torque ASTON MARTIN V8 VANTAGE 2010 Workshop Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 879 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 33 of 43

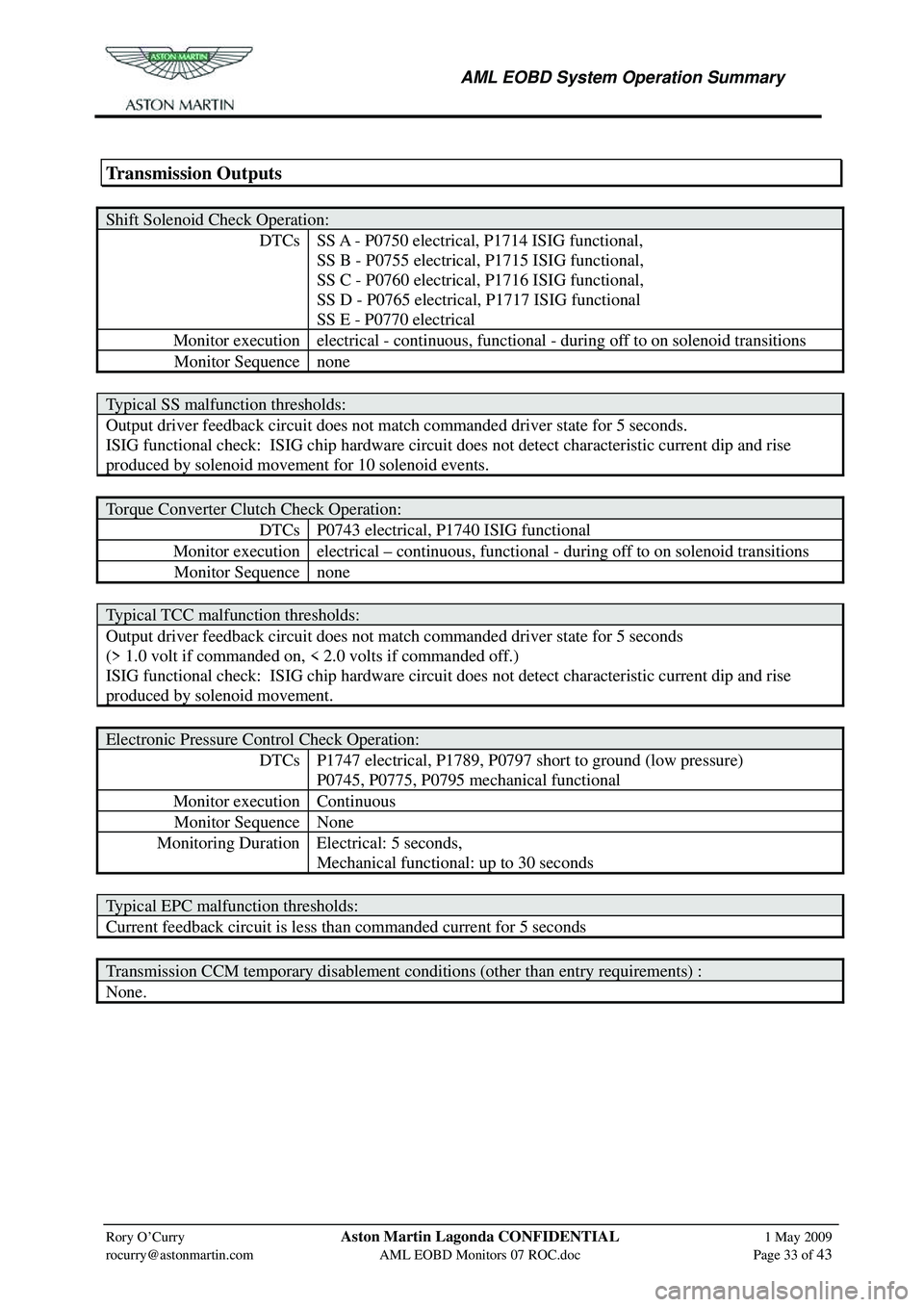

Transmission Outputs

Shift Solenoid Check Operation:

DTCs SS A - P0750 electrical, P1714 ISIG functional,

SS B - P0755 electrical, P1715 ISIG functional,

SS C - P0760 electrical, P1716 ISIG functional,

SS D - P0765 electrical, P1717 ISIG functional

SS E - P0770 electrical

Monitor execution electrical - continuous, functi onal - during off to on solenoid transitions

Monitor Sequence none

Typical SS malfunction thresholds:

Output driver feedback circuit does not match commanded driver state for 5 seconds.

ISIG functional check: ISIG chip hardware circu it does not detect characteristic current dip and rise

produced by solenoid movement for 10 solenoid events.

Torque Converter Clutch Check Operation:

DTCs P0743 electrical, P1740 ISIG functional

Monitor execution electrical – continuous, functi onal - during off to on solenoid transitions

Monitor Sequence none

Typical TCC malfunction thresholds:

Output driver feedback circuit does not match commanded driver state for 5 seconds

(> 1.0 volt if commanded on, < 2.0 volts if commanded off.)

ISIG functional check: ISIG chip hardware circu it does not detect characteristic current dip and rise

produced by solenoid movement.

Electronic Pressure Control Check Operation:

DTCs P1747 electrical, P1789, P0797 short to ground (low pressure)

P0745, P0775, P0795 mechanical functional

Monitor execution Continuous

Monitor Sequence None

Monitoring Duration Electrical: 5 seconds,

Mechanical functional: up to 30 seconds

Typical EPC malfunction thresholds:

Current feedback circuit is less than commanded current for 5 seconds

Transmission CCM temporary disablement conditions (other than entry requirements) :

None.

