engine control system BMW 528i 1998 E39 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: 528i, Model: BMW 528i 1998 E39Pages: 1002

Page 413 of 1002

Downloaded from www.Manualslib.com manuals search engine

- -.

Fuel Injection

SIEMENS MIS 42.0 AND 43.0

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also illuminates

if an emissions-related fault is detected.

When faults arise, or

if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus, MoDiC, GTI or equivalent scan tool. The

capabilities of OBD

II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CAUTION-

* The tests in this section may set fault codes (DTCs) in tlie

ECM and illuminate the MIL. After all testing is completed,

access and clear DTC fault

memory using an OBD I/ or

BMW compatible scan tool. See

OBD On-Board Diag-

nostics.

Only use a

dgital multimeter for electrical tests.

Relay positions can vary. Be sure to confirm

relayposi-

tion by identifying the wiring in the socket using the wir-

ing diagrams found in

ELE Electrical Wiring

Diagrams.

NOTE-

- OBD I1 fault memory. (including an illuminated MIL! can

only be reset using the special scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault memory.

The BMW-dedicated 20-pin diagnostic

linlc connector

(DLC) is in the right rear of the engine compartment The

20-pin DLC is discontinued on models after

6/2000.

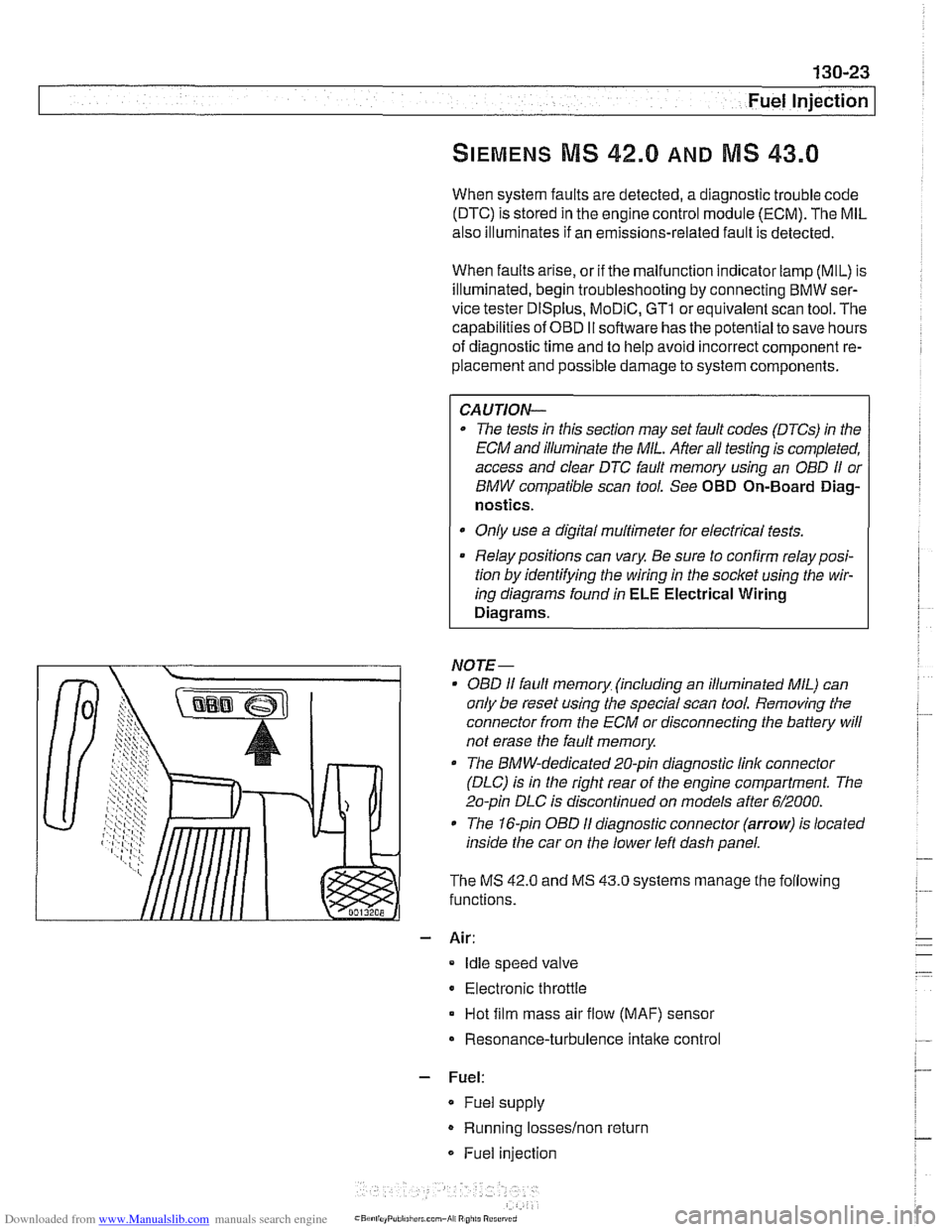

The 1 &pin OBD I1 diagnostic connector (arrow) is located

inside the car on the lower left dash panel.

The MS

42.0 and MS 43.0 systems manage the following

functions.

