AUDI Q3 2016 Owners Manual

Manufacturer: AUDI, Model Year: 2016, Model line: Q3, Model: AUDI Q3 2016Pages: 252, PDF Size: 62.81 MB

Page 221 of 252

.... N

c:i ::J CX)

.... I.Cl U"I

N I.Cl ......

Fuses and bulbs

Fuses

Replacing fuses

A fuse that has blown will have metal strips that

have burned through .

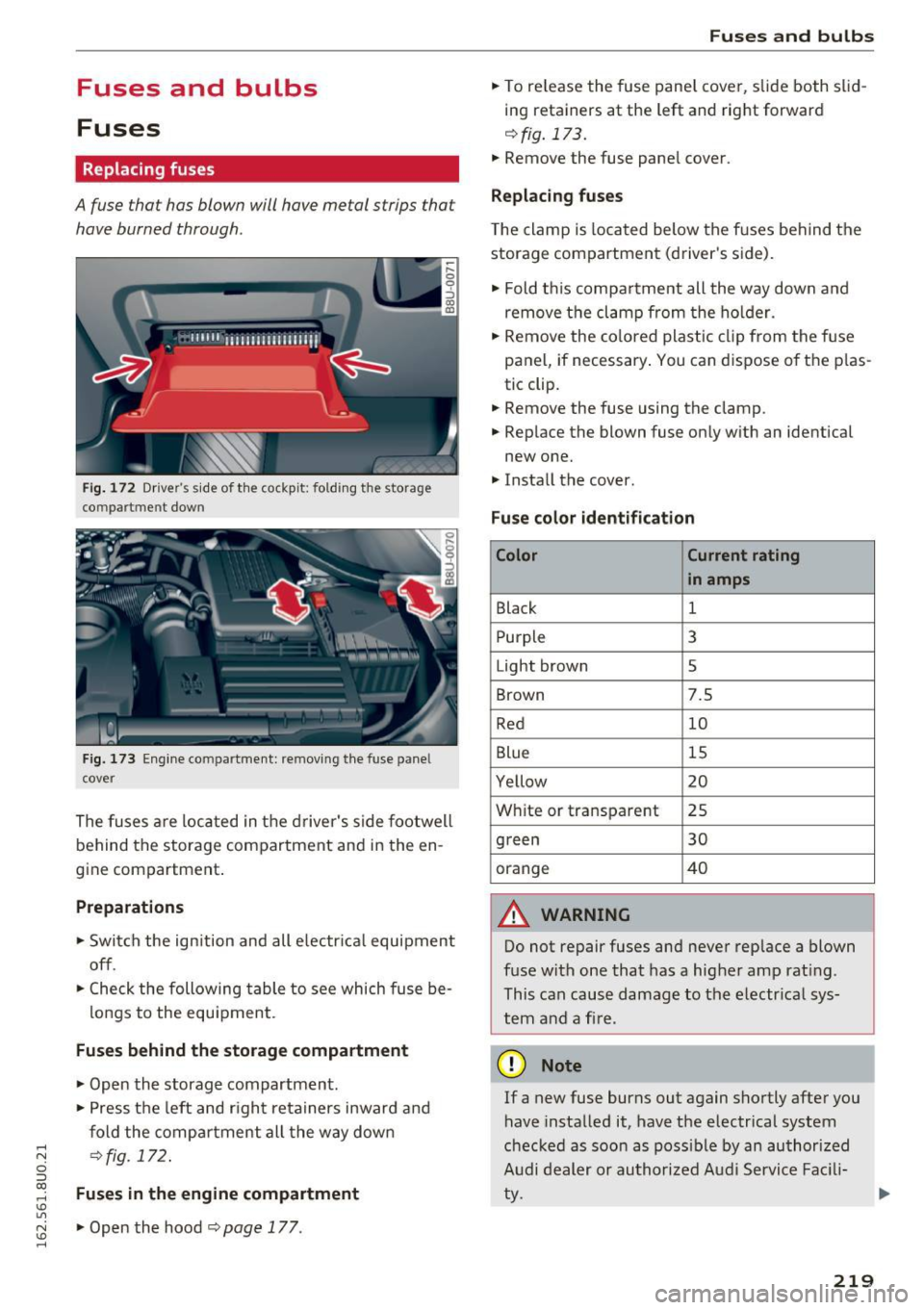

Fig. 172 Driver's side of the cockpit: fol ding the storage

co mpartme nt dow n

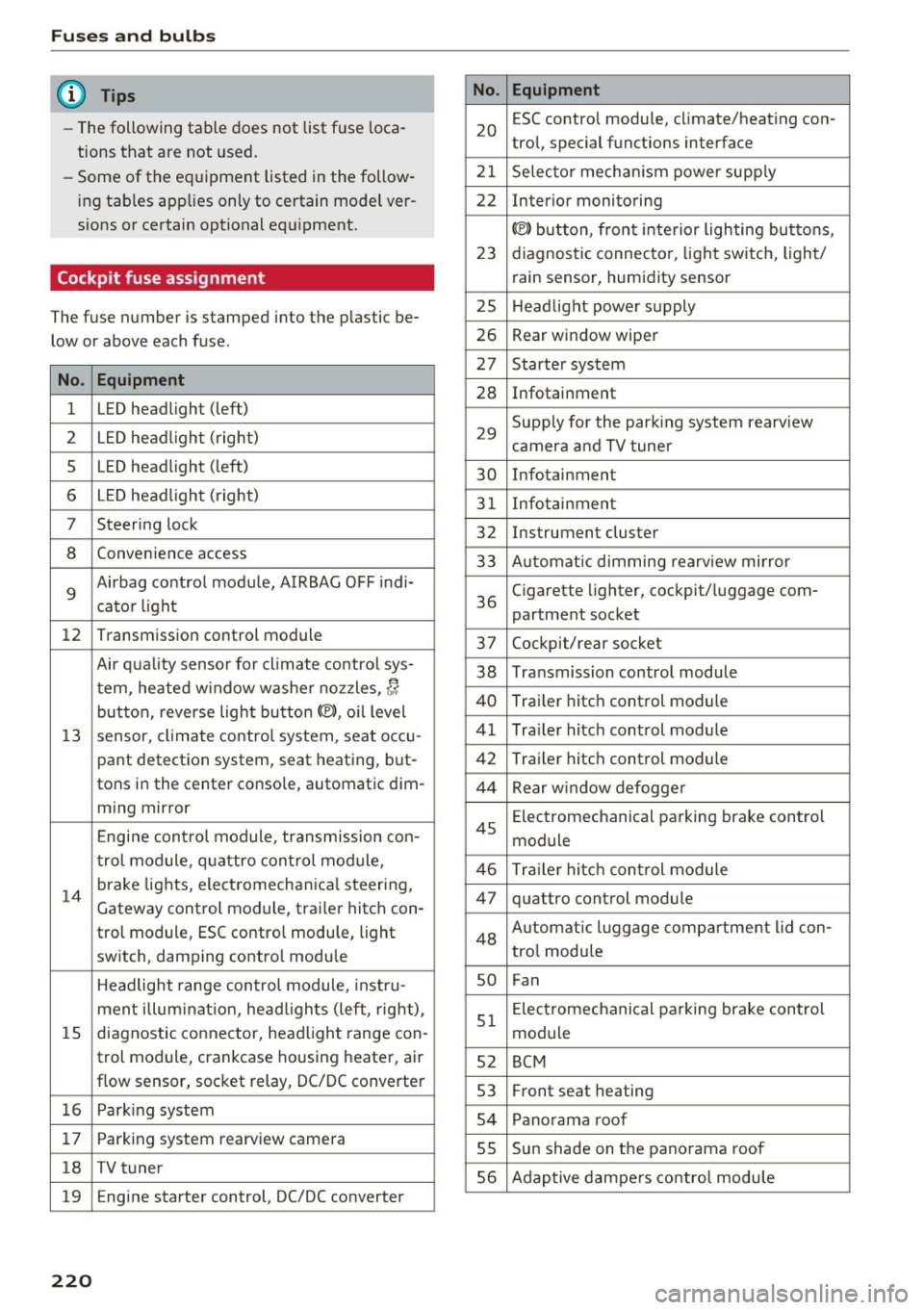

Fig. 173 Engine compartment: removing the fuse pane l

cover

The fuses are located in the driver's side footwell

beh ind th e storage compartment and in the en

gin e compartment .

Preparations

.. Switch the ign ition and all electr ical equipment

off.

.. Check the following table to see which fuse be-

longs to the equipment .

Fuses behind the storage compartment

.. Open the storage compartment .

.. Press the left and right retainers inward and

fold the compartm ent all the way down