Page 883 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 37 of 43

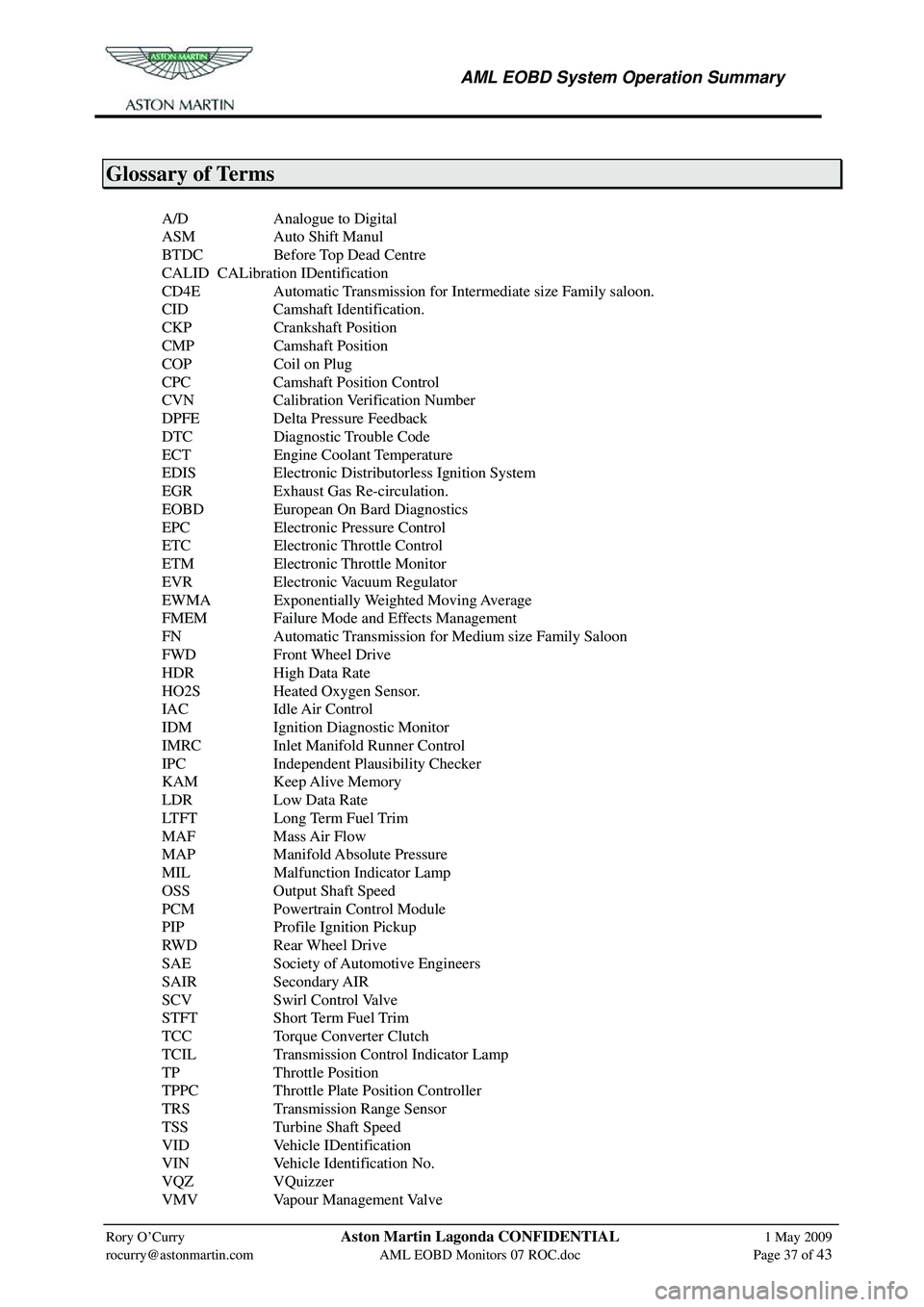

Glossary of Terms

A/D Analogue to Digital

ASM Auto Shift Manul

BTDC Before Top Dead Centre

CALID CALibration IDentification

CD4E Automatic Transmission for Intermediate size Family saloon.

CID Camshaft Identification.

CKP Crankshaft Position

CMP Camshaft Position

COP Coil on Plug

CPC Camshaft Position Control

CVN Calibration Verification Number

DPFE Delta Pressure Feedback

DTC Diagnostic Trouble Code

ECT Engine Coolant Temperature

EDIS Electronic Distributorless Ignition System

EGR Exhaust Gas Re-circulation.

EOBD European On Bard Diagnostics

EPC Electronic Pressure Control

ETC Electronic Throttle Control

ETM Electronic Throttle Monitor

EVR Electronic Vacuum Regulator

EWMA Exponentially Weighted Moving Average

FMEM Failure Mode and Effects Management

FN Automatic Transmission for Medium size Family Saloon

FWD Front Wheel Drive

HDR High Data Rate

HO2S Heated Oxygen Sensor.

IAC Idle Air Control

IDM Ignition Diagnostic Monitor

IMRC Inlet Manifold Runner Control

IPC Independent Plausibility Checker

KAM Keep Alive Memory

LDR Low Data Rate

LTFT Long Term Fuel Trim

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MIL Malfunction Indicator Lamp

OSS Output Shaft Speed

PCM Powertrain Control Module

PIP Profile Ignition Pickup

RWD Rear Wheel Drive

SAE Society of Automotive Engineers

SAIR Secondary AIR

SCV Swirl Control Valve

STFT Short Term Fuel Trim

TCC Torque Converter Clutch

TCIL Transmission Control Indicator Lamp

TP Throttle Position

TPPC Throttle Plate Position Controller

TRS Transmission Range Sensor

TSS Turbine Shaft Speed

VID Vehicle IDentification

VIN Vehicle Identification No.

