^

The Aston Martin Lagonda Diagnostic System

Users Guide

Print Facility

The print trace and print screen facilities provided on

DB7 CD2 will enable the Dealer to print directly to a

serial printer via an isolated RS 232 cable.

General Information

This cable isdesigned to provide full electrical isolation

between the Portable Diagnostic Unit (PDU) and a

device using the RS232 serial communication port.

The cable is constructed with an in-line module that

contains the optical isolation circuitry, powered from

the PDU.

Printer type

The cable is supplied configured to suite an Epson

LX300 printer. This is the only instal lation verified and

approved by Aston Martin Lagonda Ltd.

Unexpected results may occur if used with an

unapproved printer.

Part Number Equipment type

3539-1114-03 Epson LX300 printer cable kit

comprising

3539-1169-03 Printer Cable

3539-1175-02 User Self Test Adaptor

Connecting to the PDU

Connection to the PDU RS232 port

is

made by plugging

the circular connector with the BLUE ident ring into

socket (1) on the PDU interface panel.

RS232 Protocol

The RS232 protocol operated by the PDU is 9600

baud,

8 bit, no parity,

1

stop bit,

RTS

/ CTS hardware

handshake.

Printer Configuration

When connected to the printer

a

hardcopy of the PDU

data can be produced.

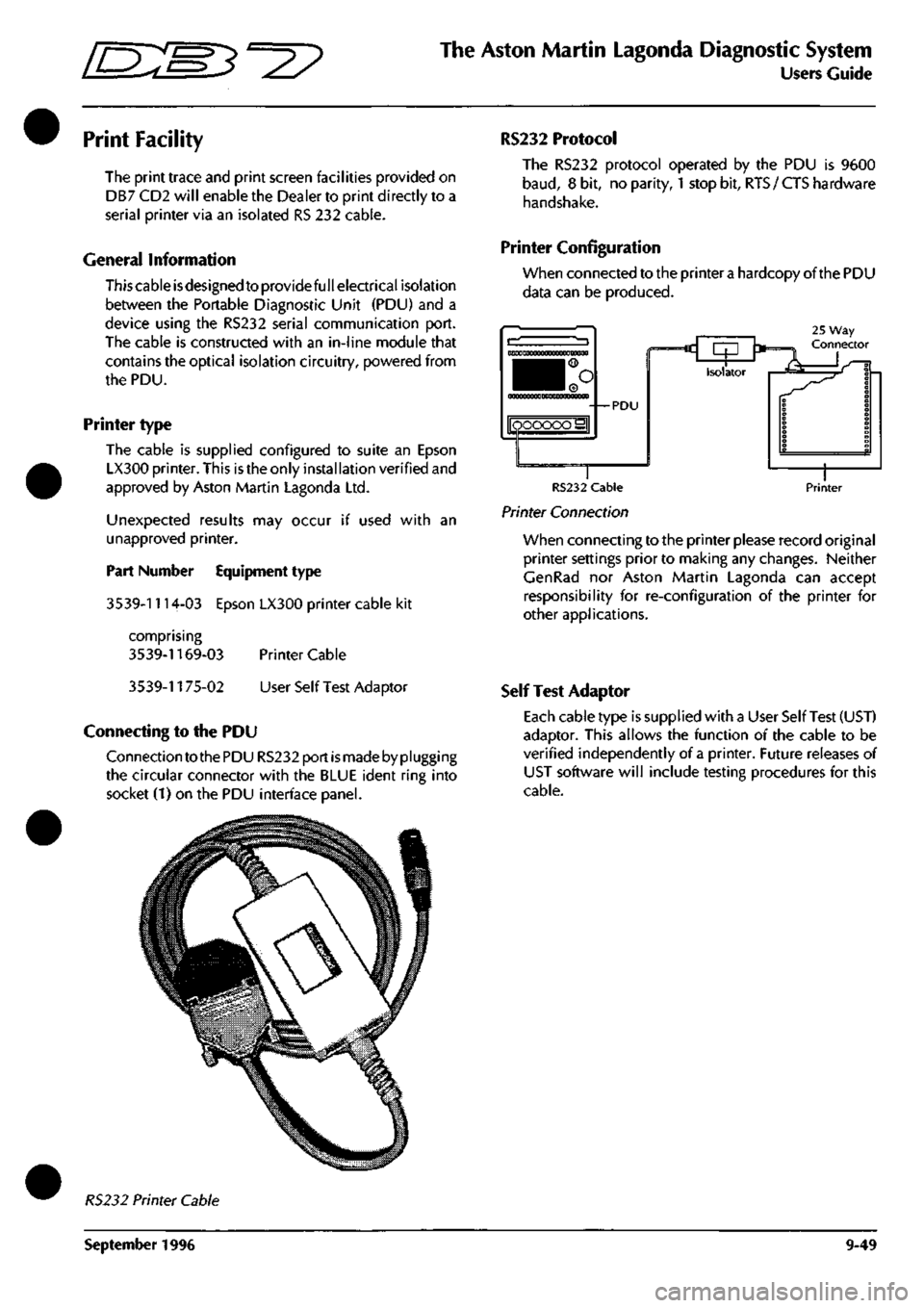

25 Way Connector c rp '*= Isolator •—*«

RS232 Cable

Printer Connection

Printer

When connecting to the printer please record original

printer settings prior to making any changes. Neither

CenRad nor Aston Martin Lagonda can accept

responsibility for re-configuration of the printer for

other applications.

Self Test Adaptor

Each cable type is supplied with a User Self Test (UST)

adaptor. This allows the function of the cable to be

verified independently of a printer. Future releases of

UST software will include testing procedures for this

cable.

RS232 Printer Cable

September 1996 9-49

Page 403 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide [S:S3^2?

The PDU will then check the cable connections. Until all

connections are correct, the PDU will not allow progression

beyond this

screen.

Pressingthe'asterisk'icon and selecting

abort returns the operator to the general screen if an

incorrect system has been chosen.

