boot ASTON MARTIN DB7 1997 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 1997, Model line: DB7, Model: ASTON MARTIN DB7 1997Pages: 421, PDF Size: 9.31 MB

Page 131 of 421

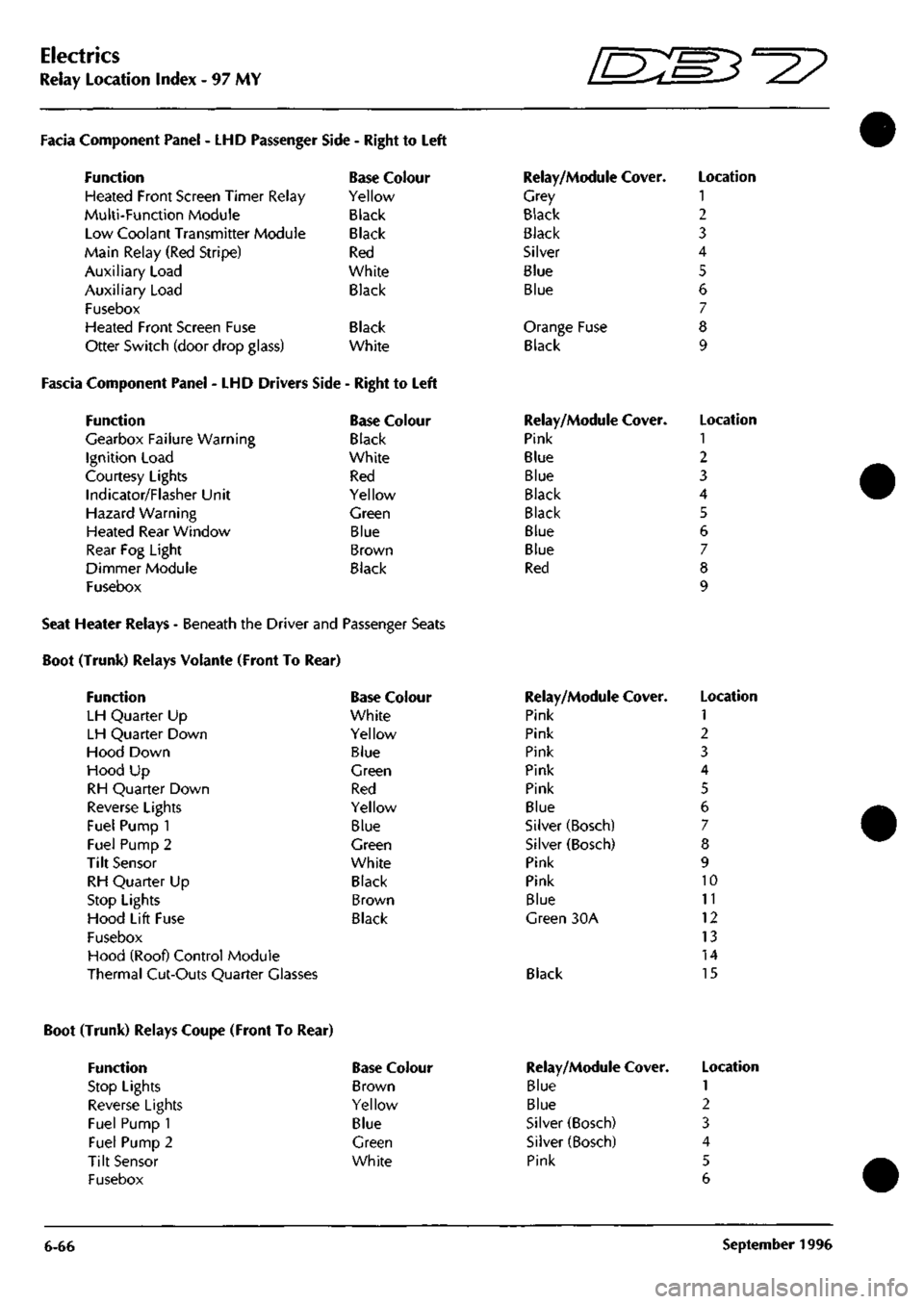

Electrics

Relay Location Index - 97 MY

D^^

Facia Component Panel

- LHD

Passenger

Function

Heated Front Screen Timer Relay

Multi-Function Module

Low Coolant Transmitter Module

Main Relay (Red Stripe)

Auxiliary Load

Auxiliary Load

Fusebox

Heated Front Screen Fuse

Otter Switch (door drop glass)

Side

-

Right

to

Left

Base Colour

Yellow

Black

Black

Red

White

Black

Black

White

Fascia Component Panel

- LHD

Drivers Side

-

Right

to

Left

Function

Gearbox Failure Warning

Ignition Load

Courtesy Lights

Indicator/Flasher Unit

Hazard Warning

Heated Rear Window

Rear

Fog

Light

Dimmer Module

Fusebox

Base Colour

Black

White

Red

Yellow

Green

Blue

Brown

Black

Relay/Module Cover.

