ECU CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 352 of 659

ENGINE-ELECTRICAL 6Y-27

timing mark on pulley lines up with timing tab.

2.

Position distributor to opening in block in normal

installed attitude (fig. 15i), noting position of vacuum

control unit.

3.

Position rotor to point toward front of engine (with

distributor housing held in installed attitude), then

turn rotor counter-clockwise approximately 1/8 turn

more toward left cylinder bank and push distributor

down to engine camshaft. It may be necessary to ro-

tate rotor slightly until camshaft engagement is felt.

4.

While pressing firmly down on distributor housing,

kick starter over a few times to make sure oil pump

shaft is engaged. Install hold-down clamp and bolt

and snug up bolt.

5. Turn distributor body slightly until points just open

and tighten distributor clamp bolt.

6. Place distributor cap in position and check to see

that rotor lines up with terminal for No. 1 spark

plug.

7. Install cap, check all high tension wire connections

and connect spark plug wires if they have been re-

moved. It is important that the wires be installed in

their location in the supports.

NOTE:

The brackets are numbered to show the

correct installation. Wires must be installed as

indicated to prevent cross firing.

8. Connect vacuum line to distributor and distributor

primary wire to coil terminal.

9. Start engine and set timing as described under Turn-

Up in Section 6.

BREAKERLESS (MAGNETIC PULSE)

DISTRIBUTOR

REMOVAL (CORVETTE)

1.

If vehicle is equipped with radio, remove three bolts

securing ignition shield over distributor and coil.

One bolt is accessible from the top of shield, the

other two are at rear of shield, facing firewall.

2.

Disconnect tachometer drive cables from distributor

housing.

3.

Disconnect pickup coil leads at connector.

4.

Remove distributor cap.

5. Crank engine so rotor is in position to fire No. 1

cylinder and timing mark on harmonic balancer is

indexed with pointer.

6. Remove vacuum line from distributor.

7. Remove distributor clamping screw and hold-down

clamp.

8. Remove distributor and distributor-to-block gasket.

It will be noted that the rotor will rotate as the

distributor is pulled out of the block. Mark the re-

lationship of the rotor and the distributor housing

after removal so that the rotor can be set in the

same position when the distributor is being installed.

DISASSEMBLY (Fig. 16i)

NOTE:

If a distributor is being disassembled

for replacement of the stationary magnetic

pickup assembly only, it will be necessary to

perform only Steps 3, 4, 5, 7, 8, 9, and 12 of the

service procedure listed below.

1.

Remove screws securing rotor and remove rotor.

2.

Remove centrifugal weight springs and weights.

3.

Remove the tachometer drive gear from the distribu-

tor (Corvette only).

4.

Remove roll pin, then remove distributor drive gear

and washer.

CAUTION: To prevent

magnet, support drive gear

;e to the permanent

?n

driving out roll

pin.

5. Remove drive shaft assembly.

6. Remove centrifugal weight support and timer core

from drive shaft.

7. Remove connector from pickup coil leads.

8. Remove retaining ring which secures magnetic

core support plate to distributor shaft bushing in

housing.

9. As a unit, remove the entire magnetic pickup assem-

bly from the distributor housing.

10.

Remove brass washer and felt pad.

11.

Remove vacuum advance unit.

12.

To reassemble distributor, perform the above steps

in reverse order.

INSTALLATION (CORVETTE)

1.

Check to see that the engine is at firing position for

No.

1 cylinder (timing mark on harmonic balancer

indexed with pointer).

2.

Position a new distributor-to-block gasket on the

block.

3.

Before installing distributor, index rotor with hous-

ing as noted when distributor was removed. Install

distributor in block so that vacuum diaphragm faces

approximately 45° forward on the right side of the

engine and the rotor points toward contact in cap for

No.

1 cylinder.

4.

Replace distributor clamp leaving screw loose

enough to allow distributor to be turned for timing

adjustment.

5. Install spark plug wires in distributor cap. Place

wire for No. 1 cylinder in tower (marked on old cap

during disassembly) then install remaining wires

clockwise around the cap according to the firing

order (1-8-4-3-6-5-7-2).

6. Attach distributor to coil primary wires.

7. Replace distributor cap.

8. Adjust timing and then fully tighten distributor clamp

screw.

9. Attach vacuum line to distributor.

10.

Connect tachometer drive cables to distributor body.

11.

Replace ignition shields.

DISTRIBUTOR OFF-ENGINE TEST

The distributor's centrifugal and vacuum advance can

be checked in a distributor testing machine or synchro-

scope specially adapted or designed to accommodate this

type distributor. However, since this involves removing

the distributor from the engine, this test may be post-

poned until other system checks have been made. A dwell

reading cannot be obtained on this distributor and it is not

likely that the centrifugal or vacuum advance will be a

cause of trouble.

COIL REPLACEMENT

1.

Disconnect ignition switch and distributor leads from

CHEVROLET CHASSIS SERVICE MANUAL

Page 353 of 659

ENGINE-ELECTRICAL 6Y-28

terminals on eoil. On Corvettes equipped with radio,

remove bolts securing ignition shield over distribu-

tor and coil.

2.

Pull high tension wire from center terminal of coil.

3.

Remove the two coil support mounting bolts or loosen

friction clamp screw and remove coil.

4.

Place new coil in position and install attaching bolts

or tighten clamp screw.

5.

Place high tension lead securely in center terminal

of coil and connect ignition switch and distributor

primary leads to terminals on coil. Replace ignition

shield on Corvettes.

6. Start engine and test coil operation.

IGNITION PULSE AMPLIFIER

DISASSEMBLY

To check the amplifier for defective components, pro-

ceed as follows:

1.

Remove the bottom plate from the amplifier.

2.

To aid in reassembly, note the locations of the lead

connections to the panel board.

3.

Remove the three panel board attaching screws, and

lift the assembly from the housing.

4.

To aid in reassembly, note any identifying markings

on the two transistors and their respective locations

on the panel board and heat sink assembly.

5.

Note the insulators between the transistors.and the

heat sink, and the insulators separating the heat sink

from the panel board.

6. Remove the transistor attaching screws, and sepa-

rate the two transistors and heat sink from the panel

board.

7.

Carefully examine the panel board for evidence of

damage.

MOUNTING

SCREW

RESISTOR R5 jgSfe. / DIODE Dl

TRANSISTOR TR2

(UNDERNEATH)

1H L >©V

[So

To

I

/'%**jt\

\

TRANSISTC>R"""

1 X ^^w^ X \ (UNDERNEATH)

9^ESISTORR^^^H|^^^^^H

^B

RESISTOR

R4

^HPH^^H

WM'

RESISTOR

R3

I^B^^^^I^U

N .6 ®

mm

N%|/MOUNTING

• tr^i^w ^\ vjR SCREW

CAPACITOR

Cl\

pNkj^^A^

\

RESISTOR

Rl

MOUNTING ^55S^^ \ CAPACITOR C3

SCREW I RESISTOR R6 CAPACITOR C2

TRANSISTOR TR3

COMPONENT CHECKS (Figs. \7\ and 18i)

With the two transistors separated from the assembly,

an ohmmeter may be used to check the transistors and

components on the panel board for defects. An ohmmeter

having a 1-1/2 volt cell, which is the type usually found

in service stations, is recommended. The low range

scale on the ohmmeter should be used except where

specified otherwise.