- Air:

Idle speed valve

Electronic throttle

Hot film mass air flow (MAF) sensor

Resonance-turbulence intake control

- Fuel:

* Fuel supply

Running losseslnon return

Fuel injection

Page 414 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

- Ignition:

Direct ignition

Knock control

4 Primary1 secondary ignition monitoring

- Emissions:

OBD II compliance

Secondary air injection

Pre- and post-catalyst oxygen sensors

0 Electrically heated DME-mapped thermostat

Misfire detection

Evaporative emission control and

leak detection

Malfunction indicator light (MIL)

Performance controls:

Dual VANOS control

Output of injection signal (TI) for fuel economy gauge

Output of engine rpm (TD) for tachometer

AIC compressor control

0 Electric radiator cooling fan

CAN-Bus communication

Stability and traction system

(ABSIASCIDSC) interlace

Electronic immobilizer (EWS)

Cruise control

ECM programming

Page 417 of 1002

Downloaded from www.Manualslib.com manuals search engine

-

Fuel Injection

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(Bc) power to many of the

engine management components and subsystems. If this re-

lay is faulty, the engine will not start.

NOTE-

The ECM relay is also referred to as the DME main relay

ECM relay powers:

ECM

Ignition coils

* Fuel injection

Evaporative leak detection pump

Idle air actuator

- Camshaft sensors Evaporative emissions valve

Hot film mass air flow sensor

Fuel pump relay

Oxygen sensor heaters

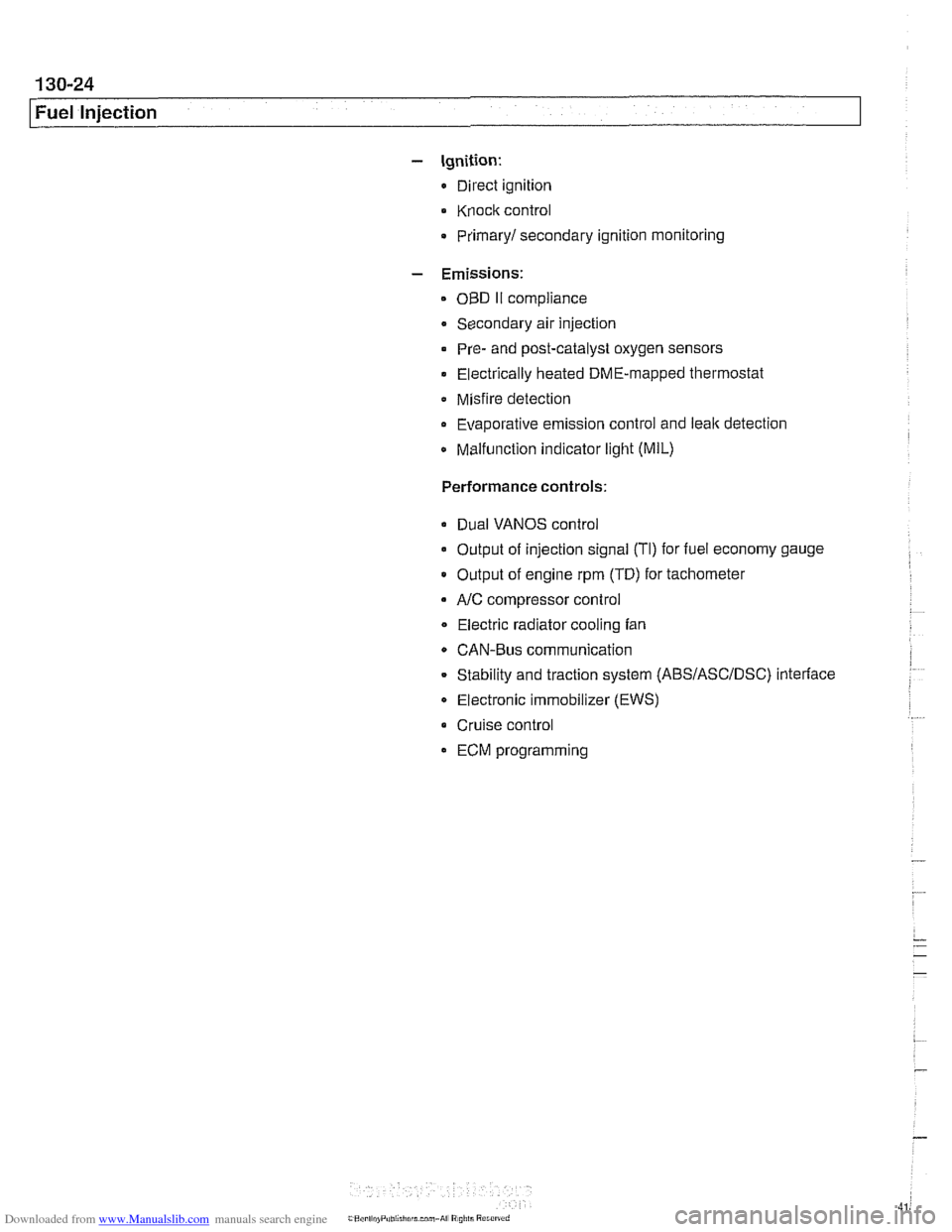

4 Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate duct inward (arrow) to unlock from bulk head and

remove duct.

Release spring lock

(C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.

With ignition off, remove ECM relay (arrow) in electronics

box (E-box) at rear of engine compartment, right side.

NOTE-

Relay locations can vary Confirm relay identification by

matching wiring colors and terminal numbers.