¢fig . 172 .

Fuses in the engine compartment

.. Open the hood ¢ page 177.

Fuses and bulbs

.. To release the fuse panel cover, slide both slid

in g reta iners at the left and right forward

¢fig. 173 .

.. Remove the fuse panel cover.

Replacing fuses

The clamp is located below the fuses behind the

storage compartm ent (driver's side) .

.. Fold th is compartment all the way down and

remove the clamp from the holder .

.. Remove the colored plastic clip from the fuse

panel, if necessary . You can dispose of the plas

tic clip .

.. Remove the fuse using the clamp .

.. Replace the blown fuse only with an identical

new one .

.. Insta ll the cover.

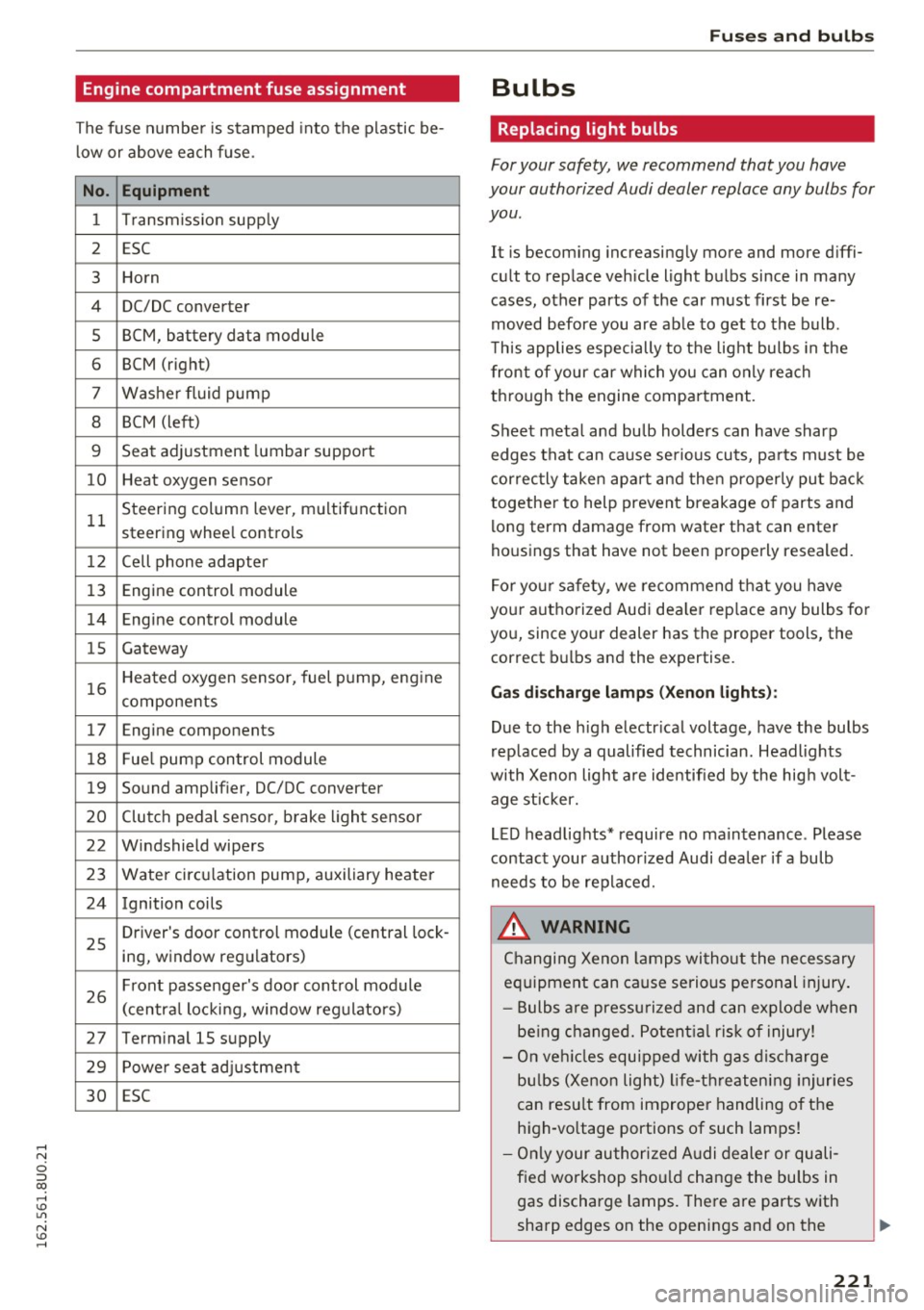

Fuse color identification

Color Current rating

in amps

Black 1

Pu rple 3

Light brown 5

Brown 7.5

Red 10

Blue 15

Yellow 20

Whi te or transparent 25

green 30

orange 40

A WARNING

Do not repair fuses and never replace a blown

fuse with one that has a higher amp rat ing .