VQZ VQuizzer

VMV Vapour Management Valve

Page 890 of 947

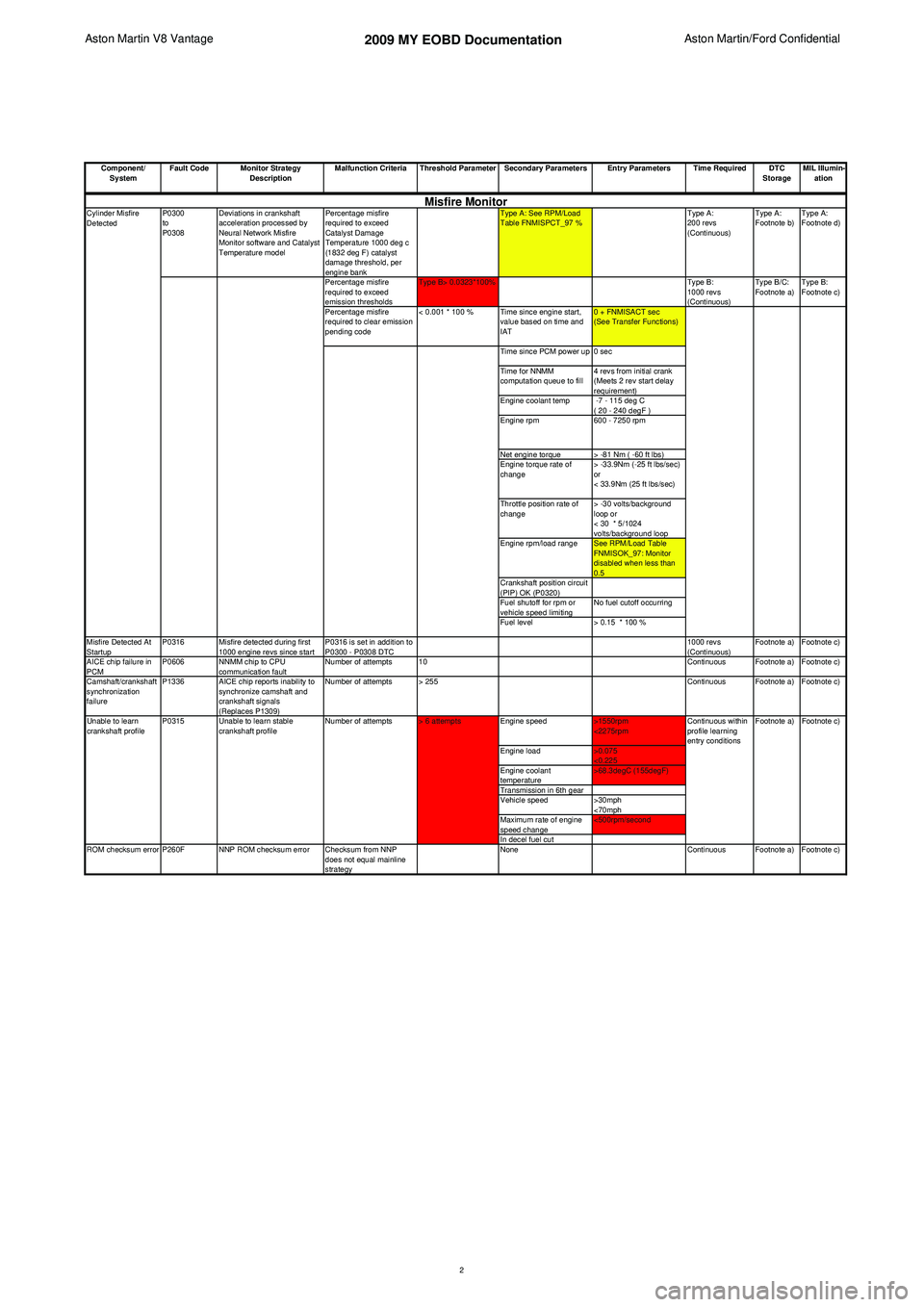

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0300

to

P0308 Deviations in crankshaft

acceleration processed by

Neural Network Misfire

Monitor software and Catalyst

Temperature model Percentage misfire

required to exceed

Catalyst Damage

Temperature 1000 deg c

(1832 deg F) catalyst

damage threshold, per

engine bank Type A: See RPM/Load

Table FNMISPCT_97 %

Type A:

200 revs

(Continuous)Type A:

Footnote b)

Type A:

Footnote d)

Percentage misfire

required to exceed

emission thresholds Type B> 0.0323*100% Type B:

1000 revs

(Continuous)Type B/C:

Footnote a)

Type B:

Footnote c)

Percentage misfire

required to clear emission

pending code < 0.001 * 100 % Time since engine start,

value based on time and

IAT 0 + FNMISACT sec

(See Transfer Functions)

Time since PCM power up 0 sec

Time for NNMM

computation queue to fill 4 revs from initial crank

(Meets 2 rev start delay

requirement)

Engine coolant temp -7 - 115 deg C ( 20 - 240 degF )

Engine rpm 600 - 7250 rpm

Net engine torque > -81 Nm ( -60 ft lbs)

Engine torque rate of

change > -33.9Nm (-25 ft lbs/sec)

or

< 33.9Nm (25 ft lbs/sec)

Throttle position rate of

change > -30 volts/background

loop or

< 30 * 5/1024

volts/background loop

Engine rpm/load range See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Crankshaft position circuit

(PIP) OK (P0320)

Fuel shutoff for rpm or

vehicle speed limiting No fuel cutoff occurring

Fuel level > 0.15 * 100 %

Misfire Detected At

Startup P0316 Misfire detected during first

1000 engine revs since start P0316 is set in addition to

P0300 - P0308 DTC 1000 revs

(Continuous)Footnote a) Footnote c)

AICE chip failure in

PCM P0606 NNMM chip to CPU

communication fault Number of attempts 10

Continuous Footnote a) Footnote c)

Camshaft/crankshaft

synchronization

failure P1336 AICE chip reports inability to

synchronize camshaft and

crankshaft signals

(Replaces P1309) Number of attempts > 255

Continuous Footnote a) Footnote c)

Engine speed >1550rpm

<2275rpm

Engine load >0.075

<0.225

Engine coolant

temperature >68.3degC (155degF)

Transmission in 6th gear

Vehicle speed >30mph

<70mph

Maximum rate of engine

speed change <500rpm/second

In decel fuel cut

ROM checksum error P260F NNP ROM checksum error Checksum from NNP does not equal mainline

strategyNone

Continuous Footnote a) Footnote c)

Cylinder Misfire

DetectedMisfire Monitor

Footnote c)

Unable to learn

crankshaft profile P0315 Unable to learn stable

crankshaft profile Number of attempts > 6 attempts Continuous within

profile learning

entry conditionsFootnote a)