Page 428 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-38

Fuel Injection

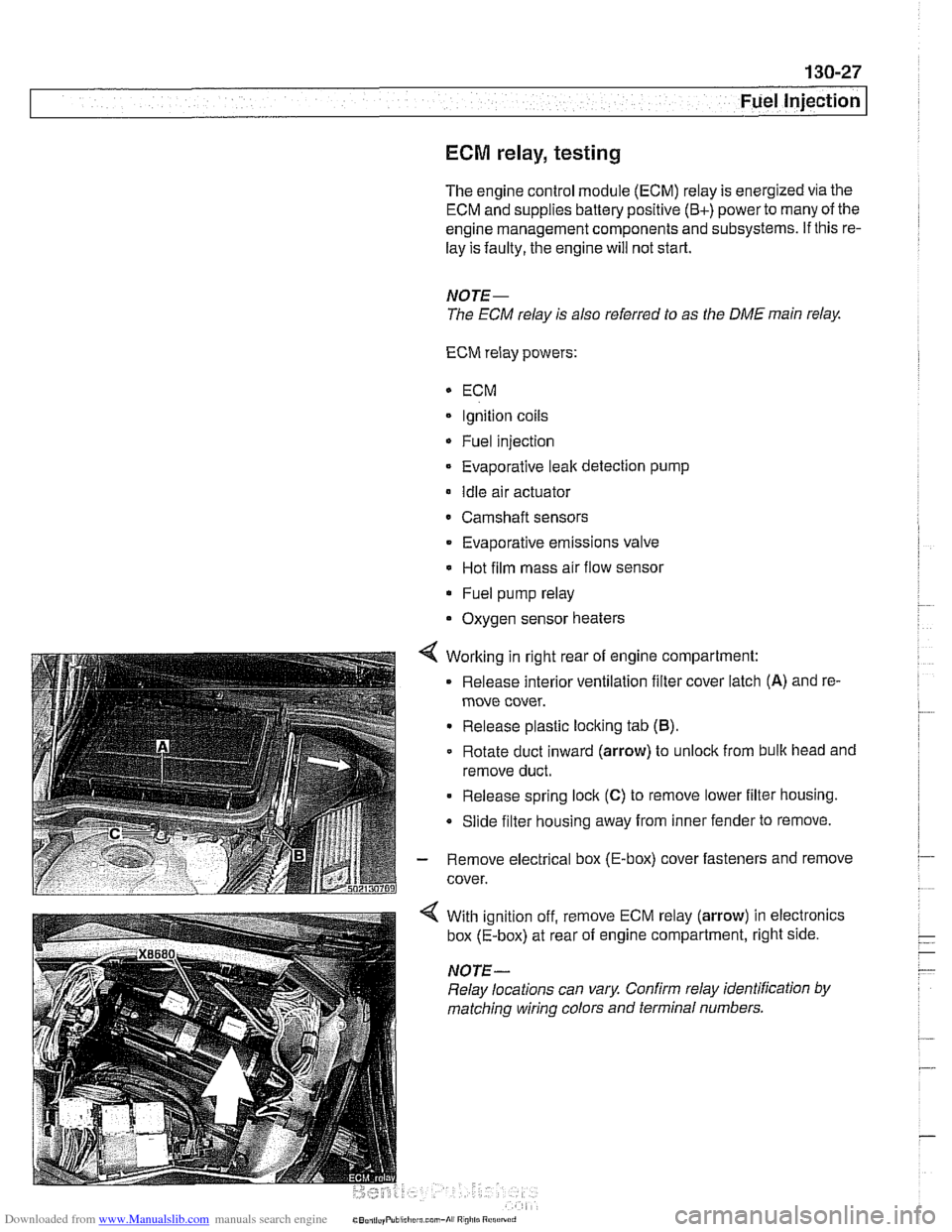

Throttle cable, adjusting

(MS 42.0)

The throttle assembly on MS 42.0 cars uses a throttle cable.

The cable should be adjusted any time it is disconnected or

replaced. This procedure requires the factory scan tool or an

equivalent to read and adjust throttle angle. It is recommend-

ed the procedure be done by an authorized

BMW dealer ser-

vice department

Basic adjustment:

Ensure that at idle (accelerator pedal in rest position) throt-

tle cable has detectable play at throttle lever attaching

point. Play must not exceed maximum allowable.

Adjust by turning knurled adjuster

(arrow) on end of throt-

tle cable sheath at throttle housing.

NOTE-

Faulty throttle adjustment values must be reset using the

BMW service tester

DISplus, MoDiC, GTI or equivalent.

Max.

play at throttle plate lever

ldle speed control valve,

checking and replacing

3 mm (0.125 in)

The Idle speed control valve regulates Idle speed by red~rect-

ing air around the throttle valve. The ldle speed control valve

is mounted

d~rectly above the throttle housing. Accessing the

valve is best accomplished by

flrst removing the air fllter

housing and associated ducting.

Thevalve is supplied with batteryvoltage from the ECM relay.

The idle speed control valve incorporates a two-coil rotary ac-

tuator. The ground sides of each coil are pulsed simulta-

neously by the ECM. The duty cycle of each circuit is varied to

achieve the required idle speed.

A faulty idle speed control valve sets a fault code and the MIL

is illuminated when

OED II fault criteria are exceeded.

Before checking the idle speed control valve, confirm that the

throttle position sensor is working correctly.

- With engine running, check that idle speed control valve is

buzzing.

- Turn on AIC system or shift transmission into drive. ldle

should remain steady or increase slightly.

- If idle speed valve is not buzzing, or if idle decreases when

AIC is turned on, stop engine and disconnect harness con-

nector from idle speed valve.

Page 429 of 1002

Downloaded from www.Manualslib.com manuals search engine

. .

