ECU CHEVROLET CAMARO 1967 1.G Chassis Owners Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 450 of 659

STEERING 9-10

SECTOR SHAFT SEAL REPLACEMENT

A faulty seal may be replaced without removal of

steering gear from car by removing pitman arm as out-

lined under Maintenance and Adjustments--Steering Gear

Adjustments and proceed as follows:

1.

Loose lash adjuster lock nut and turn lash adjuster

screw several turns counterclockwise.

2.

Remove three cap screws holding side cover to gear

bushing.

3.

Pull side cover and sector shaft from gear housing

as a unit. Do not separate side cover from sector

shaft.

4.

Pull sector shaft seal from gear housing using

hooked tool or pliers.

5. Coat new seal with chassis grease and position in

sector shaft bore.

6. Place a socket or piece of pipe of suitable diameter

on top of seal and drive seal into bore by tapping

pipe or socket with soft hammer.

7. Install sector shaft side cover assembly, being care-

ful not to damage new seal with splines on end of

shaft; splines may be wrapped with a few turns of

tape to prevent this.

8. Install new side cover gasket and align side cover on

gear housing and install cap screw.

9. Perform steering gear adjustment and install pitman

arm as outlined under Maintenance and Adjustments.

STEERING COLUMN

All models are equipped with new energy absorbing

steering columns. The columns are of five basic designs

as follows:

1.

Syncromesh. The syncromesh column is used on

models with standard, column mounted, conventional

shift levers. The shift tube, within the outer mast

jacket, includes two lower shift levers for connection

to the transmission control linkage.

2.

Automatic and floor shift. This column is used on

models equipped with column mounted powerglide

shift levers, or models with floor shift. If the ve-

hicle has the column mounted powerglide shift con-

trol, the inner shift tube has a single lower shift

lever for connection to the transmission control

linkage. On floor shift models, no lower shift levers

are present on the shift tube.

3.

Tilt wheel option. The upper end and steering shaft

of this column is specially designed to accommodate

the optional tilt steering wheel.

4.

Standard Corvette Column. The standard Corvette

column is similar in design to the Automatic and

Floor Shift column used on other models, except

no shift tube is used. Other differences are pointed

out in the disassembly and assembly procedures for

Standard Corvette column.

5. Telescopic wheel option. The upper end and steering

shaft of this column is specially designed to ac-

commodate the optional telescoping steering wheel.

To perform service procedures on steering column

upper end components, it is not necessary to remove the

column from the vehicle. The steering wheel, horn com-

ponents, turn signal switch, upper housing with bearing,

shift control lever, hazard warning knob, and upper shift

bowl may all be removed with the column remaining in

the vehicle. When servicing the above components, omit

the removal procedure and proceed with the applicable

disassembly procedures. Because of the numerous dif-

ferences in steering column types, be sure to refer to the

set of instructions below which apply to the exact column

to be serviced:

CAUTION: The outer mast jacket, shift tube, _

steering shaft, and instrument panel column

mounting b

racket

are designed as energy ab-

sorbing units. Because of the design of these

components, it is absolutely necessary to handle

the column with care when performing any serv-

ice operation required. Avoid hammering, jar-

ring, dropping, or leaning on any portion of the

column.

Removal

1.

Disconnect steering column harness at connector.

Disconnect neutral safety switch and back-up lamp

switch connectors if so equipped.

Remove steering wheel as outlined in this section.

Remove nuts and washers securing flanged end of

column to steering gear. On Chevy H models, re-

move nut and clamp bolt securing lower end of steer-

ing column to steering gear.

Disconnect transmission control linkage, if so

equipped, from lower column shift tube, levers.

Chevrolet and Chevy II only: Remove screws at-

taching upper and lower mast jacket covers together.

On Chevrolet, remove screws attaching lower cover

to instrument panel (figs. 15 and 18). Remove lower

cover.

Chevelle only: Remove screws securing mast jacket

trim cover to instrument panel and remove cover

(fig. 15).

Corvette, only: Remove screws securing escutcheon

to instrument panel. Remove screws securing upper

and lower covers together and remove covers.

On Chevrolet and Chevelle columns with Powerglide

shift levers, loosen set screw at six o'clock position

at bottom of column and remove the transmission

shift indicator pointer (fig. 15).

