power steering ASTON MARTIN V8 VANTAGE 2010 Owner's Guide

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 751 of 947

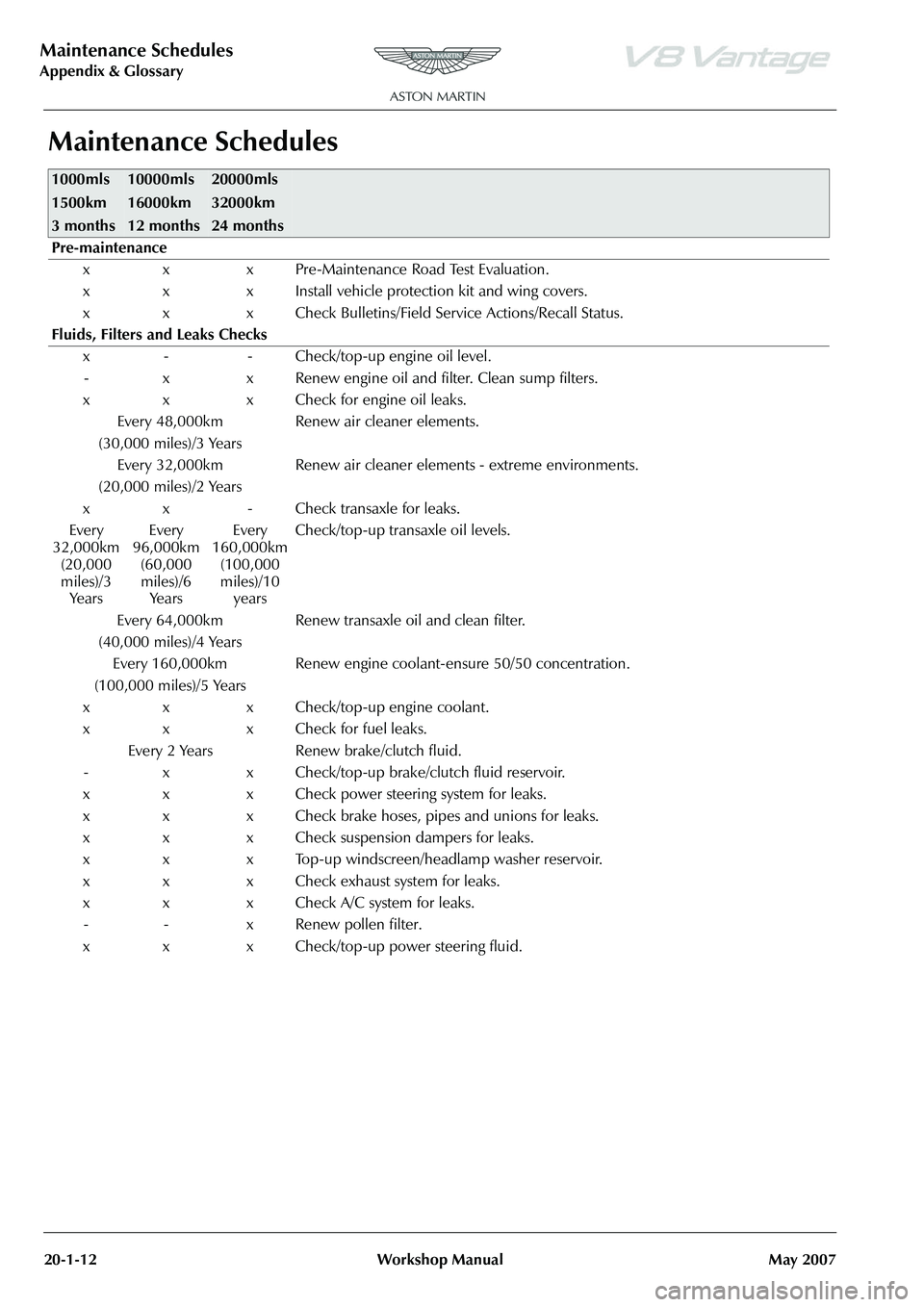

Maintenance Schedules

Appendix & Glossary20-1-12 Workshop Manual May 2007

Maintenance Schedules

1000mls

1500km

3 months10000mls

16000km

12 months20000mls

32000km

24 months

Pre-maintenance

x x x Pre-Maintenance Road Test Evaluation.

x x x Install vehicle protection kit and wing covers.

x x x Check Bulletins/Field Service Actions/Recall Status.

Fluids, Filters and Leaks Checks x - - Check/top-up engine oil level.- x x Renew engine oil and filter. Clean sump filters.

x x x Check for engine oil leaks. Every 48,000km

(30,000 miles)/3 Years Renew air cleaner elements.

