CHERY TIGGO 2009 Service Repair Manual

Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 941 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Exhaust Pipe Assembly

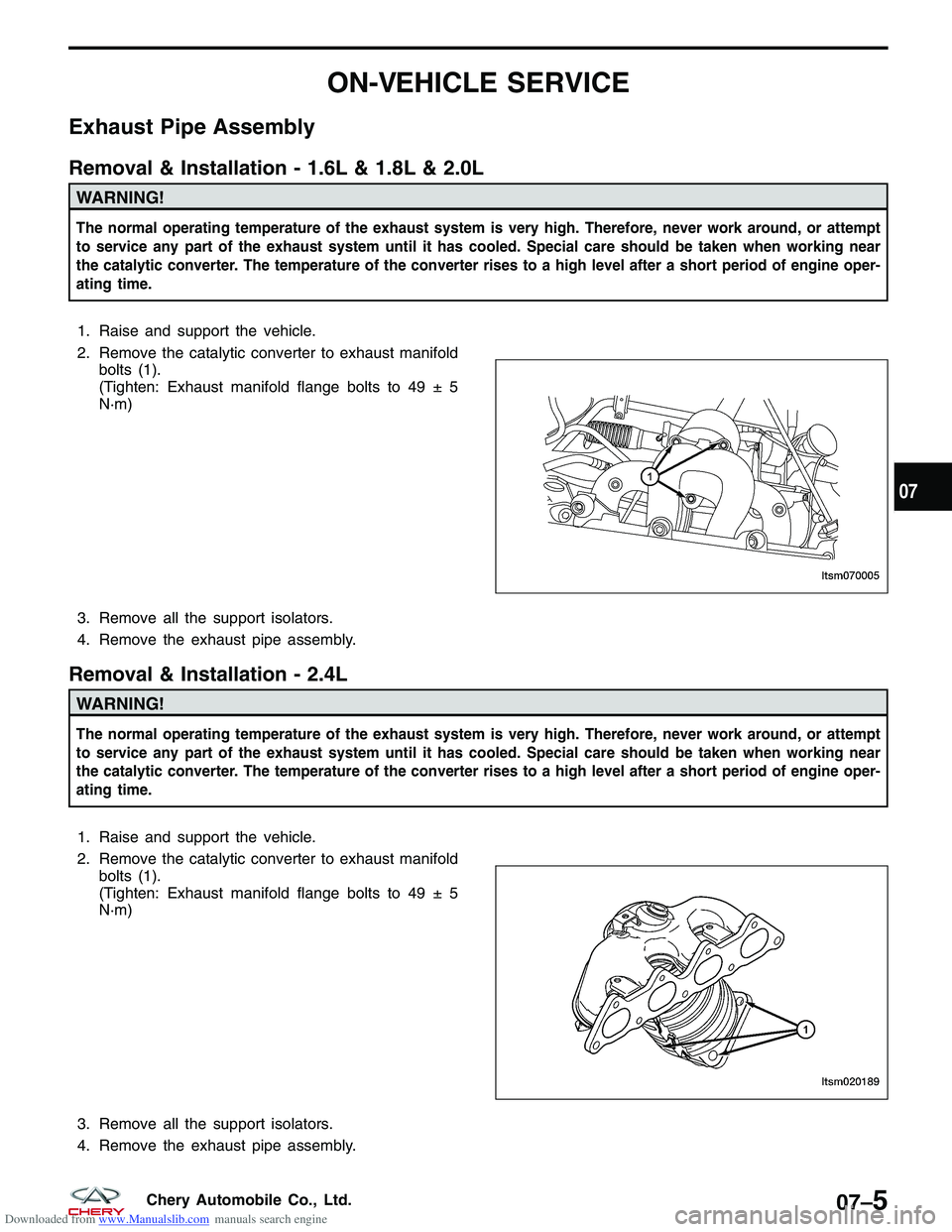

Removal & Installation - 1.6L & 1.8L & 2.0L

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the catalytic converter to exhaust manifoldbolts (1).

