hand brake ASTON MARTIN V8 VANTAGE 2010 User Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 435 of 947

Rear Suspension (04.02)

Suspension (04.00)

May 2007 Workshop Manual 4-2-1

Suspension (04.00)

Rear Suspension (04.02)

Description

Anti-roll Bar

An anti-roll bar, mounted on the rear subframe connects to

the LH and RH lower suspension arms via drop links. The

drop links, with a ball joint at either end, transmit vertical

movement of the rear suspension to the anti-roll bar,

minimising body roll.

Vertical Link

The vertical link carries the hub, the cartridge wheel bearing,

the ABS rotor, the wheel speed sensor, the brake caliper, the

hand brake caliper and the brake disc and shield.

A toe control (track-rod) arm secures the rear of the vertical

link to the subframe. The toe control arm is adjustable, on

an eccentric cam, to alter the rear road wheel toe alignment.

04-02-001

Upper Wishbone

Rear Hub Assy

Rear Subframe Lower WishboneAnti Roll Bar LinkAnti Roll Bar

Track Control Arm

Track Control Arm

Page 436 of 947

Rear Suspension (04.02)

Suspension (04.00)4-2-2 Workshop Manual May 2007

Specifications

Maintenance

RH/LH Rear Hub and Bearing Assembly-

Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove RH/LH rear drivesha ft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

4. Ease caliper pistons to release pads.

5. Remove caliper Allen bolts (x2) release caliper and tie aside.

6. Remove handbrake caliper bolts (x2) and tie caliper aside. 7. Remove brake disc Torx screws (x2), remove disc.

8. Disconnect multiplug fr

om wheel speed sensor.

9. Remove Torx securing wheel speed sensor to vertical link, remove sensor.

10. Remove Allen bolts (x4) se curing hub bearing assembly

in vertical link.

11. Release/remove hub bearing a ssembly from vertical link.

Installation

1. Clean vertical link and mating face on hub bearing

carrier.

2. Install hub bearing assembly. Install and torque tighten Allen bolts (x4).

3. Clean wheel speed sensor.

4. Install wheel speed sensor, install and torque tighten Torx screw.

5. Connect multiplug to wheel sped sensor.

6. Clean disc.

7. Install disc, install and torq ue tighten Torx screws (x2).

8. Install caliper, install and torque tighten Allen bolts (x2).

9. Install handbrake caliper, install and torque tighten

retaining bolts (x2).

10. Install RH/LH driveshaft (see Workshop Manual

procedure 05.05.BB/05.05.AB Drive Shaft Assembly -

RH/LH - Renew).

11. Pump brake pedal.

12. Install road wheel(s).

13. Lower vehicle on ramp.

RH/LH Rear Lower Arm Assembly-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove nut, anti-roll bar li nk to lower suspension arm.

Release link.

4. Remove bolt securing damper to lower suspension arm.

5. Remove bolt and nut/bolt, securing lower suspension arm to subframe.

6. Remove nut/bolt securing lower suspension arm to

vertical link.

7. Release/remove lower suspension arm from subframe and vertical link.

Installation

1. Clean lower suspension arm and mating faces on vertical link, subframe, damper and anti-roll bar link.

2. Install lower suspension ar m to subframe and vertical

link.

Torque Figures

DescriptionNmlb. / ft.

Brake Dust Shield. 9 7

Bearing Assembly to the Vertical

link. 50 37

Halfshaft Nut 300 221.5

Spring and Damper Bracket

Mounting 75-80 55.5-59.5

Spring and Damper Top

Mounting to Bracket 22.5 17

Spring and Damper Lower

Mounting 175 129.5

Track rod Arm to Vertical Link 115 85

Anti-roll Bar Link 110 81.5

Anti-roll Bar Mounting Bolts

Torque bolt 1, then bolt 2, then

bolt 1 again (to allow for rubber

compression) 22.5 17

Ride Height Sensor M8 22.5 17

Torque the following suspensi on fixings with the vehicle

at normal ride height

Vertical Link to the Lower

Suspension Arm. 175 129.5

Vertical Link to the Upper

Suspension Arm. 115 85

Lower Suspension Arm to the

Subframe. 115 85

Upper Suspension Arm to the

Subframe 115 85

Track-Rod Arm to Subframe 115 85

Normal ride height: 2 x 37.5kg in front seats (37.5kg in

each seat) plus a full fuel tank.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Rear Lower Arm Assembly-Renew RH04.02.AC

