air filter CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 178 of 1903

Downloaded from www.Manualslib.com manuals search engine 2.4L ENGINE MECHANICAL

GENERAL INFORMATION02-151

Description 02-151

Operation 02-151

Specifications 02-151

Special Tools 02-154

Lubrication System 02-160

DIAGNOSIS & TESTING02-163

Engine Performance Diagnostics 02-163

Engine Mechanical Diagnostics 02-164

Cylinder Compression Pressure Test 02-165

Cylinder Head Gasket Test 02-166

Engine Oil Pressure Test 02-166

ON-VEHICLE SERVICE02-167

Accessory Drive Belt 02-167

Removal & Installation 02-167

Air Cleaner Element 02-168

Removal & Installation 02-168

Air Cleaner Housing 02-169

Removal & Installation 02-169

Cylinder Head Cover 02-170

Removal & Installation 02-170

Camshaft 02-171

Removal & Installation 02-171

Cylinder Head 02-175

Removal & Installation 02-175

Front Crankshaft Oil Seal 02-177

Removal & Installation 02-177

Rear Crankshaft Oil Seal 02-179

Removal & Installation 02-179

Engine Mounts 02-181

Removal & Installation - Left Mount 02-181

Removal & Installation - Right Mount 02-182

Removal & Installation - Front Mount 02-182

Removal & Installation - Rear Mount 02-183

Engine Assembly 02-183

Removal & Installation 02-183

Engine Timing Belt 02-189

Removal & Installation 02-189

Inspection 02-194

Timing Belt Automatic Tensioner 02-196

Removal & Installation 02-196

Inspection 02-197

Upper Balance Shaft Timing Belt 02-198

Removal & Installation 02-198Exhaust Manifold

02-200

Removal & Installation 02-200

Intake Manifold 02-201

Removal & Installation 02-201

Upper Balance Shaft 02-204

Removal & Installation 02-204

Upper Balance Shaft Bearing

Replacement 02-207

Lower Balance Shaft 02-208

Removal & Installation 02-208

Lower Balance Shaft Bearing

Replacement 02-211

Oil Filter 02-212

Removal & Installation 02-212

Oil Pan 02-213

Removal & Installation 02-213

Oil Pump 02-215

Removal & Installation 02-215

Oil Strainer 02-216

Removal & Installation 02-216

ENGINE UNIT REPAIR02-217

Engine Block 02-217

Specifications 02-217

Disassembly 02-218

Inspection 02-220

Assembly 02-220

Pistons 02-221

Specifications 02-221

Disassembly 02-222

Inspection 02-224

Assembly 02-226

Connecting Rods 02-229

Specifications 02-229

Disassembly 02-229

Inspection 02-230

Assembly 02-231

Crankshaft 02-233

Specifications 02-233

Disassembly 02-234

Inspection 02-236

Assembly 02-237

02–149Chery Automobile Co., Ltd.

Page 192 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Engine Performance Diagnostics

CONDITIONPOSSIBLE CAUSES CORRECTION

Engine Does Not Start 1. Weak battery.

2. Corroded or loose battery

connections.

3. Faulty starter.

4. Faulty coil(s) or control unit.

5. Incorrect spark plug gap.

6. Contamination in fuel system.

7. Faulty fuel pump.

8. Incorrect timing.1. Test battery. Charge or replace if

necessary.

2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Test starting system. Check for

codes. (Refer to Appropriate

Diagnostic Information)

4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Set gap.

6. Clean system and replace fuel

filter.

7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Check for a skipped timing belt.

Engine Stalls Or Idles Rough 1. Idle speed too low.

2. Incorrect fuel mixture.

3. Intake manifold leakage.

4. Faulty ignition coil(s).1. Test minimum air flow. (Refer to

Appropriate Diagnostic Information)

2. (Refer to Appropriate Diagnostic

Information)

3. Inspect intake manifold, manifold

gasket, and vacuum hoses.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Loss Of Power 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

3. Faulty fuel pump.

4. Incorrect valve timing.

5. Leaking cylinder head gasket.

6. Low compression.

7. Burned, warped, excessive

clearance, or pitted valves.

8. Plugged or restricted exhaust

system.

9. Faulty ignition coil(s).

10. Burned spark plugs.1. Clean spark plugs and set gap.

2. Clean system and replace fuel

filter.

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Correct valve timing.

5. Replace cylinder head gasket.

6. Test compression of each

cylinder.

7. Replace valves.

8. Perform exhaust restriction test.

Install new parts.

9. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

10. Replace spark plugs.

DIAGNOSIS & TESTING

02

02–163Chery Automobile Co., Ltd.

Page 193 of 1903

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSES CORRECTION

Engine Miss On Acceleration 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

7. Burned, warped, excessive

clearance, or pitted valves.

4. Faulty ignition coil(s).1. Clean spark plugs and set gap.

2. Clean fuel system and replace

fuel filter.

3. Replace valves.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Miss At High Speed 1. Dirty or incorrect spark plug gap.

