service CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 259 of 659

BRAKES 5-26

PRESSURE

REGULATOR

VALVE

CHEVROLET

PRESSURE

REGULATOR

VALVE

CAMARO

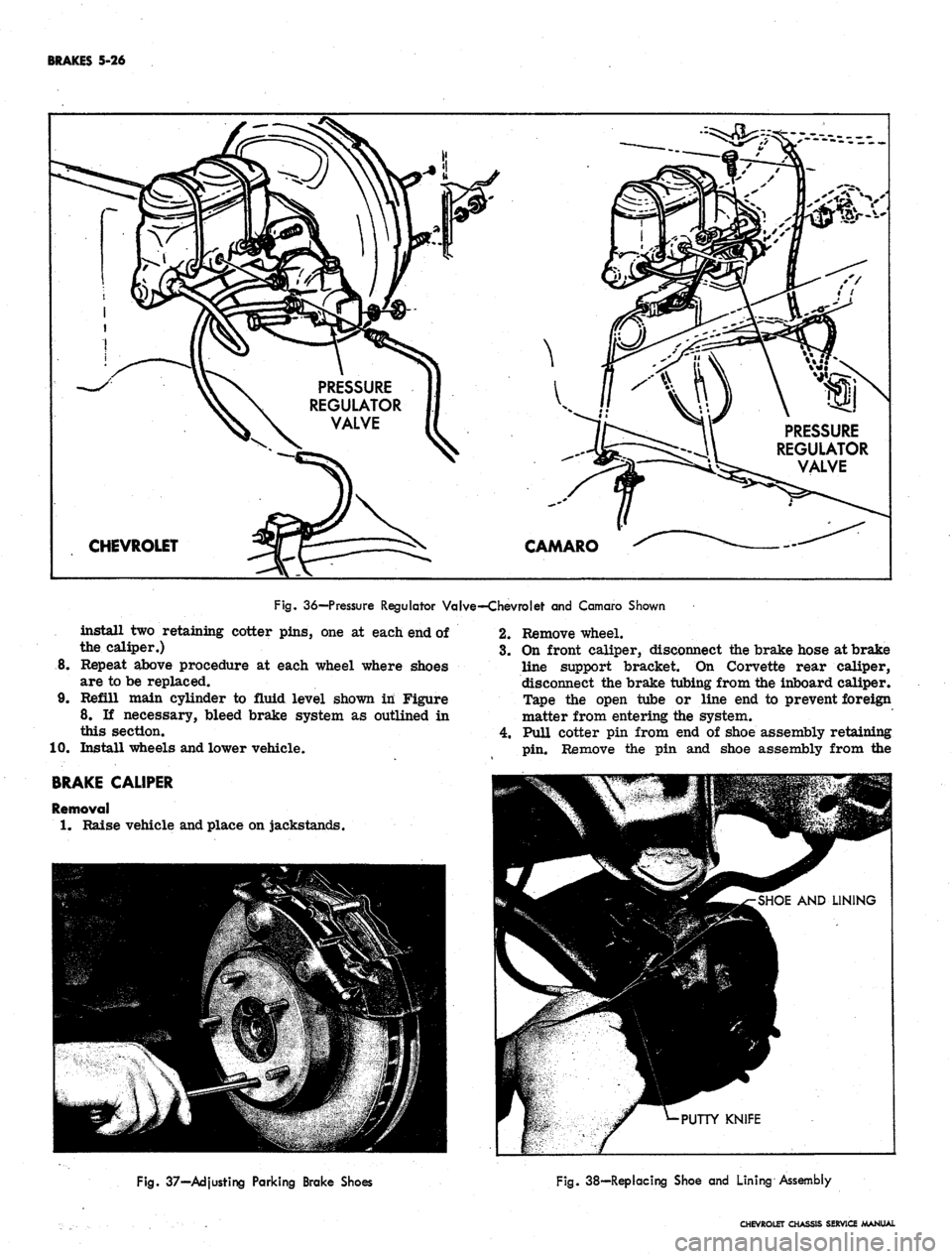

Fig.

36—Pressure Regulator Valve—Chevrolet and Camaro Shown

install two retaining cotter pins, one at each end of

the caliper.)

8. Repeat above procedure at each wheel where shoes

are to be replaced.

9. Refill main cylinder to fluid level shown in Figure

8. If necessary, bleed brake system as outlined in

this section.

10.

Install wheels and lower vehicle.

BRAKE

CALIPER

Removal

1.

Raise vehicle and place on jackstands.

2.

Remove wheel.

3.

On front caliper, disconnect the brake hose at brake

line support bracket. On Corvette rear caliper,

disconnect the brake tubing from the inboard caliper.

Tape the open tube or line end to prevent foreign

matter from entering the system.

4.

Pull cotter pin from end of shoe assembly retaining

pin.