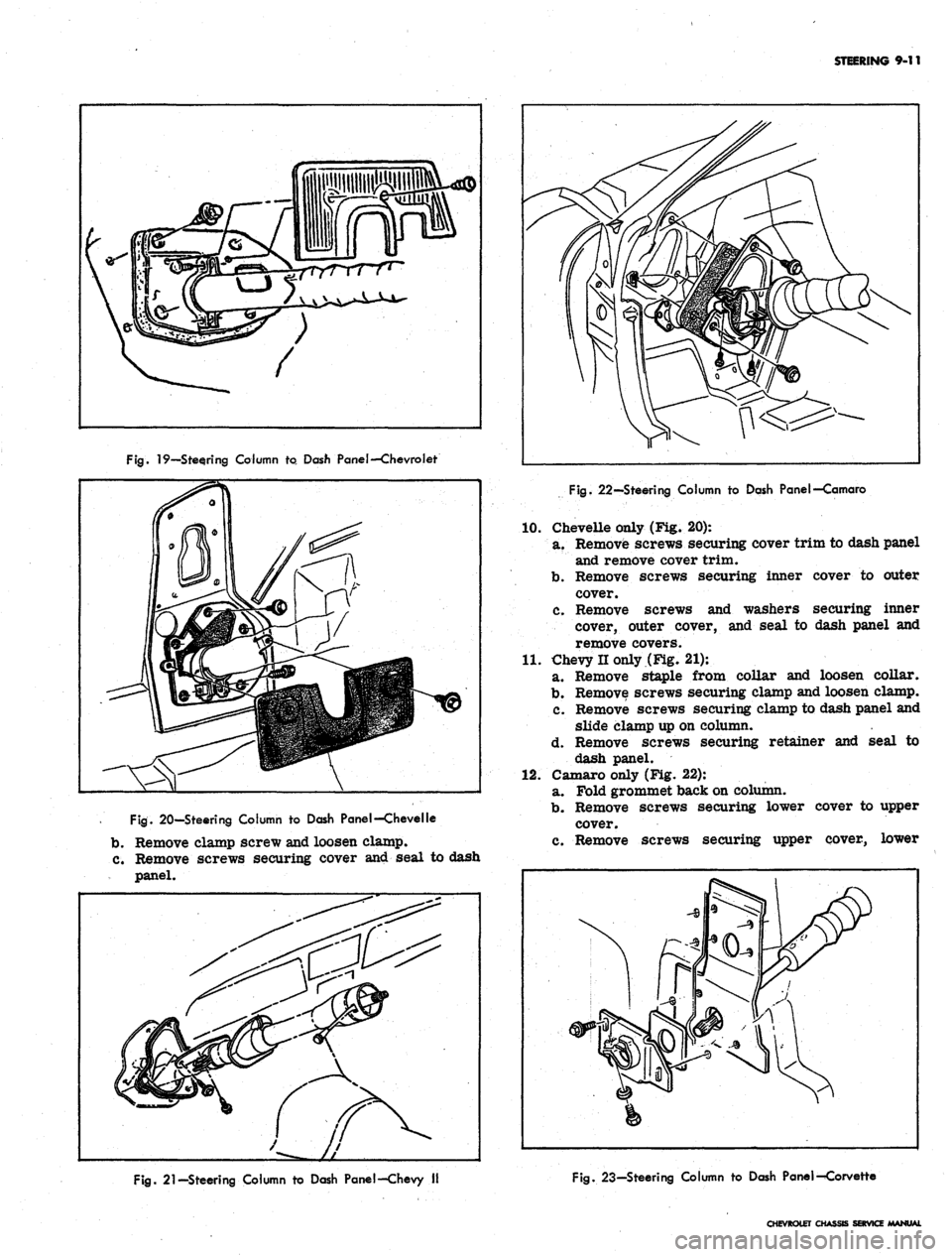

9. Chevrolet only (fig. 19):

a. Remove screws securing cover trim to dash

panel and remove cover trim.

2.

3.

4.

5.

6.

7.

8.

Fig.

18—Mast Jacket Cover Attachments—Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 451 of 659

STEERING 9-11

Fig.

19—Steering Column to. Dash Panel—Chevrolet

Fig.

20—Steering Column to Dash Panel—Chevelle

b.

Remove clamp screw and loosen clamp.

c. Remove screws securing cover and seal to dash

panel.

Fig.

22—Steering Column to Dash Panel—Camaro

10.

Chevelle only (Fig. 20):

a. Remove screws securing cover trim to dash panel

and remove cover trim.

b.

Remove screws securing inner cover to outer

cover.

c. Remove screws and washers securing inner

cover, outer cover, and seal to dash panel and

remove covers.

11.

Chevy U only (Fig. 21):

a. Remove staple from collar and loosen collar.

b.

Remove screws securing clamp and loosen clamp.

c. Remove screws securing clamp to dash panel and

slide clamp up on column.

d. Remove screws securing retainer and seal to

dash panel.

12.

Camaro only (Fig. 22):

a. Fold grommet back on column.

b.

Remove screws securing lower cover to upper

cover.

c. Remove screws securing upper cover, lower

Fig.

21—Steering Column to Dash Panel—Chevy II

Fig.

