ECU CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 179 of 659

FRONT SUSPENSION 3-15

4.

Insert Spring Compressor J-

6874-

4-

5 with Adapters

J-6874-8-9 into upp^r spring tower so that lower

MU"

bolt fits into shock absorber mounting holes in

spring seat (fig. 23). Secure the two lower studs to

the spring seat with nuts.

5.

Fit the tool upper pilot to top of spring and compress

spring by tightening upper nut (fig. 24). Compress

spring until screw is bottomed out.

6. Remove lower spring seat retaining nuts, lift spring

and seat assembly from control arm and guide it

down and out through fender skirt (fig. 25).

Spring Seat Replacement (Fig. 26)

1.

Release spring tension and disconnect spring com-

pressor from spring seat.

2.

Install new spring seat to spring compressor.

Installation

1.

If spring is to be replaced, install new spring into

tool and compress spring until screw is bottomed

out.

NOTE: Spring coil ends must be against spring

stops in upper and lower seats.

2.

Lift spring and tool assembly into place and position

so that the upper spring stop is inboard.

NOTE: Locating tab on upper spring seat may

be flattened before reinstalling spring.

3.

Install lower spring seat to control arm and torque

nuts as shown in the Specifications.

4.

Loosen spring compressor until spring is properly

seated in upper spring tower and remove.

5.

Install shock abosrber as outlined under Shock Ab-

sorber—Installation in this section.

Corvette

Removal

1.

With car on suitable hoist or jack, (support vehicle

by frame so control arms may swing free) remove

wheel and tire assembly, stabilizer bar and shock

absorber. Loosen the lower ball joint to steering

knuckle nut, and the' two lower control arm cross

shaft bushing bolts.

2.

Place Tool J-6874-1 across top of sixth coil (ap-

prox.),

then loosely secure Tool J-6874-2 to the up-

per shoe, with attaching capscrews and lock washers.

The upper shoe "V" notch and lower shoe raised land

should contact spring.

3.

Insert Tool J-6874 up through center of spring and

attach to upper and lower shoe assembly.

4.

Position spacers under shock absorber mounting hole

and against bottom of lower control arm. Install

special bearing washer and Tool J-6874-5. Locate

bearing against spacer and large washer against

bearing. Feed screw up through large washer bear-

ing and spacer and thread into Tool J-6874 and

tighten snugly (fig. 22).

5.

Center shoe assembly on spring and tighten screw

until a very slight compression is placed on spring

(fig. '22). Then firmly tighten down the two cap-

screws securing the upper and lower shoes to lock

these shoes to spring.

6. Turn head of screw until spring is compressed just

enough to clear the spring tower, then remove the

lower ball joint to steering knuckle nut (fig. 22).

NOTE: It may be necessary to assist the

spring out of the spring tower with a pry bar or

a similar tool.

7.

Disconnect the lower ball joint from the steering

knuckle and lower the control arm with the com-

pressed spring. Immediately release compression

on spring by backing off long screw. Release spring

and tool and withdraw spring.

CAUTION: The spring force under compres-

sion is very large. Exercise every safety pre-

caution when performing this operation to see

that individuals and materials subject to damage

are removed from the path of the spring when

the control arm is being lowered. Also, the

compressed spring

be relaxed immedi-

ately after lowering the control arm to reduce

the time of exposure to the large compressive

force.

Installation

1.

Position spring with closely coiled end up. Place

Tool J-6874-1 across the top of the sixth coil (ap-

prox.) then loosely secure Tool J-6874-2 to the

upper shoe with attaching capscrews and lock wash-

ers.

The upper shoe MV" notch and lower shoe

raised land should contact spring.

2.

Insert Tool J-6874 up through center of spring and

attach to upper and lower shoe assembly with bolt

and nut.

3.

Set spring in its seat on the lower control arm.

4.

Position spacers centrally under shock absorber

mounting hole and against bottom of lower control

arm. Install bearing, large washer and Tool

J-6874-5.

Locate bearing against spacer and large

washer against bearing. Feed the screw up through

large washer, bearing and spacer and thread into

yoke rod. Tighten snugly, but do not start to draw

down yet

5.

Center the shoe assembly on the spring and tighten

the lag screw until a very slight compression is

placed on spring, then firmly tighten down the two

capscrews securing the upper and lower shoes. This

will lock the shoes to the coil spring.

6. Turn head of screw until spring is compressed just

enough to clear the spring tower.

NOTE: It may be necessary to assist the

spring into the spring tower with a pry bar or

similar tool.

7.

Immediately install the lower ball joint into steering

knuckle and secure in place with attaching nut.

8. Release compression on spring and at the same time

use a drift to guide the coil spring into its proper

seat. End of coils must be 3/8" from coil stops in

spring seat.

9. Tighten the lower ball joint to steering knuckle nut

and lock with cotter key.

10.

Install shock absorber and stabilizer bar.

11.

Install wheel, tire and drum assembly.

12.

Remove car from hoist or jack stands.

13.

Tighten the two lower control cross shaft bushing

bolts to 45-55 lbs. ft. torque.

NOTE: If a suitable adjustable jack-stand is

CHEVROLET CHASSIS SERVICE MANUAL

Page 181 of 659

FRONT SUSPENSION 3-17

4.

Replace the wheel and tire.

5.

Lower the vehicle.