Remove the pin and shoe assembly from the

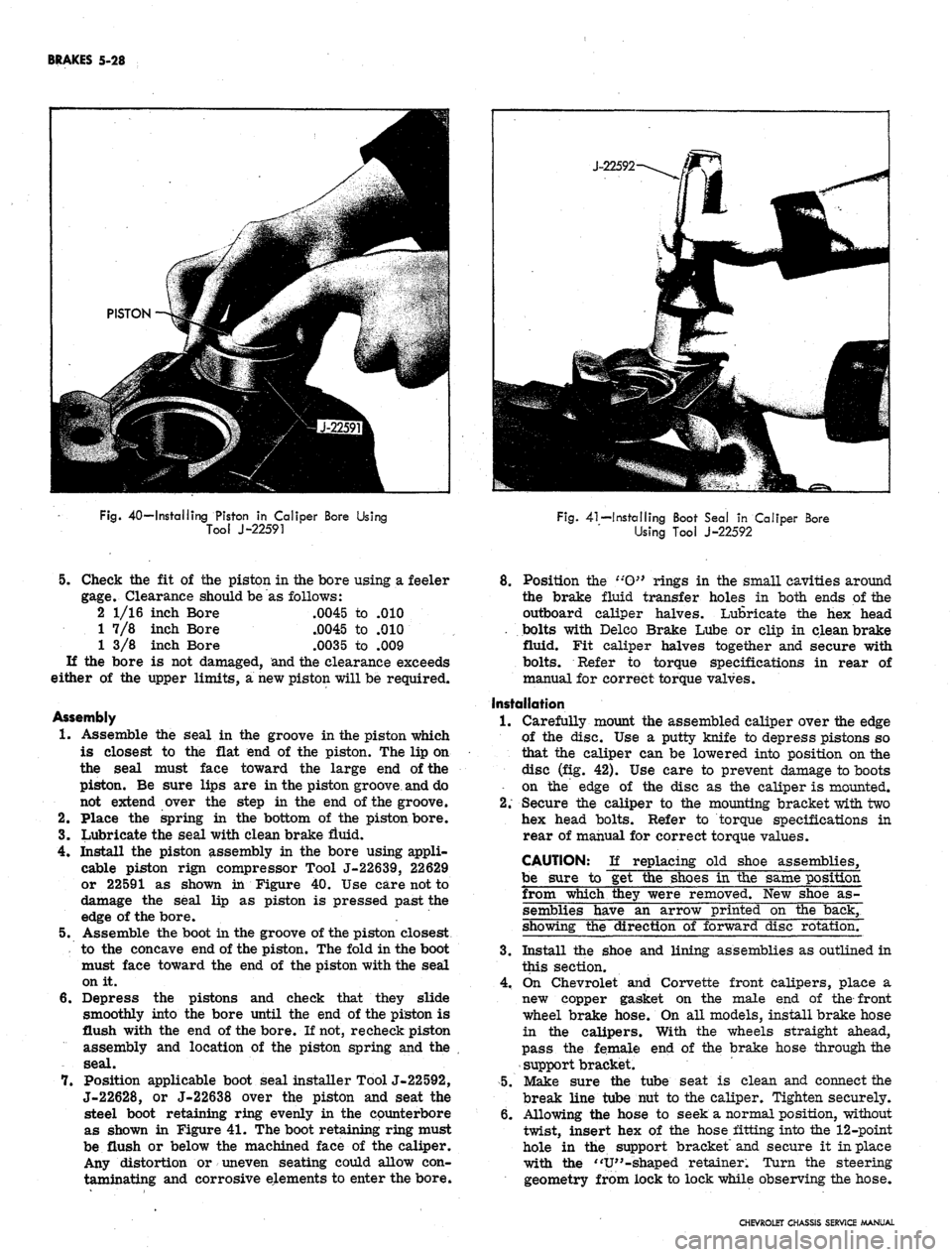

Fig.

37—Adjusting Parking Brake Shoes

Fig.

38—Replacing Shoe and Lining Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 260 of 659

BRAKES 5-27

CHEVELLE

, CHEVY II AND CAMARO SHOWN

1.

Caliper Belts

2.

Bleeder Valve

3. Caliper Half

4.

Piston Spring

Fig.

39-Caliper Assembly-Exploded View

5. Seal

6. Piston

7. Piston Boot

8. Brake Shoes

9. "O" Ri

10.

Caliper

11.

Retaining Pin

12.

Cotter Pin

caliper. Two retaining pins must be removed on

heavy duty Corvette front calipers. Identify the

inboard and outboard shoe if they are to be reused.

5. Remove the end of brake hose at bracket by re-

moving U-shaped retainer from the hose fitting and

withdrawing the hose from bracket.

6. Remove the caliper assembly from the mounting

bracket by removing two hex head bolts.

Disassembly (Fig. 39)

1.

Clean exterior of caliper with Declene, or equivalent.

On Chevrolet and Corvette front caliper, remove

brake hose.

2.

Separate the caliper halves by removing the two

large hex head bolts. Remove the two small "O"

rings from the cavities around the fluid transfer

holes in the two ends of the caliper halves.

3.

To free the piston boots so that the pistons may be

removed, push the piston down into the caliper

as far as it will go. Insert a screwdriver blade

under the inner edge of the steel ring in the boot,

and using the piston as a fulcrum, pry the boot from

its seat in the caliper

half.

CAUTION: Use care not to puncture seal when

removing pistons from caliper. ' ~

4.

Remove the pistons and piston springs from the

caliper

half.

Remove the boot and seal from their

grooves in the piston.

Cleaning and Inspection

1.

Clean all metal parts using Declene, or equivalent.

Remove all traces of dirt and grease. Do not use

mineral base solvents to clean brake parts.

2.

Using an air hose, blow out all fluid passages in the

caliper halves, making sure that there is no dirt

or foreign material blocking any of these passages.

3.

Discard all rubber parts. Boots, seals, and "O"

rings should be replaced with new service kit parts.

4.

Carefully inspect the piston bores in the caliper

halves. They must be free of scores and pits. A

scored or otherwise damaged bore will cause leaks

and unsatisfactory brake operation. Replace the

caliper half if either bore is damaged to the extent

that polishing with very fine crocus cloth will not

restore it.