Rear Lower Arm Assembly-Renew LH04.02.AD

Page 438 of 947

Rear Suspension (04.02)

Suspension (04.00)4-2-4 Workshop Manual May 2007

Installation

1. Clean anti-roll bar, bushes, bush straps and links.

2. Install links (x2), to anti-roll bar. Install washers (x2) and nuts (x2). Do not torque tighten.

3. Install bushes (x2) on anti-roll bar.

4. Position anti-roll bar, align bushes (x2), install straps (x2), install bolts (x4). Do not torque tighten.

5. Position anti-roll bar drop links to lower arms, install

nuts (x2). Do not torque tighten.

6. Install rear undertray (see Workshop Manual procedure 01.02.PB Undertray - Rear - Renew).

7. Lower vehicle on ramp.

8. Torque tighten link nuts (x4).

9. Torque tighten bush strap bolts (x4).

Rear Pair-Anti-Roll Bar Bushing-Renew

Removal

1. Raise vehicle on ramp.

2. Remove rear undertray(see Workshop Manual procedure01.02.PB Undertray - Rear - Renew).

3. Remove bolts (x4) securing anti-roll bar bush straps (x2) to subframe.

4. Release/remove bush straps.

5. Remove bushes (x2) from anti-roll bar.

Installation

1. Clean anti-roll bar and bush straps.

2. Install bushes onto anti-roll bar.

3. Install bush straps (x2), install bolts (x4). Do not torque tighten at this stage.

4. Install rear undertray(see Workshop Manual procedure 01.02.PB Undertray - Rear - Renew).

5. Lower vehicle on ramp.

6. Torque tighten all suspension nuts/bolts.

RH/LH Rear Anti-Roll Bar Link-Renew

Removal

1. Raise vehicle on ramp.

1. Remove nut, collect wash er, link to anti-roll bar.

1. Remove nut, link to lower suspension arm. Remove link.

Installation

1. Clean link and mating faces on anti-roll bar and lower suspension arm.

2. Install link to anti-roll bar, install washer and nut. Do not

torque tighten at this stage.

3. Position link to lower suspension arm, install nut). Do not torque tighten at this stage.

4. Lower vehicle on ramp.

5. Torque tighten link nuts (x2).

RH/LH Rear Hub Vertical Link-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel/s

3. With assistance, remove rear hub nut.

4. Remove nut/bolt, securing toe rod to vertical link, release toe rod.

5. Disconnect ABS sensor multiplug.

6. Remove Torx screw securing ABS sensor, remove sensor

7. Ease caliper pistons to release pads.

8. Remove caliper Allen bolts (x2) release caliper and tie aside.

9. Remove handbrake caliper bolts (x2) and tie caliper aside.

10. Remove brake disc Torx screws (x2) remove disc.

11. Remove nut/bolt securing lower suspension arm to

vertical link.

12. Remove nut/bolt securing vertical link to upper

suspension arm.

13. Release vertical link from driveshaft, remove vertical

link.

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this will over stress the suspension bushes when the suspension is deflected to maximum

upward travel.

Repair Operation Time (ROT)

Repair Operation Time (ROT)

ItemCode

Rear Anti-Roll Bar Link-Renew RH04.02.BD

Rear Anti-Roll Bar Link-Renew LH04.02.BE

Caution

Final tightening of suspen sion components must be

carried out with the suspension arms at normal ride

height. Failure to do this wi ll over stress the suspension

bushes when the suspension is deflected to maximum

upward travel.

Repair Operation Time (ROT)

ItemCode

Rear Hub Vertic al Link-Renew RH04.02.HB

Rear Hub Vertic al Link-Renew LH04.02.GB

Page 439 of 947

Rear Suspension (04.02)

Suspension (04.00)

May 2007 Workshop Manual 4-2-5

14. Tie driveshaft aside.

15. Remove Allen bolts (x4) securing hub bearing assembly in vertical link.

16. Release/remove hub bearing assembly from vertical link.

17. Remove Torx screws (x4) secu ring disc shield to vertical

link.

Installation

1. Clean vertical link, disc sh ield and hub bearing carrier.

2. Install disc shield to vert ical link, install and torque

tighten Torx screws (x4).