(Tighten: Exhaust manifold flange bolts to 49 ± 5

N·m)

3. Remove all the support isolators.

4. Remove the exhaust pipe assembly.

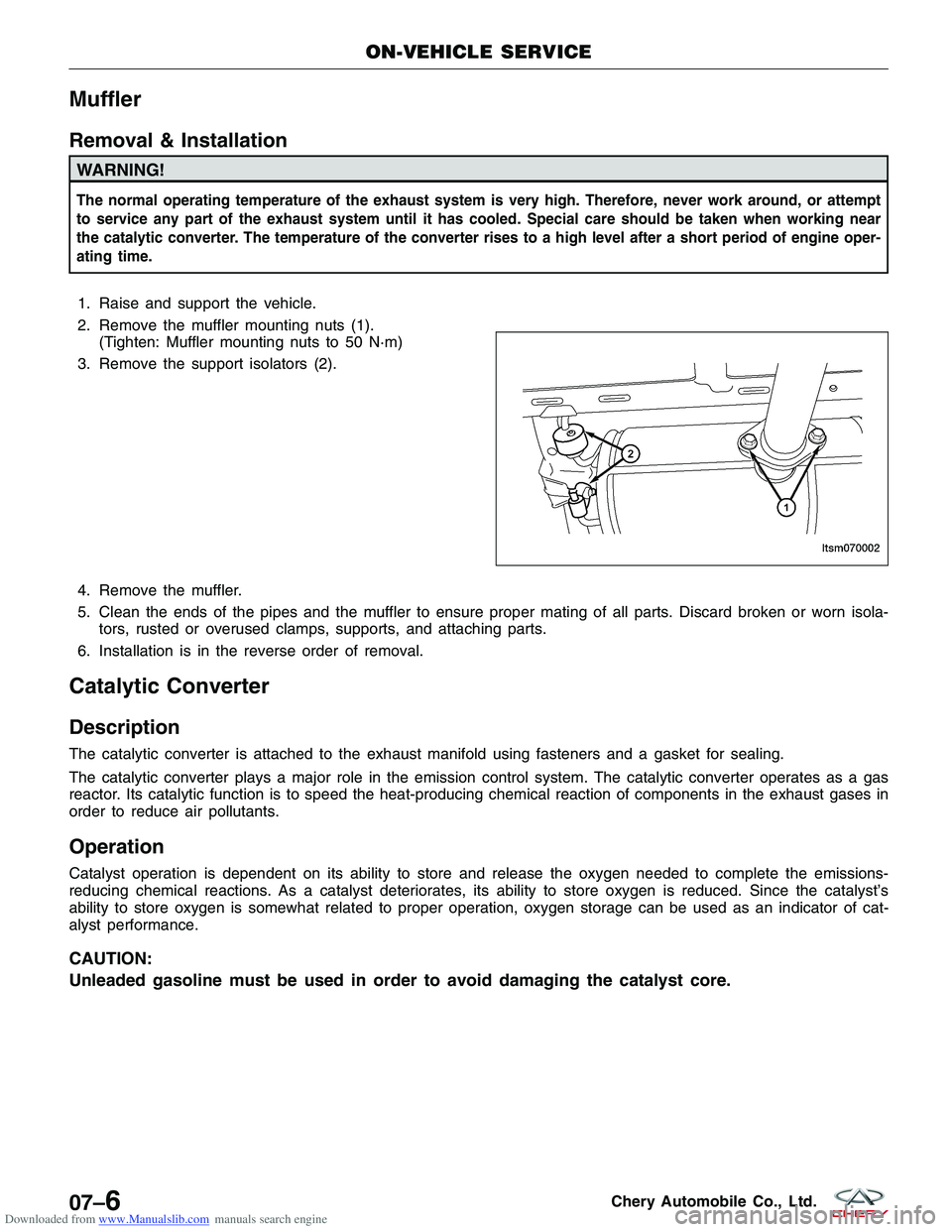

Removal & Installation - 2.4L

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Raise and support the vehicle.

2. Remove the catalytic converter to exhaust manifold bolts (1).

(Tighten: Exhaust manifold flange bolts to 49 ± 5

N·m)

3. Remove all the support isolators.

4. Remove the exhaust pipe assembly.

LTSM070005

LTSM020189

07

07–5Chery Automobile Co., Ltd.

Page 942 of 1903

Downloaded from www.Manualslib.com manuals search engine Muffler

Removal & Installation

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around, or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