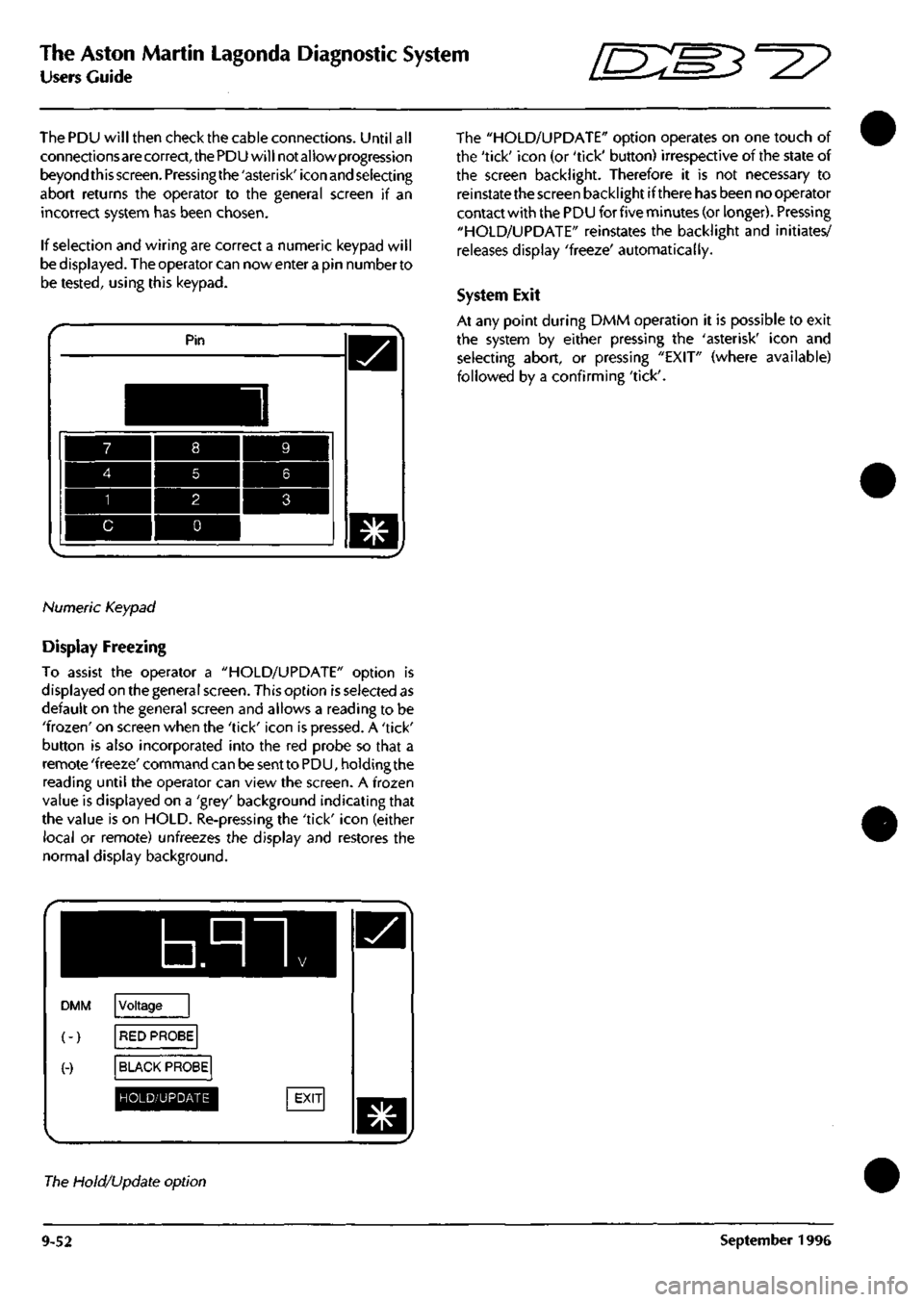

If selection and wiring are correct a numeric keypad will

be displayed. The operator can nowenterapin numberto

be tested, using this keypad.

Pin

Numeric Keypad

Display Freezing

To assist the operator a "HOLD/UPDATE" option is

displayed on the general screen. This option is selected as

default on the general screen and allows a reading to be

'frozen'

on screen when the 'tick' icon is pressed. A 'tick'

button is also incorporated into the red probe so that a

remote 'freeze' command can be sent to PDU, holding the

reading until the operator can view the screen. A frozen

value is displayed on a 'grey' background indicating that

the value is on HOLD. Re-pressing the 'tick' icon (either

local or remote) unfreezes the display and restores the

normal display background.

b.nn

DMM

(-)

(-)

Voltage

RED PROBE

BLACK PROBE

HOLD/UPDATE

The "HOLD/UPDATE" option operates on one touch of

the 'tick' icon (or 'tick' button) irrespective of the state of

the screen backlight. Therefore it is not necessary to

reinstate the screen backlight if there has been no operator

contact with the PDU for five minutes (or longer). Pressing

"HOLD/UPDATE" reinstates the backlight and initiates/

releases display 'freeze' automatically.

System Exit

At any point during DMM operation it is possible to exit

the system by either pressing the 'asterisk' icon and

selecting abort, or pressing "EXIT" (where available)

followed by a confirming 'tick'.

The Hold/Update option

9-52 September 1996

Page 408 of 421

^

The Aston Martin Lagonda Diagnostic System

Users Guide

Parameter Name

Parameters can be fault codes, inputs to, or specific

outputs from, a vehicle control module.

The number of parameters selectable is limited to 32.

If the number of parameters available for customization

exceeds the d isplay

area,

the arrow buttons wi

11

be present,

allowing display area scrolling.

The parameters declared to Datalogger are initially