This can cause damage to the electr ical sys

tem and a fire.

(D Note

If a new fuse burns out again shortly after you

have installed it, have the electrical system

checked as soon as poss ible by an authorized

Audi dealer or authorized Audi Service Facili

ty .

219

Page 222 of 252

Fuses and bulbs

(D Tips

- The following table does not list fuse loca

tions that are not used.

- Some of the equipment listed in the follow

ing tables applies only to certain model ver

sions or certain optional equipment.

Cockpit fuse assignment

The fuse number is stamped into the plastic be

low or above each fuse.

No. Equipment

1 LED headlight (left)

2 LED headlight ( right)

5 LED headlight (left)

6 LED headlight (right)

7 Steering lock

8 Convenience access

9

Airbag control module, AIRBAG OFF indi-

cator light

12 Transmission control module

Air quality sensor for climate contro l sys-

tern, heated w indow washer nozzles,~

button, reverse light button<®>, oil level

13 sensor, climate control system, seat occu-

pant detection system, seat heating , but-

tons in the center console, automatic dim-

ming mirror

Engine control module, transmission con-

trol module, quattro control module,

14

brake lights, electromechanica l steering,

Gateway cont rol module, trailer hitch con-

trol module, ESC contro l module, light

switch, damping control module

Headlight range control module, instru-

ment illuminat ion, headl ights (left, right),

15 diagnostic connector, headlight range con-

trol module, crankcase housing heater, air

flow sensor, socket relay, DC/DC converter

16 Park ing system

17 Parking system rearview camera

18 TV tuner

19 E ngine starter control, DC/DC converter

220

No . Equipment

20

ESC contro l module, climate/heating con-

tro l, special functions interface

21 Selecto r mechanism power supply

22 Interior monitoring

© button, front interior lighting buttons,

23 diagnostic connector, light switch, light/

rain sensor, humidity sensor

25 Headlight power supply

26 Rear window wiper

27 Starter system

28 Infotainment

29

Supply for the park ing system rearv iew

camera and TV tuner

30 Infotainment

31 Infotainment

32 Instrument cluster

33 A utomat ic dimming rearview mirror

36

Cigarette lighter, cockpit/ luggage com-

partment socket

37 Cockpit/rear socket

38 Transmission control module

40 Trailer hitch control module

41 Trailer hitch control module

42 Trailer hitch control module

44 Rear window defogger

45

Electromechanical parking brake control

module

46 Trailer hitch control module

47 quattro control module

48 Aut omat ic lu ggage compartment lid con-

tro l module

so Fan

51

Electromechanical parking brake control

module

52 BCM

53 Fr ont seat heating

54 Panorama roof

55 Sun shade on the panorama roof

56 Adaptive dampers control module

Page 223 of 252

Engine compartment fuse assignment

The fuse number is stamped into the plastic be

low or above each fuse.

No. Equipment

1 Transmiss ion supply

2 ESC

3 Horn

4 DC/DC

converter

5 BCM, battery data module

6 BCM (right)

7 Washer fluid pump

8 BCM (left)

9 Seat adjustment lumbar support

10 Heat oxygen sensor

11 Steering

column lever, multifunction

steering wheel contro ls

1 2 Cell phone adapter

13 Engine control

module

14 Engine control module

15 Gateway

16 Heated oxygen sensor, fuel pump,

engine

components

17 Engine components

18 Fue l pump control module

19 Sound

amplifier, DC/DC converter

20 Clutch pedal sensor, brake light sensor

22 Windshield wipers

23 Water circu

lation pump, auxiliary heater

24 Ignition coils

25 Driver's door

control module (central lock-

ing, window regu lators)

26 Front

passenger's door control module

(centra l locki ng, window reg ulators)

27 Terminal 15 supply

29 Powe r seat adjustment

30 ESC

Fuses an d bulb s

Bulbs

Replacing light bulbs

For your safety, we recommend that you have

your authorized Audi dealer replace any bulbs for

you .

It is becoming increasingly more and more diffi

cult to replace vehicle light bulbs since in many

cases, other parts of the car m ust first be re

moved before you are able to get to the bulb .

T his applies especially to the light bulbs in the

front of your car which you can only reach

through the engine compartment .

Sheet metal and bu lb holders can have sharp

edges that can cause serious cuts, pa rts must be

correctly taken apart and then properly put back

together to help prevent breakage o f parts and

long term damage from water that can enter

housings that have not been properly resealed.

For your safety, we recommend t hat you have

your authorized Aud i dea le r rep lace any bulbs fo r

you, since your dealer has the proper tools, the

correct bulbs and the expertise.

Gas di schar ge la mps (Xe no n light s):

Due to the high electr ical voltage, have the bulbs

rep laced by a qualified technician. Headlights

with Xenon light are identified by the hig h volt

age st icker.

LED headlights* require no maintenance . Please

contact your authorized Audi dea ler if a bulb

needs to be replaced.

_&. WARNING

Changing Xenon lamps wi thout the necessary

equipment can cause serious personal injury .

- Bulbs are pressu rized and can explode when

be ing changed. Potent ial ris k of injury!

- On veh icles equipped with gas disc harge

bu lbs (Xenon light) life-threatening injuries

can resu lt from improper handling of the

high-vo ltage portions of such lamps!

- Only your authorized A udi dealer or quali

fied workshop sho uld change the bulbs in

gas discharge lamps. There are parts with

sharp edges on the openings and on the

221

Page 224 of 252

Fuses and bulbs

bulb holders that can ca use serio us cuts . If

yo u are uncertain about what to do, have

the work performed by an authorized Audi dealer or qualif ied workshop . Serious per

sonal in ju ry may resu lt from imprope rly per·

formed work .

@ Tips

-If you still prefer to rep lace the light bulbs

yourself, be aware that the engine compart ment is a haza rdous a rea to work

in Q page 177 ~&. .