Every 32,000km

(20,000 miles)/2 Years Renew air cleaner elements - extreme environments.

x x - Check transaxle for leaks.

Every

32,000km (20,000

miles)/3 Ye a r s Every

96,000km (60,000

miles)/6 Ye a r s Every

160,000km (100,000

miles)/10 years Check/top-up transaxle oil levels.

Every 64,000km

(40,000 miles)/4 Years Renew transaxle oil and clean filter.

Every 160,000km

(100,000 miles)/5 Years Renew engine coolant-ensure 50/50 concentration.

x x x Check/top-up engine coolant.

x x x Check for fuel leaks. Every 2 Years Renew brake/clutch fluid.

- x x Check/top-up brake/clutch fluid reservoir.

x x x Check power steering system for leaks.

x x x Check brake hoses, pipes and unions for leaks.

x x x Check suspension dampers for leaks.

x x x Top-up windscreen/headlamp washer reservoir.

x x x Check exhaust system for leaks.

x x x Check A/C system for leaks. - - x Renew pollen filter.

x x x Check/top-up power steering fluid.

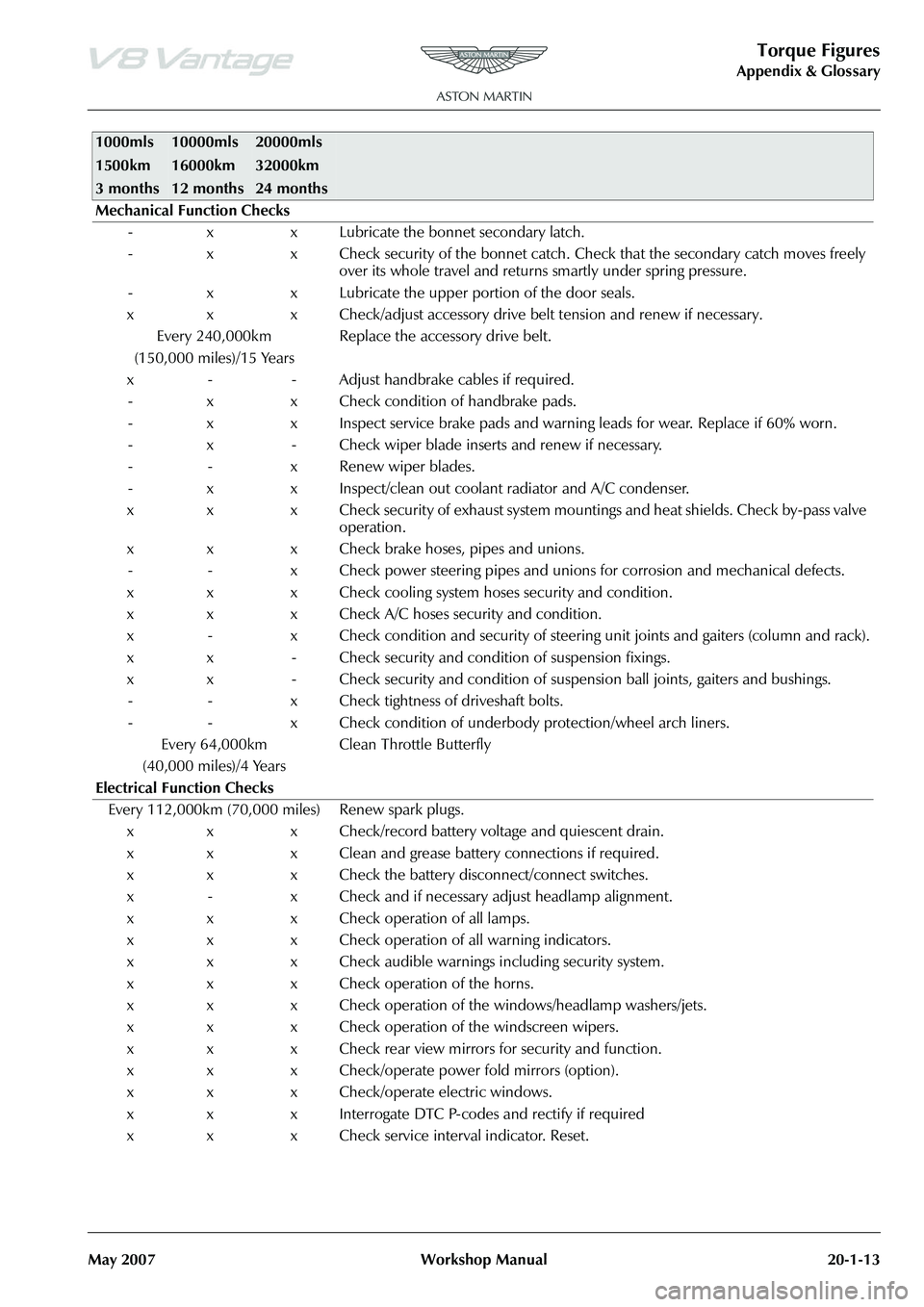

Page 752 of 947

Torque Figures

Appendix & Glossary

May 2007 Workshop Manual 20-1-13

Mechanical Function Checks - x x Lubricate the bonnet secondary latch.

- x x Check security of the bonnet catch. Ch eck that the secondary catch moves freely

over its whole travel and returns smartly under spring pressure.

- x x Lubricate the upper portion of the door seals.

x x x Check/adjust accessory drive belt tension and renew if necessary. Every 240,000km

(150,000 miles)/15 Years Replace the accessory drive belt.

x - - Adjust handbrake cables if required. - x x Check condition of handbrake pads.

- x x Inspect service brake pads and warnin g leads for wear. Replace if 60% worn.

- x - Check wiper blade inserts and renew if necessary.

- - x Renew wiper blades.

- x x Inspect/clean out coolant radiator and A/C condenser.

x x x Check security of exhaust system mountings and heat shields. Check by-pass valve operation.

x x x Check brake hoses, pipes and unions. - - x Check power steering pipes and unions for corrosion and mechanical defects.

x x x Check cooling system hoses security and condition.

x x x Check A/C hoses security and condition.

x - x Check condition and security of steering unit joints and gaiters (column and rack).

x x - Check security and condition of suspension fixings.

x x - Check security and condition of susp ension ball joints, gaiters and bushings.

- - x Check tightness of driveshaft bolts.

- - x Check condition of underbody protection/wheel arch liners.

Every 64,000km

(40,000 miles)/4 Years Clean Throttle Butterfly

Electrical Function Checks Every 112,000km (70,000 miles) Renew spark plugs. x x x Check/record battery voltage and quiescent drain.

x x x Clean and grease battery connections if required.

x x x Check the battery disconnect/connect switches.

x - x Check and if necessary adjust headlamp alignment.

x x x Check operation of all lamps.

x x x Check operation of all warning indicators.

x x x Check audible warnings including security system.

x x x Check operation of the horns.

x x x Check operation of the windows/headlamp washers/jets.

x x x Check operation of the windscreen wipers.

x x x Check rear view mirrors for security and function.

x x x Check/operate power fold mirrors (option).

x x x Check/operate electric windows.

x x x Interrogate DTC P-codes and rectify if required

x x x Check service interval indicator. Reset.