presented in alphabetical order.

Record Enabled

Record enabled is used to select which signals are to be

recorded.

To select a signal for recording, touch the rectangle next

to the signal name.

The record button will then be displayed.

Nofe:

Additional rectangles may appear in other columns

beside a selected signal name, indicating that the signal

units may be changed or that the signal may be used

as

a

trigger.

It should be noted that the more parameters you select to

record the slower the PDU's sample rate will be for each

parameter e.g. The PDU may be able to monitor six

parameters sampling each parameter twice a second. If

the number of parameters is increased to twelve then the

PDU would only be able to sample each parameter once

per second, thus reducing its ability to capture fast faults;

therefore it

is

recommended that the number of parameters

is kept to a minimum.

Display Order

Parameters may be displayed on the waveform/ bargraph

screen in any order.

To set the parameter display order, press the required

rectangle to create a numbered list.

Note: It

is

not

necessary to

display all of the parameters

required to be recorded.

This has particular benefits if a parameter is to be used as

a trigger but is not required to be displayed.

Trigger Action

For a detailed description of trigger action, refer to the

Trigger Customisation description on the following page.

S.I.

Units

Certain parameters can be measured / displayed in a

number of different units eg temperature in °C or °F. If a

rectangle appears around the displayed units in the

'S.I.'

column then the units are selectable. Each time the

rectangle is pressed, the selectable units scroll one step

through the available options.

Other Features

To make parameter customization easier two icons have

been introduced on to the bottom of the screen, these are:

This icon simply puts all ofthesignals selected for

recording in alphabetical order irrespective of

the language.

