ing harness BMW M3 1995 E36 Repair Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1995, Model line: M3, Model: BMW M3 1995 E36Pages: 759

Page 245 of 759

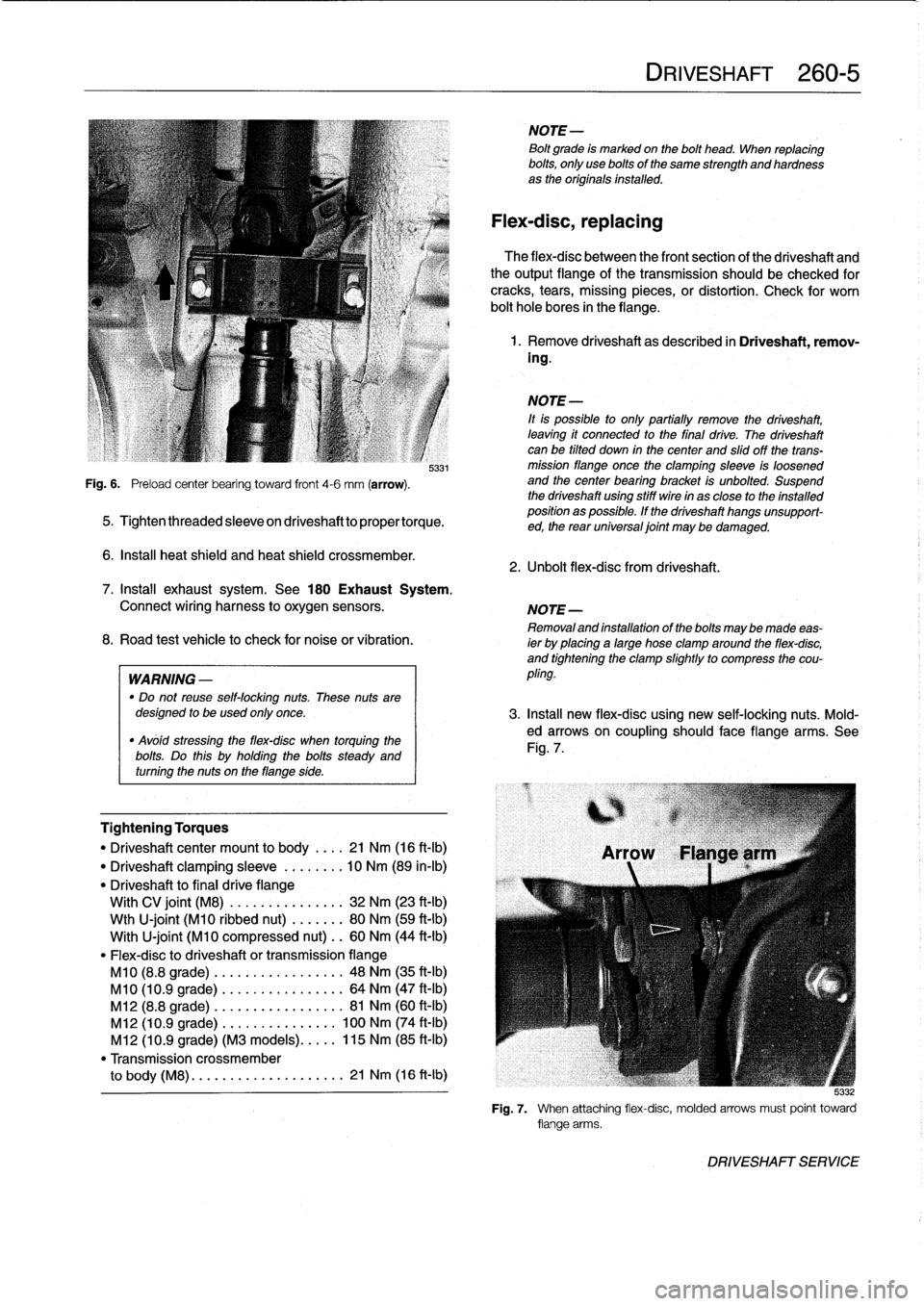

Fig

.

6

.

Preload

center

bearing

toward

front

4-6

mm

(arrow)

.

5331

5

.

Tightenthreadedsleeveondriveshafttopropertorque

.

6

.

Insta¡¡

heat

shield

and

heat

shield

crossmember

.

Tightening

Torques

"

Driveshaftcenter

mount

to

body

.

.

..

21

Nm

(16

ft-Ib)

"

Driveshaft

clamping

sleeve

.....

.

.

.

10

Nm

(89

in-lb)

"

Driveshaft

to

final

drive

flange

With

CV

joint

(M8)

............

...

32

Nm

(23

ft-Ib)

Wth

U-joint

(M10

ribbed

nut)

....

...

80

Nm

(59

ft-Ib)

With

U-joint

(M10

compressed

nut)

..

60

Nm

(44

ft-Ib)

"

Flex-disc

to

driveshaft

or

transmissionflange

M10

(8.8

grade)

.........

.

....

..

.

48

Nm

(35

ft-Ib)

M10

(10

.9

grade)

........

.

....

...

64

Nm

(47

ft-Ib)

M12

(8.8

grade)

........

.....

..

.

.

81

Nm

(60

ft-Ib)

M12

(10

.9

grade)

.

.

....

......

...

100

Nm

(74

ft-Ib)

M12

(10

.9

grade)

(M3

models)

..

.

.

.

115

Nm

(85

ft-Ib)

"

Transmission

crossmember

to

body

(M8)

.

....

...........

....

21

Nm

(16

ft-Ib)

NOTE-

Bolt

grade

is

markedon

the

bolt

head

.

When

replacing

bolts,

only

use

bolts

of

the

same

strength

and

hardnessas

the

originalsinstalled

.

Flex-disc,

replacing

The

flex-disc

between

the

front

section

of

the

driveshaft

and

theoutputflange

of

the

transmission

should

be

checked

for

cracks,

tears,

missing

pieces,

or

distortion

.

Check

for

worn

bolt

hole

bores

in

theflange

.

1

.

Remove

driveshaft

as

described

in

Driveshaft,

remov-

ing

.

NOTE-

¡t

is

possible

to

only

partially

remove

the

driveshaft,

leaving

it

connected

to

the

final

drive

.

The

driveshaft

canbe

tilted

down

in

thecenter

and

slidoff

the

trans-

mission

flange

once

the

clamping

sleeve

is

loosened

and

the

center

bearing

bracket

is

unbolted

.

Suspend

the

driveshaft

using

stiff

wire

in

as

close

to

the

installed

position

as

possible

.

If

the

driveshaft

hangs

unsupport-

ed,

the

rear

universal

joint

may

be

damaged

.

2

.

Unbolt

flex-dísc

from

driveshaft

.

DRIVESHAFT

260-

5

7

.

Install

exhaust

system

.

See

180

Exhaust

System

.

Connect

wiring

harness

to

oxygen

sensors

.

NOTE-

Removaland

installation

of

the

boltsmaybe

made

eas-

8

.

Road

test

vehicle

to

check

for

noiseor

vibration

.

ier

by

placing

a

large

hose

clamp

around

the

flex-disc,

and

tightening

the

clamp

slightlyto

compress

the

cou

WARNING

-

pling

.

"

Do

not

reuse

self-locking

nuts

.

These

nuts

aredesigned

to

beused

only

once

.

