ignition ASTON MARTIN V8 VANTAGE 2010 Repair Manual

[x] Cancel search | Manufacturer: ASTON MARTIN, Model Year: 2010, Model line: V8 VANTAGE, Model: ASTON MARTIN V8 VANTAGE 2010Pages: 947, PDF Size: 43.21 MB

Page 837 of 947

Electronics Training Programme

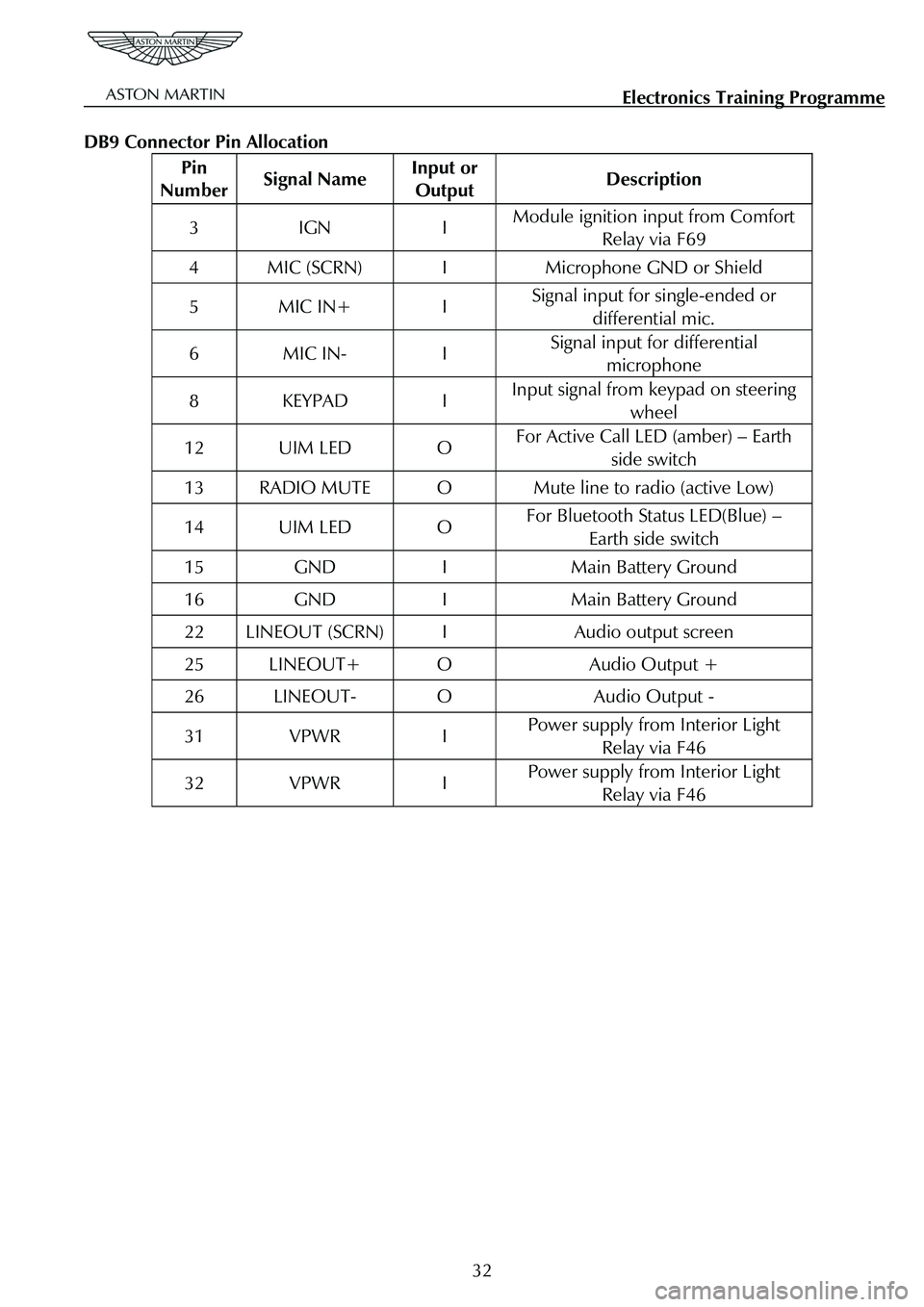

DB9 Connector Pin Allocation

Pin

Number Signal Name Input or

Output Description

3 IGN I Module ignition input from Comfort

Relay via F69

4 MIC (SCRN) I Microphone GND or Shield

5 MIC IN+ I Signal input for single-ended or

differential mic.