CHEVROLET CHASSIS SERVICE MANUAL

Page 261 of 659

BRAKES 5-28

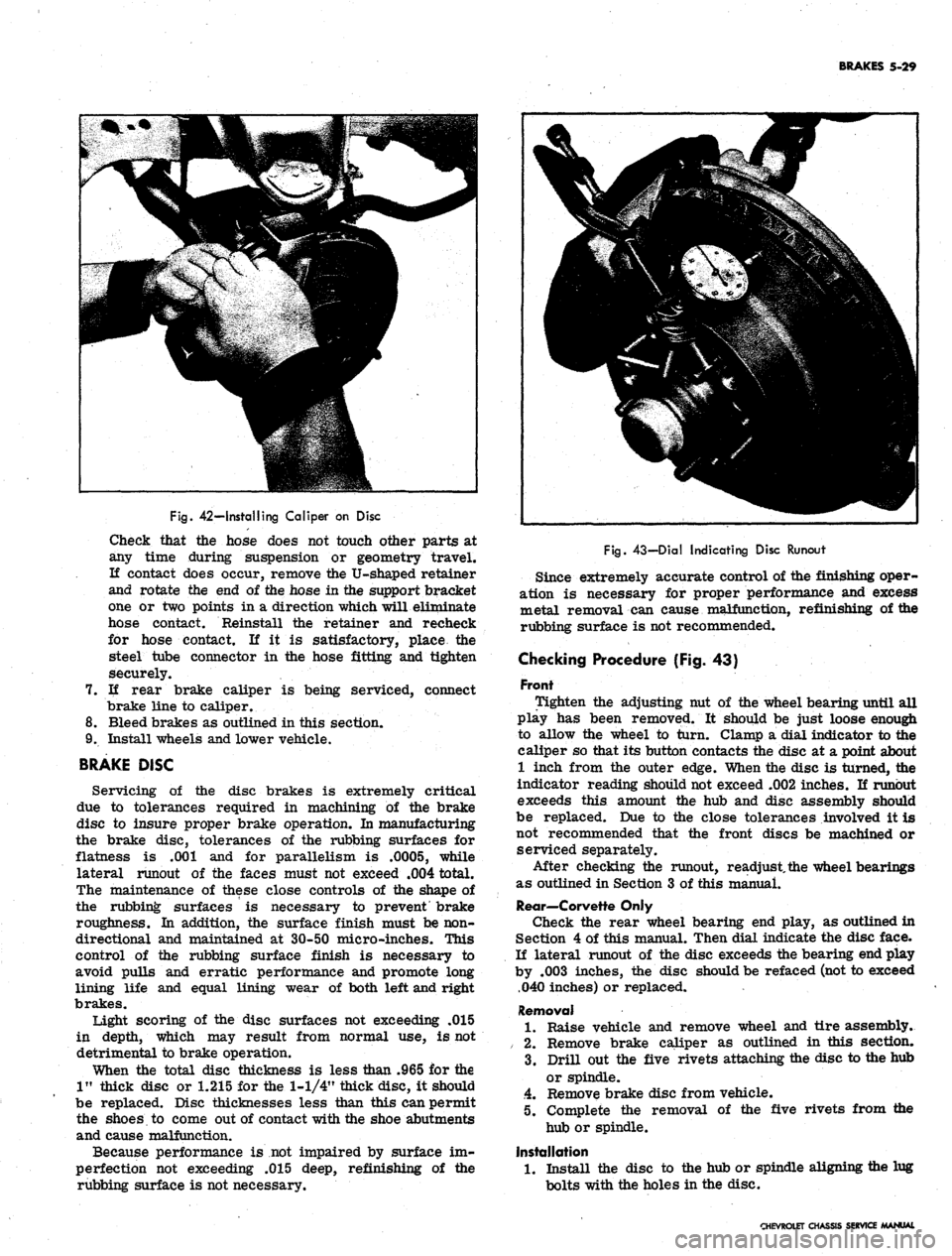

Fig.

40—Installing Piston in Caliper Bore Using

Tool J-22591

Fig.

41—Installing Boot Seal in Caliper Bore

Using Tool J-22592

5.

Check the fit of the piston in the bore using a feeler

gage.

Clearance should be as follows:

2 1/16 inch Bore .0045 to .010

1 7/8 inch Bore .0045 to .010

1 3/8 inch Bore .0035 to .009

If the bore is not damaged, and the clearance exceeds

either of the upper limits, a new piston will be required.

Assembly

1.

Assemble the seal in the groove in the piston which

is closest to the flat end of the piston. The lip on

the seal must face toward the large end of the

piston. Be sure lips are in the piston groove and do

not extend over the step in the end of the groove.

2.

Place the spring in the bottom of the piston bore.

3.

Lubricate the seal with dean brake fluid.

4.

Install the piston assembly in the bore using appli-

cable piston rign compressor Tool J-22639, 22629

or 22591 as shown in Figure 40. Use care not to

damage the seal lip as piston is pressed past the

edge of the bore. .

5.

Assemble the boot in the groove of the piston closest

to the concave end of the piston. The fold in the boot

must face toward the end of the piston with the seal

on it.

6. Depress the pistons and check that they slide

smoothly into the bore until the end of the piston is

flush with the end of the bore. If not, re check piston

assembly and location of the piston spring and the

seal.

7.

Position applicable boot seal installer Tool J-22592,

J-22628, or J-22638 over the piston and seat the

steel boot retaining ring evenly in the counterbore

as shown in Figure 41. The boot retaining ring must

be flush or below the machined face of the caliper.

Any distortion or uneven seating could allow con-

taminating and corrosive elements to enter the bore.

8. Position the t:O}> rings in the small cavities around

the brake fluid transfer holes in both ends of the

outboard caliper halves. Lubricate the hex head

. bolts with Delco Brake Lube or clip in clean brake

fluid. Fit caliper halves together and secure with

bolts.

Refer to torque specifications in rear of

manual for correct torque valves.

Installation

1.

Carefully mount the assembled caliper over the edge

of the disc. Use a putty knife to depress pistons so

that the caliper can be lowered into position on the

disc (fig. 42). Use care to prevent damage to boots

• on the edge of the disc as the caliper is mounted.

2.

Secure the caliper to the mounting bracket with two

hex head bolts. Refer to torque specifications in

rear of manual for correct torque values.

CAUTION: If replacing old shoe assemblies,

be sure to get the shoes in the same position

from which they were removed. New shoe as-

semblies have an arrow printed on the back,

showing the direction of forward disc rotation.

3.

Install the shoe and lining assemblies as outlined in

this section.

4.

On Chevrolet and Corvette front calipers, place a

new copper gasket on the male end of the front

wheel brake hose. On all models, install brake hose

in the calipers. With the wheels straight ahead,

pass the female end of the brake hose through the

support bracket.

5.

Make sure the tube seat is clean and connect the

break line tube nut to the caliper. Tighten securely.

6. Allowing the hose to seek a normal position, without

twist, insert hex of the hose fitting into the 12-point

hole in the support bracket and secure it in place

with the "V"-shaped retainer. Turn the steering

geometry from lock to lock while observing the hose.

CHEVROLET CHASSIS SERVICE MANUAL

Page 262 of 659

BRAKES 5-29

Fig.

42—Installing Caliper on Disc

Check that the hose does not touch other parts at

any time during suspension or geometry travel.

If contact does occur, remove the U-shaped retainer

and rotate the end of the hose in the support bracket

one or two points in a direction which will eliminate

hose contact. Reinstall the retainer and recheck

for hose contact. If it is satisfactory, place the

steel tube connector in the hose fitting and tighten

securely.

If rear brake caliper is being serviced, connect

brake line to caliper.

Bleed brakes as outlined in this section.

Install wheels and lower vehicle.

BRAKE DISC

Servicing of the disc brakes is extremely critical

due to tolerances required in machining of the brake

disc to insure proper brake operation. In manufacturing

the brake disc, tolerances of the rubbing surfaces for

flatness is .001 and for parallelism is .0005, while

lateral runout of the faces must not exceed .004 total.

The maintenance of these close controls of the shape of

the rubbing surfaces is necessary to prevent brake

roughness. In addition, the surface finish must be non-

directional and maintained at 30-50 micro-inches. This

control of the rubbing surface finish is necessary to

avoid pulls and erratic performance and promote long

lining life and equal lining wear of both left and right

brakes.

tight scoring of the disc surfaces not exceeding .015

in depth, which may result from normal use, is not

detrimental to brake operation.

When the total disc thickness is less than .965 for the

1"

thick disc or 1.215 for the 1-1/4" thick disc, it should

be replaced. Disc thicknesses less than this can permit

the shoes to come out of contact with the shoe abutments

and cause malfunction.

Because performance is not impaired by surface im-

perfection not exceeding .015 deep, refinishing of the

rubbing surface is not necessary.