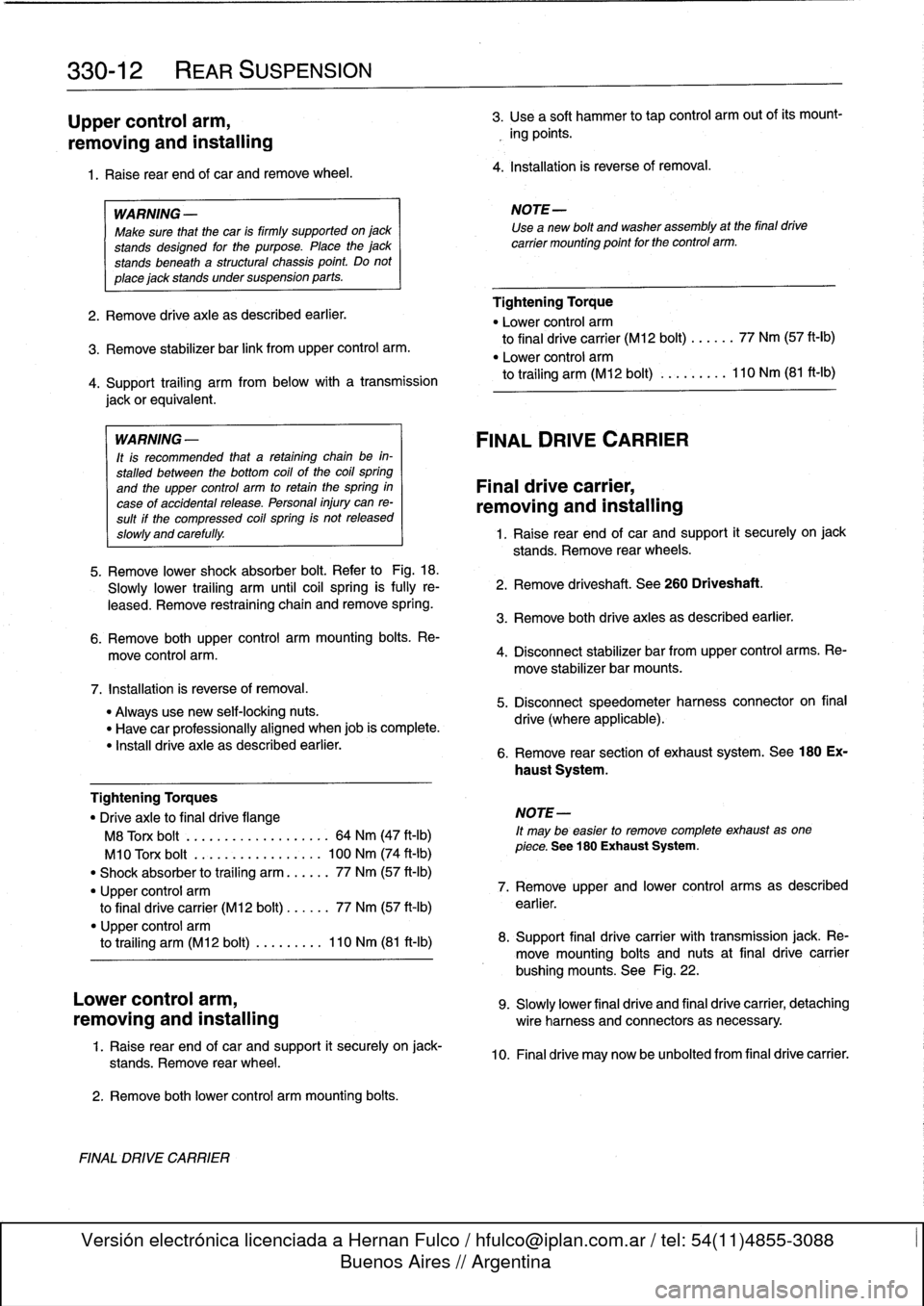

3

.

Insta¡¡

new

flex-disc

using

new

self-locking

nuts

.

Mold-

"

Avóid

stressing

the

flex-disc

when

torquing

the

ed

arrows

on

coupling

should

face

flange

arms

.

See

bolts

Do

this

holding

the

bolts

Fig

.

7

.

steady

and

.

uy

turning

the

nuts

on

theflange

side

.

5

:132

Fig

.

7

.

When

attaching

flex-disc,

molded

arrows

must

point

toward

flange

arms

.

DRIVESHAFT

SERVICE

Page 258 of 759

310-2

FRONT

SUSPENSION

WARNING-

"

Physical

safety

could

be

impaired

if

procedures

described

here

areundertaken

without

the

proper

service

tools

and

equipment

.

Be

sure

to

have

the

right

tools

onhand

before

beginning

any

job

.

"

Do

notreuse

self-locking

nuts

or

bolts

.

They

are

designed

to

beused

only

once

and

may

fail

if

re-

used

.

Always

replace

self-locking

fasteners

any

timethey

are

loosenedor

removed

.

"

Do

not

install

bolts

and

nuts

coated

with

under-

coating

wax,

as

the

correct

tightening

torque

can-

not

beassured

.

Always

clean

the

threads

with

solventbefore

installation,

or

install

new

parts

.

"

Do

not

attempt

to

weld

or

straighten

any

suspen-

sion

components

.

Replace

damaged

parts

.

SHOCK

ABSORBERS

AND

SPRINGS

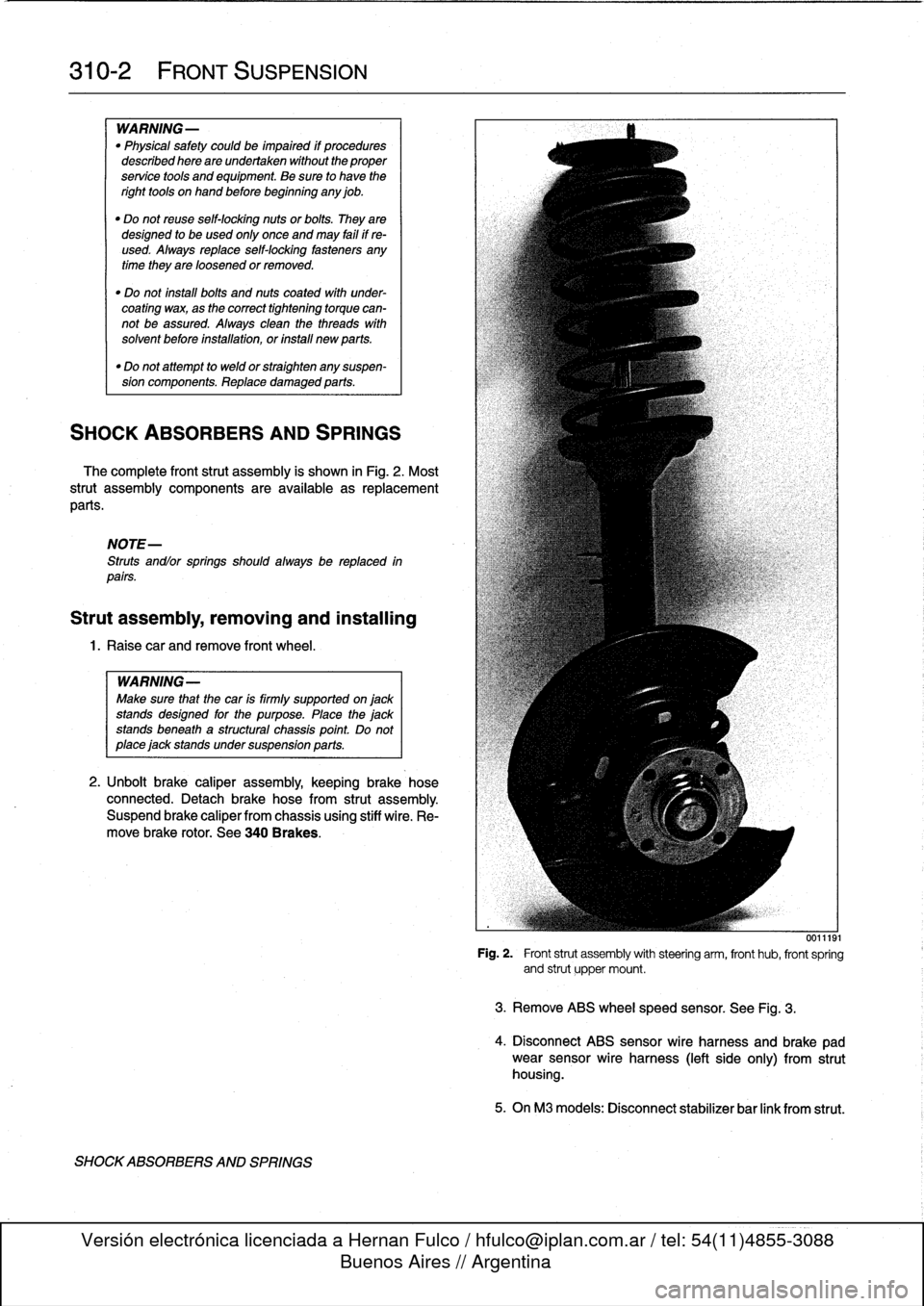

The

complete

front

strut

assembly

is

shown

in

Fig

.

2

.

Most

strut

assembly

components

are

available

asreplacement

parts

.

NOTE-

Struts

andlor

springs

shouldalways

be

replaced

in

parts

.

Strut

assembly,

removing

and

installing

1

.

Raisecar

and

remove

front

wheel

.