Fuel Injection

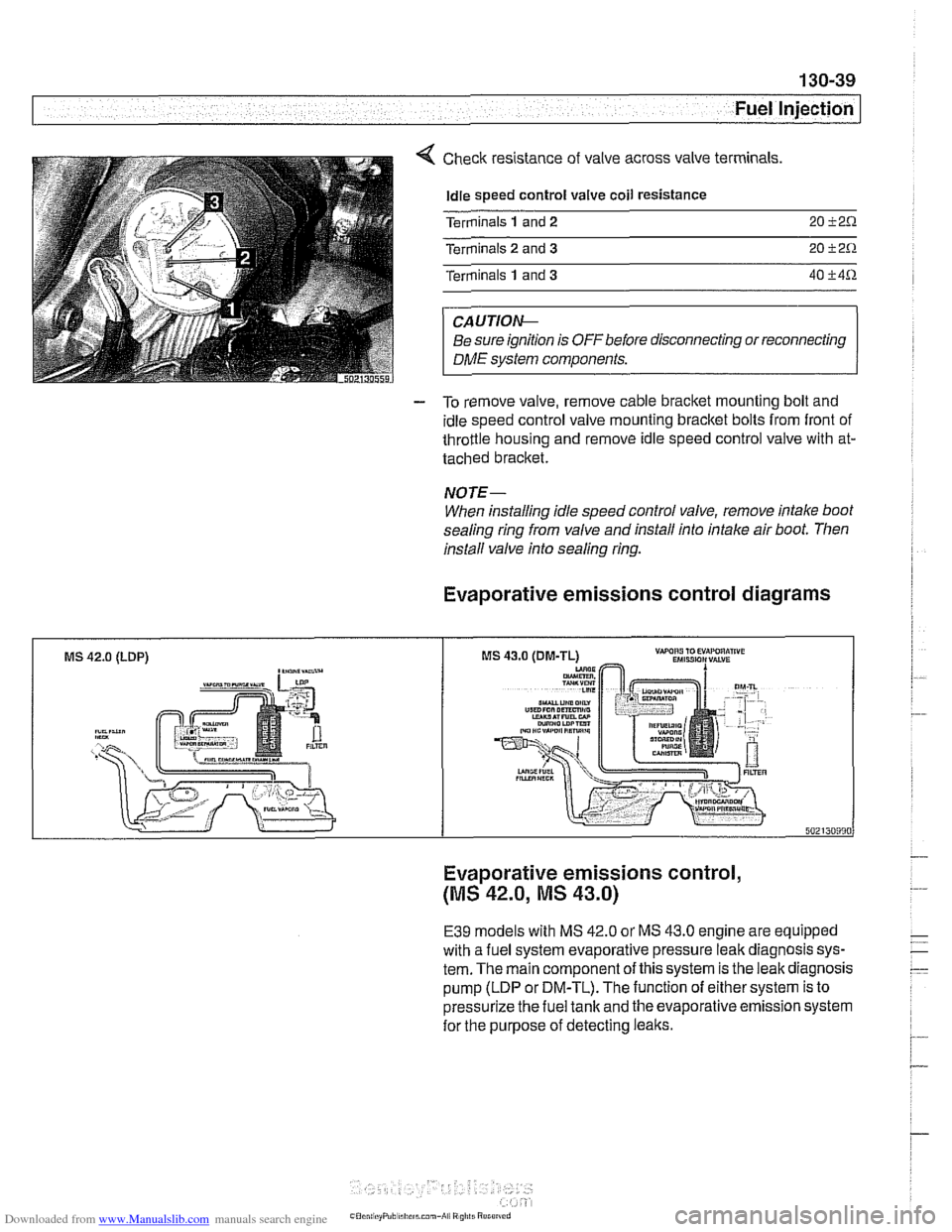

Check resistance of valve across valve terminals

Idle speed control valve coil resistance

Terminals

1 and 2 20 i2.0.

Terminals 2 and 3 20 i2.0.

Terminals 1 and 3 40 i4.0.

CAUTIOIG

Be sure ignition is OFFbefore disconnecting or reconnecting

DME system components.

- To remove valve, remove cable bracket mounting bolt and

idle speed control valve mounting bracket bolts from front of

throttle housing and remove idle speed control valve with at-

tached bracket.

NOTE-

When installing idle speed control valve, remove intake boot

sealing ring from valve and install into intake air boot. Then

install valve info sealing

ring.