- It is best to ask your authorized A udi dealer

whenever yo u want to change a b ulb.

222

Page 225 of 252

Emergency situations

General

This chapter is intended for trained emergency

crews and working personnel who have the nec

essary tools and equipment to perform these

operations.

Starting by pushing or

towing

(D Note

Vehicles with an automatic transmission

cannot be started by pushing or towing.

Starting with jumper

cables

If necessary, the engine can be started by con

necting it to the battery of another vehicle .

If the engine should fail to start because of a dis

charged or weak battery, the battery can be con

nected to the battery of

another vehicle, using a

pair of jumper cables to start the engine.

Jumper cables

Use only jumper cables of sufficiently large cross

section

to carry the starter current safely. Refer

to the manufacturer's specifications.

Use only jumper cables with

insulated terminal

clamps which are distinctly marked :

plus(+) cable in most cases colored red

minus(·) cable

in most cases colored black.

A WARNING

Batteries contain electricity, acid, and gas.

Any of these can cause very serious or fatal in

jury. Follow the instructions below for safe

handling of your vehicle's battery.

-Always shield your eyes and avoid leaning

over the battery whenever possible.

-A discharged battery can freeze at tempera

tures just below 32 °F (0 °C). Before con

necting a jumper cable, you must thaw the

Emergency situations

frozen battery completely, otherwise it

could explode .

- Do not allow battery acid to contact eyes or

skin. Flush any contacted area with water immediately.

- Improper use of a booster battery to start a

vehicle may cause an explosion.

- Vehicle batteries generate explosive gases.

Keep sparks, flame and lighted cigarettes

away from batteries.

- Do not try to jump start any vehicle with a

low acid level in the battery .

- The voltage of the booster battery must also

have a 12-Volt rating. The capacity (Ah) of

the booster battery should not be lower

than that of the discharged battery. Use of

batteries of different voltage or substantial

ly different "Ah" rating may cause an explo

sion and personal injury .

- Never charge a frozen battery. Gas trapped

in the ice may cause an explosion.

- Never charge or use a battery that has been

frozen . The battery case may have be weak

ened .

- Use of batteries of different voltage or sub

stantially different capacity (Ah) rating may

cause an explosion and injury. The capacity

(Ah) of the booster battery should not be

lower than that of the discharged battery.

- Before you check anything in the engine

compartment, always read and heed all

WARNINGS

r::!)page 177.

(D Note

-Applying a higher voltage booster battery

will cause expensive damage to sensitive

electronic components, such as control

units, relays, radio, etc.

- There must be no electrical contact between

the vehicles as otherwise current could al

ready start to flow as soon as the positive

(+) terminals are connected.

(D Tips

- The discharged battery must be properly

connected to the vehicle's electrical system. ..,.

223

Page 226 of 252

Emergency situations

When jump starting or charging the bat

tery, never connect the negative ground ca

ble to the battery negative post because the

battery manager system must be able to de

tect the battery's state of charge. Always

connect the negative ground cable to the

negative ground post of the battery manag

er contro l unit.

Use of jumper cables

Make sure to connect the jumper cable clamps in

exactly the order described below!