A 25 watt soldering gun is recommended, and a 60% tin

40%

lead solder should be used when re-soldering. Avoid

excessive heat which may damage the panel board. Chip

away any epoxy involved, and apply new epoxy which is

commercially available.

In order to check the panel board assembly, it is

necessary to unsolder at the locations indicated in Fig-

ure 18i the two capacitors C2 and C3. In all of the fol-

lowing checks, connect the ohmmeter as shown and then

reverse the ohmmeter leads to obtain two readings. The

amplifier circuitry is shown in Figure 19i.

1.

Transistors TR1 and TR2: Check each transistor by

referring to Figure 20i. If both readings in Step 1

are zero, the transistor is shorted. If both readings

in Step 2 are zero, the transistor is shorted; and if

both readings are infinite, the transistor is open.

Interpret Step 3 the same as Step 2.

2.

Trigger Transistor TR3:

11

both readings in Step 1

are zero, the transistor is shorted. If both readings

in Step 2 are zero, the transistor is shorted; and if

both readings are infinite, the transistor is open.

Interpret Step 3 the same as Step 2.

3.

Diode Dl: 11 both readings are zero, the diode is

shorted; and if both readings are infinite, the diode

is open.

4.

Capacitor Cl: If both readings are zero, the capaci-

tor is shorted.

5.

Capacitors C2 and C3: Connect the ohmmeter across

CHECKING

RESISTOR Rl

UNSOLDER

I

CHECKING TRIGGER

TRANSISTOR TR3

CHECKING

CAPACITOR C

Fig.

171—Pulse Amplifier Panel Board

Fig.

18i—Pulse

Amplifier

Component

Checks

CHEVROLET CHASSIS SERVICE MANUAL

Page 366 of 659

CLUTCH AND TRANSMISSIONS 7-7

MAINTENANCE AND ADJUSTMENTS

CHEVROLET, CHEVELLE, CHEVY II, CAMARO,

SHIFT LINKAGE ADJUSTMENT

In cases where the gearshift linkage has been discon-

nected, it should be adjusted as follows:

1.

Move both transmission shift levers until transmis-

sion is in neutral. Neutral detents in transmission

cover must both be engaged to make this adjustment

correctly. (To check, start engine with clutch dis-

engaged, and release clutch slowly.)

2.

Move selector lever to neutral position. Align first

and reverse tube lever with the second and third

shifter tube lever on the mast jacket. This may be

done by having an assistant hold the mast .jacket shift

levers aligned in neutral position or use a simple

gauge or pin to align these levers in neutral.

3.

Make necessary adjustment to align shift control

rods and transmission levers in neutral position.

Move selector lever through all positions to check ad-

justment and to insure over-travel in all positions.

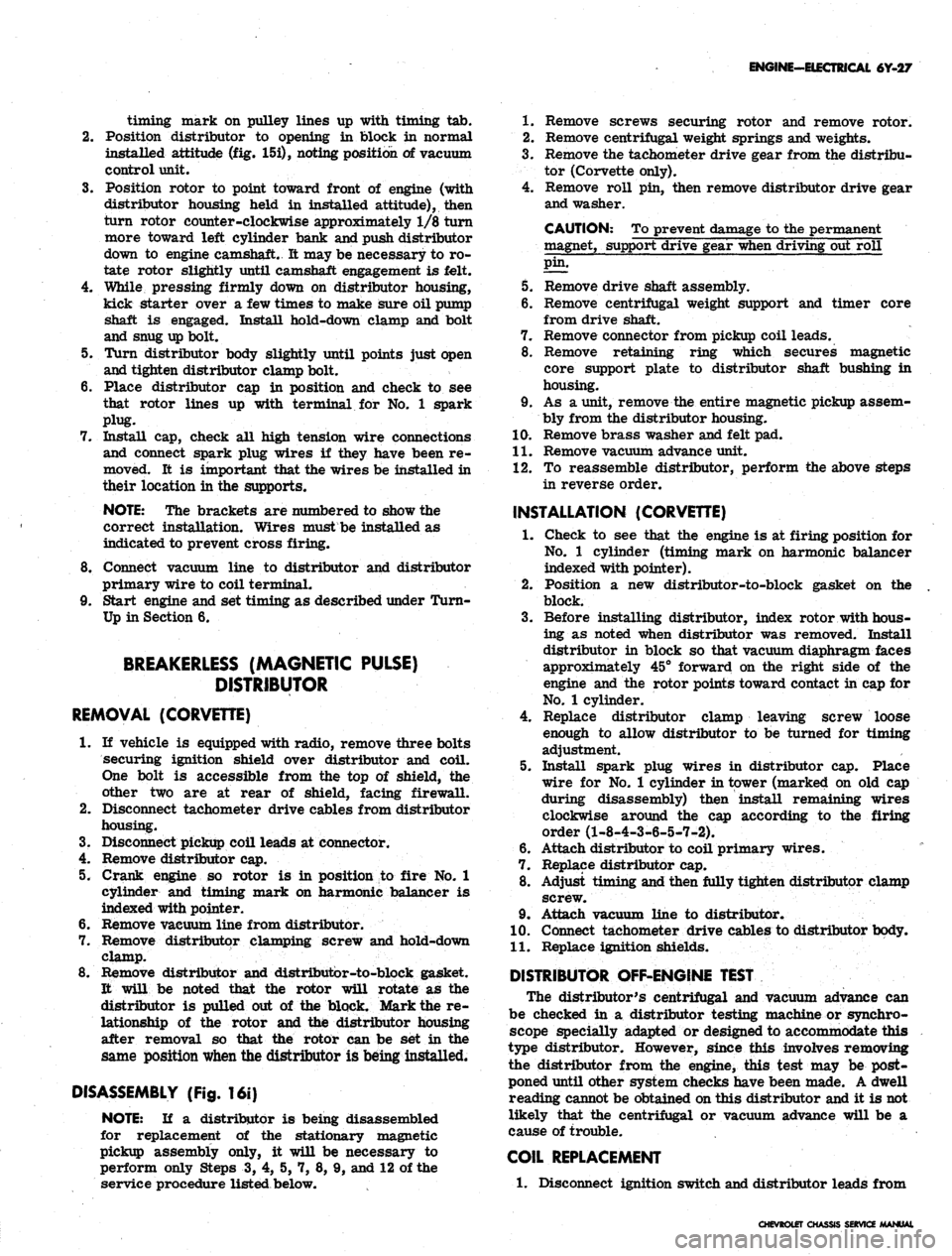

FLOOR SHIFT LINKAGE ADJUSTMENT

1.

Set Transmission Levers (K) and (L) in neutral de-

tent position.

2.

Move Transmission Control Lever (A) to neutral de-

tent and insert Locating Pin (D) into notch of Lever

and Bracket Assembly.

3.

Install Nut (N) and Clevis (M) on Rod (J) loosely,

attach Rod to Lever (B) and secure with retainer.

4.

With Lever (B) against Locating Pin, adjust Clevis

at Lever (L) until Clevis pin passes freely through

holes and secure with washer and cotter pin. Tighten

Nut (N).

5.

Install Nuts (E) and (G) and Swivel (F) loosely on Rod

(H),

attach Rod to Lever (K) and secure with retainer.

6. With Lever (C) against Locating Pin, attach Swivel to

lever and secure with retainer. iRun Nut (G) against

Swivel, then tighten Nut (E) against Swivel.

