ECU CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 461 of 659

STEERING 9-21

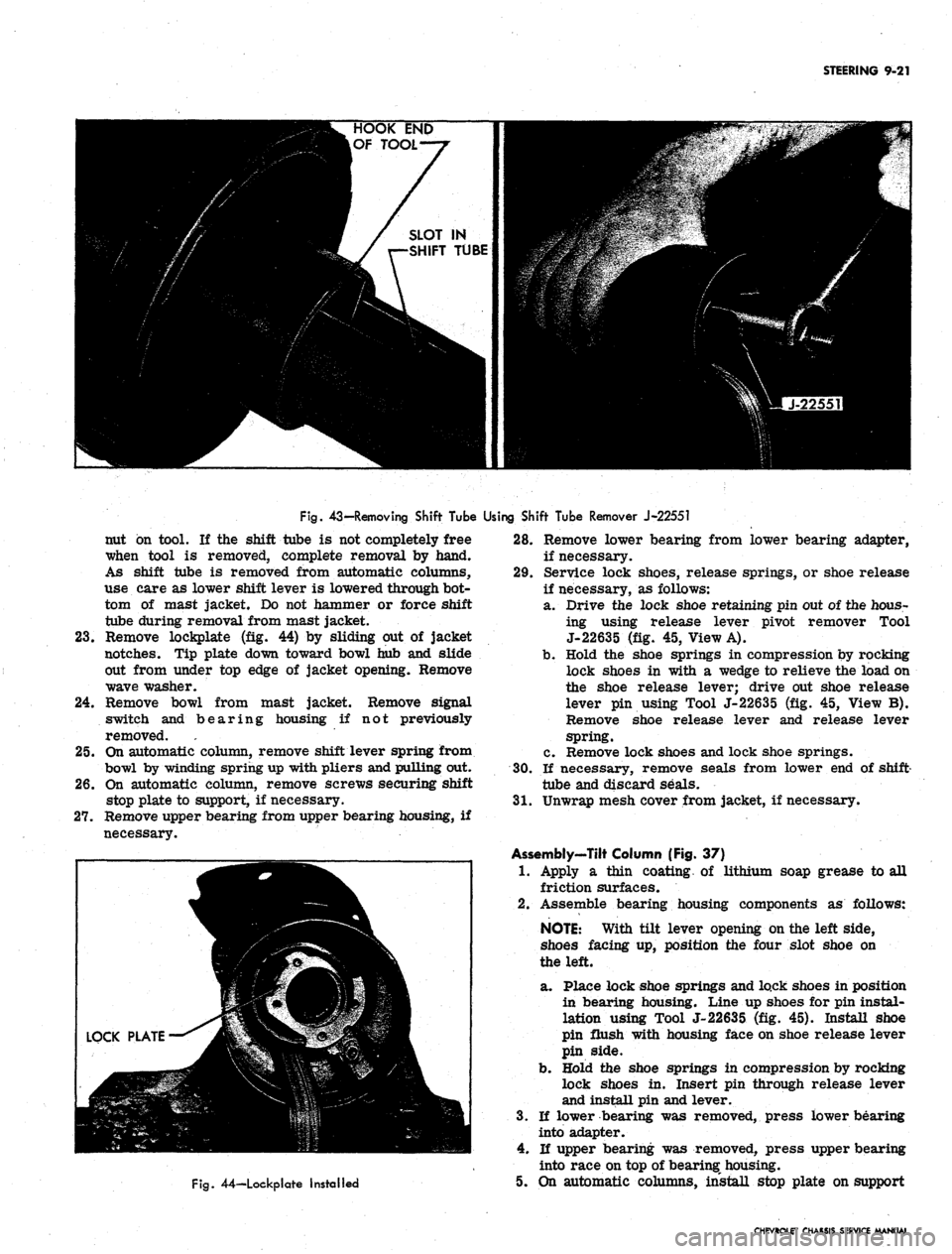

Fig.

43-Removing Shift Tube Using Shift Tube Remover J-22551

nut on tool. If the shift tube is not completely free

when tool is removed, complete removal by hand.

As shift tube is removed from automatic columns,

use care as lower shift lever is lowered through bot-

tom of mast jacket. Do not hammer or force shift

tube during removal from mast jacket.

23.

Remove lockplate (fig. 44) by sliding out of jacket

notches. Tip plate down toward bowl hub and slide

out from under top edge of jacket opening. Remove

wave washer.

24.

Remove bowl from mast jacket. Remove signal

switch and bearing housing if not previously

removed.

25.

On automatic column, remove shift lever spring from

bowl by winding spring up with pliers and pulling out.

26.

On automatic column, remove screws securing shift

stop plate to support, if necessary.

27.

Remove upper bearing from upper bearing housing, if

necessary.