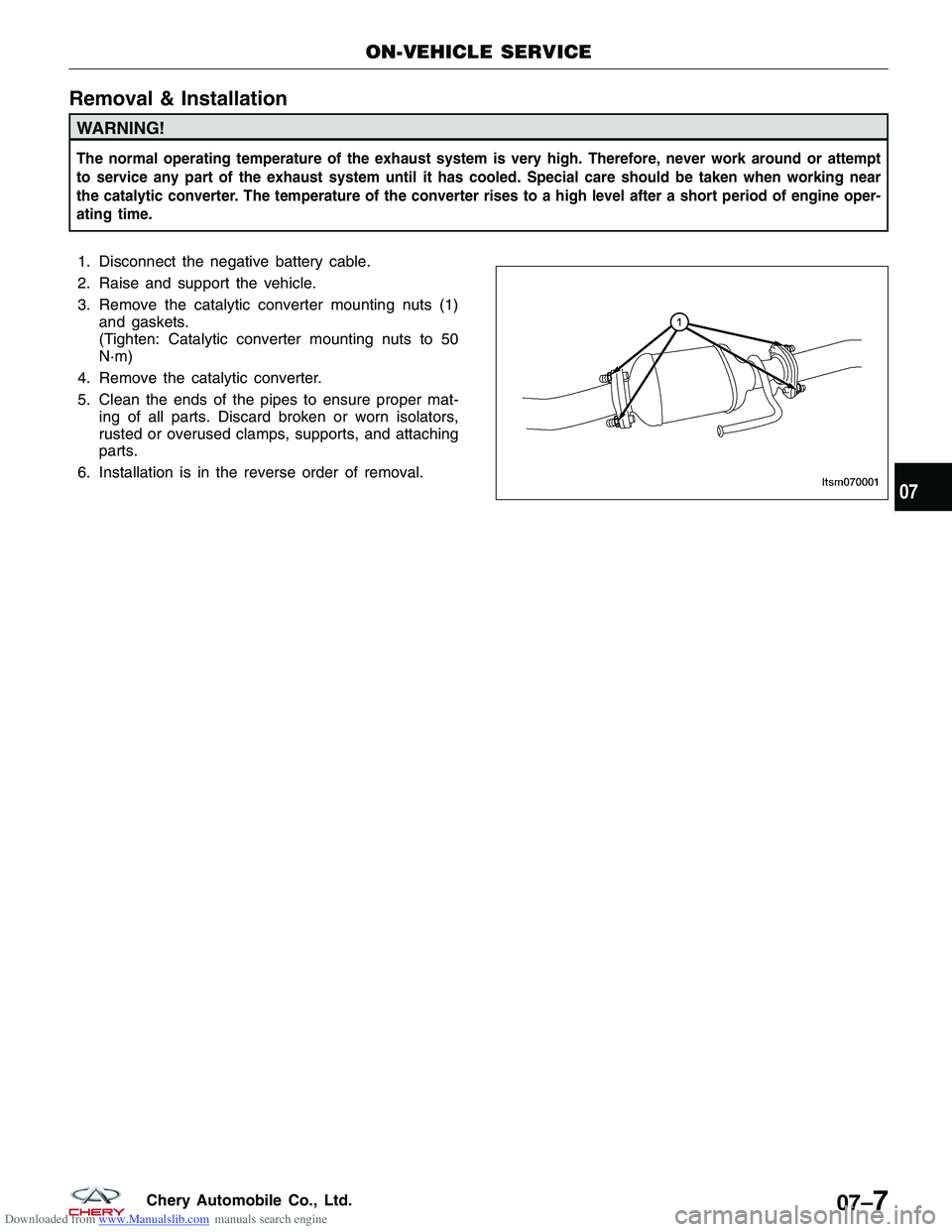

1. Raise and support the vehicle.

2. Remove the muffler mounting nuts (1).(Tighten: Muffler mounting nuts to 50 N·m)

3. Remove the support isolators (2).

4. Remove the muffler.

5. Clean the ends of the pipes and the muffler to ensure proper mating of all parts. Discard broken or worn isola- tors, rusted or overused clamps, supports, and attaching parts.

6. Installation is in the reverse order of removal.

Catalytic Converter

Description

The catalytic converter is attached to the exhaust manifold using fasteners and a gasket for sealing.

The catalytic converter plays a major role in the emission control system. The catalytic converter operates as a gas

reactor. Its catalytic function is to speed the heat-producing chemical reaction of components in the exhaust gases in

order to reduce air pollutants.

Operation

Catalyst operation is dependent on its ability to store and release the oxygen needed to complete the emissions-

reducing chemical reactions. As a catalyst deteriorates, its ability to store oxygen is reduced. Since the catalyst’s

ability to store oxygen is somewhat related to proper operation, oxygen storage can be used as an indicator of cat-

alyst performance.

CAUTION:

Unleaded gasoline must be used in order to avoid damaging the catalyst core.

ON-VEHICLE SERVICE

LTSM070002

07–6Chery Automobile Co., Ltd.

Page 943 of 1903

Downloaded from www.Manualslib.com manuals search engine Removal & Installation

WARNING!

The normal operating temperature of the exhaust system is very high. Therefore, never work around or attempt

to service any part of the exhaust system until it has cooled. Special care should be taken when working near

the catalytic converter. The temperature of the converter rises to a high level after a short period of engine oper-

ating time.

1. Disconnect the negative battery cable.

2. Raise and support the vehicle.

3. Remove the catalytic converter mounting nuts (1)and gaskets.

(Tighten: Catalytic converter mounting nuts to 50

N·m)

4. Remove the catalytic converter.

5. Clean the ends of the pipes to ensure proper mat- ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

6. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM07000107

07–7Chery Automobile Co., Ltd.