1000mls

1500km

3 months10000mls

16000km

12 months20000mls

32000km

24 months

Page 791 of 947

Squeaks and Rattles Repair Manual

July 2010 Page 7 of 21

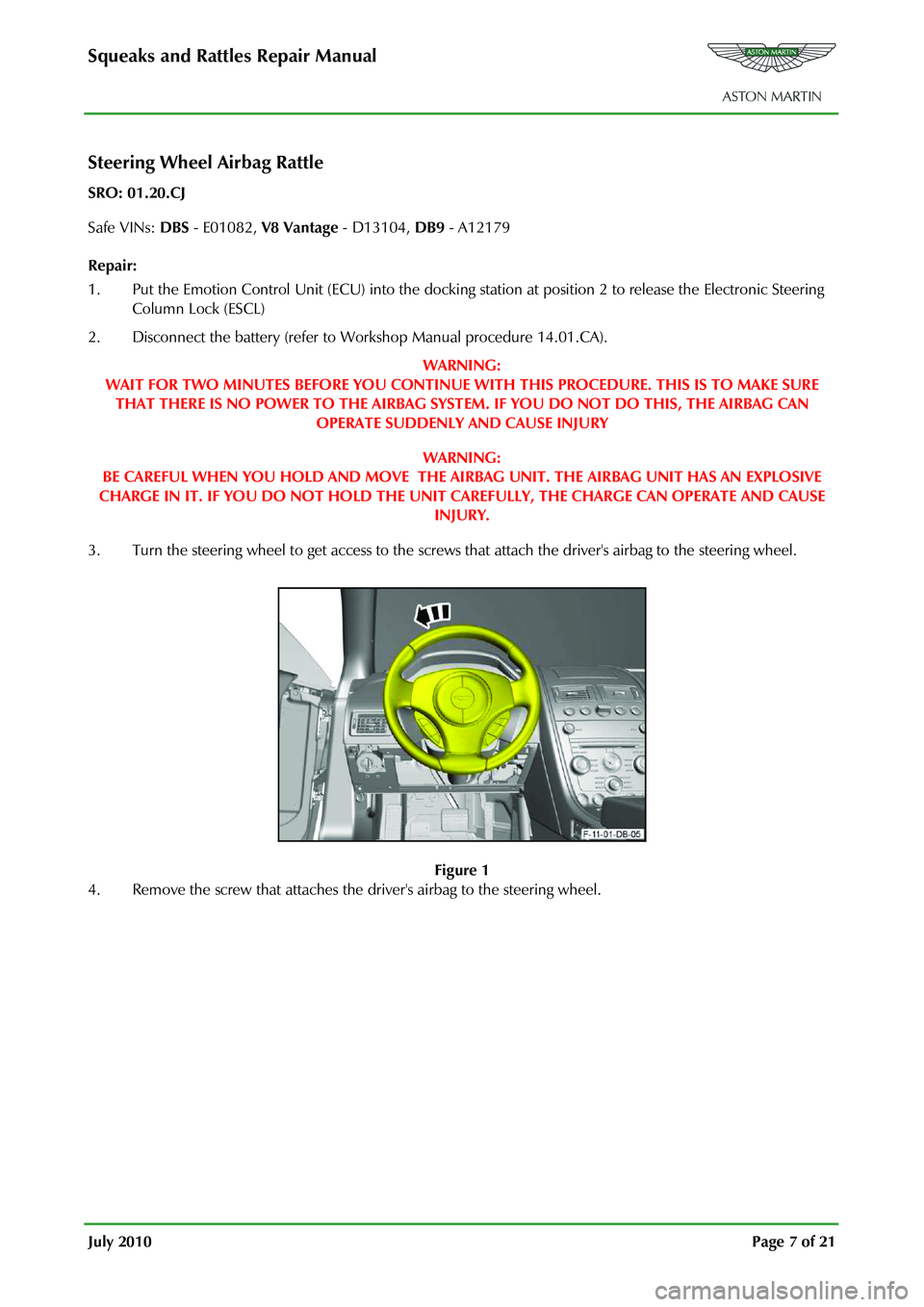

Steering Wheel Airbag Rattle

SRO: 01.20.CJ

Safe VINs: DBS - E01082, V8 Vantage - D13104, DB9 - A12179

Repair:

1. Put the Emotion Control Unit (ECU) into the docking station at position 2 to release the Electronic Steering

Column Lock (ESCL)

2. Disconnect the battery (refer to Workshop Manual procedure 14.01.CA).

WARNING:

WAIT FOR TWO MINUTES BEFORE YO U CONTINUE WITH THIS PROCEDURE. THIS IS TO MAKE SURE

THAT THERE IS NO POWER TO TH E AIRBAG SYSTEM. IF YOU DO NOT DO THIS, THE AIRBAG CAN

OPERATE SUDDENLY AND CAUSE INJURY

WARNING:

BE CAREFUL WHEN YOU HOLD AND MOVE THE AIRB AG UNIT. THE AIRBAG UNIT HAS AN EXPLOSIVE

CHARGE IN IT. IF YOU DO NOT HOLD THE UNIT CAREFULLY, THE CHARGE CAN OPERATE AND CAUSE

INJURY.

3. Turn the steering wheel to get access to the screws that attach the driver's airbag to the steering wheel.

Figure 1

4. Remove the screw that attaches the driver's airbag to the steering wheel.

Page 816 of 947

Electronics Training Programme

SYSTEM LAYOUT

V8 Vantage Layout

Bluetooth enabled and

paired phone

Bluetooth receiver module

Amplifier module

LED Indicator (Bluetooth display module)

Front speaker Switcher box

Microphone Steering column control

switches

Power Supply

Door speaker (drivers side) Door speaker

(passenger side)

11

Page 818 of 947

Electronics Training Programme

DB9 Layout

Bluetooth enabled and

paired phone

Bluetooth receiver module

Microphone

Amplifier module

Power Supply

Steering column control switches

LED Indicator (Bluetooth display module)

Door speaker (drivers side) Door speaker

(passenger side)

13

Page 820 of 947

Electronics Training Programme

INPUTS

The Bluetooth system relies on a number of signals it receives either from the car (via hard wiring) or

the users phone (via wireless Bluetooth communication network).

The Bluetooth system will only function if the us ers mobile phone has Bluetooth enabled and it is

‘paired’ to the car. For more information refer to the user’s guide for your mobile phone.