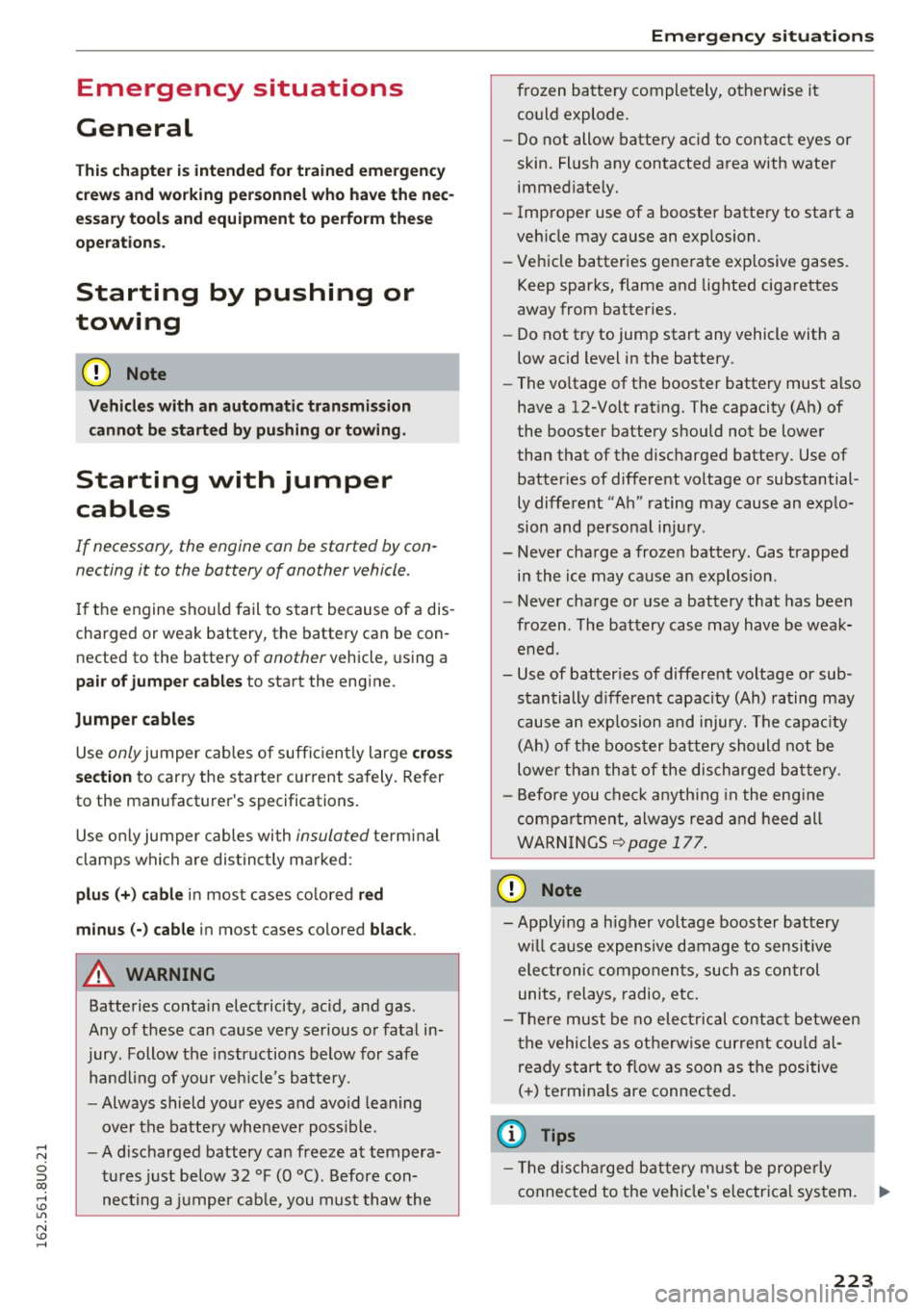

F ig . 1 74 Engine compar tment: Connectors for jumper ca

bles and charger

N N ~ 9 ::, 00 CXl

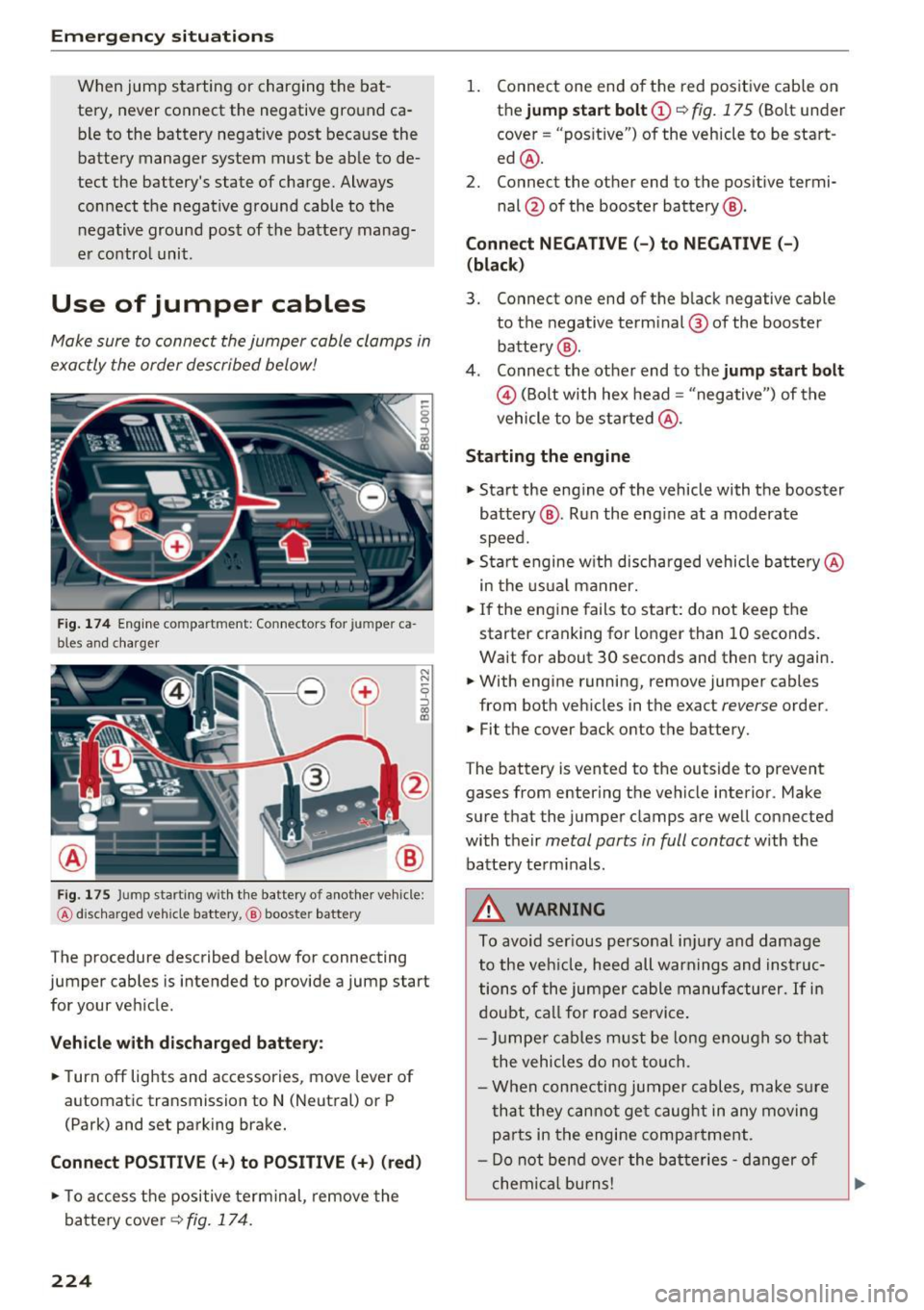

F ig. 175 Jump starti ng wit h the battery of another veh icle:

@ discharged vehicle battery,@booster battery

The procedure described below for connecting

jumper cables is intended to provide a jump start for your vehicle.

Vehicle with discharged battery:

• Turn off lights and accessories, move lever of

automatic transmission to N (Neutral) or P

(Park) and set parking brake.

Connect POSITIVE (+) to POSITIVE (+) (red)

• To access the positive terminal, remove the

battery cover

c::> fig. 17 4.

224

1. Connect one end of the red pos itive cable on

the

jump start bolt (D c::> fig. 175 (Bolt under

cover= "positive") of the vehicle to be start

ed @.

2. Connect the other end to the positive termi-

nal @ of the booster battery @.

Connect NEGATIVE (- ) to NEGATIVE (-)

(black)

3. Connect one end of the black negative cable

to the negative term inal @ of the booster

battery @.

4. Connect the other end to the

jump start bolt

@ (Bolt with hex head = "negative") of the

vehicle to be started @.

Starting the engine

• Start the eng ine of the vehicle with the booster

battery @. Run the eng ine at a moderate

speed.

• Sta rt engine w ith discharged vehicle ba ttery @

in the usual manner.

• If the engine fails to start: do not keep the

starter cranking for longer than 10 seconds.

Wait for about 30 seconds and then try again.

• With engine running, remove jumper cables

from both vehicles in the exact

reverse order.

• Fit the cover back onto the battery.

The battery is vented to the outside to prevent

gases from entering the vehicle interior . Make

sure that the jumper clamps are well connected

with their

metal parts in full contact with the

battery terminals.

&_ WARNING

To avoid ser ious personal injury and damage

to the vehicle, heed all warnings and instruc

tions of the jumper cable manufacturer. If in

doubt, call for road service.

- Jumper cables must be long enough so that

the vehicles do not touch .