3. Install hub bearing assembly in vertical link. Install and tighten Allen bolts.

4. Release driveshaft.

5. Align to driveshaft, install vertical link to upper suspension arm. Install bolt/nut. Do not torque tighten at

this stage.

6. Align vertical link to lower suspension arm. Install bolt/ nut. Do not torque tighten at this stage.

7. Install hub nut. Do not torque tighten at this stage.

8. Clean brake disc.

9. Install disc and Torx screws (x2) and tighten Torx screws.

10. Install caliper and Allen bolts (x2) and tighten to.

11. Install handbrake caliper and retaining bolts (x2), tighten bolts.

12. Install ABS speed sensor, install and torque tighten Torx screw.

13. Install ABS sensor multiplug.

14. Install toe rod to vertical link, install bolt/nut. Do not torque tighten at this stage.

15. Install road wheel/s

16. Pump brake pedal.

17. Lower vehicle on ramp.

18. With assistance, torque tighten rear hub nut.

19. Correctly torque tighten all suspension nuts/bolts.

20. 4 wheel alignment - check/ adjust(see Workshop Manual

procedure 04.00.AD 4 Wheel Alignment - Check and

Adjust)

Repair Operation Time (ROT)

Page 446 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-6 Workshop Manual May 2007

9. Release sensor harness clips (x2) from toe control arm (see Fig. 3).

10. Remove bolts (x2) each side from handbrake calliper to rear hub and release calliper an d position aside (see Fig.

4)

.

11. Remove nuts and bolts both sides from toe control arms (see Fig. 5). 12. Remove nuts and bolts each side from lower damper

mountings (see Fig. 6).

13. Remove bolts (x4) each side from damper upper mounting (see Fig. 7).

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Page 447 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-7