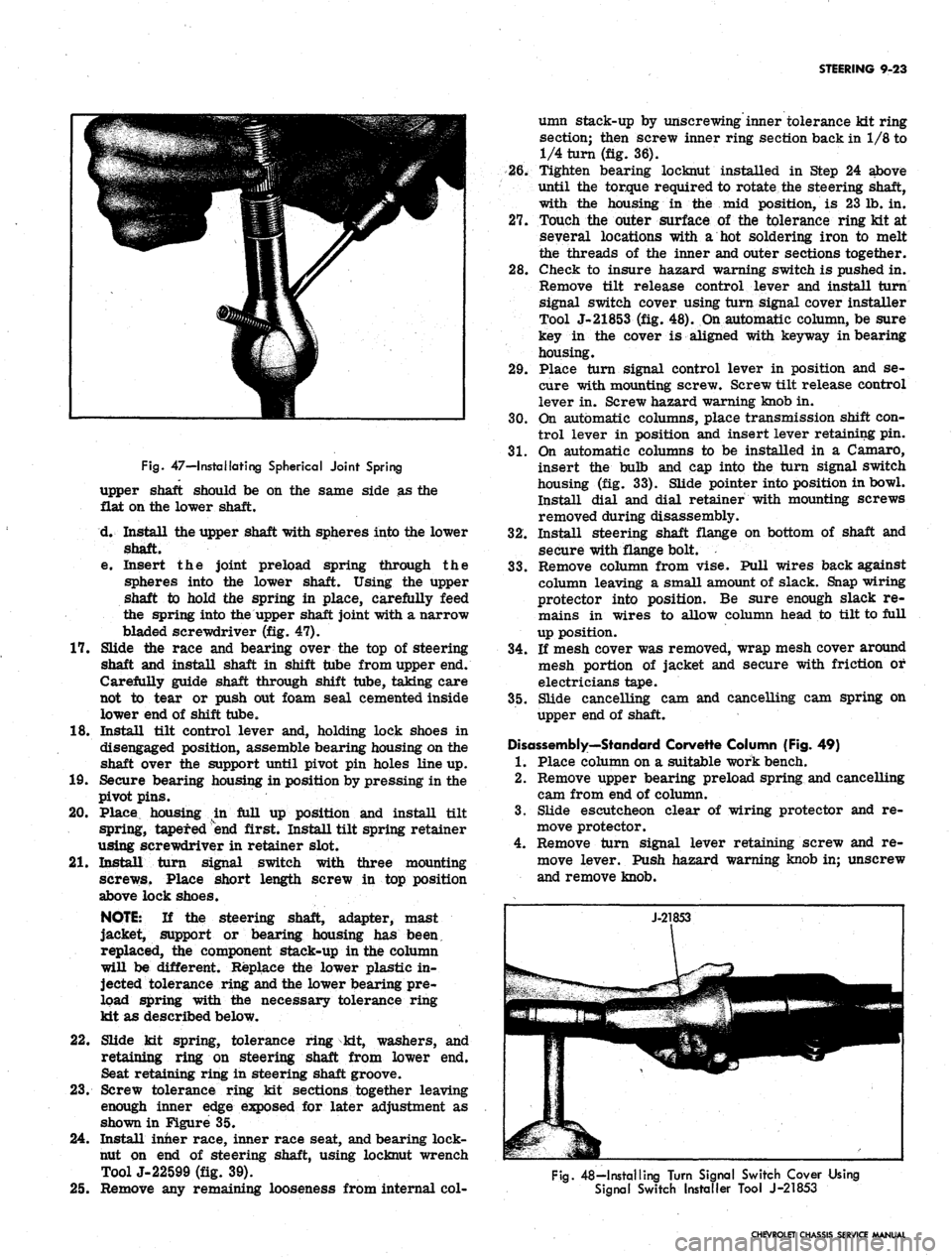

Fig.

44—Lockplate Installed

28.

Remove lower bearing from lower bearing adapter,

if necessary.

29.

Service lock shoes, release springs, or shoe release

if necessary, as follows:

a. Drive the lock shoe retaining pin out of the hous-

ing using release lever pivot remover Tool

J-22635 (fig. 45, View A).

b.

Hold the shoe springs in compression by rocking

lock shoes in with a wedge to relieve the load on

the shoe release lever; drive out shoe release

lever pin using Tool J-22635 (fig. 45, View B).

Remove shoe release lever and release lever

spring.

c. Remove lock shoes and lock shoe springs.

30.

If necessary, remove seals from lower end of shift-

tube and discard seals.

31.

Unwrap mesh cover from jacket, if necessary.

Assembly-Tilt Column (Fig. 37)

1.

Apply a thin coating of lithium soap grease to all

friction surfaces.

2.

Assemble bearing housing components as follows:

NOTE:

With tilt lever opening on the left side,

shoes facing up, position the four slot shoe on

the left.

a. Place lock shoe springs and lock shoes in position

in bearing housing. Line up shoes for pin instal-

lation using Tool J-22635 (fig. 45). Install shoe

pin flush with housing face on shoe release lever

pin side.

b.

Hold the shoe springs in compression by rocking

lock shoes in. Insert pin through release lever

and install pin and lever.

3.

If lower bearing was removed, press lower bearing

into adapter.

4.

If upper bearing was removed, press upper bearing

into race on top of bearing housing.