2. Faulty ignition coil(s).

3. Dirty fuel injector(s).

4. Contamination in fuel system.1. Clean spark plugs and set gap.

2. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Clean system and replace fuel

filter.

Engine Mechanical Diagnostics

CONDITION

POSSIBLE CAUSES CORRECTION

Valve Train Noise 1. High or low oil level in crankcase.

2. Thin or diluted oil.

3. Thick oil.

4. Low oil pressure.

5. Worn cam lobe.

6. Worn valve guides.

7. Excessive runout of valve seats

on valve faces.1. Check and correct engine oil

level.

2. Change oil to correct viscosity.

3. Change engine oil and filter.

4. Check and correct engine oil

level.

5. Install new camshaft.

6. Replace cylinder head.

7. Grind valve seats and replace

valves.

Connecting Rod Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Connecting rod journal out-of-

round.

6. Connecting rod out-of-round.

7. Misaligned connecting rods.

8. Connecting rod nuts loose.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Replace crankshaft or grind

surface.

6. Replace connecting rod.

7. Replace bent connecting rods.

8. Tighten the connecting rod nuts.

Main Bearing Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Excessive end play.

6. Crankshaft journal out-of-round or

worn.

7. Loose flywheel or torque

converter.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Check thrust bearing for wear on

flanges.

6. Replace crankshaft or grind

journals.

7. Tighten to correct torque.

DIAGNOSIS & TESTING

02–164Chery Automobile Co., Ltd.

Page 194 of 1903

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSES CORRECTION

Oil Pressure Drop 1. Low oil level.

2. Faulty oil pressure sending unit.

3. Low oil pressure.

4. Clogged oil filter.

5. Thin or diluted oil.

6. Excessive bearing clearance.1. Check engine oil level.

2. Install new sending unit.

3. Check sending unit and main

bearing oil clearance.

4. Install new oil filter.

5. Change oil to correct viscosity.

6. Measure bearings for correct

clearance.

Oil Leaks 1. Misaligned or deteriorated

gaskets.

2. Loose fastener, broken or porous

metal part.

3. Misaligned or deteriorated cup or

threaded plug.1. Replace gasket.

2. Tighten, repair or replace the part.

3. Replace if necessary.

Oil Consumption Or Spark Plugs

Fouled 1. PCV system malfunction.

2. Worn, scuffed or broken rings.

3. Carbon in oil ring slots.

4. Rings fitted too tightly in grooves.

5. Worn valve guide(s).

6. Valve stem seal(s) worn or

damaged.1. Check system and repair if

necessary.

2. Hone cylinder bores. Install new

rings.

3. Install new rings.

4. Remove rings and check grooves.

If groove is not proper width, replace

piston.