A B C

This icon will put all of the signals selected for

recording at the top of the parameter list in

numerical order.

^T/^

After the parameter customization process is completed,

return to the Datalogger main menu.

Default Customisation

To cancel all customisations, press the

Customisation Reset

icon.

This will reset the

customisation on all parameters to the default

setting.

Trigger Customisation

Datalogger operates using a 'rolling memory'.

When the Record icon is selected on the waveform

display, PDU will start to record data, it will then continue

to record data until its memory is

full.

At this point it will continue recording by overriding the

oldest

data.

This process will continue indefinitely or until

the trigger is activated.

When the trigger is activated it performs a number of

functions.

a) The first function istoplaceazerotimepointwithin

the stored data, this enables the trigger point to be

easily accessible in later stages.

b) The second function is to set a timer, ensuring that

the PDU wil

I

only continue recording for the time

selected in 'test-duration'.

September 1996 9-57

Page 411 of 421

The Aston Martin Lagonda Diagnostic System

Users Guide ^?

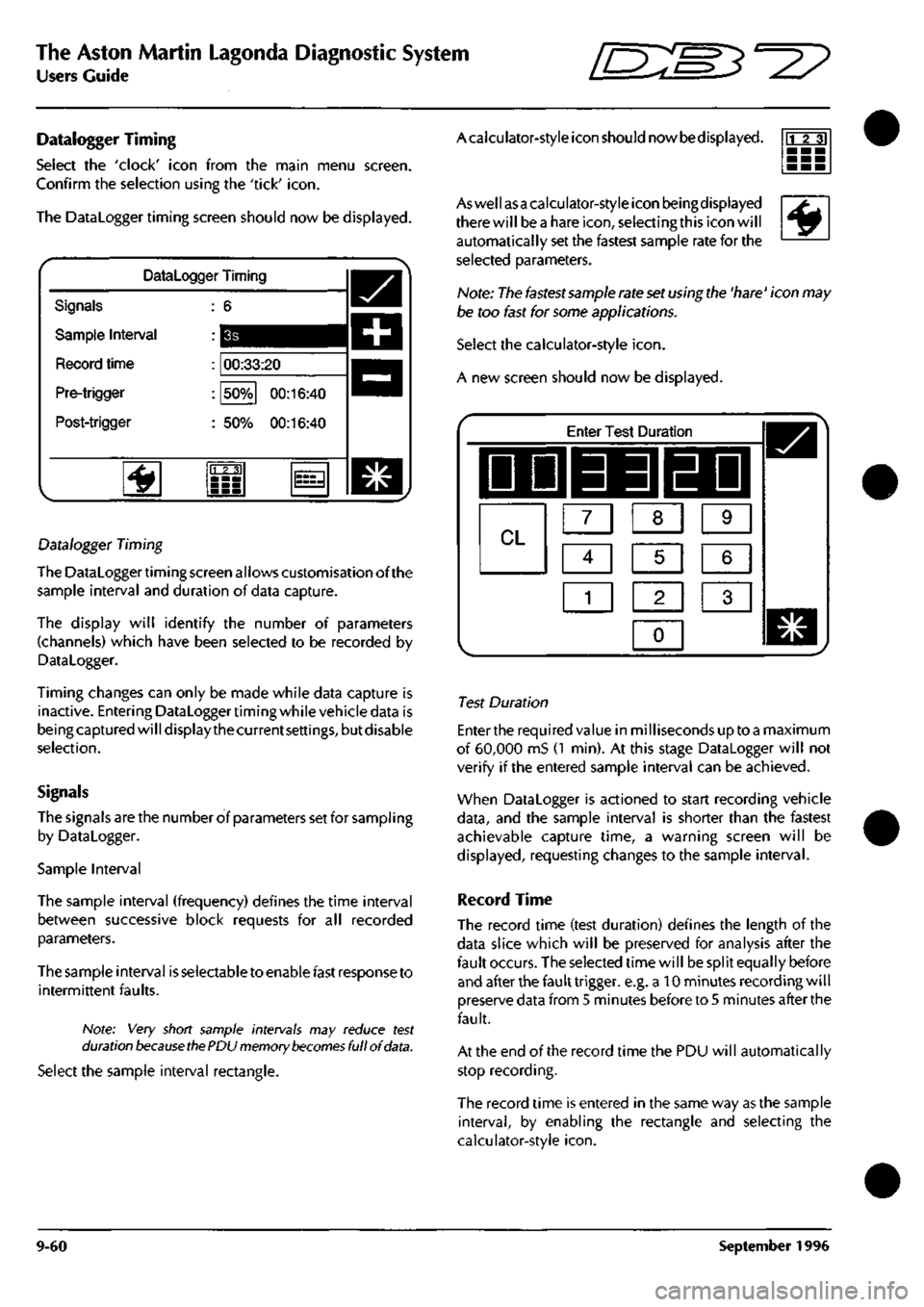

Datalogger Timing

Select the 'clock' icon from the main menu screen.