5. On automatic columns, install stop plate on support

CHEVROLET CHASSIS SERVICE MANUAL

Page 463 of 659

STEERING 9-23

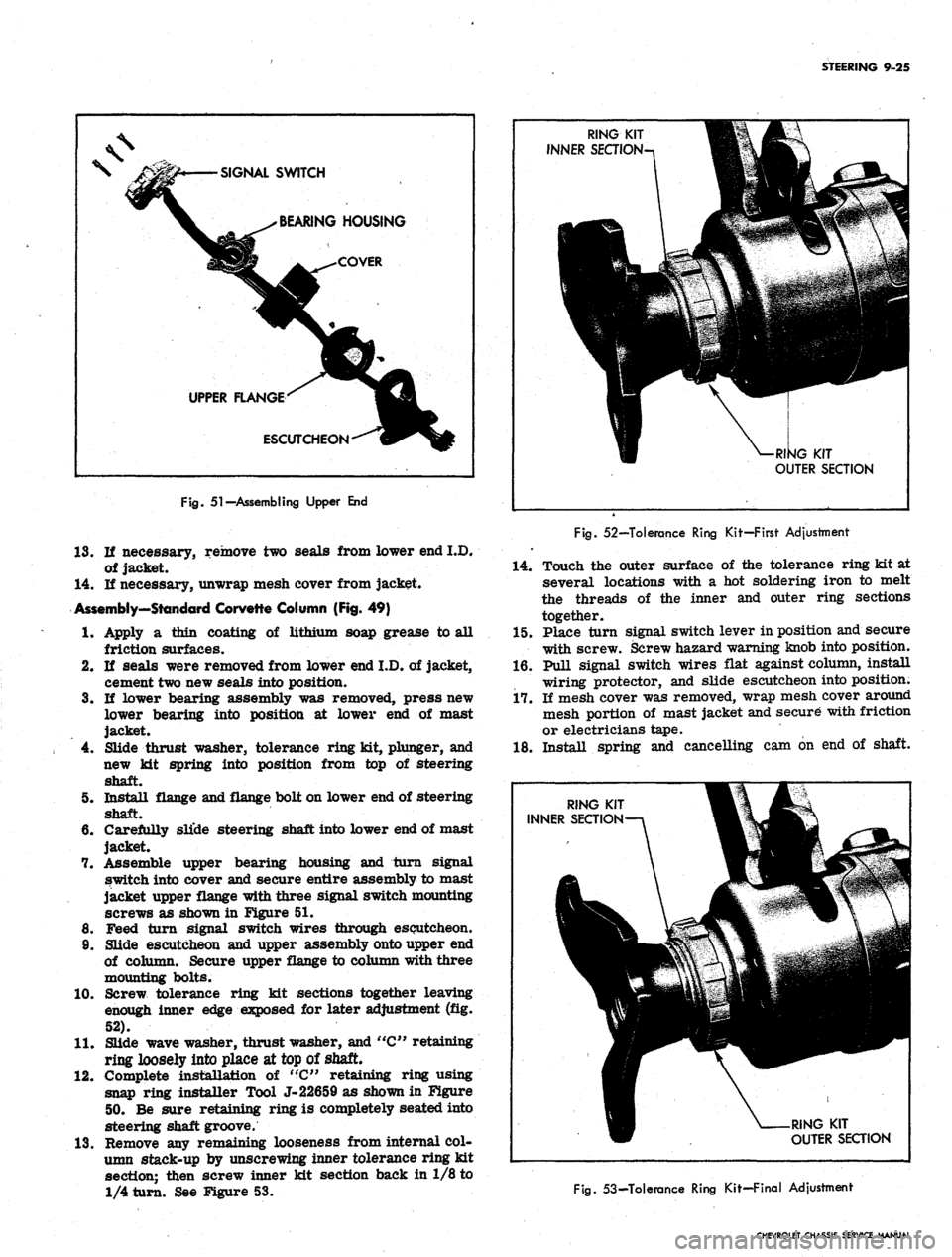

Fig.

47—I retaliating Spherical Joint Spring

upper shaft should be on the same side as the

flat on the lower shaft.

d. Install the upper shaft with spheres into the lower

shaft.

e. Insert the joint preload spring through the

spheres into the lower shaft. Using the upper

shaft to hold the spring in place, carefully feed

the spring into the upper shaft joint with a narrow

bladed screwdriver (fig. 47).

17.

Slide the race and bearing over the top of steering

shaft and install shaft in shift tube from upper end.

Carefully guide shaft through shift tube, taking care

not to tear or push out foam seal cemented inside

lower end of shift tube.

18.

Install tilt control lever and, holding lock shoes in

disengaged position, assemble bearing housing on the

shaft over the support until pivot pin holes line up.

19.

Secure bearing housing in position by pressing in the

pivot pins.

20.

Place housing in full up position and install tilt

spring, tapered end first. Install tilt spring retainer

using screwdriver in retainer slot.

21.

Install turn signal switch with three mounting

screws. Place short length screw in top position

above lock shoes.

NOTE:

If the steering shaft, adapter, mast

jacket, support or bearing housing has been,

replaced, the component stack-up in the column

will be different. Replace the lower plastic in-

jected tolerance ring and the lower bearing pre-

load spring with the necessary tolerance ring

kit as described below.

22.

Slide kit spring, tolerance ring kit, washers, and

retaining ring on steering shaft from lower end.

Seat retaining ring in steering shaft groove.

23.

Screw tolerance ring kit sections together leaving

enough inner edge exposed for later adjustment as

shown in Figure 35.

24.

Install inner race, inner race seat, and bearing lock-

nut on end of steering shaft, using locknut wrench

ToolJ-22599 (fig. 39).

25.

Remove any remaining looseness from internal col-

umn stack-up by unscrewing inner tolerance kit ring

section; then screw inner ring section back in 1/8 to

1/4 turn (fig. 36).

26.

Tighten bearing locknut installed in Step 24 above

until the torque required to rotate the steering shaft,

with the housing in the mid position, is 23 lb. in.

27.

Touch the outer surface of the tolerance ring kit at

several locations with a hot soldering iron to melt

the threads of the inner and outer sections together.

28.

Check to insure hazard warning switch is pushed in.

Remove tilt release control lever and install turn

signal switch cover using turn signal cover installer

Tool J-21853 (fig. 48). On automatic column, be sure

key in the cover is aligned with keyway in bearing

housing.

29.

Place turn signal control lever in position and se-

cure with mounting screw. Screw tilt release control

lever in. Screw hazard warning knob in.

30.

On automatic columns, place transmission shift con-

trol lever in position and insert lever retaining pin.

31.

On automatic columns to be installed in a Camaro,

insert the bulb and cap into the turn signal switch

housing (fig. 33). Slide pointer into position in bowl.

Install dial and dial retainer with mounting screws

removed during disassembly.

32.

Install steering shaft flange on bottom of shaft and

secure with flange bolt.

33.

Remove column from vise. Pull wires back against

column leaving a small amount of slack. Snap wiring

protector into position. Be sure enough slack re-

mains in wires to allow column head to tilt to full

up position.

34.

If mesh cover was removed, wrap mesh cover around

mesh portion of jacket and secure with friction or

electricians tape.

35.

Slide cancelling cam and cancelling cam spring on

upper end of shaft.