5. Replace cylinder head.

6. Replace seal(s).

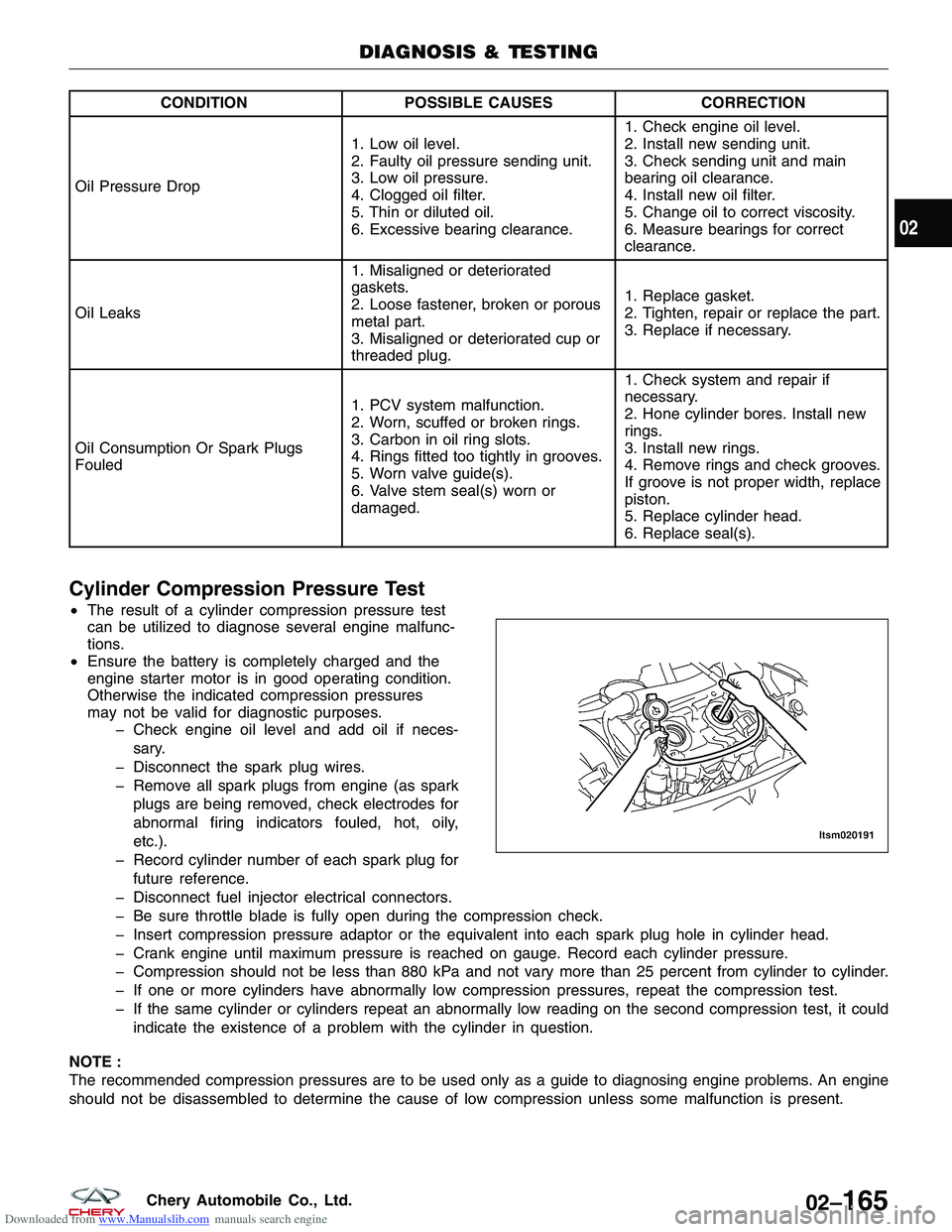

Cylinder Compression Pressure Test

•

The result of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

• Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures

may not be valid for diagnostic purposes.

� Check engine oil level and add oil if neces-

sary.

� Disconnect the spark plug wires.

� Remove all spark plugs from engine (as spark plugs are being removed, check electrodes for

abnormal firing indicators fouled, hot, oily,

etc.).

� Record cylinder number of each spark plug for future reference.

� Disconnect fuel injector electrical connectors.

� Be sure throttle blade is fully open during the compression check.

� Insert compression pressure adaptor or the equivalent into each spark plug hole in cylinder head.

� Crank engine until maximum pressure is reached on gauge. Record each cylinder pressure.

� Compression should not be less than 880 kPa and not vary more than 25 percent from cylinder to cylinder.

� If one or more cylinders have abnormally low compression pressures, repeat the compression test.

� If the same cylinder or cylinders repeat an abnormally low reading on the second compression test, it could indicate the existence of a problem with the cylinder in question.

NOTE :

The recommended compression pressures are to be used only as a guide to diagnosing engine problems. An engine

should not be disassembled to determine the cause of low compression unless some malfunction is present.

DIAGNOSIS & TESTING

LTSM020191

02

02–165Chery Automobile Co., Ltd.

Page 234 of 1903

Downloaded from www.Manualslib.com manuals search engine NOTE :

The following special tools are required to perform the repair procedure:

•MB-991603 - Balance Shaft Bearing Puller Limiter

• MD-998162 - Plug Spanner

• MD-998371 - Balance Shaft Bearing Puller

• MD-998372 - Balance Shaft Bearing Puller

• MD-998375 - Crankshaft Front Oil Seal Installer

• MD-998705 - Balance Shaft Bearing Installer

• MD-998727 - Oil Pan Remover

• MD-998783 - Plug Spanner Fixer

• MB-991828 - Oil Filter Wrench

• MB-991396 - Oil Filter Wrench

1. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

2. Remove the upper balance shaft timing belt (See Upper Balance Shaft Timing Belt Removal & Installation in Section 02 Engine).

