ECU CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 212 of 659

REAR SUSPENSION AND DRIVE LINE 4-22

Fig.

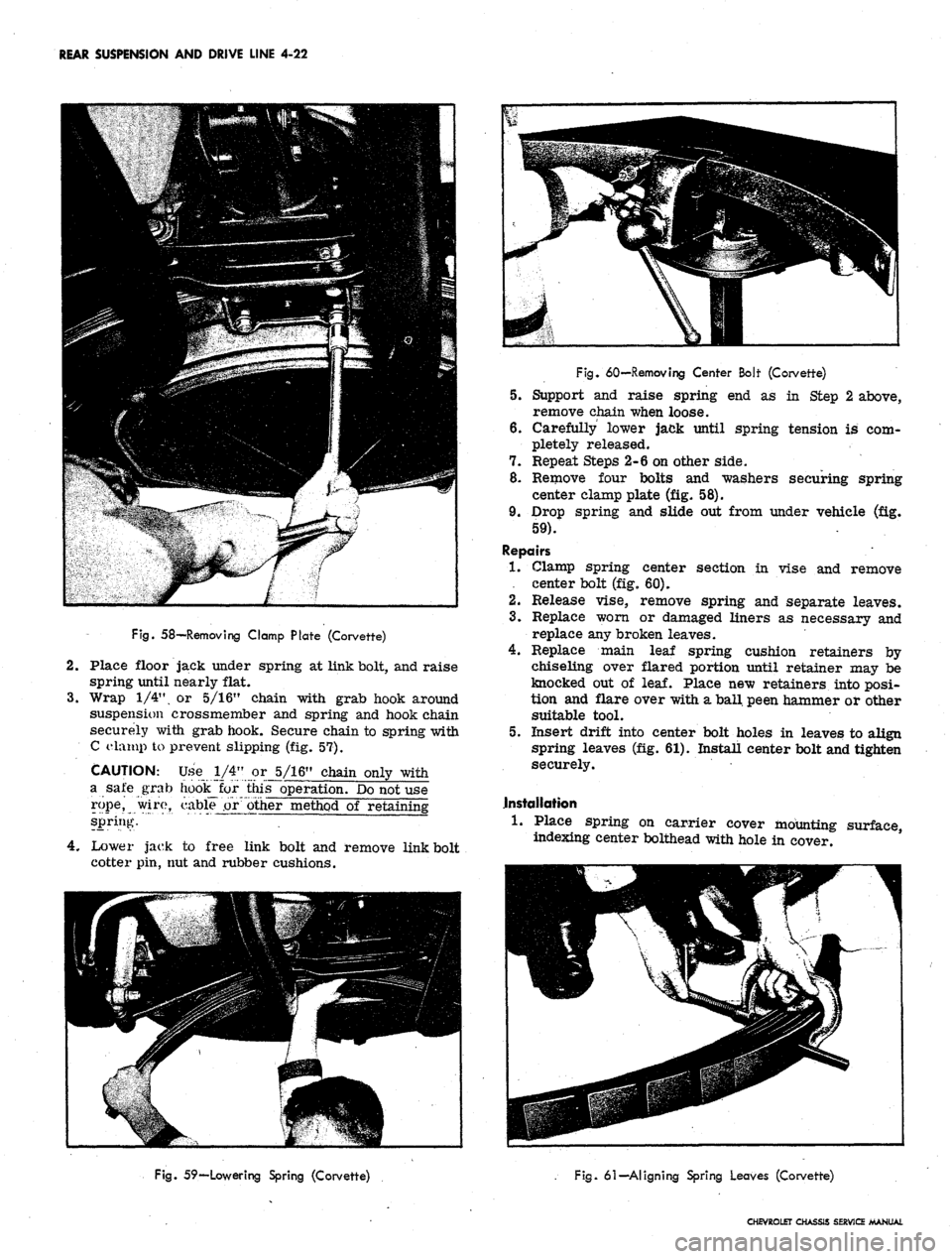

58—Removing Clamp Plate (Corvette)

2.

Place floor jack under spring at link bolt, and raise

spring until nearly flat.

3.

Wrap 1/4", or 5/16" chain with grab hook around

suspension crossmember and spring and hook chain

securely with grab hook. Secure chain to spring with

C ela rnp to prevent slipping (fig. 57).

CAUTION: Use 1/4" or 5/16" chain only with

a sate grab hoo^for this operation. Do not use

rope,

wiro, cable .or other method of retaining

spring.

4.

Lower jack to free link bolt and remove link bolt

cotter pin, nut and rubber cushions.

Fig.

60—Removing Center Boit (Corvette)

5.

Support and raise spring end as in Step 2 above,

remove chain when loose.

6. Carefully lower jack until spring tension is com-

pletely released.

7.

Repeat Steps 2-6 on other side.

8. Remove four bolts and washers securing spring

center clamp plate (fig. 58).

9. Drop spring and slide out from under vehicle (fig.

59).

Repairs

•1.

Clamp spring center section in vise and remove

. center bolt (fig. 60).

2.

Release vise, remove spring and separate leaves.

3.

Replace worn or damaged liners as necessary and

replace any broken leaves.

4.

Replace main leaf spring cushion retainers by

chiseling over flared portion until retainer may be

knocked out of

leaf.

Place new retainers into posi-

tion and flare over with a ball peen hammer or other

suitable tool.

5.

Insert drift into center bolt holes in leaves to align

spring leaves (fig. 61). Install center bolt and tighten

securely.

installation

1.

Place spring on carrier cover mounting surface,

indexing center bolthead with hole in cover.

Fig.

59—Lowering Spring (Corvette)

Fig.

61—-Aligning Spring Leaves (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 213 of 659

REAR SUSPENSION AND DRIVE LINE 4-23

Fig.

62—Torque Control Arm (Corvette)

2.

Place center clamp plate in position and install four

bolts and washers. Tighten bolts and torque to

specifications.

3.

Raise spring outer end with floor jack until spring

is nearly flat and secure with chain as in Step 3-

Removal.

.4.

Lower jack, align torque control arm with spring

end and insert link bolt, rubber cushions and re-

tainers. Install castellated nut on link bolt and

tighten until cotter pin hole in bolt is visible. In-

sert new cotter pin and bend ends around.

5. Raise spring end with jack under link bolt, and re-

move chain and C clamp when loose.

6. Carefully lower jack, making sure rubber cushions

remain indexed in retainers.

7. Remove jack and repeat on opposite side. Install

wheels and tires, remove frame supports and lower

vehicle to floor.