Chevy II

inspection

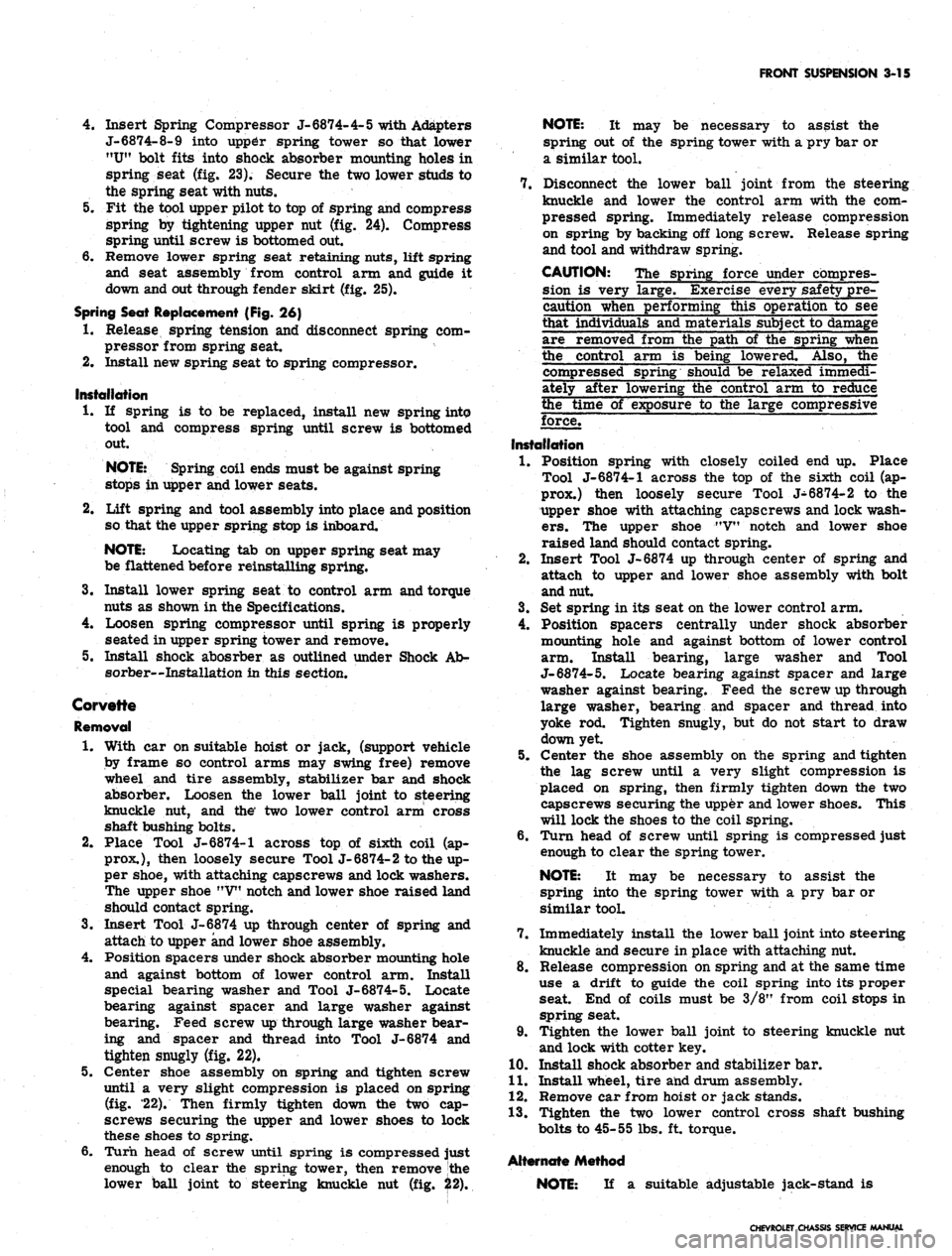

Fig.

28 - Installing Lower Ball Joint - Chevelle & Camaro

retain in place with special bolts and nuts supplied

with new joint.

CAUTION: Use only alloy bolts supplied for

this operation. The special thick headed bolt

must be installed in the forward side of the

control arm.

2.

Tighten bolts and nut on ball stud to Specification

shown at the end of this book.

3.

Lubricate the joint.

Chevelle and Camaro

Removal

1.

Support lower control arm at outer end of floor jack,

with hoist or jack pad clear of lower ball stud and

remove the wheel.

2.

Remove the upper and lower ball stud nuts, free the

ball studs from the steering knuckle and wire the

knuckle and brake drum assembly out of the way to

preclude interference while completing the lower ball

stud removal procedure.

3.

Use a screw driver to pry off the seal and retainer.

Install Tools J-9519-10, J-9519-17 and J-9519-7 as

shown in Figure 27 and turn down on the hex head

screw until the ball stud is pushed out.

Installation

1.

Start the replacement ball stud into the control arm

and install Tools J-9519-10, J^9519-16 and J-9519-17

as shown in Figure 28.

2.

Turn down on the hex head screw until the ball stud

is seated properly in the control arm.

3.

Install the stud into the steering knuckle, secure in

place with the attacking nut and install the cotter pin.

1.

With upper control arm support in position as in

Figure 15, disconnect the lower ball stud from steer-

ing knuckle.

2.

Assemble nut to lower ball stud and check rotating

torque with torque wrench. Specifications for new

joints are 9 lbs. ft. If torque readings are exces-

sively high or low, replace ball joint.

Removal

1.

While vehicle weight is still on front wheels, position

support between upper control arm and frame side

rail (fig. 15).

2.

Raise vehicle and remove cotter pin and nut from

lower ball joint stud (fig. 29).

3.

Disconnect stabilizer at upper link. Break loose the

lower ball stud. Drop lower control arm until lower

ball joint is easily accessible.

, 4. Using a large chisel, cut off the three ball joint re-

taining plate rivet heads. It may be necessary to

drill out rivet heads before chiseling.

NOTE: Additional support to lower control

arm will be necessary to perform this operation.

5.

Remove ball joint from arm and clean arm.

6. Inspect ball joint seat and rivet holes for evidence of

fatigue such as cracking or bending. If defects are

evident, replace lower control arm as outlined later

in this section.

Installation

1.

Install ball joint in arm using special bolts furnished

with replacement kit.

NOTE: Use only special hardened bolts fur-

nished with this replacement kit. Do not attempt

to use other non-hardened bolts and do not at-

tempt to rivet replacement ball joint to arm.

Fig.

29- Disassembling Lower Ball Stud - Chevy

CHEVROLET CHASSIS SERVICE MANUAL

Page 183 of 659

FRONT

SUSPENSION 3-19

spacer between upper control arm and frame side

rail (fig. 15). Raise vehicle.

2.

Remove lower control arm ball stud cotter pin and

loosen hut.

3.

Loosen ball stud and remove nut. Drop lower control

arm.

CAUTION: Use extreme care not to damage

the seal during this operation? "~~~~

4.

Mark lower control arm pivot bolt and adjusting cam

for realignment. Remove nut securing pivot bolt and

cam assembly. Remove pivot bolt and cam. Remove

lower control arm.

Installation

1.

Insert lower control arm into its support bracket,

index pivot bolt and cams, pivot nut and tighten to

torque shown in Specifications.

2.

Raise lower control arm ball stud into steering

knuckle boss and install nut. Tighten nut to torque

shown in Specifications and insert new cotter pin.

3.

Lower vehicle and remove upper control arm to

frame support.

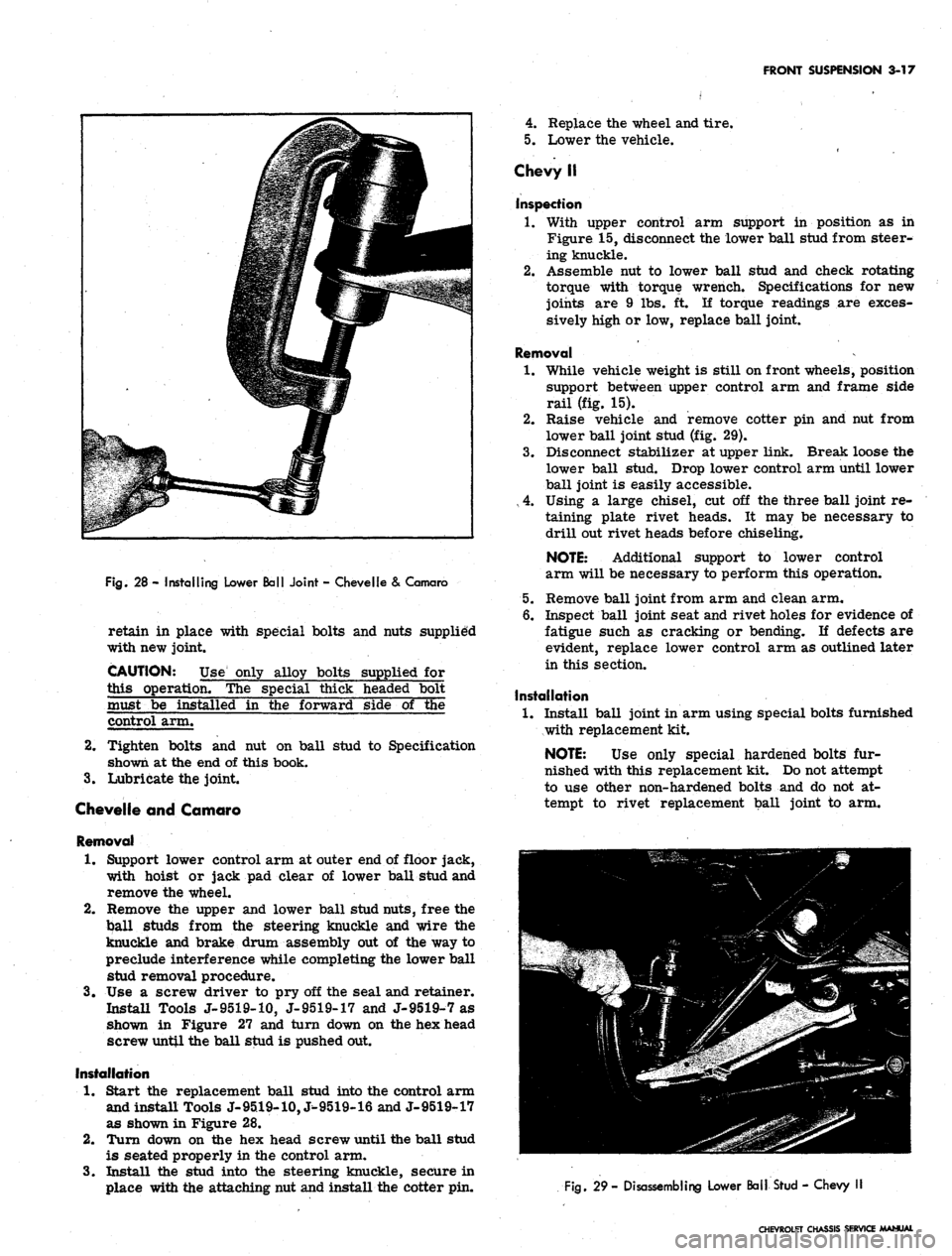

Corvette (Fig. 30)

Removal

1.