Page 944 of 1903

Downloaded from www.Manualslib.com manuals search engine TRANSAXLE & TRANSFER CASE

08

CONTENTSpage

DP0 Automatic Transaxle .............................................................. 08-1

F4A4 Automatic Transaxle ........................................................... 08-143

5-Speed Manual Transaxle ........................................................... 08-246

Front Differential ................................................................... 08-307

Clutch System ..................................................................... 08-316

Transfer Case (4x4) ................................................................. 08-326

DP0 AUTOMATIC TRANSAXLE

GENERAL INFORMATION08-3

Description 08-3

Operation 08-6

Specifications 08-7

Special Tools 08-8

Electrical Schematics 08-10

DP0 Transaxle Control Module (TCM)

Connector Pin-Out Table 08-18

DIAGNOSIS & TESTING08-19

Diagnostic Help 08-19

Intermittent DTC Troubleshooting 08-19

Ground Inspection 08-19

Diagnostic Tools 08-19

Diagnostic Trouble Code (DTC) List 08-20

DP0 Automatic Transaxle DTC List 08-20

Diagnostic Trouble Code (DTC) Tests 08-22

P0641 - Sensor Feed 08-22

P0657 - Solenoid Power Supply Circuit

Shorted To Voltage 08-28

P0657 - Solenoid Power Supply Circuit

Open 08-32

P0705 - Multi-Function Switch:

Prohibited Position 08-37

P0710 - Fluid Temperature Sensor 08-42

P0715 - Turbine Speed Sensor Affected

By Interference 08-46

P0730 - Ratio Of Transaxle Error 08-50

P0753 - Shift Solenoid Valve 1 (SSV1)

Open Circuit Or Short To Power Supply

Or Short To Ground 08-56 P0758 - Shift Solenoid Valve 2 (SSV2)

Open Circuit Or Short To Power Supply

Or Short To Ground 08-62

P0763 - Shift Solenoid Valve 3 (SSV3)

Short To Power Supply, P0763 - Shift

Solenoid Valve 3 (SSV3) Open Or

Short To Ground Circuit 08-68

P0768 - Shift Solenoid Valve 4 (SSV4)

Short To Power Supply, P0768 - Shift

Solenoid Valve 4 (SSV4) Open Or

Short To Ground Circuit 08-74

P0773 - Shift Solenoid Valve 5 (SSV5)

Short To Power Supply, P0773 - Shift

Solenoid Valve 5 (SSV5) Open Or

Short To Ground Circuit 08-81

P0775 - EVM (Modulation Solenoid

Valve) Open Circuit Or Short To

Ground, P0775 - EVM (Modulation

Solenoid Valve) Shorted To Voltage 08-87

P0795 - Torque Converter Lock

Solenoid Valve (EVLU) Open Circuit Or

Short To Ground, P0795 - Torque

Converter Lock Solenoid Valve (EVLU)

Short To Voltage 08-93

P0840 - Pressure Sensor 08-99

P1928 - Shift Lock Solenoid Valve

Circuit Shorted To Voltage 08-104

P1928 - Shift Lock Solenoid Valve

Open Circuit Or Short To Ground 08-109

P2709 - Shift Solenoid Valve 6 (SSV6)

Short To Power Supply 08-114

P2709 - Shift Solenoid Valve 6 (SSV6)

Open Circuit Or Short To Ground 08-119

08

08–1Chery Automobile Co., Ltd.

Page 945 of 1903

Downloaded from www.Manualslib.com manuals search engine P2753 - EPDE Circuit Or Short To

Power Supply, P2753 - EPDE Open

Circuit Or Short To Ground 08-125

U0001 - CAN Communication Error 08-130ON-VEHICLE SERVICE08-136

DPO Automatic Transaxle Assembly 08-136

Removal & Installation 08-136

Automatic Shifter Selector 08-140

Removal & Installation 08-140

Transaxle Control Module (TCM) 08-142

Removal & Installation 08-142

08–2Chery Automobile Co., Ltd.

Page 946 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The DP0 automatic transaxle is a four-speed transaxle that is a conventional hydraulic/mechanical transaxle assem-

bly with an integral differential, and is controlled with adaptive electronic controls and monitors. The hydraulic system

of the transaxle consists of the transaxle fluid, fluid passages, hydraulic valves, fluid pump, and various line pressure

control components.

The Transaxle Control Module (TCM) is the heart of the electronic control system and relies on information from

various direct and indirect inputs (sensors, switches, etc.) to determine driver demand and vehicle operating condi-

tions. With this information, the ECM/TCM can calculate and perform timely and quality shifts through various output

or control devices.