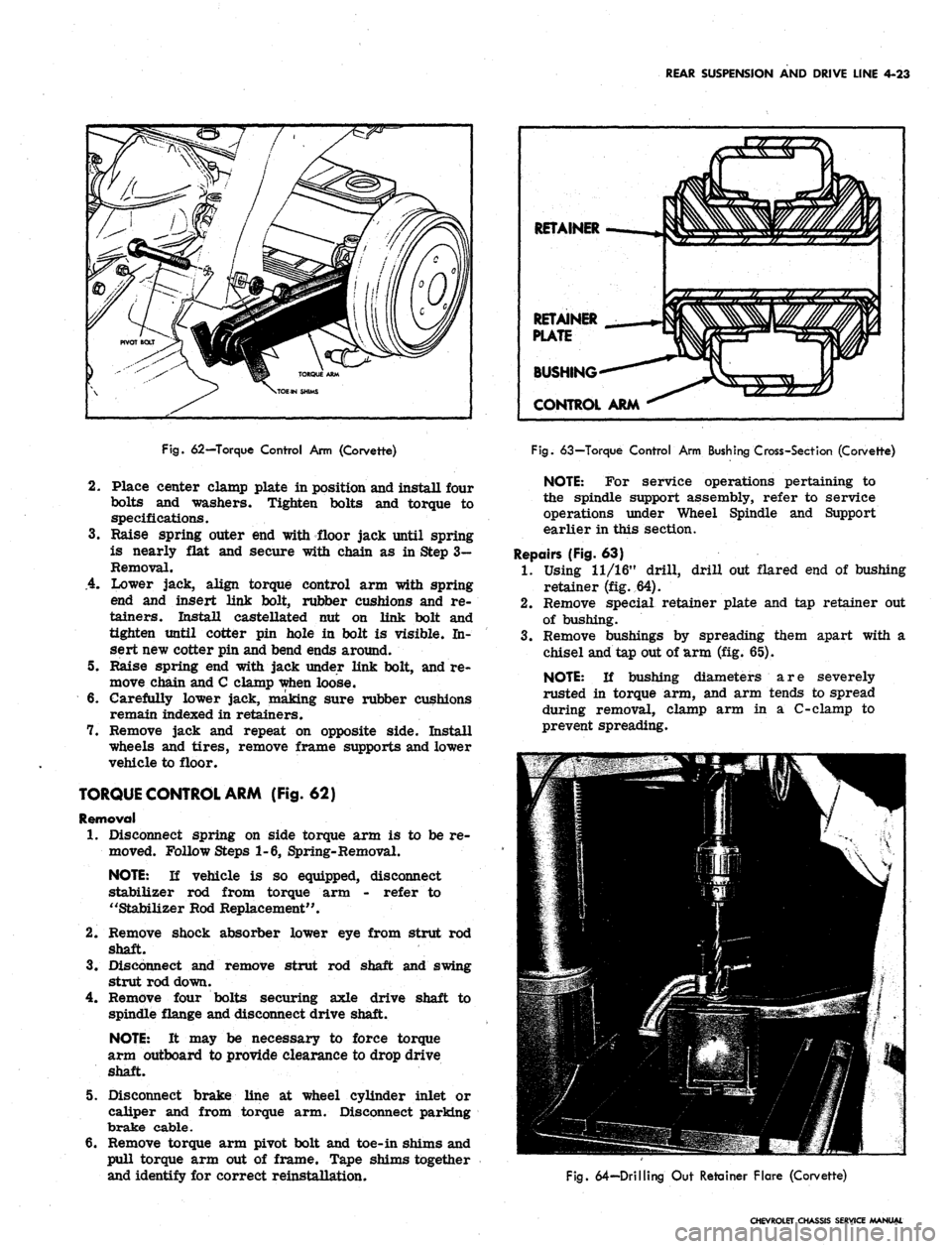

TORQUE CONTROL ARM (Fig. 62)

Removal

1.

Disconnect spring on side torque arm is to be re-

moved. Follow Steps 1-6, Spring-Removal.

NOTE:

If vehicle is so equipped, disconnect

stabilizer rod from torque arm - refer to

"Stabilizer Rod Replacement".

2.

Remove shock absorber lower eye from strut rod

shaft.

3.

Disconnect and remove strut rod shaft and swing

strut rod down.

4.

Remove four bolts securing axle drive shaft to

spindle flange and disconnect drive shaft.

NOTE:

It may be necessary to force torque

arm outboard to provide clearance to drop drive

shaft.

5. Disconnect brake line at wheel cylinder inlet or

caliper and from torque arm. Disconnect parking

brake cable.

6. Remove torque arm pivot bolt and toe-in shims and

pull torque arm out of frame. Tape shims together

and identify for correct reinstallation.

RETAINER

RETAINER

PLATE

BUSHING

CONTROL ARM

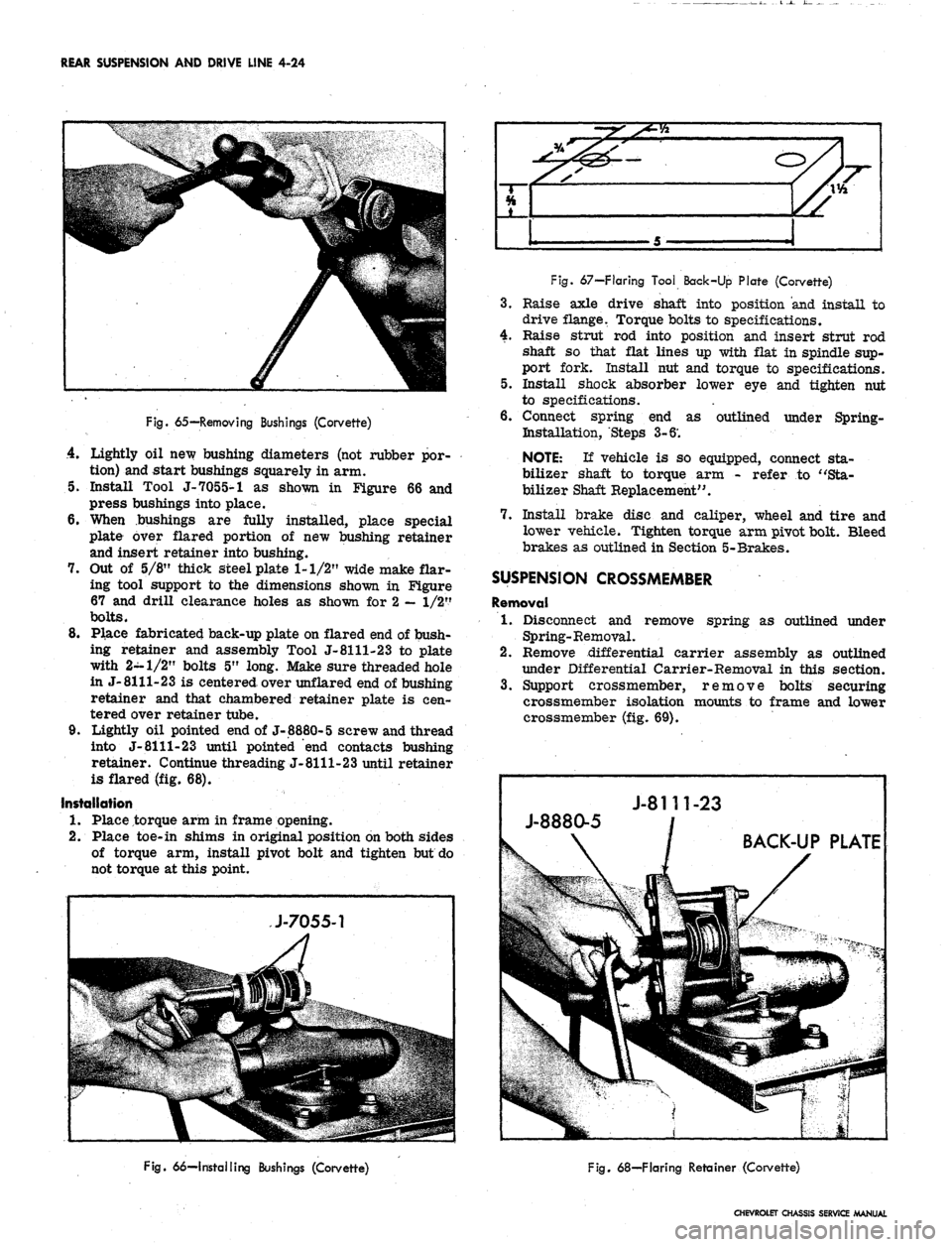

Fig.

63—Torque Control Arm Bushing Cross-Sect ion (Corvette)

NOTE:

For service operations pertaining to

the spindle support assembly, refer to service

operations under Wheel Spindle and Support

earlier in this section.

Repairs (Fig. 63)

1.

Using 11/16" drill, drill out flared end of bushing

retainer (fig. 64).

2.

Remove special retainer plate and tap retainer out

of bushing.

3.

Remove bushings by spreading them apart with a

chisel and tap out of arm (fig. 65).

NOTE:

If bushing diameters are severely

rusted in torque arm, and arm tends to spread

during removal, clamp arm in a C-clamp to

prevent spreading.

Fig.