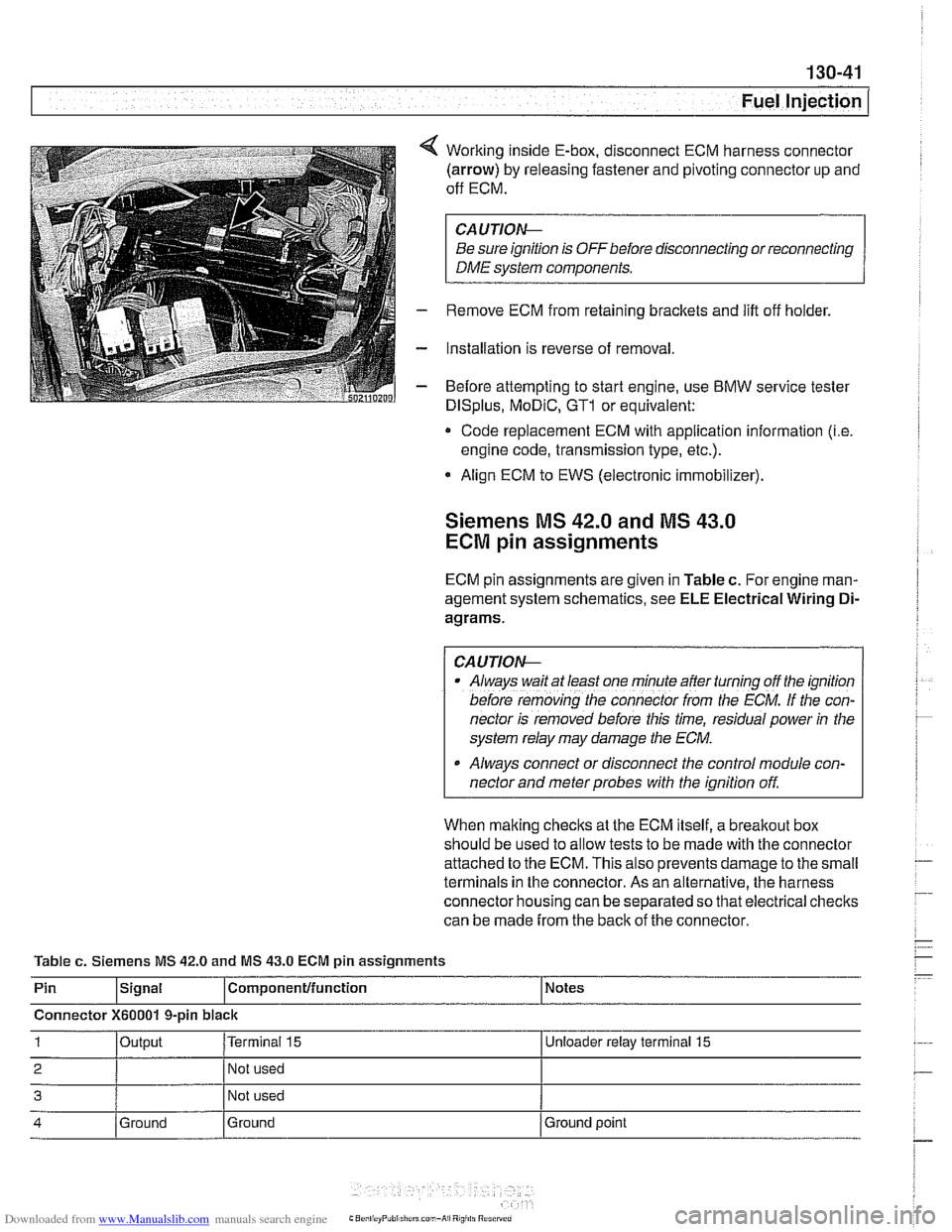

Evaporative emissions control diagrams

MS 42.0 (LDP) ,-a"-

Evaporative emissions control,

(MS 42.0, MS 43.0)

E39 models with MS 42.0 or MS 43.0 engine are equipped

with a fuel system evaporative pressure leak diagnosis sys-

tem. The main component of this system is the leak diagnosis

pump (LDP or DM-TL). The function of either system is to

pressurize the fuel tank and the evaporative emission system

for the purpose of detecting leaks.