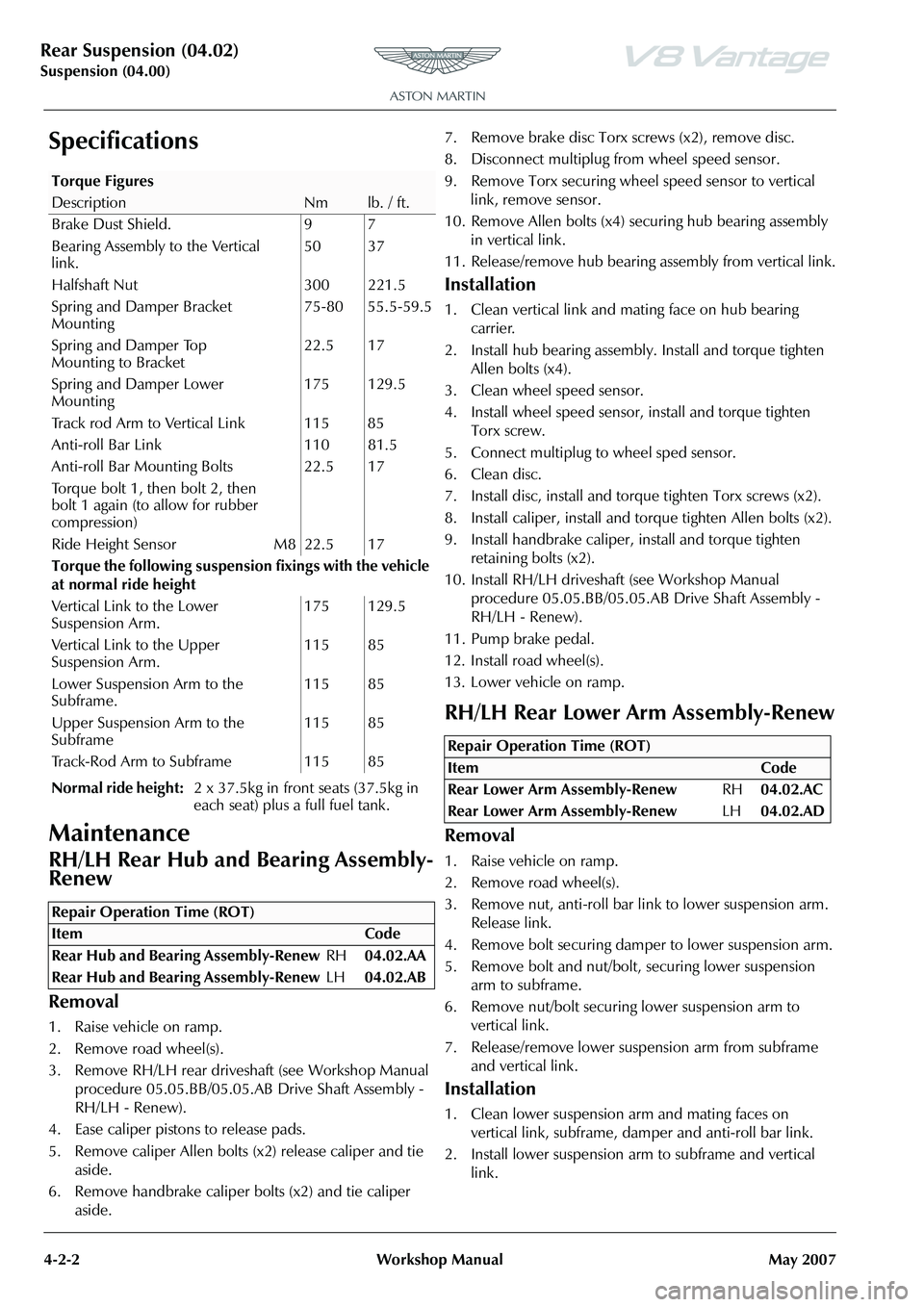

14. Remove spring and damper assembly (see Fig. 8).

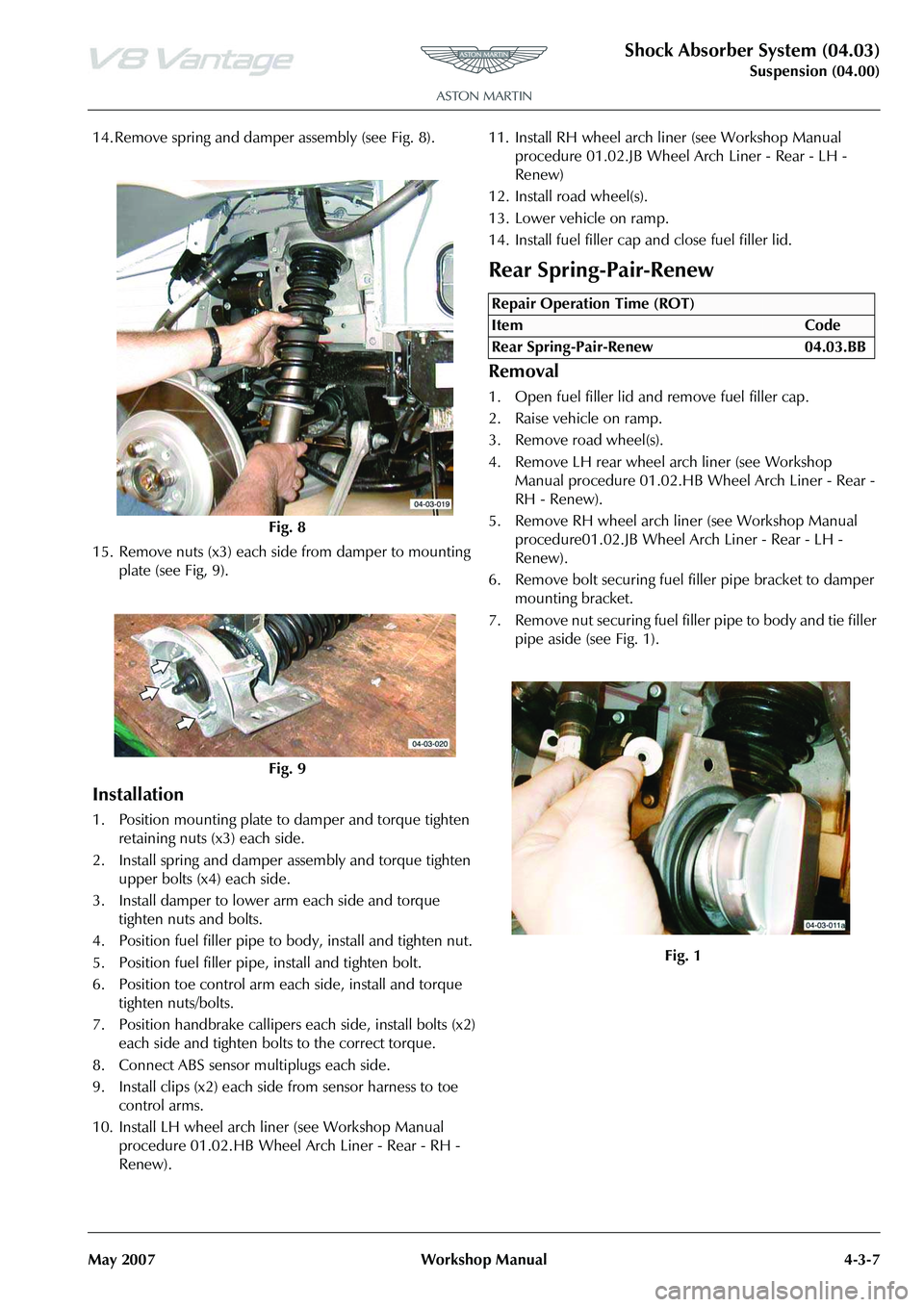

15. Remove nuts (x3) each side from damper to mounting plate (see Fig, 9).

Installation

1. Position mounting plate to damper and torque tighten retaining nuts (x3) each side.

2. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

3. Install damper to lower arm each side and torque tighten nuts and bolts.

4. Position fuel filler pipe to body, install and tighten nut.

5. Position fuel filler pipe, install and tighten bolt.

6. Position toe control arm each side, install and torque tighten nuts/bolts.

7. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

8. Connect ABS sensor multiplugs each side.

9. Install clips (x2) each side from sensor harness to toe control arms.

10. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew). 11. Install RH wheel arch li

ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

12. Install road wheel(s).

13. Lower vehicle on ramp.

14. Install fuel filler cap and close fuel filler lid.

Rear Spring-Pair-Renew

Removal

1. Open fuel filler lid and remove fuel filler cap.

2. Raise vehicle on ramp.

3. Remove road wheel(s).

4. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew).

5. Remove RH wheel arch liner (see Workshop Manual procedure01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

6. Remove bolt securing fuel filler pipe bracket to damper

mounting bracket.