64—Drilling Out Retainer Flare (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 214 of 659

REAR SUSPENSION AND DRIVE LINE 4-24

4

i*

5

Fig.

65—Removing Bushings (Corvette)

4.

Lightly oil new bushing diameters (not rubber por-

tion) and start bushings squarely in arm.

5. Install Tool J-7055-1 as shown in Figure 66 and

press bushings into place.

6. When bushings are fully installed, place special

plate over flared portion of new bushing retainer

and insert retainer into bushing.

7. Out of 5/8" thick steel plate 1-1/2" wide make flar-

ing tool support to the dimensions shown in Figure

67 and drill clearance holes as shown for 2

—

1/2"

bolts.

8. Place fabricated back-up plate on flared end of bush-

ing retainer and assembly Tool J-8111-23 to plate

with 2-1/2" bolts 5" long. Make sure threaded hole

in J-8111-23 is centered over unflared end of bushing

retainer and that chambered retainer plate is cen-

tered over retainer tube.

9. Lightly oil pointed end of J-8880-5 screw and thread

into J-

8111-23

until pointed "end contacts bushing

retainer. Continue threading J-8111-23 until retainer

is flared (fig. 68).

Installation

1.

Place torque arm in frame opening.

2.

Place toe-in shims in original position on both sides

of torque arm, install pivot bolt and tighten but do

not torque at this point.

Fig.

67—Flaring Tool Back-Up Plate (Corvette)

3.

Raise axle drive shaft into position and install to

drive flange. Torque bolts to specifications.

4.

Raise strut rod into position and insert strut rod

shaft so that flat lines up with flat in spindle sup-

port fork. Install nut and torque to specifications.

5. Install shock absorber lower eye and tighten nut

to specifications.

6. Connect spring end as outlined under Spring-

Bistallation, Steps 3-6'.

NOTE:

If vehicle is so equipped, connect sta-

bilizer shaft to torque arm - refer to "Sta-

bilizer Shaft Replacement".

7. Install brake disc and caliper, wheel and tire and

lower vehicle. Tighten torque arm pivot bolt. Bleed

brakes as outlined in Section 5-Brakes.

SUSPENSION CROSSMEMBER

Removal

1.

Disconnect and remove spring as outlined under

Spring-Removal.

2.

Remove differential carrier assembly as outlined

under Differential Carrier-Removal in this section.

3.

Support crossmember, remove bolts securing

crossmember isolation mounts to frame and lower

crossmember (fig. 69).

Fig.

66—Installing Bushings (Corvette)

Fig.

68—Flaring Retainer (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 215 of 659

REAR SUSPENSION AND DRIVE LINE 4-25

Fig.

69—Removing Crossmember (Corvette)

4.

Remove bolts securing carrier cover to cross-

member.

5.

Inspect rubber isolation mounts for aging and re-

place where necessary.

Repairs—Isolation Mount

1.

Bend back isolation mount tabs to allow mount re-

moval (fig. 70).

2.

Place crossmember on a suitable support and press

mount out of arm using a piece of suitable size pipe

or tubing on outer shell or inner insert.

3.

Place new mount into position on crossmember,

compress outer sleeve and press mount into place

until it is fully and squarely seated.

4.

After installation, bend over locking tabs.

Installation

1.

Install carrier cover to crossmember and torque

bolts to specifications.

2.

Raise crossmember into position and install mount-

ing bolts. Torque bolts to specifications.

3.

Install differential carrier assembly as outlined

under Differential Carrier

-

Installation in this

section.

4.

Install wheels and tires, remove frame supports and

lower vehicle.

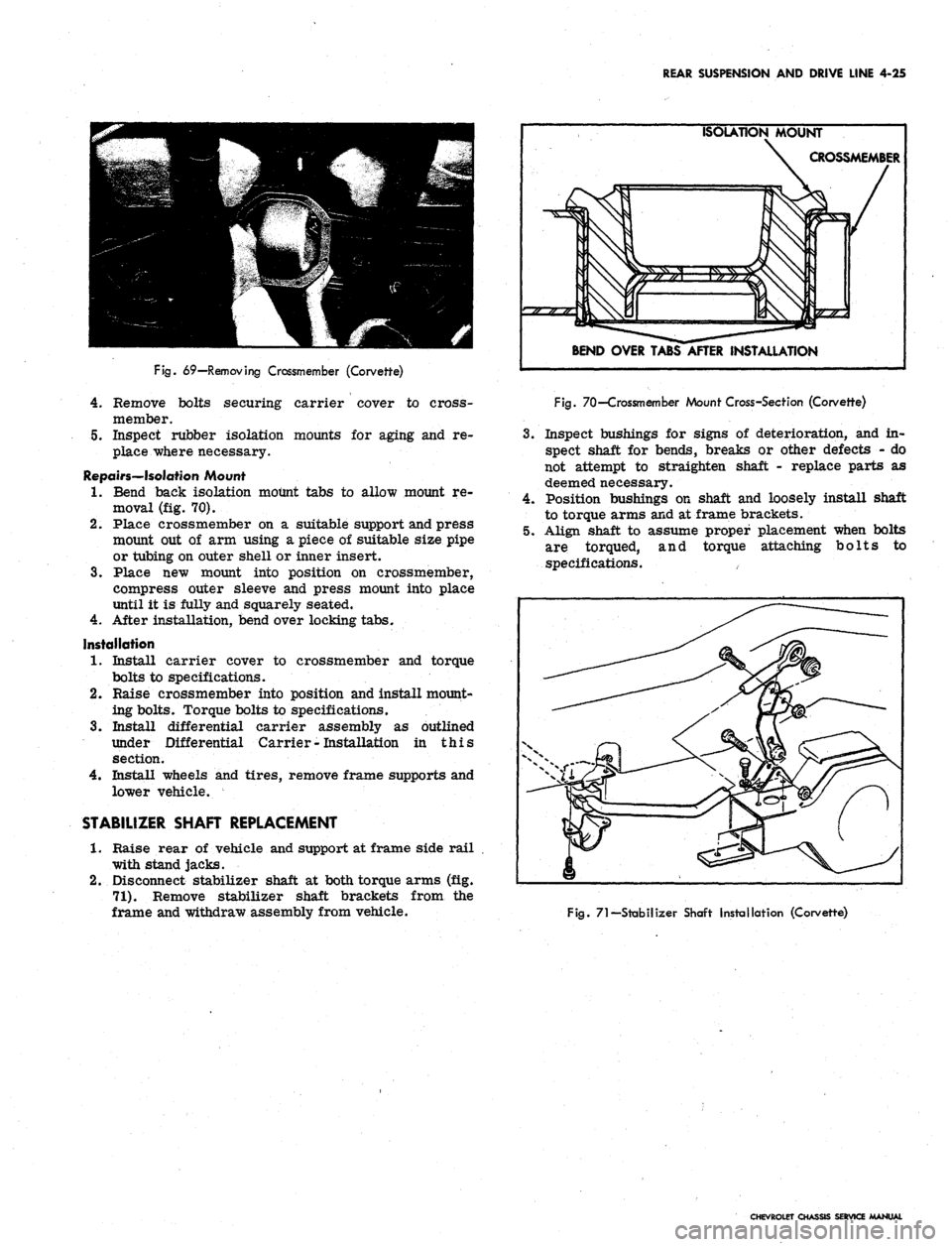

STABILIZER SHAFT REPLACEMENT

1.

Raise rear of vehicle and support at frame side rail

with stand jacks.

2.

Disconnect stabilizer shaft at both torque arms (fig.

71).

Remove stabilizer shaft brackets from the

frame and withdraw assembly from vehicle.

ISOLATION MOUNT

CROSSMEMBER

BEND OVER TABS AFTER INSTALLATION

Fig.

70—Crossmember Mount Cross-Section (Corvette)

3.

Inspect bushings for signs of deterioration, and in-

spect shaft for bends, breaks or other defects - do

not attempt to straighten shaft - replace parts as

deemed necessary.