6 MIC IN- I Signal input for differential microphone

8 KEYPAD I Input signal from keypad on steering

wheel

12 UIM LED O For Active Call LED (amber) – Earth side switch

13 RADIO MUTE O Mute line to radio (active Low)

14 UIM LED O For Bluetooth Status LED(Blue) – Earth side switch

15 GND I Main Battery Ground

16 GND I Main Battery Ground

22 LINEOUT (SCRN) I Audio output screen

25 LINEOUT+ O Audio Output +

26 LINEOUT- O Audio Output -

31 VPWR I Power supply from Interior Light Relay via F46

32 VPWR I Power supply from Interior Light Relay via F46

32

Page 851 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 5 of 43

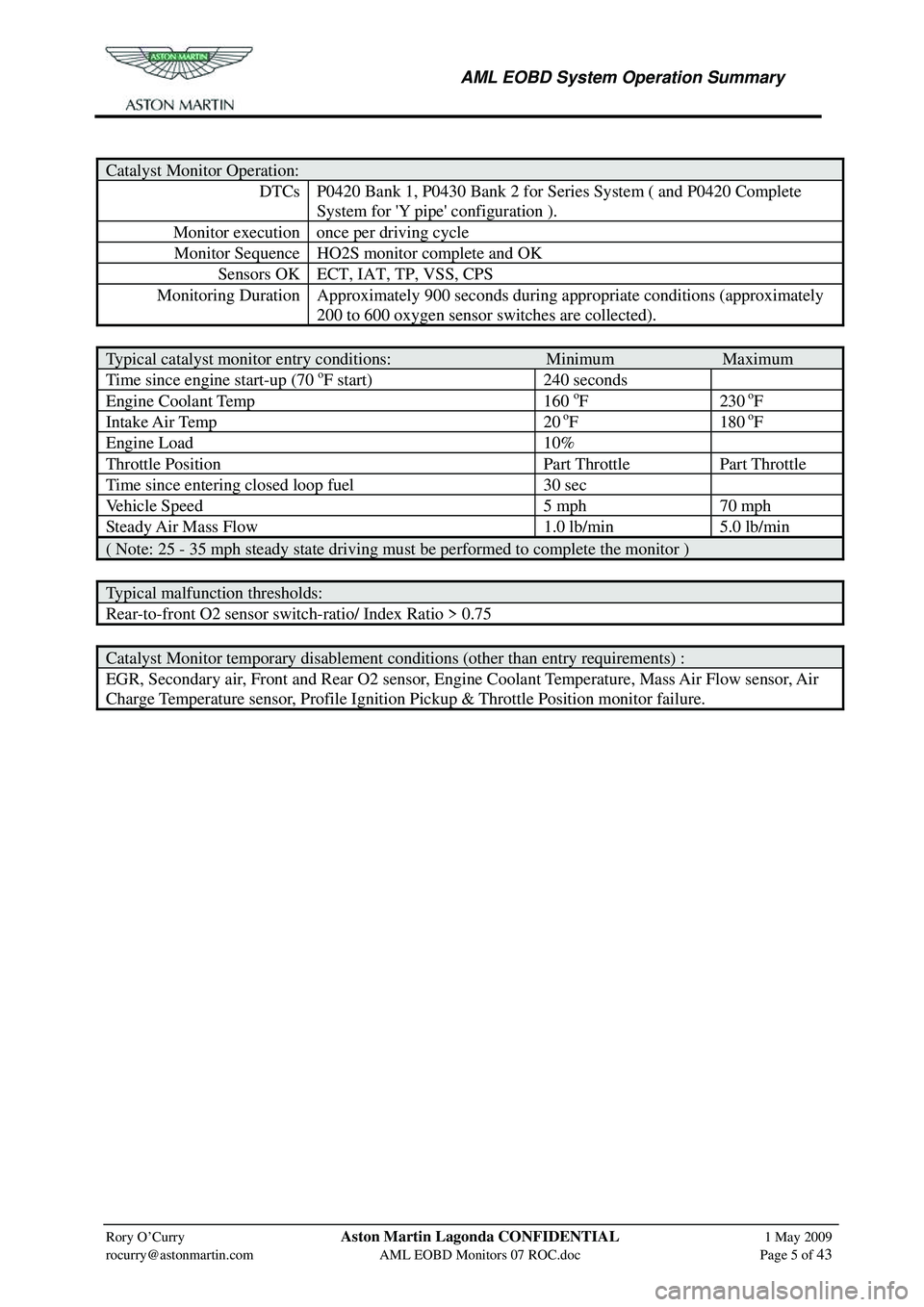

Catalyst Monitor Operation:

DTCs P0420 Bank 1, P0430 Bank 2 for Series System ( and P0420 Complete

System for 'Y pipe' configuration ).

Monitor execution once per driving cycle

Monitor Sequence HO2S monitor complete and OK

Sensors OK ECT, IAT, TP, VSS, CPS

Monitoring Duration Approximately 900 seconds dur ing appropriate conditions (approximately

200 to 600 oxygen sensor switches are collected).

Typical catalyst monitor entry conditions: Minimum Maximum

Time since engine start-up (70 oF start) 240 seconds

Engine Coolant Temp 160 oF 230 oF

Intake Air Temp 20 oF 180 oF

Engine Load 10%

Throttle Position Part Throttle Part Throttle

Time since entering closed loop fuel 30 sec

Vehicle Speed 5 mph 70 mph

Steady Air Mass Flow 1.0 lb/min 5.0 lb/min

( Note: 25 - 35 mph steady state driving must be performed to complete the monitor )

Typical malfunction thresholds:

Rear-to-front O2 sensor switch-ratio/ Index Ratio > 0.75

Catalyst Monitor temporary disablement conditions (other than entry requirements) :

EGR, Secondary air, Front and Rear O2 sensor, Engine Coolant Temperature, Mass Air Flow sensor, Air

Charge Temperature sensor, Profile Ignition Pickup & Throttle Position monitor failure.

Page 871 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 25 of 43

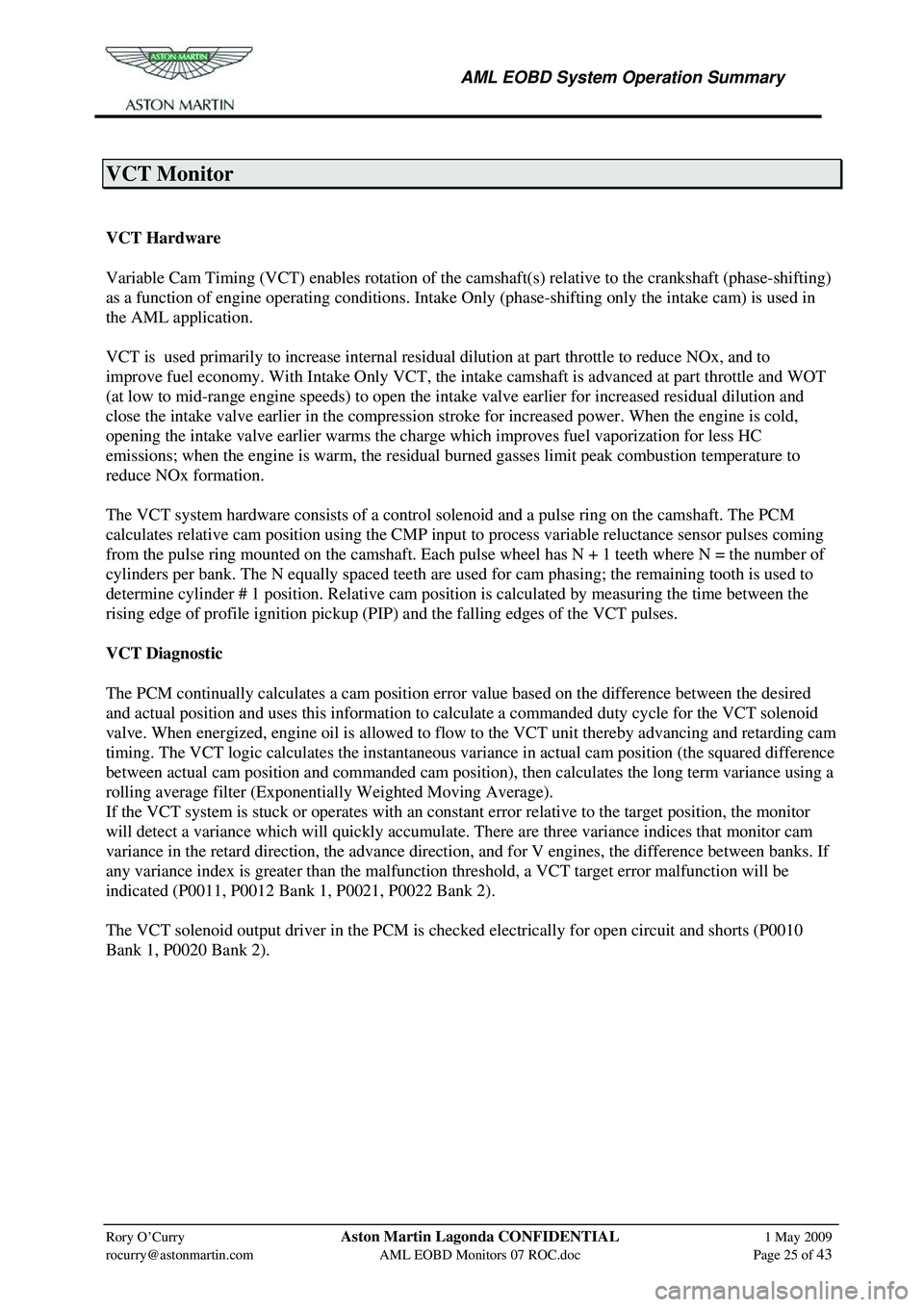

VCT Monitor

Variable Cam Timing System Monitor

VCT Hardware

Variable Cam Timing (VCT) enables rotation of the camshaft(s) relative to the crankshaft (phase-shifting)

as a function of engine operating conditions. Intake Only (phase-shifting only the intake cam) is used in

the AML application.

VCT is used primarily to increase internal residua l dilution at part throttle to reduce NOx, and to

improve fuel economy. With Intake Only VCT, the in take camshaft is advanced at part throttle and WOT

(at low to mid-range engine speeds) to open the in take valve earlier for increased residual dilution and

close the intake valve earlier in the compression stroke for increased power. When the engine is cold,

opening the intake valve earlier warms the charge which improves fuel vaporization for less HC

emissions; when the engine is warm, the residua l burned gasses limit peak combustion temperature to

reduce NOx formation.

The VCT system hardware consists of a contro l solenoid and a pulse ring on the camshaft. The PCM

calculates relative cam position using the CMP input to process variable reluctance sensor pulses coming

from the pulse ring mounted on the camshaft. Each pul se wheel has N + 1 teeth where N = the number of

cylinders per bank. The N equally spaced teeth are used for cam phasing; the remaining tooth is used to

determine cylinder # 1 position. Relative cam position is calculated by measuring the time between the

rising edge of profile ignition pickup (PIP ) and the falling edges of the VCT pulses.