V8 Vantage Power Supplies

Description Supplied From Source Protection

Wakeup signal Central Electronic Module Comfort Relay F68 (5 Amp)

Power supply 1 Central Electronic Module Interior Lights Relay F46 (5Amp)

Power supply 2 Central Electronic Module Interior Lights Relay F46 (5Amp)

DB9 Power Supplies

Description Supplied From Source Protection

Wakeup signal Central Electronic Module Comfort Relay F69 (5 Amp)

Power supply 1 Central Electronic Module Interior Lights Relay F46 (5Amp)

Power supply 2 Central Electronic Module Interior Lights Relay F46 (5Amp)

V8 Vantage Signal Inputs

Input Description Signal Characteristic

MIC In Input signal from microphone Varying current signal direct from microphone

Keypad Steering wheel controls input Variable resistance to earth signal

DB9 Signal Inputs

Input Description Signal Characteristic

MIC In + Input signal from microphone Varying current signal supplied via amplifier

MIC In - Input signal from microphone Varying current signal supplied via amplifier

Keypad Steering wheel controls inpu t Variable resistance to earth

Screens

Some of the signals in and out of the Bluetooth modu le require screening to avoid interference being

picked up. A signal screen is a single wire running along side t he signal wire(s) which will absorb

electro magnetic interference (EMI).

The Bluetooth module on the V8 Vantage features only one screen so as to protect the signal from the

microphone. This screen wire is simply an earth but it is also used as a datum from which to reference

the microphone signal.

The Bluetooth module used on DB9’s features two screens. One is as on the V8 Vantage but is used

only as a screen (because the microphone signal from the amplifie r has two signal wires) and no

datum is required. The second screen on the module is used to screen the ‘Lineout’ signals to the

amplifier. As with the microphone scr een this wire is connected to earth.