Page 431 of 1002

Downloaded from www.Manualslib.com manuals search engine

. -

Fuel Injection I

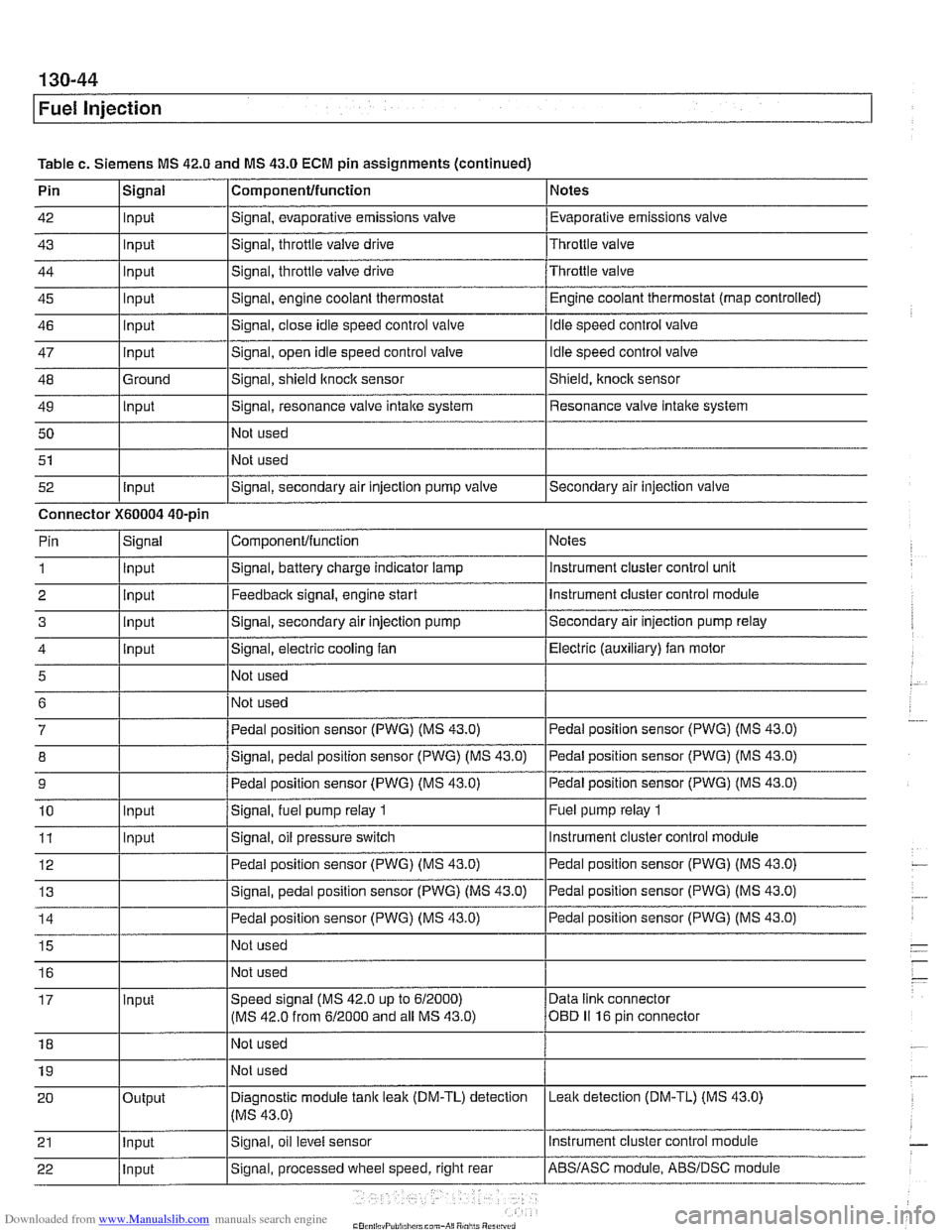

Working inside E-box, disconnect ECM harness connector

(arrow) by releasing fastener and pivoting connector up and

off ECM.

CA UTIOW

Be sure ignition is OFF before disconnecting or reconnecting

DME system components.

Remove ECM from retaining brackets and lift off holder.

Installation is reverse of removal

Before attempting to start engine, use

BMW service tester

DISplus, MoDiC, GTl or equivalent:

* Code replacement ECM with application information (i.e

engine code, transmission type, etc.).

Align ECM to EWS (electronic immobilizer).

Siemens MS 42.0 and MS 43.0

ECM pin assignments

ECM pin assignments are given in Table c. For engine man-

agement system schematics, see

ELE Electrical Wiring Di-

agrams.

/ CAUTIOW I

Al~ays wait at least one mfnule after turning off the ignition

before

remov;ng [he connecror irom rhe ECM. If the con-

nector is removed before this time, residual power

in the

system relay may damage the

ECM.

Always connect or disconnect the control module con-

nector and meter probes with the ignition off.

When making checks at the ECM itself, a

breakout box

should be used to allow tests to be made with the connector

attached to the ECM. This also prevents damage to the small

terminals in the connector. As an alternative, the harness

connector housing can be separated so that electrical checks

can be made from the back of the connector.

Table

c. Siemens MS 42.0 and MS 43.0 ECM pin assignments

Pin

lslgnal l~om~onentlfunction 1 Notes

Connector

X60001 9-pin black

1 loutput I~erminai 15 I Unloeder relay terminal 15

2 I 1 Not used I

3 Not used

4 Ground

Ground Ground

point

Page 434 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

Table c. Siemens MS 42.0 and MS 43.0 ECM pin assignments (continued)

Pin

42

43

44

45

46

47

48

49 50

51

52 Componentlfunction

Signal, evaporative emissions valve

Signal, throttle

valve drive

Signal, throttle valve drive

Signal, engine coolant thermostat

Signal, close idle speed control valve

Signal, open idle speed control valve

Signal, shield

ltnock sensor

Signal, resonance valve

intake system

Not used

Not used

Signal, secondary air injection pump valve

Signal

Input

Input

Input

Input

input

Input

Ground

Input

Input

Notes

Evaporative emissions valve

Throttle valve

Throttle valve Engine coolant thermostat (map controlled)

idle speed control valve

Idle speed control valve

Shield,

knock sensor

Resonance valve intake system

Secondary air injection valve

Connector

X60004 40-pin Notes

instrument cluster control unit

Instrument cluster control module

Secondary air injection pump relay

Electric (auxiliary) fan motor

Pedal position sensor (PWG) (MS 43.0)

Pedal position sensor (PWG) (MS 43.0)

Pedal position sensor (PWG) (MS 43.0)

Fuel pump relay

1

Instrument cluster control module

ComponenVfunction

Signal, battery charge indicator lamp

Feedback signal, engine start

Signal, secondary air injection pump

Signal, electric cooling fan

Not used

Not used

Pedal position sensor (PWG) (MS 43.0)

Signal, pedal position sensor (PWG) (MS 43.0)

Pedal position sensor (PWG) (MS 43.0)