- When connecting jumper cables, make sure

that they cannot get caug ht in any moving

parts in the engine compartment.

- Do not bend over the batteries - danger of

chemical burns!

Page 227 of 252

.... N

c:i ::J CX)

.... I.Cl U"I

N I.Cl ......

-The battery cell lock ing screws must be

t ightened secure ly.

- Befo re yo u check anything in the en gine

compartment, a lways read and heed a ll

WARNINGS

¢ page 177.

(D Note

Imp ro per hook -u p of jum pe r cables can r uin

the gene rato r.

-Always con nect POSIT NE

(+ ) to POSITI VE

(+ ), and NEGATIVE( -) to NEGATIVE( -)

ground post of the battery manager contro l

u nit .

- Check that all sc rew p lugs on the batter y

ce lls are screwed in firmly . If not, t ighten

pl ugs prior to connecting clamp on negative

batte ry te rminal.

- Please note t hat the procedure fo r con nect

i ng a jumper cab le as desc ribed above ap

p lies specif ica lly to the case of yo ur vehicle

being jump start ed. Wh en you are giv ing a

ju mp sta rt to anothe r vehicle, do

not con

n ec t t he neg ative (-) ca b le to the negative

( -) t ermina l on the disch arged b attery @

¢

fig. 175. In ste ad , secure ly connec t the

negative( -) ca b le to either a solid me tal

com ponent th at is f irm ly bolted to the e n

gine block o r to t he engine block i tsel f. If

the battery that is be ing c ha rged does not

vent to the outs ide, escap ing batte ry ga s

could ignite and exp lode!

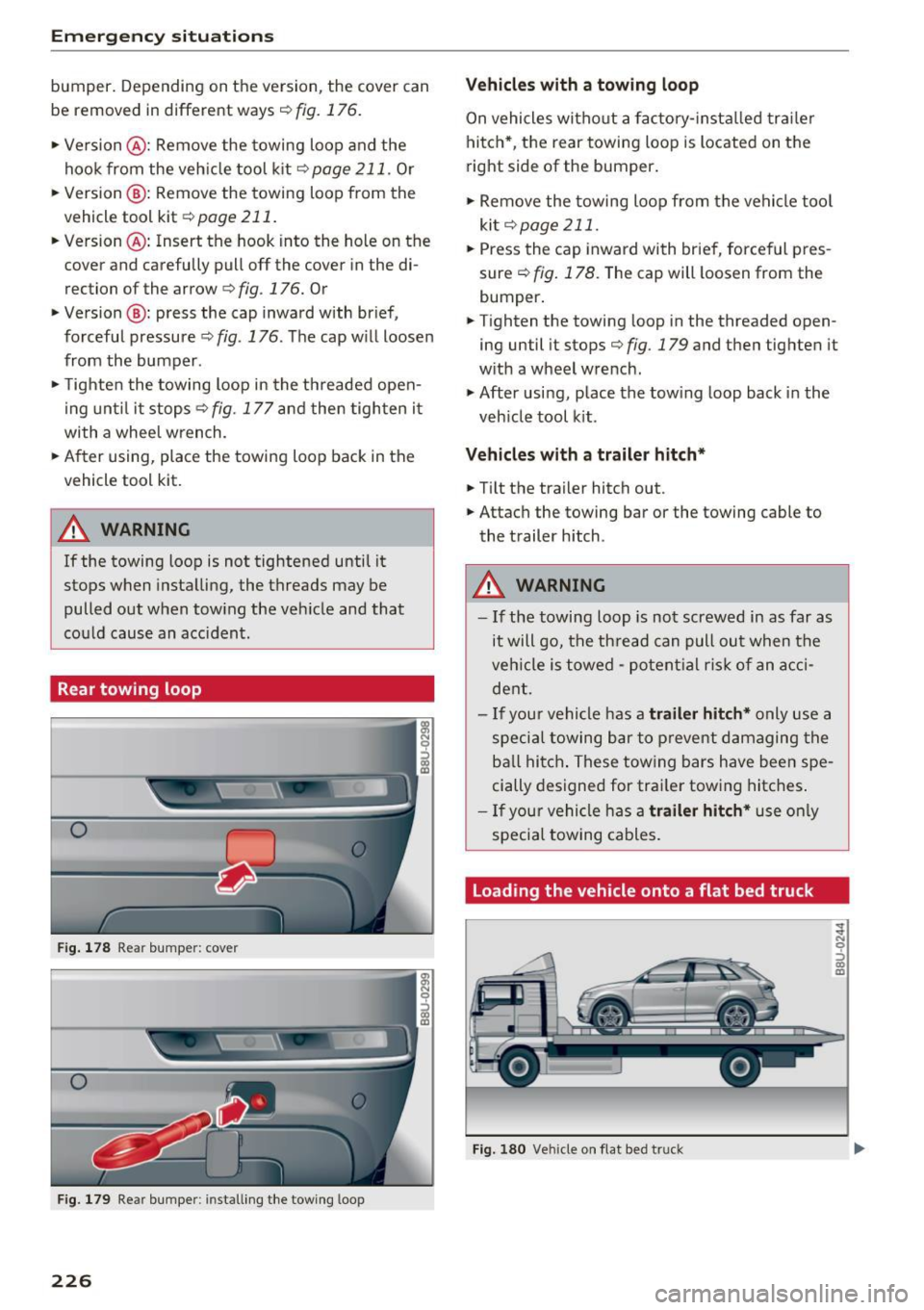

Towing with a tow truck

General hints

Your Audi requires s pecial handling for towing .

The following informa tion is to be used by com

mercia l tow tr uck operators who know how to op

e ra te the ir equip men t safely.

- Ne ver tow your Audi, towing will cause dam

age to the engine and transmission .

- Never wrap the safety chains or winch cables

around the brake lines.

- To prevent unnecessary damage, your Audi

must be transported with a flat bed truck .

Emergency situations

-To load the vehicle on to the flat bed , use the

towing loop found in the vehicle tools and at

tach to the front or rear anchorage

¢ page 225 and ¢ page 226.

A WARNING

A veh icle being towed is not safe for passen

ge rs. Neve r allow a nyo ne to ride in a vehicle

b eing towed, for any reason .