2

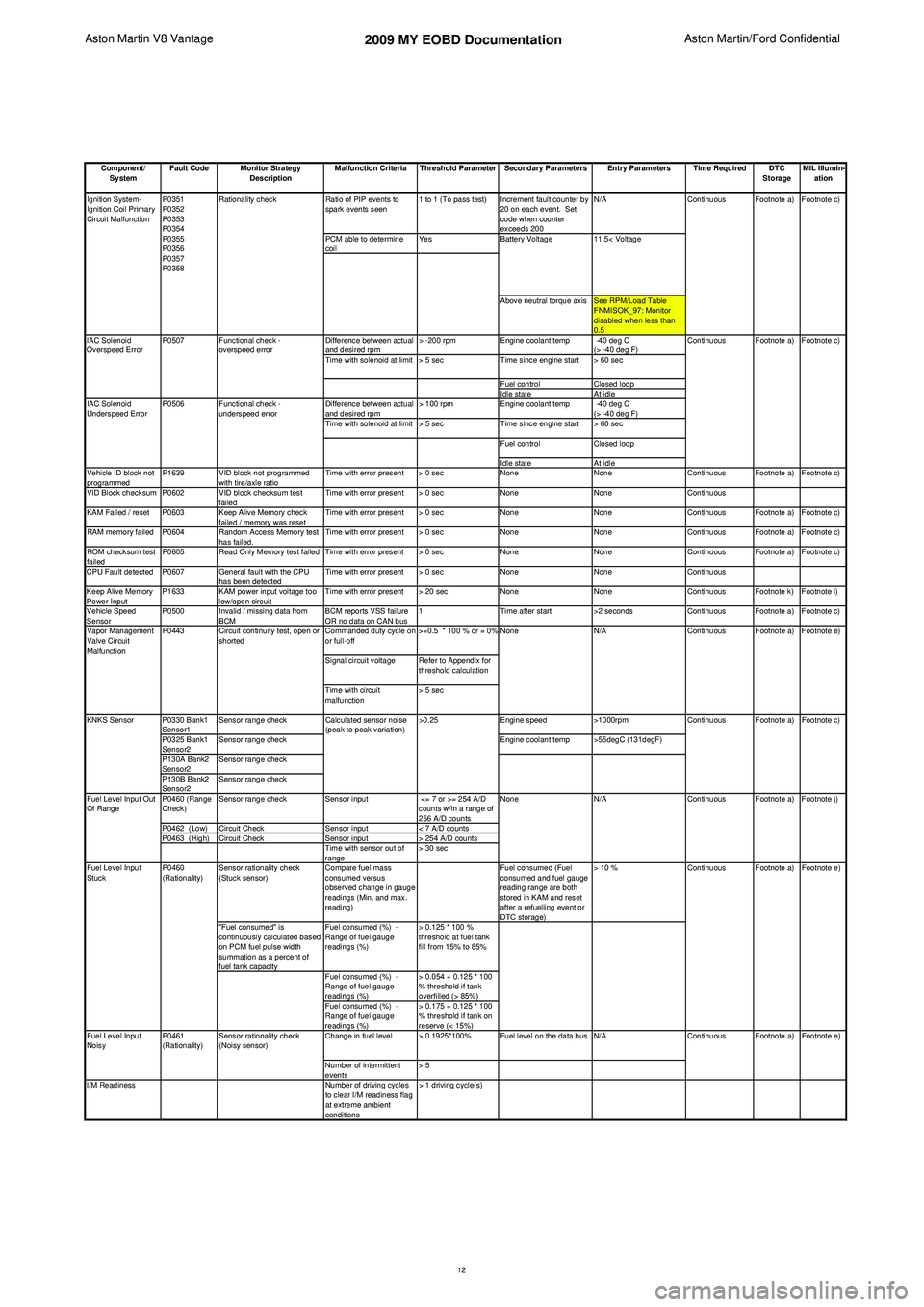

Page 894 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

PCM able to determine

failure

Time with failure >5seconds

PCM able to determine

failure

Time with failure >5seconds

P0011 (Bank1) Cam position error vs

target >12.4deg CRK Engine coolant

temperature >-7c (20f)

P0021 (Bank2) Cam position error bank1

vs bank2 >16deg CRK Engine oil temperature >-7c (20f)

<121c (250f)

Time exceeding threshold >5 seconds Cam angle sensitivity

modifier for cam position

bank1 vs bank2 CAM_RANGE_SENS

(See function)

Cam angle error filter for

target error calculation FNCAM_ACT_FK

(See function)

Filter for target error

calculation 0.25*100%

Intake air temp sensor OK

(P0112/0113)

Engine coolant temp

sensor OK (P0117/0118)

Engine oil temp sensor OK

(P0197/0198)

Throttle Position Sensor

OK (P0122/0123)

Crankshaft position circuit

(PIP) OK (P0320)

Mass Air Flow sensor OK

(P0101 to P010F)

Camshaft ID circuit (CMP)

OK (P0340)

P0012

(Bank1) Cam position error vs

target>12.4deg CRK Engine coolant

temperature >-7c (20f)

P0022 (Bank2) Cam position error bank1

vs bank2 >16deg CRK Engine oil temperature >-7c (20f)

<121c (250f)

Time exceeding threshold >5 seconds Cam angle sensitivity

modifier for cam position

bank1 vs bank2 CAM_RANGE_SENS

(See function)

Cam angle error filter for

target error calculation FNCAM_ACT_FK

(See function)

Filter for target error

calculation 0.25*100%

Intake air temp sensor OK

(P0112/0113)

Engine coolant temp

sensor OK (P0117/0118)

Engine oil temp sensor OK

(P0197/0198)

Throttle Position Sensor

OK (P0122/0123)

Crankshaft position circuit

(PIP) OK (P0320)

Mass Air Flow sensor OK

(P0101 to P010F)

Camshaft ID circuit (CMP)

OK (P0340)

P0016

(Bank1) Engine speed

>600rpm

<1100rpm

P0018

(Bank2) Indicated torque

>25 Nm (18.4ftlb)

<95 Nm (70ftlb)

Time after start >25sec

<16383sec

Engine coolant

temperature >71.1degC (160degF)

<104.4degC (220degF)

Filter for position error 1.5

Air charge temperature >-17.7degC (0degF) <65.5degC (150degF)

Circuit MalfunctionVariable Cam Timing MonitorContinuous Footnote a) Footnote c)

VCT actuator

malfunction P0010 (Bank1)

P0020(Bank2)

VCT target error Measured Cam Position Over

advanced

VCT target error Measured Cam Position Over

retarded

Footnote c)

>8deg CRK Once per driving

cycle Footnote a)

Circuit Malfunction

CAM / CRANK

Misalignment Cam position error

Measured Cam Position with

VCT locked fully retarded

6

Page 900 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Ratio of PIP events to

spark events seen 1 to 1 (To pass test) Increment fault counter by

20 on each event. Set

code when counter

exceeds 200 N/A

PCM able to determine

coil Yes

Above neutral torque axis See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Difference between actual

and desired rpm > -200 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Difference between actual

and desired rpm > 100 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Vehicle ID block not

programmed P1639 VID block not programmed

with tire/axle ratio Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

VID Block checksum P0602 VID block checksum test failedTime with error present > 0 sec

NoneNoneContinuous

KAM Failed / reset P0603 Keep Alive Memory check failed / memory was resetTime with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

RAM memory failed P0604 Random Access Memory test has failed.Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

ROM checksum test

failed P0605 Read Only Memory test failed Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

CPU Fault detected P0607 General fault with the CPU has been detectedTime with error present > 0 sec