Signal,

fuel pump relay 1

Signal, oil pressure switch

Pin

1

2 3

4

5

6

7

8

9

10

11 Signal

Input

Input

input

input

Input

Input

Page 436 of 1002

Downloaded from www.Manualslib.com manuals search engine

130-46

Fuel Injection

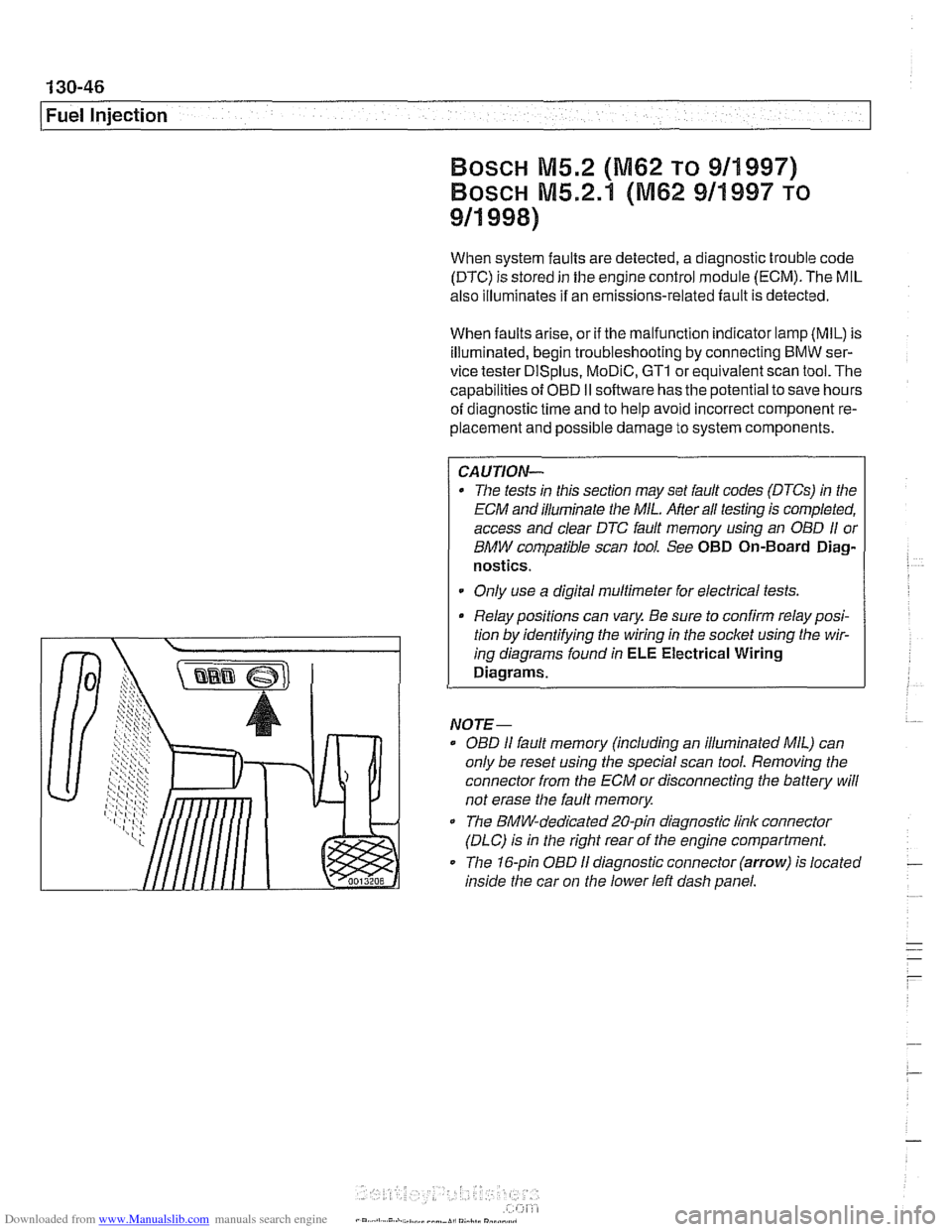

When system faults are detected, a diagnostic trouble code

(DTC) is stored in the engine control module (ECM). The MIL

also illuminates if an emissions-related fault is detected.

When faults arise, or

if the malfunction indicator lamp (MIL) is

illuminated, begin troubleshooting by connecting BMW ser-

vice tester

DISplus. MoDiC, GTI or equivalent scan tool. The

capabilities of

OED II software has the potential to save hours

of diagnostic time and to help avoid incorrect component re-

placement and possible damage to system components.

CA UTIOiU-

The tests in this section may set fault codes (DTCs) in the

ECM and illuminate the MIL. After ail testing is completed,

access and clear DTC fault

memory using an OED I/ or

BMW compatible scan tool. See OBD On-Board Diag-

nostics.

Only use a digital

multimeter for electrical tests.

Relay positions can vary. Be sure to confirm relay

posi-

. tion by identifying the wiring in the socket using the wir-

ing diagrams-found in ~~~~lectrical Wiring

Diagrams.

NOTE-

OED I1 fault memory (including an illuminated MIL) can

only be reset

using~the special scan tool. Removing the

connector from the ECM or disconnecting the battery will

not erase the fault

memory.

The BMW-dedicated 20-pin diagnostic link connector

(DLC) is in the right rear of the engine compartment.

The 16-pin OBD

I1 diagnostic connector (arrow) is located

inside the car on

the lower left dash panel.

Page 437 of 1002

Downloaded from www.Manualslib.com manuals search engine

Fuel Injection

M5.2 system features

The Bosch M5.2 system used on 1997 540i models uses an

88-pin control unit. The

M5.2 system has the following func-

tions and capabilities:

Fully sequential cylinder-individual fuel injection.

Integrated adaptive knock control.

Oxygen sensor fuel mixture control.

0 Self-diagnosis and emergency operation characteristics.

CAN-Bus link.

0 OED II functions (misfire detection, catalytic converter

monitoring, oxygen sensor monitor, and fuel tank ventila-

tion system).

Electronic vehicle immobilization via EWS.

One-touch starter function.

Control of characteristic map thermostat.

M5.2.1 system features

The Bosch M5.2.1 system is used on 1998 540i models. The

M5.2.1 control module utilizes the SKE (standard shell con-

struction housing) with 5 connectors and a combined total of

134 pins.

The M5.2.1 systefn has

tile following functions or capabilities:

Separate power supply relay for ignition coils. Leak diagnosis pump (LDP) control and feedback

rnonitor-

ing for evaporative system leak testing.