Grey

Black

Black

Silver

Blue

Blue

Orange Fuse

Black

Relay/Module Cover.

Pink

Blue

Blue

Black

Black

Blue

Blue

Red

Location

1

2

3

4

5

6

7

8

9

Location

1

2

3

4

5

6

7

8

9

Seat Heater Relays - Beneath the Driver and Passenger Seats

Boot (Trunk) Relays Volante (Front To Rear)

Function

LH Quarter

Up

LH Quarter Down

Hood Down

Hood

Up

RH Quarter Down

Reverse Lights

Fuel Pump

1

Fuel Pump

2

Tilt Sensor

RH Quarter

Up

Stop Lights

Hood Lift Fuse

Fusebox

Hood (Roof) Control Module

Thermal Cut-Outs Quarter Glasses

Base Colour

White

Yellow

Blue

Green

Red

Yellow

Blue

Green

White

Black

Brown

Black

Relay/Module Cover.

Pink

Pink

Pink

Pink

Pink

Blue

Silver (Bosch)

Silver (Bosch)

Pink

Pink

Blue

Green

30A

Black

Location

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Boot (Trunk) Relays Coupe (Front To Rear)

Function

Stop Lights

Reverse Lights

Fuel Pump 1

Fuel Pump 2

Tilt Sensor

Fusebox

Base Colour

Brown

Yellow

Blue

Green

White

6-66

Relay/Module

Blue

Blue

Silver (Bosch)

Silver (Bosch)

Pink

Cover. Location

1

2

3

4

5

6

September

1996

Page 132 of 421

^^?