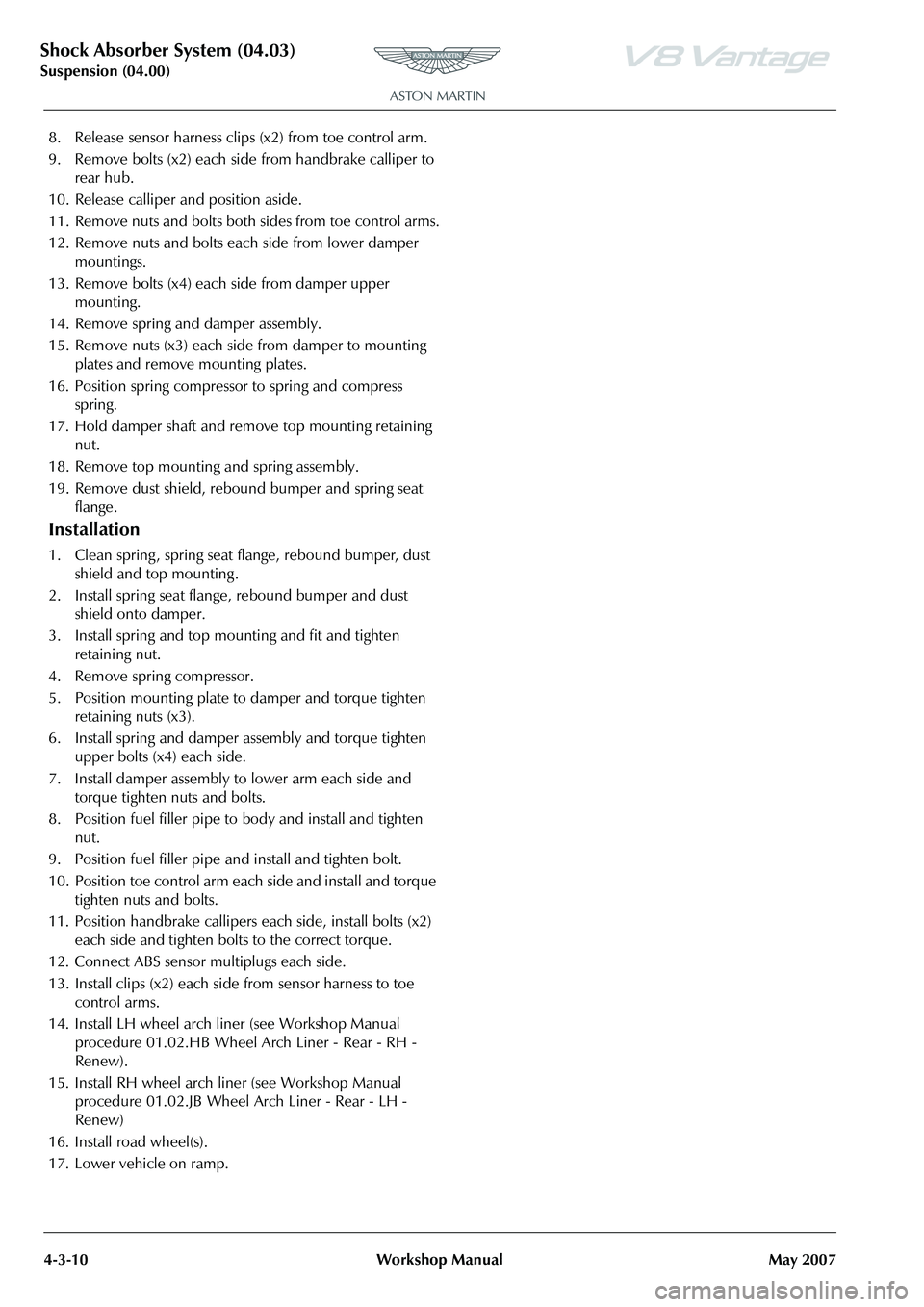

7. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside (see Fig. 1).

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 448 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-8 Workshop Manual May 2007

8. Disconnect ABS sensor multiplug (see Fig. 2).

9. Release sensor harness clips (x2) from toe control arm (see Fig. 3).

10. Remove bolts (x2) each side from handbrake calliper to rear hub and release calliper an d position aside (see Fig.

4)

.

11. Remove nuts and bolts both sides from toe control arms (see Fig. 5).

12. Remove nuts and bolts each side from lower damper mountings (see Fig. 6).

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Page 449 of 947

Shock Absorber System (04.03)

Suspension (04.00)