Confirm the selection using the 'tick'

icon.

The Datalogger timing screen should now be displayed.

Datalogger Timing

Signals

Sample Interval

Record time

Pre-trigger

Post-trigger

00:33:20

50%

00:16:40

50%

00:16:40

'^

23]

Datalogger Timing

The Datalogger timing screen allows customisation of the

sample interval and duration of data capture.

The display will identify the number of parameters

(channels) which have been selected to be recorded by

Datalogger.

Timing changes can only be made while data capture is

inactive. Entering Dataloggertiming while vehicle data is

being captured will display the current

settings,

but disable

selection.

Signals

The signals are the number of parameters set for sampIing

by Datalogger.

Sample Interval

The sample interval (frequency) defines the time interval

between successive block requests for all recorded

parameters.

The sample interval is selectable to enable fast response to

intermittent faults.

Note: Very short sample intervals may reduce test

duration

because ttie

PDU memory

becomes

full of

data.

Select the sample interval rectangle.

Acaiculator-style icon should nowbedisplayed. rrr?]

^

Aswellasa calculator-style icon beingdisplayed

there will bea hare

icon,

selecting this icon will

automatically set the fastest sample rate for the

selected parameters.

Note: The fastest sannple rate set using the 'hare' icon may

be too fast for some applications.

Select the calculator-style

icon.

A new screen should now be displayed.

Enter Test Duration

IDD 33 EDI

CL m m [Z]

Ci] ra [I]

1

1 2 1 3 1

0

1

Test Duration

Enter the required value in milliseconds up toa maximum

of 60,000 mS (1 min). At this stage Datalogger will not

verify if the entered sample interval can be achieved.

When Datalogger is actioned to start recording vehicle

data,

and the sample interval is shorter than the fastest

achievable capture time, a warning screen will be

displayed,

requesting changes to the sample interval.

Record Time

The record time (test duration) defines the length of the

data slice which will be preserved for analysis after the

fault occurs. The selected time will be split equally before

and after the fault trigger, e.g. a 10 minutes recording will

preserve data from 5 minutes before to 5 minutes after the

fault.

At the end of the record time the PDU will automatically

stop recording.

The record time is entered in the same way as the sample

interval,

by enabling the rectangle and selecting the

calculator-style

icon.

9-60 September 1996

Page 412 of 421

•

^m:E3^^?