WARNING-

Make

sure

that

the

car

is

firmly

supported

on

jack

standsdesigned

for

the

purpose

.

Place

the

jack

standsbeneath

a

structural

chassis

point

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Unbolt

brake

caliper

assembly,

keepingbrake

hose

connected

.

Detach

brake

hose

from

strut

assembly

.

Suspend

brake

caliper

from

chassis

using

stiff

wire

.

Re-

move

brake

rotor

.

See

340

Brakes

.

SHOCKABSORBERS

AND

SPRINGS

0011191

Fig

.

2

.

Front

strut

assembly

with

steering

arm,

front

hub,

front

spring

and

strut

upper

mount

.

3

.

Remove

ABS

wheelspeed

sensor

.

See

Fig

.

3

.

4

.

Disconnect

ABS

sensor

wire

harness

and

brake

pad

wear

sensor

wire

harness

(left

side

only)

from

strut

housing

.

5

.

OnM3

modeis

:

Disconnect

stabilizer

bar

link

from

strut

.

Page 284 of 759

330-

1

2

REAR

SUSPENSION

Upper

control

arm,

removing

and

installing

1.

Raise

rear

end

of

car

and

remove

wheel

.

WARNING

-

Make

sure

that

the

car

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

beneatha

structural

chassis

point

.

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Remove

drive

axle

as

described

earlier

.

3

.

Remove

stabilizer

bar

link

fromupper

control

arm

.

4

.

Support

trailing

arm

from

below

with

a

transmission

jackorequivalent

.

WARNING

-

It

is

recommended

that

a

retaining

chain

be

in-

stalled

between

the

bottom

coil

of

the

coil

spring

and

the

upper

control

arm

to

retain

thespring

in

case

of

accidental

release

.

Personal

injury

can

re-

sult

if

the

compressed

coil

spring

ís

not

released

slowly

and

carefully

.

5

.

Remove

lower

shock

absorber

bolt

.

Refer

to

Fig

.

18

.

Slowly

lower

trailing

arm

until

coil

spring

is

fully

re-

leased

.

Remove

restraining

chain

and

remove

spring

.

7

.

Installation

is

reverse

of

removal

.

"

Always

use

new

self-locking

nuts

.

"

Have

car

professionally

aligned

when

job

is

complete

.

"

Insta¡¡

drive

axle

as

described

earlier

.

Tightening

Torques

"

Drive

axleto

final

drive

flange

M8

Torx

bolt

..........

..

.

..

....

64

Nm

(47

ft-Ib)

M10

Torx

bolt

.........

..

..

.

...

100

Nm

(74

ft-Ib)

"

Shock

absorber

to

trailing

arm

..

..

..

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

final

drive

carrier

(M12

bolt)

...

..

.

77

Nm

(57

ft-Ib)

"

Upper

control

arm

to

trailing

arm

(M12

bolt)

.........

110

Nm

(81

ft-Ib)

Lower

control

arm,

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack-

stands

.

Remove

rear

wheel

.

2

.

Remove

both

lower

control

arm

mounting

bolts

.

FINAL

DRIVE

CARRIER

3

.

Use

a

soft

hammer

to

tap

control

arm

out

of

its

mount-

ing

points

.

4

.

Installation

is

reverse

of

removal

.

NOTE-

Use

a

new

bolt

and

washer

assembly

at

the

final

drive

carrier

mountíng

point

forthe

control

arm

.

Tightening

Torque

"

Lower

control

arm

to

final

drive

carrier

(M12

bolt)

......

77

Nm

(57

ft-Ib)

"

Lower

control

arm

to

trailing

arm

(M12

bolt)

....

..

.

..

110

Nm

(81

ft-Ib)

FINAL

DRIVE

CARRIER

Final

drive

carrier,

removing

and

installing

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

.

See

260

Driveshaft

.

3

.

Remove

both

drive

axles

as

described

earlier

.

6

.

Remove

both

upper

control

arm

mounting

bolts

.

Re-

move

control

arm

.

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

move

stabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Remove

rear

section

of

exhaust

system

.

See

180

Ex-

haust

System

.

NOTE-

It

may

be

easier

to

remove

complete

exhaust

asonepiece

.

See

180

Exhaust

System

.

7

.

Remove

upper

and

lower

control

arms

as

described

earlier

.

8

.

Support

final

drive

carrierwith

transmissíon

jack

.

Re-

move

mounting

bolts

and

nuts

at

final

drive

carrier

bushing

mounts

.

See

Fig

.

22

.

9

.

Slowly

lower

final

drive

and

final

drive

carrier,

detaching

removing

and

installing

wire

harness

and

connectors

as

necessary

.

10

.

Finaldrive

may

now

be

unbolted

from

final

drive

carrier

.

Page 289 of 759

Final

driveinputshaft

oil

sea¡,

replacing

1

.

Raise

car

and

support

safely

.

2

.

Drain

final

drive

oil

as

described

earlier

.

3

.

Remove

driveshaft

from

final

drive

inputshaft

flange

.

See

260

Driveshaft

.

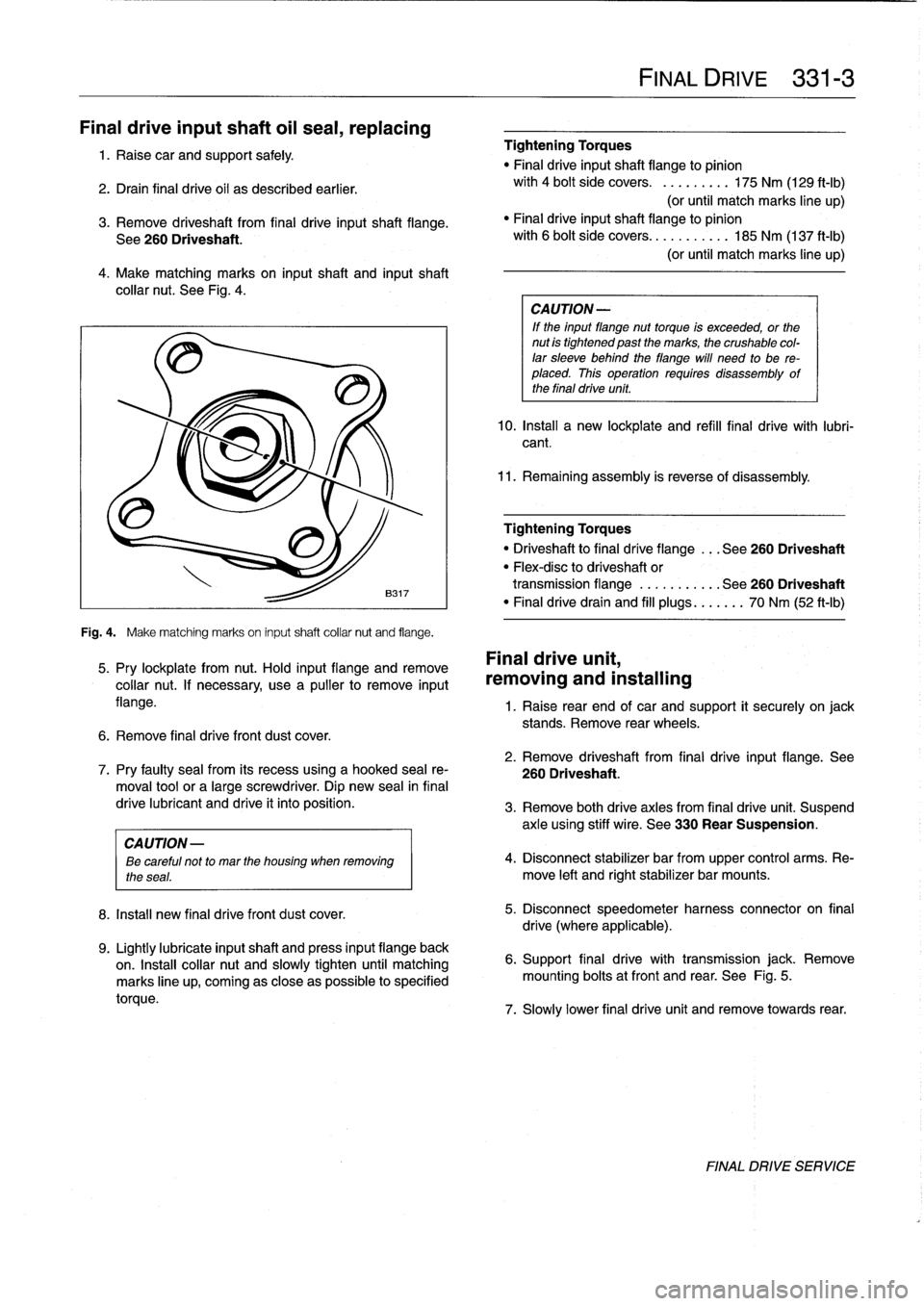

4

.

