AUDI Q3 2015 Owners Manual

Manufacturer: AUDI, Model Year: 2015, Model line: Q3, Model: AUDI Q3 2015Pages: 258, PDF Size: 64.9 MB

Page 221 of 258

M N

M N

0 ::i co ,...., \!) ..,.,

,...., ..,., ,....,

A WARNING 1=

You or your passengers could be injured

while changing a wheel if you do not fol

low these safety precautions:

- If you have a flat tire, move a safe dis

tance off the road. Turn off the engine,

turn the emergency flashers on and use

other warning devices to alert other mo

torists.

- Make sure that passengers wait in a safe

place away from the vehicle and well

away from the road and traffic.

- To help prevent the vehicle from moving

suddenly and possibly slipping off the

jack, always fully set the parking brake

and block the wheel diagonally opposite

the wheel being changed with the fold

ing chocks or other objects. When one

front wheel is lifted off the ground, plac ing the Automatic Transmission in "P"

(Park) will

not prevent the vehicle from

moving .

- Before you change a wheel, be sure the

ground is level and firm. If necessary,

use a sturdy board under the jack.

- Always store the vehicle tool kit, the jack

and the replaced tire in the luggage com

partment

¢ page 100.

(D Note

If you are changing the wheel on a steep

incline, use the folding chock¢

page 217

to block the opposite wheel to prevent the

vehicle from moving.

(!) Tips

Obey all laws.

Changing a wheel

When you change a wheel, follow the se

quence described below step-by-step and in

exactly that order .

-

1. Remove the decorative wheel cover* or

the

wheel bolt caps*. For more details see

also

¢ page 220.

2. Loosen the wheel bolts<=:> page 220 .

What do I do now? 219

3.

4.

5.

6.

7.

8.

Locate the proper mounting point for the

jack and align the jack below that point

¢ page 221.

Lift the car with the jack ¢ page 221.

Remove the wheel with the flat tire and

then install the

spare tire <=:>page 222.

Tighten all wheel bolts lightly.

Lower the vehicle with the jack .

Use the wheel bolt wrench and

firmly

tighten all wheel bolts in a crisscross pat

tern ¢

page 220.

9. Replace the decorative wheel cover* or

the

wheel bolt caps*.

A WARNING

Always read and follow all WARNINGS and information<=:>

A in Raising the vehicle on

page 221

and <=:> page 223.

After changing a wheel

A wheel change is not complete without the

doing the following.

.,. Always store the vehicle tool kit, the jack4

and the replaced tire in the luggage com

partment

¢ page 100.

.,. Check the tire pressure of the spare tire as

soon as possible .

.,. As soon as possible, have the

tightening

torques

on all wheel bolts checked with a

torque wrench. The correct tightening tor

que is 105 ft lbs. (140 Nm).

.,. Have the flat tire

replaced as soon as possi

ble.

(D Tips

- If you notice that the wheel bolts are

corroded and difficult to turn while

changing a tire, they should be replaced

before you check the tightening torque.

- Drive at reduced speed until you have the

tightening torques checked.