The TCM also performs certain self-diagnostic functions and provides comprehensive information (sensor data,

DTCs, etc.) which is helpful in proper diagnosis and repair. This information can be viewed with the X-431 scan tool.

08

08–3Chery Automobile Co., Ltd.

Page 947 of 1903

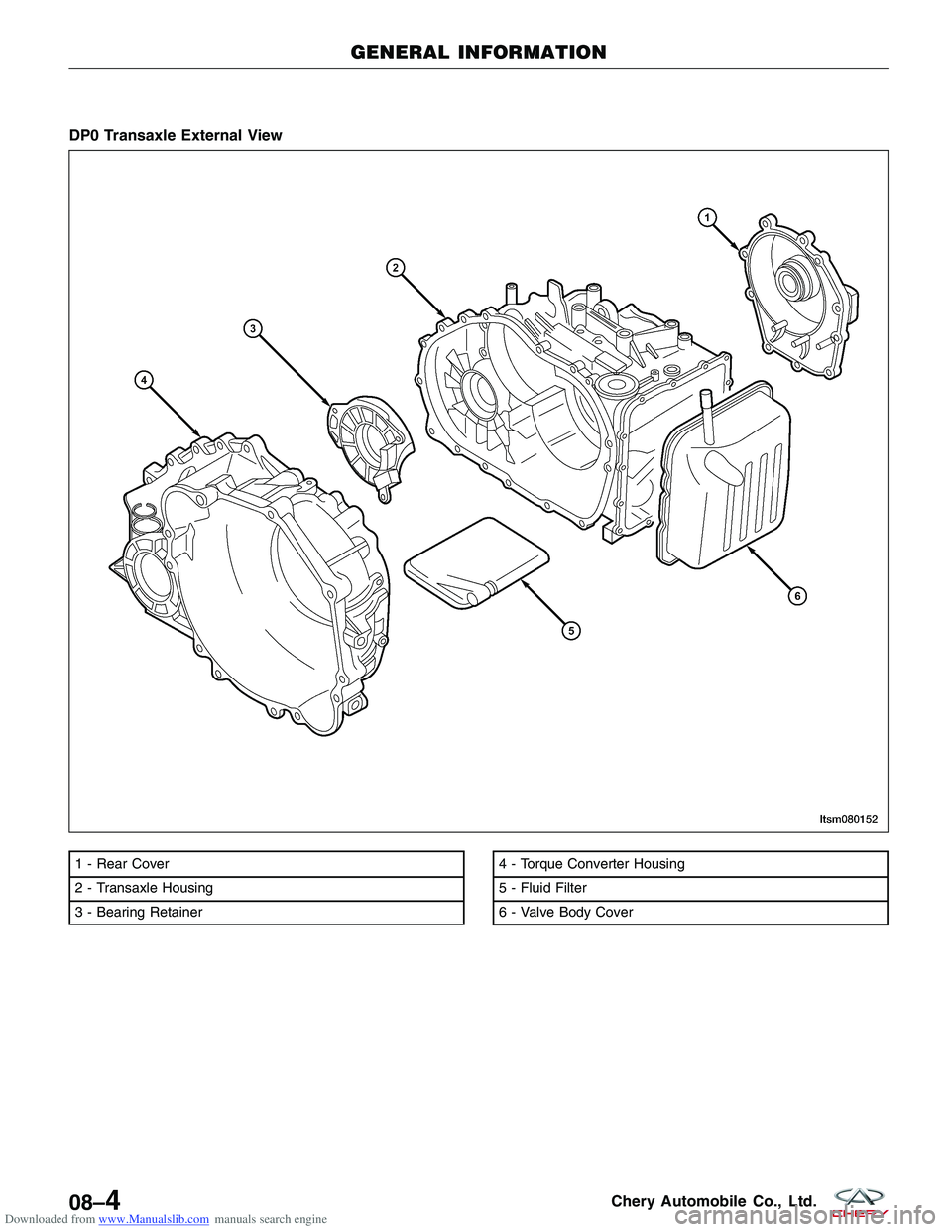

Downloaded from www.Manualslib.com manuals search engine DP0 Transaxle External View

1 - Rear Cover

2 - Transaxle Housing

3 - Bearing Retainer4 - Torque Converter Housing

5 - Fluid Filter

6 - Valve Body Cover

GENERAL INFORMATION

LTSM080152

08–4Chery Automobile Co., Ltd.