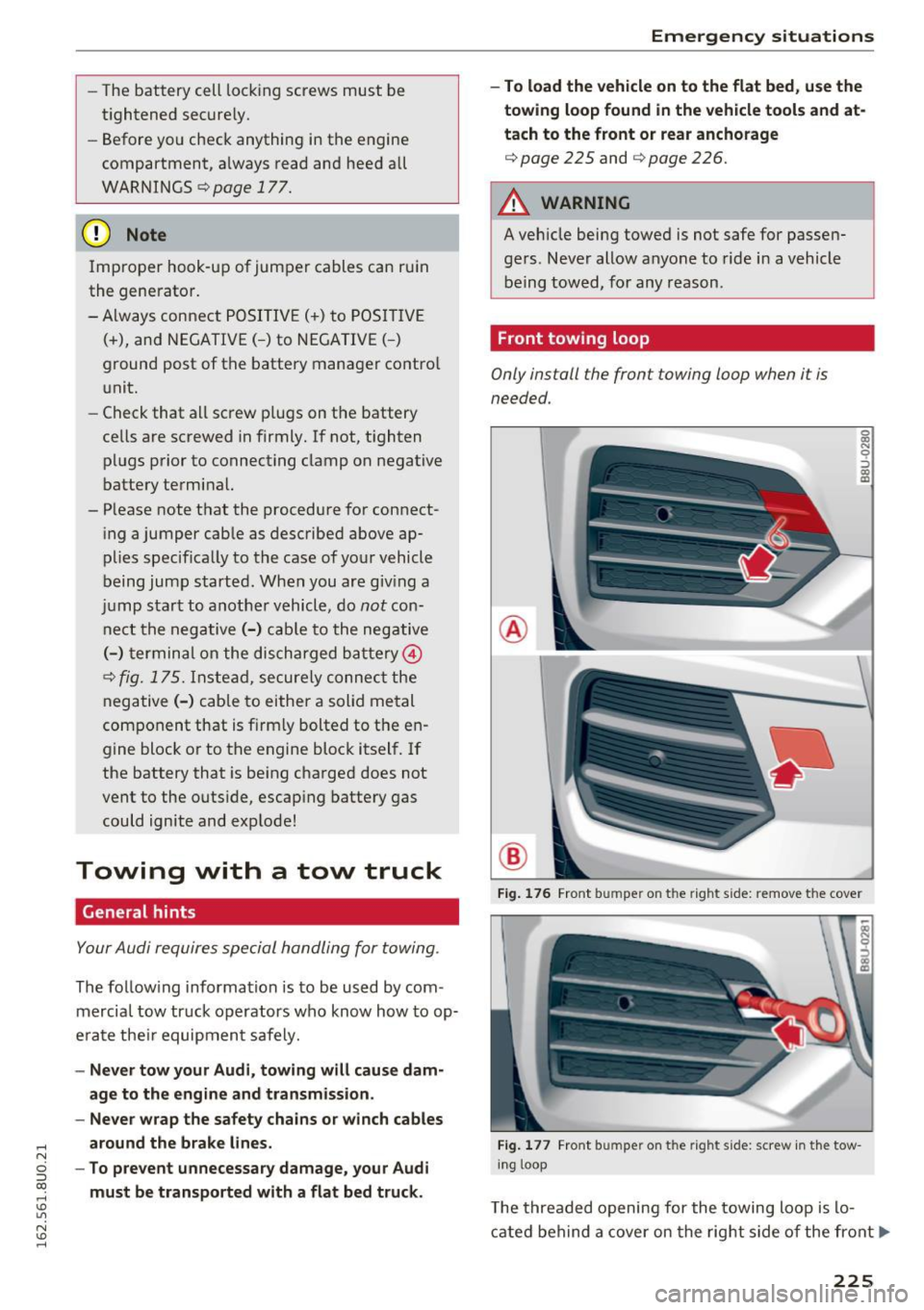

Front towing loop

Only ins tall the front towing loop when i t is

needed .

®

®

-

0 0) N 9 ::>

gi

Fig. 176 Front bum pe r o n th e rig "h t side : remove t he co ver

Fi g. 177 Fron t bum per o n th e right sid e: screw in t he tow

in g loop

The threaded opening for the towing loop i s lo

cate d be hind a cove r on t he rig ht side of the front .,.

225

Page 228 of 252

Emergency situations

bumper. Depending on the version, the cover can

be removed in different ways ¢

fig. 176.

• Version @: Remove the towing loop and the

hook from the veh icle tool kit ¢

page 211. Or

• Version @: Remove the towing loop from the

vehicle tool kit ¢

page 211.

•Version @: Insert the hook into the hole on the

cover and carefully pull off the cover in the di

rection of the arrow ¢

fig. 176. Or

• Ve rsion @: press the cap inward with brief,

forceful pressure

¢fig. 176. The cap w ill loosen

from the bumper.

• Tighten the towing loop in the th readed open

ing until it stops¢

fig. 177 and then tighten it

with a wheel wrench.

• After using, place the towing loop back in the

vehicle tool kit.

A WARNING

If the towing loop is not tightened until it

stops when installing, the threads may be

pulled out when towing the veh icle and that

could cause an accident.

Rear towing loop

Fig. 178 Rear bumper: cover

Fig. 179 Rear bumper: installing the towing loop

226

Vehicles with a towing loop

On vehicles witho ut a factory-installed trailer

hitch*, the rear towing loop is located on the

right side of the bumper .

• Remove the towing loop from the vehicle too l

kit

¢ page 211.

• Press the cap inward with brief, forceful pres

sure¢

fig. 178. The cap will loosen from the

bumper.

• Tighten the towing loop in the threaded open

ing until it stops¢

fig. 179 and then tighten it

w ith a wheel wrench.

• After using, place the tow ing loop back in the

vehicle tool kit.

Vehicles with a trailer hitch*

• Tilt the trailer hitch out.

• Attach the towing bar or the towing cable to

the trailer hitch.

A WARNING

- If the towing loop is not screwed in as far as

it will go, the thread can pull out when the

veh icle is towed - potential risk of an acci

dent.

- If your vehicle has a

trailer hitch* only use a

specia l towing bar to prevent damaging the

ball hitch. These towing bars have been spe

cially designed for trailer towing hitches .

- If your vehicle has a

trailer hitch* use only

special towing cables.

Loading the vehicle onto a flat bed truck

Fig. 180 Vehicle on flat bed truck

~ 0 ::', (IC) m

Page 229 of 252

.... N

c:i ::J CX)

.... I.Cl U"I

N I.Cl ......

Front hook up

• Align the vehicle w ith the centerline of the car

earner ramp .

• Attach the winch hook to the front towline eye

previously installed.