4.

Position bushings on shaft and loosely install shaft

to torque arms and at frame brackets.

5.

Align shaft to assume proper placement when bolts

are torqued, and torque attaching bolts to

specifications.

Fig.

71—Stabilizer Shaft Installation (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 217 of 659

REAR SUSPENSION AND DRIVE LINE 4-27

SHIM AND

SERVICE

12

14

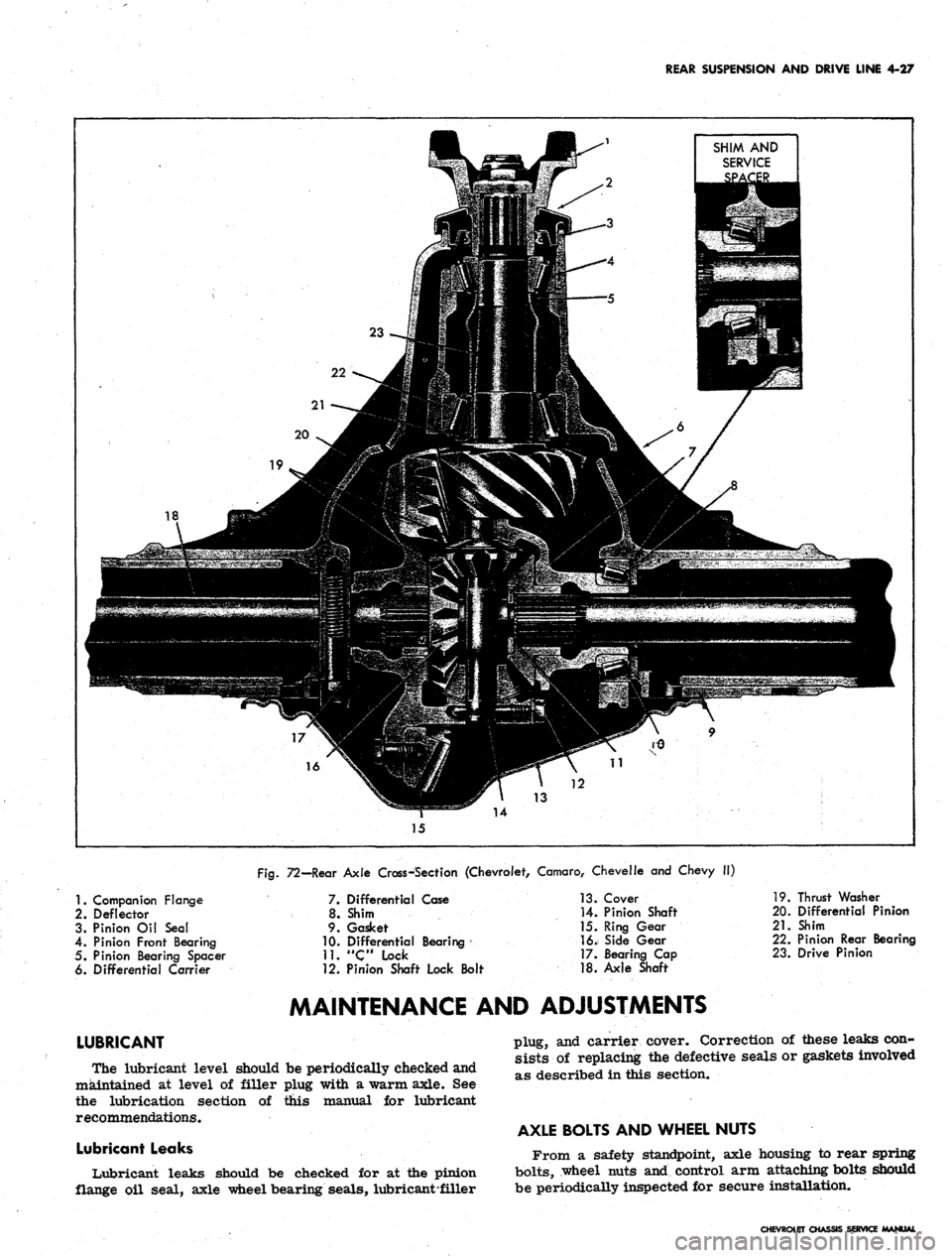

Fig.

72—Rear Axle Cross-Section (Chevrolet, Camaro, Chevelle and Chevy II)

1.

Companion Flange

2.

Deflector

3. Pinion Oil Seal

4.

Pinion Front Bearing

5. Pinion Bearing Spacer

6. Differential Carrier

LUBRICANT

7. Differential Case

8. Shim

9. Gasket

10.

Differential Bearing

11.

"Clock

12. Pinion Shaft Lock Bolt

13.

Cover

14.

Pinion Shaft

15.

Ring Gear

16.

Side Gear

17.

Bearing Cap

18.

Axle Shaft

19.

Thrust Washer

20.

Differential Pinion

21.

Shim

22.

Pinion Rear Bearing

23.

Drive Pinion

MAINTENANCE AND ADJUSTMENTS

The lubricant level should be periodically checked and

maintained at level of filler plug with a warm axle. See

the lubrication section of this manual for lubricant

recommendations.

Lubricant Leaks

Lubricant leaks should be checked for at the pinion

flange oil seal, axle wheel bearing seals, lubricant-filler

plug, and carrier cover. Correction of these leaks con-

sists of replacing the defective seals or gaskets involved

as described in this section.

AXLE BOLTS AND WHEEL NUTS

From a safety standpoint, axle housing to rear spring

bolts,

wheel nuts and control arm attaching bolts should

be periodically inspected for secure installation.

CHEVROLET CHASSIS SERVICE MANUAL

Page 220 of 659

REAR SUSPENSION AND DRIVE LINE 4-30

Fig.