7.

Remove Locating Pin and check shifts to insure

proper operation. Readjust clevis and swivel if nec-

essary.

LEVER (A)

LEVER (L) CLEVIS (M)-NUT (N

LEVER (C)

ROD(J).

" - -

LEVER (K) ROD (H)^ NUT '(G) SWIVEL (F) ^NUT (E)

SHIFT CONTROL LEVER AND BRACKET ASSEMBLY

If disassembly of this control lever and bracket assem-

bly is necessary refer to Figure 2A for parts breakdown

and relative positioning for assembly.

SPEEDOMETER DRIVEN GEAR

Disconnect speedometer cable, remove lock plate to ex-

tension bolt and lock washer and remove lock plate. In-

sert screwdriver in lock plate slot in fitting and pry fitting

gear and shaft from extension. Pry "O" ring from groove

in fitting.

Install new "OM ring in groove in fitting. Coat "O" ring

and driven gear shaft with transmission lubricant and in-

sert shaft.

Hold the assembly so slot in fitting is toward lock plate

boss on extension and install in extension. Push fitting

into extension until lock plate can be inserted in groove

and attach to extension.

EXTENSION OIL SEAL REPLACEMENT

.1.

Remove propeller shaft as outlined in Section 4 and

disconnect any necessary items to obtain clearance.

2.

Pry seal out of extension.

3.

Wash counterbore with cleaning solvent and inspect

for damage.

4.

Prelubricate between sealing lips and coat new seal

O.D. with Permatex or equivalent and start straight

in bore in case extension. Using Tool J-5154, tap

seal into counterbore until flange bottoms against

extension.

Fig.

1A- Shift Linkage Adjustment (Typical)

Fig.

2A - Corvette 3 Speed Control Lever and Bracket Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 373 of 659

CLUTCH AND TRANSMISSIONS 7-14

SPEED HEAVY DUTY TRANSMISSION

(WARNER MODEL T 16)

INDEX

General Description ......

Maintenance and Adjustments

Shift Linkage Adjustment

Side Cover ........

Removal .........

Disassembly

7-14

7-14

7-14

7-14

7-14

7-14

Assembly 7-14

Installation • 7-15

Other Maintenance

&

Adjustment

Operations See 3-Speed Saginaw Section

Transmission Replacement . . . See 3-Speed Saginaw Section

GENERAL DESCRIPTION

The Borg-Warner heavy duty three speed fully syn-

chronized (all forward gears) transmission incorporates

helical gears throughout specially designed to provide

high torque capacity, and gear teeth proportion to operate

at high speeds with neither excessive heat generation nor

excessive frictional losses. Shafts, bearings, high ca-

pacity clutches and other precision parts are held to

close limits providing proper clearances necessary for

durability during extended heavy usage.

The main drive gear is supported by a heavy duty ball

bearing at the front end of the transmission case and is

piloted at its front end in an oil impregnated bushing

mounted in the engine crankshaft. The front end of the

mainshaft is piloted in a row of roller bearings set into

the hollow end of the main drive gear and the rear end

is carried by a heavy duty ball bearing mounted in the

front of the extension housing.

The countergear is carried on a double row of rollers

at both ends while thrust is taken on thrust washers lo-

cated between the ends of the gear and the thrust bosses

in the case. An anti-rattle plate assembly at the front

of the countergear provides a constant spring tension be-

tween the counter and clutch gears to reduce torsional

vibrations. The reverse idler gear is carried on 25

roller bearings while thrust is taken on thrust washers

located between the ends of the gear and the thrust bosses

of the case.

Gear shifting is manual through shift control rods from

the shifter tube in the mast jacket to the rearward shift

lever of the side cover assembly for first and reverse

gear; and through a cross shaft assembly attached to the

forward side cover lever for second and third gear. All

three forward gears are fully synchronized. The syn-

chronizer assemblies consist of a clutch hub, clutch

sleeve, two clutch key springs and three energizer clutch

keys and are retained as an assembly on the main shaft

by a snap ring. The transmission may be used as an aid

in deceleration by downshifting in sequence without

double-clutching or any gear clashing. Reverse is not

synchronized, however, it is a helical gear to insure

quiet operation.

MAINTENANCE AND ADJUSTMENTS

Refer to similar procedures under the 3-speed Saginaw

Transmission Section for—Column Mounted Shift Linkage

Adjustment, Speedometer Driven Gear and Oil Seal Re-

placement, Extension Oil Seal Replacement and Trans-

mission Replacement. ~~

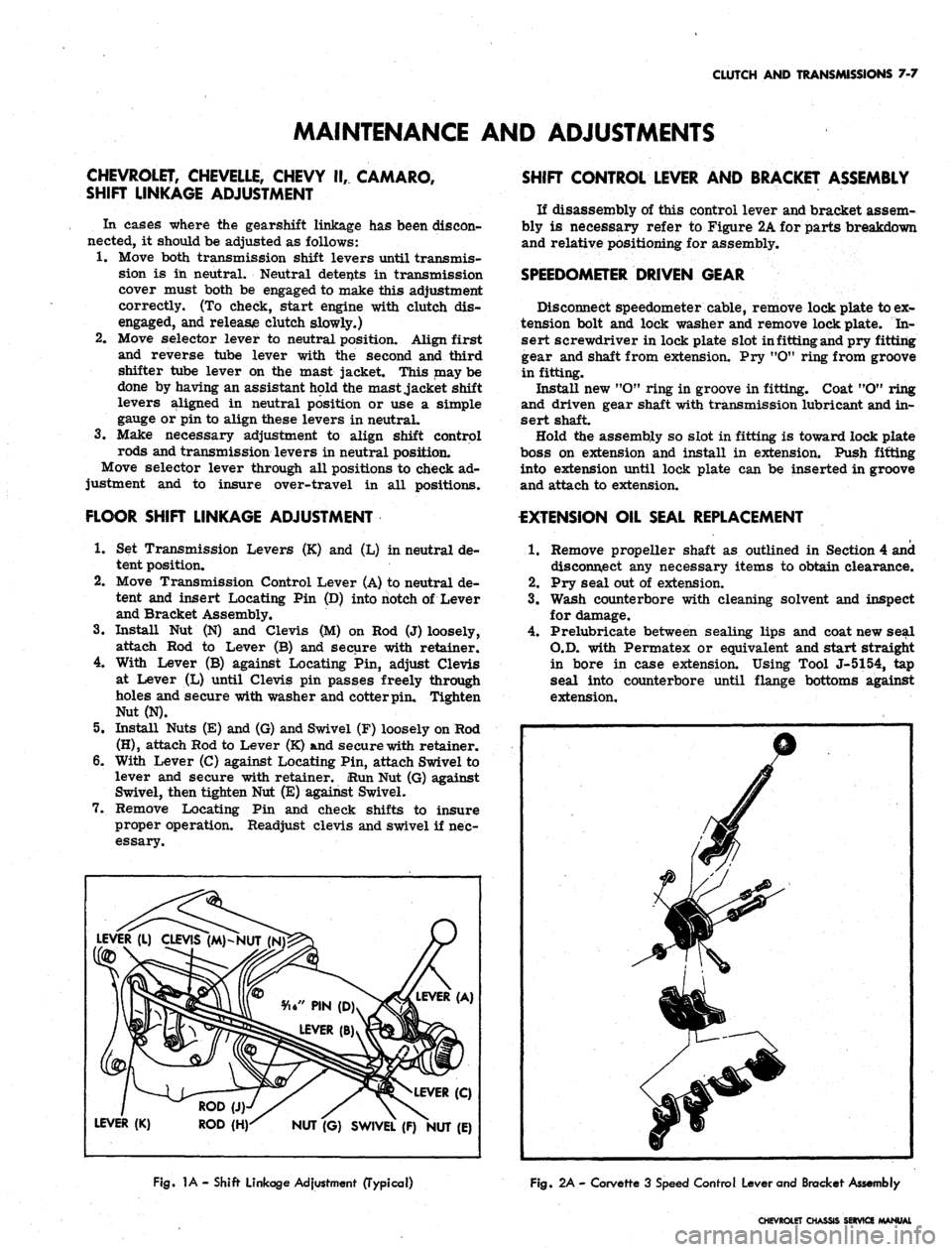

Camaro and Corvette Floor Shift Linkage Adjustment

(Fig.

lc)

1.