Rear hook up

• Al ign the vehicle w ith the centerline of the car

carr ier ramp .

• Attach the winch hook to the rear towline eye

previously installed.

@ Tips

Check carefully to make sure the hook-up is

secure befo re moving the car up the flatbed

truck ramp.

Raising the vehicle

Lifting with workshop hoist and with floor

jack

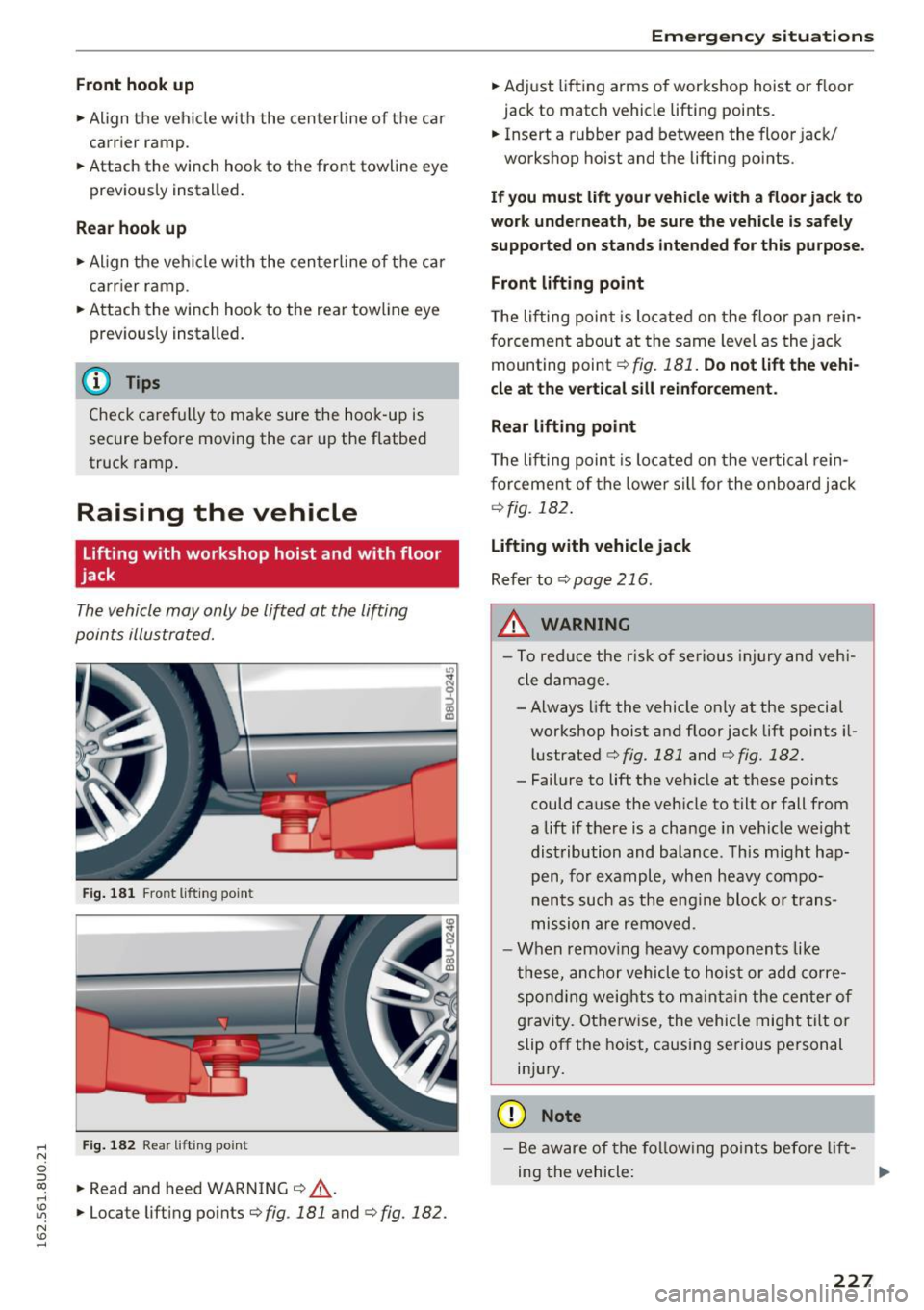

The vehicle may only be lifted at the lifting

points illustrated.

Fig. 181 Front lifting point

F ig . 182 Rear lifting point

• Read and heed WARNING¢,&..

I

• Locate lifting points ¢fig.181 and ¢ fig. 182.

Emergency situations

• Adjust lifting arms of workshop hoist or floor

jack to match vehicle lifting points .

• Insert a rubber pad between the floor jack/

workshop hoist and the lifting points .

If you must lift your vehicle with a floor jack to

work underneath, be sure the vehicle is safely

supported on stands intended for this purpose .

Front lifting point

T he lifting point is located on the floor pan rein

forcement about at the same level as the jack

mounting point ¢

fig. 181. Do not lift the vehi

cle at the vertical sill reinforcement .

Rear lifting point

The lifting point is located on the vertical rein

forcement of the lower sill for the on board jack

¢fig . 182.

Lifting with vehicle jack

Refer to¢ page 216.

&_ WARNING

- To reduce the risk of se rious injury and vehi

cle damage.

- Always lift the vehicle on ly at the special

workshop hoist and floor jack lift points il

lustrated ¢

fig. 181 and ¢ fig. 182.

- Failure to lift the vehicle at these points

could cause the vehicle to tilt or fall from

a lift if there is a change in vehicle weight

distribution and balance . This might hap

pen, for example, when heavy compo

nents such as the engine block or trans

mission are removed.

- When remov ing heavy components like

these, anchor vehicle to hoist or add corre

sponding weights to maintain the center of

gravity. Otherw ise, the vehicle might tilt or

slip off the hoist, causing serious personal

injury .

([) Note

-Be aware of the following points before lift-

ing the vehicle: ..,_

227

Page 230 of 252

Emergency situations

-The vehicle should never be lifted or

jacked up from underneath the engine oil

pan, the transmission housing, the front

or rear axle or the body side members.

This could lead to serious damage.

- To avoid damage to the underbody or

chassis frame, a rubber pad must be in

serted between the floor jack and the lift

points .

- Before driving over a workshop hoist,

check that the vehicle weight does not

exceed the permissible lifting capacity of

the hoist .

- Before driving over a workshop hoist, en

sure that there is sufficient clearance be

tween the hoist and low parts of the ve hicle.

228