15

Page 836 of 947

Electronics Training Programme

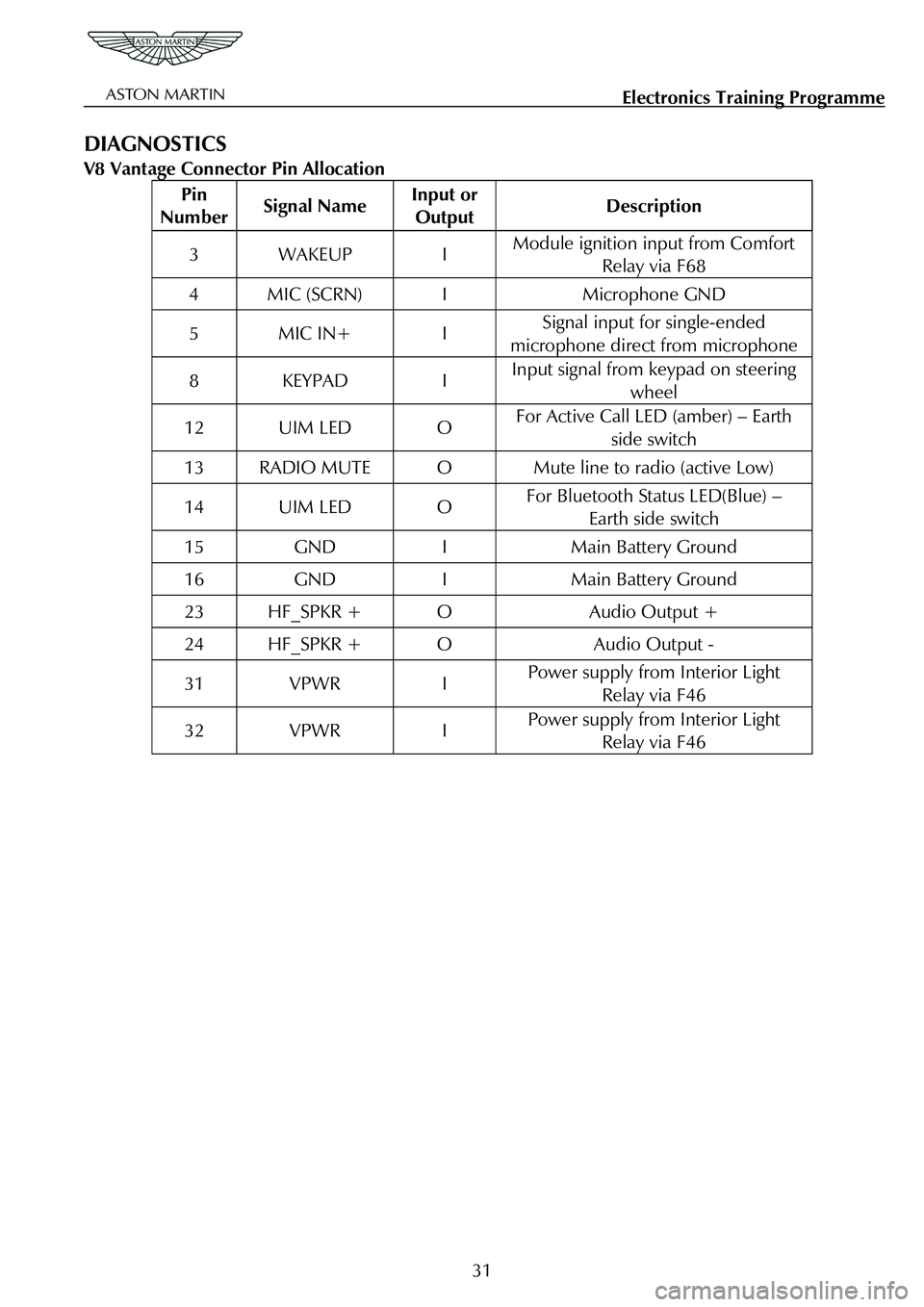

DIAGNOSTICS

V8 Vantage Connector Pin Allocation

Pin

Number Signal Name Input or

Output Description

3 WAKEUP I Module ignition input from Comfort

Relay via F68

4 MIC (SCRN) I Microphone GND

5 MIC IN+ I Signal input for single-ended

microphone direct from microphone

8 KEYPAD I Input signal from keypad on steering wheel

12 UIM LED O For Active Call LED (amber) – Earth

side switch

13 RADIO MUTE O Mute line to radio (active Low)

14 UIM LED O For Bluetooth Status LED(Blue) – Earth side switch