Page 948 of 1903

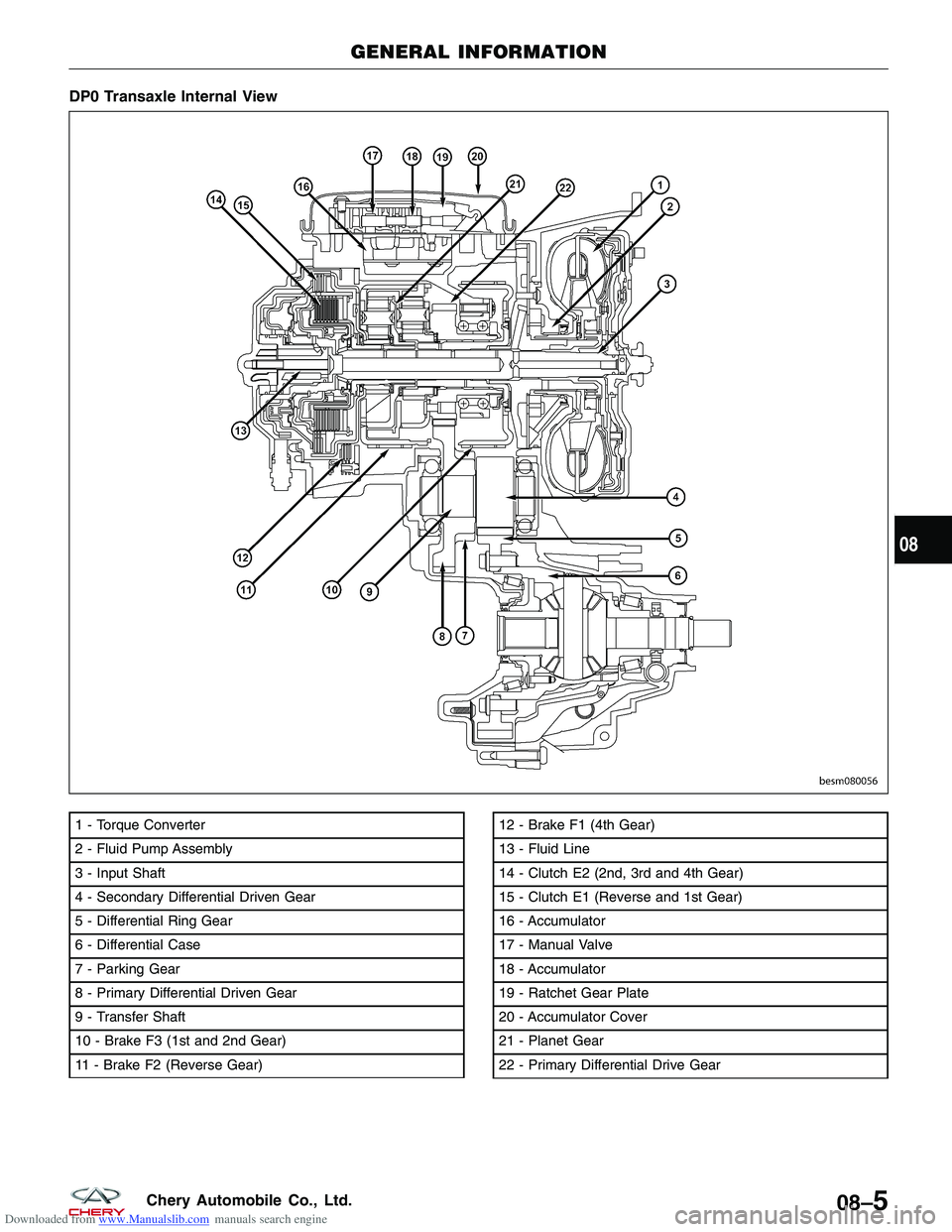

Downloaded from www.Manualslib.com manuals search engine DP0 Transaxle Internal View

1 - Torque Converter

2 - Fluid Pump Assembly

3 - Input Shaft

4 - Secondary Differential Driven Gear

5 - Differential Ring Gear

6 - Differential Case

7 - Parking Gear

8 - Primary Differential Driven Gear

9 - Transfer Shaft

10 - Brake F3 (1st and 2nd Gear)

11 - Brake F2 (Reverse Gear)12 - Brake F1 (4th Gear)

13 - Fluid Line

14 - Clutch E2 (2nd, 3rd and 4th Gear)

15 - Clutch E1 (Reverse and 1st Gear)

16 - Accumulator

17 - Manual Valve

18 - Accumulator

19 - Ratchet Gear Plate

20 - Accumulator Cover

21 - Planet Gear

22 - Primary Differential Drive Gear

GENERAL INFORMATION

BESM080056

08

08–5Chery Automobile Co., Ltd.