Disassembly—Standard Corvette Column (Fig. 49)

1.

Place column on a suitable work bench.

2.

Remove upper bearing preload spring and cancelling

cam from end of column.

3.

Slide escutcheon clear of wiring protector and re-

move protector.

4.

Remove turn signal lever retaining screw and re-

move lever. Push hazard warning knob in; unscrew

and remove knob.

Fig.

48—Installing Turn Signal Switch Cover Using

Signal Switch Installer Tool J-21853

CHEVROLET CHASSIS SERVICE MANUAL

Page 465 of 659

STEERING 9-25

\

£$&+

SIGNAL SWITCH

^ ^-BEARING

UPPER FLANGE^

HOUSING

COVER

»,

ESCUTCHEON

"^^^^^fr

Fig.

51-Assembling Upper End

13.

If necessary, remove two seals from lower end I.D.

of jacket.

14.

If necessary, unwrap mesh cover from jacket.

Assembly—Standard Corvette Column (Fig. 49)

RING KIT V

INNER SEaiON-n 1

\

[1

3

^^•-

'^p|§

W- - V: -: ';'^ /

W ^-RI^G KIT

OUTER SECTION

Fig.

52—Tolerance Ring Kit—First Adjustment

14.

Touch the outer surface of the tolerance ring kit at

several locations with a hot soldering iron to melt

the threads of the inner and outer ring sections

together.

1.

4.

5.

6.

of lithium soap grease to all 15. Place turn signal switch lever in position and secure

10.

11.

12.

13.

Apply a thin coating

friction surfaces.

If seals were removed from lower end I.D. of jacket,

cement two new seals into position.

If lower bearing assembly was removed, press new

lower bearing into position at lower end of mast

jacket.

Slide thrust washer, tolerance ring kit, plunger, and

new kit spring into position from top of steering

shaft.

Install flange and flange bolt on lower end of steering

shaft.

Carefully slide steering shaft into lower end of mast

jacket.

Assemble upper bearing housing and turn signal

switch into cover and secure entire assembly to mast

jacket upper flange with three signal switch mounting

screws as shown in Figure 51.

Feed turn signal switch wires through escutcheon.

Slide escutcheon and upper assembly onto upper end

of column. Secure upper flange to column with three

mounting bolts.

Screw tolerance ring kit sections together leaving

enough inner edge exposed for later adjustment (fig.

52).

Slide wave washer, thrust washer, and "C" retaining

ring loosely into place at top of shaft.

Complete installation of "C" retaining ring using

snap ring installer Tool J-22659 as shown in Figure

50.

Be sure retaining ring is completely seated into

steering shaft groove.

Remove any remaining looseness from internal col-

umn stack-up by unscrewing inner tolerance ring kit

section; then screw inner kit section back in 1/8 to

1/4 turn. See Figure 53.

with screw. Screw hazard warning knob into position.

16.

Pull signal switch wires flat against column, install

wiring protector, and slide escutcheon into position.

17.

If mesh cover was removed, wrap mesh cover around

mesh portion of mast jacket and secure with friction

or electricians tape.

18.

Install spring and cancelling cam on end of shaft.

RING KIT

OUTER SECTION

fig.

53-Tolerance Ring Kit-Final Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 467 of 659

STEERING 9-27

Fig.

55— Removing Lower Bearing Retaining Ring

bearing assembly from lower end of shaft.

9. Push upper steering shaft section into lower section

until spring pin is visible at pin access hole in lower

section. Drive out spring pin.

10.

Remove upper shaft section from lower section. If

necessary, replace locking wedge and locking rod at

this time.

11.

Remove bumper key strap (fig. 56). Remove keys and

bumper assembly.

12.

Remove screws securing bottom of wiring protector

to column.

13.

Slide inner jacket section, switch cover, switch,

upper bearing housing, wiring protector, and es-

cutcheon off top end of jacket.

14.

If necessary, remove three turn signal switch mount-

ing screws and remove switch and upper bearing

housing.

15.

If necessary, remove seals from I.D. of mast jacket.

16.

If necessary, unwrap mesh cover from jacket.

Assembly—Corvette Telescoping Column (Fig. 54)

1.

Apply a thin coating of lithium soap grease to all

friction surfaces.

2.

If seals were removed from I.D. of mast jacket,

cement new seals in positions where old seals were

removed.

3.

Place locking wedge and locking rod into upper shaft

and slide upper shaft into lower shaft.

4.

Align upper and lower shafts and insert spring pin

into access hole.

5. Install bearing, packing, spring, washer, and retain-

ing ring on bottom of steering shaft. Seat the re-

taining ring into the steering shaft groove with a

screwdriver.

6. Carefully slide steering shaft into lower end of mast

jacket.

7. Install bearing retainer over lower end of shaft and

lower end of jacket. Secure retainer with three

screws.

8. Install flange and flange bolt on lower end of steering

shaft.

9. Feed wires of turn signal switch through turn signal

switch cover and escutcheon, and place switch and

upper bearing housing in cover. Secure switch to

cover with three mounting screws.

10.

Place wiring protector inside escutcheon.

11.

Start escutcheon and wiring protector, with signal

switch wires, over end of outer jacket.

12.

Slide inner jacket section into outer jacket section.

13.

Secure switch cover to flange of inner jacket section

by tightening the signal switch mounting screws.

14.

Secure the bottom of the wiring protector to the col-

umn with two screws.

15.

Assemble keys and bumper and place the entire as-

sembly in position in the jacket. Install bumper key

strap.

16.

Slide wave washer, thrust washer, and upper retain-

ing ring into place at top of shaft. Seat retaining ring

in steering shaft groove with a screwdriver.

17.

Place turn signal switch lever in position and secure

with screw. Screw hazard warning knob into position.

18.

If mesh cover was removed, wrap mesh cover around

mesh section of jacket and secure with electricians

or friction tape.