3. Raise and support the vehicle.

4. Loosen the oil drain plug and drain the oil.

5. Remove the oil pan retaining bolts. (Tighten: Oil pan bolts to 18 N·m)

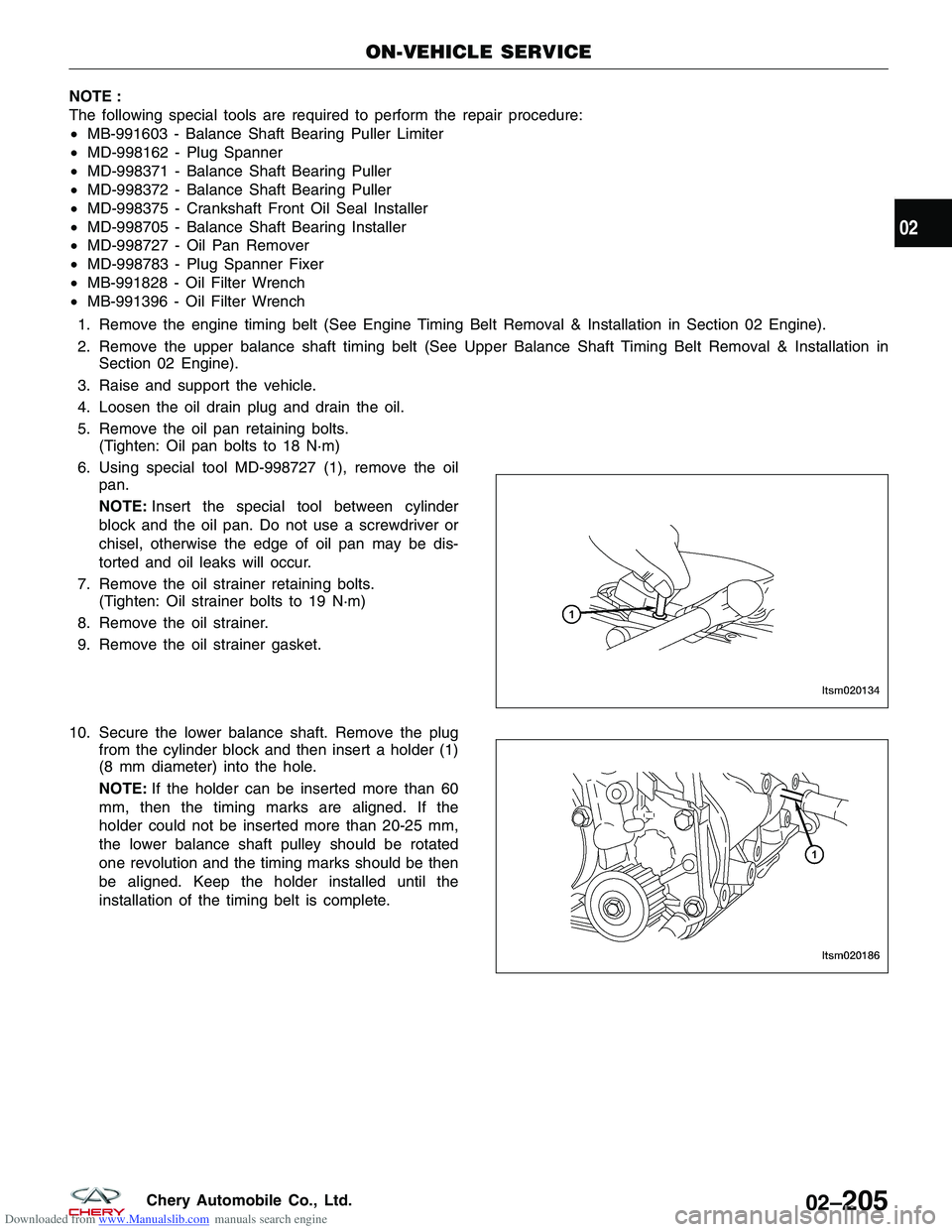

6. Using special tool MD-998727 (1), remove the oil pan.

NOTE: Insert the special tool between cylinder

block and the oil pan. Do not use a screwdriver or

chisel, otherwise the edge of oil pan may be dis-

torted and oil leaks will occur.