Set Lever (L), (K) in neutral position.

2.

Move Lever Assembly (A) and Levers (C), (D) to

neutral position and insert Locating Gauge (B) into

control Lever Bracket Assembly.

3.,

Install Rod (H) with Retainer (M) on Lever (L).

4.

With two Jam Nuts (G), (E) and Swivel (F) loose on

Rod (H) insert and attach Swivel with Retainer (N)

to Lever (D).

5.

Repeat steps 3 and 4 for Rod (J) and Levers (C

&

K).

6. Remove' Locating Gauge and check shift to insure

proper operation.

SIDE COVER ASSEMBLY

Removal

1.

Drain transmission and disconnect control rod and

cross shaft from side cover levers. *

2.

Remove nine cap screws securing the transmission

side cover assembly to transmission, case and re-

move cover assembly, shifting forks, and gasket.

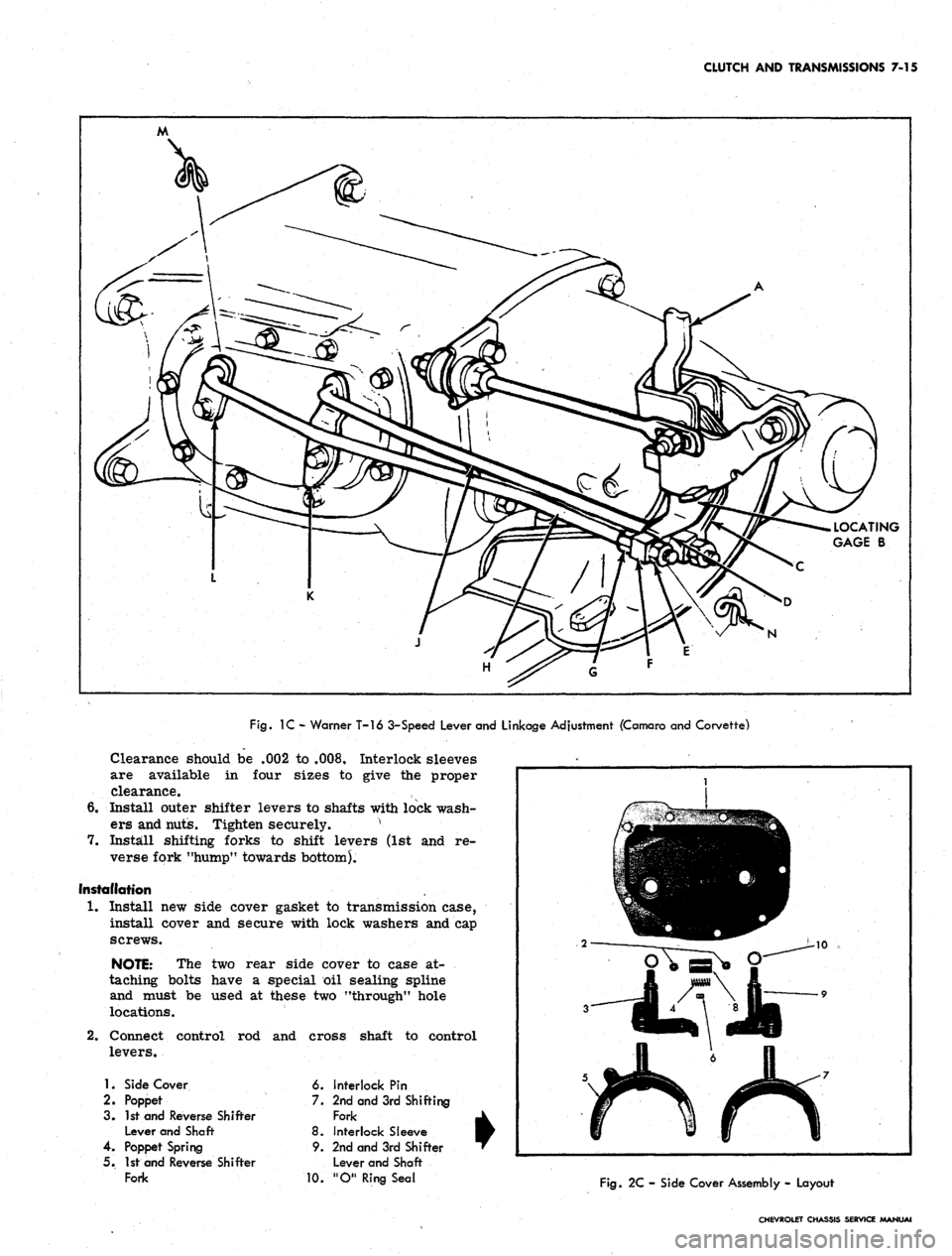

Disassembly (Fig. 2C) '

1.

Remove shifting forks from shift lever assemblies.

2.

Remove nut and lock washer from each shift lever

shaft.

3.

Remove outer shift levers and lightly tap shift lever

shafts from assembly.

4.

Remove two steel balls, poppet spring, interlock pin

and interlock sleeve from cover.

5.

Remove "O" ring seals from shift lever shafts.

Assembly (Fig. 2C)

1.

Install new "O" ring seals to shift lever shafts.

2.

Install low and reverse shifter shaft and plate as-

sembly to cover.

3.

Place shifter shaft and plate assembly in neutral po-

sition, middle detent, and install interlock sleeve,

ball, poppet spring and interlock pin.

4.

Install remaining poppet ball and then install second

and third shifter shaft and plate assembly.

NOTE: Installation is easiest if shifter shaft

and plate assembly passes over ball in its neu-

tral position.

5.

Check clearance between end of interlock sleeve and

shifter shaft and plate cams when one plate is in

neutral and the other is shifted into gear position.

CHEVROLET CHASSIS SERVICE MANUAL

Page 374 of 659

CLUTCH AND TRANSMISSIONS 7-15

LOCATING

GAGE B

N

Fig.

1C - Warner T-16 3-Speed Lever and Linkage Adjustment (Camaro and Corvette)

Clearance should be .002 to .008. Interlock sleeves

are available in four sizes to give the proper

clearance.

6. Install outer shifter levers to shafts with lock wash-

ers and nuts. Tighten securely. v

7.

Instill shifting forks to shift levers (1st and re-

verse fork "hump" towards bottom).

Installation

1.

Install new side cover gasket to transmission case,

install cover and secure with lock washers and cap

screws.