19.

Slide cancelling cam and upper bearing preload

spring over top end of shaft.

Installation

NOTE:

Before placing column in position in

vehicle, refer to figures 19 through 23 and slide

dash panel seals, covers, plates, and clamps

loosely into position on column for later

installation.

1.

Move front seat back as far as possible to provide

Fig.

56—Removing Bumper Key Strap

CHEVROLET CHASSIS SERVICE MANUAL

Page 469 of 659

STEERING 9-29

column mounting bracket, and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws and bracket to instrument panel

washers and bolts.

NOTE: Steering shaft to gear clamp must be

tightened before column attaching bolts are

torqued. Refer to "Steering Gear-Chevy n",

installation procedure, for correct Chevy II

steering column alignment procedure.

5.

Camaro only (fig. 60):

Lay wedge shim in position on instrument panel

column mounting bracket and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws, nuts, and washer and bolt as shown

in Figure 60.

6. Corvette only (fig. 61):

Loosely secure column mounting bracket to sup-

port plate and instrument panel with washers and

bolts.

7.

Secure flanged end of column to steering coupling

with lockwashers and nuts. On Chevy n, connect col-

umn to steering gear with clamp, clamp bolt, and

nut. On Corvette, slide steering shaft flange into

lower coupling

half,

and install upper clamp bolt

loosely; also secure support, seal and clamp loosely

at dash on engine side.

8. Tighten instrument panel mounting bracket bolts and

nuts.

Refer to torque specifications at rear of manual

for correct torque values.

9. Chevrolet only (fig. 15):

Place upper and lower mast jacket covers in po-

sition and secure covers together and to instrument

panel using nuts and screws as shown in Figure 15.

10.

Chevy H only (fig. 18):

Place lower mast jacket cover in position under

mast jacket and secure to upper cover with screws.

11.

CheveUe only (fig. 15):

Place mast jacket trim cover in position over col-

Fig.

61—Instrument Panel Mounting Bracket and

Support Plqte—Corvette

umn on underside of instrument panel and secure

with screws.

12.

Corvette only (fig. 14):

Slide escutcheon into position at instrument panel

and secure with screws. Place upper end lower

covers in position and secure with screws.

13.

On Chevrolet and CheveUe models with column

mounted powerglide controls, secure transmission

shift indicator pointer into position with set screw

(fig. 15). ,

14.

Chevrolet only (fig. 19):

a. Secure seal and cover to dash panel with screws.

b.

Place clamp assembly in position and install

clamp screw.

c. Install dash panel trim cover with mounting

screws.

15.

Chevelle only (fig. 20):

a. Secure seal and inner and outer covers to dash

panel with screws.

b.

Secure inner and outer covers together with

screws.

c. Install trim cover to dash panel with two

retainers.

16.

Chevy H only (fig. 21):

a. Secure seal, retainer, and clamp to dash panel

with screws.

b.

Install clamp screw.

c. Slide collar into position. Pinch and staple upper

tabs together.

17.

Camaro only (fig. 22):

a. Secure seal, upper cover, and lower cover to

dash panel with screws.

b.

Secure upper and lower cover together with

screws.

c. Fold rubber boot over securely against dash panel

to conceal covers.

18.

Corvette only (fig. 23):

a. Secure seal and support assembly to dash panel

on engine compartment side.

b.

Tighten clamp, washer, and clamp bolt on engine

compartment side.

19.

Connect transmission linkage to lower shift tube

levers in engine compartment, if column is so

equipped. Adjust levers as outlined in Section 7.

20.

Install steering wheel as outlined in this section.

21.

Connect directional signal, horn, back-up lamp, and

neutral start switch at wiring harness plugs. Adjust

back-up lamp, neutral start switch as outlined in

Section 12.

22.

Adjust steering gear and align and center steering

wheel as outlined in this section.

STEERING LINKAGE (Fig. 62)

TIE RODS

There are two tie rod assemblies used on all models.

Each assembly is of three piece construction, consisting

of a sleeve and two tie rod ends. The ends are threaded

into the sleeve and locked with clamps. Right and left

hand threads are provided to facilitate toe-in adjustment

and steering gear centering.

The tie rod ends are self-adjusting for wear and re-

quire no attention in service other than periodic lubrica-

tion and occasional inspection to see that ball studs are

tight. Replacement of tie rod ends should be made when

CHEVROLET CHASSIS SERVICE MANUAL

Page 471 of 659

STEERING 9-31

Fig.

63—Freeing Ball Stud

rod threads with EP Chassis lube and install ends on

tie rod making sure both ends are threaded ah equal

distance from the tie rod.

2.

Make sure that threads on ball stud and in ball stud

nuts are perfectly clean and smooth. Install neoprene

seals on ball studs.

NOTE: If threads are not clean and smooth,

ball studs may turn in tie rod ends when at-

tempting to tighten nut.

3.

Install ball studs in steering arms and relay rod.

4.

Install ball stud nut, and install cotter pins. Lubri-

cate tie rod ends.

5.

Adjust toe-in as described in Section 3.

NOTE: Before locking clamp bolts on the rods,

make sure that the tie rod ends are in alignment

with their ball studs (each ball joint is in the

center of its travel). If the tie rod is not in

alignment with the studs, binding will result.

RELAY ROD-ALL MODELS EXCEPT CORVETTE

Removal

1.

Remove inner ends of tie rods from relay rod as

described under Tie Rod - Removal.

2.

Remove cotter pin and nut from relay rod ball stud

attachment at pitman arm.

3.

Detach relay rod from pitman arm. Shift steering

linkage as required to free pitman arm from relay

rod.

4.

Remove cotter pin and nut from idler arm and re-

move relay rod from idler arm.

Installation

1.

Install relay rod to idler arm, making certain idler

stud seal is in place, then install and tighten nut.