15 GND I Main Battery Ground

16 GND I Main Battery Ground

23 HF_SPKR + O Audio Output +

24 HF_SPKR + O Audio Output -

31 VPWR I Power supply from Interior Light Relay via F46

32 VPWR I Power supply from Interior Light Relay via F46

31

Page 837 of 947

Electronics Training Programme

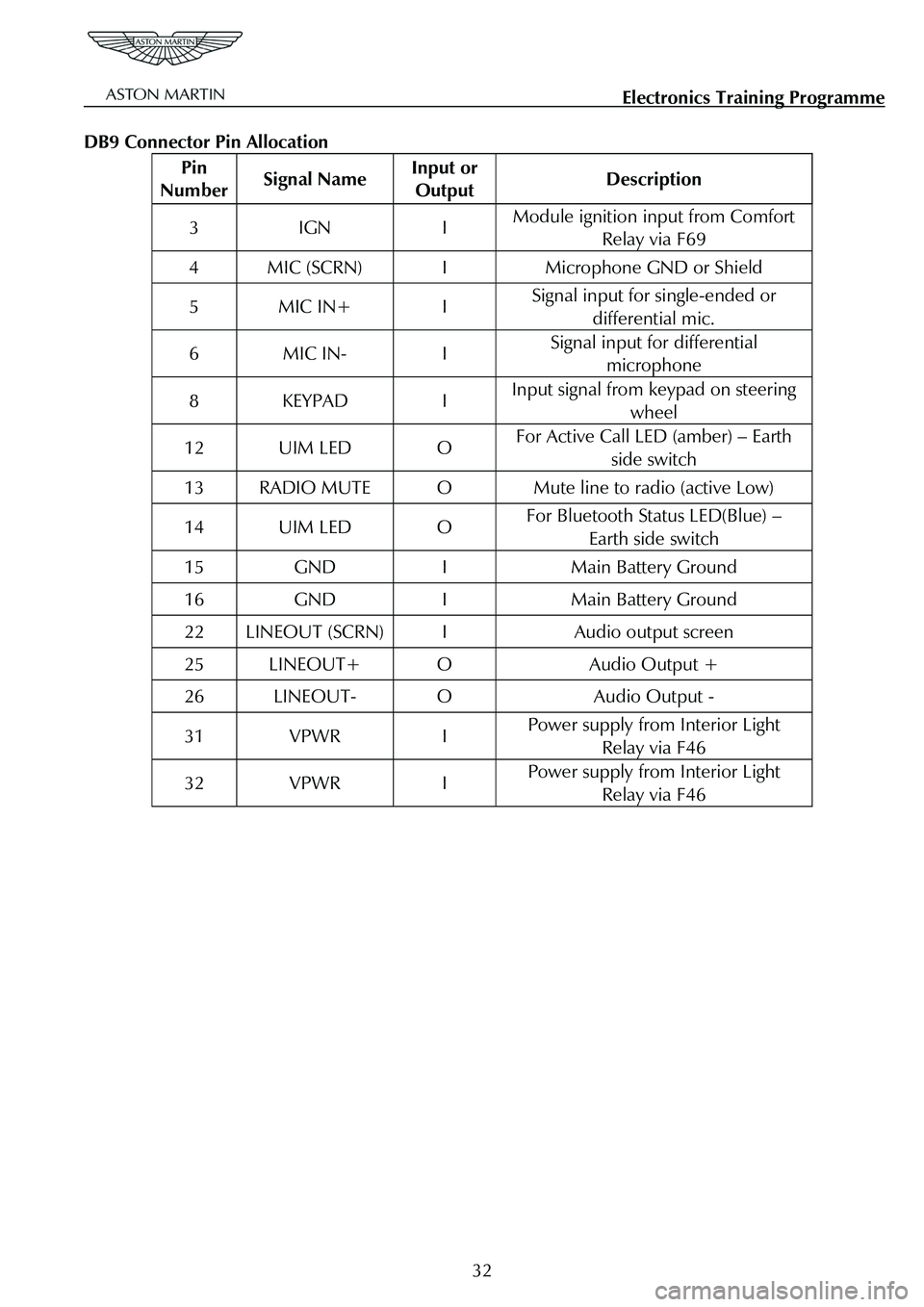

DB9 Connector Pin Allocation

Pin

Number Signal Name Input or

Output Description

3 IGN I Module ignition input from Comfort

Relay via F69

4 MIC (SCRN) I Microphone GND or Shield

5 MIC IN+ I Signal input for single-ended or

differential mic.