7. Remove the oil strainer retaining bolts. (Tighten: Oil strainer bolts to 19 N·m)

8. Remove the oil strainer.

9. Remove the oil strainer gasket.

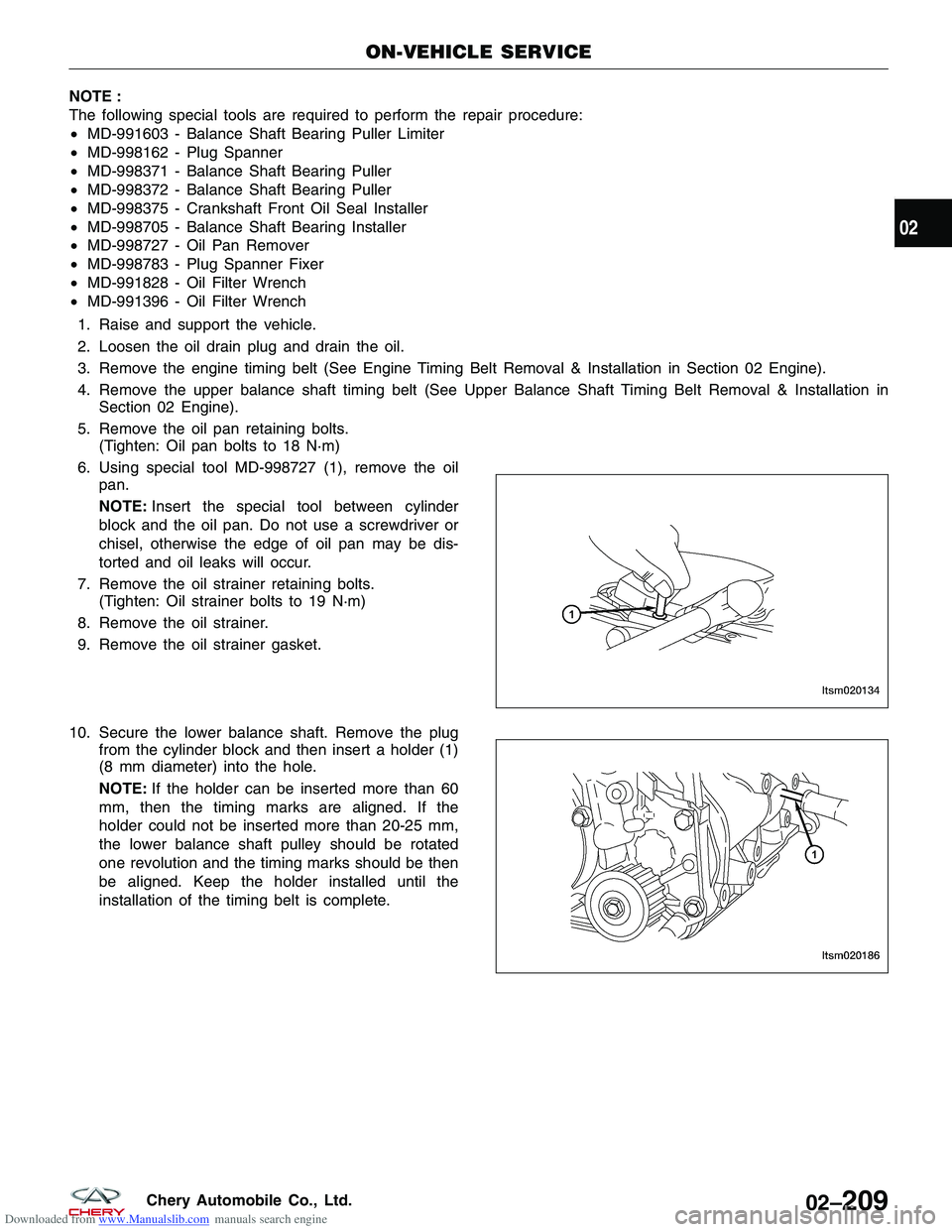

10. Secure the lower balance shaft. Remove the plug from the cylinder block and then insert a holder (1)

(8 mm diameter) into the hole.

NOTE: If the holder can be inserted more than 60

mm, then the timing marks are aligned. If the

holder could not be inserted more than 20-25 mm,

the lower balance shaft pulley should be rotated

one revolution and the timing marks should be then

be aligned. Keep the holder installed until the

installation of the timing belt is complete.

ON-VEHICLE SERVICE

LTSM020134

LTSM020186

02

02–205Chery Automobile Co., Ltd.

Page 238 of 1903

Downloaded from www.Manualslib.com manuals search engine NOTE :

The following special tools are required to perform the repair procedure:

•MD-991603 - Balance Shaft Bearing Puller Limiter

• MD-998162 - Plug Spanner

• MD-998371 - Balance Shaft Bearing Puller

• MD-998372 - Balance Shaft Bearing Puller

• MD-998375 - Crankshaft Front Oil Seal Installer

• MD-998705 - Balance Shaft Bearing Installer

• MD-998727 - Oil Pan Remover

• MD-998783 - Plug Spanner Fixer

• MD-991828 - Oil Filter Wrench

• MD-991396 - Oil Filter Wrench

1. Raise and support the vehicle.

2. Loosen the oil drain plug and drain the oil.

3. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

4. Remove the upper balance shaft timing belt (See Upper Balance Shaft Timing Belt Removal & Installation in Section 02 Engine).

5. Remove the oil pan retaining bolts. (Tighten: Oil pan bolts to 18 N·m)

6. Using special tool MD-998727 (1), remove the oil pan.

NOTE: Insert the special tool between cylinder

block and the oil pan. Do not use a screwdriver or

chisel, otherwise the edge of oil pan may be dis-

torted and oil leaks will occur.

7. Remove the oil strainer retaining bolts. (Tighten: Oil strainer bolts to 19 N·m)

8. Remove the oil strainer.

9. Remove the oil strainer gasket.

10. Secure the lower balance shaft. Remove the plug from the cylinder block and then insert a holder (1)

(8 mm diameter) into the hole.

NOTE: If the holder can be inserted more than 60

mm, then the timing marks are aligned. If the

holder could not be inserted more than 20-25 mm,

the lower balance shaft pulley should be rotated

one revolution and the timing marks should be then

be aligned. Keep the holder installed until the

installation of the timing belt is complete.

ON-VEHICLE SERVICE

LTSM020134

LTSM020186

02

02–209Chery Automobile Co., Ltd.