Advance nut just enough to align castellation with

cotter pin hole and install pin.

2.

Raise end of rod and install on pitman arm. Secure

with nut and cotter pin.

3.

Install tie rod ends to relay rod as previously

described under Tie Rods. Lubricate tie rod ends.

4.

Adjust toe-in (see Section 3) and align steering wheel

as described previously in this section under Steer-

ing Wheel Alignment and High Point Centering.

RELAY ROD-CORVETTE

Removal

1.

Remove steering damper from relay rod as outlined

under Steering Damper-Removal. Remove anchor

bracket from relay rod by disconnecting two mount-

ing bolts.

2.

Remove inner ends of tie rods from relay rod as

described under Tie Rod--Removal.

3.

Remove cotter pin from end of relay rod at pitman

arm ball stud attachment, and remove stud nut.

4.

Tap brJl stud out of pitman arm and lower relay rod.

5.

Remove cotter key and nut from idler arm and re-

move relay rod from idler arm. Remove washer and

seal from idler arm.

Installation

1.

Place relay rod on idler arm stud, making certain

idler stud seal and washer are in place, then install

and tighten nut. Advance nut just enough to align

castellation with cotter pin hole and install pin.

2.

Install new seal and clamp over ball at end of pitman

arm.

3.

Install inner spring seat and spring to relay rod.

4.

Raise end of rod and install on pitman arm.

5.

Install spring seat, spring, and end plug.

6. Tighten end plug until springs are compressed and

plug bottoms, then back off 3/4 turn plug amount

necessary to insert cotter pin. Insert cotter pin to

lock adjustment.

7.

Install tie rod ends to relay rod as previously de-

scribed under Tie Rods.

8. Lubricate tie rod ends and pitman arm to relay rod

ball joint.

9. Install steering damper bracket and tighten bolts.

Install damper as outlined under Steering Damper--

Installation.

10.

Adjust toe-in and align steering wheel as described

previously in this section.

IDLER ARM

Chevrolet, Chevelle, Comoro, and Corvette (Fig. 62)

Removal

1.

Remove idler arm to frame nut, washer, and bolt.

No washer is used on Corvette.

2.

Remove cotter pin and nut from idler arm to relay

rod ball stud.

3.

Remove relay rod from idler arm by tapping relay

rod with a hammer using a heavy hammer as a

backing.

4.

Remove idler arm.

Installation

1.

On Chevrolet, place seal in position on idler arm

stud; position stud up through frame, and secure with

lock washer and nut.

2.

On Chevelle, Camaro, and Corvette, position idler

CHEVROLET CHASSIS SERVICE MANUAL

Page 472 of 659

STEERING

9-32

arm on frame and install mounting bolts, washers

and nuts. No washer is used on Corvette.

Install relay rod to idler arm, ^making certain seal

is on stud. Install and tighten nut.

Install cotter pin.

Refer to torque specifications at rear of manual for'

correct torque values.

Chevy II (Fig. 62}

Removal

1.

Remove cotter pin, nut and washer securing idler

arm to relay rod.

2.

Remove relay rod from idler arm.

3.

If equipped with power steering disconnect power

cylinder shaft from idler arm bracket.

4.

Remove three idler bracket to frame bolts and nuts

and remove bracket and idler arm assembly.

5.

Remove cotter pin, nut, washer and bolt securing the

idler arm to the bracket.

6. Press out the idler arm bushing for replacement.

Installation

NOTE: Installation must be done with front

wheels straight ahead or the car will lead to one

side.

1.

Install idler arm bushing, if previously removed.

NOTE: Make certain the outer sleeve of the

bushing does not protrude above surface of idler

arm.

2.

Reverse removal procedure and torque all nuts ac-

cording to specifications.

PITMAN ARM

Removal

1.

Remove cotter pin from pitman arm ball stud and

remove nut.

2.

Remove relay rod from pitman arm by tapping on

side of rod or arm in which the stud mounts with a

hammer while using a heavy hammer or similar tool

as a backing. Pull down on relay rod to remove

from stud.

3.

Remove pitman arm nut from sector shaft and mark

relation of arm position to shaft.

4.

Remove pitman arm with Tool J-6632 as shown in

Figure 2.

Installation

1.

Install pitman arm on sector shaft, lining up the

• marks made upon removal.

2.

Install sector shaft nut.

3.

Position relay rod on to pitman arm. Install nut.

Continue to tighten arm enough to align castellation

with hole in stud and install cotter pin.

STEERING ARM

If, through collision or other damage, it becomes nec-

essary to remove and replace either steering arm, pro-

ceed as follows:

Removal

1.

Remove tie rod from steering arm as outlined in this

section.

2.

Remove front wheel, hub and brake drum as a unit

by removing hub cap and dust cap, cotter pin from

spindle nut and the spindle nut. Pull assembly to-

ward outside of vehicle. If removal is difficult, it

may be necessary to back off brake adjustment to

increase brake shoe-to-drum clearance; see Hy-

draulic Brake Adjustment, Section 5. On models

with disc brakes, remove caliper and disc.

3.

With wheel and drum assembly or caliper and disc

removed, steering arm retaining bolt heads are ac-

cessible and removal of steering arm from vehicle

may be accomplished by removing retaining nuts.

Installation

1.

Place steering arm in position on vehicle and install

retaining bolts*

2.

Install nuts. Use only the special locknut listed for

this use in the Chevrolet Parts Catalog.

3.

Pack wheel bearings using a high quality wheel

bearing lubricant. Install bearings and wheel-hub-

brake drum assembly removed previously. On disc

brake models, install disc and caliper.

4.

Install keyed washer and spindle nut. Proceed as out-

lined under t{ Front Wheel Bearing Adjustment" in

Section 3.

5.

Install tie rod ball stud in steering arm. Be sure that

the dust cover is in place on ball stud.