VCT Diagnostic

The PCM continually calculates a cam position error value based on the difference between the desired

and actual position and uses this information to cal culate a commanded duty cycle for the VCT solenoid

valve. When energized, engine oil is allowed to flow to the VCT unit thereby advancing and retarding cam

timing. The VCT logic calculates the instantaneous va riance in actual cam position (the squared difference

between actual cam position and commanded cam position), then calculates the long term variance using a

rolling average filter (Exponentially Weighted Moving Average).

If the VCT system is stuck or operates with an consta nt error relative to the target position, the monitor

will detect a variance which will quickly accumulate. There are three variance indices that monitor cam

variance in the retard direction, the advance directi on, and for V engines, the difference between banks. If

any variance index is greater than the malfunction threshold, a VCT target error malfunction will be

indicated (P0011, P0012 Bank 1, P0021, P0022 Bank 2).

The VCT solenoid output driver in the PCM is check ed electrically for open circuit and shorts (P0010

Bank 1, P0020 Bank 2).

VCT Monitor Operation:

Page 873 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 27 of 43

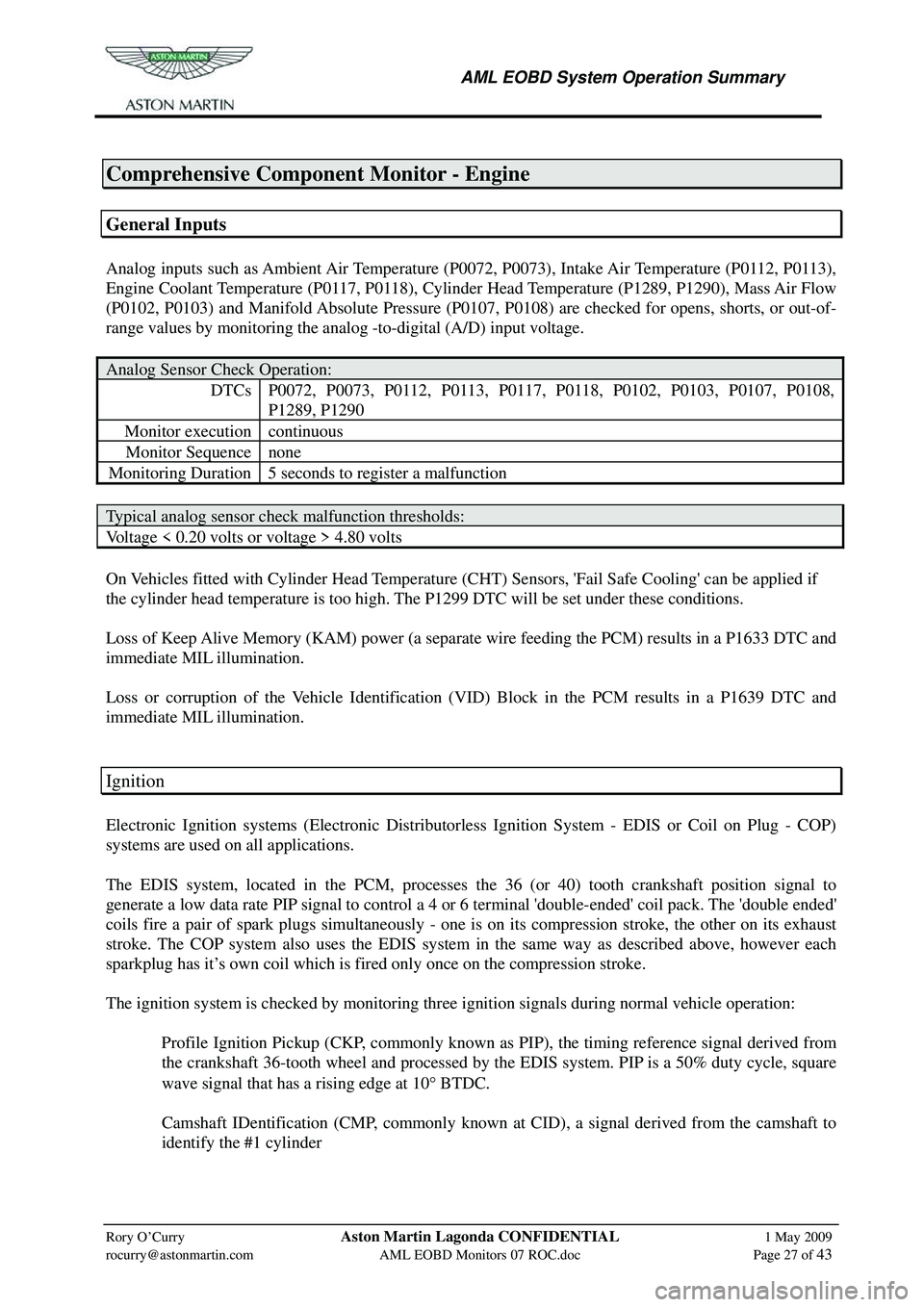

Comprehensive Component Monitor - Engine

General Inputs

Analog inputs such as Ambient Air Temperature (P0072, P0073), Intake Air Temperature (P0112, P0113),

Engine Coolant Temperature (P0117, P0118), Cylinder Head Temperature (P1289, P1290), Mass Air Flow

(P0102, P0103) and Manifold Absolute Pressure (P0107, P0108) are checked for opens, shorts, or out-of-

range values by monitoring the analog -to-digital (A/D) input voltage.

Analog Sensor Check Operation:

DTCs P0072, P0073, P0112, P0113, P0117, P0118, P0102, P0103, P0107, P0108,

P1289, P1290

Monitor execution continuous

Monitor Sequence none

Monitoring Duration 5 seconds to register a malfunction

Typical analog sensor check malfunction thresholds:

Voltage < 0.20 volts or voltage > 4.80 volts

On Vehicles fitted with Cylinder Head Temperature (CHT ) Sensors, 'Fail Safe Cooling' can be applied if

the cylinder head temperature is too high. The P1299 DTC will be set under these conditions.

Loss of Keep Alive Memory (KAM) power (a separate wire feeding the PCM) results in a P1633 DTC and

immediate MIL illumination.

Loss or corruption of the Vehicle Identification (VID) Block in the PCM results in a P1639 DTC and

immediate MIL illumination.

Ignition

Electronic Ignition systems (Electronic Distributorless Ignition System - EDIS or Coil on Plug - COP)

systems are used on all applications.

The EDIS system, located in the PCM, processes the 36 (or 40) tooth crankshaft position signal to

generate a low data rate PIP signal to control a 4 or 6 terminal 'double-ended' coil pack. The 'double ended'

coils fire a pair of spark plugs simultaneously - one is on its compression stroke, the other on its exhaust

stroke. The COP system also uses the EDIS system in the same way as described above, however each

sparkplug has it’s own coil which is fired only once on the compression stroke.