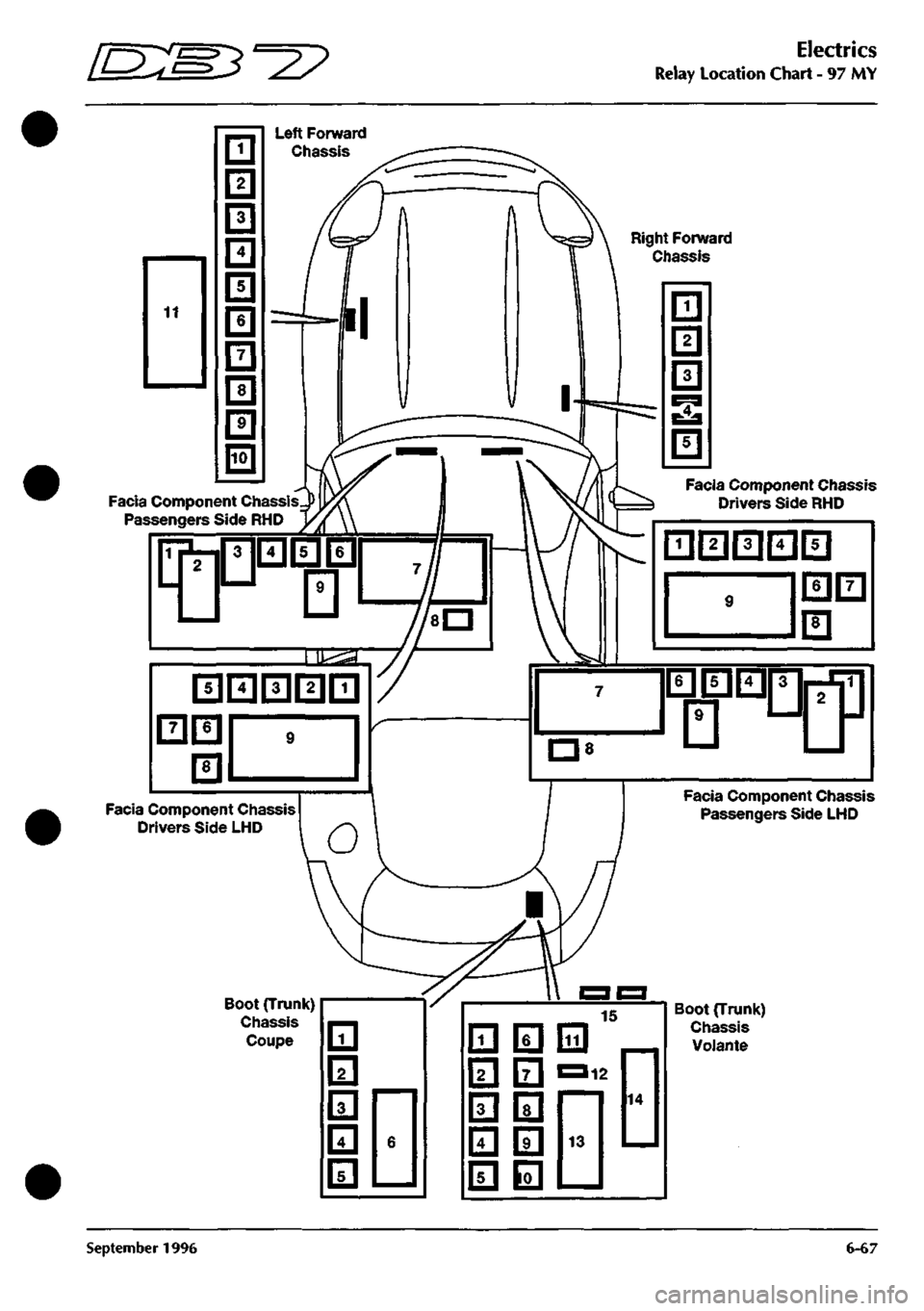

Electrics

Relay Location Chart - 97 MY

Right Forward

Chassis

Facia Component Chassis

Passengers Side RHD

Facia Component Chassis

Drivers Side LliD

Boot (Trunk)

Chassis

Coupe 111

I2I

131

m

fsl

6

Boot (Trunlt)

Chassis

VoJante

September 1996 6-67

Page 164 of 421

NO

COLOUR

PIN

AREA I0S8

KB I

I7.B3-I79 JAO

OC 2 H.BI

WINDOW LIFT NO COLOUR

PIN

AREA I0S3

GR I

I6.A3 1051

GW 2

I6.A3

I

NO

COLOUR AREA 1829

RN

I4.BI

I HEATED BACKLIGHTi

VAPOUR MANAGEMENT VALVE

HOOD LIFT NO COLOUR 1054

GW

1053

GR

1060 GW lOEl

GR

1

I

4

I

AREA I6.AI le.AI

I5.ei-I54A I5.BI-I54B

NO COLOUR

PIN

1096 BW 828

BG

AREA I4.AI I4.BI

I4.B5-I60 I4.BI

FUEL PUMP

I

NO COLOUR

PIN

1086

B 1

1087 UG

2

AREA I6.B3 I7.A2

NO COLOUR

PIN

AREA 16.85 I7.A3

INTERIOR LIGHT NO COLOUR

PIN

AREA

1056 P I I4.C4-I56 1057 PW 2 I4.C4-I57

m

fsD

1ST SECURITY STEM

I

AERIAL

I

NO

COLOUR

PIN

799

BR I

1800

B 2

AREA 14.Al 14.Al

I

NO

COLOUR ||055

TIN

AREA I7.B6

LINK PINS

I a 2

LING

PIN 3 a 4

NO COLOUR

PIN

AREA

1062

NP

792

VG

I6.B3-I68 I4.AI

6)[5]o[4)|3J

02 01 Qi 03

REAR LAMP

SHORTING

PLUG

02 01 Ql 03

NO COLOUR PINAREA

1064

GP I

IG.B5-I74

1065 GP

2 16.01 1066 RU 3 I4.C5-I59

1067

RU 4 16,01

Ql D3 D2 01

LINK PINS

I 8 4

RH REAR LAMP

NO COLOUR 1067

RU

1068

ON

1069 CW 1070

B

1071

RG

1065

GP

PIN 1 ? ^ 4 •) 6

AREA 16.01 I6.B3-I7I I6.BI-I67 I6.C3-IG9 I6.C3-I70 16.01

mmra CEIinnn

(—\ Qi 01

cr

D 0 I—I 03 06 SHEET 18 '• AREA B/CI

0

01 Qi 0 D 03 06

NO COLOUR AREA 813

LGO 14.01

1080

B

I6.B4-I73 FUEL TANK SENDER UNIT

NO COLOUR AREA 1086

B

1088

B

1090

B

1091

B

I6.A5 I6.A6 16.84-173 I6.C3-I69

TH^

SHEET 17 AREA Bl

-» ^

-F^Pl-'