6. Install castellated nut on ball stud, tighten securely

and install cotter pin.

7.

Following directions given in Section 3 to check cor-

nering wheel relationship and toe-in; correct as

required.

STEERING DAMPER-CORVETTE

Removal

1.

Remove bolt from damper pivot bracket at relay rod.

2.

Remove nut from damper pivot at frame bracket and

withdraw damper assembly.

Damper is serviced as a unit. Replace damper if

3.

damaged or excessively worn.

Installation

1.

Place piston rod end into frame bracket and install

retainers, bushings, and nut.

2.

Insert cylinder end pivot into relay rod bracket and

install through bolt.

CHEVROLET CHASSIS SERVICE MANUAL

Page 475 of 659

STEERING 9-35

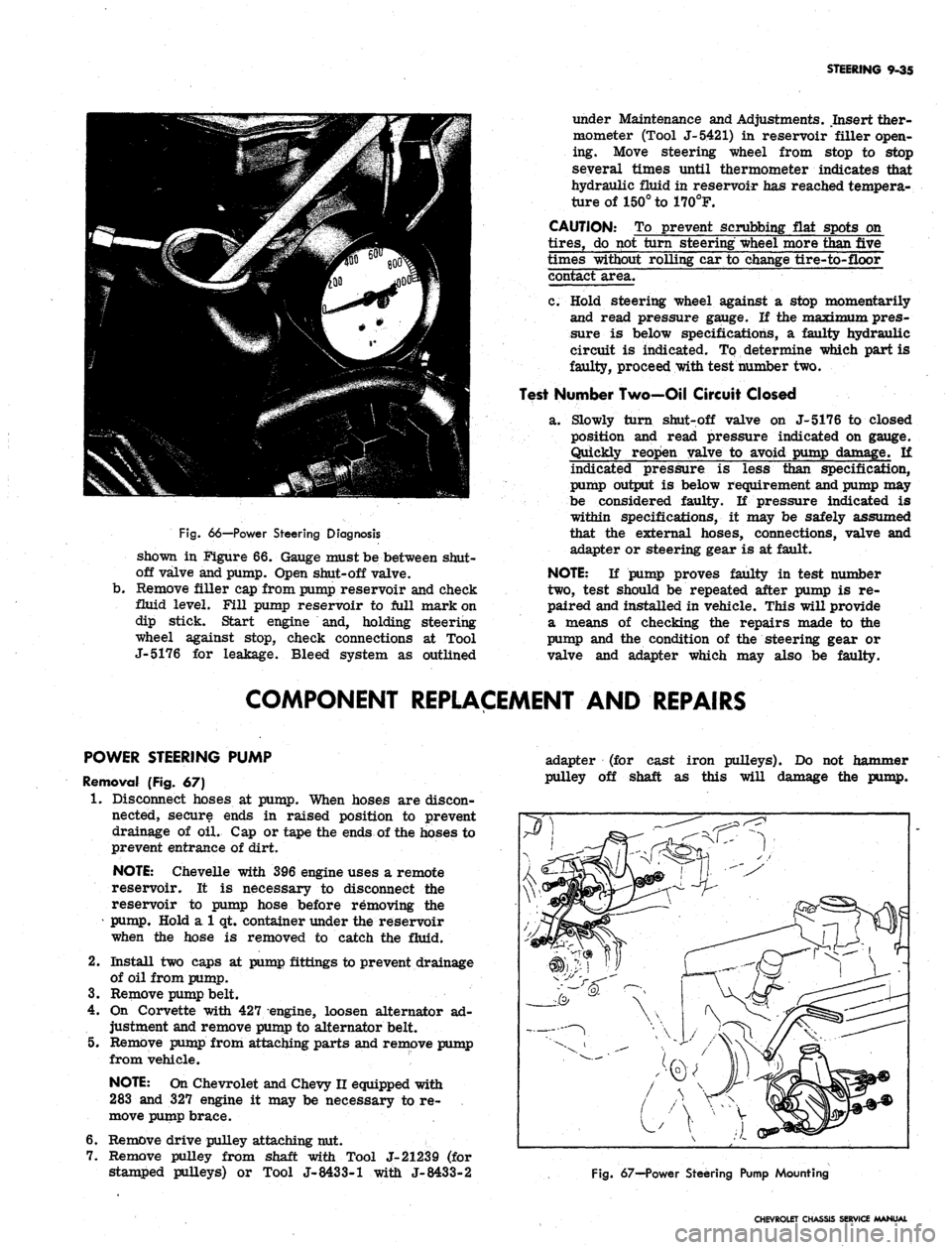

Fig.

66—Power Steering Diagnosis

shown in Figure 66. Gauge must be between shut-

off valve and pump. Open shut-off valve,

b.

Remove filler cap from pump reservoir and check

fluid level. Fill pump reservoir to full mark on

dip stick. Start engine and, holding steering

wheel against stop, check connections at Tool

J-5176 for leakage. Bleed system as outlined

under Maintenance and Adjustments. Insert ther-

mometer (Tool J-5421) in reservoir filler open-

ing. Move steering wheel from stop to stop

several times until thermometer indicates that

hydraulic fluid in reservoir has reached tempera-

ture of 150° to 170°F.

CAUTION: To prevent scrubbing flat spots on

tires,

do not turn steering wheel more than five

times without rolling car to change tire-to-floor

contact area.

c. Hold steering wheel against a stop momentarily

and read pressure gauge. If the maximum pres-

sure is below specifications, a faulty hydraulic

circuit is indicated. To determine which part is

faulty, proceed with test number two.

Test Number Two—Oil Circuit Closed

a. Slowly turn shut-off valve on J-5176 to closed

position and read pressure indicated on gauge.