NOTE: The two rear side cover to case at-

taching bolts have a special oil sealing spline

and must be used at these two "through" hole

locations.

2.

Connect control rod and cross shaft to control

levers.

1.

Side Cover

2.

Poppet

3. 1st and Reverse Shifter

Lever and Shaft

4.

Poppet Spring

5. 1st and Reverse Shifter

Fork

6. Interlock Pin

7. 2nd and 3rd Shifting

Fork

8. Interlock Sleeve

9. 2nd and 3rd Shifter

Lever and Shaft

10.

"O11 Ring Seal

Fig.

2C - Side Cover Assembly - Layout

CHEVROLET CHASSIS SERVICE MANUAl

Page 388 of 659

CLUTCH AND TRANSMISSIONS 7-29

ROD

(E)~X\

or

POINT OF-i-7V

CONTACT

i

(2)

-

VIEW

^ROD

(C

LLEVER

r-D

I

j

.——j

A

{

(D)

ETENT

FWD.

B

\_

(?) LOAD (X)

SWIVEL (J)-\

ROD(CK V

NUT (B)-—-^

SPACER

(H)-^

K

/ / n

/LOAD (Y)

I^-NUT

(A)

k-.O94

/^A

VIEWB

L-DETENT

(F)

AQUATING LEVER

-PART

OF

LEVER

&

(G)

BRKT. ASM.

Fig.

10PG - Corvette Gear Shift Control Adjustment

Fig.

9PG - Comoro Floor Shift Linkage Adjustment

The foregoing procedure will provide a .050" over

travel gap in the notches of Detent (F).

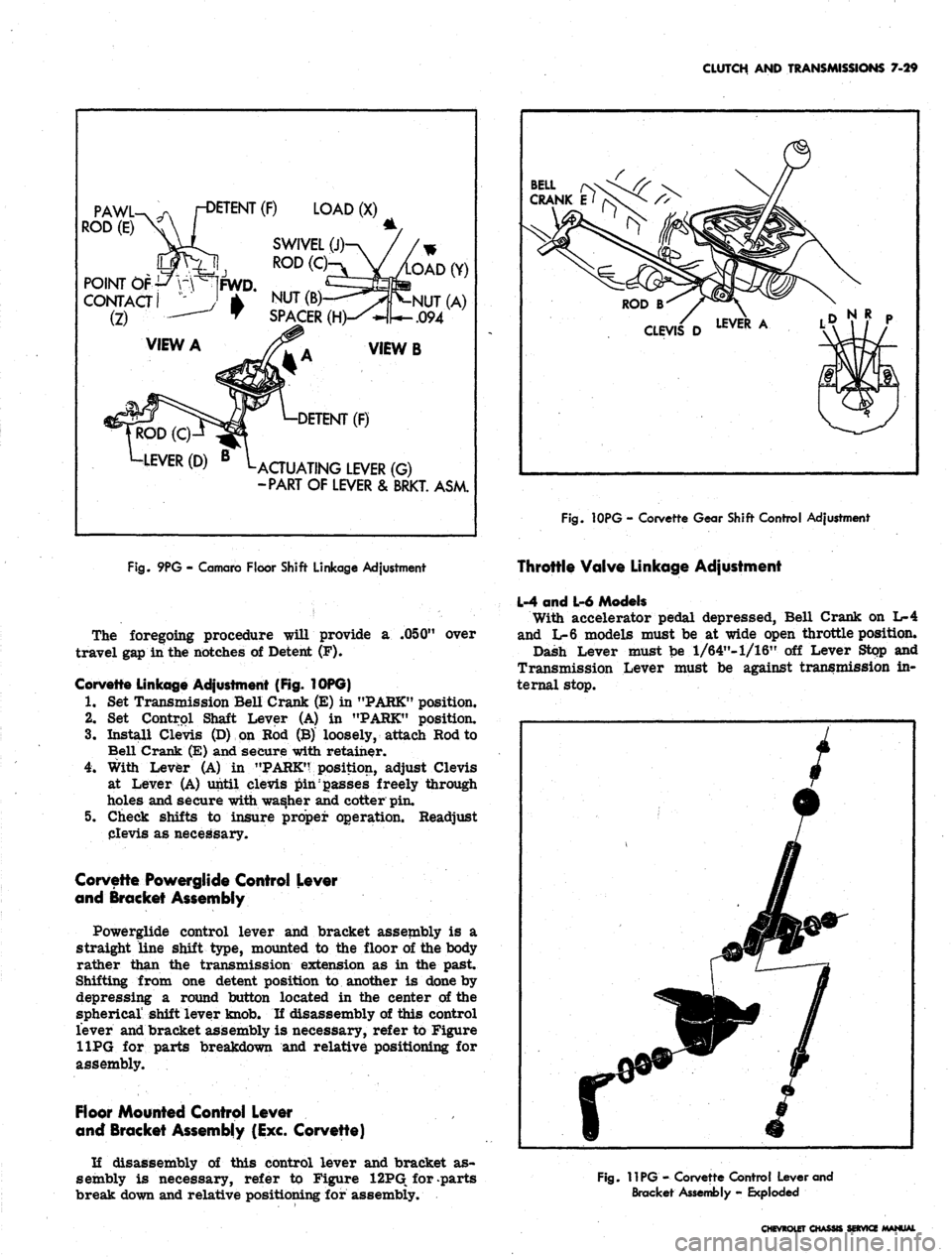

Corvette Linkage Adjustment (Fig. 10PG)

1.

Set Transmission Bell Crank (E) in "PARK" position.

2.

Set Control Shaft Lever (A) in "PARK" position.

3.

Install Clevis (D) on Rod (B) loosely, attach Rod to

Bell Crank (E) and secure with retainer.

4.

With Lever (A) in "PARK'? position, adjust Clevis

at Lever (A) until clevis pin passes freely through

holes and secure with washer and cotter pin.

5. Check shifts to insure proper operation. Readjust

Clevis as necessary.

Corvette Powerglide Control Lever

and Bracket Assembly

Powerglide control lever and bracket assembly is a

straight line shift type, mounted to the floor of the body

rather than the transmission extension as in the past.

Shifting from one detent position to another is done by

depressing a round button located in the center of the

spherical' shift lever knob. If disassembly of this control

lever and bracket assembly is necessary, refer to Figure

11PG for parts breakdown and relative positioning for

assembly.

Floor Mounted Control Lever

and Bracket Assembly (Exc. Corvette)

If disassembly of this control lever and bracket as-

sembly is necessary, refer to Figure 12PG for parts

break down and relative positioning for assembly.

Throttle Valve Linkage Adjustment

L-4 and L-6 Models

With accelerator pedal depressed, Bell Crank on L-4

and L-6 models must be at wide open throttle position.

Dash Lever must be 1/64"-1/16" off Lever Stop and

Transmission Lever must be against transmission in-

ternal stop.

Fig.