NO COLOUR

PIN

AREA

1094

BR U

16.86-178

1095 BR W 16.84-172

NO COLOUR PIN 797 S I

1092

B 2

652

WU 3

1093

HP 4

AREA 14.01

I6.B4-I73 14.01 I6.B5-I75

NO COLOUR AREA 2183

B

I6.C5-2I8 1084 RG

16.04

RADIO TELEPHONE

E

Di 05 D 0 D D 04 08/

4

8

J^Q a

£o 0 PO 0

T?D 0 ^ 1 S ^

NO COLOUR

PIN

1081

BR I

1082 PG

2

3

NO COLOUR AREA

1078

NP

I6.B3-I68 1079

BR

I6.B4-I72

AREA I6.B4-I72 I7.C6

1084

RG 1085 B 16.03-170 I6.B4-I73

NO COLOUR

PIN

1081

BR I

1082

PG 2

3 i

RS 4

5 6 1084 RG

7

1085

B 8

AREA le.CG 16.CG

I6.C6 I6.C5-2I8

Zl

1

RH NUMBER PLATE LAMP

NO COLOUR

PIN

AREA 1081

BR I

I6.C4 2184

B 2

l6.C5-2ia

BOOT LOCK ACTUATOR NO COLOUR

PIN

AREA 2185

B I

I6.C5-2I8 1082

PG 2

I6.C4

^[}

[}

JLH

NUMBER

PLATE LAMP

NO COLOUR AREA 2186

B

I6.C5-2I6 ;I083

RS

I6.D4

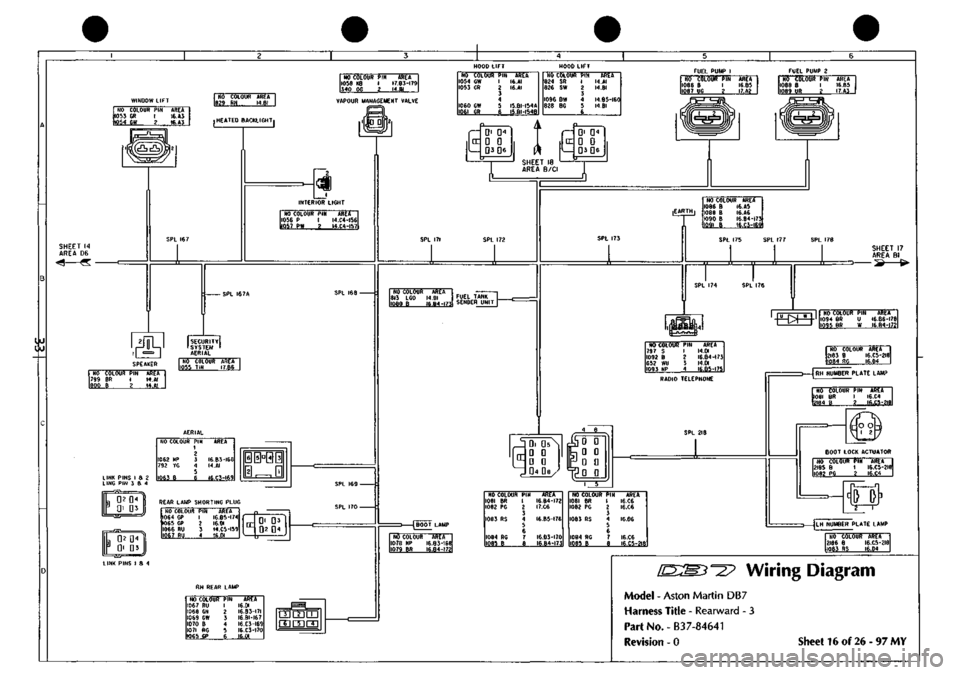

Wiring Diagram

Model - Aston Martin DB7

Harness Title - Rearward - 3

Part No. -

B3

7-84641

Revision - 0 Sheet 16 of 26-97 MY

Page 166 of 421

STOP LAMP

NO COLOUR 807

CB

1097

G

1098

GP

1099

G

RELAY

PIN AREA 85 I4.CI 86 I7.D2 87 I6.B5-I74

87A

30

17X2

REVERSE LAMP RELAY FUEL PUMP RELAY 1

NO COLOUR 803

SLG

1100

W

IIOI

GN

1102

NP

PIN 85 88

8/

R7A 30

AREA M.CI 17.02 I6.B3-I7I

I6B5-I75

NO COLOUfl 335 OR 1103 KB 1087 UG 337 RN 1104 NP

PIN BS R6 87 R7A 30

AREA I4.CI I7.B3-I79 I6.A5 14.01 17.02

FUEL PUMP RELAY 2

NO COLOUR 336 0 1105 KB 1089 UR 809 YN 1106 NP

PIN AREA 85 I4.CI 86 I7.B3-I79 87 le.AG 87A I4.CI 30 I7.C2

TILT SENSOR RELAY

NO COLOUfl 1109 B 1110 WK

nil BO 1112 B

PIN AREA 85 17.84-183 S6 I7.B4-I82 87 87A I4.B4-I58 30 I7.B4-I83

I^OBROWN

BASE

87A ^JSSPBL

[jylYELLOW

BASE

ma

3«-i

J¥tU

SHEET

16

AREA

B6

10 in

'-fts'^B^-'

lijZ-il

[NATURAL

BASE

L 3JA

NO COLOUR AREA 1107

N

17.83-180 llOe

N

17.83-181

NO COLOUR 1125

N

1126

G

1127

G

1128

N

1130

N

1072

R

1075

R

1133

G

1135

N

1137

G

1138

N

1140

N

PIN 1 2 3 4 5 6

/

8 9 10 II

12 13

AREA 17.83-180 16.86-177 16.86-177 I7.B3-I8I I7.B3-I80 14.84-155 14.84-155 16.86-177 17.83-180 I6.B6-I77 I7.B3-I8I I7.B3-I8I

c

SHEET

25

AREA

B/C6

CZE

BOOT FUSEBOX HARNESS

•^-

rp

NO COLOUR

iioe NP 1099 G 1097 G 1129 NP 1115 NS 1131 RS 1132 RG 1134 m 1136 NS 1100 W 1139 NP 1104 NP