Make

matching

marks

on

input

shaft

and

inputshaft

collar

nut

.

See

Fig

.

4

.

Fig

.

4

.

Make

matching

marks

on

input

shaft

collar

nut

and

flange

.

5

.

Pry

lockplate

from

nut

.

Hold

input

flange

andremove

collar

nut

.

If

necessary,

usea

pullerto

remove

input

flange

.

6

.

Remove

final

drive

front

dust

cover

.

8

.

Install

new

final

drivefront

dust

cover

.

9

.

Lightly

lubricate

inputshaft

and

press

input

flange

back

on

.

Insta¡¡

collar

nut

and

slowly

tighten

until

matching

marks

line

up,

coming

as

close

aspossible

to

specified

torque

.

Tightening

Torques

"

Final

driveinputshaft

flange

to

pinion

with

4

bolt

side

covers

.

.........

175

Nm

(129

ft-Ib)

(or

until

match

marks

line

up)

"

Finaldriveinputshaft

flange

to

pinion

with

6

bolt

side

covers

...........

185

Nm

(137

ft-Ib)

(or

until

match

marks

line

up)

CA

UTION-

If

the

input

flange

nuttorque

is

exceeded,

or

the

nut

is

tightened

past

the

marks,

the

crushable

col-

lar

sleeve

behind

theflange

will

need

to

be

re-

placed

.

This

operation

requires

disassembly

of

the

final

drive

unit

.

10

.

Install

a

new

lockplate

and

refill

final

drive

with

lubri-

cant

.

11

.

Remaining

assembly

is

reverse

of

disassembly

.

Tightening

Torques

"

Driveshaftto

final

dríve

flange

...

See260

Driveshaft

"

Flex-disc

to

driveshaft

or

transmission

flange

...........

See260

Driveshaft

"

Finaldrivedrain

and

fill

plugs

...

.

..

.

70

Nm

(52

ft-Ib)

Final

drive

unit,

removing

and

installing

FINAL

DRIVE

331-

3

1

.

Raise

rear

end

of

car

and

support

it

securely

on

jack

stands

.

Remove

rear

wheels

.

2

.

Remove

driveshaft

from

final

drive

input

flange

.

See

7

.

Pry

faulty

sea¡

from

its

recess

using

a

hooked

sea¡

re-

260

Driveshaft

.

moval

toolor

a

large

screwdriver

.

Dip

new

sea¡

in

final

drive

lubricant

and

drive

it

into

position

.

3

.

Remove

both

drive

axles

from

final

drive

unit

.

Suspend

axle

using

stiff

wire

.

See

330

Rear

Suspension

.

CAUTION

-

ee

careful

not

to

mar

the

housing

when

removing

4

.

Disconnect

stabilizer

bar

from

upper

control

arms

.

Re-

the

seas

.

move

left

and

rightstabilizer

bar

mounts

.

5

.

Disconnect

speedometer

harness

connector

on

final

drive

(where

applicable)

.

6

.

Support

final

drive

with

transmission

jack

.

Remove

mounting

bolts

atfront

and

rear

.

See

Fig

.

5

.

7

.

Slowly

lower

final

drive

unit

and

remove

towards

rear

.

FINAL

DRIVE

SERVICE

Page 302 of 759

340-

1

2

BRAKES

ABS

is

self-tested

by

the

ABS

diagnostic

unit

each

time

the

car

is

started

.

Once

the

test

is

complete,

the

ABS

dashboard

light

tucos

off

.

If

the

light

remains

lit

or

comes

on

at

any

time

during

driving,

a

system

fault

has

occurred

and

ABS

is

elec-

tronically

disabled

.

The

conventional

braking

systemremains

fully

functioning

.

ABS

Inspection

A

visual

inspection

of

the

ABS

may

help

to

locate

system

faults

.

If

no

visual

faults

can

befound

and

the

ABS

light

re-

mains

on,

have

the

system

diagnosedbyan

authorized

BMW

dealer

.

Carefully

inspect

the

entire

ABS

wiring

harness,

particularly

the

pulse

sensorharnesses

and

connectors

near

each

wheel

.

Look

for

chafing

or

damage

due

to

incorrectly

routed

wires

.

Carefully

remove

the

wheelspeed

sensors

.

Clean

the

sen-

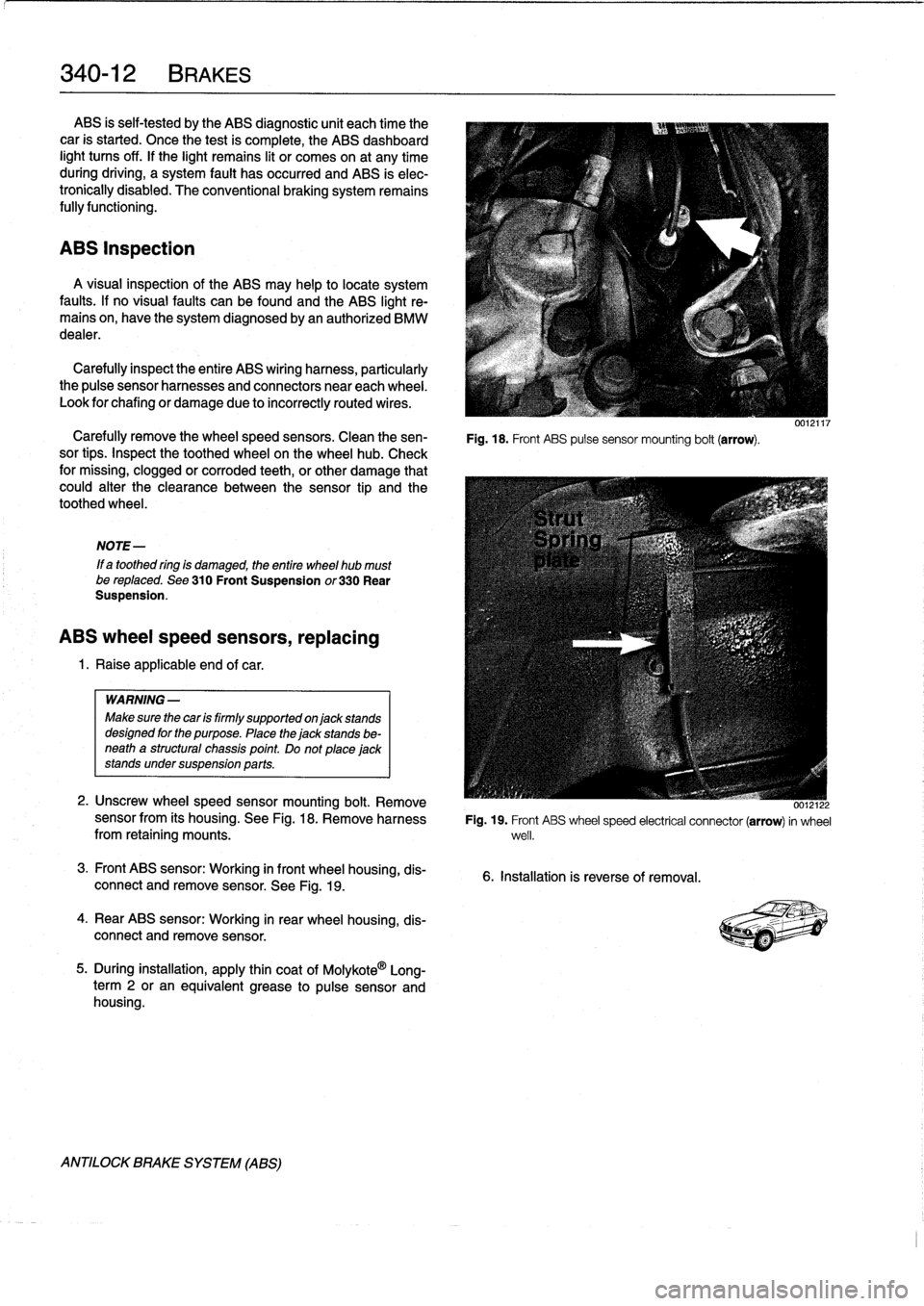

Fig

.

18

.