The Aston Martin Lagonda Diagnostic System

Users Guide

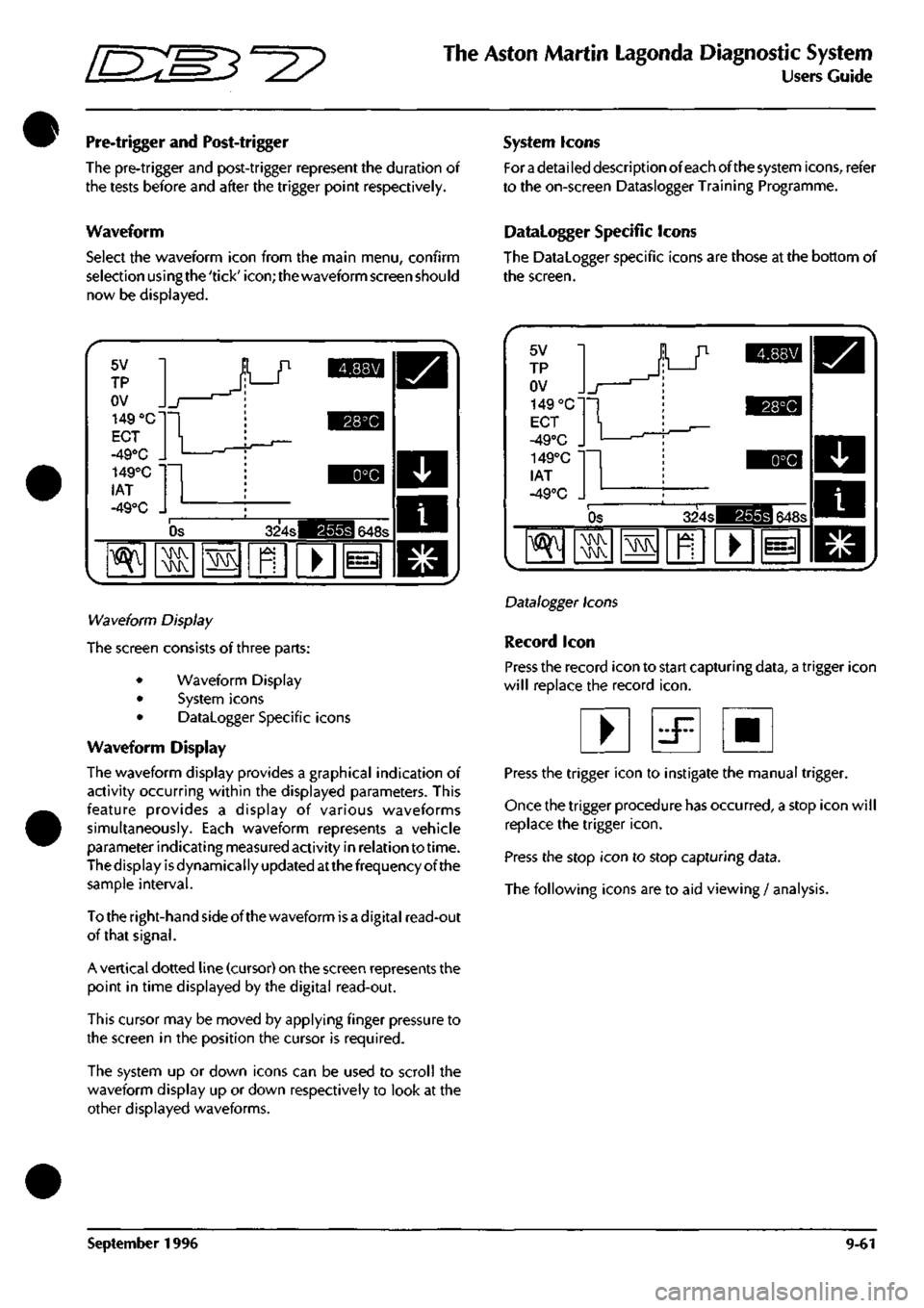

Pre-trigger and Post-trigger

The pre-trigger and post-trigger represent the duration of

the tests before and after the trigger point respectively.

Waveform

Select the waveform icon from the main menu, confirm

selection usingthe'tick'icon;thewaveform screen should

now be displayed.

System Icons

For

a

detai led description of each of the system icons, refer

to the on-screen Dataslogger Training Programme.

Datalogger Specific Icons

The Datalogger specific icons are those at the bottom of

the screen.

5V

TP

OV

149 "C

ECT

-49°C .

149°C •

lAT

-49°C .

_r

1

^Jh

r

Os 324s 648s

^

\N

• 1=3

Wa\/eiorm Display

The screen consists of three parts:

• Waveform Display

• System icons

• Datalogger Specific icons

Waveform Display

The waveform display provides a graphical indication of

activity occurring within the displayed parameters. This

feature provides a display of various waveforms

simultaneously. Each waveform represents a vehicle

parameterindicatingmeasuredactivity in relation to time.

The display is dynamically updated atthe frequency of the

sample interval.

Totheright-handsideofthewaveform isadigital read-out

of that signal.

A vertical dotted line (cursor) on the screen represents the

point in time displayed by the digital read-out.

This cursor may be moved by applying finger pressure to

the screen in the position the cursor is required.

The system up or down icons can be used to scroll the

waveform display up or down respectively to look at the

other displayed waveforms.

5V

TP

OV

149 °C'

ECT

-49°C ,

149°C

lAT

-49°C . 1

Os 324s 648s

"^

MMV MMV

MMV

1^

•

Datalogger Icons

Record icon

Press the record icon to start capturing data, a trigger icon

will replace the record

icon.

• d^ •

Press the trigger icon to instigate the manual trigger.

Once the trigger procedure has occurred, a stop icon will

replace the trigger

icon.

Press the stop icon to stop capturing data.

The following icons are to aid viewing / analysis.

September 1996 9-61