May 2007 Workshop Manual 4-3-9

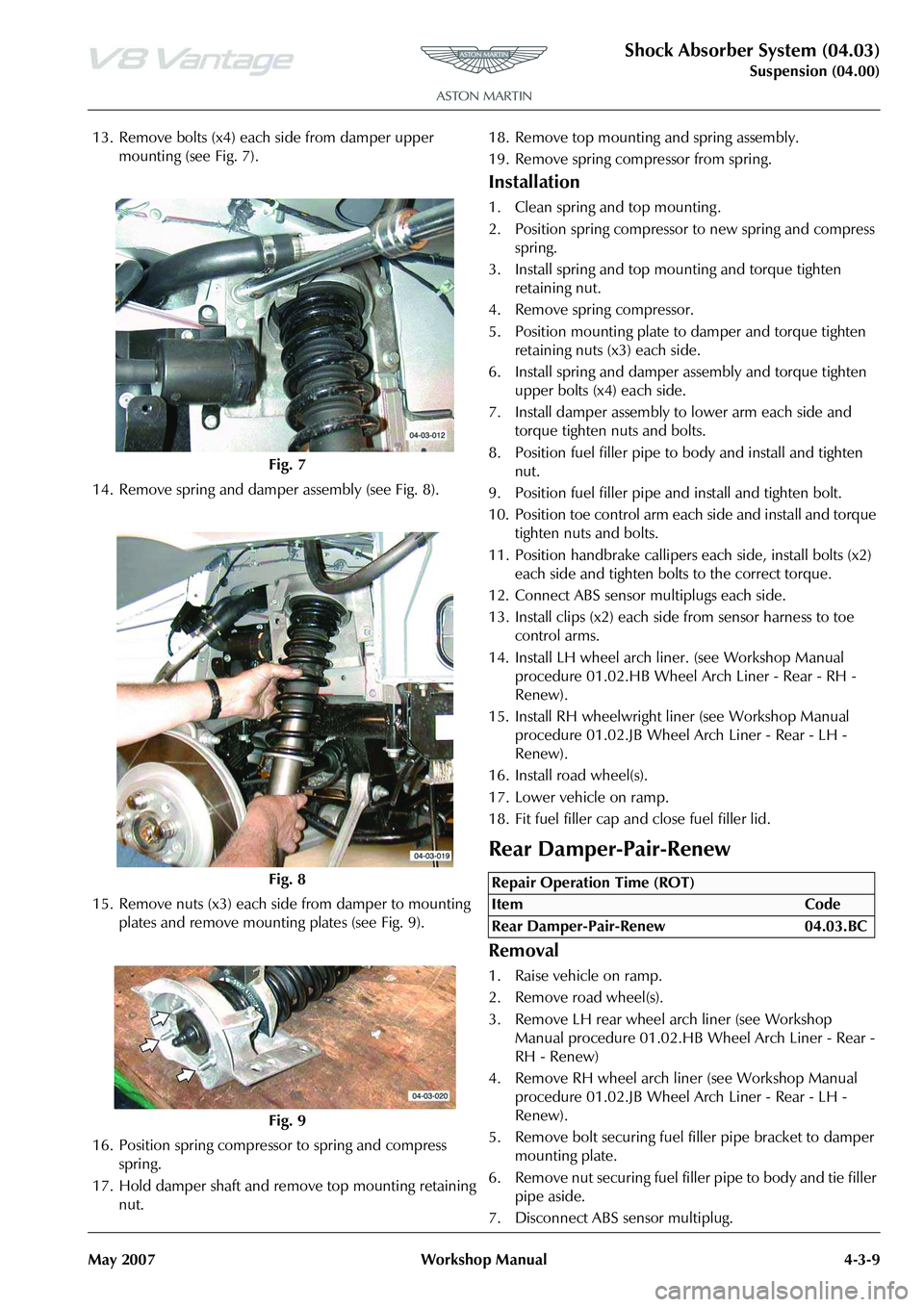

13. Remove bolts (x4) each side from damper upper mounting (see Fig. 7).

14. Remove spring and damper assembly (see Fig. 8).

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates (see Fig. 9).

16. Position spring compresso r to spring and compress

spring.

17. Hold damper shaft and remove top mounting retaining nut. 18. Remove top mounting and spring assembly.

19. Remove spring compressor from spring.

Installation

1. Clean spring and top mounting .

2. Position spring compressor to new spring and compress

spring.

3. Install spring and top mounting and torque tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten

retaining nuts (x3) each side.

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch li ner. (see Workshop Manual

procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheelwright li ner (see Workshop Manual

procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

16. Install road wheel(s).

17. Lower vehicle on ramp.

18. Fit fuel filler cap and close fuel filler lid.

Rear Damper-Pair-Renew

Removal

1. Raise vehicle on ramp.

2. Remove road wheel(s).

3. Remove LH rear wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear -

RH - Renew)

4. Remove RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew).

5. Remove bolt securing fuel filler pipe bracket to damper

mounting plate.

6. Remove nut securing fuel fille r pipe to body and tie filler

pipe aside.

7. Disconnect ABS sensor multiplug.

Fig. 7

Fig. 8

Fig. 9

Repair Operation Time (ROT)

Page 450 of 947

Shock Absorber System (04.03)

Suspension (04.00)4-3-10 Workshop Manual May 2007

8. Release sensor harness clips (x2) from toe control arm.

9. Remove bolts (x2) each side from handbrake calliper to rear hub.

10. Release calliper and position aside.

11. Remove nuts and bolts both sides from toe control arms.

12. Remove nuts and bolts each side from lower damper mountings.

13. Remove bolts (x4) each side from damper upper mounting.

14. Remove spring and damper assembly.

15. Remove nuts (x3) each side from damper to mounting plates and remove mounting plates.

16. Position spring compressor to spring and compress spring.

17. Hold damper shaft and remove top mounting retaining nut.

18. Remove top mounting and spring assembly.

19. Remove dust shield, rebound bumper and spring seat flange.

Installation

1. Clean spring, spring seat flange, rebound bumper, dust

shield and top mounting .