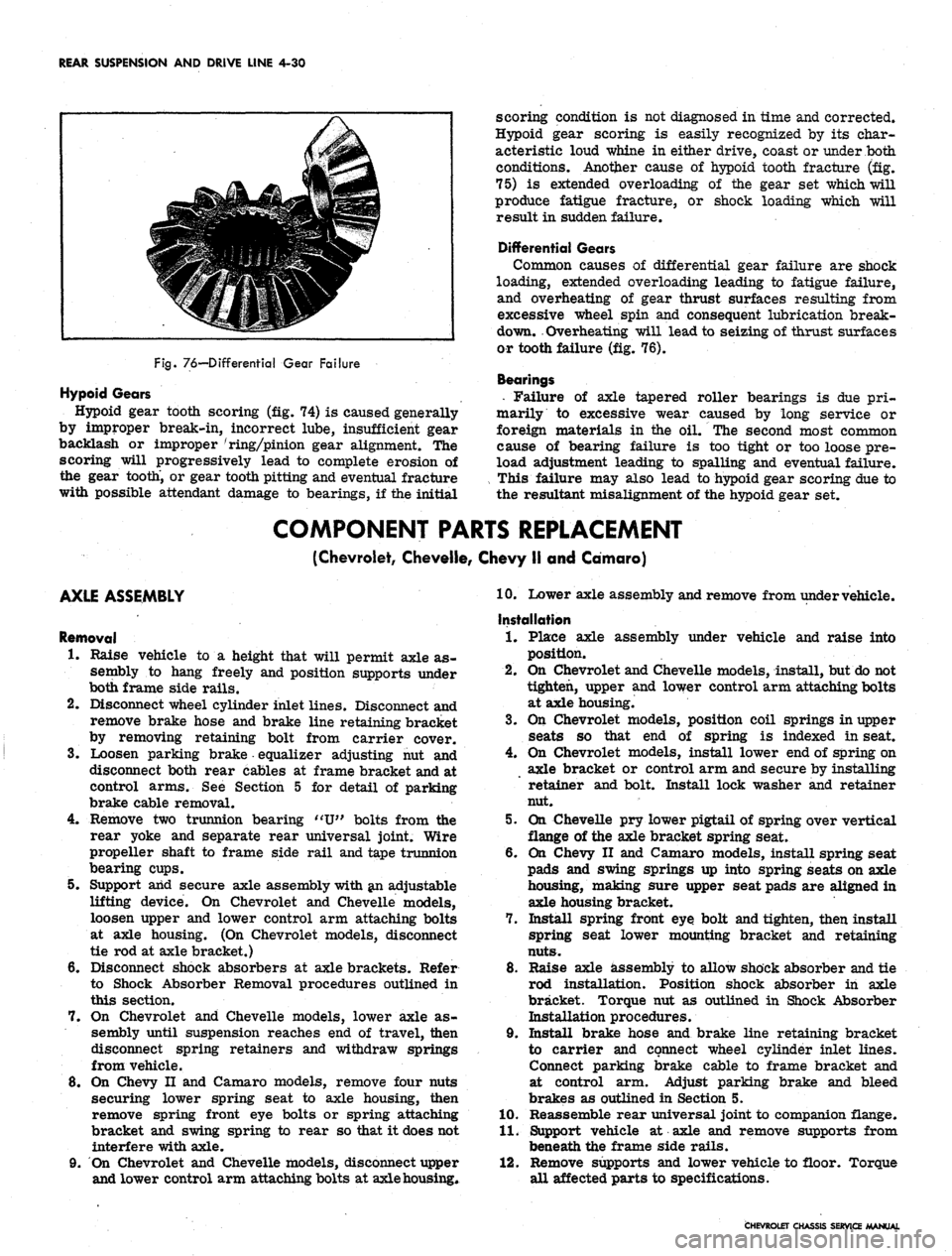

76—Differential Gear Failure

Hypoid Gears

Hypoid gear tooth scoring (fig. 74) is caused generally

by improper break-in, incorrect lube, insufficient gear

backlash or improper 'ring/pinion gear alignment. The

scoring will progressively lead to complete erosion of

the gear tooth, or gear tooth pitting and eventual fracture

with possible attendant damage to bearings, if the initial

scoring condition is not diagnosed in time and corrected.

Hypoid gear scoring is easily recognized by its char-

acteristic loud whine in either drive, coast or under both

conditions. Another cause of hypoid tooth fracture (fig.

75) is extended overloading of the gear set which will

produce fatigue fracture, or shock loading which will

result in sudden failure.

Differential Gears

Common causes of differential gear failure are shock

loading, extended overloading leading to fatigue failure,

and overheating of gear thrust surfaces resulting from

excessive wheel spin and consequent lubrication break-

down. Overheating will lead to seizing of thrust surfaces

or tooth failure (fig. 76).

Bearings

• Failure of axle tapered roller bearings is due pri-

marily to excessive wear caused by long service or

foreign materials in the oil. The second most common

cause of bearing failure is too tight or too loose pre-

load adjustment leading to spalling and eventual failure.

This failure may also lead to hypoid gear scoring due to

the resultant misalignment of the hypoid gear set.

COMPONENT PARTS REPLACEMENT

(Chevrolet, Cheveile, Chevy II and Camaro)

AXLE ASSEMBLY

Removal

1.

Raise vehicle to a height that will permit axle as-

sembly to hang freely and position supports under

both frame side rails.

2.

Disconnect wheel cylinder inlet lines. Disconnect and

remove brake hose and brake line retaining bracket

by removing retaining bolt from carrier cover.

3.

Loosen parking brake equalizer adjusting nut and

disconnect both rear cables at frame bracket and at

control arms. See Section 5 for detail of parking

brake cable removal.

4.

Remove two trunnion bearing "U" bolts from the

rear yoke and separate rear universal joint. Wire

propeller shaft to frame side rail and tape trunnion

bearing cups.

5. Support arid secure axle assembly with an adjustable

lifting device. On Chevrolet and Cheveile models,

loosen upper and lower control arm attaching bolts

at axle housing. (On Chevrolet models, disconnect

tie rod at axle bracket.)

6. Disconnect shock absorbers at axle brackets. Refer

to Shock Absorber Removal procedures outlined in

this section.

7. On Chevrolet and Cheveile models, lower axle as-

sembly until suspension reaches end of travel, then

disconnect spring retainers and withdraw springs

from vehicle.

8. On Chevy II and Camaro models, remove four nuts

securing lower spring seat to axle housing, then

remove spring front eye bolts or spring attaching

bracket and swing spring to rear so that it does not

interfere with axle.

9. On Chevrolet and Cheveile models, disconnect upper

and lower control arm attaching bolts at axle housing*

10.

Lower axle assembly and remove from under vehicle.

Installation

1.

Place axle assembly under vehicle and raise into

position.

2.

On Chevrolet and Cheveile models, install, but do not

tighten, upper and lower control arm attaching bolts

at axle housing.

3.

On Chevrolet models, position coil springs in upper

seats so that end of spring is indexed in seat.

4.

On Chevrolet models, install lower end of spring on

axle bracket or control arm and secure by installing

retainer and bolt. Install lock washer and retainer

nut.

5. On Cheveile pry lower pigtail of spring over vertical

flange of the axle bracket spring seat.

6. On Chevy II and Camaro models, install spring seat

pads and swing springs up into spring seats on axle

housing, making sure upper seat pads are aligned in

axle housing bracket.

7. Install spring front eye bolt and tighten, then install

spring seat lower mounting bracket and retaining

nuts.

8. Raise axle assembly to allow shock absorber and tie

rod installation. Position shock absorber in axle

bracket. Torque nut as outlined in Shock Absorber

Installation procedures.

9. Install brake hose and brake line retaining bracket

to carrier and connect wheel cylinder inlet lines.

Connect parking brake cable to frame bracket and

at control arm. Adjust parking brake and bleed

brakes as outlined in Section 5.

10.

Reassemble rear universal joint to companion flange.

11.

Support vehicle at axle and remove supports from

beneath the frame side rails.

12.

Remove supports and lower vehicle to floor. Torque

all affected parts to specifications.

CHEVROLET CHASSIS SERVICE MANUAL

Page 221 of 659

REAR SUSPENSION AND DRIVE LINE 4-31

Fig.