Remove the front coil spring as outlined under

"Front Spring, Removal".

2.

Remove the two front cross shaft to frame attaching

bolts and lock washers and the rear frame attaching

nut and lock washer.

3.

Remove the lower control arm assembly from the

vehicle.

THRUST

BEARING

FLAT

WASHER

REMOVAL

J-21878

J-21830-7

J-21058-8

J-21474-8

/J-21058-15

J-9519-17

J-21830-7

INSTALLATION

J-21058-15

J-2/878 FLAT

REMOVAL

BUSHING

INSTALLATION

BUSHING

CONTROL

J22175

THRUST

ARM

^ ,. / BEARING

Fig.

32 - Lower Control Arm Bushing - Large - Chevelle & Comoro

Installation

1.

Place the control arm so that the cross shaft aligns

with its attaching points.

2.

Attach the cross shaft at the front with two bolts and

lock washers inserted from below into the anchor

BUSHING

REMOVAL

J21474-6

J21474-5

TTf\ ft^\- NUT

BOLT

VHRUST

^22323-^ J21058"8

J21058-15

REARING, / ^_ ^

J21474-13

INSTALLATION

Fig.

31 - Lower Control Arm Bushing - Chevrolet

Fig.

33 - Lower Control Arm Bushing - Small -

Chevelle

& Comoro

CHEVROLET CHASSIS SERVICE MANUAL

Page 195 of 659

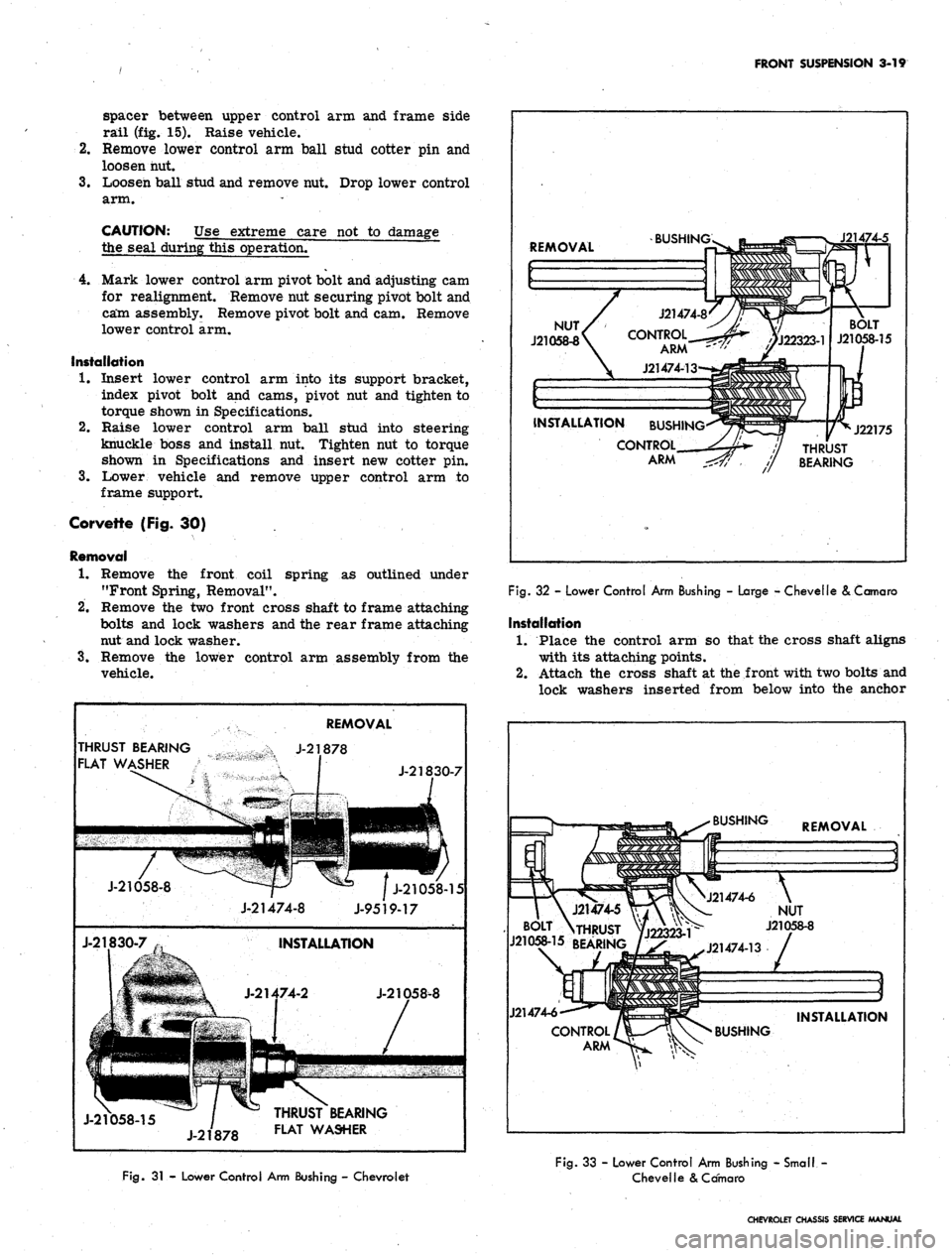

REAR SUSPENSION AND DRIVE LINE 4-5

Fig.

6—Measuring Rear Riding Height (Chevrolet and Chevelle)

RIDING HEIGHT CHECK

(Chevrolet, Chevelle Camaro and Chevy II)

In case of vehicle riding height complaints, a spring

height check will show if the rear suspension is at the

right height.

1.

Position car on smooth level floor.

2.

Vehicle must be at curb weight (full gas tank, no

passengers, spare and jack in trunk). Car should be

raised up a few times to allow suspension to settle

with car weight to eliminate friction at arm pivots.

3.

On Chevrolet and Chevelle models, measure riding

Fig.

8—Measuring Rear Riding Height (Camaro)

height as the distance from the top of the axle hous-

ing to frame kick-up (fig. 6).

4.

On Chevy II models, measure riding height as the

distance from lower surface of bumper support

bracket to top of axle housing (fig. 7).

5.

On Camaro models measure riding height as the

distance from jounce bumper upper attaching bolt to

top of axle housing (fig. 8).

6. Riding heights vary between models* Refer to speci-

fications section for vehicle and model application.