11PG - Corvette Control Lever and

Bracket Assembly - Exploded

CHEVtOLET CHASSIS SERVICE

Page 407 of 659

SECTION 8

FUEL TANK AND EXHAUST SYSTEMS

CONTENTS OF THIS SECTION

Page

Chevrolet .. . . 8-1

Fuel Tanks 8-1

Exhaust Systems 8-5

Chevelle 8-8

Fuel Tanks 8-8

Exhaust Systems 8-11

Chevy n ...... 8-13

Fuel Tanks 8-13

Page

Exhaust Systems 8-16

Corvette 8-18

Fuel Tanks 8-18

Exhaust Systems 8-24

Camaro 8-26

Fuel Tank 8-26

Exhaust System 8-30

Special Tools 8-33

CHEVROLET

FUEL TANKS

INDEX

Page

Page

General Description

Component Part Replacement

Fuel Tank

8-1 Fuel Lines 8-3

8-2 Fuel Tank Vent Lines 8-4

8-2 Metering Units (Gauge Sending Unit ) 8-4

GENERAL DESCRIPTION

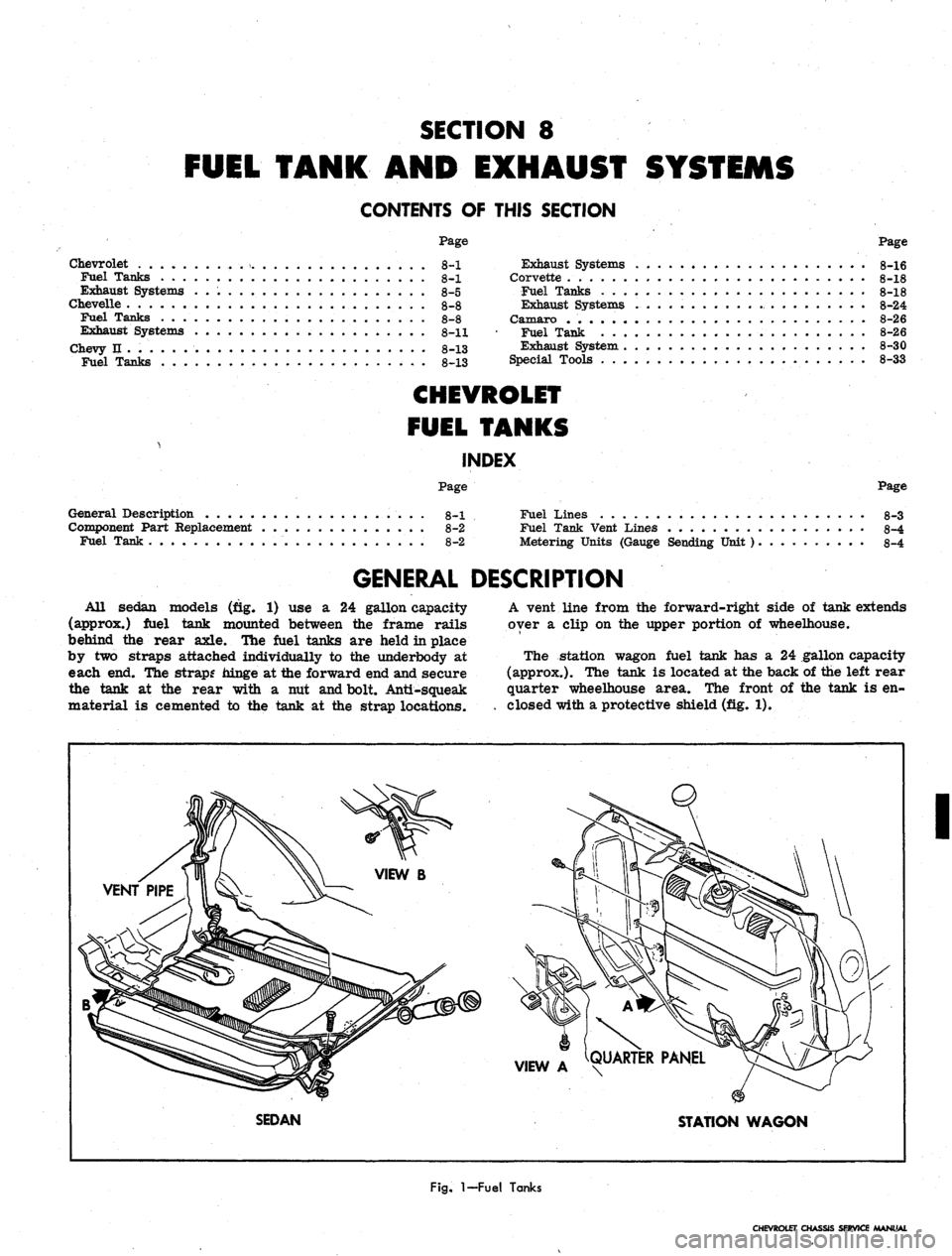

All Sedan models (fig. 1) use a 24 gallon capacity

(approx.) fuel tank mounted between the frame rails

behind the rear axle. The fuel tanks are held in place

by two straps attached individually to the underbody at

each end. The strap? hinge at the forward end and secure

the tank at the rear with a nut and bolt. Anti-squeak

material is cemented to the tank at the strap locations.

A vent line from the forward-right side of tank extends

over a clip on the upper portion of wheelhouse.

The station wagon fuel tank has a 24 gallon capacity

(approx.). The tank is located at the back of the left rear

quarter wheelhouse area. The front of the tank is en-

closed with a protective shield (fig. 1).

VIEW A ^QUARTER PANEL

SEDAN

STATION WAGON

I

Fig.