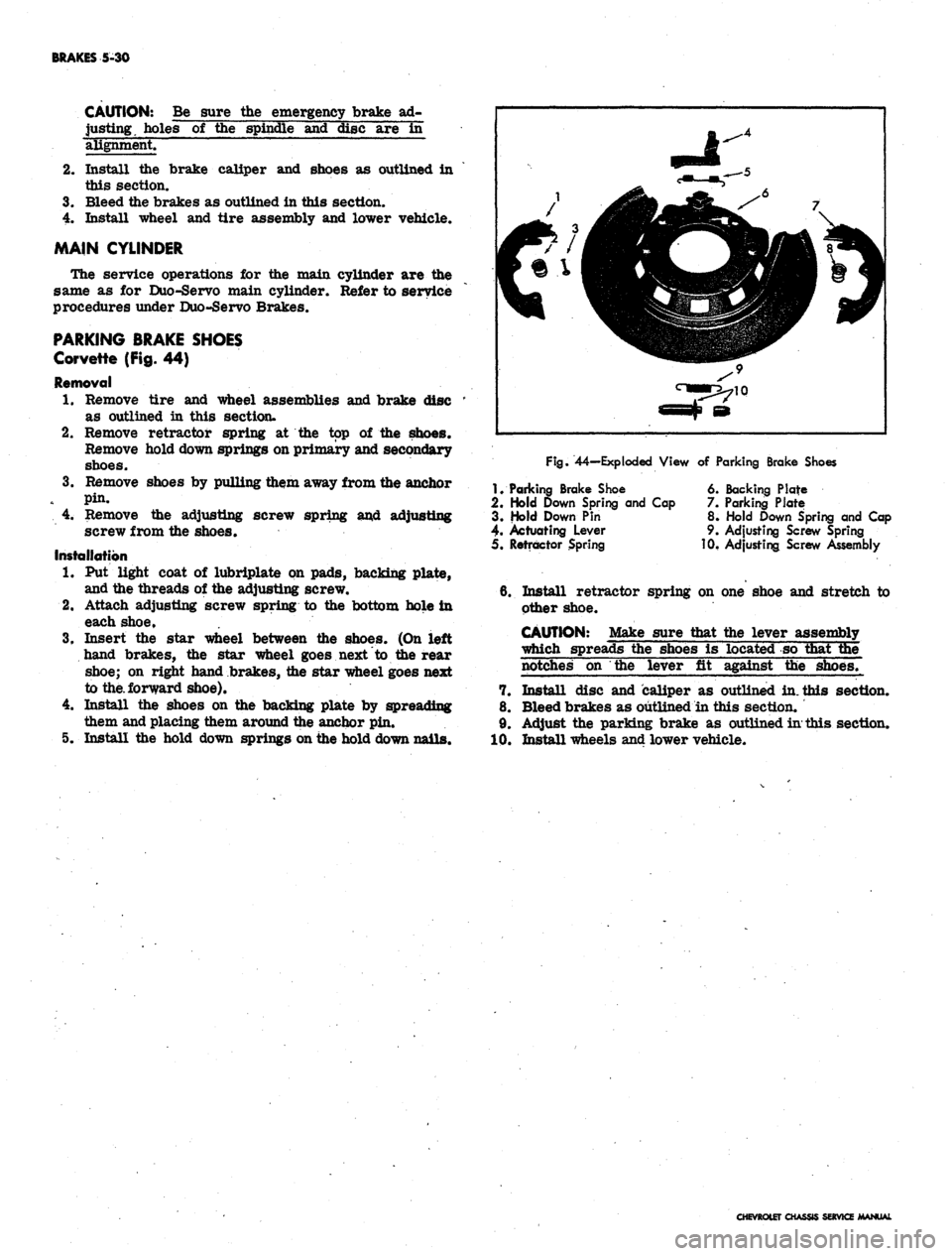

Fig.

43—Dial Indicating Disc Runout

Since extremely accurate control of the finishing oper-

ation is necessary for proper performance and excess

metal removal can cause malfunction, refinishing of the

rubbing surface is not recommended.

Checking Procedure (Fig. 43)

Front

Tighten the adjusting nut of the wheel bearing until all

play has been removed. It should be just loose enough

to allow the wheel to turn. Clamp a dial indicator to the

caliper so that its button contacts the disc at a point about

1 inch from the outer edge. When the disc is turned, the

indicator reading should not exceed .002 inches. If runout

exceeds this amount the hub and disc assembly should

be replaced. Due to the close tolerances involved it is

not recommended that the front discs be machined or

serviced separately.

After checking the runout, readjust, the wheel bearings

as outlined in Section 3 of this manual.

Rear—Corvette Only

Check the rear wheel bearing end play, as outlined in

Section 4 of this manual. Then dial indicate the disc face.

If lateral runout of the disc exceeds the bearing end play

by .003 inches, the disc should be refaced (not to exceed

.040 inches) or replaced.

Removal

1.

Raise vehicle and remove wheel and tire assembly.

/ 2. Remove brake caliper as outlined in this section.

3.

Drill out the five rivets attaching the disc to the hub

or spindle.

4.

Remove brake disc from vehicle.

5. Complete the removal of the five rivets from the

hub or spindle.

Installation

1.

Install the disc to the hub or spindle aligning the lug

bolts with the holes in the disc.

CHEVROLET CHASSIS SERVICE MANUAL

Page 263 of 659

BRAKES 5-30

CAUTION: Be sure the emergency brake ad-

justing, holes of the spindle and disc are in

alignment.

2.

Install the brake caliper and shoes as outlined in

this section.

3.

Bleed the brakes as outlined in this section.

4.

Install wheel and tire assembly and lower vehicle.

MAIN CYLINDER

The service operations for the main cylinder are the

same as for Duo-Servo main cylinder. Refer to service

procedures under Duo-Servo Brakes.

PARKING BRAKE SHOES

Corvette (Fig. 44)

Removal

1.

Remove tire and wheel assemblies and brake disc

as outlined in this section.

2.

Remove retractor spring at the top of the shoes.

Remove hold down springs on primary and secondary

shoes.

3.

Remove shoes by pulling them away from the anchor

pin.

4.

Remove the adjusting screw spring and adjusting

screw from the shoes.

Installation

1.

Put light coat of lubriplate on pads, backing plate,

and the threads of the adjusting screw.

2.

Attach adjusting screw spring to the bottom hole in

each shoe.

3.

Insert the star wheel between the shoes. (On left

hand brakes, the star wheel goes next to the rear

shoe; on right hand brakes, the star wheel goes next

to

the.

forward shoe).

4.

Install the shoes on the backing plate by spreading

them and placing them around the anchor pin.

5. Install the hold down springs on the hold down nails.

Fig.