•

•

Page 222 of 258

220 What do I do now?

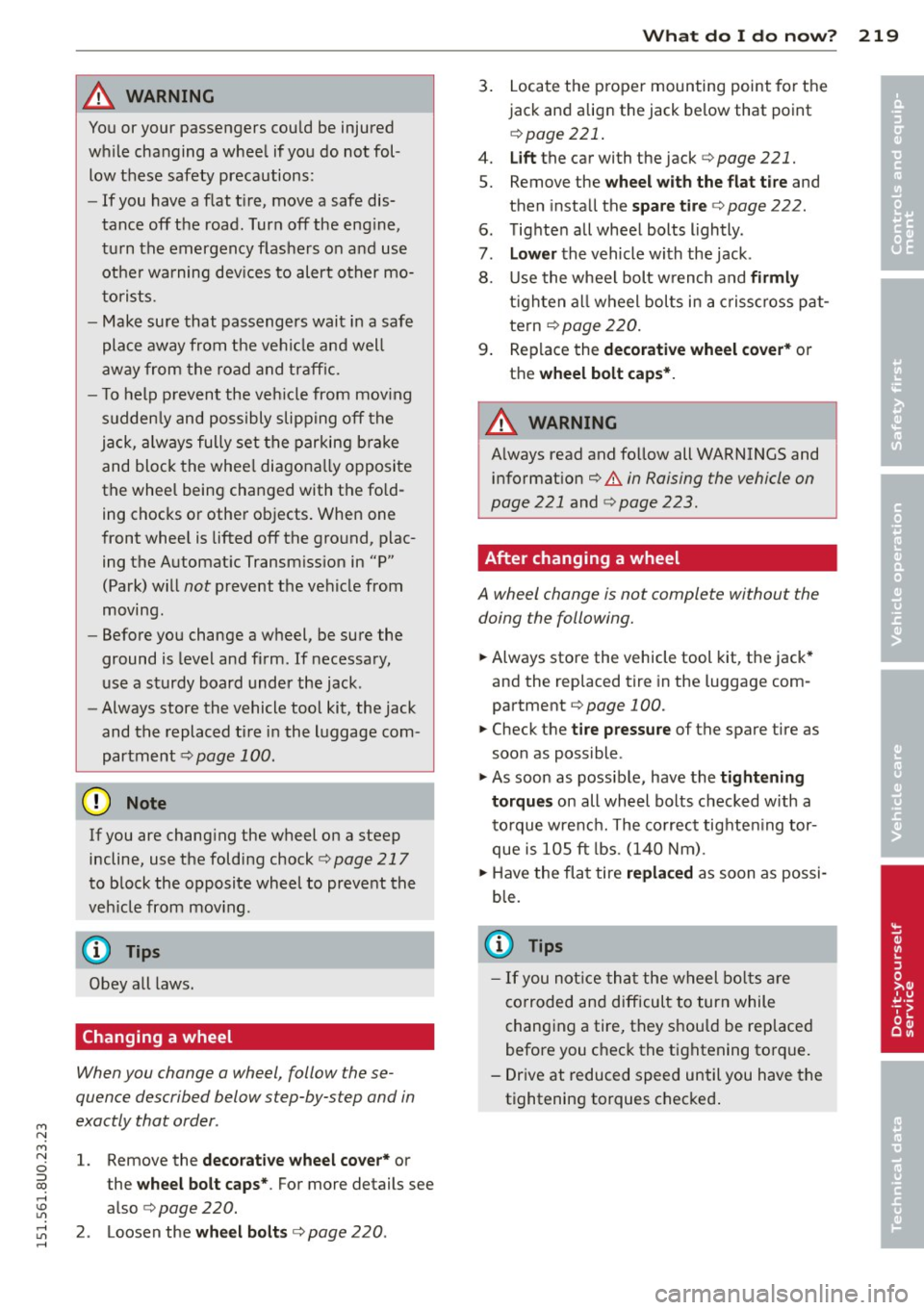

Removing the wheel covers/bolt caps

Fig. 162 Cha ng in g a w hee l: re mov ing the w heel cover

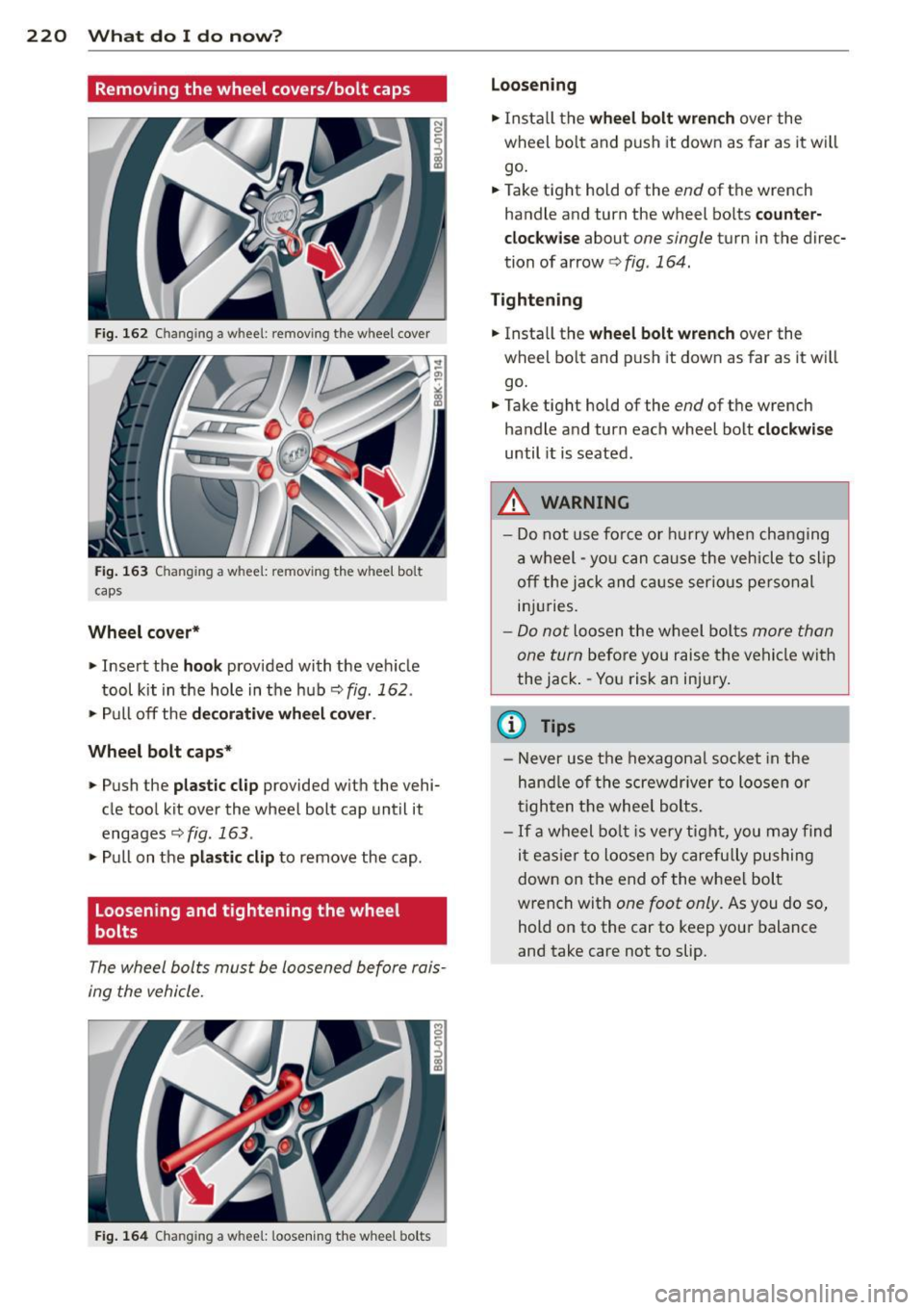

Fig. 163 Chan gin g a w hee l: re mov ing the w heel bo lt

c aps

Wheel cover*

• Insert the hook provided with the vehicle

tool kit in the hole in the hub

¢ fig. 162 .

• Pull off the decorative wheel cover .

Wheel bolt caps*

• Push the plastic clip provided with the vehi

cle tool kit over the wheel bolt cap until it

engages

¢ fig. 163 .

• Pull on the plastic clip to remove the cap.

Loosening and tightening the wheel

bolts

The wheel bolts must be loosened before rais

ing the vehicle.

Fig. 164 Chan ging a whee l: loosening th e wh eel b olts

Loosening

• Install the wheel bolt wrench over the

wheel bolt and push it down as far as it will

go .

.. Take tight hold of the

end of the wrench

handle and turn the wheel bolts

counter

clockwise

about one single turn in the direc

tion of arrow

¢ fig . 164.

Tightening

• Install the wheel bolt wrench over the

wh eel bolt and push it down as far as it will

go.

• Take tight hold of the

end of the wrench

handle and turn each wheel bolt

clockwise

until it is seated .

.&_ WARNING

=

-Do not use force or hurry when changing

a wheel - you can cause the vehicle to slip

off the jack and cause serious personal

injuries.

- Do not loosen the wheel bolts more than

one turn

before you raise the vehicle with

the jack. -You risk an injury.

(D Tips

- Never use the hexagonal socket in the

handle of the screwdriver to loosen or

tighten the wheel bolts.

-If a wheel bolt is very tight, you may find

it easier to loosen by carefully pushing

down on the end of the wheel bolt

wrench with

one foot only. As you do so,

hold on to the car to keep your balance

and take care not to slip.