23—Steering Column to Dash Panel-Corvette

CHEVROLET CHASSIS SERVICE MANUAL

Page 452 of 659

STEERING 9-12

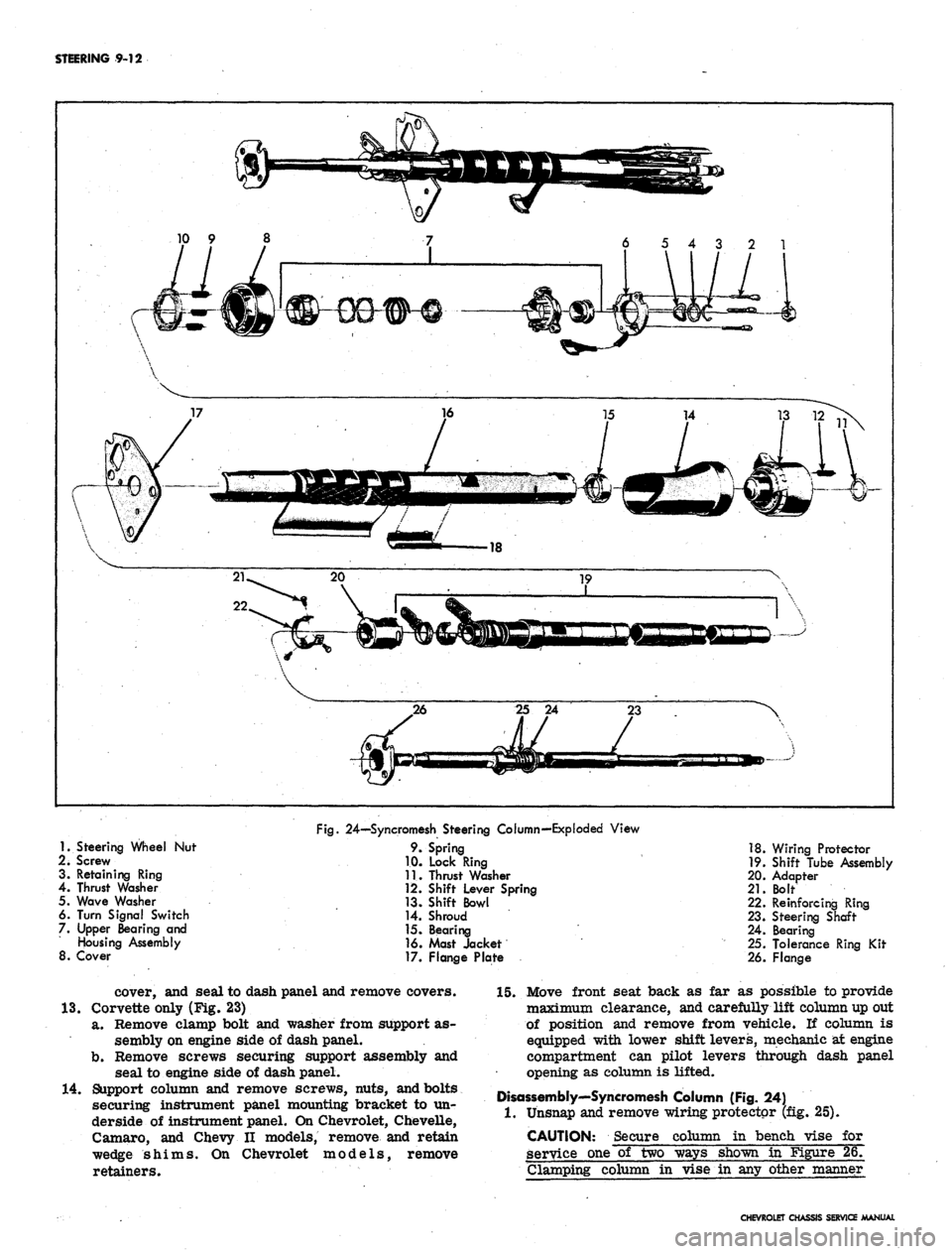

1.

Steering Wheel Nut

2i Screw

3. Retaining Ring

4.

Thrust Washer

5. Wave Washer

6. Turn Signal Switch

7. Upper Bearing and

Housing Assembly

8. Cover

Fig.

24—Syncromesh Steering Column—Exploded View

9. Spring

1.0. Lock Ring

11.

Thrust Washer

12.

Shift Lever Spring

13.

Shift Bowl

14.

Shroud

15.

Bearing

16.

Mast Jacket

17.

Flange Plate

18.

Wiring Protector

19.

Shift Tube Assembly

20.

Adapter

21.

Bolt

22.

Reinforcing Ring

23.

Steering Shaft

24.

Bearing

25.

Tolerance Ring Kit

26.

Flange

cover, and seal to dash panel and remove covers.

13.

Corvette only (Fig. 23)

a. Remove clamp bolt and washer from support as-

sembly on engine side of dash panel.

b.

Remove screws securing support assembly and

seal to engine side of dash panel.

14.

Support column and remove screws, nuts, and bolts

securing instrument panel mounting bracket to un-

derside of instrument panel. On Chevrolet, Chevelle,

Camaro, and Chevy II models, remove and retain

wedge shims. On Chevrolet models, remove

retainers.

15.

Move front seat back as far as possible to provide

maximum clearance, and carefully lift column up out

of position and remove from vehicle. If column is

equipped with lower shift levers, mechanic at engine

compartment can pilot levers through dash panel

opening as column is lifted.

Disassembly'—Syncromesh Column (Fig. 24)

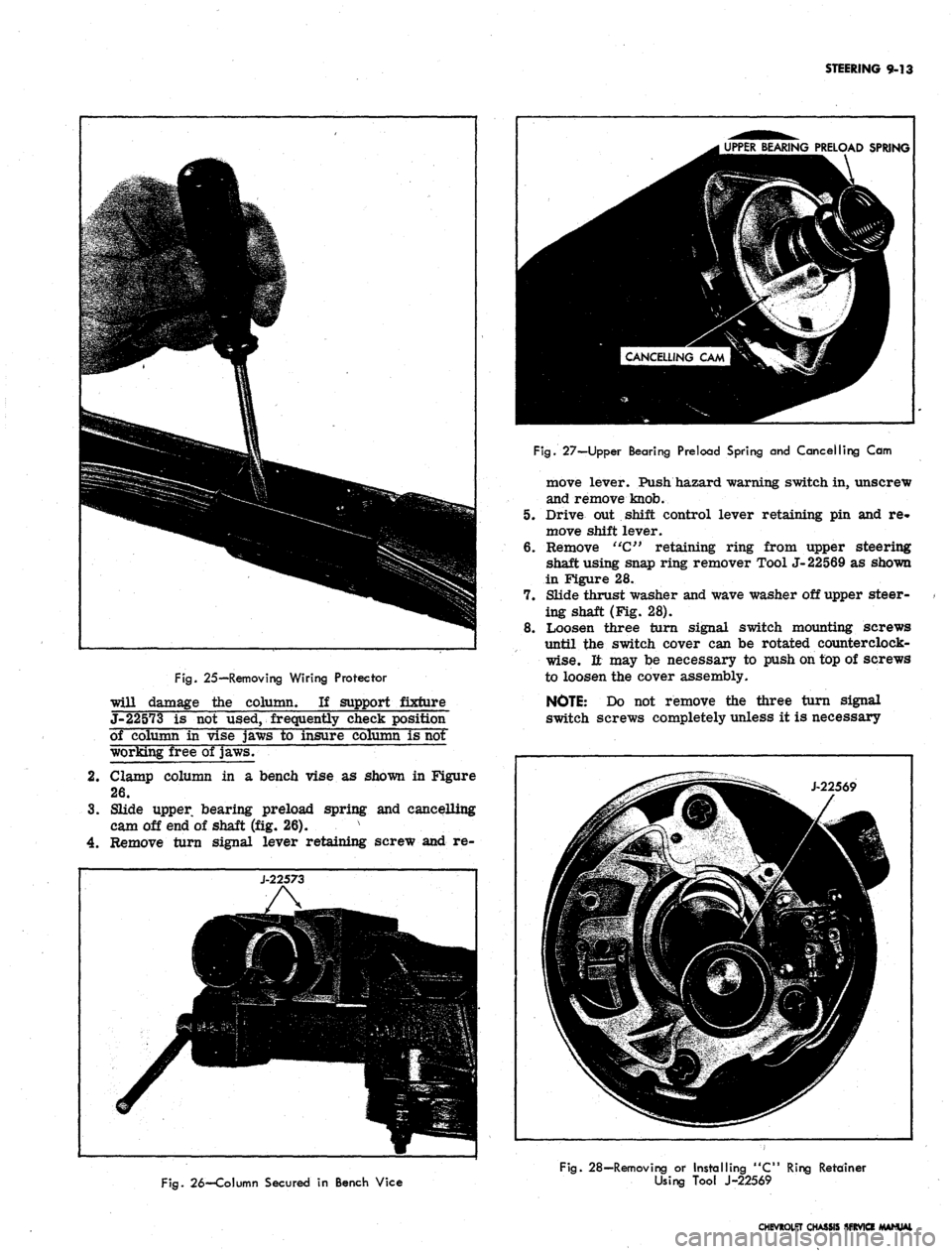

1.