NoneNoneContinuous

Keep Alive Memory

Power Input P1633 KAM power input voltage too

low/open circuit Time with error present > 20 sec

NoneNoneContinuous Footnote k) Footnote i)

Vehicle Speed

Sensor P0500 Invalid / missing data from

BCM BCM reports VSS failure

OR no data on CAN bus1

Time after start >2 secondsContinuous Footnote a) Footnote c)

Commanded duty cycle on

or full-off >=0.5 * 100 % or = 0%

Signal circuit voltage Refer to Appendix for threshold calculation

Time with circuit

malfunction > 5 sec

P0330 Bank1

Sensor1 Sensor range check

Engine speed>1000rpm

P0325 Bank1

Sensor2 Sensor range check

Engine coolant temp >55degC (131degF)

P130A Bank2

Sensor2 Sensor range check

P130B Bank2

Sensor2 Sensor range check

P0460 (Range

Check) Sensor range check

Sensor input <= 7 or >= 254 A/D

counts w/in a range of

256 A/D counts

P0462 (Low) Circuit Check Sensor input< 7 A/D counts

P0463 (High) Circuit Check Sensor input> 254 A/D counts

Time with sensor out of

range > 30 sec

Sensor rationality check

(Stuck sensor) Compare fuel mass

consumed versus

observed change in gauge

readings (Min. and max.

reading) Fuel consumed (Fuel

consumed and fuel gauge

reading range are both

stored in KAM and reset

after a refuelling event or

DTC storage)> 10 %

"Fuel consumed" is

continuously calculated based

on PCM fuel pulse width

summation as a percent of

fuel tank capacity Fuel consumed (%) -

Range of fuel gauge

readings (%)

> 0.125 * 100 %

threshold at fuel tank

fill from 15% to 85%

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.054 + 0.125 * 100

% threshold if tank

overfilled (> 85%)

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.175 + 0.125 * 100

% threshold if tank on

reserve (< 15%)

Change in fuel level > 0.1925*100% Fuel level on the data bus N/A

Number of intermittent

events > 5

I/M Readiness Number of driving cycles

to clear I/M readiness flag

at extreme ambient

conditions > 1 driving cycle(s) Footnote e)

Footnote a)

Footnote c)

Footnote a) Footnote j) Footnote e)

Fuel Level Input

Noisy Continuous Footnote a)

Continuous Footnote a)

P0461

(Rationality) Sensor rationality check

(Noisy sensor)

Fuel Level Input

Stuck

P0460

(Rationality) Continuous

N/A Continuous

Calculated sensor noise

(peak to peak variation)

>0.25

KNKS Sensor

Fuel Level Input Out

Of Range NoneFootnote a) Footnote e)

Vapor Management

Valve Circuit

Malfunction P0443 Circuit continuity test, open or

shorted None

N/A Continuous

11.5< Voltage

Ignition System-

Ignition Coil Primary

Circuit Malfunction

IAC Solenoid

Underspeed Error P0507

P0506

Functional check -

overspeed error

Functional check -

underspeed error

IAC Solenoid

Overspeed Error

Footnote a) Footnote c)

Continuous

P0351

P0352

P0353

P0354

P0355

P0356

P0357

P0358

Rationality check

Continuous Footnote a) Footnote c)

Battery Voltage

12

Page 914 of 947

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

P0300

to

P0312 Deviations in crankshaft

acceleration processed by

Neural Network Misfire

Monitor software and Catalyst

Temperature model Percentage misfire

required to exceed

Catalyst Damage

Temperature 900 deg c

(1650 deg F) catalyst

damage threshold, per

engine bank Type A: See RPM/Load

Table FNMISPCT_97 %

Type A:

200 revs

(Continuous)Type A:

Footnote b)

Type A:

Footnote d)

Full-range misfire capability Percentage misfire required to exceed

emission thresholdsType B: > 0.01 * 100

%

Type B:

1000 revs

(Continuous)Type B/C:

Footnote a)

Type B:

Footnote c)

Percentage misfire

required to clear emission

pending code < 0.001 * 100 % Time since engine start,

value based on time and

IAT 0 + FNMISACT sec

(See Transfer Functions)

Full-range misfire redline:

6900 rpm Time since PCM power up 0 sec

Time for NNMM

computation queue to fill4 revs from initial crank

(Meets 2 rev start delay

requirement)

Engine coolant temp -7 - 121 deg C ( 20 - 250 deg )

Engine rpm 500 - 4000rpm

Engine rpm in neutral

(Auto trans. only) < 3100 rpm

Net engine torque > -68 Nm ( -50 ft lbs)

Engine torque rate of

change > -34 Nm/s or < 41 Nm/s

(> -25 ft lbs/sec or

< 30 ft lbs/sec)

Throttle position rate of

change > -20 volts/background

loop or

< 30 * 5/1024

volts/background loop

Closed throttle

deceleration

(Dashpot mode) Closed throttle,

vehicle speed < 4 mph,

dashpot airflow adder

present

Engine rpm/load range See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Crankshaft position circuit

(PIP) OK (P0320)