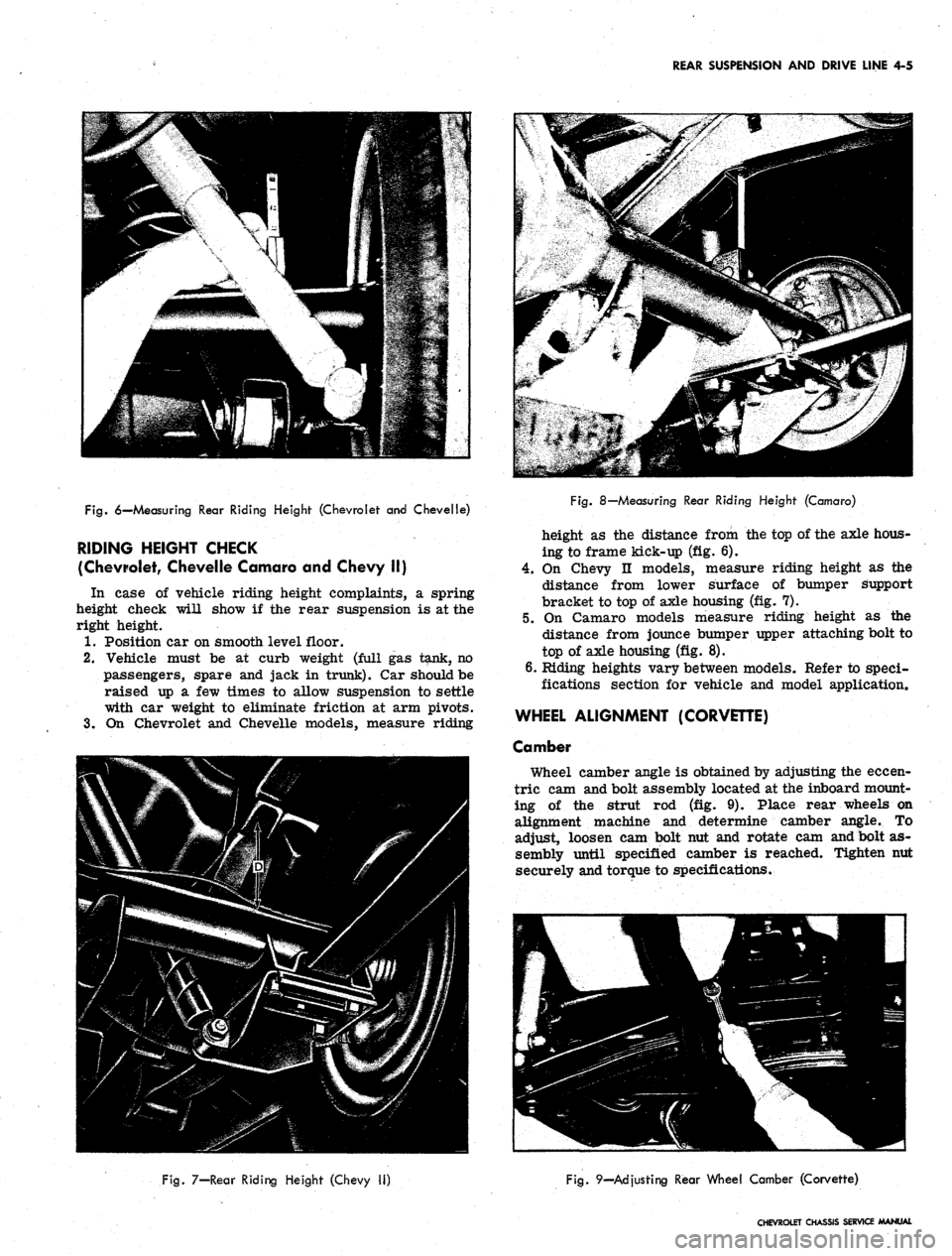

WHEEL ALIGNMENT (CORVETTE)

Camber

Wheel camber angle is obtained by adjusting the eccen-

tric cam and bolt assembly located at the inboard mount-

ing of the strut rod (fig. 9). Place rear wheels on

alignment machine and determine camber angle. To

adjust, loosen cam bolt nut and rotate cam and bolt as-

sembly until specified camber is reached. Tighten nut

securely and torque to specifications.

Fig.

7—Rear Riding Height (Chevy II)

Fig.

9—Ad

justing

Rear Wheel Camber (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 199 of 659

REAR SUSPENSION AND DRIVE LINE 4-9

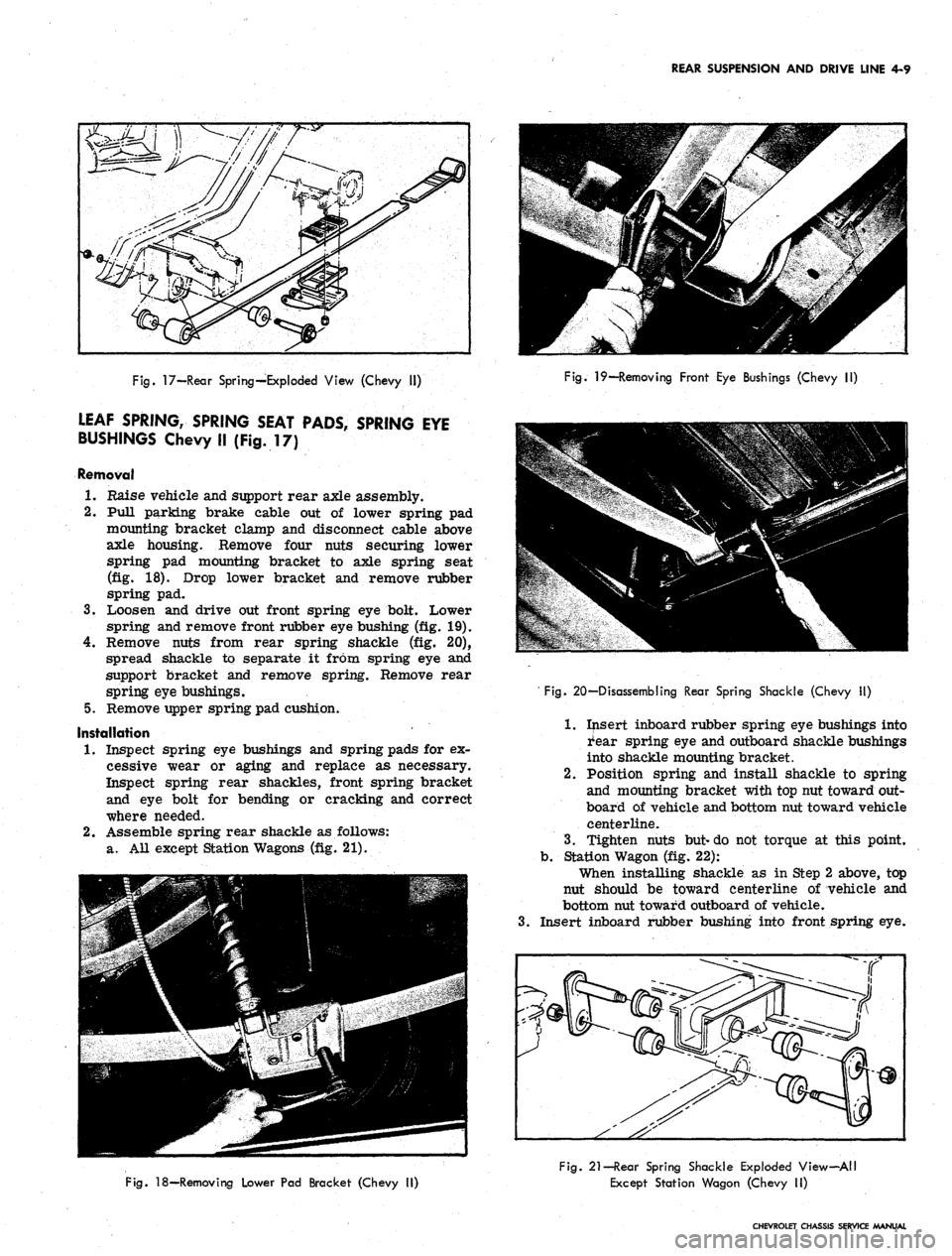

Fig.

17—Rear Spring—Exploded View (Chevy II)

LEAF SPRING, SPRING SEAT PADS, SPRING EYE

BUSHINGS Chevy II (Fig. 17)

Removal

1.

Raise vehicle and support rear axle assembly.

2.