Page 223 of 258

M N M N

0 ::i co

rl I.O

"' rl

"' rl

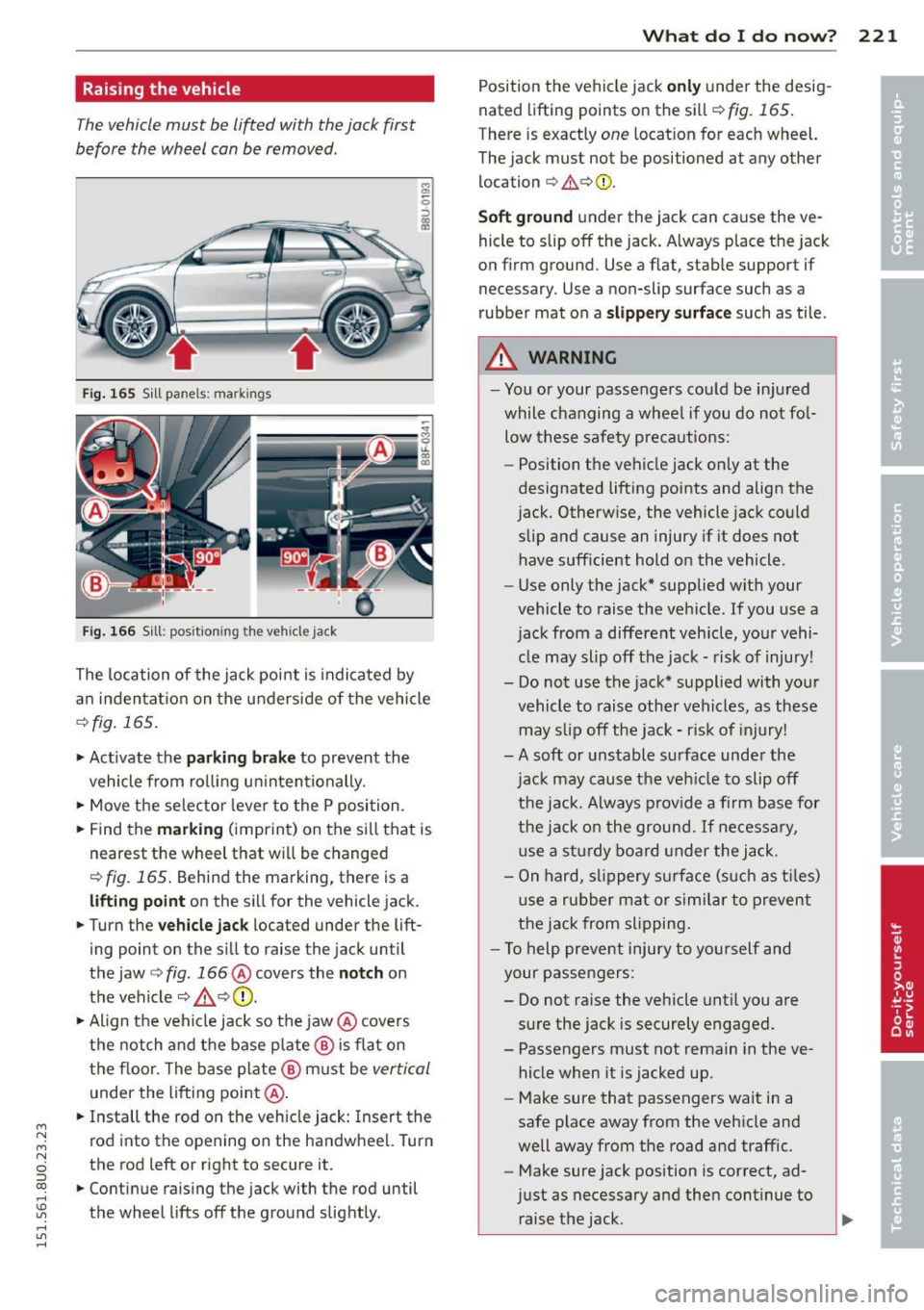

Raising the vehicle

The vehicle must be li~ed with the jack first

before the wheel can be removed .

Fig. 165 S ill pane ls: markings

Fi g. 166 Sill: posit ion ing th e vehicle jack

The location of the jack point is indicated by

a n in den ta ti on on the underside of the vehicle

c::> fig . 165.

"'Activate the parking b rak e to prevent the

vehicle from ro lling u ninten tionally.

"' Move the selector lever to the P position .

"' Find the

markin g (imprint) on the si ll that is

nearest the wheel that w ill be changed

c::>fig. 165 . Behind the marking, there is a

lifting po int on the sill for the vehicle jack .

"' Turn the

vehicle jack located under the lift

ing point on the sill to raise the jack until

the jaw

c::> fig . 166 @ covers the notch on

the vehicle

c::> .&_ c::>0 .

"'Align the vehi cle jack so the jaw @covers

the notch and the base p late @ is flat on

t h e f loor. The base p late @ must be

vertical

under the lifting point @.

"' Install the rod on the vehicle jack : Insert the

rod into the opening on the handwheel. Turn

the rod left or right to secure it.

"' Continue raising the jack with the rod until

the wheel lifts off the ground slightly .

What do I do now ? 221

Position the vehicle jack only under the desig

nated lifting po ints on the si ll

c::>fig. 165 .

There is exactly one locat ion for each wheel.

The jack must not be positioned at any other

location

c::> .&. c::> (D .

Soft g round under the jack can cause the ve

hicle to slip off the jack. A lways p lace the jack

on firm ground. Use a f lat, stable support if

necessary. Use a non-slip surface such as a

rubber mat o n a

slippery surface such as tile.

A WARNING

- You or your passengers co uld be inju red

while changing a wheel if you do not fo l

low these safety p re ca utions:

- Position the vehicle jack on ly at the

designated lifting points and align the

j ack. Otherw ise, the vehicle jack could

slip and cause an injury if it does not

have sufficient hold on the vehicle.

- Use only the jack* supplied with your

vehicle to raise the veh icle . If you use a

j ac k from a different veh icle, you r vehi

cle may slip off the jac k -ris k of injury !

- Do not use the jack* supplied with yo ur

vehicle to raise other vehicles, as these

may s lip off the jack -risk of injury!

- A soft o r unstable surface unde r the

j ac k m ay cause the veh icle to slip off

the jack . Always prov ide a fi rm base for

the jack o n the ground.

If necess ary,

u se a st urdy board under the jack.

- On hard, sl ippery su rface (such as t iles)

u se a r ubber mat or s imi lar to prevent

the jack from slipping .