Fuel shutoff for rpm or

vehicle speed limiting No fuel cutoff occurring

Fuel level > 0.15 * 100 %

Cylinder Misfire

Detected

Misfire Monitor

3

Page 933 of 947

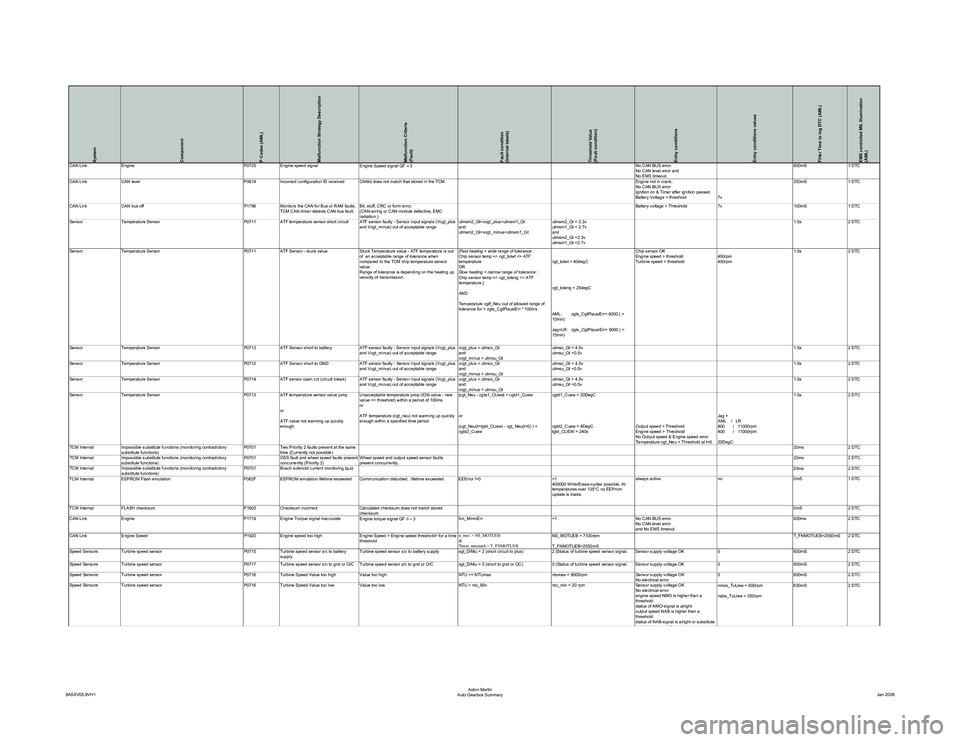

System

Component

P Codes (AML)

Malfunction Strategy Description

Malfunction Criteria

(Fault)

Fault condition

(Internal labels)

Threshold Value

(Fault condition)

Entry conditions

Entry conditions values

Filter Time to log DTC (AML)

EMS controlled MIL Illumination

(AML)

CAN LinkEngine P0725Engine speed signal

Engine Speed signal QF ≠ 3 No CAN BUS error.

No CAN level error and

No EMS timeout.600mS

1 DTC

CAN Link CAN level P0614Incorrect configuration ID received CANid does not match that stored in the TCM Engine not in crank.

No CAN BUS error

Ignition on & Timer after ignition passed.

Battery Voltage > threshold7v250mS

1 DTC

CAN Link CAN bus off P1796Monitors the CAN for Bus or RAM faults.

TCM CAN driver detects CAN bus fault. Bit, stuff, CRC or form error,

(CAN-wiring or CAN-module defective, EMC

radiation.) Battery voltage > Threshold

7v100mS1 DTC

Sensor Temperature Sensor P0711 ATF temperature sensor short circuit ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range utmsm2_Gt

utmsm2_Gt

and

utmsm2_Gt =2.3v

utmsm1_Gt =2.7v 1.5s

2 DTC

Sensor Temperature Sensor P0711ATF Sensor - stuck value Stuck Temperature value - ATF temperature is out

of an acceptable range of tolerance when

compared to the TCM chip temperature sensor

value.

Range of tolerance is depending on the heating up

velocity of transmission . [

Fast heating = wide range of tolerance :

Chip sensor temp +/- cgt_tolwt <> ATF

temperature

OR

Slow heating = narrow range of tolerance :

Chip sensor temp +/- cgt_toleng <> ATF

temperature.]

AND

Temperature cgtf_Neu out of allowed range of

tolerance for > zgts_CgtPlausiErr * 100ms cgt_tolwt = 40degC

cgt_toleng = 25degC

AML: zgts_CgtPlausiErr= 6000 ( =

10min)

Jag+LR: zgts_CgtPlausiErr= 9000 ( =

15min)Chip sensor OK

Engine speed > threshold

Turbine speed > threshold

450rpm

450rpm1.5s

2 DTC

Sensor Temperature Sensor P0713ATF Sensor short to battery ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range vcgt_plus > utmso_Gt

and

vcgt_minus > utmsu_Gtutmso_Gt = 4.5v

utmsu_Gt =0.5v

1.5s

2 DTC

Sensor Temperature Sensor P0712ATF Sensor short to GND ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range vcgt_plus < utmso_Gt

and

vcgt_minus < utmsu_Gtutmso_Gt = 4.5v

utmsu_Gt =0.5v

1.5s

2 DTC

Sensor Temperature Sensor P0714ATF sensor open cct (circuit break) ATF sensor faulty - Sensor input signals (Vcgt_plus

and Vcgt_minus) out of acceptable range vcgt_plus > utmso_Gt

and

vcgt_minus < utmsu_Gtutmso_Gt = 4.5v

utmsu_Gt =0.5v

1.5s

2 DTC

Sensor Temperature Sensor P0713 ATF temperature sensor value jump

or

ATF value not warming up quickly

enough Unacceptable temperature jump (lOld value - new

value <> threshold) within a period of 100ms

or

ATF temperature (cgt_neu) not warming up quickly

enough within a specified time period

|cgt_Neu - cgta1_CUew| > cgtd1_Cuew

or

(cgt_Neu(t=tgtd_CUew) - cgt_Neu(t=0) ) <

cgtd2_Cuewcgtd1_Cuew = 20DegC

cgtd2_Cuew = 4DegC

tgtd_CUEW = 240s

Output speed > Threshold

Engine speed > Threshold

No Output speed & Engine speed error

Temperature cgt_Neu < Threshold at t=0Jag +

AML / LR

800 / 11000rpm

400 / 11000rpm

20DegC1.5s

2 DTC

TCM Internal Impossible substitute functions (monitoring contradictory

substitute functions) P0701

Two Priority 2 faults present at the same

time (Currently not possible) 20ms

2 DTC

TCM Internal Impossible substitute functions (monitoring contradictory

substitute functions) P0701

OSS fault and wheel speed faults present

concurrently (Priority 3) Wheel speed and output speed sensor faults

present concurrently. 20ms

2 DTC

TCM Internal Impossible substitute functions (monitoring contradictory

substitute functions) P0701

Bosch solenoid current monitorin

g fault 20ms 2 DTC

TCM Internal EEPROM Flash emulation P062FEEPROM emulation lifetime exceeded Communication disturbed, lifetime exceeded EEError !=0 =1

400000 Write/Erase-cycles possible. At

temperatures over 135°C no EEProm

update is made.always active

no0mS1 DTC

TCM Internal FLASH checksum P1603Checksum incorrect Calculated checksum does not match stored

checksum 0mS

2 DTC

CAN Link Engine P1719Engine Torque signal inaccurate

Engine torque signal QF 0 = 3 fcn_MmmErr

=1No CAN BUS error.