PIN 1 2 3 4 5 6 7 8 9 10 II

\l

AREA I7.A3 I7.AI I7.AI 16.83-168 I7.C4 I6.B5-I76 I6.C3-I70 17.84-182 I7.B5-I84 I7.A2 16.85-175 I7.A2

I

D

a

D

D

D

D,

D

c^

D

D

D

0

D

D

NO COLOUR

PIN

1113

VS A

1114

NS B

AREA 17.86 I7.C6

i'^AAA'

ITYRE

COMPRESSORI

NO COLOUR AREA 1115

NS

I7.DI 1116

8 I7.B4-IB3

5^

\_/

SECURITY NO COLOUR 1055

TIN

1026

KB

1117

BR

1118

BR

1028

HI

772

OR

1027

U

1119

WY

3

YS

1113

YS

1120

GR

1121

8

1122

8RD

1021

UO

773

OU

374

0

1

LG

1082

PG

1123

GW

1114

NS

1124

NS

SYSTEM

PIN 1 ? 3 4 5 6

7 8 9 10

II II 12 13

14 15

16

17 18 19 20 ?l

22 23 24 25 2b

AREA I6.C2 I4.B6 16.84-172 16.86-178 14 .C6 I4.CI 14.06

17.84-182 M.BI I7.B5 I5.B1-163 17.84-183 I6.82-I67A

I4.C4 I4.CI

I5.BI

I4.CI ie.C4 16.81-167 17.85 17.85-184

'^7

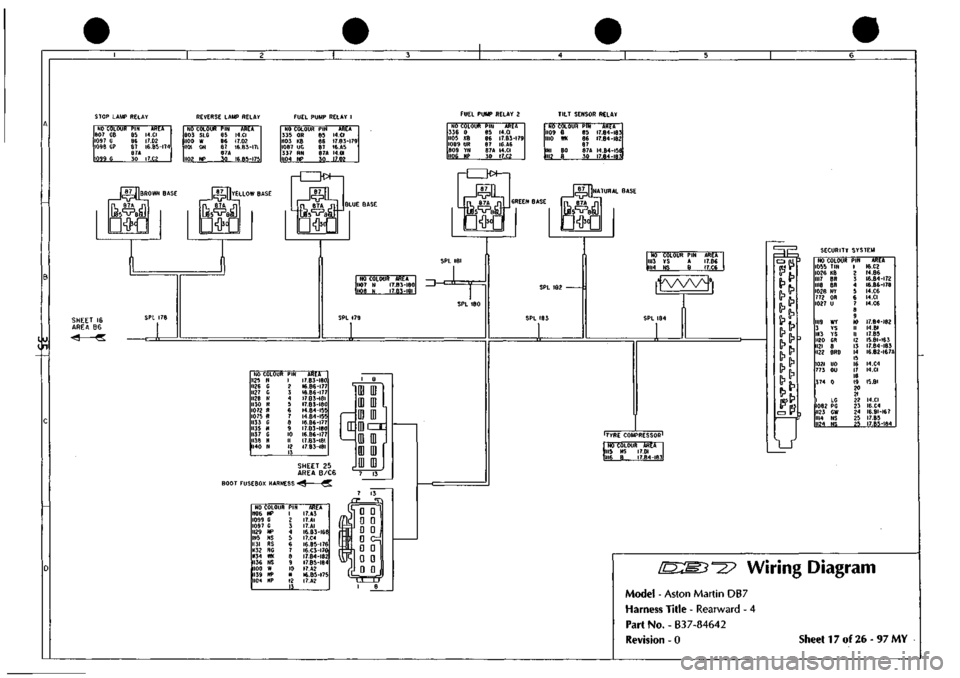

Wiring Diagram

Model

- Aston Martin DB7

Harness

Title - Rearward - 4

Part

No. - B37-84642

Revision

- 0

Sheet

17 of 26-97 MY

Page 182 of 421

\L^C=£

NO

COLOUR

1106 HP 1099 G 1097 G 1129 NP 1115 NS 1131 RS 113? RG 1134 WK 1136 NS 1100 W 1139 H? 1104 NP

PIN 1 2 3 4 5 6 t S 9 10 II 12 13

AREA

2T.a

2?.CI 27.CI

27.01

27.CI 27.CI 27.C2 27.C2 27.C2 27.C2 27.C2 27.02

SHEET

17

AREA

Dl

NO

COLOUR

1125 N 1126 G 1127 G 1128 N 1130 M 1072 RS 1075 RG 1133 G 1135 N 1137 0 1136 N 1140 N

PIN 1 2 3 4 S 6 7 S 9 10 II 12 13

AREA 27.CI 27.CI 27.CI 27.CI

n.a

27.CI 27.C2 27.C2 27.02

27 C2

27.C2 27.C2

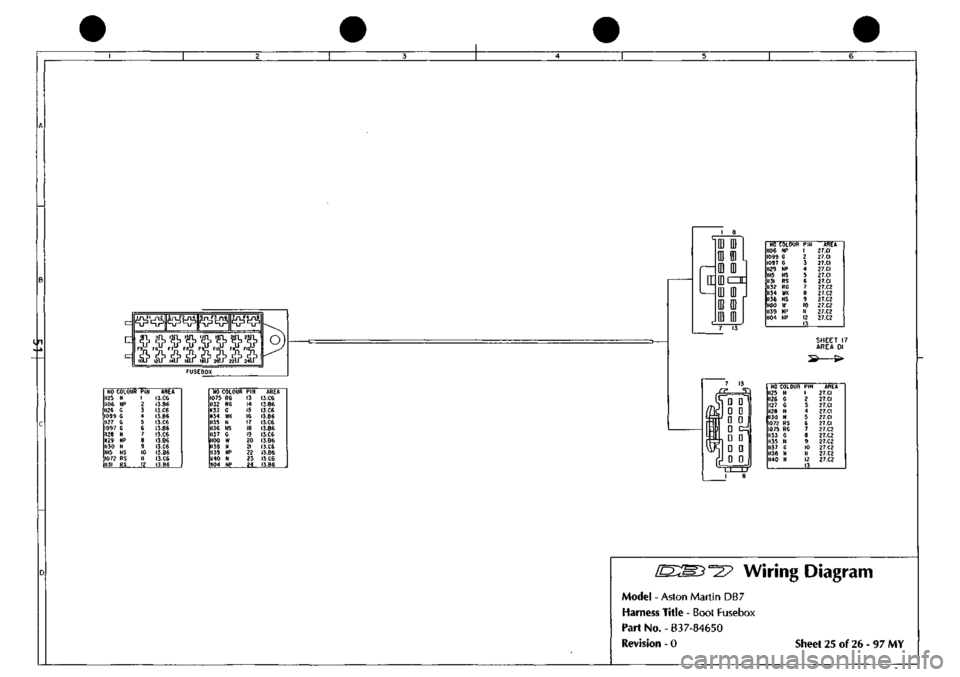

Wiring Diagram

Model

-

Aston Martin

DB7

Harness Title

-

Boot Fusebox

Part

No. -

837-84650

Revision

- 0

Sheet

25 of

26-97

MY

in

^n^P^F^^j^Fj^T^rj^

NO

COLOUF

1125 N

iioe

NP 1126 G 1099

G

1127 G 1097 G 1128 N 1129 NP 1130 N 1115 NS 1072 RS 1131 RS

PIN 1 2 3 4 5 6 / 8 9 10 II 12

AREA I3.C6

13.86

I3.C6