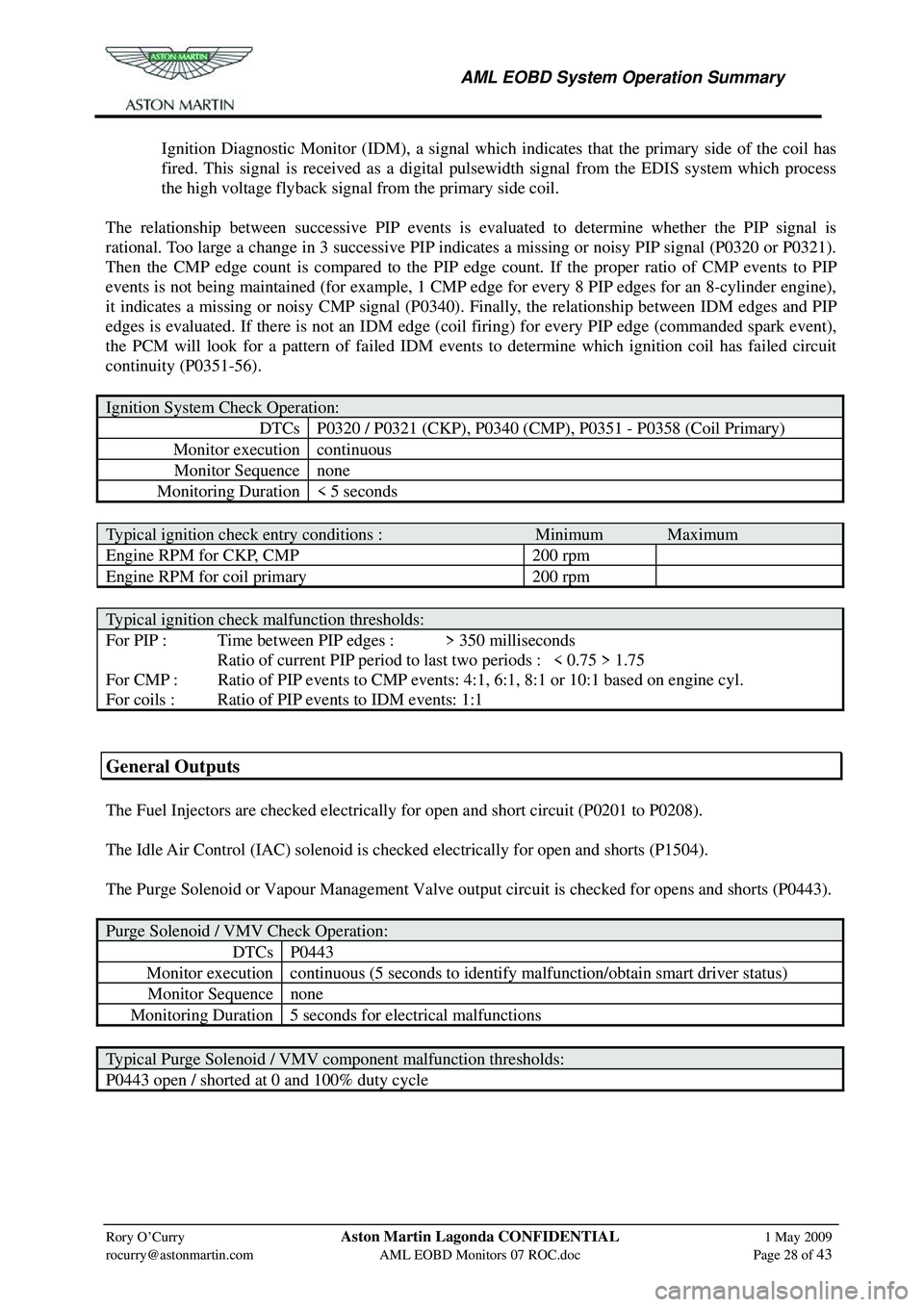

The ignition system is checked by monitoring three ignition signals during normal vehicle operation:

Profile Ignition Pickup (CKP, commonly known as PIP), the timing reference signal derived from the crankshaft 36-tooth wheel and processed by the EDIS system. PIP is a 50% duty cycle, square

wave signal that has a rising edge at 10 ° BTDC.

Camshaft IDentification (CMP, commonly known at CID), a signal derived from the camshaft to identify the #1 cylinder

Page 874 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 28 of 43

Ignition Diagnostic Monitor (IDM), a signal which indicates that the primary side of the coil has

fired. This signal is received as a digital pulsewidth signal from the EDIS system which process

the high voltage flyback signal from the primary side coil.

The relationship between successive PIP events is ev aluated to determine whether the PIP signal is

rational. Too large a change in 3 successive PIP indicates a missing or noisy PIP signal (P0320 or P0321).

Then the CMP edge count is compared to the PIP e dge count. If the proper ratio of CMP events to PIP

events is not being maintained (for example, 1 CMP e dge for every 8 PIP edges for an 8-cylinder engine),

it indicates a missing or noisy CMP signal (P0340). Finally, the relationship between IDM edges and PIP

edges is evaluated. If there is not an IDM edge (co il firing) for every PIP edge (commanded spark event),

the PCM will look for a pattern of failed IDM events to determine which ignition coil has failed circuit

continuity (P0351-56).

Ignition System Check Operation:

DTCs P0320 / P0321 (CKP), P0340 (CMP), P0351 - P0358 (Coil Primary)

Monitor execution continuous

Monitor Sequence none

Monitoring Duration < 5 seconds

Typical ignition check entry conditions : Minimum Maximum

Engine RPM for CKP, CMP 200 rpm

Engine RPM for coil primary 200 rpm

Typical ignition check malfunction thresholds:

For PIP : Time between PIP edges : > 350 milliseconds

Ratio of current PIP period to last two periods : < 0.75 > 1.75

For CMP : Ratio of PIP events to CMP events: 4:1, 6:1, 8:1 or 10:1 based on engine cyl.

For coils : Ratio of PIP events to IDM events: 1:1

General Outputs

The Fuel Injectors are checked electrically for open and short circuit (P0201 to P0208).

The Idle Air Control (IAC) solenoid is checked electrically for open and shorts (P1504).

The Purge Solenoid or Vapour Management Valve output circuit is checked for opens and shorts (P0443).

Purge Solenoid / VMV Check Operation:

DTCsP0443

Monitor execution continuous (5 seconds to identify malfunction/obtain smart driver status)

Monitor Sequencenone

Monitoring Duration 5 seconds for electrical malfunctions

Typical Purge Solenoid / VMV component malfunction thresholds:

P0443 open / shorted at 0 and 100% duty cycle

Page 883 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 37 of 43

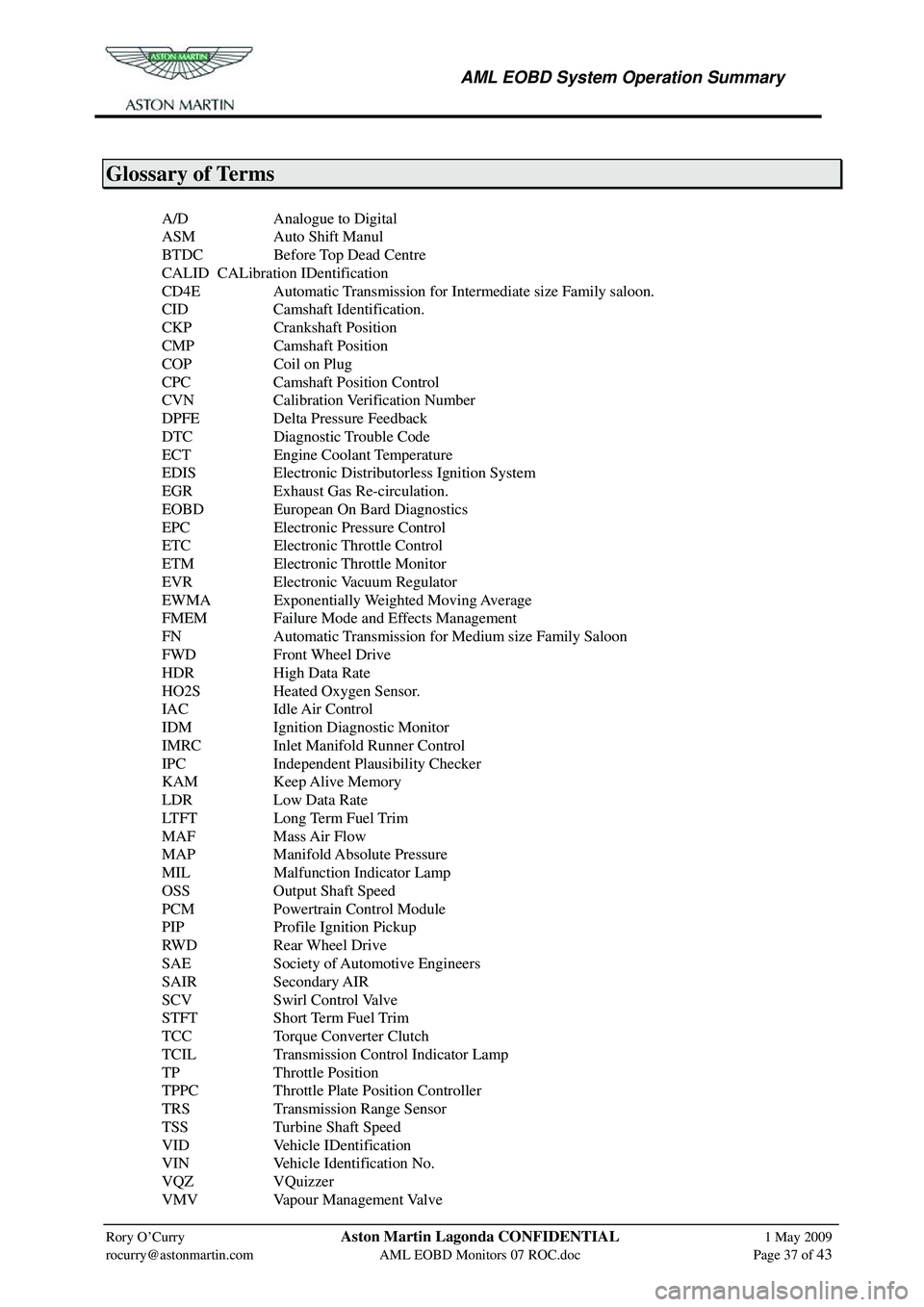

Glossary of Terms

A/D Analogue to Digital

ASM Auto Shift Manul

BTDC Before Top Dead Centre

CALID CALibration IDentification

CD4E Automatic Transmission for Intermediate size Family saloon.

CID Camshaft Identification.

CKP Crankshaft Position

CMP Camshaft Position

COP Coil on Plug

CPC Camshaft Position Control

CVN Calibration Verification Number

DPFE Delta Pressure Feedback

DTC Diagnostic Trouble Code

ECT Engine Coolant Temperature

EDIS Electronic Distributorless Ignition System

EGR Exhaust Gas Re-circulation.

EOBD European On Bard Diagnostics

EPC Electronic Pressure Control

ETC Electronic Throttle Control

ETM Electronic Throttle Monitor

EVR Electronic Vacuum Regulator

EWMA Exponentially Weighted Moving Average

FMEM Failure Mode and Effects Management

FN Automatic Transmission for Medium size Family Saloon

FWD Front Wheel Drive

HDR High Data Rate

HO2S Heated Oxygen Sensor.

IAC Idle Air Control

IDM Ignition Diagnostic Monitor

IMRC Inlet Manifold Runner Control

IPC Independent Plausibility Checker

KAM Keep Alive Memory

LDR Low Data Rate

LTFT Long Term Fuel Trim

MAF Mass Air Flow

MAP Manifold Absolute Pressure

MIL Malfunction Indicator Lamp

OSS Output Shaft Speed

PCM Powertrain Control Module

PIP Profile Ignition Pickup

RWD Rear Wheel Drive

SAE Society of Automotive Engineers

SAIR Secondary AIR

SCV Swirl Control Valve

STFT Short Term Fuel Trim

TCC Torque Converter Clutch

TCIL Transmission Control Indicator Lamp

TP Throttle Position

TPPC Throttle Plate Position Controller

TRS Transmission Range Sensor

TSS Turbine Shaft Speed

VID Vehicle IDentification

VIN Vehicle Identification No.

VQZ VQuizzer

VMV Vapour Management Valve

Page 885 of 947

AML EOBD System Operation Summary

Rory O’Curry Aston Martin Lagonda CONFIDENTIAL 1 May 2009

[email protected] AML EOBD Monitors 07 ROC.doc Page 40 of 43

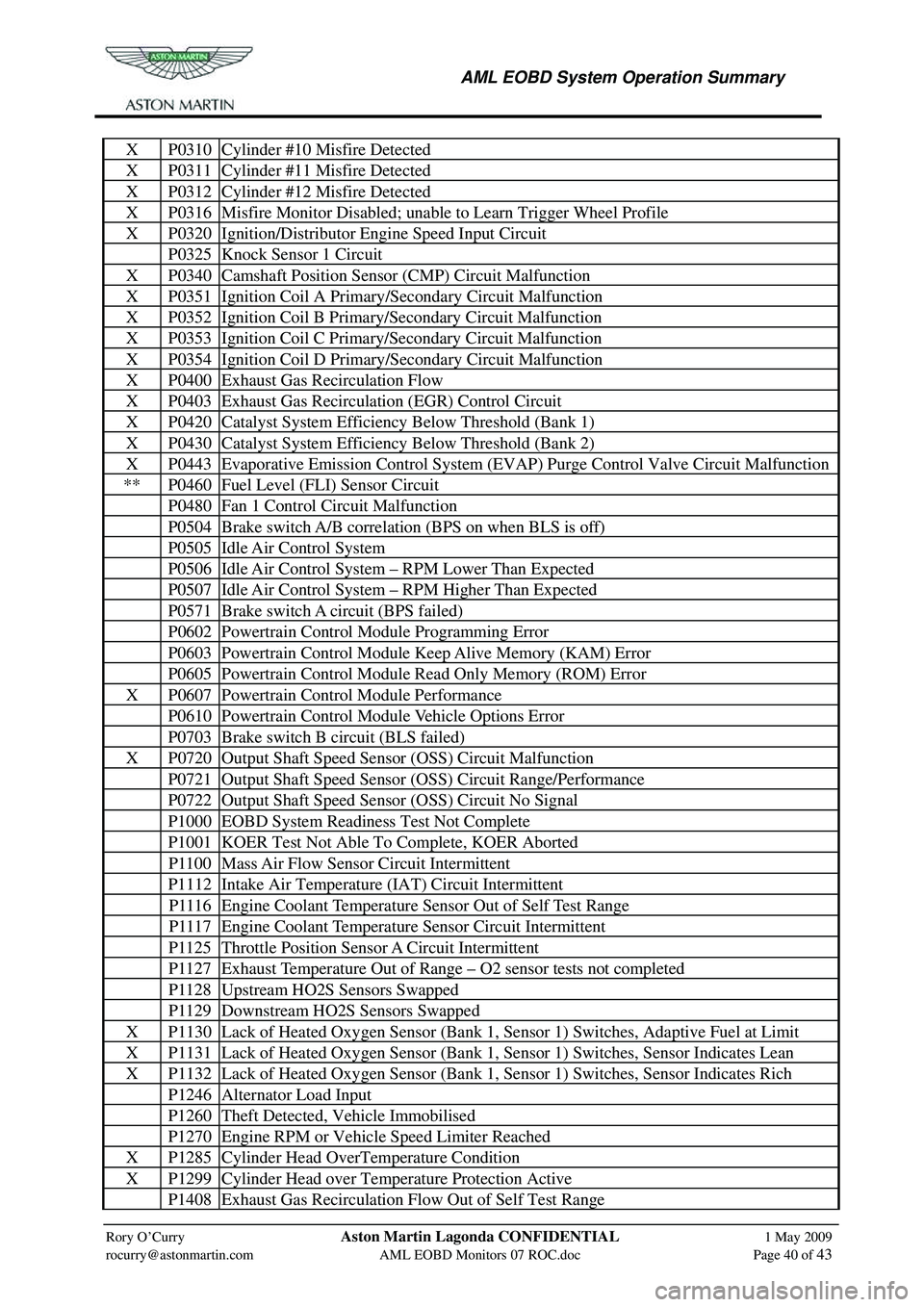

X P0310 Cylinder #10 Misfire Detected

X P0311 Cylinder #11 Misfire Detected

X P0312 Cylinder #12 Misfire Detected

X P0316 Misfire Monitor Disabled; unable to Learn Trigger Wheel Profile

X P0320 Ignition/Distributor Engine Speed Input Circuit

P0325 Knock Sensor 1 Circuit

X P0340 Camshaft Position Sens or (CMP) Circuit Malfunction

X P0351 Ignition Coil A Primary/Secondary Circuit Malfunction

X P0352 Ignition Coil B Primary/Secondary Circuit Malfunction

X P0353 Ignition Coil C Primary/Secondary Circuit Malfunction

X P0354 Ignition Coil D Primary/Secondary Circuit Malfunction

X P0400 Exhaust Gas Recirculation Flow

X P0403 Exhaust Gas Recirculation (EGR) Control Circuit

X P0420 Catalyst System Efficiency Below Threshold (Bank 1)