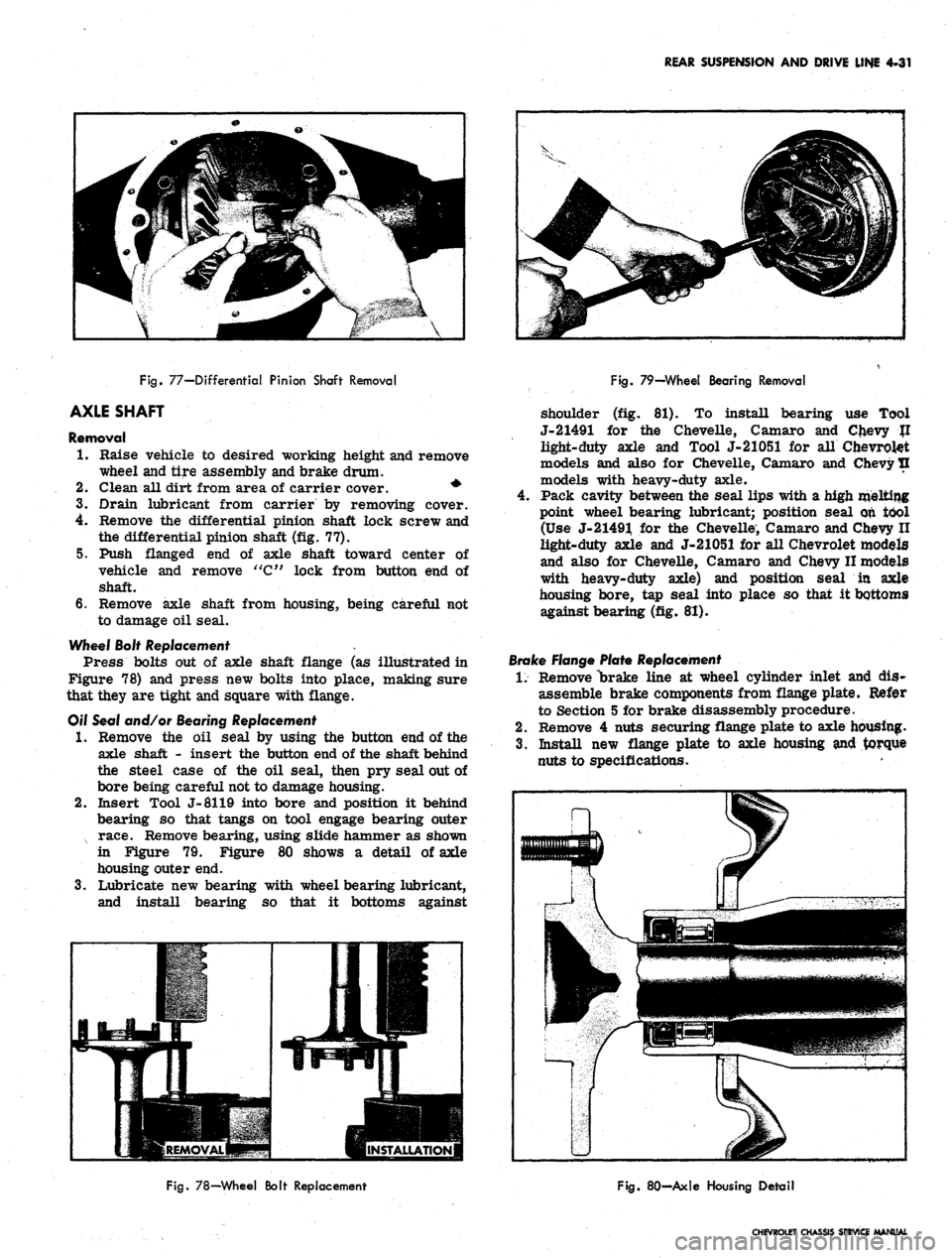

77—Differential Pinion Shaft Removal

AXLE SHAFT

Removal

1.

Raise vehicle to desired working height and remove

wheel and tire assembly and brake drum.

2.

Clean all dirt from area of carrier cover. *

3.

Drain lubricant from carrier by removing cover.

4.

Remove the differential pinion shaft lock screw and

the differential pinion shaft (fig. 77).

5. Push flanged end of axle shaft toward center of

vehicle and remove "C" lock from button end of

shaft.

6. Remove axle shaft from housing, being careful not

to damage oil seal.

Wheel Bolt Replacement .

Press bolts out of axle shaft flange (as illustrated in

Figure 78) and press new bolts into place, making sure

that they are tight and square with flange.

Off Seal and/or Bearing Replacement

•1.

Remove the oil seal by using the button end of the

axle shaft - insert the button end of the shaft behind

the steel case of the oil seal, then pry seal out of

bore being careful not to damage housing.

2.

Insert Tool J-8119 into bore and position it behind

bearing so that tangs on tool engage bearing outer

x race. Remove bearing, using slide hammer as shown

in Figure 79. Figure 80 shows a detail of axle

housing outer end.

3.

Lubricate new bearing with wheel bearing lubricant,

and install bearing so that it bottoms against

Fig.

79—Wheel Bearing Removal

shoulder (fig. 81). To install bearing use Tool

J-21491 for the Chevelle, Camaro and Chevy JI

light-duty axle and Tool J-21051 for all Chevrolet

models and also for Chevelle, Camaro and Chevy tl

models with heavy-duty axle.

Pack cavity between the seal lips with a high melting

point wheel bearing lubricant; position seal on tool

(Use J-21491 for the Chevelle, Camaro and Chevy II

light-duty axle and J-21051 for all Chevrolet models

and also for Chevelle, Camaro and Chevy II models

with heavy-duty axle) and position seal in axle

housing bore, tap seal into place so that it bottoms

against bearing (fig. 81).

Brake Flange Plate Replacement

1.

Remove "brake line at wheel cylinder inlet and dis-

assemble brake components from flange plate. Refer

to Section 5 for brake disassembly procedure.

2.

Remove 4 nuts securing flange plate to axle housing.

3.

Install new flange plate to axle housing and torque

nuts to specifications.

Fig.

78—Wheel Bolt Replacement

Fig.

80-Axle Housing Detail

CHEVROLET CHASSIS SERVICE MANUAL

Page 224 of 659

REAR SUSPENSION AND DRIVE LINE 4-34

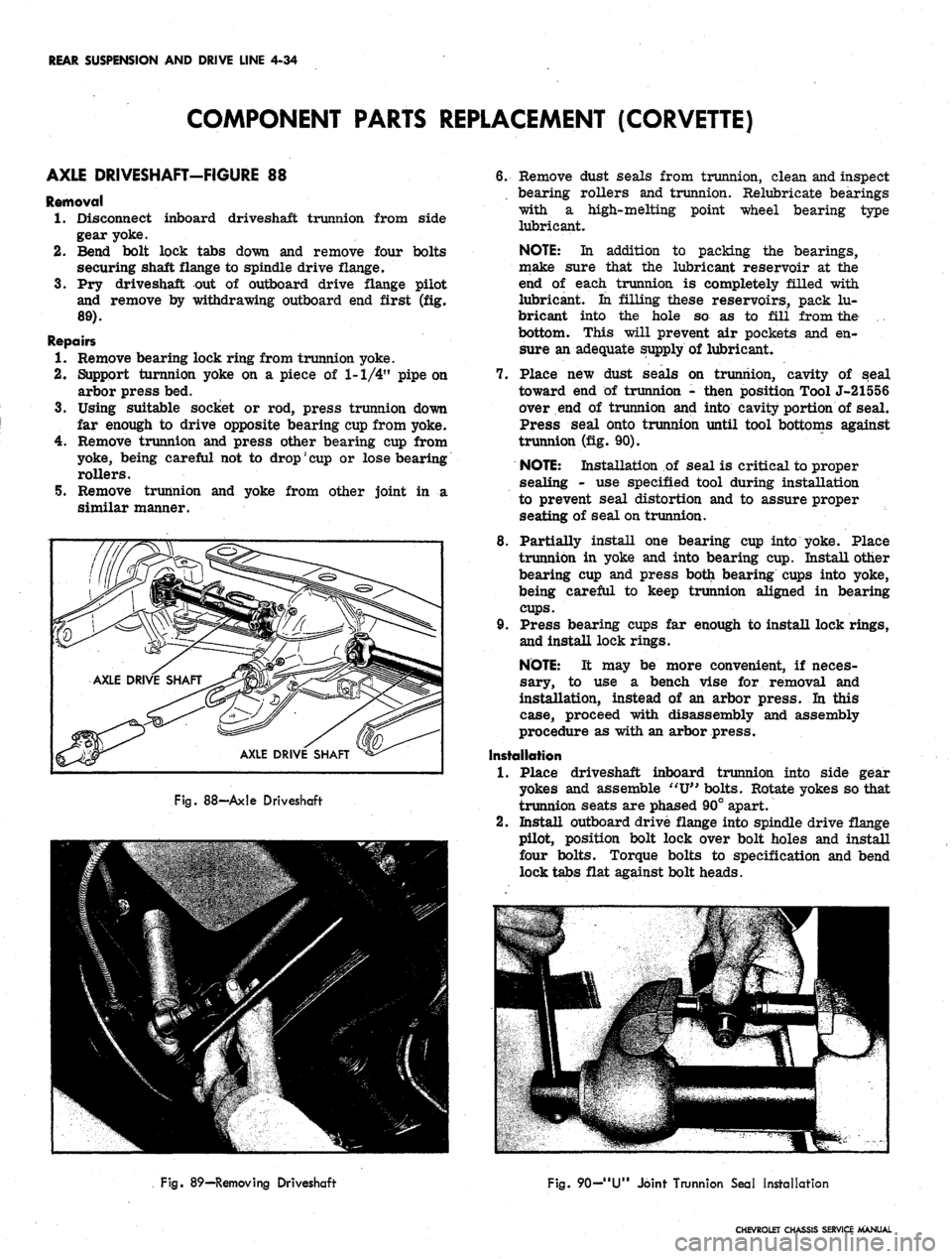

COMPONENT PARTS REPLACEMENT (CORVETTE)

AXLE DRIVESHAFT-FIGURE 88

Removal

1.