- To help prevent injury to yo urself and

your p asse ngers:

- Do not ra ise the vehicle until you are

sure the jack is securely engaged.

- Passengers must not remain in the ve

hicle when it is jacked up.

- Make sure that passengers wait in a

safe place away from the veh icle and

well away from the road and traffic .

- Make sure jack position is correct, ad

j ust as necessary and then cont inue to

raise the jack .

Page 224 of 258

222 What do I do now?

-If work has to be done under the vehi

cle , ensure that it is safely supported

on suitable stands -risk of injury!

- Never start the engine when the vehi

cle is on the jack -risk of accident!

CD Note

Do not lift the vehicle by the si ll. Position

the vehicle jack only at the designated lift

ing points on the sill. Otherwise, your vehi

cle will be damaged.

Taking the wheel off/installing the spare

tire

Follow these instructions step-by-step for

changing the wheel.

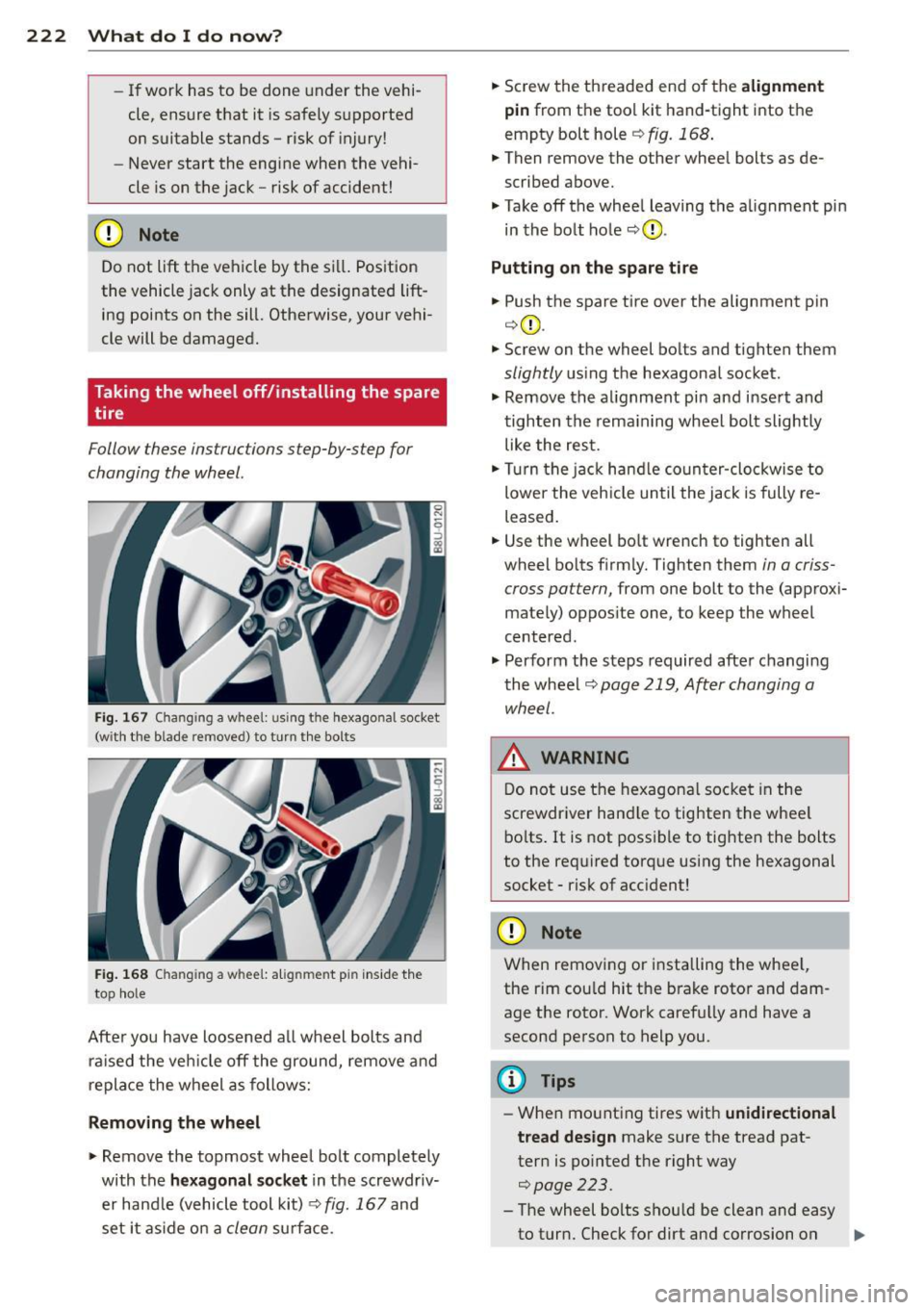

Fig. 167 Changing a whee l: u sing the hexago nal socket

(w ith the blade removed) to turn the bolts

Fig. 168 Changing a w hee l: a lignm en t pi n inside the

top hole

After you have loosened a ll wheel bolts and

ra ised the veh icle off the ground, remove and

replace the wheel as follows:

Removing the wheel

> Remove the topmost wheel bolt completely

with the

hexagonal socket in the screwdriv

er handle (vehicle tool kit)

r=;; fig. 167 and

set it as ide on a

clean su rface. >

Screw the threaded end of the

alignment

pin

from the tool kit hand-tight into the

empty bolt hole

¢ fig. 168 .

... Then remove the other whee l bolts as de

scribed above.

> Takeoff the whee l leaving the alignment pin

in the bolt hole

r=;; (D.

Putting on the spare tire

... Push the spare tire over the alignment pin

¢ CD.

... Screw on the wheel bolts and tighten them

slightly using the hexagonal socket .

> Remove the alignment pin and insert and

tighten the remaining wheel bolt slightly

like the rest.

... Turn the jack handle counter -clockwise to

lower the veh icle until the jack is fully re

leased .

... Use the wheel bolt wrench to tighten all

wheel bo lts firm ly. Tighten them

in a criss

cross pattern,

from one bolt to the (approx i

mately) oppos ite one, to keep the wheel

centered.

> Perform the steps required after changing

the wheel

¢ page 219, After changing a

wheel.

A WARNING

-

Do not use the hexagonal socket in the

screwdriver hand le to tighten the whee l

bolts. It is not possible to tighten the bolts

to the required torque using the hexagonal

socket - risk of accident!