44-Exploded View of Parking Brake Shoes

1.

Parking Brake Shoe

2.

Hold Down Spring and Cap

3. Hold Down Pin

4. Actuating Lever

5. Retractor Spring

6. Backing Plate

7. Parking Plate

8. Hold Down Spring and Cap

9. Adjusting Screw Spring

0, Adjusting Screw Assembly

6. Install retractor spring on one shoe and stretch to

other shoe.

CAUTION: Make sure that the lever assembly

which spreads the shoes is located so that the

notches on the lever fit against the shoes.

7. Install disc and caliper as outlined in. this section.

8. Bleed brakes as outlined in this section.

9. Adjust the parking brake as outlined in this section.

10.

Install wheels and lower vehicle.

CHEVROLET CHASSIS SERVICE MANUAL

Page 264 of 659

BRAKES

5-31

POWER BRAKES

INDEX

General Description 5-31

Maintenance

and"

Adjustments 5-31

Inspection . ... 5_31

Lubrication 5-31

Bleeding Instructions . . . 5.31

Air Cleaner Service . . . , 5.31

Page

Component Replacement 5-31

Power Brake Cylinder ......* 5-31

Removal . . 5-31

Disassembly and Assembly See Overhaul Manual

Installation . . . . 5-31

GENERAL DESCRIPTION

The Power Brake Unit is a self-contained hydraulic

and vacuum unit, utilizing manifold vacuum and atmos-

phere pressure for its power.

This unit permits the use of a low brake pedal as well

as less pedal effort than is required with the conventional

(nonpower) hydraulic brake system. Only two external

line connections are necessary -

one

a vacuum connection

from manifold to check valve located on front shell; the

other, a hydraulic connection from the main cylinder

outlet directly into the hydraulic system. The unit is

mounted on the engine side of the fire wall and directly

connected to the brake pedal.

MAINTENANCE AND ADJUSTMENTS

INSPECTIONS

1.

Check vacuum line and vacuum line connections as

well as vacuum check valve in front shell of power

unit for possible vacuum loss.

2.

Inspect all hydraulic lines and connections at the

wheel cylinders and main cylinder for possible

hydraulic leaks.

3.

Check brake assemblies for scored drums, grease

or brake fluid on linings, worn or glazed linings,

and make necessary adjustments.

4.

Check brake fluid level in the hydraulic reser-

voirs.

The reservoirs should be filled to the levels

shown in Figure 8.

5. Check for loose mounting bolts at main cylinder and

at power section.

6. Check air cleaner filter in power piston extension

and replace filter if necessary.

7. Check brake pedal for binding and misalignment

between pedal

-and

push rod.

LUBRICATION

The power brake unit is lubricated at assembly and

needs no further lubrication other than maintaining

normal reservoir fluid level. The reservoir should be

filled as described in this section.

BLEEDING INSTRUCTIONS

The power system may be bled manually or with a

pressure bleeder as outlined in this section. Use only

GM

Supreme 11 Brake Fluid or equivalent. Do not use the

power assist while bleeding. The engine should not be

running and the vacuum reserve should be reduced to

zero by applying the brake several times before starting

the bleeding procedure.

AIR CLEANER SERVICE

Servicing of the air cleaner is recommended and the

element replaced when restriction becomes severe

enough to affect power brake response. At any other

time, if cleaning of the filter is felt necessary, it should

be shaken free of dirt or washed in soap and water and

thoroughly dried.

COMPONENT REPLACEMENT

POWER BRAKE CYLINDER

Removal

1.

Remove vacuum hose from vacuum check valve.

2.

Disconnect hydraulic lines at main cylinder.

Disconnect push rod at brake pedal assembly.

Remove nuts and lock washers securing power unit

to fire wall, and remove power unit from engine

compartment.

3.

4.

NOTE:

Chevy

to fire wall.

has a three stud attachment

Repair procedures for the power cylinder are outlined

in the Brake Section of the Overhaul Manual-for service

of the main cylinder refer to applicable portion of

"Standard Brakes" in this manual.

Installation

1.

Mount the power brake assembly in place and install

the attaching nuts and lock washers.

2.

Attach vacuum line to check valve.

3.

Secure hydraulic lines to main cylinder.

4.

Attach push rod to brake pedal assembly, and check

operation of stop light.

5. Bleed brakes as outlined in this section.

CAUTION: After replacing the unit on the vehi-

cle,

start the engine and allow vacuum to build

up before applying the brake.