Front

ABS

pulse

sensor

mounting

bolt

(arrow)

.

sor

tips

.

Inspect

the

toothed

wheel

on

thewheel

hub

.

Check

for

missing,

clogged

or

corroded

teeth,

or

other

damage

that

could

alter

the

clearance

between

the

sensor

tip

and

the

toothed

wheel

.

NOTE-

If

a

toothed

ring

is

damaged,

the

entire

wheel

hub

mustbe

reptaced

.

See

310

Front

Suspension

or330

Rear

Suspension

.

ABS

wheel

speed

sensors,

replacing

1

.

Raise

applicable

end

of

car

.

WARNING

-

Make

sure

thecar

is

firmly

supportedon

jack

stands

designed

for

the

purpose

.

Place

the

jack

stands

be-

neath

a

structural

chassis

point

Do

not

place

jack

stands

under

suspension

parts

.

2

.

Unscrew

wheelspeed

sensor

mounting

bolt

.

Remove

sensor

from

its

housing

.

See

Fig

.

18

.

Remove

harnessfrom

retaining

mounts

.

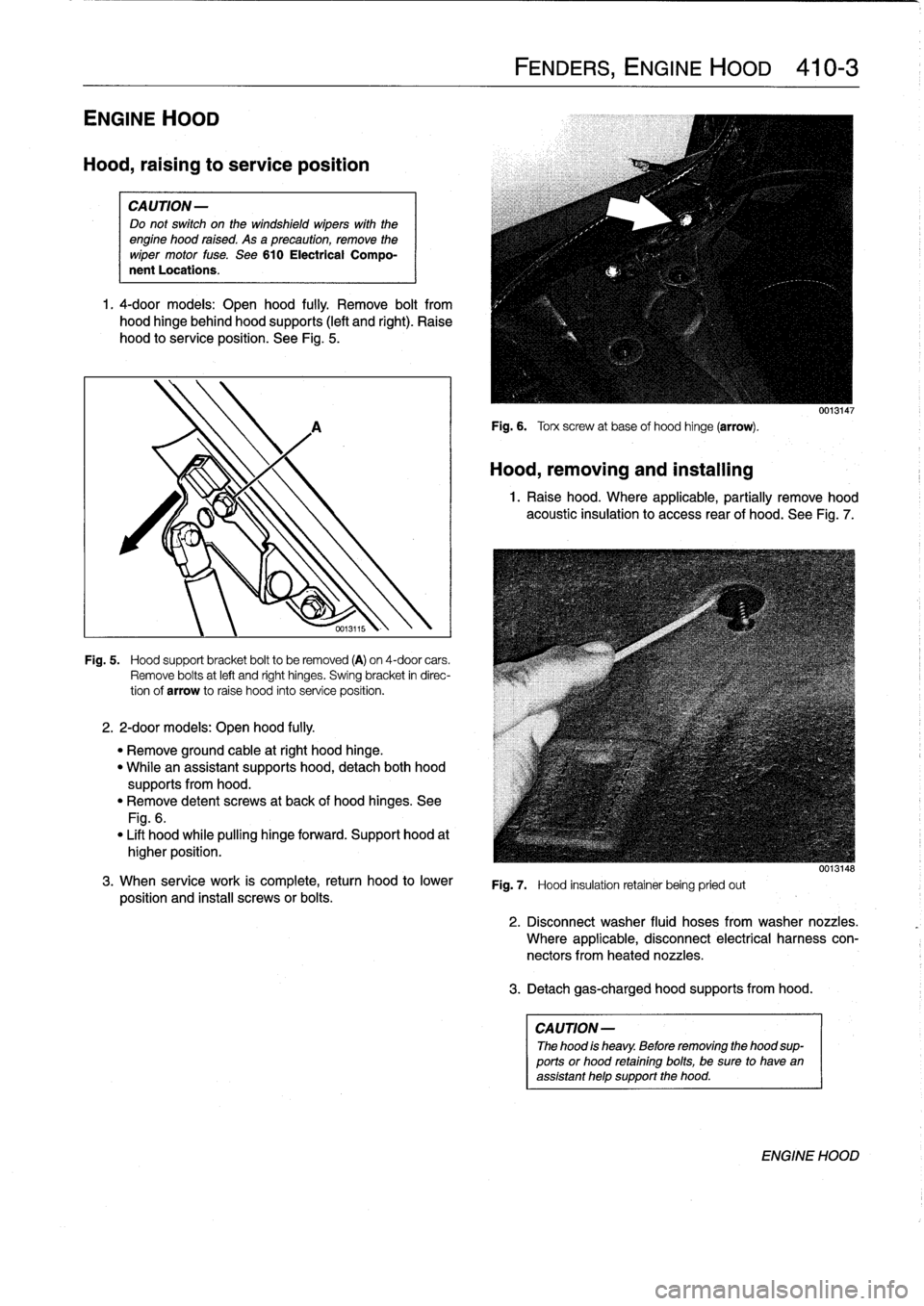

3

.

Front

ABS

sensor

:

Working

in

front

wheel

housing,

dis-

connect

and

remove

sensor

.

See

Fig

.

19

.

4

.

Rear

ABS

sensor

:

Working

in

rear

wheel

housing,

dis-

connect

andremove

sensor

.

5

.

During

installation,

apply

thin

coat

of

Molykote

0

Long-

term

2

or

an

equivalent

grease

to

pulse

sensor

and

housing

.

ANTILOCK

BRAKE

SYSTEM

(ABS)

0012122

Fig

.

19

.

Front

ABS

wheel

speed

electrical

connector

(arrow)

in

wheel

well

.

6

.

Installation

is

reverse

of

removal

.

Page 311 of 759

ENGINE

HOOD

Hood,

raising

to

service

position

CA

UTION-

Do

not

switch

on

the

windshield

wipers

wlth

the

engine

hood

raised

.

As

a

precaution,

remove

the

wiper

motor

fuse

.

See

610

Electrical

Compo-

nent

Locations

.