Disconnect inboard driveshaft trunnion from side

gear yoke.

2.

Bend bolt lock tabs down and remove four bolts

securing shaft flange to spindle drive flange.

3.

Pry driveshaft out of outboard drive flange pilot

and remove by withdrawing outboard end first (fig.

89).

Repairs

1.

Remove bearing lock ring from trunnion yoke.

2.

Support turnnion yoke on a piece of 1-1/4" pipe on

arbor press bed.

3.

Using suitable socket or rod, press trunnion down

far enough to drive opposite bearing cup from yoke.

4.

Remove trunnion and press other bearing cup from

yoke, being careful not to

drop'

cup

or lose bearing

rollers.

5. Remove trunnion and yoke from other joint in a

similar manner.

3

AXLE

II 1

i

c

DRI\

c

y

'E SHAFT ^

AXLE

v

DRIVE^

SHAFT

•

Fig.

88—Axle Driveshaft

6. Remove dust seals from trunnion, clean and inspect

bearing rollers and trunnion. Relubricate bearings

with a high-melting point wheel bearing type

lubricant.

NOTE:

In addition to packing the bearings,

make sure that the lubricant reservoir at the

end of each trunnion is completely filled with

lubricant. In filling these reservoirs, pack lu-

bricant into the hole so as to fill from the .

bottom. This will prevent air pockets and en-

sure an adequate supply of lubricant.

7. Place new dust seals on trunnion, cavity of seal

toward end of trunnion - then position Tool J-21556

over end of trunnion and into cavity portion of seal.

Press seal onto trunnion until tool bottoms against

trunnion (fig. 90).

NOTE:

Installation of seal is critical to proper

sealing - use specified tool during installation

to prevent seal distortion and to assure proper

seating of seal on trunnion.

8. Partially install one bearing cup into yoke. Place

trunnion in yoke and into bearing cup. Install other

bearing cup and press both bearing cups into yoke,

being careful to keep trunnion aligned in bearing

cups.

9. Press bearing cups far enough to install lock rings,

and install lock rings.

NOTE:

It may be more convenient, if neces-

sary, to use a bench vise for removal and

installation, instead of an arbor press. In this

case, proceed with disassembly and assembly

procedure as with an arbor press.

Installation

1.

Place driveshaft inboard trunnion into side gear

yokes and assemble

"XJ"

bolts. Rotate yokes so that

trunnion seats are phased 90° apart.

2.

Install outboard drive flange into spindle drive flange

pilot, position bolt lock over bolt holes and install

four bolts. Torque bolts to specification and bend

lock tabs flat against bolt heads.

Fig. 89—Removing Driveshaft

Fig.

90—

"U"

Joint Trunnion Seal Installation

CHEVROLET CHASSIS SERVICE MANUAL

Page 226 of 659

REAR SUSPENSION AND DRIVE LINE 4-36

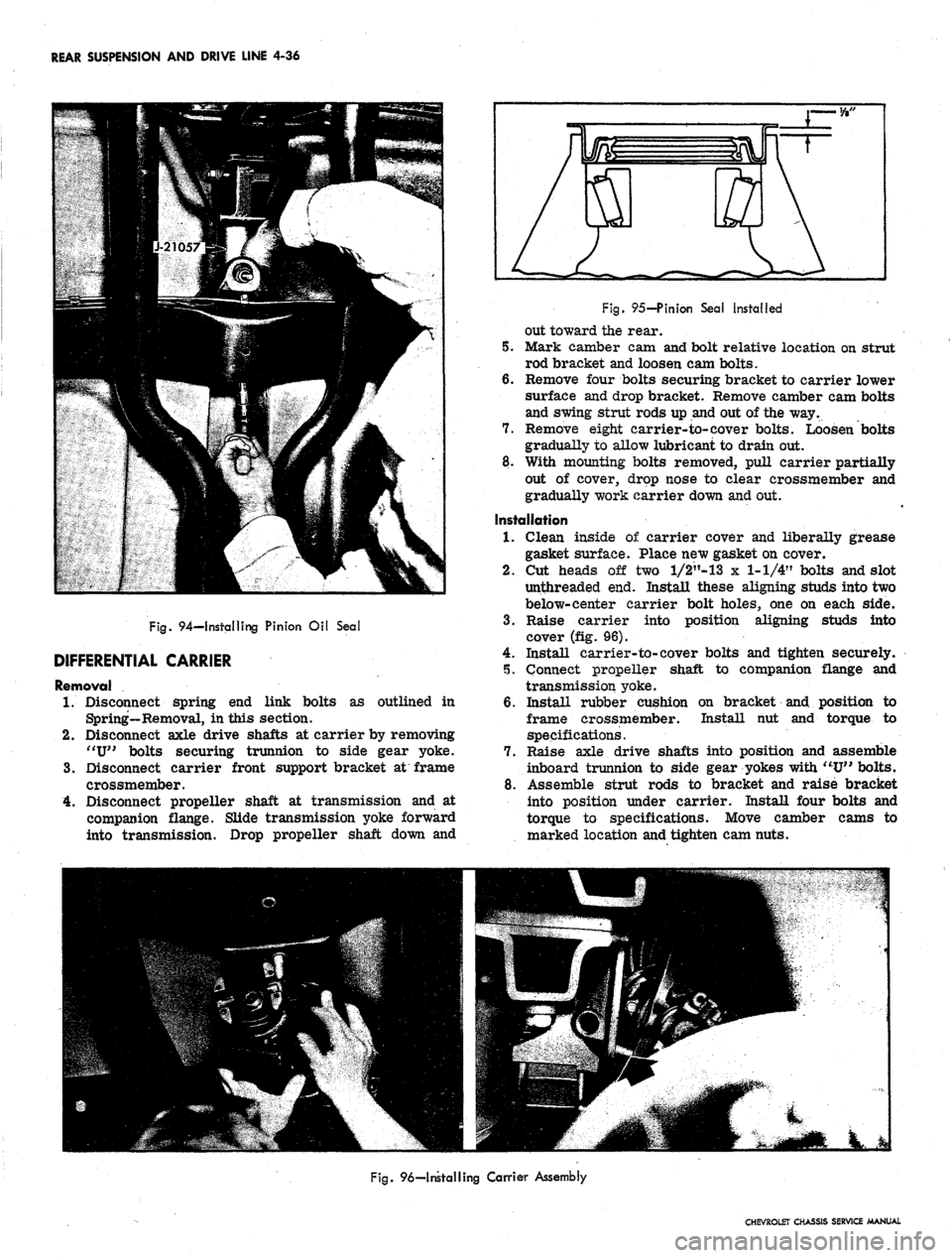

Fig.

94—Installing Pinion Oil Seal

DIFFERENTIAL CARRIER

Removal

1.

Disconnect spring end link bolts as outlined in

Spring—Removal, in this section.

2.

Disconnect axle drive shafts at carrier by removing

"U"

bolts securing trunnion to side gear yoke.

3.

Disconnect carrier front support bracket at frame

crossmember.

4.

Disconnect propeller shaft at transmission and at

companion flange. Slide transmission yoke forward

into transmission. Drop propeller shaft down and

Fig.

95-Pinion Sea! Installed

out toward the rear.

5. Mark camber cam and bolt relative location on strut

rod bracket and loosen cam bolts.