CHEVROLET CHASSIS SERVICE

Page 265 of 659

BRAKES 5-32

SPECIAL TOOLS

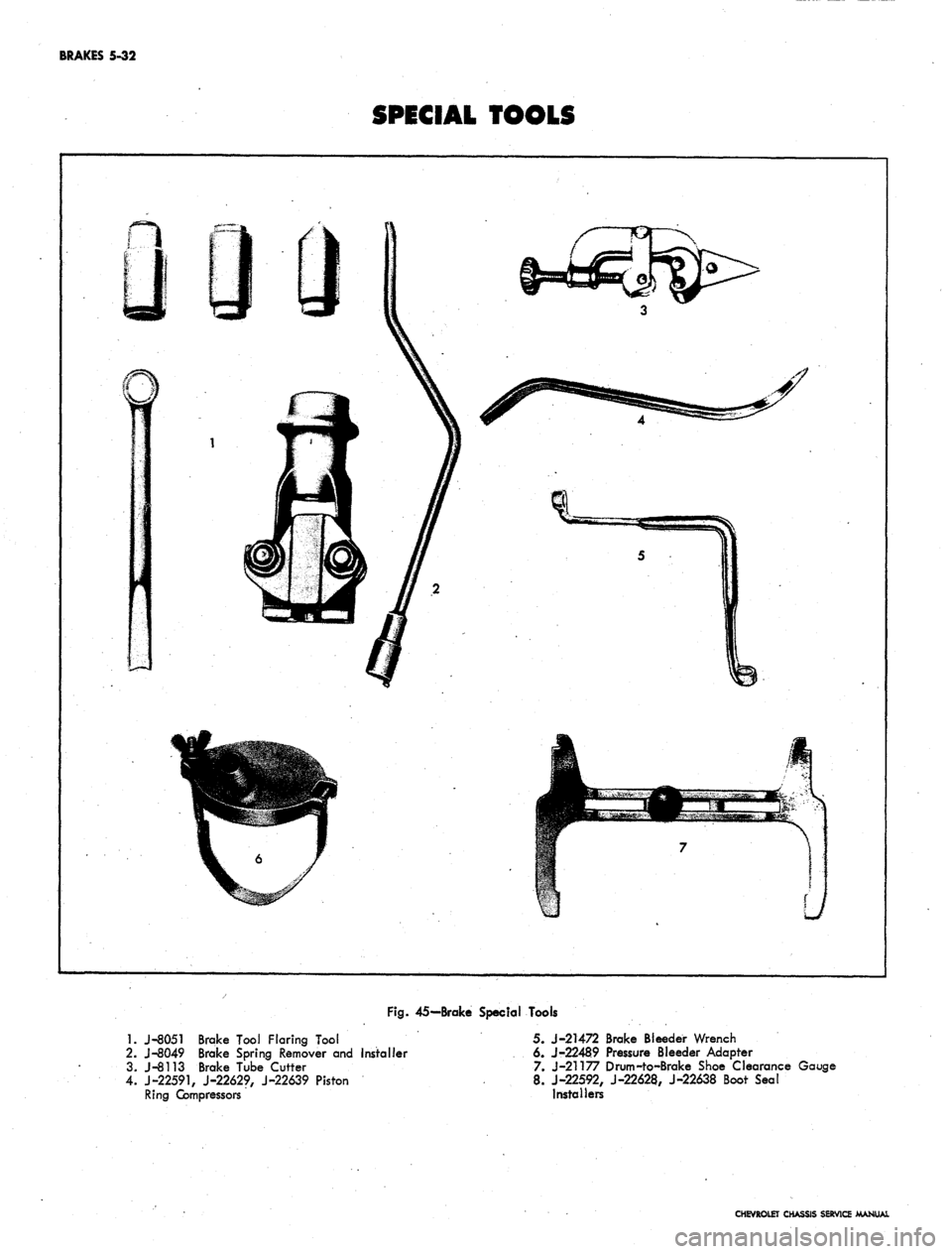

Fig.

45-Brake Special Tools

1.

J-8051 Brake Tool Flaring Tool

2.

J-8049 Brake Spring Remover and Installer

3. J-8113 Brake Tube Cutter

4.

J-22591,

J-22629, J-22639 Piston

Ring Compressors

5. J-21472 Brake Bleeder Wrench

6. J-22489 Pressure Bleeder Adapter

7. J-21177 Drum-ro-Brake Shoe Clearance

8. J-22592, J-22628, J-22638 Boot Seal

Installers

Gauge

CHEVROLET CHASSIS SERVICE MANUAL

Page 266 of 659

SECTION 6

ENGINE

CONTENTS

OF

THIS SECTION

Page

Engine Tune Up

6-1

Torque Sequence

Engine Mechanical

(In

Line)

6-12

Special Tools

. .

Engine Mechanical (V8)

6-24

Page

6-39

6-40

ENGINE TUNE UP

INDEX

Page

General Description

. 6-1

Mechanical Checks and Adjustments

6-1

Spark Plug Removal

6-1

Test Compression

6-1

Service and Install Spark Plugs

6-2

Service Ignition System

6-3

Service Battery

and

Battery Cables

6-5

Service Delcotron

and

Regulator

6-5

Service

Fan

Belt

6-5

Service Manifold Heat Valve

6-5

Tighten Manifold

6-5

Service Fuel Lines

and

Fuel Filter ..........

6-6

Service Cooling System

6-6

Check and Adjust Accelerator Linkage

6-6

Service Crankcase Ventilation

6-6

Service

Air

Injection Reactor System

6-6

Choke Adjustment

6-7

Page

Instrument Cheek-Out

6-7

Instrument Hook-Up.

. 6*7

Check and Adjust Dwell

6-7

Check Dwell Variation

6-7

Check and Adjust Timing

6-8

Adjust Idle Speed

and

Mixture

6-8

Additional Checks and Adjustments

. 6-8

Testing Crankcase Ventilation Valve

. 6-8

Testing Cranking Voltage

6-8

Cylinder Balance Test

. 6-8

Battery

6-8

Ignition

; 6-8

Carburetor

6-11

Fuel Pump

6-11

Cooling System

. 6-11

Cylinder Head Torque and Valve Adjustment

..... 6-11

GENERAL DESCRIPTION

The engine tune up

is

important

to the

modern automo-

tive engine with

its

vastly improved power and perform-

ance.

The

higher compression ratios, improved electri-

cal systems

and

other advances

in

design, make today1 s

engines more sensitive

and

have

a

decided effect

on

power, performance and fuel consumption.

It

is

seldom advisable

to

attempt

a

tune up

by

correc-

tion

of one or two

items only. Time will normally

be

saved

and

more lasting results assured

if the

technician

will follow

a

definite

and

thorough procedure

of

analysis

and correction

of all

items affecting power, performance

and economy.

The tune

up

will

be

performed

in

two parts.

The

first

part will consist

of

visual and mechanical checks and

ad-

justments;

the

second part will consist

of

an instrument

checkout that

can be

performed with

any one of the

units

of service equipment available

for

this purpose. Always

follow

the

instructions provided

by the

manufacturer

of

the particular equipment

to be

used.

Additional checks

and

adjustments

are

included

in the

latter part

of

this section

for use as

required. Many

of

these operations

can be

used

to

isolate and correct trou-

ble located during

the

tune up. Where conditions

are

UB-

covered requiring major corrective action, refer

to the

appropriate section

of

this manual

or the

Passenger

Chassis Overhaul Manual

for

detailed service informa-

tion.

Typical illustrations

and

procedures

are

used except

where specific illustrations

or

procedures

are

necessary

to clarify

the

operation. Illustrations showing bench

op-

erations

are

used

for

clarification however

all

operations

can

be

performed

on the

vehicle.

MECHANICAL CHECKS

AND

ADJUSTMENTS

Spark Plug Removal

Remove any foreign matter from around spark plugs

by

blowing

out

with compressed

air,

then disconnect wires

and remove plugs.

Test Compression

(Fig. 1)

The compression check

is

important because

an

engine

with

low or

uneven compression cannot

be

tuned success-

fully.

It is

essential that improper compression

be cor-

rected before proceeding with

the

engine tune

up.

1.

Remove

air

cleaner

and

block throttle

and

choke

in

wide open position.

2.

Hook

up

starter remote control cable

and

insert

compression gauge firmly

in

spark plug port.

CAUTION: Whenever

the

engine

is

cranked

CHEVROLET

C*

IS SERVICE MANUAL

Page 267 of 659

ENGINE 6-2

remotely at the starter, with a special jumper

cable or other means, the primary distributor

lead must be disconnected from the negative

post on the coil and the ignition switch must be

in the "ON" position. Failure to do this will

result in a damaged grounding circuit in the

ignition switch.

3.

Crank engine through at least four compression

strokes to obtain highest possible reading.

4.

Check and record compression of each cylinder.