CD Note

When removing or installing the whee l,

the rim cou ld hit the brake rotor and dam

age the rotor. Work carefu lly and have a

second person to help you.

(D Tips

-When mount ing tires with unidirectional

tread design

make sure the tread pat

tern is po inted the right way

r=;;page223.

- The wheel bolts shou ld be clean and easy

to turn. Check for dirt and corrosion on

Page 225 of 258

M N

M N

0 ::i co ,...., \!) 1.1'1 ,...., 1.1'1 ,....,

th e mat ing s urfaces o f both the whee l

and t he hub . R emove a ll dirt f rom these

su rfaces before remo untin g t he wheel.

Tires with unidirectional tread design

Tires with uni directional tread design must be

mounted with their tread pattern pointed in the right direction.

Using a spare tire with a tread pattern

intended for use in a specific direction

W hen using a spa re tire w it h a t read patte rn

intended fo r use in a specific direction, p lease

note t he followi ng:

- The di rection of rotation is ma rked by an

ar

row on the side of the t ire.

- If the s pare tire has to be inst alled in the in

correct di rection, use the spare tire only

temporarily since the t ire wi ll not be a ble to

achieve its optimum pe rformance character

ist ics with regard t o aquaplani ng, noise and

wea r.

- We recommend that you pay particular at

tent io n to this fact during wet weather and

t h at y ou adjust y our speed to matc h road

co ndi tions .

- Rep lace the flat tire w ith a new one and

have it installed on your ve hicle as soon as

poss ible to restore the handling a dvan tages

of a uni direct io na l ti re.

Notes on wheel changing

Please re ad the inform ation ~ p age 206 , New

tires and repl acing tires and wheels

if you are

goi ng to use a s pare t ire which is different

from the tires on your ve hicle .

A ft er you ch ange a tire:

- Check the tire pressure on the spare imme

diately after installation .

- Have the wheel bolt tightening torque

checked with a torque wrench as soon as possible by your authorized Audi dealer or

qualified workshop. What do I do now? 223

- With steel and alloy wheel r ims, the wheel

bolts are correctly tightened at a torque of

90 ft lbs. (120 Nm).

- If you notice that the wheel bolts are cor

roded and difficult to turn while changing

a tire, they should be replaced before you

check the tightening torque.

- Replace the flat tire with a new one and

have it installed on your vehicle as soon as

possible. Remount the wheel cover .

Until then , drive with extra care and at re

duced speeds.

_& WARNING

- If you are goin g to e quip your ve hicle

wit h tires o r rims which differ from th ose

which were facto ry installed, then be

sure to r ead th e information

~ pag e 206,

N ew tir es and replacing tir es and

w heels.

- Always make sur e the d amag ed wh eel o r

ev en a fl at ti re a nd the j ack and t ool kit

a re pr operly se c u red in the lugg age co m

partment and are not loose in the pas

sen ger c omp artment.

- In an accide nt or su dde n maneuver they

co uld fly forw ard, in ju ring anyone in the

ve hicl e.

- Always s tore dama ged wheel, j ack and

to ols se curely in the lugg age comp art

ment . Othe rwise, in an accident o r su d

den maneuver the y co uld fly forwa rd,

causing inju ry to passengers in the ve hi

cle.

([) Note

Do not use comme rcially ava ila bl e tire

sea lants. Ot herwise , th e e lectr ica l compo

nents of the tire pressu re monitoring sys

tem* wi ll no l onge r wor k properly an d the

se nsor fo r th e tire pressur e mo nitor ing

syste m* will have to be replaced by quali

fied wor kshop. •

•

Page 226 of 258

224 Fuses and bulbs

Fuses and bulbs

Fuses

Replacing a fuse

Fuses that have blown will have metal strips

that have burned through .