Quickly reopen valve to avoid pump damage, if

indicated pressure is less than specification,

pump output is below requirement and pump may

be considered faulty. If pressure indicated is

within specifications, it may be safely assumed

that the external hoses, connections, valve and

adapter or steering gear is at fault.

NOTE:

If pump proves faulty in test number

two,

test should be repeated after pump is re-

paired and installed in vehicle. This will provide

a means of checking the repairs made to the

pump and the condition of the steering gear or

valve and adapter which may also be faulty.

COMPONENT REPLACEMENT AND REPAIRS

POWER STEERING PUMP

Removal (Fig. 67)

1.

Disconnect hoses at pump. When hoses are discon-

nected, secure ends in raised position to prevent

drainage of oil. Cap or tape the ends of the hoses to

prevent entrance of dirt.

NOTE:

Chevelle with 396 engine uses a remote

reservoir. It is necessary to disconnect the

reservoir to pump hose before removing the

pump.

Hold a 1 qt. container under the reservoir

when the hose is removed to catch the fluid.

2.

Install two caps at pump fittings to prevent drainage

of oil from pump.

3.

Remove pump belt.

4.

On Corvette with 427 engine, loosen alternator ad-

justment and remove pump to alternator belt.

5. Remove pump from attaching parts and remove pump

from vehicle.

NOTE:

On Chevrolet and Chevy II equipped with

283 and 327 engine it may be necessary to re-

move pump brace.

6. Remove drive pulley attaching nut.

7. Remove pulley from shaft with Tool J-21239 (for

stamped pulleys) or Tool J-8433-1 with J-8433-2

adapter (for cast iron pulleys). Do not hammer

pulley off shaft as this will damage the pump.

Fig.

67—Power Steering Pump Mounting

CHEVROLET CHASSIS SERVICE MANUAL

Page 479 of 659

STEERING 9-39

4.

Remove cotter pin, nut and ball stud at relay rod.

5. Remove the power cylinder from the vehicle.

Inspection

1.

Inspect the seals for leaks; if leaks are present,

replace the seals using the procedure outlined under

"Disassembly."

2.

Examine the brass fitted hose connection seats for

cracks or damage and replace if necessary.

3.

For service other than ball seat or seal replacement

and ball stud removal, replace the power cylinder.

4.

Check the frame bracket parts for wear.

Disassembly

1.

To remove the piston rod seal remove the snap ring;

then pull out on the rod, being careful not to spray

oil.

2.

Remove the piston rod scraper and scraper element,

back up washer and piston rod seal from the rod.

3.

At the ball stud end of the cylinder, remove the ball

stud seal.

4.

Remove the snap ring retaining the end plug with the

lube fitting.

5. Push on the end of the ball stud and remove the end

plug, spring, spring seat and ball stud.

6. Remove the "O" ring seal from the top lip of the

power cylinder ball stud opening.

7. If the ball seat is to be replaced, it must be pressed

out using Tool J-8937.

Assembly

1.

Reassemble the piston rod seal components by re-

versing the disassembly procedure. Apply a thin

coat of Lubriplate or equivalent on the inner sur-

faces of the seal and scraper before assembly.

2.

Reverse the disassembly procedure when reassem-

bling the ball stud.

3.

In each case be sure that the snap ring is securely,

seated in the ring groove.

Installation

1.

Install the power cylinder on the vehicle by reversing

the removal procedure.

2.

Reconnect the two hydraulic lines, fill the system

with fluid and bleed out air using the procedure out-

lined under "Maintenance and Adjustments." Grease

ball joint.

POWER STEERING HOSES

When servicing the power steering hoses be sure to

align the hoses in their correct position as shown in

Figure 71. On Chevelle models with 396 engine, install

the upper hose so that there is at least .6 inch clearance

between the hose and the Delcotron or the inner fender

skirt.

It is important that the power steering hoses be in-

stalled correctly. Hoses installed out of position may be

subjected to chafing or other abuses during sharp turns.

Always make hose installations with front wheels in

straight ahead position. Do not twist hoses unneces-

sarily during installation.

CAUTION: Do not start engine with any power

steering hose disconnected.

CHEVROLET CHASSIS SERVICE MANUAL

Page 483 of 659

WHEELS AND TIRES 10-3

Fig.

3 - Spof Wear

to cautioning the owner of his driving habits, is to inter-

change tires regularly.

Side

This may be caused by incorrect wheel camber, under-

inflation, high cambered roads or taking corners at too

high a rate of speed.

The first two causes are the most common. Camber

wear can be readily identified because it occurs only on

one side of the treads, whereas underinflation causes

wear on both sides (fig. 2).

There is, of course, no correction for high cambered

roads.

Cornering wear is discussed further on.

Center

This is caused primarily by overinflation pf the tire

(fig. 2). Invisible fabric damage can also be caused by

overinflation.

Uneven

Uneven or spotty wear (fig. 3) is due to such irregu-

larities as unequal caster or camber, bent front or rear

suspension parts, out-of-balance wheels, brake drums

Fig.

4 - Cornering Wear

out-of-round, brakes out-of-adjustment, or other me-

chanical conditions. The remedy in each case consists

of locating the mechanical defect and correcting it.

Cornering

Since the introduction of independent spring front and

rear wheels, improvements in spring suspension have

enabled drivers to negotiate curves at higher rates of

speed with the same feeling of security that they had

with the older cars at lower speeds. Consequently,

curves are being taken at higher speeds with the result

that a type of tire wear called "Cornering Wear" (fig. 4),

frequently appears.

When a car makes an extremely fast turn, the weight

is shifted from a normal loading on all four wheels to an

abnormal load on the tires on the outside of the curve

and a very light load on the inside tires due to centrifugal

force. This unequal loading may have two unfavorable

results.

First, the rear tire on the inside of the curve may be

relieved of so much load that it is no longer geared to

CHEVROLET CHASSIS SERVICE MANUAL