5.

If one or more cylinders read low tor uneven, inject

about a tablespoon of engine oil on top of pistons

in low reading cylinders (through spark plug

port).

Crank engine several times and recheck

compression.

• If compression comes up but does not necessarily

reach normal, rings are worn.

• If compression does not improve, valves are

burnt, sticking or not seating properly.

• If two adjacent cylinders indicate low compres-

sion and injecting oil does not increase compres-

sion, the cause may be a head gasket leak between

the cylinders. Engine coolant and/or oil in cylin-

ders could result from this defect.

NOTE: If a weak cylinder cannot be located

with the compression check, see "Cylinder Bal-

ance Test" under "Additional Checks and Adjust-

ments" in this section.

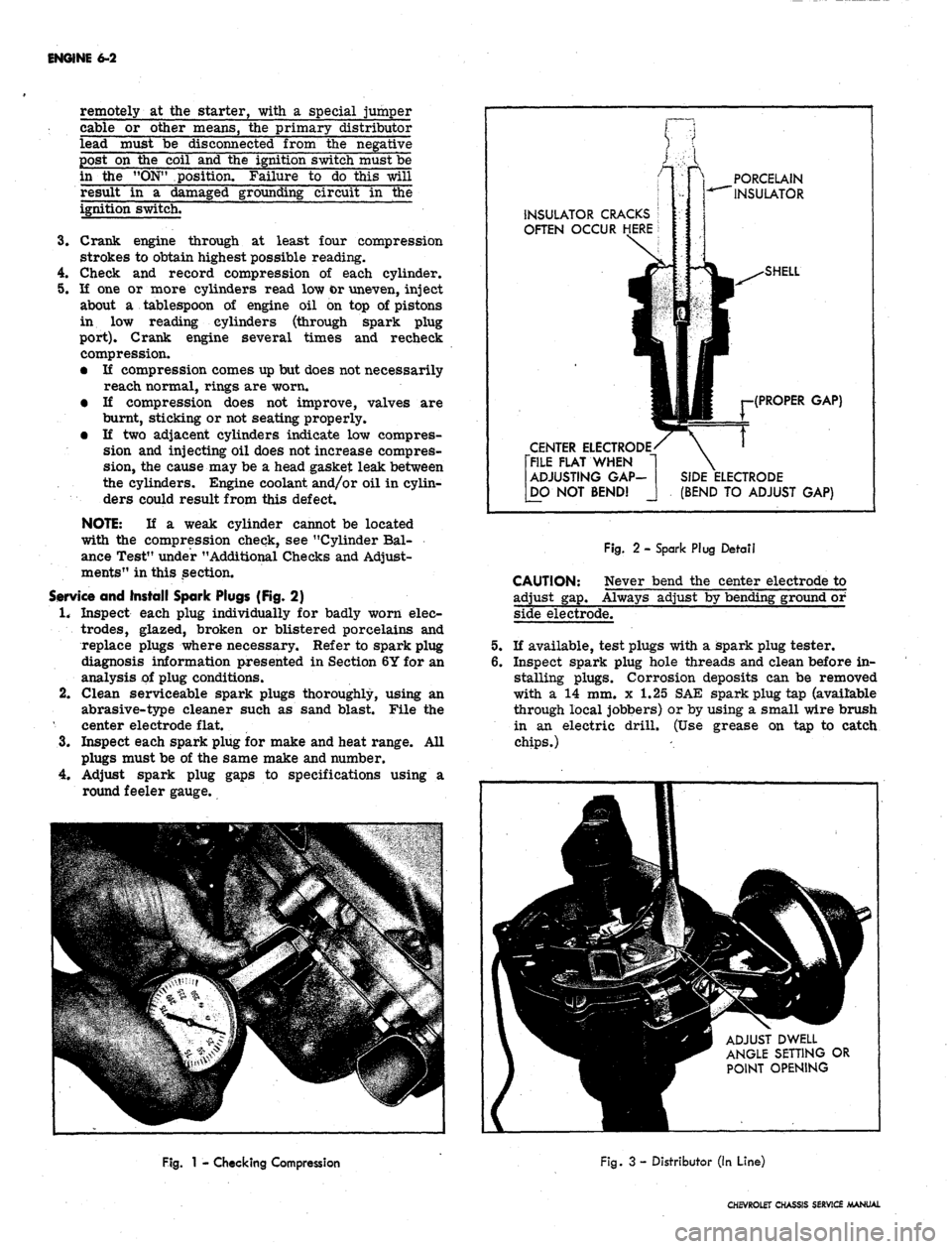

Service and Install Spark Plugs (Fig. 2)

1.

Inspect each plug individually for badly worn elec-

trodes,

glazed, broken or blistered porcelains and

replace plugs where necessary. Refer to spark plug

diagnosis information presented in Section 6Y for an

analysis of plug conditions.

2.

Clean serviceable spark plugs thoroughly, using an

abrasive-type cleaner such as sand blast. File the

center electrode flat.

3.

Inspect each spark plug for make and heat range. All

plugs must be of the same make and number.

4.

Adjust spark plug gaps to specifications using a

round feeler gauge.

PORCELAIN

INSULATOR

INSULATOR CRACKS

OFTEN OCCUR HERE

CENTER ELECTRODE

[FILE FLAT WHEN

ADJUSTING GAP-

[DO NOT BEND!

(PROPER GAP)

(BEND TO ADJUST GAP)

CAUTION:

adjust gap.

Fig.

2 - Spark Plug Detail

Never bend the center electrode to

Always adjust by bending ground or

side electrode.

If available, test plugs with a spark plug tester.

Inspect spark plug hole threads and clean before in-

stalling plugs. Corrosion deposits can be removed

with a 14 mm. x 1.25 SAE spark plug tap (available

through local jobbers) or by using a small wire brush

in an electric drill. (Use grease on tap to catch

chips.)

ADJUST DWELL

ANGLE SETTING OR

POINT OPENING

Fig.

1 - Checking Compression

Fig.

3 - Distributor (In Line)

CHEVROLET CHASSIS SERVICE MANUAL

Page 268 of 659

ENGINE

6-3

(ROUND) Y~~fll^H

CENTRIFUGAL

A ^k

ADVANCE--jflgKpl

MECHANISM

UB|

CAM

KSK^2

LUBRICATOR

VlSMi

REPLACEMENT

^BK

-^ADJUST

SQUARELY

AND

JUST

TOUCHING

LOBE

OF

CAM

/ROTOR

HBB

__

I^BH^F

?

(SOUARE)

^K^ I /—

CAM

jKft^J / LUBRICATOR

H^T^

CAUTION!