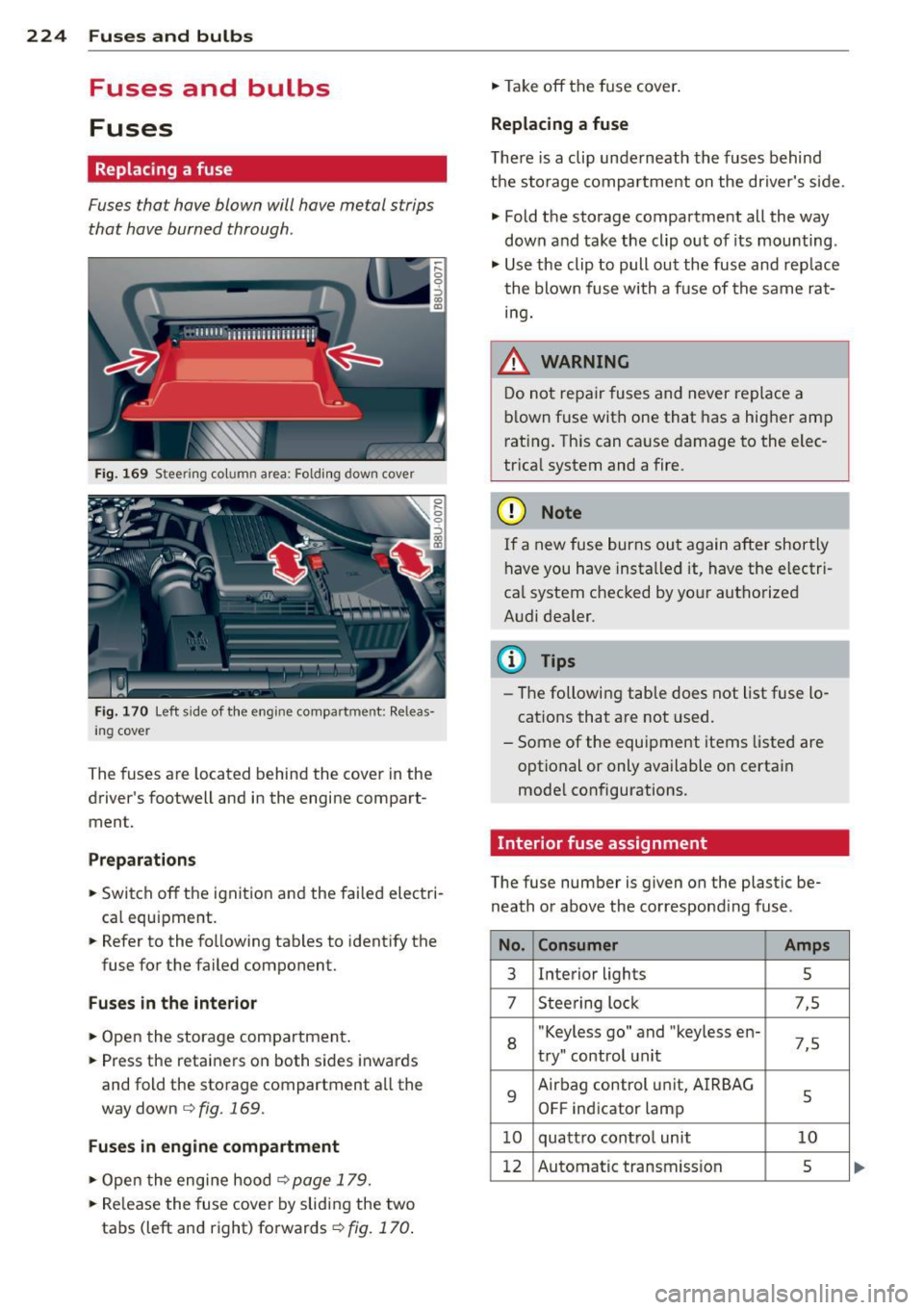

Fig . 169 Stee ring co lu m n area: Fold ing down cover

Fig . 170 Left side o f the engi ne compa rt me nt: Re leas·

i n g cove r

The fuses a re located behind the cover in the

driver's footwell and in the engine compart ment.

Preparations

• Switch off t he ignition and the fai le d elec tri

ca l equ ipme nt.

• Refer to the fo llowing tab les to ident ify the

fuse for t he failed component.

Fuses in the interior

• Open the storage compartmen t.

• Press the retainers on both s ides inwar ds

and fold the sto rage compartment a ll the

way down

q fig. 169.

Fuses in engine compartment

• Open the engine hood q page 179.

• Re lease the fuse cove r by sliding the two

tabs (left and right) fo rwards

Q fig. 170 .

• Take off the fuse cover .

Replacing a fuse

There is a clip underneath th e fuses behind

the sto rage compa rtme nt on the driver's side.

• Fold the storage compartment all the way

down and take the clip o ut of its mounting .

• Use the clip to pull out the fuse and rep lace

t he blown fu se wi th a f use of the same ra t

ing .

_& WARNING ~ -

Do not repair fuses and never re place a

b lown f use with one that has a hig her am p

rat ing . This can ca use damage to the elec

tr ica l system and a fire .

(D Note

If a new fuse burns ou t again after short ly

have you have insta lled it, have the e lectri

ca l system chec ked by yo ur autho rize d

A udi dealer .

(@ Tips

-The followi ng table does not list fuse lo

cat ions that are not used.

- Some of the equipment items listed are

optio nal or only available on certain

mode l configurations.

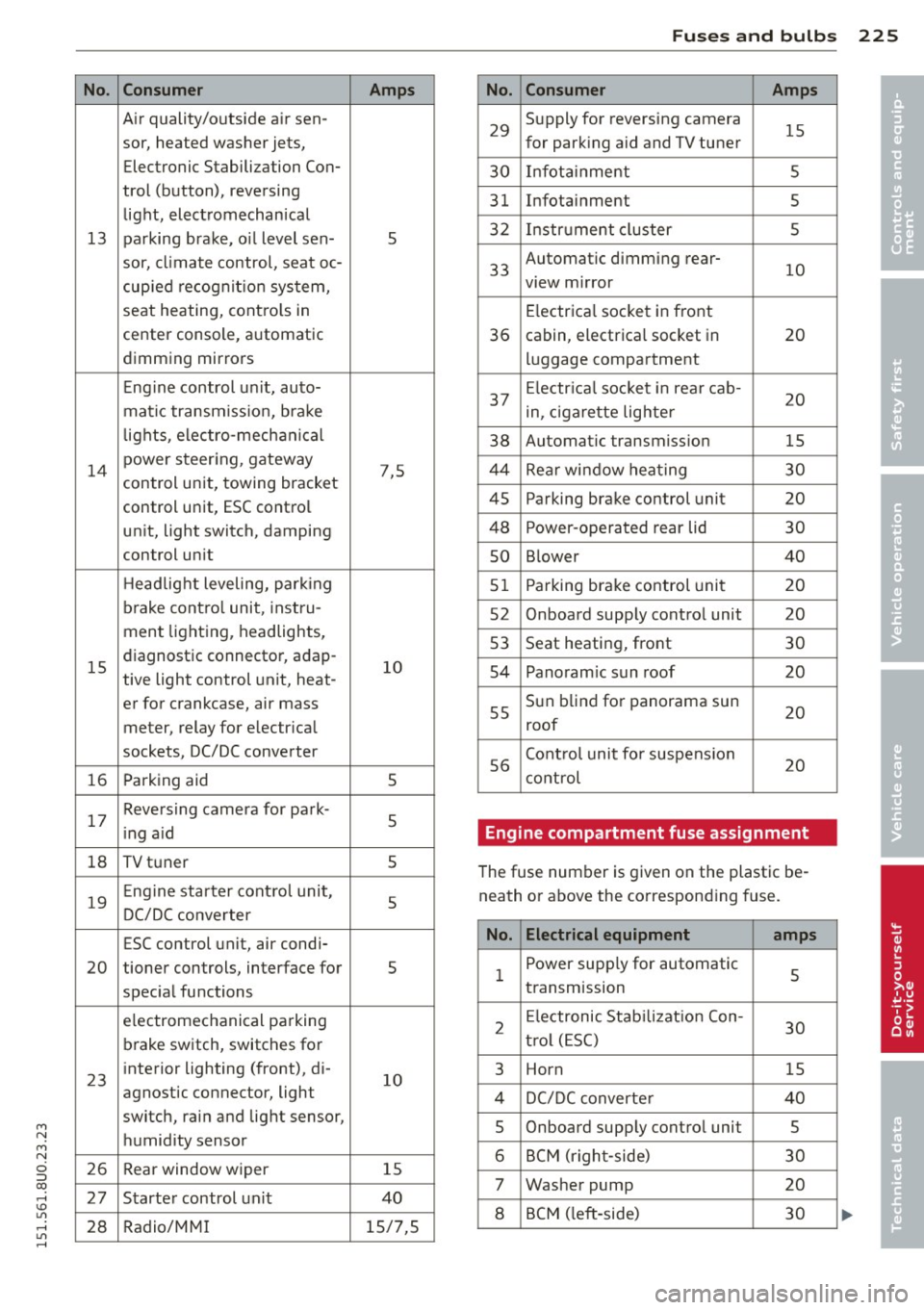

Interior fuse assignment

The fuse number is given on the plastic be

neath o r above the co rrespond ing fuse .