Page 241 of 1903

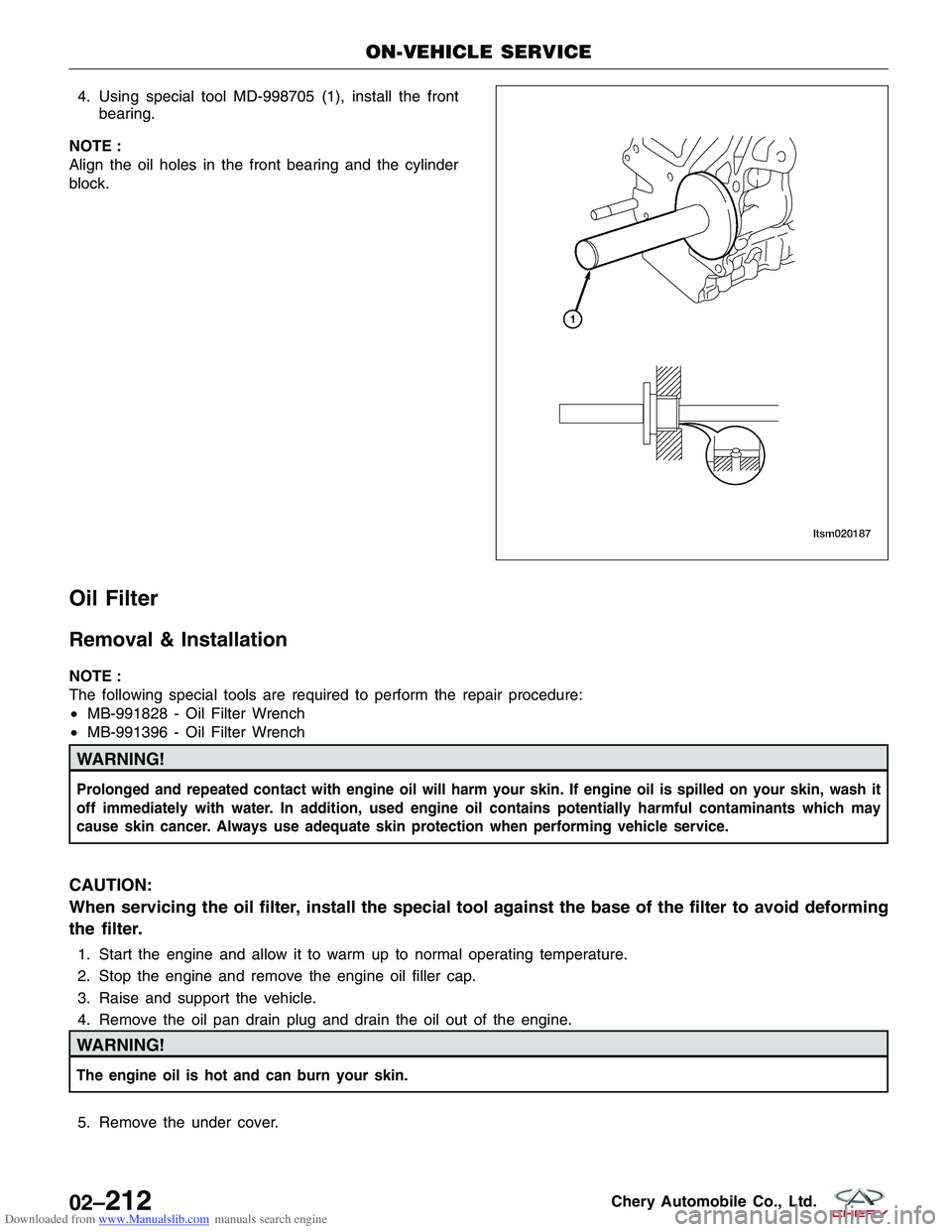

Downloaded from www.Manualslib.com manuals search engine 4. Using special tool MD-998705 (1), install the frontbearing.

NOTE :

Align the oil holes in the front bearing and the cylinder

block.

Oil Filter

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

• MB-991828 - Oil Filter Wrench

• MB-991396 - Oil Filter Wrench

WARNING!

Prolonged and repeated contact with engine oil will harm your skin. If engine oil is spilled on your skin, wash it

off immediately with water. In addition, used engine oil contains potentially harmful contaminants which may

cause skin cancer. Always use adequate skin protection when performing vehicle service.

CAUTION:

When servicing the oil filter, install the special tool against the base of the filter to avoid deforming

the filter.

1. Start the engine and allow it to warm up to normal operating temperature.

2. Stop the engine and remove the engine oil filler cap.

3. Raise and support the vehicle.

4. Remove the oil pan drain plug and drain the oil out of the engine.

WARNING!

The engine oil is hot and can burn your skin.

5. Remove the under cover.

ON-VEHICLE SERVICE

LTSM020187

02–212Chery Automobile Co., Ltd.