Fuel evaporative system providing ORVR (on-board refuel-

ing vapor recovery) compliancy.

Batterylalternator charge logic (idle speed varied with the

battery state of charge).

CAN-Bus communications with the instrument cluster

EWS

Ill "rolling code" ISN interface.

More sensitive ignition

knock sensors.

Pulse width modulated (P-W-M) Heating and

AIC (IHKA)

status signal.

Running loss (312-way) solenoid valve.

Page 439 of 1002

Downloaded from www.Manualslib.com manuals search engine

- Fuel Injection

ECM relay, testing

The engine control module (ECM) relay is energized via the

ECM and supplies battery positive

(B+) power to many of the

engine

management components and subsystems. If this re-

lay is faulty, the engine will not start.

CAUTIOI\C

Relay positions can vary. Be sure to confirm relay position by

identifying the wiring

in the socket using the wiring diagrams

in ELE Electrical Wiring Diagrams.

NOTE-

The ECM relay is also referred to as the DME main relay.

ECM relay powers:

* ECM

Ignition coils

Fuel injection

Evaporative leak detection pump

(5.2.1 only)

Idle air actuator

Camshaft sensors Evaporative emissions valve

Hot film mass air flow sensor

Fuel pump relay

Oxygen sensor heaters

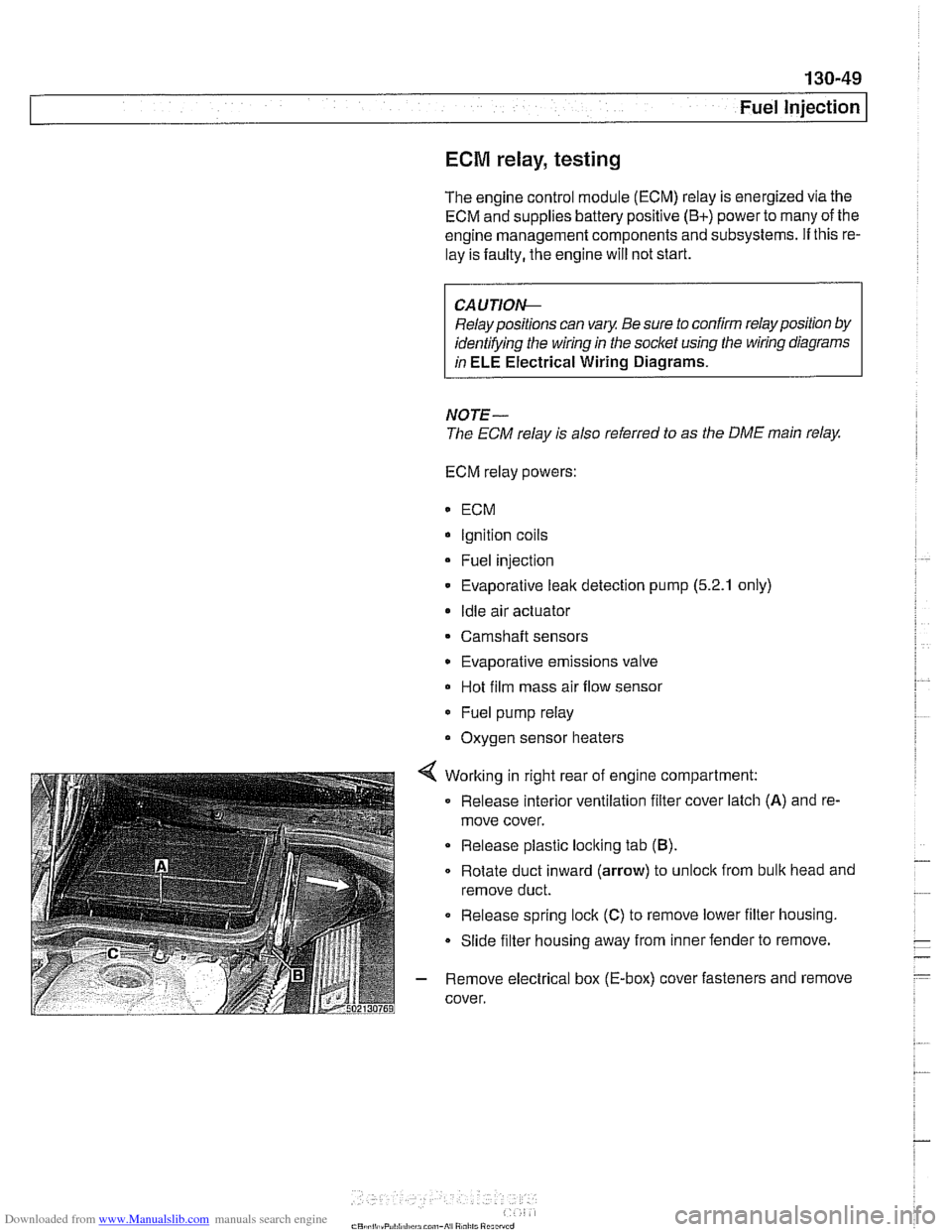

4 Working in right rear of engine compartment:

Release interior ventilation filter cover latch

(A) and re-

move cover.

Release plastic locking tab

(B).

Rotate duct inward (arrow) to unloclc from bulk head and

remove duct.

0 Release spring lock (C) to remove lower filter housing.

Slide filter housing away from inner fender to remove.

- Remove electrical box (E-box) cover fasteners and remove

cover.