Unsnap and remove wiring protector (fig. 25).

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

CHEVROLET CHASSIS SERVICE MANUAL

Page 453 of 659

STEERING

9-13

Fig.

25—Removing

Wiring

Protector

will damage the column. If support fixture

J- 22573 is not used, frequently check position

of column in vise jaws to insure column is not

working free of jaws.

2.

Clamp column in a bench vise as shown in Figure

26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft (fig. 26).

4.

Remove turn signal lever retaining screw and re-

J

/

P TT-T. ,,.. "~~ ••• -£;:«s-tu

4

• h ^•--

:z:--:vmM

UPPER

BEARING

PRELOAD

SPRING

Fig.

27—Upper

Bearing

Preload

Spring

and

Cancelling

Cam

move lever. Push hazard warning switch in, unscrew

and remove knob.

5. Drive out shift control lever retaining pin and re-

move shift lever.

6. Remove "C" retaining ring from upper steering

shaft using snap ring remover Tool J-22569 as shown

in Figure 28.

7. Slide thrust washer and wave washer off upper steer-

ing shaft (Fig. 28).

8. Loosen three turn signal switch mounting screws

until the switch cover can be rotated counterclock-

wise. It may be necessary to push on top of screws

to loosen the cover assembly.

NOTE:

Do not remove the three turn signal

switch screws completely unless it is necessary

Fig.

26—Column

Secured

in

Bench Vice

Fig.

28—Removing

or

Installing

"C"

Ring

Retainer

Using Tool

J-22569

CHEVROLET CHASSIS 3ERV1CI MANUAL

Page 454 of 659

STEERING 9-14

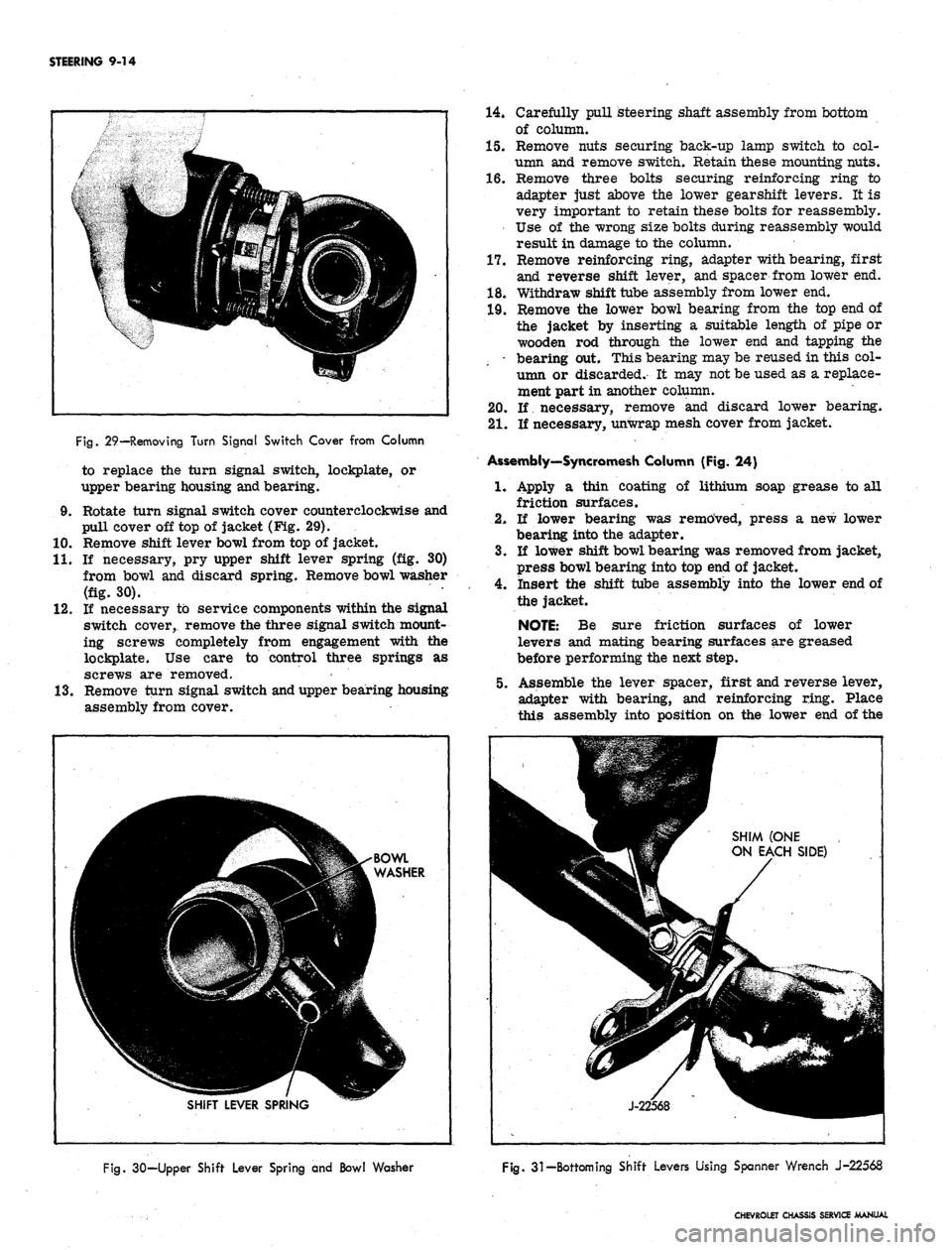

Fig.

29—Removing Turn Signal Switch Cover from Column

to replace the turn signal switch, lockplate, or

upper bearing housing and bearing.

9. Rotate turn signal switch cover counterclockwise and

pull cover off top of jacket (Fig. 29).

10.

Remove shift lever bowl from top of jacket.

11.