13.86 13.C6 13.86

I3.C6 I3.8G I3.C6 I3.B6 I3.C6 I3.B6

NO

COLOUF

1075 RG 1132 RG 1133 G 1134 WK 1135 N 1136 NS 1137 G 1100 W 1138 N 1139 NP 1140 N 1104 NP

PIN 13 14 15 16 17 18 19 ?0 21 ?? 23 24

AREA I3.C6

13.86

I3.C6

13.86

I5.C6

13.86

I3.ce

13.86

I3.C6

13.86

I3.C6

13.86

Page 187 of 421

^=2?

Electrics

Airbag System

Eye Protection

Chemical protective goggles are recommended

where there is a possibility of eye contact with the

propellant. Safety glasses with side shields are

recommended for all other operations.

Protective Clothing

Approved protective gloves, overalls and shoes/

boots should be worn.

Handling and Storage Precautions

Do not store airbag modules near live electrical

equipment or circuitry. Store in a dry environment

at ambient temperatures.

Good housekeeping and engineering practices

should be employed to prevent the generation and

accumulation of

dusts.

Store in compliance with all

local state and federal regulations.

Driver and Passenger Airbag Modules

Assembly/Removal/Service Instructions

WARNING: In the event of a vehicle impact where the

airbags and the seatbeltpretensioner (if fitted) are

deployed, the following actions MUST be

performed:

Check the condition of the seatbelts, steering

wheel,

steering column, all connections to airbags,

and the column switchgear connectors for integrity

and damage. If in any

doubt,

replace suspected

parts for new parts.

Replace both crash

sensors,

the

safing sensor

and

the seatbelt pretensioner module (if fitted).

On completion of all repair procedures, switch on

the ignition and check that the

Airbag/SRS

warning

light comes on when the ignition is switched on

and extinguishes after approximately six seconds

indicating satisfactory completion of the airbag

and pretensioner

system

self

tests.