1-Fuel

Tanks

CHEVROLET CHASSIS SERVICE MANUAL

Page 410 of 659

FUEL TANK AND EXHAUST SYSTEMS 8-4

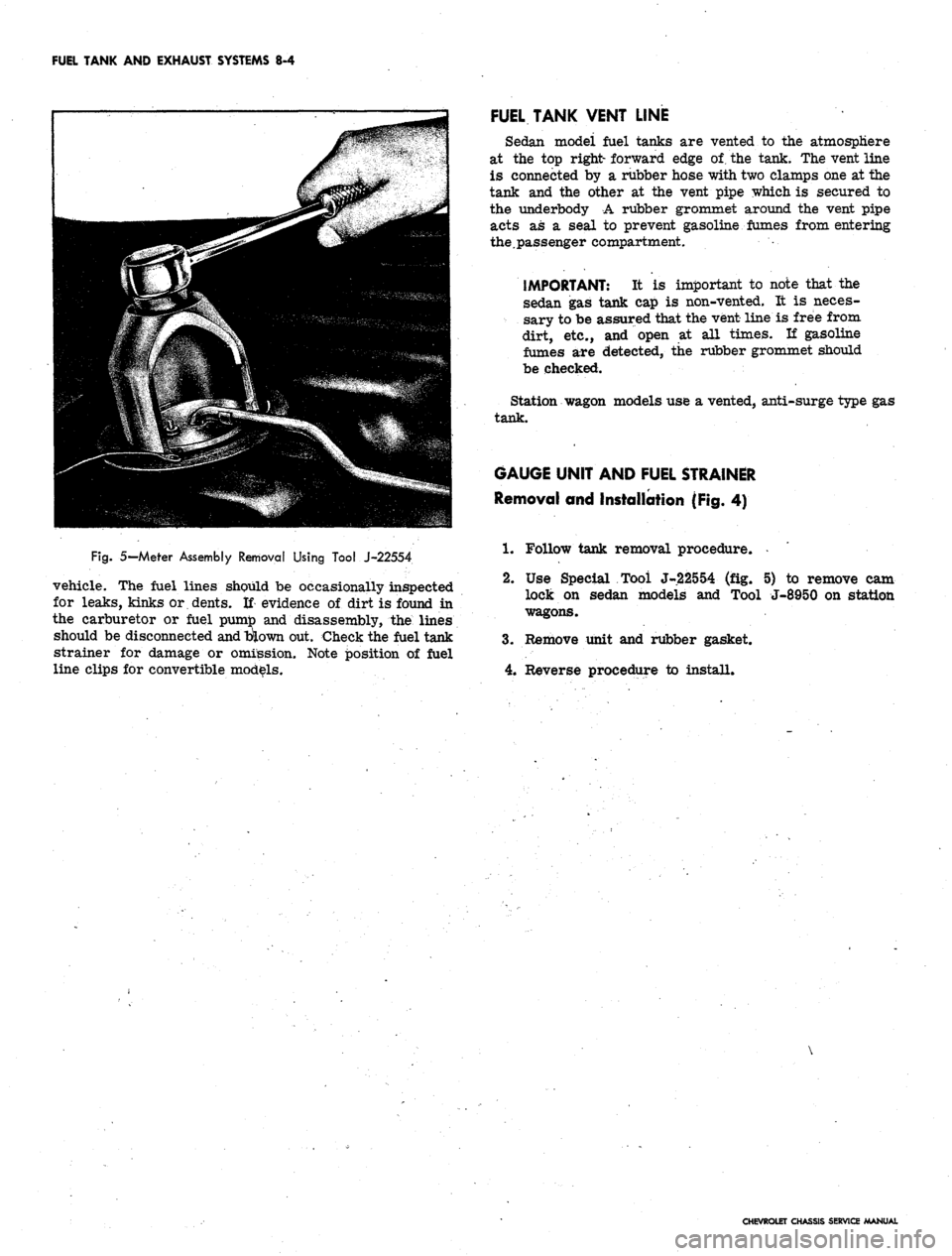

Fig.

5— Meter Assembly Removal Using Tool J-22554

vehicle. The fuel lines should be occasionally inspected

for leaks, kinks or dents. If evidence of dirt is found in

the carburetor or fuel pumto and disassembly, the lines

should be disconnected

and

blown out. Check the fuel tank

strainer for damage or omission. Note position of fuel

line clips for convertible models.

FUEL TANK VENT LINE

Sedan modei fuel tanks are vented to the atmosphere

at the top right- forward edge of. the tank. The vent line

is connected by a rubber hose with two clamps one at the

tank and the other at the vent pipe which is secured to

the underbody A rubber grommet around the vent pipe

acts as a seal to prevent gasoline fumes from entering

the.passenger compartment.

IMPORTANT: It is important to note that the

sedan gas tank cap is non-vented. It is neces-

sary to be assured that the vent line is free from

dirt, etc., and open at all times. If gasoline

fumes are detected, the rubber grommet should

be checked.

Station wagon models use a vented, anti-surge type gas

tank.

GAUGE UNIT AND FUEL STRAINER

Removal and Installation (Fig. 4)

1.

Follow tank removal procedure.

2.

Use Special Tool J-22554 (fig. 5) to remove cam

lock on sedan models and Tool J-8950 on station

wagons.

3.

Remove unit and rubber gasket.

4.

Reverse procedure to install.

CHEVROLET CHASSIS SERVICE MANUAL

Page 411 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-5

EXHAUST SYSTEMS

INDEX

Page

General Description

. . 8-5

Component Part Replacement

8-5

Muffler Assembly.

8-5

Exhaust Pipes.

8-5

Tail Pipes.

8-5

GENERAL DESCRIPTION

All exhaust systems used

on the 1967

Chevrolet

are

exhaust systems

(fig. 7) are

available

as

regular produc-

the split system type

in

which the. component parts

are

tion equipment

on the 427 cu. in.

displacement

V-8 en-

secured together with clamps.

The

single exhaust system gines

and as an

option

on the

other (except

283 cu. in.)

used

on L-6

engine models

(fig. 6)

consists

of an

exhaust

V-8

engines. These systems consist

of two

exhaust

pipe, muffler, tailpipe

and

attaching hardware.

On V-8

pipes, mufflers, tailpipes with resonators

and

attaching

engine single exhaust models

a

crossover pipe

is

added hardware.

All

exhaust systems

are

suspended on brackets

to connect

the

right exhaust manifold

to the

system. Dual with insulators

for

rattle free operation.

COMPONENT PART REPLACEMENT

Care should

be

taken

to

have

the

exhaust pipe, muffler

or tail pipe

in

proper relation with each other. Incorrect

alignment frequently causes annoying rattles

due to in-

correct clearances.

MUFFLER ASSEMBLY

Remove

and

Replace

1.

Remove "U" bolt clamp

at

center mounting.

2.

Remove

"U"

bolt clamp

at

forward

end of

muffler

pipe.

3.

Disengage muffler

at

exhaust

and

tail pipe

connections.

4.

Three-fourths inch clearance should

be

allowed

be-

tween

the

muffler bracket (hanger)

and

crossmember

at installation.

5. Install unit with

the

flat side

of the

muffler showing.

EXHAUST PIPE (CROSSOVER WITH

V-8

ENGINE)

Remove

and

Replace

1.

Remove

two

nuts, extension

and

packings-separate

pipe from manifold.

2.

3.

Disassemble

pipe.

"U"

damp from muffler

and

remove

Attach pipe

to

muffler, then secure

to

manifold. Note

clearances

for the

standard

and

automatic control

linkages, underbody

and

crossmember. Contact

of

exhaust pipe

to

engine panrail

is

permissible.

4.

Tighten nuts uniformly.

TAIL PIPE AND/OR RESONATOR

Remove

and

Replace

1.

Remove

"U"

clamp attachment

at

muffler.

2.

Remove screw attachment

at

tail pipe rear hanger

assembly.

3.

Remove tail pipe.

4.

Replace tail pipe

at

muffler, then install

at

hanger

Do

not

secure attachments until clearances have been

checked. Check position

of

hanger

so

that interplates

are parallel.

5. Torque nuts

7-9 ft. lbs. at

hanger

and 10-15 ft. lbs.

at muffler.

CHEVROLET CHASSIS

SEI

Page 414 of 659

FUEL TANK AND EXHAUST SYSTEMS

8-8

CHEVELLE

FUEL TANKS

INDEX

Page

General Description.

g.g

Component Part Replacement

8-8

Fuel Tanks

. 8-8

Fuel Lines

8-8

Metering Units (Gauge, Sending Unit)

Fuel Tank Filler Neck Caps.

. .