QV NEVER

OIL

•L-^

CAM LUBRICATOR-

REPLACE

WICK

WHEN

NECESSARY

LATERAL

MISALIGNMENT

PROPER

LATERAL ALIGNMENT

Fig.

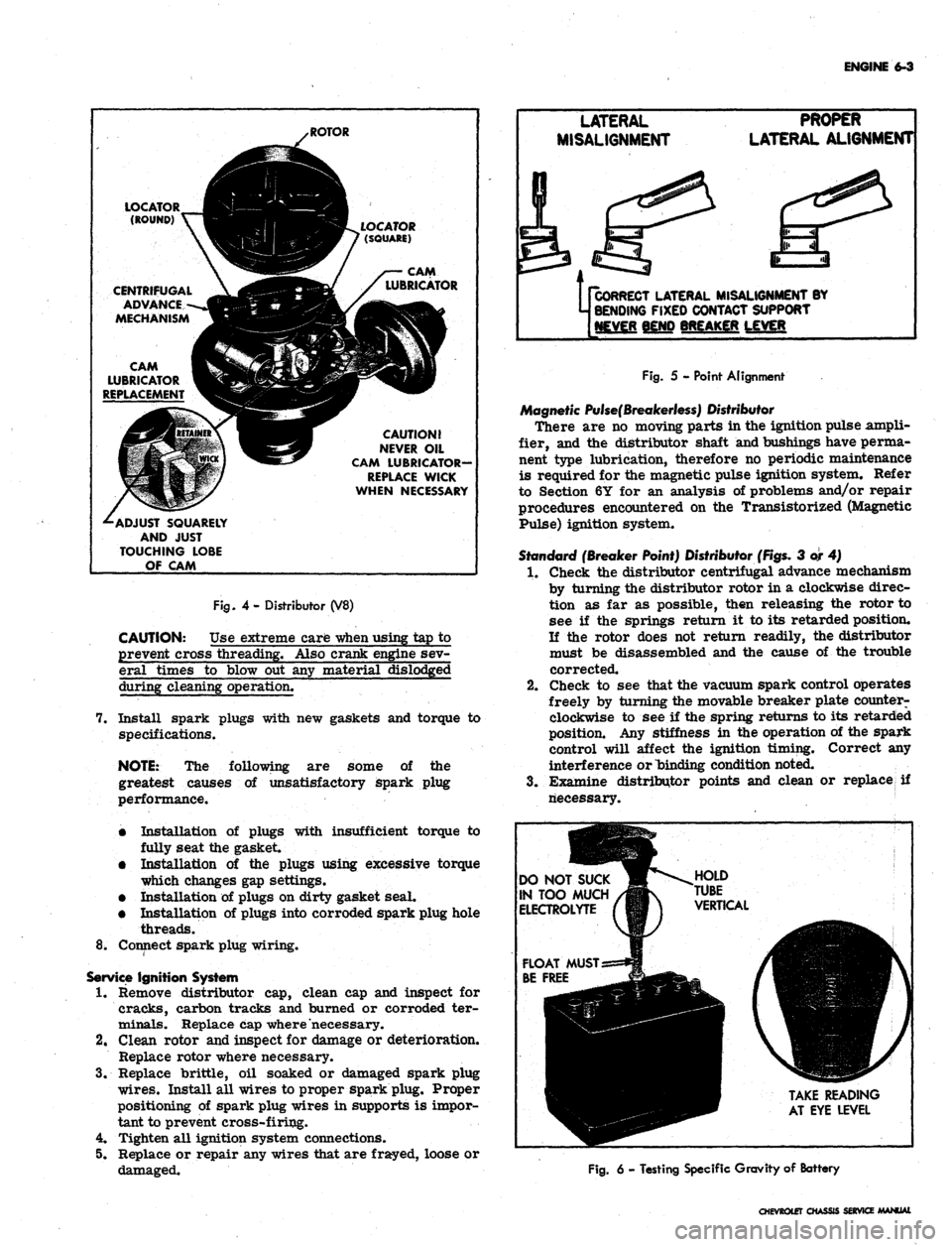

4- Distributor (V8)

CAUTION: Use extreme care

-when

using tap to

prevent cross threading. Also crank engine sev-

eral times to blow out any material dislodged

during cleaning operation.

7. Install spark plugs with new gaskets and torque to

specifications.

NOTE:

The following are some of the

greatest causes of unsatisfactory spark plug

performance.

•

Installation of plugs with insufficient torque to

fully seat the gasket.

•

Installation of the plugs using excessive torque

which changes gap settings.

•

Installation of plugs on dirty gasket seal.

•

Installation of plugs into corroded spark plug hole

threads.

8^ Connect spark plug wiring.

Service

Ignition System

1.

Remove distributor cap, clean cap and inspect for

cracks, carbon tracks and burned or corroded ter-

minals. Replace cap where necessary.

2.

Clean rotor and inspect for damage or deterioration.

Replace rotor where necessary.

3.

Replace brittle, oil soaked or damaged spark plug

wires.

Install all wires to proper spark plug. Proper

positioning of spark plug wires in supports is impor-

tant to prevent cross-firing.

4.

Tighten all ignition system connections.

5. Replace or repair any wires that are frayed, loose or

damaged.

Us

CORRECT

LATERAL MISALIGNMENT BY

j BENDING

FIXED CONTACT SUPPORT

[NEVER

BEND BREAKER LEVER

Fig.

5 - Point Alignment

Magnetic

Pulse(Breakerless)

Distributor

There are no moving parts in the ignition pulse ampli-

fier, and the distributor shaft and bushings have perma-

nent type lubrication, therefore no periodic maintenance

is required for the magnetic pulse ignition system. Refer

to Section 6Y for an analysis of problems and/or repair

procedures encountered on the Transistorized (Magnetic

Pulse) ignition system.

Standard

(Breaker Point) Distributor

(Figs.

3 or 4)

1.

Check the distributor centrifugal advance mechanism

by turning the distributor rotor in a clockwise direc-

tion as far as possible, then releasing the rotor to

see if the springs return it to its retarded position.

If the rotor does not return readily, the distributor

must be disassembled and the cause of the trouble

corrected.

2.

Check to see that the vacuum spark control operates

freely by turning the movable breaker plate counter-

clockwise to see if the spring returns to its retarded

position. Any stiffness in the operation of the spark

control will affect the ignition timing. Correct any

interference or binding condition noted.

3.

Examine distributor points and clean or replace if

riecessary.

DO

NOT SUCK

IN

TOO MUCH

ELECTROLYTE

TAKE

READING

AT

EYE LEVEL

Fig.

6 - Testing Specific Gravity of Battery

CHEVROtET

CHASSIS SERVICE MANUAL