WARNING: Before starting

work,

ensure

that the ignition

switch is in position 'O' and the ignition key is

removed.

Disconnect the battery negative lead

within 12 seconds of switching off the ignition to

prevent the alarm system triggering.

As the airbag control module is equipped with a

back-up power source and due to the risk of the

airbag being inadvertently deployed, wait one

minute or longer after disconnecting the battery

before starting work on the airbag module.

• Disconnectingthe battery negative cable cancels

the memory for the 'one-touch' window down

system and stops the vehicle clock. Reset the

window memory and the clock when work is

completed.

• Never use airbags from other vehicles, always

use new parts.

• After work is completed, reconnect the battery

and perform the airbag warning light check

• Never use electrical probes to check voltage or

electrical resistance of the airbag modules.

• Disconnect the airbag before carrying out any

work on, or in the vicinity of the module, or

when using electric welding equipment.

• Always ensure that the battery negative lead has

been disconnected for at least one minute before

commencing any removal procedure.

September 1996 6-71

Page 231 of 421

^"^

Body and Trim

Body Repair

Precautions

Paint

Ensure that there is efficient ventilation at all times. Paint spraying should be confined to spray booths.

Anyone with a history asthma should not be engaged in any process which involves the use of isocyanates.

Any operator working inside a spray booth where isocyanates are present must use air-fed breathing equipment.

Supplied air to the visor should be fed at the recommended pressure and filtered to remove oil, water and fumes.

Operators involved in handling, mixing or spraying should wear protective clothing, gloves and goggles to avoid

skin and eye contact. A Paticle mask or canister typr respirator should be worn when sanding.

Applied heat

When welding, flame cutting or brazing and so on, goggles, a mask or fume extractor and flameproof protective

clothing should be used always.

It is especially important when working with polyurethane compounds to use air-fed breathing equipment.

Ensure that at all times the appropriate fire fighting equipment isavailableand that personnel are trained in its use.

Metal repair

Wear appropriate eye and hand protection when sanding, drilling, cutting, chiselling, flatting or welding. Wear a

face mask or air-fed visor when sanding or flatting either body solder or

fillers.

When a soldering operation has been

completed,

remove swarf from the work area and wash your hands thoroughly.

General Repair Notes

The following precautions should be noted before any work is carried out:

• disconnect the vehicle battery ground

lead,

taking note of the reconnection procedures

• Make sure that you have read and understood the safety related procedures in this section.

Caution:

Electric arc

welding must not

be

used on the

vehicle as the high

voltages produced by

this process

will

cause

irreparable

damage

to the electrical control and

microprocessor

systems.

All trim and electrical components in the locality of the repair must be removed or disconnected prior to panel

removal or replacement.

Welding and Gas Process Special Notes

Resistance spot welding, MIG welding and all gas processes may only be carried out on bare, unpainted or unplated

metal.

The flanges of panels, which are to be welded together, must be clean, corrosion free and treated as

appropriate with either weld-through or inter-weld sealer.

The resistance spot welding equ ipment used in vehicle repair does not always produce

a

weld of

equ

ivalent strength

to that produced in manufacturing. This means that a single row of spot welds should be spaced on a pitch of 19-

25 mm, which will usually result in more spot welds than found in the original factory joint.

Use a resistance spot weld cutter to remove resistance spot welds. Where a new joint is to be MIC welded, cut the

old resistance spot welds from the panel that is to be retained; the resulting holes are then used for plug welding.

Suitable holes may be drilled or punched as follows:

• 8.0 mm for sections up to 1.5 mm thickness

• 10.0 mm for thicker sections.

Always refer to the welding equipment manufacturers diagrams and tables for the relevant procedure.

May 1996 7-3

Page 266 of 421

^=2?