X P0430 Catalyst System Efficiency Below Threshold (Bank 2)

X P0443 Evaporative Emission Control System (EVAP) Purge Control Valve Circuit Malfunction

** P0460 Fuel Level (FLI) Sensor Circuit

P0480 Fan 1 Control Circuit Malfunction

P0504 Brake switch A/B correlation (BPS on when BLS is off)

P0505 Idle Air Control System

P0506 Idle Air Control System – RPM Lower Than Expected

P0507 Idle Air Control System – RPM Higher Than Expected

P0571 Brake switch A circuit (BPS failed)

P0602 Powertrain Control Module Programming Error

P0603 Powertrain Control Module Keep Alive Memory (KAM) Error

P0605 Powertrain Control Module Read Only Memory (ROM) Error

X P0607 Powertrain Control Module Performance

P0610 Powertrain Control Module Vehicle Options Error

P0703 Brake switch B circuit (BLS failed)

X P0720 Output Shaft Speed Sensor (OSS) Circuit Malfunction

P0721 Output Shaft Speed Sensor (OSS) Circuit Range/Performance

P0722 Output Shaft Speed Sensor (OSS) Circuit No Signal

P1000 EOBD System Readiness Test Not Complete

P1001 KOER Test Not Able To Complete, KOER Aborted

P1100 Mass Air Flow Sensor Circuit Intermittent

P1112 Intake Air Temperature (IAT) Circuit Intermittent

P1116 Engine Coolant Temperature Sensor Out of Self Test Range

P1117 Engine Coolant Temperature Sensor Circuit Intermittent

P1125 Throttle Position Sensor A Circuit Intermittent

P1127 Exhaust Temperature Out of Range – O2 sensor tests not completed

P1128 Upstream HO2S Sensors Swapped

P1129 Downstream HO2S Sensors Swapped

X P1130 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Adaptive Fuel at Limit

X P1131 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Lean

X P1132 Lack of Heated Oxygen Sensor (Bank 1, Sensor 1) Switches, Sensor Indicates Rich