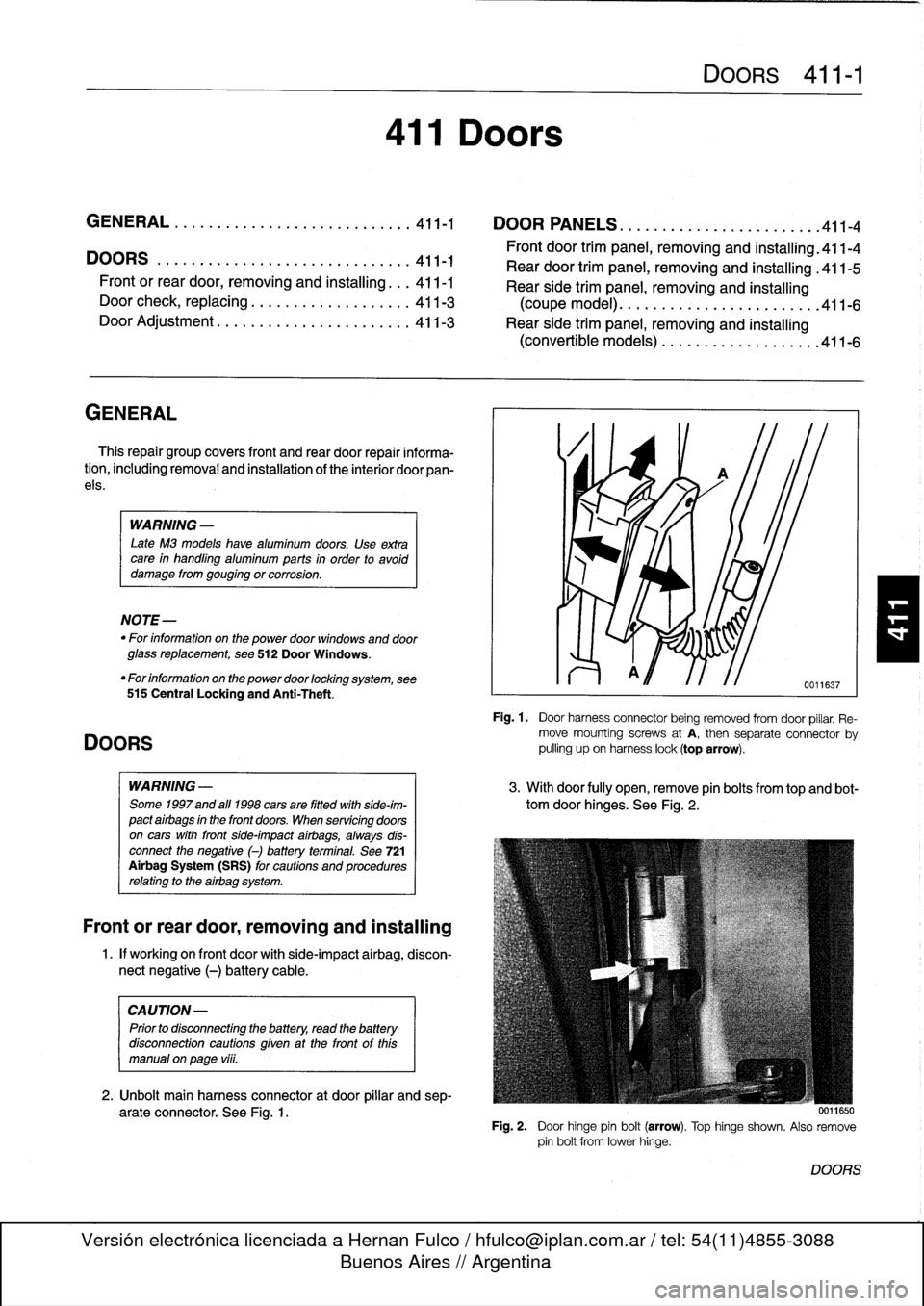

1

.

4-door

models

:

Open

hood

fully

.

Remove

bolt

from

hood

hinge

behind

hood

supports

(left

and

right)

.

Raise

hood

to

service

position

.

See

Fig

.

5

.

2

.

2-door

models

:

Open

hood

fully

.

Fig

.

5

.

Hood

support

bracket

boltto

be

removed

(A)

on

4-door

cars

.

Remove

bolts

at

left

and

right

hinges

.

Swing

bracket

in

direc-

tion

of

arrow

to

raise

hood

into

service

position

.

"

Remove

ground

cable

atright

hood

hinge

.

"

Whilean

assistant

supports

hood,

detach

both

hood

supportsfrom

hood

.

"

Remove

detent

screws

at

back

of

hood

hinges

.

See

Fig

.

6

.

"

Lift

hood

while

pulling

hinge

forward

.

Support

hood

at

higher

position

.

3

.

When

service

work

is

complete,

return

hood

to

lower

position

and

instaf

screws

or

bolts

.

FENDERS,

ENGINE

HOOD

410-

3

Fig

.

6

.

Torx

screw

at

base

of

hood

hinge

(arrow)

.

Hood,

removing

and

installing

0013147

1

.

Raise

hood

.

Where

applicable,

partially

remove

hood

acoustic

insulation

to

access

rear

of

hood

.

See

Fig

.

7

.

Fig

.

7

.

Hood

insulation

retainer

being

pried

out

3

.

Detachgas-charged

hood

supportsfrom

hood

.

CAUTION

-

The

hood

is

heavy

.

Before

removing

the

hood

sup-

ports

or

hood

retainingbolts,

be

sure

to

have

an

assistant

help

support

the

hood

.

0013148

2

.

Disconnect

washer

fluid

hoses

from

washer

nozzles

.

Where

applicable,

disconnect

electrical

harness

con-

nectors

fromheated

nozzles

.

ENGINE

HOOD

Page 315 of 759

GENERAL

This

repair

group

covers

front

and

rear

door

repair

informa-

tion,

including

removal

and

installationof

the

interior

doorpan-

els

.

DOORS

WARNING

-

Late

M3

moddis

havealuminum

doors

.

Use

extra

care

in

handling

aluminum

parts

in

order

to

avoid

damage

from

gouging

or

corrosión

.

NOTE-

"

For

information

on

the

power

door

windows

and

door

glass

replacement,

sea512Door

Windows

.

"

Forinformation

on

the

power

door

locking

system,

see

515

Central

Locking

and

Anti-Theft

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

(-)

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

Front

orrear

door,

removing

and

installing

1

.

If

workingon

front

door

with

side-impact

airbag,

discon-

nect

negative

(-)

battery

cable

.

CAUTION

-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

vüi

.

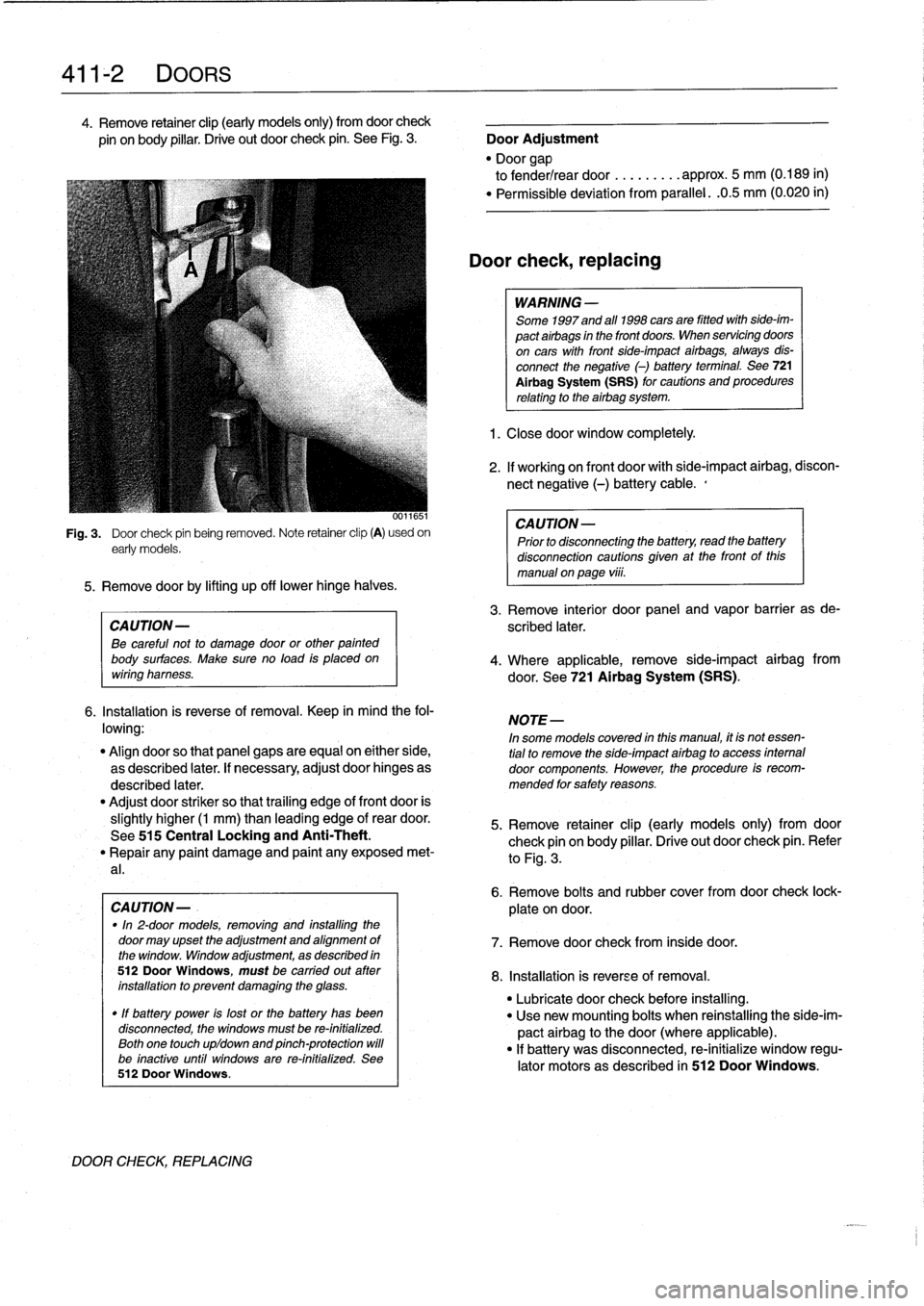

2

.

Unbolt

main

harness

connector

at

door

pillar

and

sep-

arate

connector

.

See

Fig

.

1

.

411

Doors

GENERAL

.............

.

.

.

.

.

.

.

.

.

.

.

.

.

..

411-1

DOOR

PANELS

.

.

.

.

.

.

.

...

.

.

.

.

.

.

.

.

.

...

.

.

411-4

Front

door

trim

panel,

removing

and

installing

.411-4

DOORS

..

.

.

.

.

.

.

.

.

.

...

.

.......

.

....

.

.

.