6 MIC IN- I Signal input for differential microphone

8 KEYPAD I Input signal from keypad on steering

wheel

12 UIM LED O For Active Call LED (amber) – Earth side switch

13 RADIO MUTE O Mute line to radio (active Low)

14 UIM LED O For Bluetooth Status LED(Blue) – Earth side switch

15 GND I Main Battery Ground

16 GND I Main Battery Ground

22 LINEOUT (SCRN) I Audio output screen

25 LINEOUT+ O Audio Output +

26 LINEOUT- O Audio Output -

31 VPWR I Power supply from Interior Light Relay via F46

32 VPWR I Power supply from Interior Light Relay via F46

32

Page 854 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 8 of 43

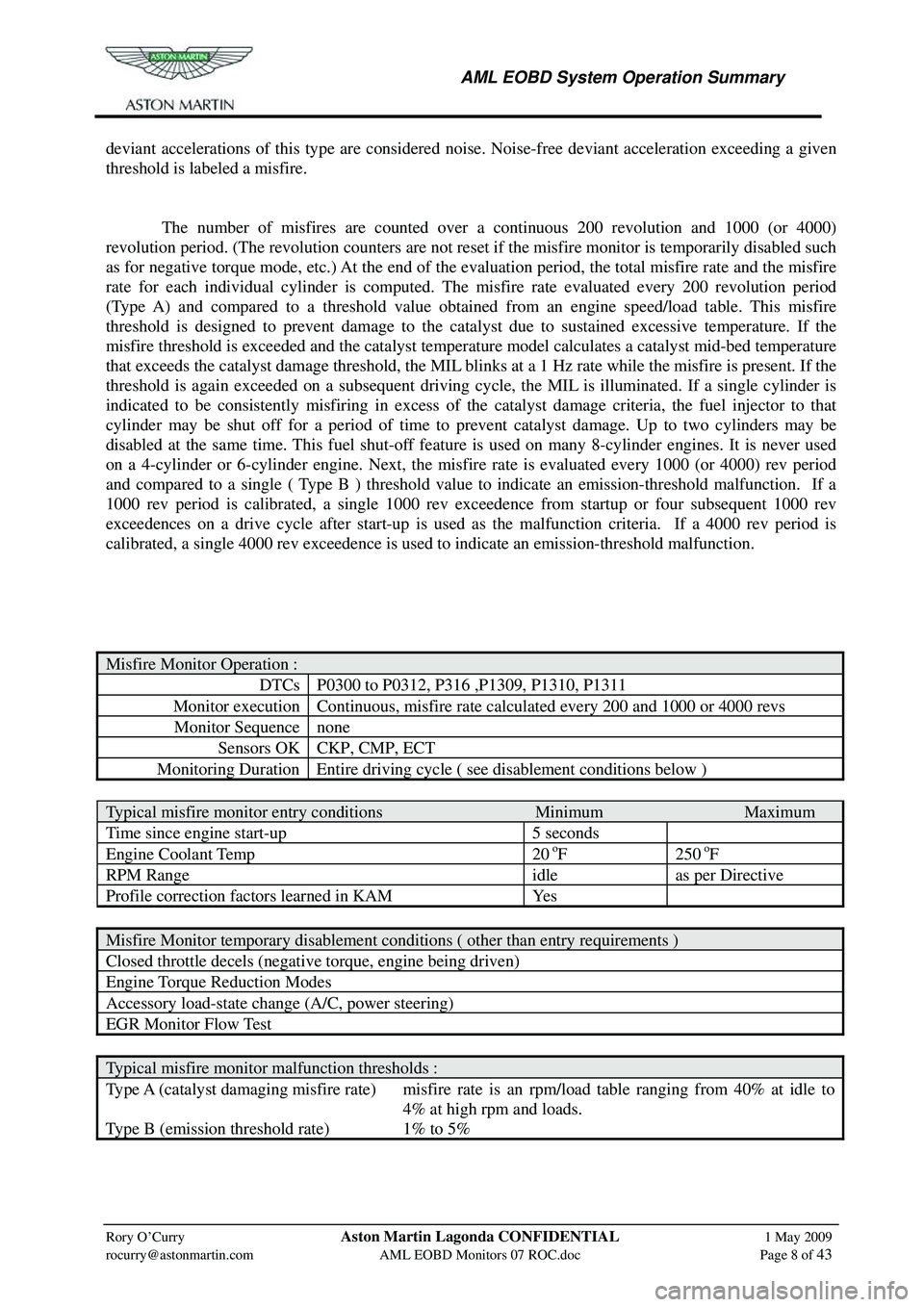

deviant accelerations of this type are considered noise. Noise-free deviant acceleration exceeding a given

threshold is labeled a misfire.

The number of misfires are counted over a continuous 200 revolution and 1000 (or 4000)

revolution period. (The revolution counters are not reset if the misfire monitor is temporarily disabled such

as for negative torque mode, etc.) At the end of the evaluation period, the total misfire rate and the misfire

rate for each individual cylinder is computed. The misfire rate evaluated every 200 revolution period

(Type A) and compared to a threshold value obtaine d from an engine speed/load table. This misfire

threshold is designed to prevent damage to the cat alyst due to sustained excessive temperature. If the

misfire threshold is exceeded and the catalyst temperature model calculates a catalyst mid-bed temperature

that exceeds the catalyst damage threshold, the MIL blinks at a 1 Hz rate while the misfire is present. If the

threshold is again exceeded on a subsequent driving cy cle, the MIL is illuminated. If a single cylinder is