Page 949 of 1903

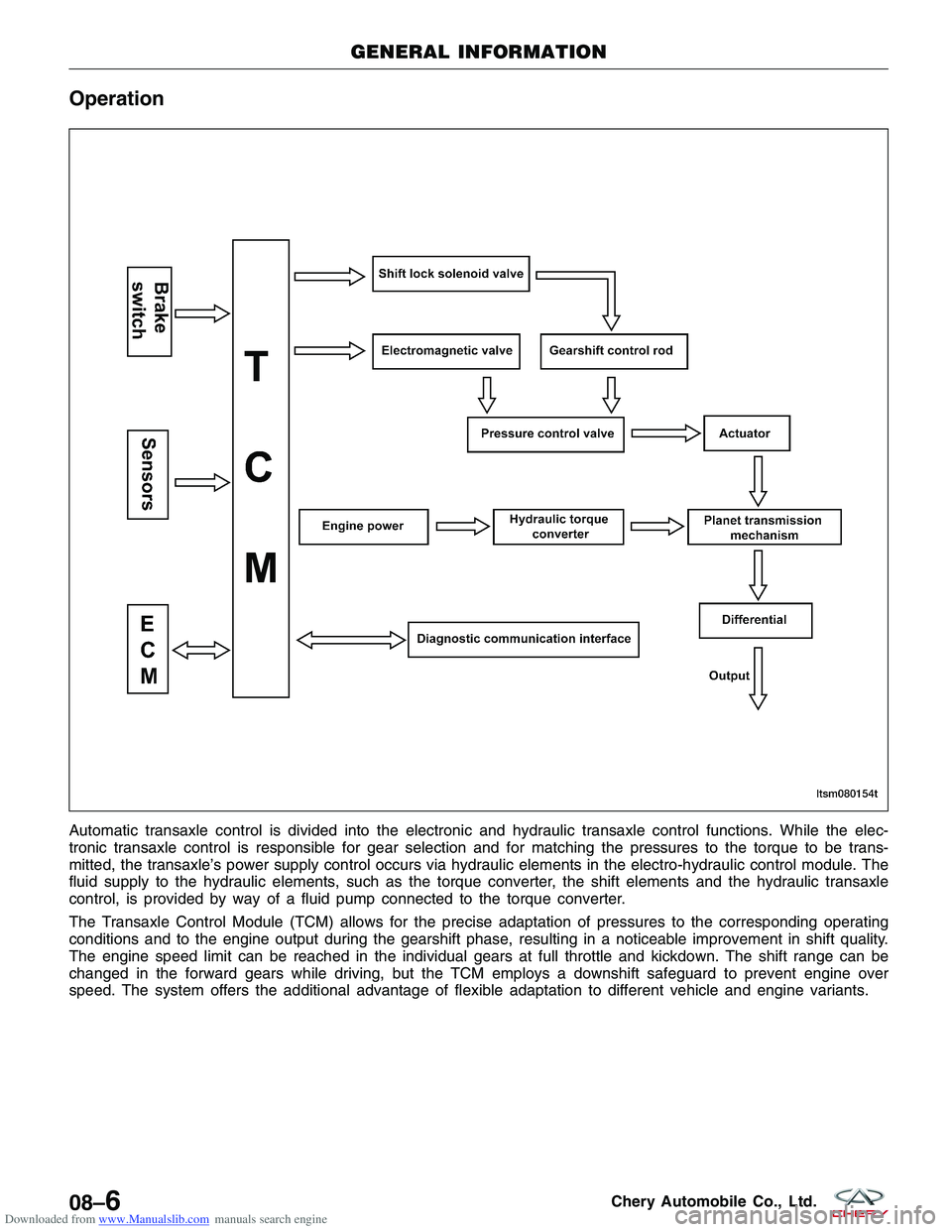

Downloaded from www.Manualslib.com manuals search engine Operation

Automatic transaxle control is divided into the electronic and hydraulic transaxle control functions. While the elec-

tronic transaxle control is responsible for gear selection and for matching the pressures to the torque to be trans-

mitted, the transaxle’s power supply control occurs via hydraulic elements in the electro-hydraulic control module. The

fluid supply to the hydraulic elements, such as the torque converter, the shift elements and the hydraulic transaxle

control, is provided by way of a fluid pump connected to the torque converter.

The Transaxle Control Module (TCM) allows for the precise adaptation of pressures to the corresponding operating

conditions and to the engine output during the gearshift phase, resulting in a noticeable improvement in shift quality.

The engine speed limit can be reached in the individual gears at full throttle and kickdown. The shift range can be

changed in the forward gears while driving, but the TCM employs a downshift safeguard to prevent engine over

speed. The system offers the additional advantage of flexible adaptation to different vehicle and engine variants.