Page 242 of 1903

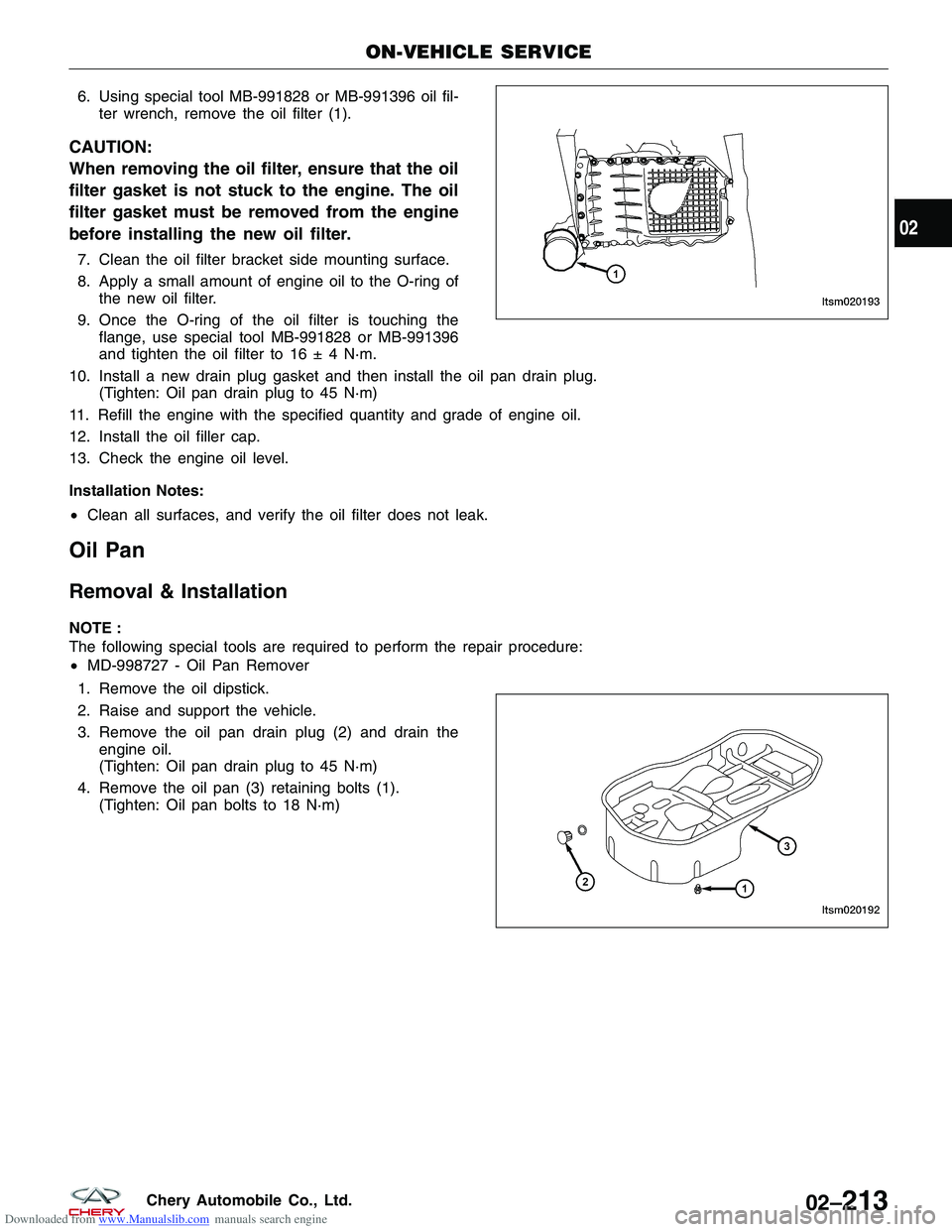

Downloaded from www.Manualslib.com manuals search engine 6. Using special tool MB-991828 or MB-991396 oil fil-ter wrench, remove the oil filter (1).

CAUTION:

When removing the oil filter, ensure that the oil

filter gasket is not stuck to the engine. The oil

filter gasket must be removed from the engine

before installing the new oil filter.

7. Clean the oil filter bracket side mounting surface.

8. Apply a small amount of engine oil to the O-ring ofthe new oil filter.

9. Once the O-ring of the oil filter is touching the flange, use special tool MB-991828 or MB-991396

and tighten the oil filter to 16 ± 4 N·m.

10. Install a new drain plug gasket and then install the oil pan drain plug. (Tighten: Oil pan drain plug to 45 N·m)

11. Refill the engine with the specified quantity and grade of engine oil.

12. Install the oil filler cap.

13. Check the engine oil level.

Installation Notes:

• Clean all surfaces, and verify the oil filter does not leak.

Oil Pan

Removal & Installation

NOTE :

The following special tools are required to perform the repair procedure:

•MD-998727 - Oil Pan Remover

1. Remove the oil dipstick.

2. Raise and support the vehicle.

3. Remove the oil pan drain plug (2) and drain the engine oil.

(Tighten: Oil pan drain plug to 45 N·m)

4. Remove the oil pan (3) retaining bolts (1). (Tighten: Oil pan bolts to 18 N·m)

ON-VEHICLE SERVICE

LTSM020193

LTSM020192

02

02–213Chery Automobile Co., Ltd.