2. Install spring seat flange, rebound bumper and dust shield onto damper.

3. Install spring and top mounting and fit and tighten retaining nut.

4. Remove spring compressor.

5. Position mounting plate to damper and torque tighten retaining nuts (x3).

6. Install spring and damper assembly and torque tighten upper bolts (x4) each side.

7. Install damper assembly to lower arm each side and torque tighten nuts and bolts.

8. Position fuel filler pipe to body and install and tighten nut.

9. Position fuel filler pipe and install and tighten bolt.

10. Position toe control arm each side and install and torque tighten nuts and bolts.

11. Position handbrake callipers each side, install bolts (x2) each side and tighten bolts to the correct torque.

12. Connect ABS sensor multiplugs each side.

13. Install clips (x2) each side from sensor harness to toe control arms.

14. Install LH wheel arch liner (see Workshop Manual procedure 01.02.HB Wheel Arch Liner - Rear - RH -

Renew).

15. Install RH wheel arch liner (see Workshop Manual procedure 01.02.JB Wheel Arch Liner - Rear - LH -

Renew)

16. Install road wheel(s).

17. Lower vehicle on ramp.

Page 453 of 947

Road Wheels and Tyres (04.04)

Suspension (04.00)

May 2007 Workshop Manual 4-4-3

Maintenance

Factory installed tyres and road wheels are designed to

operate satisfactory when inflated to the recommended

inflation pressures (Refer to ’Inspection and Verification’,

page 4-4-4). The recommended pressures apply to vehicle

loads up to and including the full-rated load capacity.

Correct tyre pressures and driving technique have an

important influence on tyre life. Heavy cornering,

excessively rapid acceleration and unnecessary sharp

braking increase tyre wear.

Replacement tyres should follow the recommended:

The use of any other size or type may seriously affect:

Wheels need to be renewed when:

Safety

Tyre Replacement and Wheel

Interchanging

When replacement of tyres is required it is preferable to

install a complete vehicle set. S hould either the front or rear

tyres only show excessive wear, new tyres must be installed

to replace worn ones. Under no circumstances interchange

tyres from side to side, front to re ar or vice versa as individual

tyre wear produces unique characteristics depending upon

their position. If the position is changed after wear has

occurred, the performance of the tyre will be adversely

affected.

New tyres must be balanced before installing to the vehicle.

•Size

•Speed rating

•Load range

• Radial construction type

•Safety

•Ride

•Handling

• Speedometer and Odometer calibration • Vehicle ground clearance

• Tyre clearance between

body and chassis

• Wheel bearing life

• Brake cooling

• Impact damaged

• Heavily corroded

• Porous • Wheel stud holes or seats

become damaged

• They have excessive radial or lateral runout.

ENSURE THAT TYRES ARE MOUNTED WITH THE

SIDEWALL MARKING ‘OUTSIDE’ SHOWING ON THE

OUTER SIDEWALL FACE.

CORRECT TYRE ROTATIONAL DIRECTION IS CRITICAL.

WA R N I N G

A TYRE AND WHEEL MUST ALWAYS BE CORRECTLY MATCHED. WIDER OR NARROWER TYRES THAN

RECOMMENDED COULD CAUSE DANGER THROUGH

SUDDEN DEFLATION.

WA R N I N G

WHEN CHANGING A WHEEL, MAKE SURE THAT THE VEHICLE CANNOT MOVE. ALWAYS APPLY THE

PARKING BRAKE AND SELE CT THE TRANSMISSION

PARK POSITION (AUTOMATIC TRANSMISSION ONLY).

WA R N I N G

NEVER RUN THE ENGINE WITH ONE WHEEL OFF THE GROUND, FOR EXAMPLE, WHEN CHANGING THE

WHEEL. THE WHEEL RESTING ON THE GROUND MAY CAUSE THE VEHICLE TO MOVE.

WA R N I N G

ALWAYS TIGHTEN THE WHEEL NUTS TO

SPECIFICATION. TOO TIGHT MAY CAUSE DAMAGE,

TOO LOOSE MAY ALLOW TH E WHEEL TO BECOME

DETACHED.

WAR NI NG

DO NOT MIX DIFFERENT TY PES OF TYRES ON THE

SAME VEHICLE. HANDLING MAY BE SERIOUSLY AFFECTED RESULTING IN LOSS OF CONTROL.

WAR NI NG

USE ONLY WHEELS AND WHEEL NUTS SUPPLIED BY

ASTON MARTIN. AFTER MARKET WHEELS OR WHEEL

NUTS MAY NOT INSTALL OR FUNCTION CORRECTLY

AND COULD CAUSE INJURY OR DAMAGE.

Caution

When a new tyre is installe d, always renew the tyre

valve.