GENERAL INFORMATION

LTSM080154T

08–6Chery Automobile Co., Ltd.

Page 950 of 1903

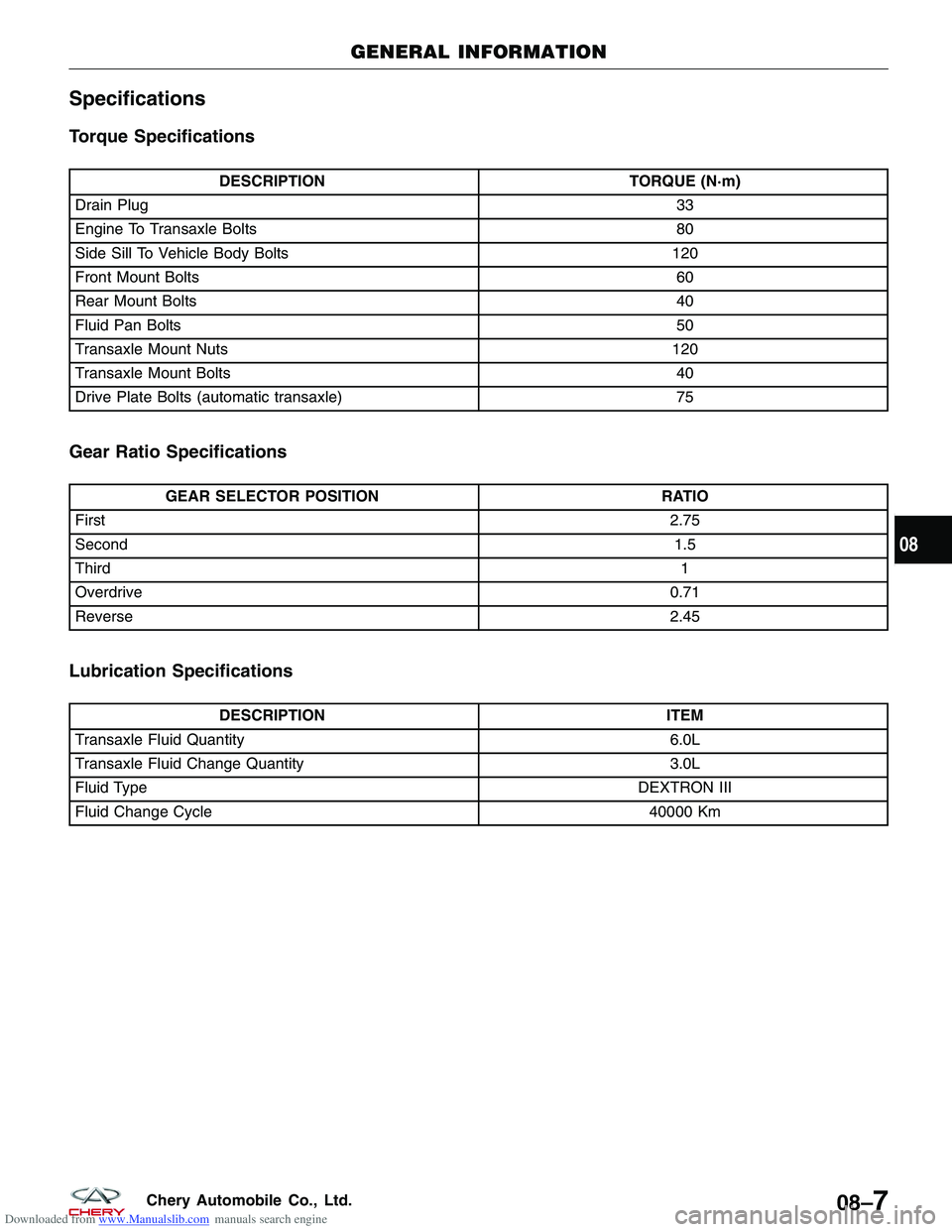

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Drain Plug 33

Engine To Transaxle Bolts 80

Side Sill To Vehicle Body Bolts 120

Front Mount Bolts 60

Rear Mount Bolts 40

Fluid Pan Bolts 50

Transaxle Mount Nuts 120

Transaxle Mount Bolts 40

Drive Plate Bolts (automatic transaxle) 75

Gear Ratio Specifications

GEAR SELECTOR POSITIONRATIO

First 2.75

Second 1.5

Third 1

Overdrive 0.71

Reverse 2.45

Lubrication Specifications

DESCRIPTIONITEM

Transaxle Fluid Quantity 6.0L

Transaxle Fluid Change Quantity 3.0L

Fluid Type DEXTRON III

Fluid Change Cycle 40000 Km

GENERAL INFORMATION

08

08–7Chery Automobile Co., Ltd.