If necessary, pry upper shift lever spring (fig. 30)

from bowl and discard spring. Remove bowl washer

(fig. 30).

12.

If necessary to service components within the signal

switch cover, remove the three signal switch mount-

ing screws completely from engagement with the

lockplate. Use care to control three springs as

screws are removed. -

13.

Remove turn signal switch and upper bearing housing

assembly from cover.

H

SHIFT

r

i

LEVER

a

SPRING

I^-BOWL

Sk WASHER

14.

Carefully pull steering shaft assembly from bottom

of column.

15.

Remove nuts securing back-up lamp switch to col-

umn and remove switch. Retain these mounting nuts.

16.

Remove three bolts securing reinforcing ring to

adapter just above the lower gearshift levers. It is

very important to retain these bolts for reassembly.

Use of the wrong size bolts during reassembly would

result in damage to the column.

17.

Remove reinforcing ring, adapter with bearing, first

and reverse shift lever, and spacer from lower end.

18.

Withdraw shift tube assembly from lower end.

19.

Remove the lower bowl bearing from the top end of

the jacket by inserting a suitable length of pipe or

wooden rod through the lower end and tapping the

- bearing out. This bearing may be reused in this col-

umn or discarded. It may not be used as a replace-

ment part in another column.

20.

If necessary, remove and discard lower bearing.

21.

If necessary, unwrap mesh cover from jacket.

Assembly—Syncromesh Column (Fig. 24)

1.

Apply a thin coating of lithium soap grease to all

friction surfaces.

2.

If lower bearing was removed, press a new lower

bearing into the adapter.

3.

If lower shift bowl bearing was removed from jacket,

press bowl bearing into top end of jacket.

4.

Insert the shift tube assembly into the lower end of

the jacket.

NOTE: Be sure friction surfaces of lower

levers and mating bearing surfaces are greased

before performing the next step.

5.

Assemble the lever spacer, first and reverse lever,

adapter with bearing, and reinforcing ring. Place

this assembly into position on the lower end of the

SHIM (ONE

ON EACH SIDE)

Fig.

30—Upper Shift Lever Spring and Bowl Washer

Fig.

31—Bottoming Shift Levers Using Spanner Wrench J-22568

CHEVROLET CHASSIS SERVICE MANUAL

Page 455 of 659

STEERING 9-15

jacket and loosely secure using the three bolts re- 8.

moved during disassembly.

Place a 0.005 maximum shim on each side of the 9.

shaft, between either one of the shift levers and the

spacer (fig. 31). 10.

Using spanner wrench J-22568 installed in spanner

holes in adapter, rotate the.adapter clockwise until

the shift levers are bottomed out (fig. 31). Bottom

the adapter against the jacket while rotating to re-

move end play. 11.

Tighten the three adapter bolts. Remove the two

0.005 shims.

Insert the steering shaft assembly into position

through the lower end of the jacket.

Attach the back-up lamp switch loosely to the jacket

using the same nuts removed during disassembly.

Install these nuts loosely, switch will be tightened to

the jacket when column is installed in vehicle and

shift levers are aligned.

If upper shift lever spring was removed, press a

10 9 8

6 5 4 3 2 1

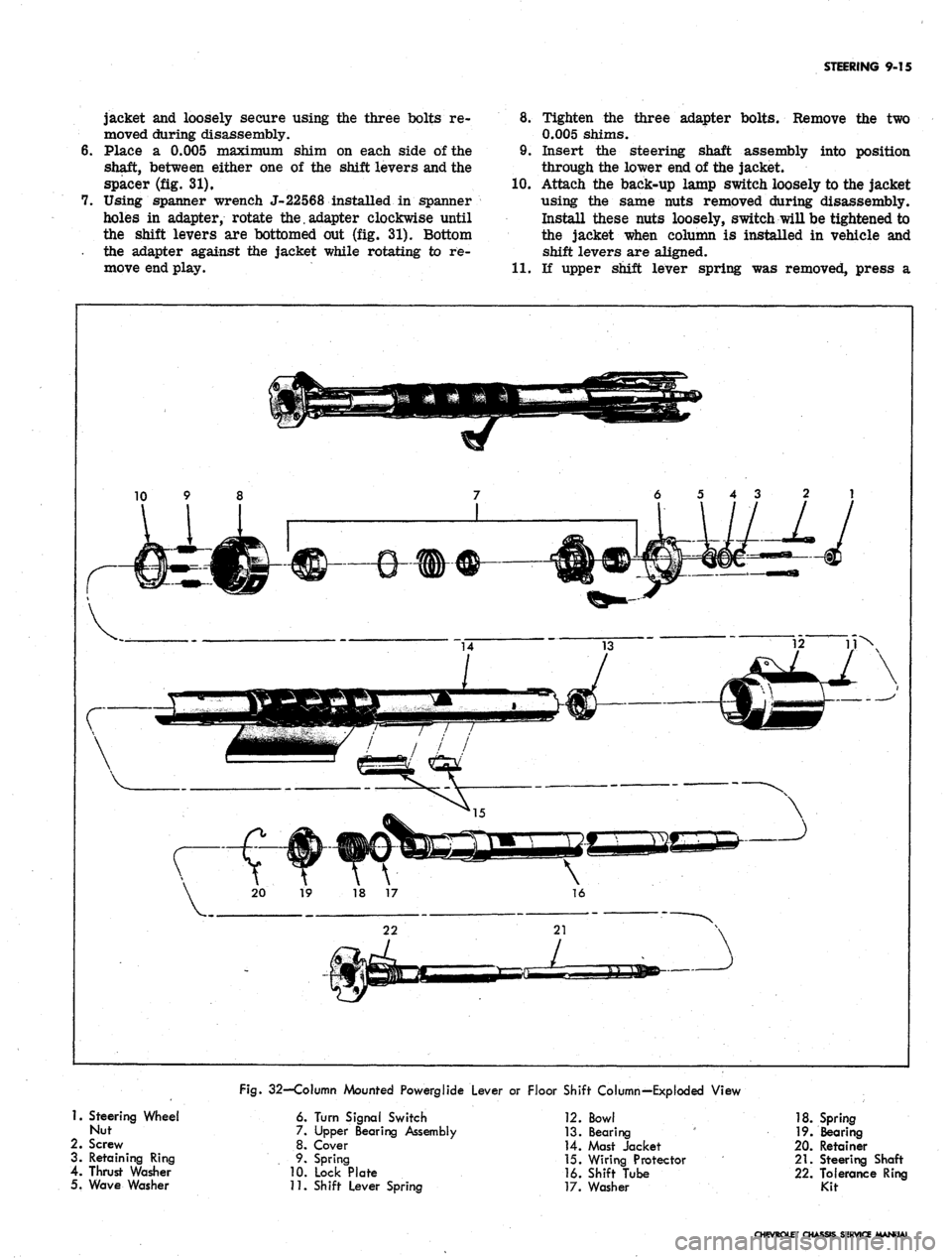

Fig.