Page 410 of 1903

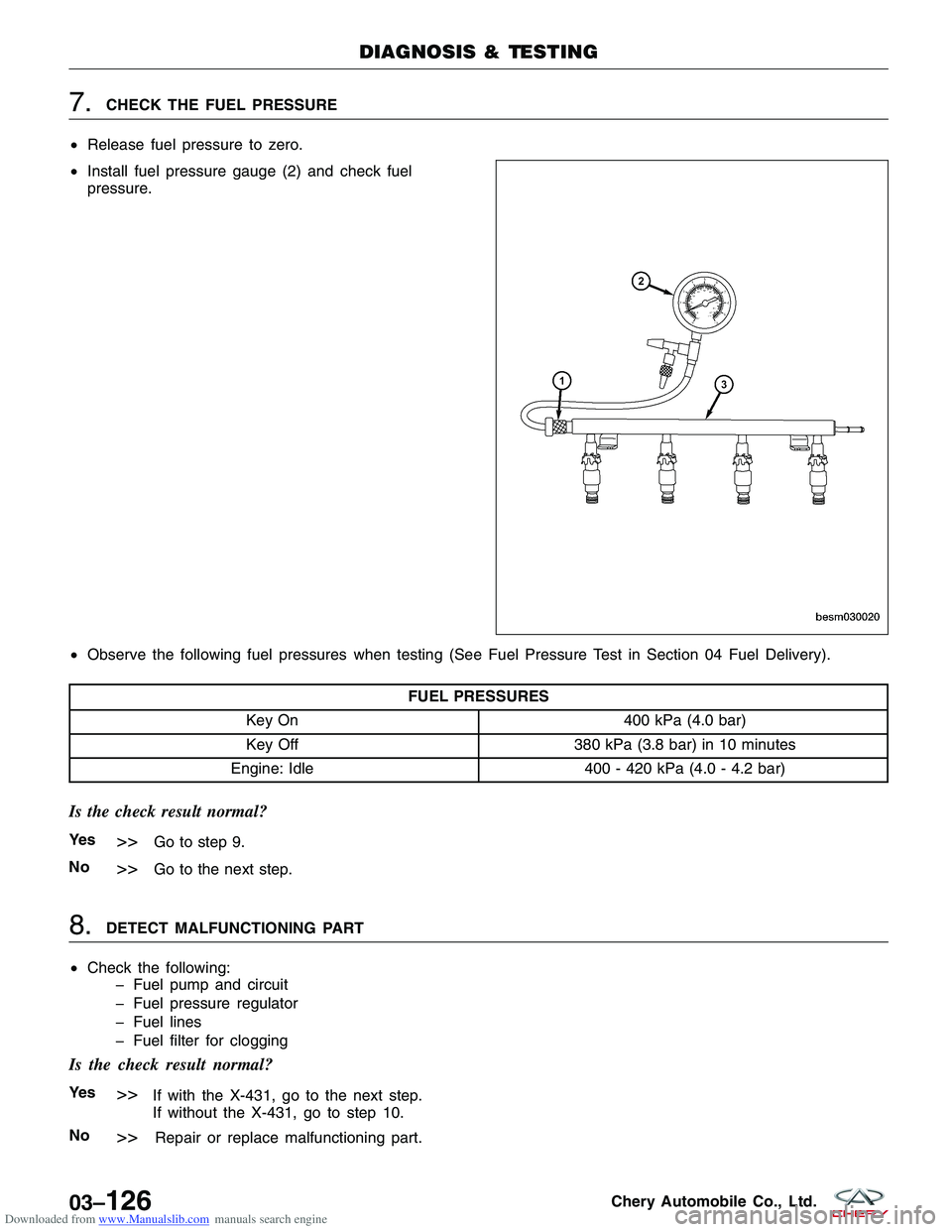

Downloaded from www.Manualslib.com manuals search engine 7.CHECK THE FUEL PRESSURE

• Release fuel pressure to zero.

• Install fuel pressure gauge (2) and check fuel

pressure.

• Observe the following fuel pressures when testing (See Fuel Pressure Test in Section 04 Fuel Delivery).

FUEL PRESSURES

Key On 400 kPa (4.0 bar)

Key Off 380 kPa (3.8 bar) in 10 minutes

Engine: Idle 400 - 420 kPa (4.0 - 4.2 bar)

Is the check result normal?

Ye s>>Go to step 9.

No

>>Go to the next step.

8.DETECT MALFUNCTIONING PART

• Check the following:

� Fuel pump and circuit

� Fuel pressure regulator

� Fuel lines

� Fuel filter for clogging

Is the check result normal?

Ye s>>If with the X-431, go to the next step.

If without the X-431, go to step 10.

No

>>Repair or replace malfunctioning part.

DIAGNOSIS & TESTING

BESM030020

03–126Chery Automobile Co., Ltd.

Page 509 of 1903

Downloaded from www.Manualslib.com manuals search engine 3. Disconnect the APP sensor electrical connector (2).

4. Remove the three APP sensor mounting bolts (1).(Tighten: APP sensor mounting bolts to 11 N·m)

5. Remove the APP sensor with the pedal.

6. Installation is in the reverse order of removal.

Electronic Throttle Control Actuator

Description

The throttle body is located on the intake manifold. It controls air into the intake manifold. The electronic throttle

control actuator consists of throttle control motor, throttle position sensor, etc. The throttle control motor is operated

by the Engine Control Module (ECM) and it opens and closes the throttle valve. The throttle position sensor detects

the throttle valve position.

Operation

Filtered air from the air cleaner enters the intake manifold through the throttle body. A throttle valve (plate) is used to

supply air for idle and driving conditions. The throttle position sensor is part the throttle body. The throttle position

sensor signal is used by the ECM to determine throttle position. The ECM controls the electronic throttle control to

meter air into the engine. This regulates engine power. The vehicle is in sense a “Drive by Wire” system.

Removal & Installation

1. Remove the engine cover.

2. Disconnect the negative battery cable.

ON-VEHICLE SERVICE

LTSM030038

03

03–225Chery Automobile Co., Ltd.