No. Consumer Amps

3 Interior lights s

7 Stee ring lock 7

,S

8

"Keyless go" and "keyless en-

7,5

t ry" control un it

9

Airbag control unit, A IRBAG

5

OFF ind icator lamp

1 0 quatt ro cont ro l unit 10

1 2

Automat ic transmiss ion s

Page 227 of 258

M N

M N

0 ::i co ,...., \!) 1.1'1 ,...., 1.1'1 ,....,

No.

13

14

15

16

17

18

19

20

23

26

27

28

Consumer

A ir quality/outside air sen-

sor, heated washer jets,

Electronic Stabilization Con-

trol (button), reversing

light, electromechanical

parking brake, o il level sen-

sor, climate control, seat oc-

cup ied recognit ion system,

seat heating, contro ls in

center console, automatic

dimming mirrors

Eng ine control u nit, auto-

matic transmiss ion, bra ke

l ights, electro-mechanical

power steer ing, gateway

control un it, towing bracket

control unit, ESC contro l

unit, light switch, damping

control un it

H eadlight leveling, park ing

brake contro l unit, inst ru-

men t lighting, headlights,

diagnostic connector, adap-

tive light control unit, heat-

er for crankcase, air mass

meter, relay for electr ical

sockets, DC/DC converter

Parking aid

Reversing camera for park-

i ng a id

TV tuner

Eng ine starter cont ro l unit,

DC/DC converter

ESC control unit, air condi-

tioner controls, interface for

spec ial functions

e lectromechanical parking

b rake switch, switches for

interior lighting (front), di-

agnostic connector, light

switch, rain and light sensor,

humidity sensor

Rear window wiper

Starter control un it

Radio/MM I

Amps

5

7,5 10 5

5

5 5

s

10

15

40

15/7,5

Fu ses and bulb s 225

No. Consumer Amps

29

Supply for reversing camera

15 for park ing aid and TV tuner

30 Infot ainment 5

31

Infotainment 5

32

Instr ument cluster 5

33

Automatic dimming rear-

view m irror

10

E lectrica l socket in front

36 cabin, electrical socket in 20

luggage compartment

37 Electr ica l soc ket i n rear cab-

20 in, ciga rette lighter

38 Automatic transmission 15

44

Rear window hea ting 30

45

Parking brake control unit 20

48

Power-operated rear lid 30

so B lower 40

51

Parking brake control unit 20

52

On board supply control unit 20

53

Seat heating, front 30

54

Panoram ic sun roof 20

55

Sun b lind for panorama sun 20

roof

56

Contro l unit fo r suspension

20 cont rol

Engine compartment fuse assignment

The fuse number is given on the plastic be

neath or above the correspond ing fuse.

No. Electrical equipment

amps

1 Power supply for automatic 5 transmission

2

E lectronic Stabilizat ion Con-

30 t ro l (E SC)