411-1

Rear

door

trim

panel,

removing

and

installing

.411-5

Front

or

reardoor,

removing

and

installing

..

.

411-1

Rear

side

trim

panel,

removing

and

installing

Door

check,

replacing

.

.

.

.

.

.

.

.

.

.

.

.

.......

411-3

(coupemodel)

.

.

.

.

.

.

....

.

.............

411-6

Door

Adjustment

.......

.

.

.

.

.

.

.

.

.

.

.

.....

411-3

Rear

side

trim

panel,

removing

and

installing

(convertible

models)

.

...

.

.

.

.

.

.

.

.

.

.

.

...

.

411-6

DOORS

411-1

Fig

.

1

.

Door

harness

connector

being

removed

fromdoor

pillar

.

Re-

move

mountingscrews

atA,

then

separate

connector

by

pulling

upon

harness

lock(top

arrow)

.

3

.

Withdoor

fully

open,

remove

pin

bolts

from

top

and

bot-

tom

door

hinges

.

See

Fig

.

2

.

0011650

Fig

.

2

.

Door

hinge

pin

bolt

(arrow)

.

Top

hinge

shown

.

Also

remove

pin

bolt

from

lowerhinge

.

DOORS

Page 316 of 759

411-2

DOORS

4

.

Remove

retainer

clip

(early

models

only)

from

doorcheck

pin

onbody

pillar

.

Drive

out

door

check

pin

.

See

Fig

.

3

.

Door

Adjustment

"

Door

gap

to

fender/rear

door

.........

approx

.

5

mm

(0

.189

in)

"

Permíssible

deviation

from

parallel

.

.0

.5

mm

(0

.020

in)

0011651

Fig

.

3

.

Door

check

pin

being

removed

.

Note

retainer

clip

(A)

usedon

early

models

.

5

.

Remove

doorby

lifting

up

off

lowerhinge

halves

.

CAUTION-

Be

careful

not

to

damage

door

or

other

painted

body

surfaces

.

Make

sure

no

load

is

placedon

wiring

harness

.

6

.

Installation

is

reverse

of

removal

.

Keep

in

mind

the

fol-

lowing

:

"

Align

doorso

that

panel

gaps

are

equal

on

either

side,

as

described

later

.

If

necessary,

adjust

door

hinges

as

described

later

.

"

Adjust

door

striker

so

that

trailing

edge

of

front

door

is

slightly

higher

(1

mm)

than

leading

edge

of

rear

door

.

See

515

Central

Locking

and

Anti-Theft

.

"

Repair

any

paint

damage

and

paínt

any

exposed

met-

al

.

CAUTION-

.

"In

2-door

models,

removing

and

installing

the

door

may

upset

the

adjustment

and

alignment

of

the

window

.

Window

adjustment,

as

described

in

512DoorWindows,

must

be

carried

out

ater

installation

to

prevent

damaging

the

glass

.

"

If

battery

power

is

lost

or

the

battery

has

been

disconnected,

the

windows

must

be

re-initialized

.

Both

one

touch

upldown

and

pinch-protection

will

be

inactive

until

windows

are

re-initialized

.

See

512

Door

Windows

.

DOOR

CHECK,

REPLACING

Door

check,replacing

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

(-)

battery

terminal

.

See

721

Al

rbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

1

.

Closedoor

window

completely

.

2

.

If

working

on

front

door

with

side-impact

airbag,

discon-

nect

negative

(-)

battery

cable

.,

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautions

gíven

at

the

front

of

this

manual

on

page

viii

.

3

.

Remove

interior

door

panel

and

vapor

barrier

as

de-

scribed

later

.

4

.

Where

applicable,

remove

side-impact

airbag

from

door

.

See

721

Airbag

System

(SRS)

.

NOTE-

In

some

models

covered

inthis

manual,

ít

is

not

essen-

tial

to

remove

the

side-ímpact

airbag

to

access

internal

door

components

.

However,

the

procedure

is

recom-

mended

for

safety

reasons

.

5

.

Remove

retainer

clip

(early

models

only)

from

door

check

pin

on

body

pillar

.

Drive

out

door

check

pin

.

Refer

to

Fig

.

3

.

6

.

Remove

bolts

and

rubber

cover

fromdoor

check

lock-

plate

ondoor

.

7

.

Remove

door

check

from

inside

door

.

8

.

Installation

is

reverse

of

removal

.

"

Lubricate

door

check

before

installing

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pact

airbag

to

thedoor(where

applicable)

.

"

If

battery

was

disconnected,

re-initialize

window

regu-

lator

motors

as

described

in

512

Door

Windows

.

Page 317 of 759

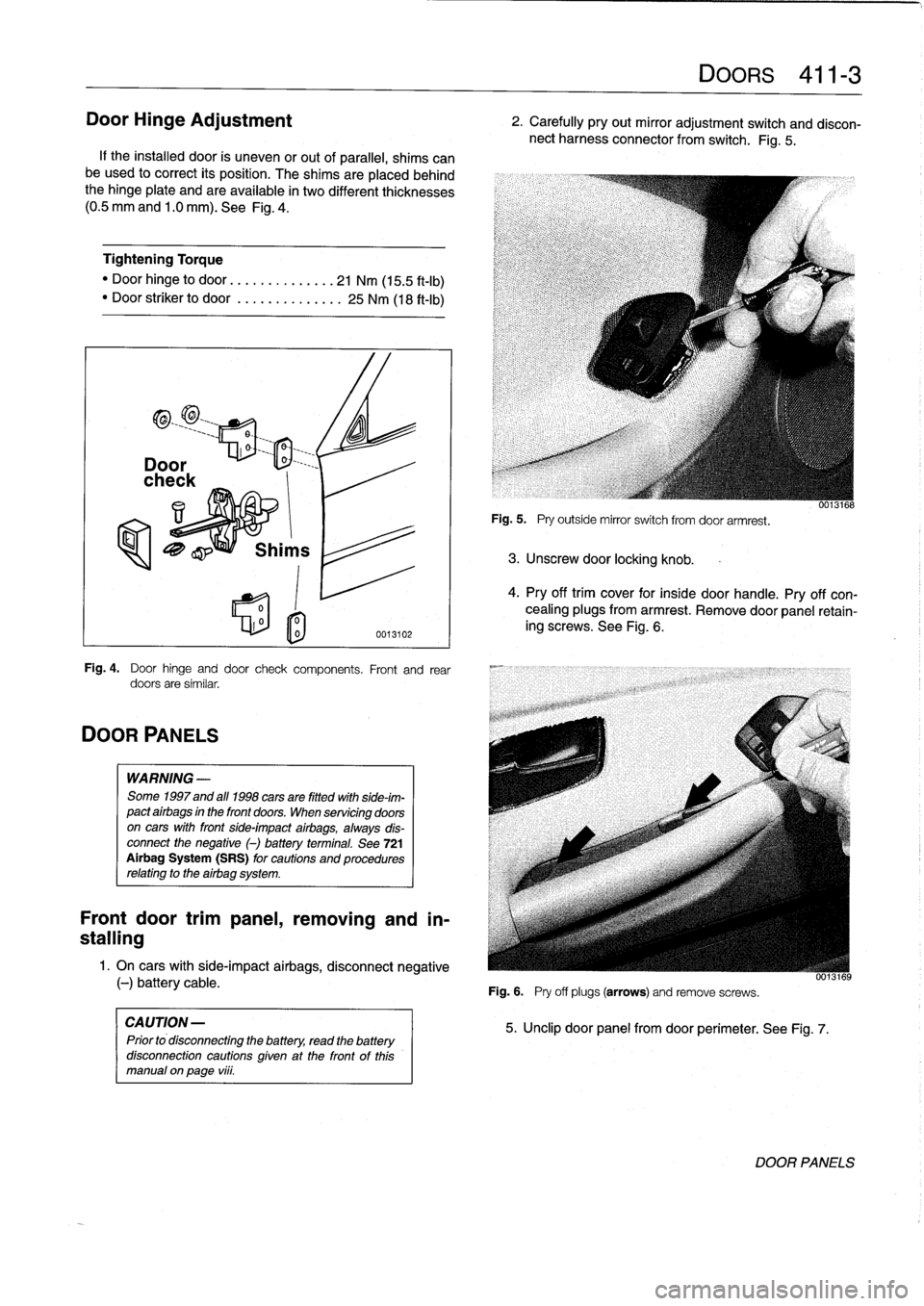

Door

Hinge

Adjustment

If

the

installed

door

is

uneven

or

out

of

parallel,

shims

can

be

used

to

correct

its

position

.