Pull parking brake cable out of lower spring pad

mounting bracket clamp and disconnect cable above

axle housing. Remove four nuts securing lower

spring pad mounting bracket to axle spring seat

(fig. 18). Drop lower bracket and remove rubber

spring pad.

3.

Loosen and drive out front spring eye bolt. Lower

spring and remove front rubber eye bushing (fig. 19).

4.

Remove nuts from rear spring shackle (fig. 20),

spread shackle to separate it from spring eye and

support bracket and remove spring. Remove rear

spring eye bushings.

5.

Remove upper spring pad cushion.

Installation

1.

Inspect spring eye bushings and spring pads for ex-

cessive wear or aging and replace as necessary.

Inspect spring rear shackles, front spring bracket

and eye bolt for bending or cracking and correct

where needed.

2.

Assemble spring rear shackle as follows:

a. All except Station Wagons (fig. 21).

Fig.

19—Removing Front Eye Bushings (Chevy II)

3.

' Fig. 20—Disassembling Rear Spring Shackle (Chevy II)

1.

Insert inboard rubber spring eye bushings into

i'ear spring eye and outboard shackle bushings

into shackle mounting bracket.

2.

Position spring and install shackle to spring

and mounting bracket with top nut toward out-

board of vehicle and bottom nut toward vehicle

centerline.

3.

Tighten nuts but-do not torque at this point,

b.

Station Wagon (fig. 22):

When installing shackle as in Step 2 above, top

nut should be toward centerline of vehicle and

bottom nut toward outboard of vehicle.

Insert inboard rubber bushing into front spring eye.

Fig.

18—Removing Lower Pad Bracket (Chevy II)

Fig.

21—Rear Spring Shackle Exploded View-All

Except Station Wagon (Chevy II)

CHEVROLET CHASSIS SERVICE MANUAL

Page 200 of 659

REAR SUSPENSION AND DRIVE LINE 4-10

Fig.

22—Rear Spring Shackle Exploded View—Station Wagon

(Chevy II)

4.

Place upper spring pad cushion on spring. Raise

spring, making sure spring cushion ribs index with

locating ribs in axle housing spring seat, and insert

spring front eye and bushing in frame bracket. In-

stall spring eye bolt, bushing, retainer, lock washer

and nut. Do not torque at this point.

5.

Place lower spring pad cushion on spring, indexing

it over locating dowel.

NOTE: Upper pad correctly installed when

aligned with lower pad.

6. Place lower mounting plate into position over lo-

cating dowel on spring pad, install four locknuts and

insert shock absorber lower eye bolt.

7.

Remove adjustable jackstands, lower vehicle to floor

and bounce several times. Torque all affected parts

to specifications. Incorrect bushing preload may

result if spring eye bolts are torqued prior to

lowering vehicle.

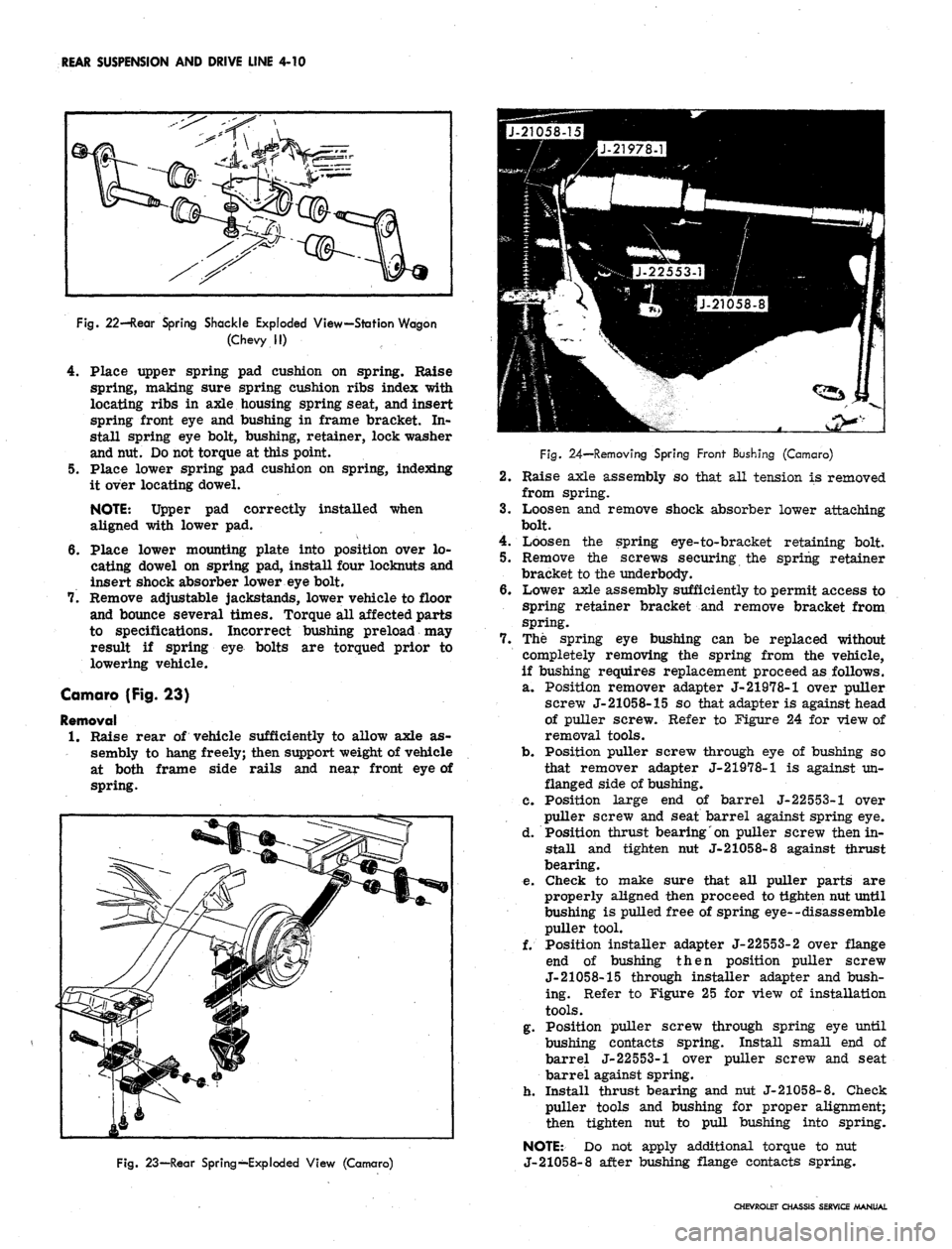

Camaro (Fig. 23)

Removal

1.

Raise rear of vehicle sufficiently to allow axle as-

sembly to hang freely; then support weight of vehicle

at both frame side rails and near front eye of

spring.

Fig.

23—Rear Spring—Exploded View (Camaro)

Fig.

24—Removing Spring Front Bushing (Camaro)

2.

Raise axle assembly so that all tension is removed

from spring.

3.

Loosen and remove shock absorber lower attaching

bolt.

4.

Loosen the spring eye-to-bracket retaining bolt.

5.

Remove the screws securing the spring retainer

bracket to the underbody.

6. Lower axle assembly sufficiently to permit access to

spring retainer bracket and remove bracket from

spring.

7.

The spring eye bushing can be replaced without

completely removing the spring from the vehicle,

if bushing requires replacement proceed as follows.

a. Position remover adapter J-21978-1 over puller

screw J-21058-15 so that adapter is against head

of puller screw. Refer to Figure 24 for view of

removal tools.

b.

Position puller screw through eye of bushing so

that remover adapter J-21978-1 is against un-

flanged side of bushing.