No CAN level error

and No EMS timeout. 600ms

2 DTC

CAN Link Engine Speed P1920Engine speed too high Engine Speed > Engine speed threshold> for a time

threshold n_mot > NS_MOTUEB

&

Timer_nmotueb > T_FNMOTUEBNS_MOTUEB = 7100rpm

T_FNMOTUEB=2550mS T_FNMOTUEB=2550mS 2 DTC

Speed Sensors Turbine speed sensor P0715Turbine speed sensor s/c to battery

supply Turbine speed sensor s/c to battery supply sgt_DiNtu = 2 (short circuit to plus)

2 (Status of turbine speed sensor signal. Sensor supply voltage OK0600mS2 DTC

Speed Sensors Turbine speed sensor P0717Turbine speed sensor s/c to gnd or O/C Turbine speed sensor s/c to gnd or O/C sgt_DiNtu = 0 (short to gnd or OC)0 (Status of turbine speed sensor signal. Sensor supply voltage OK 0600mS2 DTC

Speed Sensors Turbine speed sensor P0716Turbine Speed Value too high Value too high NTU >= NTUmaxntumax = 8000rpmSensor supply voltage OK

No electrical error 0

600mS2 DTC

Speed Sensors Turbine speed sensor P0716Turbine Speed Value too low Value too low NTU < ntu_Minntu_min = 20 rpmSensor supply voltage OK

No electrical error

engine speed NMO is higher than a

threshold:

status of NMO-signal is alright

output speed NAB is higher than a

threshold:

status of NAB-signal is alright or substitute

fltfl fb Ei t t

nmos_TuUew = 600rpm

nabs_TuUew = 250rpm 600mS

2 DTC

8ASXV05.9VH1 Aston Martin

Auto Gearbox Summary Jan 2008

Page 934 of 947

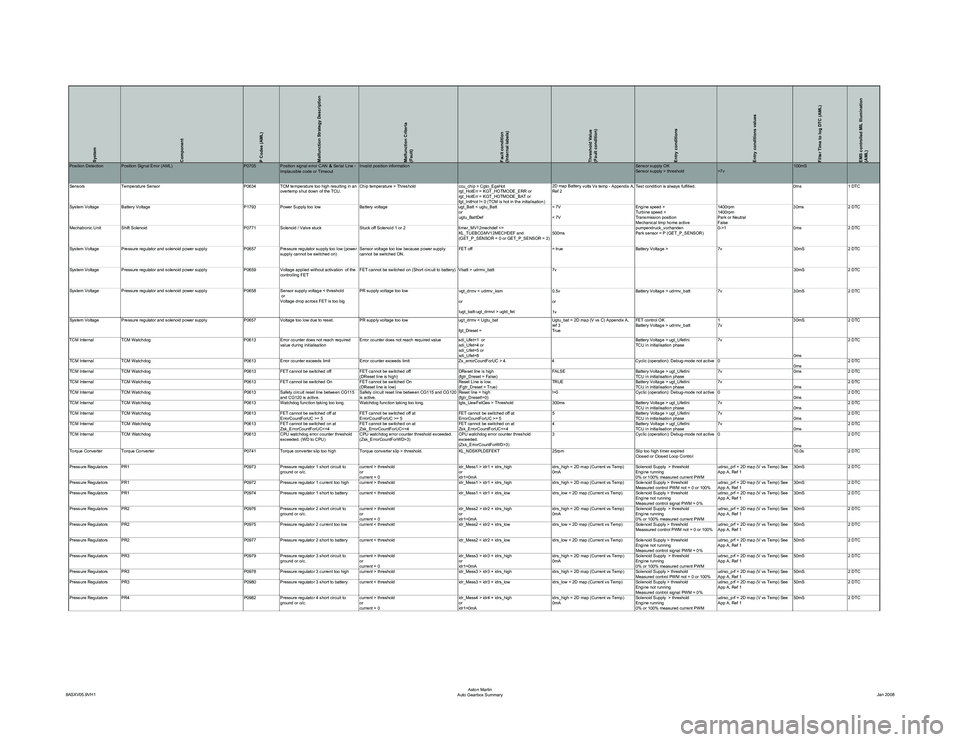

System

Component

P Codes (AML)

Malfunction Strategy Description

Malfunction Criteria

(Fault)

Fault condition

(Internal labels)

Threshold Value

(Fault condition)

Entry conditions

Entry conditions values

Filter Time to log DTC (AML)

EMS controlled MIL Illumination

(AML)

y volts Vs temp - Appendix A,

Ref 2 Test condition is always fulfilled. 0ms 1 DTC

System Voltage Battery Voltage P1793 Power Supply too low Battery voltage ugt_Batt < ugtu_Batt or

ugtu_BattDef< 7V

< 7VEngine speed >

Turbine speed >

Transmission position

Mechanical limp home active1400rpm

1400rpm

Park or Neutral

False30ms

2 DTC

Mechatronic Unit Shift Solenoid P0771Solenoid / Valve stuck Stuck off Solenoid 1 or 2 timer_MV12mechdef <=

KL_TUEBCGMV12MECHDEF and

(GET_P_SENSOR = 0 or GET_P_SENSOR = 2) 500mspumpendruck_vorhanden

Park sensor = P (GET_P_SENSOR)0->1

0ms2 DTC

System Voltage Pressure regulator and solenoid power supply P0657Pressure regulator supply too low (power

supply cannot be switched on) Sensor voltage too low because power supply

cannot be switched ON. FET off

= trueBattery Voltage > 7v30mS2 DTC

System Voltage Pressure regulator and solenoid power supply P0659Voltage applied without activation of the

controlling FET FET cannot be switched on (Short circuit to battery) Vbatt > udrmv_batt

7v 30mS2 DTC

System Voltage Pressure regulator and solenoid power supply P0658Sensor supply voltage < threshold

or

Voltage drop across FET is too big PR supply voltage too low

u

gt_drmv < udrmv_ksm

or

lugt_batt-ugt_drmvl > ugtd_fet 0.5v

or

1vBattery Voltage > udrmv_batt

7v30mS2 DTC

System Voltage Pressure regulator and solenoid power supply P0657Voltage too low due to reset. PR supply voltage too low ugt_drmv < Ugtu_bat

fgt_Dreset = Ugtu_bat = 2D map (V vs C) Appendix A,

ref 3

TrueFET control OK

Battery Voltage > udrmv_batt

1

7v30mS

2 DTC

TCM Internal TCM Watchdog P0613Error counter does not reach required

value during initialisation Error counter does not reach required value sdi_Ufet=1 or

sdi_Ufet=4 or

sdi_Ufet=5 or

sdi_Ufet=8 Battery Voltage > ugt_UfetIni

TCU in initialisation phase

7v

0ms2 DTC

TCM Internal TCM Watchdog P0613Error counter exceeds limit Error counter exceeds limit Zs_errorCountForUC > 4.4Cyclic (operation): Debug-mode not active 0

0ms2 DTC

TCM Internal TCM Watchdog P0613FET cannot be switched off FET cannot be switched off

(DReset line is high) DReset line is high

(fgtr_Dreset = False)FALSE

Battery Voltage > ugt_UfetIni

TCU in initialisation phase7v

0ms2 DTC

TCM Internal TCM Watchdog P0613FET cannot be switched On FET cannot be switched On

(DReset line is low) Reset Line is low.