3 Horn 15

4

DC/DC converter 40

5

Onboard supply control unit 5

6

BCM (righ t-side) 30

7

Washer pump 20

8

BCM ( left -side) 30

•

•

Page 228 of 258

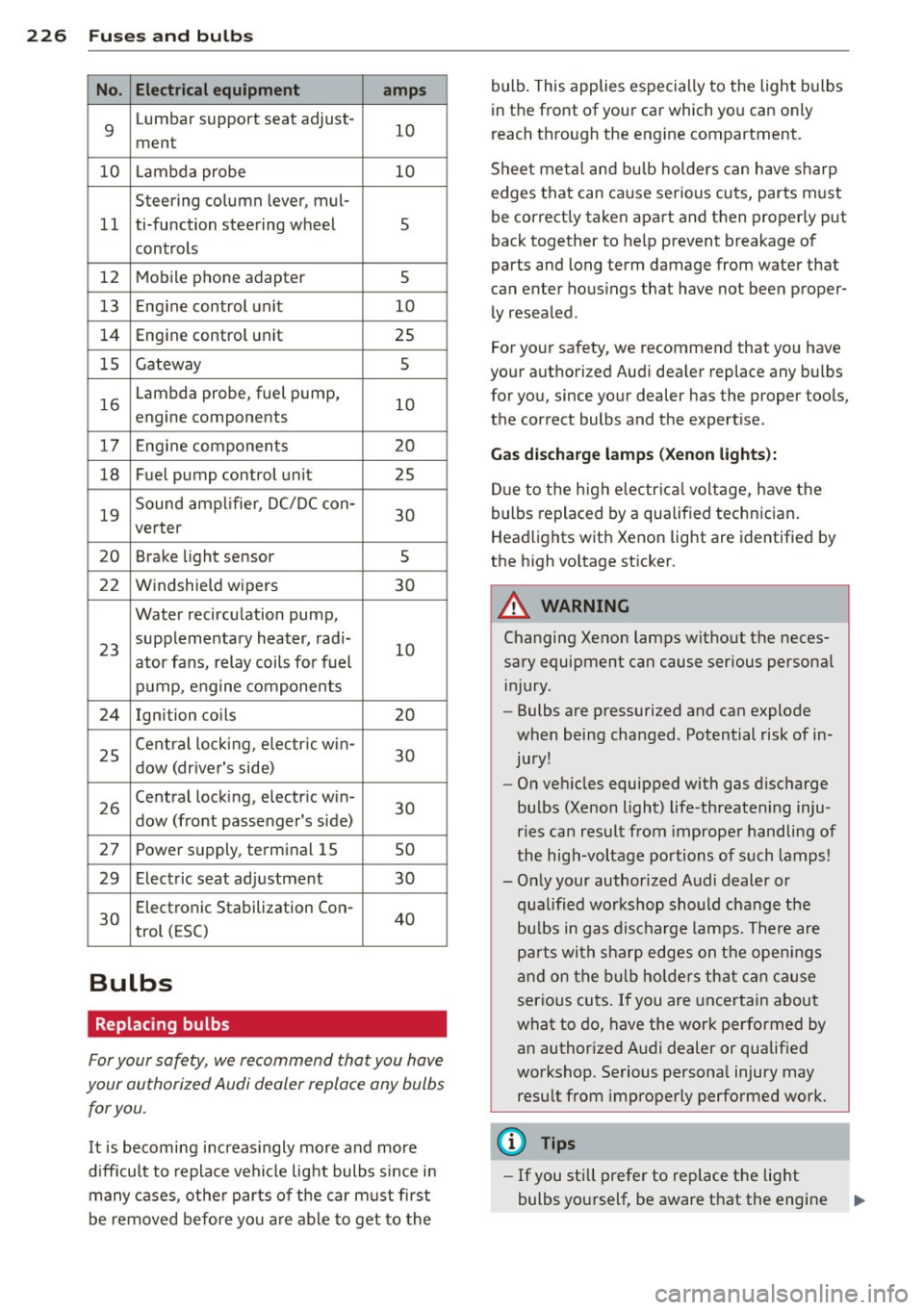

226 Fuses and bulbs

No. Electrical equipment amps

9 Lumbar support seat adjust-

ment

10

10 Lambda probe 10

Steering column lever, mul-

11 ti-function steering wheel

s

controls

12 Mobile phone adapter

s

13 Engine control unit 10

14 Engine control

unit

25

15 Gateway 5

16 Lambda

probe, fuel pump,

10

engine components

17 Eng ine components 20

18 Fuel pump control unit

2S

19 Sound

amplifier, DC/DC con-

verter 30

20 Brake light sensor

s

22 Windshield

wipers

30

Water recirculation pump,

23

supplementary heater, rad i-

10 a tor fans, relay coils for fuel

pump , engine components

24 Ignition coils 20

2S Central locking

, e lectr ic win-

30

dow (driver's side)

26 Central locking, e

lectr ic win-

30

dow (front passenger's side)

27 Power supply, terminal 15

so

29 Electric seat adjustment 30

30 Electronic Stabilization Con-

40

trol (ESC)

Bulbs

Replacing bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for you.

It is becoming increas ingly more and more

difficult to replace vehicle lig ht bulbs s ince in

many cases, other parts of the car must first

be removed before you are able to get to the bulb.

This applies especially to the light bulbs

in the front of your car which you can only

reach through the engine compartment.

Sheet meta l and bulb holders can have sharp

edges that can cause serious cuts, parts must

be correct ly taken apart and then properly put

back together to he lp prevent breakage of

parts and long term damage from water that

can enter housings that have not been proper

ly resealed.

For your safety, we recommend that you have

your authori zed Audi dea ler replace any bulbs

for you, since your dealer has the proper tools,

the correct bulbs and the expertise.

Gas discharge lamps (Xenon lights ):

Due to the high e lectr ica l voltage, have the

bulbs replaced by a qualified technician.

Headlights with Xenon light are identified by

the high voltage st icker.

A WARNING "--

Changing Xenon lamps without the neces-

sary equipment can cause serious persona l

injury.

- Bulbs are pressurized and can explode

when being changed. Potential risk of in

jury!

- On veh icles equipped with gas discharge

bulbs (Xenon light) life-threatening inju

ries can result from improper handling of

the high-voltage portions of such lamps!

- Only your authorized Audi dealer or qualified workshop should change the

bu lbs in gas discharge lamps. There are

pa rts with sharp edges on the openings

and on the bulb holders that can cause

serious cuts. If you are uncertain about

what to do, have the work performed by

an authorized Audi dealer or qualified

workshop. Serious personal injury may

result from improperly performed work.

@ Tips

-If you still prefer to replace the light

bulbs yourself, be aware that the engine ..,.

Page 229 of 258

M N

M N

0 ::i co ,...., \!) ..,.,

,...., ..,., ,....,

compartment is a hazardous area to

work inc::>

page 179 c::> & .

-It is best to ask your authorized A udi

dealer whenever you want to change a

bulb.

Fu ses and bulb s 227

•

•

Page 230 of 258

228 Emergency situations

Emergency situations

General

This chapter is intended for trained emer

gency crews and working personnel who

have the necessary tools and equipment to

perform these ope rations.

Starting by pushing or

towing

Q;) Note

Vehicles with an automati c transmission

cannot be started by pushing or towing .

Starting with jumper

cables

If necessary, the engine can be started by

connecting it to the battery of another vehi

cle.

If the engine should fail to start because of a

discharged or weak battery, the battery can be

connected to the battery of

another veh icle,

using a

pair of jumper cables to start the en

g ine .

Jumper cables

Use only jumper cables of sufficiently large

cross section to carry the starter current safe

ly. Refer to the manufacturer's specifications.

Use only jumper cables with

insulated termi

na l clamps which are distinctly marked:

plus(+) cable in most cases colored red

minu s(-) cable

in most cases colored black .

A WARNING

Batteries contain electricity, ac id, and gas .

Any of these can cause very serious or fatal

inju ry. Follow the instructions below for

safe handling of your veh icle's battery.

- Always shield you r eyes and avoid lean

ing over the battery whenever possible.

- A discharged battery can freeze at tem

peratures just be low 32 °F (0 °C). Before connecting a

jumper cable, you must

thaw the frozen battery complete ly, oth

erwise it could explode.

- Do not allow battery acid to contact eyes

or skin . Flush any contacted area with

water immediately .

- Improper use of a booster battery to start a vehicle may cause an explosion.

- Vehicle batteries generate explosive gas

es. Keep sparks, flame and lighted ciga

rettes away from batteries.

- Do not try to jump start any vehicle with a low ac id level in the battery.

- The vo ltage of the booster battery must

also have a 12-Volt rating . The capacity

(Ah) of the booster battery should not be

lower than that of the discharged bat

tery . Use of batteries of d ifferent voltage

or substantially different "Ah" rating

may cause an exp losion and personal in

jury.

- Never charge a frozen batte ry. Gas trap

ped in the ice may cause an explosion.

- Never charge or use a battery that has

been frozen. The battery case may have

be weakened.

- Use of batter ies of different voltage or

substantially different capacity (Ah) rat

ing may cause an exp losion and injury.

The capacity (Ah) of the booster battery

should not be lower than that of the dis

charged battery.

- Before you check anything in the engine

compartment, always read and heed a ll

WARNINGS ¢

page 179.

(D Note

-App lying a higher voltage booster bat

tery will cause expensive damage to sen

sitive electronic components, such as

control units, relays, radio, etc .

- Th ere must be no electrical contact be

tween the vehicles as otherwise current cou ld already start to f low as soon as the

positive(+) terminals are connected. .,.