C. Position large end of barrel J-22553-1 over

puller screw and seat barrel against spring eye.

d. Position thrust bearing on puller screw then in-

stall and tighten nut J-21058-8 against thrust

bearing.

e. Check to make sure that all puller parts are

properly aligned then proceed to tighten nut until

bushing is pulled free of spring eye--disassemble

puller tool.

f. Position installer adapter J-22553-2 over flange

end of bushing then position puller screw

J-21058-15 through installer adapter and bush-

ing. Refer to Figure 25 for view of installation

tools.

g. Position puller screw through spring eye until

bushing contacts spring. Install small end of

barrel J-22553-1 over puller screw and seat

barrel against spring.

h. Install thrust bearing and nut J-21058-8. Check

puller tools and bushing for proper alignment;

then tighten nut to pull bushing into spring.

NOTE: Do not apply additional torque to nut

J-21058-8 after bushing flange contacts spring.

CHEVROLET CHASSIS SERVICE MANUAL

Page 201 of 659

REAR SUSPENSION AND DRIVE LINE 4-11

lower cushion

correct.

will be aligned if installation is

Fig.

25—Installing Spring Front Bushing (Camaro)

Unnecessary torque applied after flange is

seated will tend to distort flange and reposition

bushing in spring.

i. Disassemble bushing installation tools and re-

move from spring.

8. Pry parking brake cable out of the retainer bracket

mounted on the spring mounting plate.

9. Remove spring bracket-to-axle bracket retaining

nuts,

remove upper and lower rubber spring pads

and bracket.

10.

Support spring, then remove lower bolt from spring

rear shackle. Separate shackle and withdraw spring

from vehicle.

11.

Remove rear spring shackle upper bolt and withdraw

shackle bushings from frame.

Installation

1.

Position spring front mounting bracket to spring

front eye. Spring attaching bolt must be installed

so that head of bolt is toward center of vehicle.

2.

Position spring shackle upper bushings in frame,

position shackles to bushings and loosely install

bolt and nut.

3.

Install bushing halves in spring rear eye, place

spring to shackles and loosely install shackle lower

bolt and nut.

NOTE: When installing spring, make sure

spring is positioned so that parking brake cable

is on underside of spring.

4.

Raise front end of spring and position bracket to

underbody. Guide spring into position so that it will

index in the axle bracket and also make sure that

the tab on spring bracket is indexed in slot pro-

vided in the underbody.

5.

Loosely install spring-to-underbody bracket.

6. Position spring upper cushion between spring and

axle bracket so that spring cushion ribs align with

axle bracket locating ribs.

7.

Place lower spring cushion on spring so that .cushion

is indexed on locating dowel. Upper cushion and

8. Place lower mounting plate over locating dowel on

spring lower pad and loosely install retaining nuts.

9. If new mounting plate was installed, transfer parking

brake cable retaining bracket to new plate.

10.

Position shock absorber to spring mounting plate and

loosely install eye bolt and nut - head of bolt should

be toward front of vehicle.

11.

Position parking brake cable in retaining bracket and

securely clamp bracket to retain cable.

12.

Remove stand jacks and lower vehicle so that weight

of vehicle rests on suspension components. Torque

all affected parts to specifications.

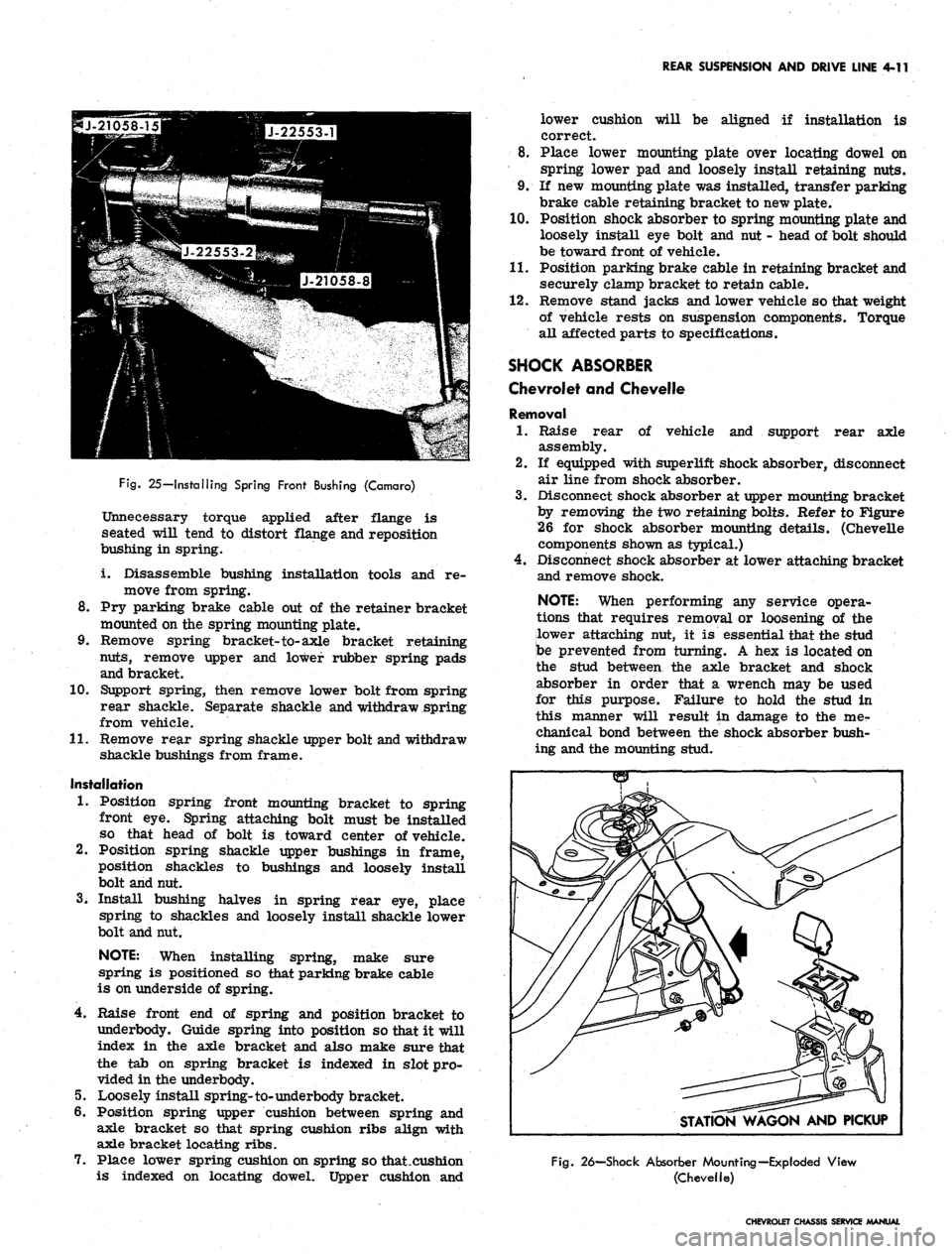

SHOCK ABSORBER

Chevrolet and Chevelle

Removal

1.

Raise rear of vehicle and support rear axle

assembly.

If equipped with superlift shock absorber, disconnect

air line from shock absorber.

Disconnect shock absorber at upper mounting bracket

by removing the two retaining bolts. Refer to Figure

26 for shock absorber mounting details. (Chevelle

components shown as typical.)

Disconnect shock absorber at lower attaching bracket

and remove shock.

NOTE: When performing any service opera-

tions that requires removal or loosening of the

lower attaching nut, it is essential that the stud

be prevented from turning. A hex is located on

the stud between the axle bracket and shock

absorber in order that a wrench may be used

for this purpose. Failure to hold the stud in

this manner will result in damage to the mer

chanical bond between the shock absorber bush-

ing and the mounting stud.

2.

3.

STATION WAGON AND PICKUP

Fig.

26—Shock Absorber Mounting—Exploded View

(Chevelle)

CHEVROLET CHASSIS SERVICE MANUAL

Page 203 of 659

REAR SUSPENSION AND DRIVE LINE 4-13

Fig.

29—Shock Absorber Mounting—Exploded View (Comoro)

crossmember.

3.

Separate the control arm bracket from the cross-

member. Remove the arm from under vehicle.