The

shims

are

placedbehind

the

hinge

plate

and

are

available

in

two

different

thicknesses

(0

.5

mm

and

1

.0

mm)

.

See

Fig

.

4

.

Tightening

Torque

"

Door

hinge

to

door

.............

..

21

Nm

(15

.5

ft-I

b)

"

Door

striker

to

door

...........

...

25

Nm

(18

ft-Ib)

DOOR

PANELS

0

l

o

0013102

Fig

.

4

.

Door

hinge

and

door

check

components

.

Front

and

rear

doors

are

similar

.

WARNING

-

Some

1997

and

all

1998

cars

are

fitted

with

side-im-

pact

airbags

in

the

front

doors

.

When

servicing

doors

on

cars

with

front

side-impact

airbags,

always

dis-

connect

the

negative

()

battery

terminal

.

See

721

Airbag

System

(SRS)

for

cautions

and

procedures

relating

to

the

airbag

system

.

Front

door

trimpanel,

removing

and

in-

stalling

1

.

On

cars

with

side-impact

airbags,

disconnect

negative

(-)

battery

cable

.

CAUTION

-

Prior

to

disconnecting

the

battery,

read

the

battery

disconnection

cautions

given

at

the

front

of

this

manual

on

page

viii

.

Fig

.

5

.

Pry

outside

mirror

switch

from

door

armrest

.

3

.

Unscrew

door

locking

knob

.

Fig

.

6

.

Pry

off

plugs

(arrows)

and

remove

screws

.

DOORS

411-

3

2

.

Carefully

pry

out

mirror

adjustment

switch

and

discon-

nect

harness

connector

from

switch

.

Fig

.

5

.

5

.

Unclip

door

panel

from

door

perimeter

.

See

Fig

.

7

.

0013168

4

.

Pry

off

trim

cover

for

insíde

door

handle

.

Pry

off

con-

cealing

plugs

from

armrest

.

Remove

door

panel

retain-

ing

screws

.

See

Fig

.

6

.

UU13169

DOOR

PANELS

Page 318 of 759

411-

4

DOORS

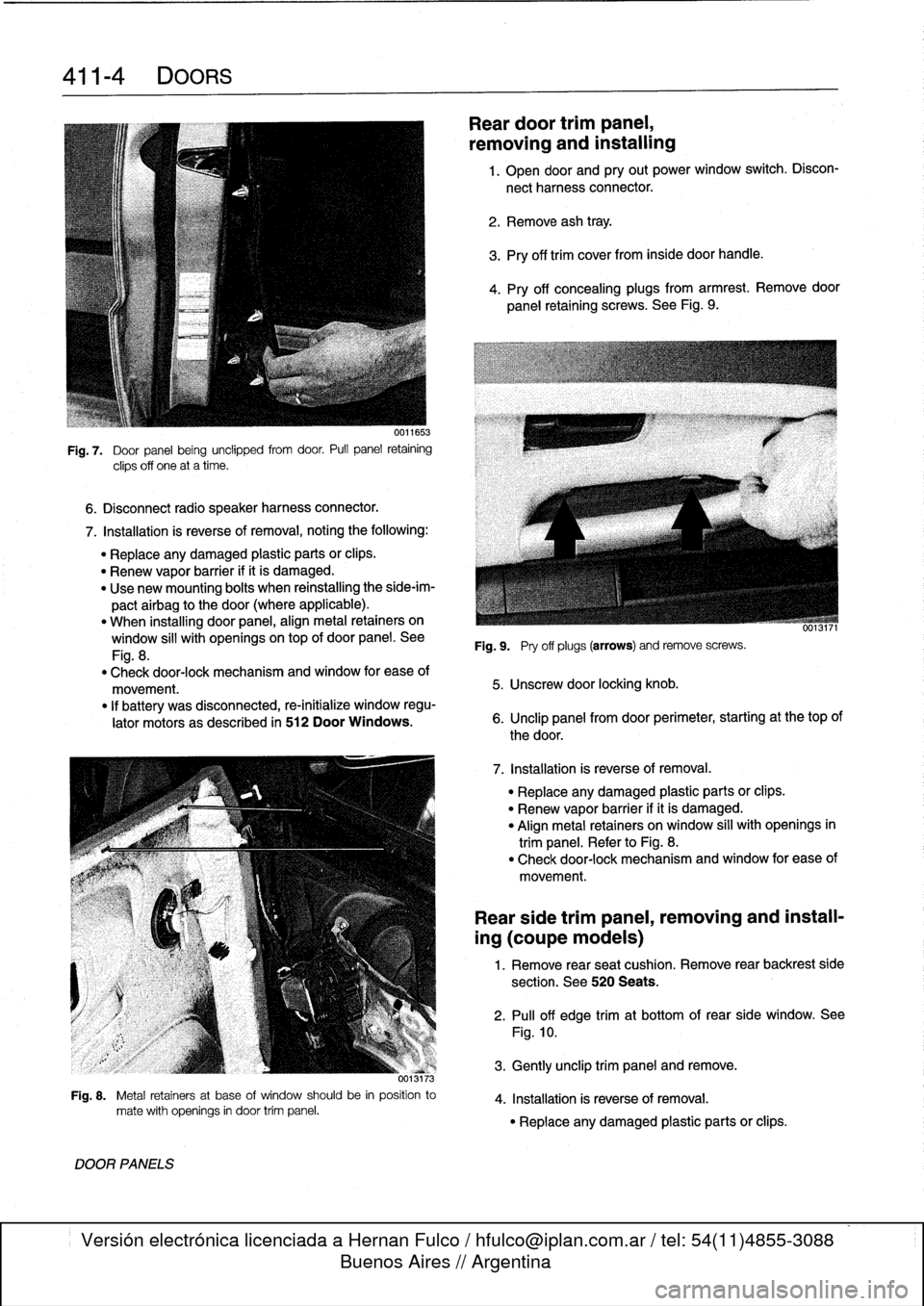

6

.

Disconnect

radio

speaker

harness

connector

.

Fig

.

7

.

Door

panel

being

unclipped

from

door

.

Pull

panel

retaining

clips

off

one

at

a

time

.

7

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Replace

any

damaged

plastic

parts

orclips

.

"

Renew

vapor

barrier

ifit

is

damaged

.

"

Use

new

mounting

bolts

when

reinstalling

the

side-im-

pactairbag

to

the

door

(where

applicable)

.

"

When

installing

door

panel,

align

metal

retainers

on

window

sill

with

openingsontop

of

door

panel

.

See

Fig

.

8

.

"

Check

door-lock

mechanism

and

window

for

ease

of

movement

.

"

If

battery

was

disconnected,

re-initialize

window

regu-

lator

motors

as

described

in

512

Door

Windows

.

373

Fig

.

8

.

Metal

retainers

at

base

of

window

should

be

in

position

to

mate

with

openings

in

door

trim

panel

.

DOOR

PANELS

Reardoor

trimpanel,

removing

and

installing

1

.

Open

door

and

pry

out

power

window

switch

.

Discon-

nect

harness

connector

.

2

.

Remove

ash

tray

.

3

.

Pry

off

trim

cover

from

inside

door

handle

.

4

.

Pry

off

concealing

plugs

from

armrest

.

Remove

door

panel

retaining

screws

.

See

Fig

.

9

.

Fig

.

9

.

Pry

off

plugs

(arrows)

andremove

screws

.

5

.

Unscrew

door

locking

knob

.

6

.

Unclip

panel

from

door

perimeter,

starting

at

thetop

of

the

door

.

7

.

Installation

is

reverse

of

removal

.

"

Replace

any

damaged

plastic

parts

or

clips

.

"

Renew

vapor

barrier

ifit

is

damaged

.

"

Align

metal

retainers

on

window

sill

with

openings

in

trim

panel

.

Refer

to

Fig

.

8

.

"

Check

door-lock

mechanism

and

window

for

ease

of

movement

.

Rear

side

trim

panel,

removing

and

install-

ing

(coupe

models)

1

.

Remove

rear

seat

cushion

.

Remove

rear

backrest

side

section

.

See

520

Seats

.

2

.

Pull

off

edge

trimat

bottom

of

rear

side

window

.

See

Fig

.

10

.

3

.

Gently

unclip

trim

panel

andremove

.

4

.

Installation

is

reverse

of

removal

.

"

Replace

any

damaged

plastic

parts

or

clips

.