32—Column Mounted Powerglide Lever or Floor Shift Column—Exploded View

1.

Steering Wheel

Nut

2.

Screw

3. Retaining Ring

4.

Thrust Washer

5. Wave Washer

6. Turn Signal Switch

7. Upper Bearing Assembly

8. Cover

9. Spring

10.

Lock Plate

11.

Shift Lever Spring

12.

Bowl

13.

Bearing

14.

Mast Jacket

15.

Wiring Protector

16.

Shift Tube

17.

Washer

18.

Spring

19.

Bearing

20.

Retainer

21.

Steering Shaft

22.

Tolerance Ring

Kit

CHEVROLET CHASSIS SERVICE MANUAL

Page 456 of 659

STEERING 9-16

new upper shift lever spring into bowl pocket. Be

sure spring is seated in bowl pocket. Install bowl

washer (fig. 30).

12.

Insert the upper bearing housing assembly and the

turn signal switch assembly into the cover, feeding

the signal switch wires through the back of the

cover.

13.

Align the signal switch and bearing housing holes

with the holes in the cover. Install three mounting

screws through the holes.

14.

Slide three springs onto screw ends at rear of cover

and place lockplate in position over screws and

springs. Turn screws three turns into lockplate.

15.

Feed switch wire through the shift lever bowl and

place upper end assembly on top of bowl.

16.

Place the shift lever bowl and signal switch cover

assembly on top of jacket, aligning the tangs on the

I.D. of the lockplate with the slots in the top of the

jacket. Shift tube key should align in bowl keyway as

bowl is pushed ono

17.

Lock upper end assembly into position by pushing

down on the cover assembly and rotating assembly

fully clockwise. Tangs of lock plate must engage

slots in jacket.

18.

Tighten three turn signal switch mounting screws in

a gradual criss-cross sequence to avoid cocking the

lockplate.

19.

Slide wave washer and thrust washer over steering

shaft and against upper bearing housing.

20.

Start "C" retaining ring over steering shaft taper.

Complete installation of. retaining ring using snap

ring installer J-22659 as shown in Figure 28. Be

sure "C" retaining ring is completely seated into

steering shaft groove.

21.

-Place turn signal switch lever in position and secure

with screw. Screw hazard warning knob into position.

22.

Remove column from vise and pull wires flat against

jacket. Snap wire protector into place.

23.

If mesh cover was removed, wrap mesh cover around

jacket and secure with electricians or friction tape.

24.

Slide cancelling cam and upper bearing preload

spring onto end of shaft.

Disassembly—Column Mounted Power glide Lever or

Floor Shift Column (Fig. 32)

NOTE: In this procedure, automatic refers to a

column with a column mounted, Powerglide shift-

ing lever. Floor shift refers to a column taken

from a vehicle with conventional or Powerglide

floor shift controls.

1.

Unsnap and remove wiring protector and wiring clip.

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

will damage the column. If support fixture

J^22573 is not used, frequently check position of

column in vise jaws to insure column is not

working free of jaws.

2.

Clamp column in a bench vise as shown in Figure 26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft.

4.

On automatic columns removed from Chevy II or

Camaro, remove screws securing dial retainer to

column and remove retainer and dial (fig. 33). Slide

Fig.

33—Powerglide Dial Indicator Assembly—Chevy II

and Camaro

indicator out of shift bowl and remove indicator. Re-

move cap and bulb from turn signal switch housing.

5.

Remove turn signal lever retaining screw and re-

move lever. Push hazard warning knob in; unscrew

and remove knob.

6. On automatic columns, drive'out shift control lever

retaining pin and remove shift lever.

7.

Remove "C" retaining ring from upper steering

shaft using snap ring remover Tool J-22569 (fig. 28).

8. Slide thrust washer and wave washer off upper steer-

ing shaft (fig. 28).

9. Loosen three turn signal switch mounting screws

until the switch cover can be rotated counterclock-

wise.

It may be necessary to push on top of screws

to loosen the cover assembly. ,

NOTE: Do not remove the three turn signal

switch screws completely unless it is necessary

to replace the turn signal switch, lockplate, or

upper bearing housing and bearing.

10.

Rotate turn signal switch cover counterclockwise

and pull cover off top of jacket (fig. 29).

11.

If necessary, pry upper shift lever spring (fig. 30)

from bowl and discard spring.

12.

Remove shift lever bowl from top of jacket.

13.

If necessary to service components within the signal

switch cover, remove the three signal switch covers,

remove the three signal switch mounting screws

completely from engagement with the lockplate. Use

care to control three springs as screws are removed.

14.

Remove turn signal switch and upper bearing housing

assembly from cover.

15.

Carefully pull steering shaft assembly from bottom

of column.

16.

Remove securing back-up lamp/neutral start switch

to column, if so equipped, and remove switch. Retain

these mounting nuts.