(Fgtr_Dreset = True)TRUE

Battery Voltage > ugt_UfetIni

TCU in initialisation phase7v

0ms2 DTC

TCM Internal TCM Watchdog P0613Safety circuit reset line between CG115

and CG120 is active. Safety circuit reset line between CG115 and CG120

is active. Reset line = high

(fgtr_Dreset!=0)!=0

Cyclic (operation): Debug-mode not active 0

0ms2 DTC

TCM Internal TCM Watchdog P0613Watchdog function taking too long. Watchdog function taking too long. tgts_UewFetGes > Threshold300msBattery Voltage > ugt_UfetIni

TCU in initialisation phase7v

0ms2 DTC

TCM Internal TCM Watchdog P0613FET cannot be switched off at

ErrorCountForUC >= 5 FET cannot be switched off at

ErrorCountForUC >= 5 FET cannot be switched off at

ErrorCountForUC >= 55

Battery Voltage > ugt_UfetIni

TCU in initialisation phase7v

0ms2 DTC

TCM Internal TCM Watchdog P0613FET cannot be switched on at

Zsk_ErrorCountForUC<=4 FET cannot be switched on at

Zsk_ErrorCountForUC<=4 FET cannot be switched on at

Zsk_ErrorCountForUC<=44

Battery Voltage > ugt_UfetIni

TCU in initialisation phase7v

0ms2 DTC

TCM Internal TCM Watchdog P0613CPU watchdog error counter threshold

exceeded. (WD to CPU) CPU watchdog error counter threshold exceeded.

(Zsk_ErrorCountForWD>3) CPU watchdog error counter threshold

exceeded.

(Zsk_ErrorCountForWD>3)3

Cyclic (operation): Debug-mode not active 0

0ms2 DTC

Torque Converter Torque Converter P0741Torque converter slip too high Torque converter slip > threshold. KL_NDSKPLDEFEKT25rpmSlip too high timer expired

Closed or Closed Loop Control 10.0s

2 DTC

Pressure Regulators PR1 P0973Pressure regulator 1 short circuit to

ground or o/c. current > threshold

or

current = 0 idr_Mess1 > idr1 + idrs_high

or

idr1=0mAidrs_high = 2D map (Current vs Temp)

0mA

Solenoid Supply > threshold

Engine running

0% or 100% measured current PWMudrso_prf = 2D map (V vs Temp) See

App A, Ref 1

30mS

2 DTC

Pressure Regulators PR1 P0972Pressure regulator 1 current too high current > threshold idr_Mess1 > idr1 + idrs_highidrs_high = 2D map (Current vs Temp) Solenoid Supply > threshold

Measured control PWM not = 0 or 100%udrso_prf = 2D map (V vs Temp) See

App A, Ref 130mS

2 DTC

Pressure Regulators PR1 P0974Pressure regulator 1 short to battery current < threshold idr_Mess1 < idr1 + idrs_lowidrs_low = 2D map (Current vs Temp) Solenoid Supply > threshold

Engine not running

Measured control signal PWM = 0%udrso_prf = 2D map (V vs Temp) See

App A, Ref 1

30mS

2 DTC

Pressure Regulators PR2 P0976Pressure regulator 2 short circuit to

ground or o/c. current > threshold

or

current = 0 idr_Mess2 > idr2 + idrs_high

or

idr1=0mAidrs_high = 2D map (Current vs Temp)

0mA

Solenoid Supply > threshold

Engine running

0% or 100% measured current PWMudrso_prf = 2D map (V vs Temp) See

App A, Ref 1

50mS

2 DTC

Pressure Regulators PR2 P0975Pressure regulator 2 current too low current < threshold idr_Mess2 < idr2 + idrs_lowidrs_low = 2D map (Current vs Temp) Solenoid Supply > threshold

Meassured control PWM not = 0 or 100%udrso_prf = 2D map (V vs Temp) See

App A, Ref 150mS

2 DTC

Pressure Regulators PR2 P0977Pressure regulator 2 short to battery current < threshold idr_Mess2 < idr2 + idrs_lowidrs_low = 2D map (Current vs Temp) Solenoid Supply > threshold

Engine not running

Measured control signal PWM = 0%udrso_prf = 2D map (V vs Temp) See

App A, Ref 1

50mS

2 DTC

Pressure Regulators PR3 P0979Pressure regulator 3 short circuit to

ground or o/c. current > threshold

or

current = 0 idr_Mess3 > idr3 + idrs_high

or

idr1=0mAidrs_high = 2D map (Current vs Temp)

0mA

Solenoid Supply > threshold

Engine running

0% or 100% measured current PWMudrso_prf = 2D map (V vs Temp) See

App A, Ref 1

50mS

2 DTC

Pressure Regulators PR3 P0978Pressure regulator 3 current too high current > threshold idr_Mess3 > idr3 + idrs_highidrs_high = 2D map (Current vs Temp) Solenoid Supply > threshold

Measured control PWM not = 0 or 100%udrso_prf = 2D map (V vs Temp) See

App A, Ref 150mS

2 DTC

Pressure Regulators PR3 P0980Pressure regulator 3 short to battery current < threshold idr_Mess3 < idr3 + idrs_lowidrs_low = 2D map (Current vs Temp) Solenoid Supply > threshold

Engine not running

Measured control signal PWM = 0%udrso_prf = 2D map (V vs Temp) See

App A, Ref 1

50mS

2 DTC

Pressure Regulators PR4 P0982Pressure regulator 4 short circuit to

ground or o/c. current > threshold

or

current = 0 idr_Mess4 > idr4 + idrs_high

or

idr1=0mAidrs_high = 2D map (Current vs Temp)

0mA

Solenoid Supply > threshold

Engine running

0% or 100% measured current PWMudrso_prf = 2D map (V vs Temp) See

App A, Ref 1

50mS

2 DTC

8ASXV05.9VH1 Aston Martin

Auto Gearbox Summary Jan 2008