6. Remove four bolts securing bracket to carrier lower

surface and drop bracket. Remove camber cam bolts

and swing strut rods up and out of the way.

7. Remove eight carrier-to-cover bolts. Loosen bolts

gradually to allow lubricant to drain out.

8. With mounting bolts removed, pull carrier partially

out of cover, drop nose to clear crossmember and

gradually work carrier down and out.

Installation

1.

Clean inside of carrier cover and liberally grease

gasket surface. Place new gasket on cover.

2.

Cut heads off two l/2"-13 x 1-1/4" bolts and slot

unthreaded end. Install these aligning studs into two

below-center carrier bolt holes, one on each side.

3.

Raise carrier into position aligning studs into

cover (fig. 96).

4.

Install carrier-to-cover bolts and tighten securely.

5. Connect propeller shaft to companion flange and

transmission yoke.

6. Install rubber cushion on bracket and position to

frame crossmember. Install hut and torque to

specifications.

7. Raise axle drive shafts into position and assemble

inboard trunnion to side gear yokes with "U" bolts.

8. Assemble strut rods to bracket and raise bracket

into position under carrier. Install four bolts and

torque to specifications. Move camber cams to

marked location and tighten cam nuts.

Fig.

96—Installing Carrier Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 238 of 659

BRAKES 5-5

LEVEL CYLINDER

TILTED CYLINDER

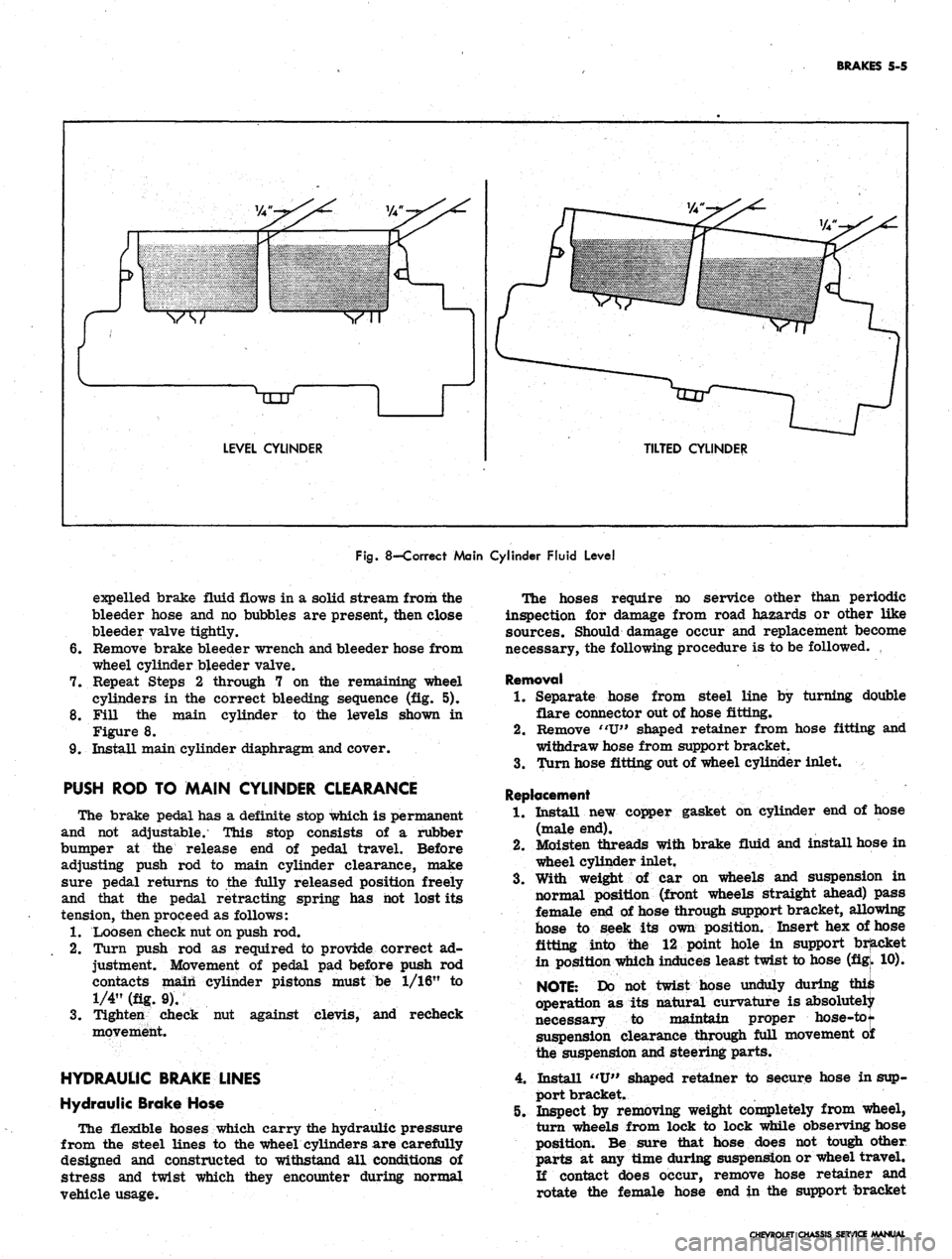

Fig.

8—Correct Main Cylinder Fluid Level

expelled brake fluid flows in a solid stream from the

bleeder hose and no bubbles are present, then close

bleeder valve tightly.

6. Remove brake bleeder wrench and bleeder hose from

wheel cylinder bleeder valve.

7. Repeat Steps 2 through 7 on the remaining wheel

cylinders in the correct bleeding sequence (fig. 5).

8. Fill the main cylinder to the levels shown in

Figure 8.

9. Install main cylinder diaphragm and cover.

PUSH ROD TO MAIN CYLINDER CLEARANCE

The brake pedal has a definite stop which is permanent

and not adjustable. This stop consists of a rubber

bumper at the release end of pedal travel. Before

adjusting push rod to main cylinder clearance, make

sure pedal returns to the fully released position freely

and that the pedal retracting spring has hot lost its

tension, then proceed as follows:

1.

Loosen check nut on push rod.

2.

Turn push rod as required to provide correct ad-

justment. Movement of pedal pad before push rod

contacts main cylinder pistons must be 1/16" to

1/4" (fig. 9).

3.

Tighten check nut against clevis, and recheck

movement.

HYDRAULIC BRAKE LINES

Hydraulic Brake Hose

The flexible hoses which carry the hydraulic pressure

from the steel lines to the wheel cylinders are carefully

designed and constructed to withstand all conditions of

stress and twist which they encounter during normal

vehicle usage.

The hoses require no service other than periodic

inspection for damage from road hazards or other like

sources. Should damage occur and replacement become

necessary, the following procedure is to be followed.

Removal

1.

Separate hose from steel line by turning double

flare connector out of hose fitting.

2.

Remove "U" shaped retainer from hose fitting and

withdraw hose from support bracket.

3.

Turn hose fitting out of wheel cylinder inlet.

Replacement

1.

Install new copper gasket on cylinder end of hose

(male end).

2.

Moisten threads with brake fluid and install hose in

wheel cylinder inlet.

3.

With weight of car on wheels and suspension in

normal position (front wheels straight ahead) pass

female end of hose through support bracket, allowing

hose to seek its own position. Insert hex of hose

fitting into the 12 point hole in support bracket

in position which induces least twist to hose (figk 10).

NOTE:

Do not twist hose unduly during ^

operation as its natural curvature is absolutely

necessary to maintain proper hose-tot

suspension clearance through full movement o£

the suspension and steering parts.

4.

Install "U" shaped retainer to secure hose in sup-

port bracket.

5. Inspect by removing weight completely from wheel,

turn wheels from lock to lock while observing hose

position. Be sure that hose does not tough other

parts at any time during suspension or wheel travel.

If contact does occur, remove hose retainer and

rotate the female hose end in the support bracket

CHEVROLET CHASSIS SERVICE MANUAL