P1246 Alternator Load Input

P1260 Theft Detected, Vehicle Immobilised

P1270 Engine RPM or Vehicle Speed Limiter Reached

X P1285 Cylinder Head OverTemperature Condition

X P1299 Cylinder Head over Temperature Protection Active

P1408 Exhaust Gas Recirculation Flow Out of Self Test Range

Page 899 of 947

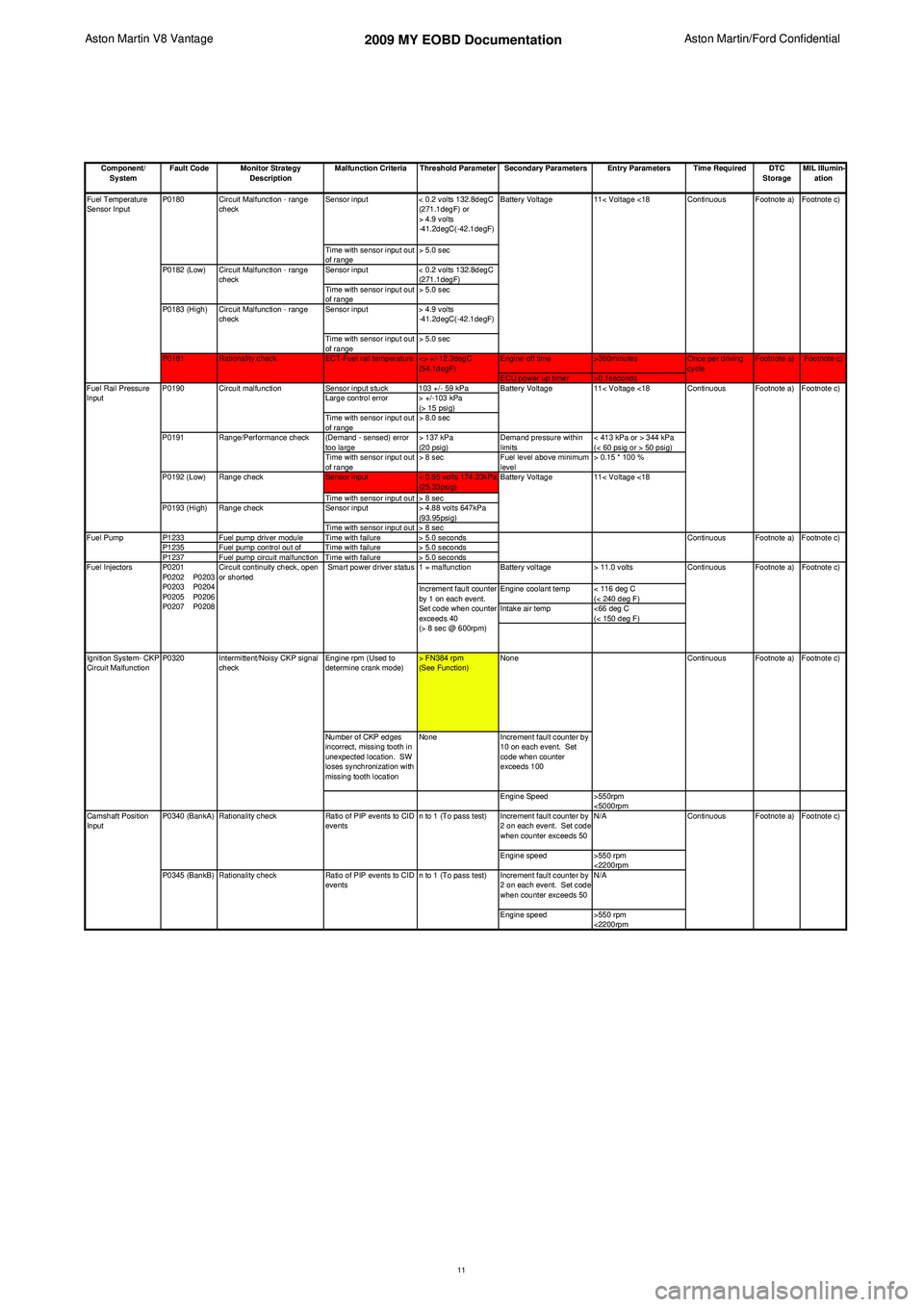

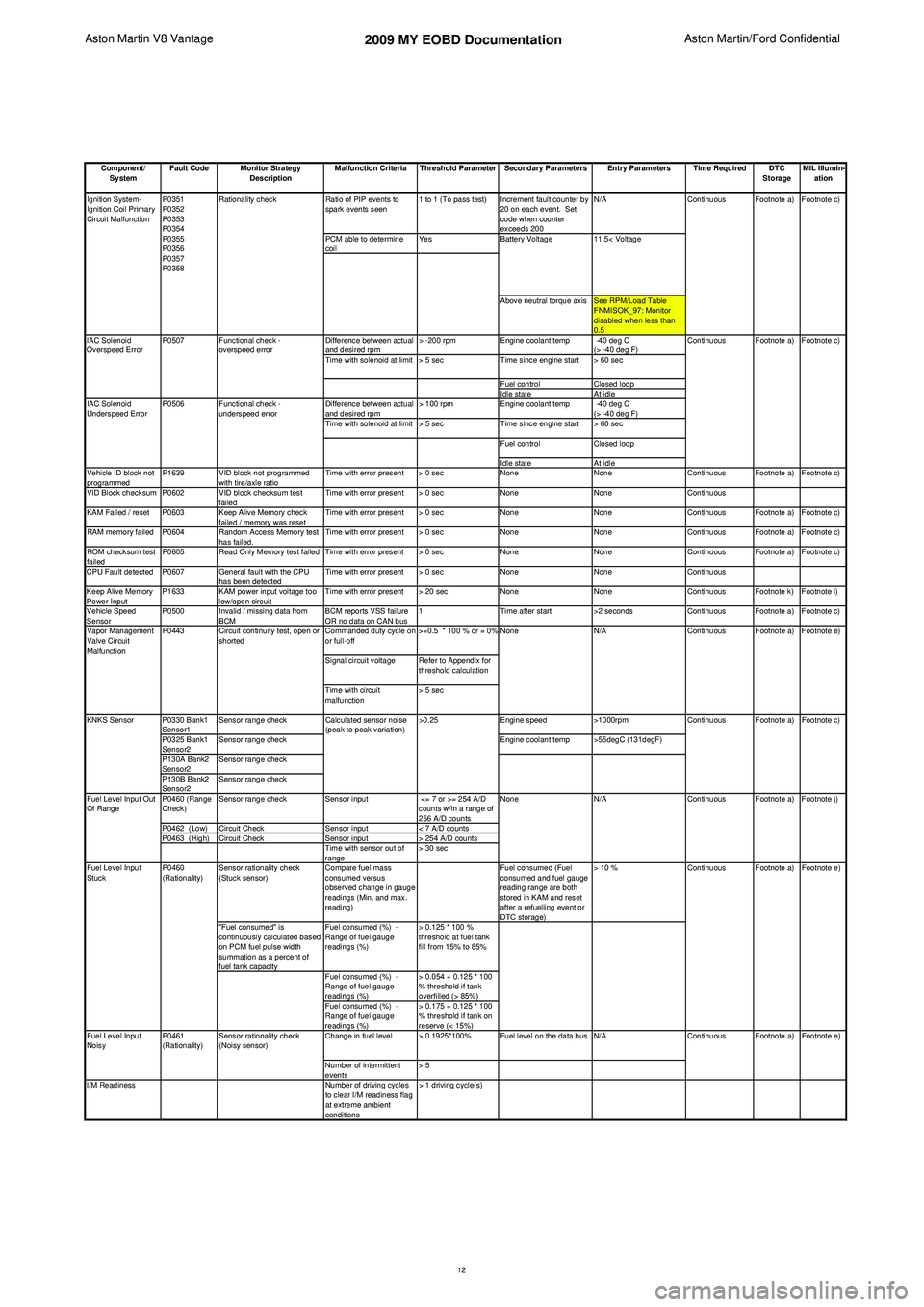

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Sensor input < 0.2 volts 132.8degC

(271.1degF) or

> 4.9 volts

-41.2degC(-42.1degF)

Time with sensor input out

of range > 5.0 sec

Sensor input < 0.2 volts 132.8degC

(271.1degF)

Time with sensor input out

of range > 5.0 sec

Sensor input > 4.9 volts

-41.2degC(-42.1degF)

Time with sensor input out

of range > 5.0 sec

Engine off time >360minutes

ECU power up timer >0.1seconds

Sensor input stuck 103 +/- 59 kPa

Large control error > +/-103 kPa (> 15 psig)

Time with sensor input out

of range > 8.0 sec

(Demand - sensed) error

too large > 137 kPa

(20 psig)Demand pressure within

limits < 413 kPa or > 344 kPa

(< 60 psig or > 50 psig)

Time with sensor input out

of range > 8 sec

Fuel level above minimum

level > 0.15 * 100 %

Sensor input < 0.95 volts 174.23kPa

(25.33psig)

Time with sensor input out > 8 sec

Sensor input > 4.88 volts 647kPa

(93.95psig)

Time with sensor input out > 8 sec

P1233 Fuel pump driver module Time with failure > 5.0 seconds

P1235 Fuel pump control out of Time with failure > 5.0 seconds

P1237 Fuel pump circuit malfunction Time with failure > 5.0 seconds 1 = malfunction Battery voltage> 11.0 volts

Engine coolant temp < 116 deg C (< 240 deg F)

Intake air temp <66 deg C

(< 150 deg F)

Engine rpm (Used to

determine crank mode) > FN384 rpm

(See Function)None

Number of CKP edges

incorrect, missing tooth in

unexpected location. SW

loses synchronization with

missing tooth location None

Increment fault counter by

10 on each event. Set

code when counter

exceeds 100

Engine Speed >550rpm

<5000rpm

Increment fault counter by

2 on each event. Set code

when counter exceeds 50 N/A

Engine speed >550 rpm

<2200rpm

Increment fault counter by

2 on each event. Set code

when counter exceeds 50 N/A

Engine speed >550 rpm

<2200rpm Footnote a) Footnote c)

Continuous

<> +/-12.3degC

(54.1degF) Once per driving

cycle

Fuel Temperature

Sensor Input

ECT-Fuel rail temperature

Circuit Malfunction - range

check

Circuit Malfunction - range

check

Circuit Malfunction - range

check

P0180

P0182 (Low)

P0181 Rationality check

P0183 (High)

Ignition System- CKP

Circuit Malfunction P0320 Intermittent/Noisy CKP signal

check Footnote c)

Footnote c)

Ratio of PIP events to CID

events Continuous Footnote a) Footnote c)

n to 1 (To pass test)

n to 1 (To pass test)

Increment fault counter

by 1 on each event.

Set code when counter

exceeds 40

(> 8 sec @ 600rpm)

Smart power driver status

P0340 (BankA)

P0345 (BankB) Circuit continuity check, open

or shorted

P0201

P0202 P0203

P0203 P0204

P0205 P0206

P0207 P0208

Camshaft Position

Input Rationality check

Rationality checkRatio of PIP events to CID

events Continuous

Footnote a)

Footnote c)

Continuous Footnote a) Footnote c) Footnote a)

Battery Voltage 11< Voltage <18

11< Voltage <18 Continuous Footnote a) Footnote c)

11< Voltage <18

Circuit malfunction

Battery Voltage

Battery Voltage

Range check

Continuous Footnote a)

Fuel Injectors

Fuel Rail Pressure

Input

P0190

P0191

P0192 (Low)

P0193 (High)

Fuel Pump Range check

Range/Performance check

11

Page 900 of 947

Aston Martin V8 Vantage 2009 MY EOBD DocumentationAston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Ratio of PIP events to

spark events seen 1 to 1 (To pass test) Increment fault counter by

20 on each event. Set

code when counter

exceeds 200 N/A

PCM able to determine

coil Yes

Above neutral torque axis See RPM/Load Table FNMISOK_97: Monitor

disabled when less than

0.5

Difference between actual

and desired rpm > -200 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Difference between actual

and desired rpm > 100 rpm

Engine coolant temp -40 deg C

(> -40 deg F)

Time with solenoid at limit > 5 sec Time since engine start > 60 sec

Fuel control Closed loop

Idle state At idle

Vehicle ID block not

programmed P1639 VID block not programmed

with tire/axle ratio Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

VID Block checksum P0602 VID block checksum test failedTime with error present > 0 sec

NoneNoneContinuous

KAM Failed / reset P0603 Keep Alive Memory check failed / memory was resetTime with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

RAM memory failed P0604 Random Access Memory test has failed.Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

ROM checksum test

failed P0605 Read Only Memory test failed Time with error present > 0 sec

NoneNoneContinuous Footnote a) Footnote c)

CPU Fault detected P0607 General fault with the CPU has been detectedTime with error present > 0 sec

NoneNoneContinuous

Keep Alive Memory

Power Input P1633 KAM power input voltage too

low/open circuit Time with error present > 20 sec

NoneNoneContinuous Footnote k) Footnote i)