4.

Remove the bolt, nut and washer attaching the upper

control arm to the bracket. Separate the control

arm from the bracket.

Bushing Replacement

1.

Clamp control arm securely in a vise and remove

bracket from forward end of arm.

2.

Place Puller Screw J-21058-15 through Puller

Adapter J-21830-2. Position puller screw through

small end of bushing then install Receiver J-21830-4

and Bridge J-21830-7 over opposite end of bushing.

Center receiver and bridge over flanged end of

bushing then position thrust bearing and Nut

J-21058-8 on puller screw. Refer to Figure 31 for

installation of removal tools.

3.

Turn Nut J-21058-8 to withdraw bushing, making

sure Remover Adapter J-21830-2 is centered and

will clear hole in control arm.

4.

Disassemble puller tools and position Installer

Adapter J-21830-2 on flanged end of new bushing.

Install Spacer J-21830-6 over small end of bushing

so that it makes contact with J-21830-2.

Fig.

30—Rear Suspension Upper Control Arm

Attaching Points (Chevrolet)

Position Puller Screw J-21058-15 through J-21830-2

and bushing so that head of screw rests against

J-21830-2. Position this assembly in control arm

as shown in Figure 32.

Install receiver, bridge, thrust bearing and nut to

complete installation as shown in Figure 32.

Turn Nut J-21058-8 to pull bushing into control

arm. Check position of bushing when installing to

make sure bushing is properly aligned. When bush-

ing is properly installed, Spacer J-21830-6 will stop

against control arm.

Disassemble bushing installation tools and reinstall

attaching bracket to control arm. Install bracket

pivot bolt so that nut will be on outboard side of arm.

Fig.

31—Upper Control Arm Bushing Removal (Chevrolet)

CHEVROLET CHASSIS SERVICE MANUAL

Page 207 of 659

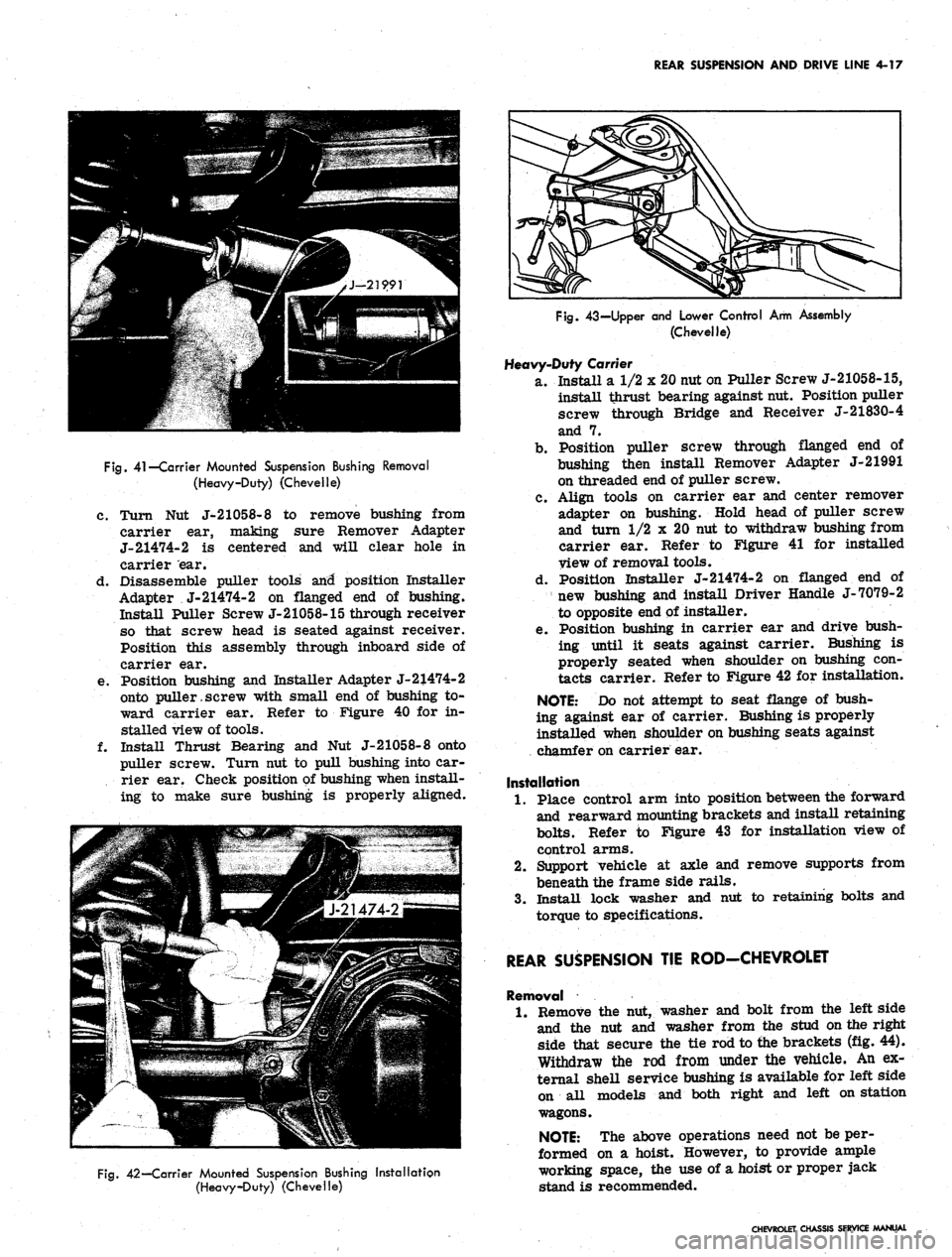

REAR SUSPENSION AND DRIVE LINE 4-17

Fig.

41—Carrier Mounted Suspension Bushing Removal

(Heavy-Duty) (Chevelle)

c. Turn Nut J-21058-8 to remove bushing from

carrier ear, making sure Remover Adapter

J-21474-2 is centered and will clear hole in

carrier ear.

d. Disassemble puller tools and position Installer

Adapter J-

21474-

2 on flanged end of bushing.

Install Puller Screw J-21058-15 through receiver

so that screw head is seated against receiver.

Position this assembly through inboard side of

carrier ear.

e. Position bushing and Installer Adapter J-21474-2

onto puller.screw with small end of bushing to-

ward carrier ear. Refer to Figure 40 for in-

stalled view of tools.

f. Install Thrust Bearing and Nut J-21058-8 onto

puller screw. Turn nut to pull bushing into car-

rier ear. Check position of bushing when install-

ing to make sure bushing is properly aligned.

b.

c.

d.

Fig.