CHEVROLET CHASSIS SERVICE MANUAL

Page 457 of 659

STEERING 9-17

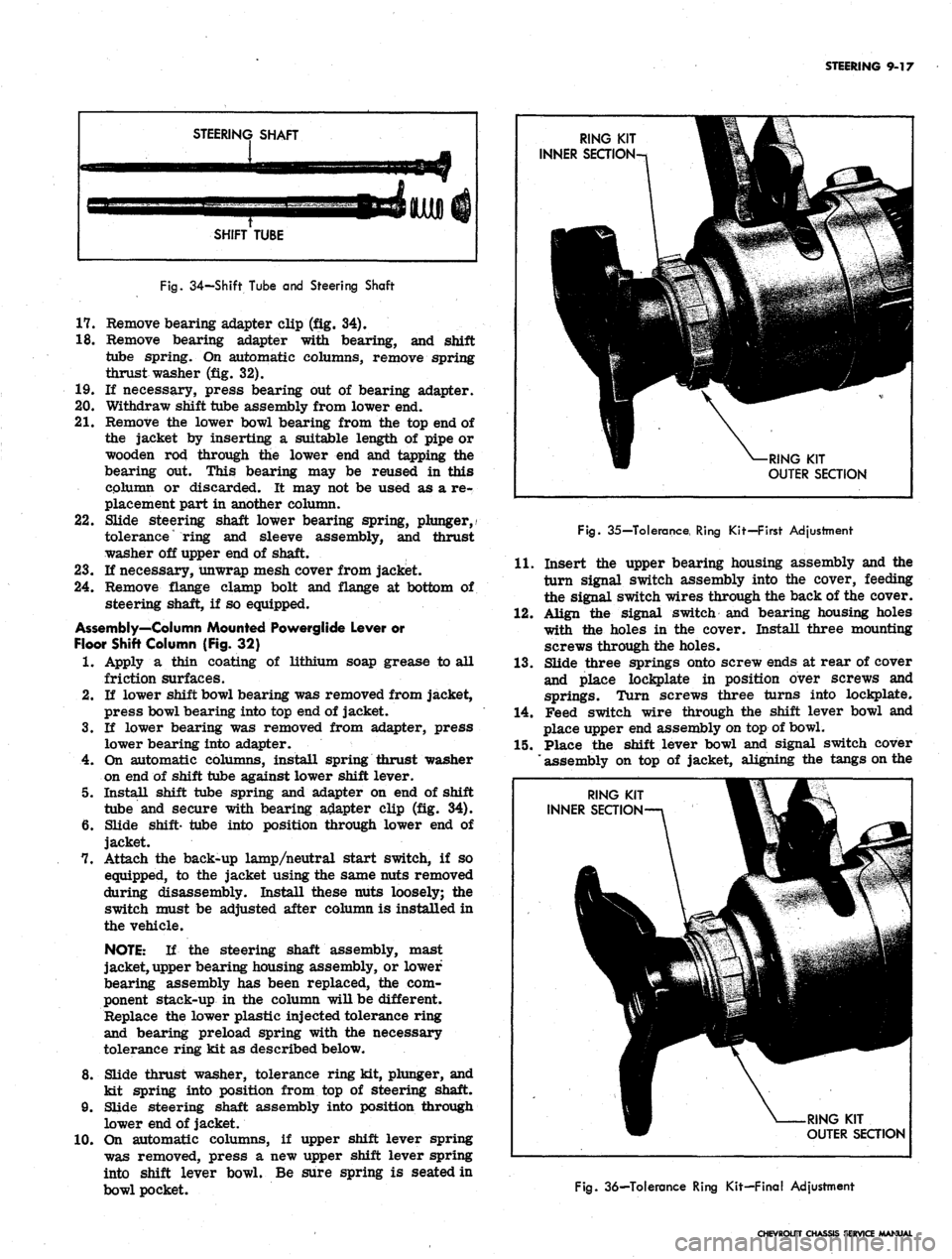

STEERING SHAFT

SHIFT TUBE

Fig.

34—Shift Tube and Steering Shaft

17.

Remove bearing adapter clip (fig. 34).

18.

Remove bearing adapter with bearing, and shift

tube spring. On automatic columns, remove spring

thrust washer (fig. 32).

19.

U necessary, press bearing out of bearing adapter.

20.

Withdraw shift tube assembly from lower end.

21.

Remove the lower bowl bearing from the top end of

the jacket by inserting a suitable length of pipe or

wooden rod through the lower end and tapping the

bearing out. This bearing may be reused in this

column or discarded. It may not be used as a re-

placement part in another column.

22.

Slide steering shaft lower bearing spring, plunger,/

tolerance

*

ring and sleeve assembly, and thrust

washer off upper end of shaft.

23.

If necessary, unwrap mesh cover from jacket.

24.

Remove flange clamp bolt and flange at bottom of

steering shaft, if so equipped.

Assembly—Column Mounted Powerglide Lever or

Floor Shift Column (Fig. 32)

1.

Apply a thin coating of lithium soap grease to all

friction surfaces.

2.

If lower shift bowl bearing was removed from jacket,

press bowl bearing into top end of jacket.

3.

If lower bearing was removed from adapter, press

lower bearing into adapter.

4.

On automatic columns, install spring thrust washer

on end of shift tube against lower shift lever.

5. Install shift tube spring and adapter on end of shift

tube and secure with bearing adapter clip (fig. 34).

6. Slide shift- tube into position through lower end of

jacket.

7. Attach the back-up lamp/neutral start switch, if so

equipped, to the jacket using the same nuts removed

during disassembly. Install these nuts loosely; the

switch must be adjusted after column is installed in

the vehicle.

NOTE:

If the steering shaft assembly, mast

jacket, upper bearing housing assembly, or lower

bearing assembly has been replaced, the com-

ponent stack-up in the column will be different.

Replace the lower plastic injected tolerance ring

and bearing preload spring with the necessary

tolerance ring kit as described below.

8. Slide thrust washer, tolerance ring kit, plunger, and

kit spring into position from top of steering shaft.

9. Slide steering shaft assembly into position through

lower end of jacket.

10.

On automatic columns, if upper shift lever spring

was removed, press a new upper shift lever spring

into shift lever bowl. Be sure spring is seated in

bowl pocket.

Fig.

35—Tolerance, Ring Kit—First Adjustment

11.

Insert the upper bearing housing assembly and the

turn signal switch assembly into the cover, feeding

the signal switch wires through the back of the cover.

12.

Align the signal switch and bearing housing holes

with the holes in the cover. Install three mounting

screws through the holes.

13.