Fuel Tank Vent Lines

Page

8-8

8-8

8-9

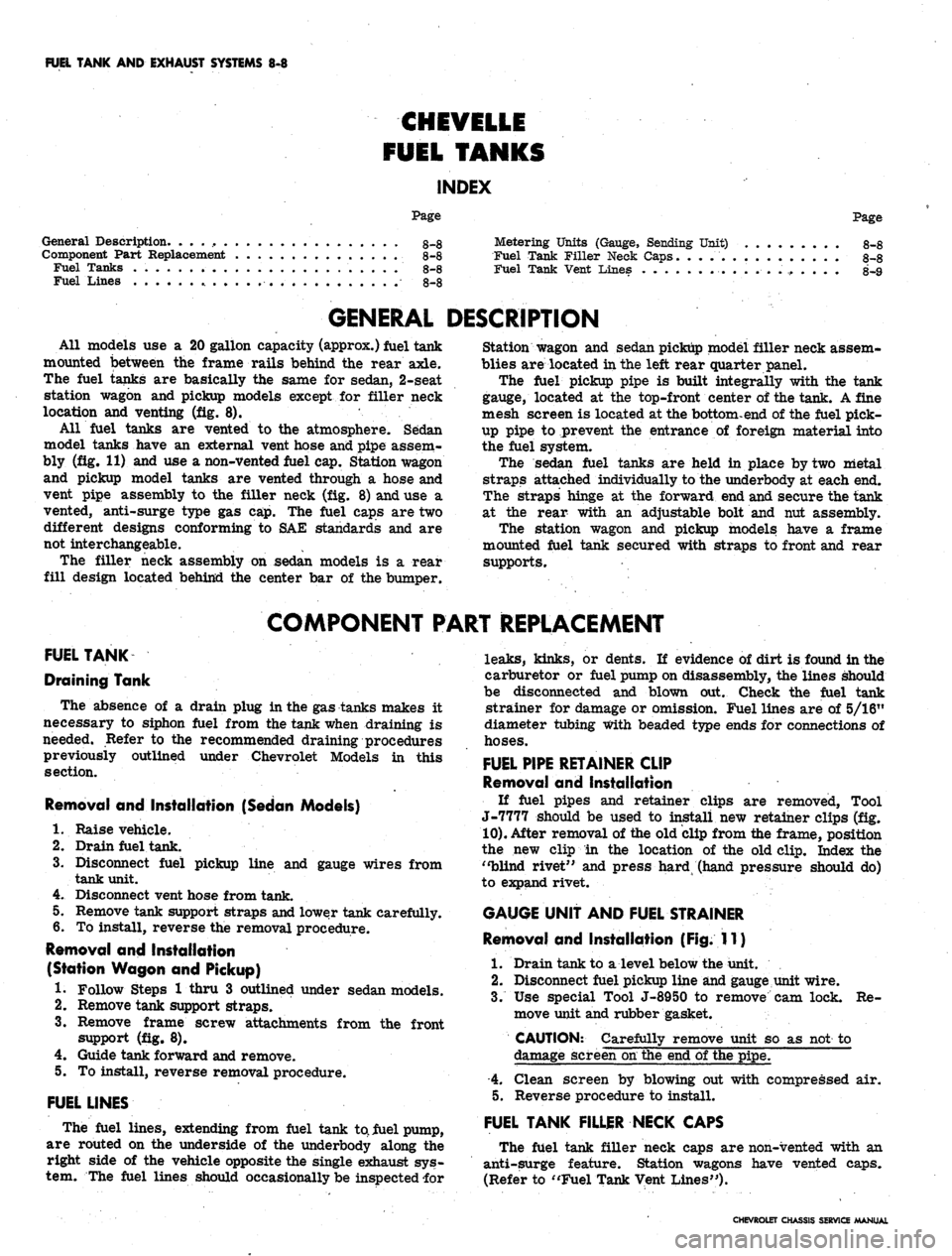

GENERAL DESCRIPTION

All models

use a 20

gallon capacity (approx.) fuel tank

mounted between

the

frame rails behind

the

rear axle.

The fuel tanks

are

basically

the

same

for

sedan, 2-seat

station wagon

and

pickup models except

for

filler neck

location

and

venting

(fig. 8).

All fuel tanks

are

vented

to the

atmosphere. Sedan

model tanks have

an

external vent hose and pipe assem-

bly

(fig. 11) and use a

non-vented fuel cap. Station wagon

and pickup model tanks

are

vented through

a

hose

and

vent pipe assembly

to the

filler neck

(fig. 8)

and

use a

vented, anti-surge type

gas cap. The

fuel caps

are two

different designs conforming

to SAE

standards

and are

not interchangeable.

The filler neck assembly

on

sedan models

is a

rear

fill design located behind

the

center

bar of the

bumper.

Station wagon

and

sedan pickup model filler neck assem-

blies

are

located

in

the left rear quarter panel.

The fuel pickup pipe

is

built integrally with

the

tank

gauge, located

at the

top-front center

of

the tank.

A

fine

mesh screen

is

located

at

the bottom-end

of the

fuel pick-

up pipe

to

prevent

the

entrance

of

foreign material into

the fuel system.

The sedan fuel tanks

are

held

in

place

by

two metal

straps attached individually

to the

underbody

at

each

end.

The straps hinge

at the

forward end and secure

the

tank

at

the

rear with

an

adjustable bolt

and nut

assembly.

The station wagon

and

pickup models have

a

frame

mounted fuel tank secured with straps

to

front and rear

supports.

COMPONENT PART REPLACEMENT

FUEL TANK

Draining Tank

The absence

of a

drain plug

in the gas

tanks makes

it

necessary

to

siphon fuel from

the

tank when draining

is

needed. Refer

to the

recommended draining procedures

previously outlined under Chevrolet Models

in

this

section.

Removal

and

Installation (Sedan Models)

1.

Raise vehicle.

2.

Drain fuel tank.

3.

Disconnect fuel pickup line

and

gauge wires from

tank unit.

4.

Disconnect vent hose from tank.

5. Remove tank support straps and lower tank carefully.

6.

To

install, reverse

the

removal procedure.

Removal

and

Installation

(Station Wagon

and

Pickup)

1.

Follow Steps

1

thru

3

outlined under sedan models.

2.

Remove tank support straps.

3.

Remove frame screw attachments from

the

front

support

(fig. 8).

4.

Guide tank forward

and

remove.

5.

To

install, reverse removal procedure.

FUEL LINES

The fuel lines, extending from fuel tank toiiuelpump,

are routed

on the

underside

of the

underbody along

the

right side

of the

vehicle opposite

the

single exhaust

sys-

tem.

The

fuel lines should occasionally

be

inspected

for

leaks,

kinks,

or

dents.

If

evidence

of

dirt

is

found

in the

carburetor

or

fuel pump

on

disassembly,

the

lines should

be disconnected

and

blown

out.

Check

the

fuel tank

strainer

for

damage

or

omission. Fuel lines

are of 5/16"

diameter tubing with beaded type ends

for

connections

of

hoses.

FUEL PIPE RETAINER

CUP

Removal

and

Installation

If fuel pipes

and

retainer clips

are

removed, Tool

J-7777 should

be

used

to

install

new

retainer clips

(fig.

10).

After removal

of the old

clip from

the

frame, position

the

new

clip

in the

location

of the old

clip. Index

the

"blind rivet"

and

press hard (hand pressure should

do)

to expand rivet.

GAUGE UNIT

AND

FUEL STRAINER

Removal

and

Installation

(Fig. 11)

1.

Drain tank

to a

level below

the

unit.

2.

Disconnect fuel pickup line

and

gauge unit wire.

3.

Use

special Tool J-8950

to

remove

cam

lock.

Re-

move unit

and

rubber gasket.

CAUTION: Carefully remove unit

so as not to

damage screen

on the end of

the pipe.

4.

Clean screen

by

blowing

out

with compressed

air.

5. Reverse procedure

to

install.

FUEL TANK FILLER NECK CAPS

The fuel tank filler neck caps

are

non-vented with

an

anti-surge feature. Station wagons have vented caps.

(Refer

to

"Fuel Tank Vent Lines").

CHEVROLET CHASSIS SERVICE MANUAL