indicated to be consistently misfiring in excess of the catalyst damage criteria, the fuel injector to that

cylinder may be shut off for a period of time to pr event catalyst damage. Up to two cylinders may be

disabled at the same time. This fuel shut-off feature is used on many 8-cylinder engines. It is never used

on a 4-cylinder or 6-cylinder engine. Next, the misf ire rate is evaluated every 1000 (or 4000) rev period

and compared to a single ( Type B ) threshold value to indicate an emission-threshold malfunction. If a

1000 rev period is calibrated, a single 1000 rev exceedence from startup or four subsequent 1000 rev

exceedences on a drive cycle after start-up is used as the malfunction criteria. If a 4000 rev period is

calibrated, a single 4000 rev exceedence is used to indicate an emission-threshold malfunction.

Misfire Monitor Operation :

DTCs P0300 to P0312, P316 ,P1309, P1310, P1311

Monitor execution Continuous, misfire rate calculated every 200 and 1000 or 4000 revs

Monitor Sequence none

Sensors OK CKP, CMP, ECT

Monitoring Duration Entire driving cycle ( see disablement conditions below )

Typical misfire monitor entry conditions Minimum Maximum

Time since engine start-up 5 seconds

Engine Coolant Temp 20 oF 250 oF

RPM Range idle as per Directive

Profile correction factors learned in KAM Yes

Misfire Monitor temporary disablement conditions ( other than entry requirements )

Closed throttle decels (negative torque, engine being driven)

Engine Torque Reduction Modes

Accessory load-state change (A/C, power steering)

EGR Monitor Flow Test

Typical misfire monitor malfunction thresholds :

Type A (catalyst damaging misfire rate) misfire rate is an rpm/load table ranging from 40% at idle to

4% at high rpm and loads.

Type B (emission threshold rate) 1% to 5%