Vehicle Speed

Sensor P0500 Invalid / missing data from

BCM BCM reports VSS failure

OR no data on CAN bus1

Time after start >2 secondsContinuous Footnote a) Footnote c)

Commanded duty cycle on

or full-off >=0.5 * 100 % or = 0%

Signal circuit voltage Refer to Appendix for threshold calculation

Time with circuit

malfunction > 5 sec

P0330 Bank1

Sensor1 Sensor range check

Engine speed>1000rpm

P0325 Bank1

Sensor2 Sensor range check

Engine coolant temp >55degC (131degF)

P130A Bank2

Sensor2 Sensor range check

P130B Bank2

Sensor2 Sensor range check

P0460 (Range

Check) Sensor range check

Sensor input <= 7 or >= 254 A/D

counts w/in a range of

256 A/D counts

P0462 (Low) Circuit Check Sensor input< 7 A/D counts

P0463 (High) Circuit Check Sensor input> 254 A/D counts

Time with sensor out of

range > 30 sec

Sensor rationality check

(Stuck sensor) Compare fuel mass

consumed versus

observed change in gauge

readings (Min. and max.

reading) Fuel consumed (Fuel

consumed and fuel gauge

reading range are both

stored in KAM and reset

after a refuelling event or

DTC storage)> 10 %

"Fuel consumed" is

continuously calculated based

on PCM fuel pulse width

summation as a percent of

fuel tank capacity Fuel consumed (%) -

Range of fuel gauge

readings (%)

> 0.125 * 100 %

threshold at fuel tank

fill from 15% to 85%

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.054 + 0.125 * 100

% threshold if tank

overfilled (> 85%)

Fuel consumed (%) -

Range of fuel gauge

readings (%) > 0.175 + 0.125 * 100

% threshold if tank on

reserve (< 15%)

Change in fuel level > 0.1925*100% Fuel level on the data bus N/A

Number of intermittent

events > 5

I/M Readiness Number of driving cycles

to clear I/M readiness flag

at extreme ambient

conditions > 1 driving cycle(s) Footnote e)

Footnote a)

Footnote c)

Footnote a) Footnote j) Footnote e)

Fuel Level Input

Noisy Continuous Footnote a)

Continuous Footnote a)

P0461

(Rationality) Sensor rationality check

(Noisy sensor)

Fuel Level Input

Stuck

P0460

(Rationality) Continuous

N/A Continuous

Calculated sensor noise

(peak to peak variation)

>0.25

KNKS Sensor

Fuel Level Input Out

Of Range NoneFootnote a) Footnote e)

Vapor Management

Valve Circuit

Malfunction P0443 Circuit continuity test, open or

shorted None

N/A Continuous

11.5< Voltage

Ignition System-

Ignition Coil Primary

Circuit Malfunction

IAC Solenoid

Underspeed Error P0507

P0506

Functional check -

overspeed error

Functional check -

underspeed error

IAC Solenoid

Overspeed Error

Footnote a) Footnote c)

Continuous

P0351

P0352

P0353

P0354

P0355

P0356

P0357

P0358

Rationality check

Continuous Footnote a) Footnote c)

Battery Voltage

12

Page 923 of 947

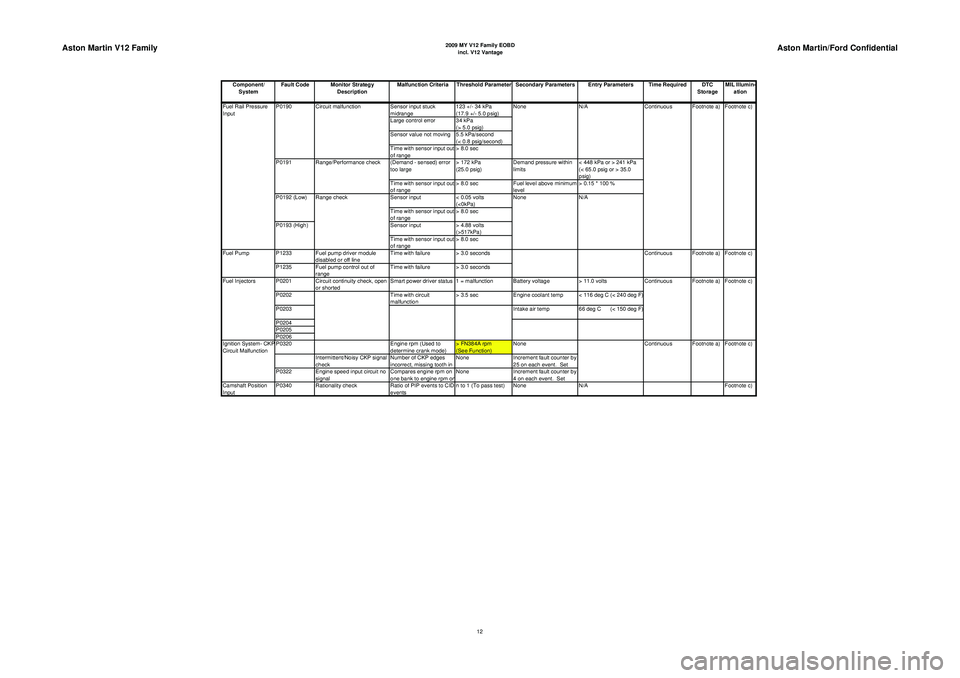

Aston Martin V12 Family

2009 MY V12 Family EOBDincl. V12 Vantage

Aston Martin/Ford Confidential

Component/ System Fault Code Monitor Strategy

Description Malfunction Criteria Threshold Parameter Secondary Parameters Entry Parameters Time Required DTC

StorageMIL Illumin-

ation

Sensor input stuck

midrange 123 +/- 34 kPa

(17.9 +/- 5.0 psig)

Large control error 34 kPa (> 5.0 psig)

Sensor value not moving 5.5 kPa/second (< 0.8 psig/second)

Time with sensor input out

of range > 8.0 sec

(Demand - sensed) error

too large > 172 kPa

(25.0 psig)Demand pressure within

limits < 448 kPa or > 241 kPa

(< 65.0 psig or > 35.0

psig)

Time with sensor input out

of range > 8.0 sec

Fuel level above minimum

level > 0.15 * 100 %

Sensor input < 0.05 volts

(<0kPa)

Time with sensor input out

of range > 8.0 sec

Sensor input > 4.88 volts

(>517kPa)

Time with sensor input out

of range > 8.0 sec

P1233 Fuel pump driver module disabled or off line Time with failure > 3.0 seconds

P1235 Fuel pump control out of range Time with failure > 3.0 seconds

P0201 Circuit continuity check, open or shorted Smart power driver status 1 = malfunction Battery voltage

> 11.0 volts

P0202 Time with circuit

malfunction > 3.5 sec

Engine coolant temp < 116 deg C (< 240 deg F)

P0203 Intake air temp66 deg C (< 150 deg F)

P0204

P0205

P0206

P0320 Engine rpm (Used to

determine crank mode) > FN384A rpm

(See Function)None

Intermittent/Noisy CKP signal

check Number of CKP edges

incorrect, missing tooth in None

Increment fault counter by

25 on each event. Set

P0322 Engine speed input circuit no signal Compares engine rpm on

one bank to engine rpm o

nNone

Increment fault counter by

4 on each event. Set

Camshaft Position

Input P0340 Rationality check

Ratio of PIP events to CID

events n to 1 (To pass test) None

N/A Footnote c)

Footnote c)

Fuel Rail Pressure

Input P0190

P0191

P0192 (Low)

P0193 (High)Range check

Range/Performance check

Fuel Pump Continuous

Circuit malfunction N/A

Continuous Footnote a) Footnote c)

None

None

N/A Footnote a)

Fuel Injectors Footnote c)

Ignition System- CKP

Circuit Malfunction Continuous Footnote a) Footnote c)

Continuous Footnote a)

12