Slide three springs onto screw ends at rear of cover

and place lockplate in position over screws and

springs. Turn screws three turns into lockplate.

14.

Feed switch wire through the shift lever bowl and

place upper end assembly on top of bowl.

15.

Place the shift lever bowl and signal switch cover

assembly on top of jacket, aligning the tangs on the

RING KIT

OUTER SECTION

Fig.

36—Tolerance Ring Kit—Final Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 459 of 659

STEERING 9-19

20.

21.

22.

23.

24.

25.

26.

27.

28.

Start "C" retaining ring over steering shaft taper.

Complete installation of retaining ring using snap

ring installer J-22659 as shown in Figure 28. Be

sure "C" retaining ring is completely seated into

steering shaft groove.

Remove any remaining looseness from internal col-

umn stack-up by unscrewing inner tolerance kit ring

section; then screw inner kit ring section back in

1/8 to 1/4 turn (fig. 36).

Touch the outer surface of the tolerance ring kit

.at

several locations with a hot soldering iron to melt

the threads of the inner and outer ring sections

together.

Place turn signal switch lever in position and se-

cure with screw. Screw hazard warning knob into

position.

If column is automatic and to be installed in a Chevy

II or Camaro, install the bulb and cap (fig. 33). Slide

the indicator into the 'shift bowl. Install dial and re-

tainer with screws removed during disassembly.

Install flange and clamp bolt at bottom of steering

shaft, if so equipped.

Remove column from vise and pull wires flat against

bottom of jacket. Snap wire protector and clip into

place.

If mesh cover was removed, wrap mesh cover around

jacket and secure with electricians or friction tape

/**% • *t 1*1* i '% •< n

Slide cancelling cam and

spring onto end of shaft.

upper bearing preload

Disassembly-Til* Column (Fig. 37)

NOTE:

This procedure covers disassembly and

assembly instructions for all tilt columns. Auto-

matic refers to a tilt column with a column

mounted, Powerglide shifting lever. Floor shift

. refers to' a tilt column taken from a vehicle with

conventional or Powerglide floor shift controls.

1.

Unsnap and remove wiring protector.

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

will damage the column. If support fixture

J-22573 is not used, frequently check position

of column in vise jaws to insure column is not

working free of jawsT

2.

Clamp column in a bench vise as shown in Figure 26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft.

Fig,

38—Removing Turn Signal Cover Using Tools

J-21486 and J-6585-1

Fig.

39—Removing Steering Shaft Bearing Lock Nut

Using Lock Nut Wrench j-22599

4.

On automatic columns removed from a Camaro, re-

move screws securing dial retainer to column and

remove retainer and dial (fig. 33). Slide pointer out

of bowl and remove pointer. Remove cap and bulb

from turn signal switch housing.

5. Remove turn signal lever retaining screw and re-

move lever. Unscrew and remove tilt release lever.

Push hazard warning knob in, unscrew and remove

knob.

6. On Automatic columns, drive out shift control lever

retaining pin and remove shift lever.

7. Assemble slide hammer Tool J-6585-1 to turn signal

cover remover Tool J-21486. Place cover remover

over turn signal cover, tighten clamp, and pull

cover from end of column with slide hammer (fig.

38).

8. Remove three turn signal switch mounting screws.

Note short length of secure removed from top

position.

9. Lift signal switch assembly off bearing housing and

allow to hang by the wires. On some columns, the

switch and wires can be removed at this time; re-

move switch and wires if possible. If switch and

wires cannot be removed, allow assembly to hang

by wires.

10.

Install tilt release lever and place column in full up

position. Remove tilt spring retainer using screw-

driver blade that just fits into slot opening. Insert

screwdriver in slot, press in approximately 3/16-

inch;

rotate retainer approximately 1/8 turn clock-

wise until ears align with grooves in housing, and

remove retainer and spring. Use care when remov-

ing spring, it is tightly compressed.

11.

Remove steering shaft bearing lock nut using lock nut

wrench Tool J-22599 (fig. 39). Remove inner race

•seat and inner "race.

12.

Remove two pivot pins from bearing housing using

pivot pin remover Tool J-21854 (fig. 40).

CHEVROLET CHASSIS SERVICE MANUAL

Page 460 of 659

STEERING 9-20

Fig.

40-Removing Pivot Pins Using Pivot Pin Removal Tool J-21854

13.

Pull up on tilt release lever to disengage lock shoes.

Remove bearing housing and hang with signal switch,

if present, until further disassembly. If signal switch

and wires were removed earlier, bearing housing

may be completely removed. Remove tilt release

lever.

14.

Remove steering shaft flange bolt and flange from

lower end of shaft.

15.

Remove retaining ring, washers, sleeve and plunger

assembly and spring from lower end of shaft.

16.

Slide steering shaft out of top end of jacket.

17.

If necessary to disassemble steering shaft, proceed

as follows:

a. Slide bearing and race off top of shaft.

b.

Turn upper shaft slightly from center line of

lower shaft.

c. Using a narrow blade screwdriver, work pre-

load spring out of upper shaft and remove spring

(fig. 41).

d. Turn upper shaft 90° from center line of lower

shaft and remove shaft.

e. Rotate centering spheres and remove spheres and

wave washer from lower shaft.

18.

Remove screws securing the support assembly to the

lockpjate and mast jacket and remove support.

19.

Remove shift tube retaining ring with a screwdriver.

Remove thrust washer (fig. 42).

20.

Remove lower bearing adapter from bottom of shift

tube by depressing plastic fingers, one at a time, and

pulling adapter out.

21.

Remove nuts securing back-up lamp, neutral start

switch to column, if so equipped, and remove switch.

Retain these mounting nuts.

22.

Remove shift tube assembly from bowl using shift

tube remover Tool J- 22551 (fig. 43). Insert the

hooked end of the tool into the notch of the shift tube

below the bowl key. Pilot sleeve into upper end of

shift tube. Force shift tube out of bowl by turning

SHIFT TUB

RETAINING RING

Fig.

41—Removing'Preload Spring from Centering Spheres

Fig. 42—Shift Tube Retaining Ring and Lower Bushing

CHEVROLET CHASSIS SERVICE MANUAL