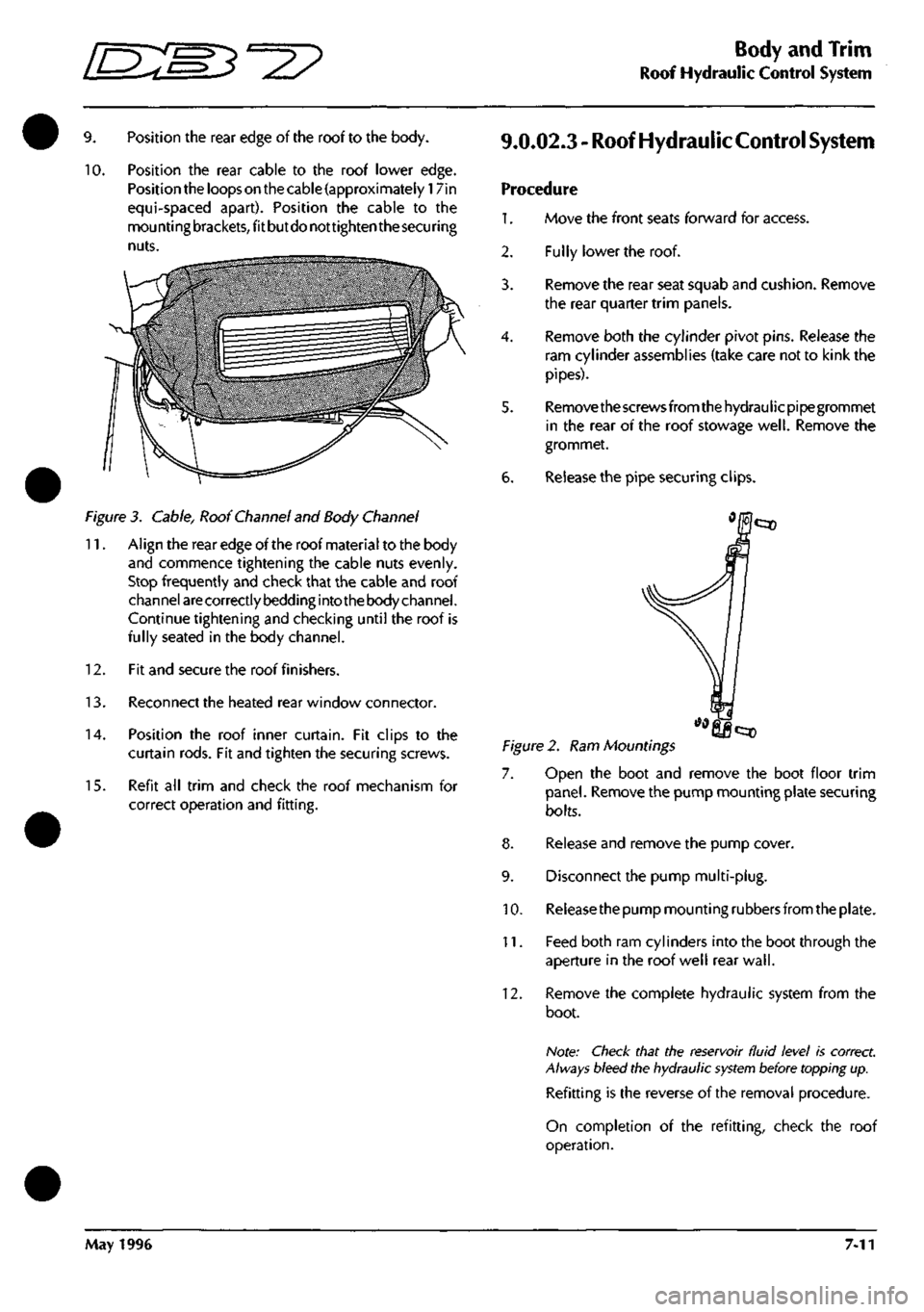

Body and Trim

Roof Hydraulic Control System

9. Position the rear edge of the roof to the body.

10.

Position the rear cable to the roof lower edge.

Position the loops on the cable (approximately 17in

equi-spaced apart). Position the cable to the

mou nti ng

brackets,

fit but do not tighten the

secu

ring

nuts.

Figure 3. Cable, Roof Channel and Body Channel

11.

Align the rear edge of the roof material to the body

and commence tightening the cable nuts evenly.

Stop frequently and check that the cable and roof

channel

are

correctly bedding into the body channel.

Continue tightening and checking until the roof is

fully seated in the body channel.

12.

Fit and secure the roof finishers.

13.

Reconnect the heated rear window connector.

14.

Position the roof inner curtain. Fit clips to the

curtain rods. Fit and tighten the securing screws.

15.

Refit all trim and check the roof mechanism for

correct operation and fitting.

9.0.02.3 - Roof Hydraulic

Control

System

Procedure

1.

Move the front seats forward for access.

Fully lower the roof.

2.

3.

4.

6.

Remove the rear seat squab and cushion. Remove

the rear quarter trim panels.

Remove both the cylinder pivot pins. Release the

ram cylinder assemblies (take care not to kink the

pipes).

Remove the screws from the hydraulicpipegrommet

in the rear of the roof stowage

well.

Remove the

grommet.

Release the pipe securing clips.

Figure 2. Ram Mountings

7. Open the boot and remove the boot floor trim

panel.

Remove the pump mounting plate securing

bolts.

8. Release and remove the pump cover.

9. Disconnect the pump multi-plug.

10.

Releasethe pump mounting rubbers from the plate.

11.

Feed both ram cylinders into the boot through the

aperture in the roof well rear

wall.

12.

Remove the complete hydraulic system from the

boot.

Note: Check that the reservoir fluid level is correct.

Always bleed the hydraulic

system

before topping up.

Refitting is the reverse of the removal procedure.

On completion of the refitting, check the roof

operation.

May 1996 7-11