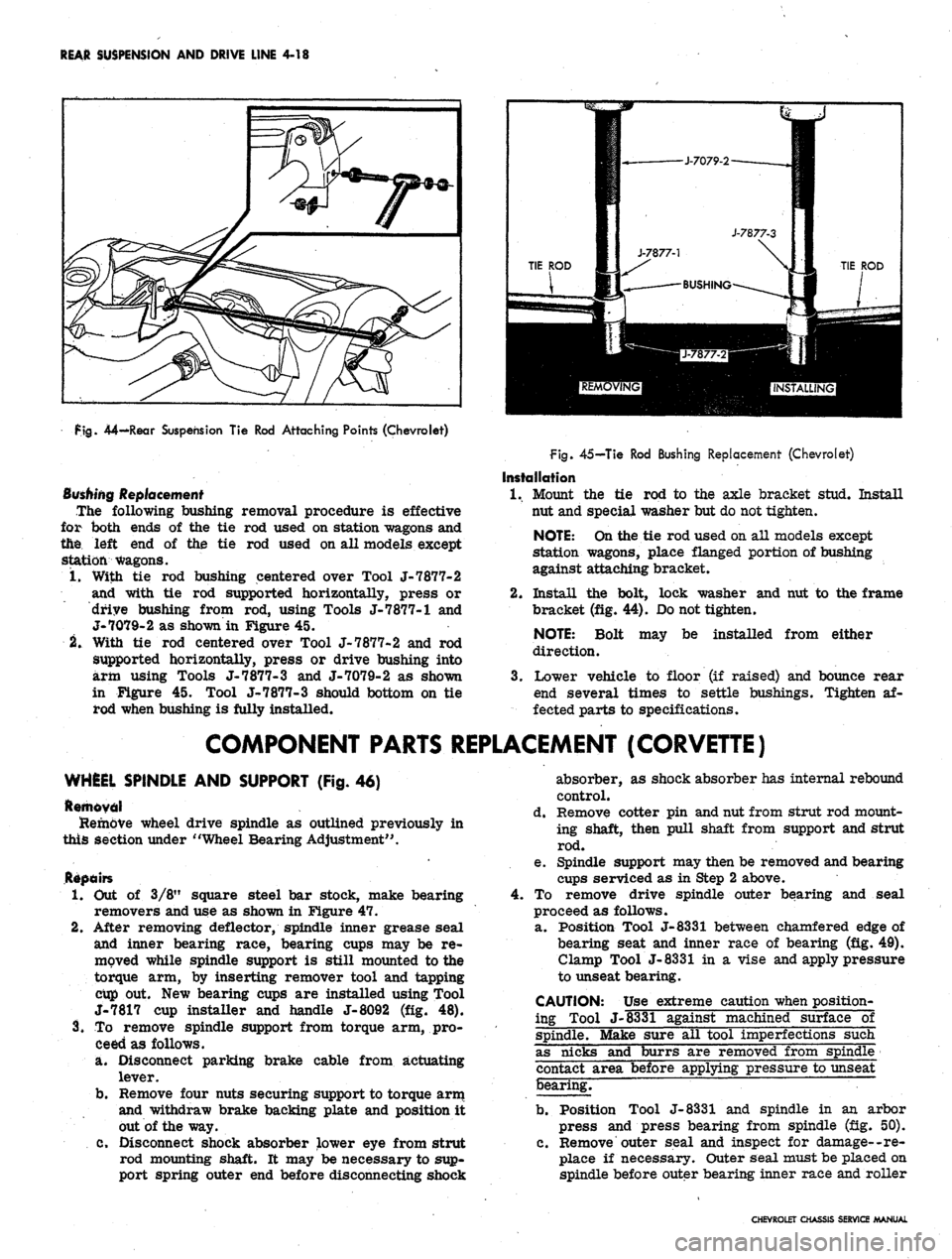

43—Upper and Lower Control Arm Assembly

(Chevelle)

Heavy-Duty

Carrier

a. Install a 1/2 x 20 nut on Puller Screw J-21058-15,

install thrust bearing against nut. Position puller

screw through Bridge and Receiver J-21830-4

and 7.

Position puller screw through flanged end of

bushing then install Remover Adapter J-21991

on threaded end of puller screw.

Align tools on carrier ear and center remover

adapter on bushing. Hold head of puller screw

and turn 1/2 x 20 nut to withdraw bushing from

carrier ear. Refer to Figure 41 for installed

view of removal tools.

Position Installer J-21474-2 on flanged end of

new bushing and install Driver Handle J-7079-2

to opposite end of installer.

e. Position bushing in carrier ear and drive bush-

ing until it seats against carrier. Bushing is

properly seated when shoulder on bushing con-

tacts carrier. Refer to Figure 42 for installation.

NOTE:

Do not attempt to seat flange of bush-

ing against ear of carrier. Bushing is properly

installed when shoulder on bushing seats against

chamfer on carrier ear.

Installation

1.

Place control arm into position between the forward

and rearward mounting brackets and install retaining

bolts.

Refer to Figure 43 for installation view of

control arms.

Support vehicle at axle and remove supports from

beneath the frame side rails.

Install lock washer and nut to retaining bolts and

2.

3.

torque to specifications.

Fig.

42—Carrier Mounted Suspension Bushing Installation

(Heavy-Duty) (Chevelle)

REAR SUSPENSION TIE ROD-CHEVROLET

Removal

1.

Remove the nut, washer and bolt from the leftside

and the nut and washer from the stud on the right

side that secure the tie rod to the brackets (fig. 44).

Withdraw the rod from under the vehicle. An ex-

ternal shell service bushing is available for left side

on all models and both right and left on station

wagons.

NOTE:

The above operations need not be per-

formed on a hoist. However, to provide ample

working space, the use of a hoist or proper jack

stand is recommended.

CHEVROLET CHASSIS SERVICE MANUAL

Page 208 of 659

REAR SUSPENSION AND DRIVE LINE 4-18

ig.

44—Rear Suspension Tie Rod Attaching Points (Chevrolet)

Bushing

Replacement

The following bushing removal procedure is effective

for both ends of the tie rod used on station wagons and

the left end of the tie rod used on all models except

station wagons.

1,

With tie rod bushing centered over Tool J-7877-2

and with tie rod supported horizontally, press or

drive bushing from rod, using Tools J-7877-1 and

J-7079-2 as shown in Figure 45.

2.

With tie rod centered over Tool J-7877-2 and rod

supported horizontally, press or drive bushing into

arm using Tools J-7877-3 and J-7079-2 as shown

in Figure 45. Tool J-7877-3 should bottom on tie

rod when bushing is fully installed.

fig.

45—Tie Rod Bushing Replacement (Chevrolet)

Installation

1.

Mount the tie rod to the axle bracket stud. Install

nut and special washer but do not tighten.

NOTE:

On the tie rod used on all models except

station wagons, place flanged portion of bushing

against attaching bracket.

2.

Install the bolt, lock washer and nut to the frame

bracket (fig. 44). Do not tighten.

NOTE:

Bolt may be installed from either

direction.

3.

Lower vehicle to floor (if raised) and bounce rear

end several times to settle bushings. Tighten af-

fected parts to specifications.

COMPONENT PARTS REPLACEMENT (CORVETTE)

WHEEL SPINDLE AND SUPPORT (Fig. 46)

Removal

Hemdve wheel drive spindle as outlined previously in

this section under "Wheel Bearing Adjustment".

Repairs

Out of 3/8" square steel bar stock, make bearing

removers and use as shown in Figure 47.

After removing deflector, spindle inner grease seal

and inner bearing race, bearing cups may be re-

moved while spindle support is still mounted to the

torque arm, by inserting remover tool and tapping

cup out. New bearing cups are installed using Tool

J-7817 cup installer and handle J-8092 (fig. 48).

To remove spindle support from torque arm, pro-

ceed as follows.

a. Disconnect parking brake cable from actuating

lever.

b.

Remove four nuts securing support to torque arm

and withdraw brake backing plate and position it

out of the way.

c. Disconnect shock absorber lower eye from strut

rod mounting shaft. It may be necessary to sup-

port spring outer end before disconnecting shock

absorber, as shock absorber has internal rebound

control.

d. Remove cotter pin and nut from strut rod mount-

ing shaft, then pull shaft from support and strut

rod.

e. Spindle support may then be removed and bearing

cups serviced as in Step 2 above.

4.

To remove drive spindle outer bearing and seal

proceed as follows.

a. Position Tool J-8331 between chamfered edge of

bearing seat and inner race of bearing (fig. 49).

Clamp Tool J-8331 in a vise and apply pressure

to unseat bearing.

CAUTION: Use extreme caution when position-

ing Tool J-8331 against machined surface of

spindle. Make sure all tool imperfections such

as nicks and burrs are removed from spindle

contact area before applying pressure to unseat

bearing.

b.

Position Tool J-8331 and spindle in an arbor

press and press bearing from spindle (fig. 50).

c. Remove outer seal and inspect for damage--re-

place if necessary. Outer seal must be placed on

spindle before outer bearing inner race and roller

CHEVROLET CHASSIS SERVICE MANUAL