lock CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 140 of 659

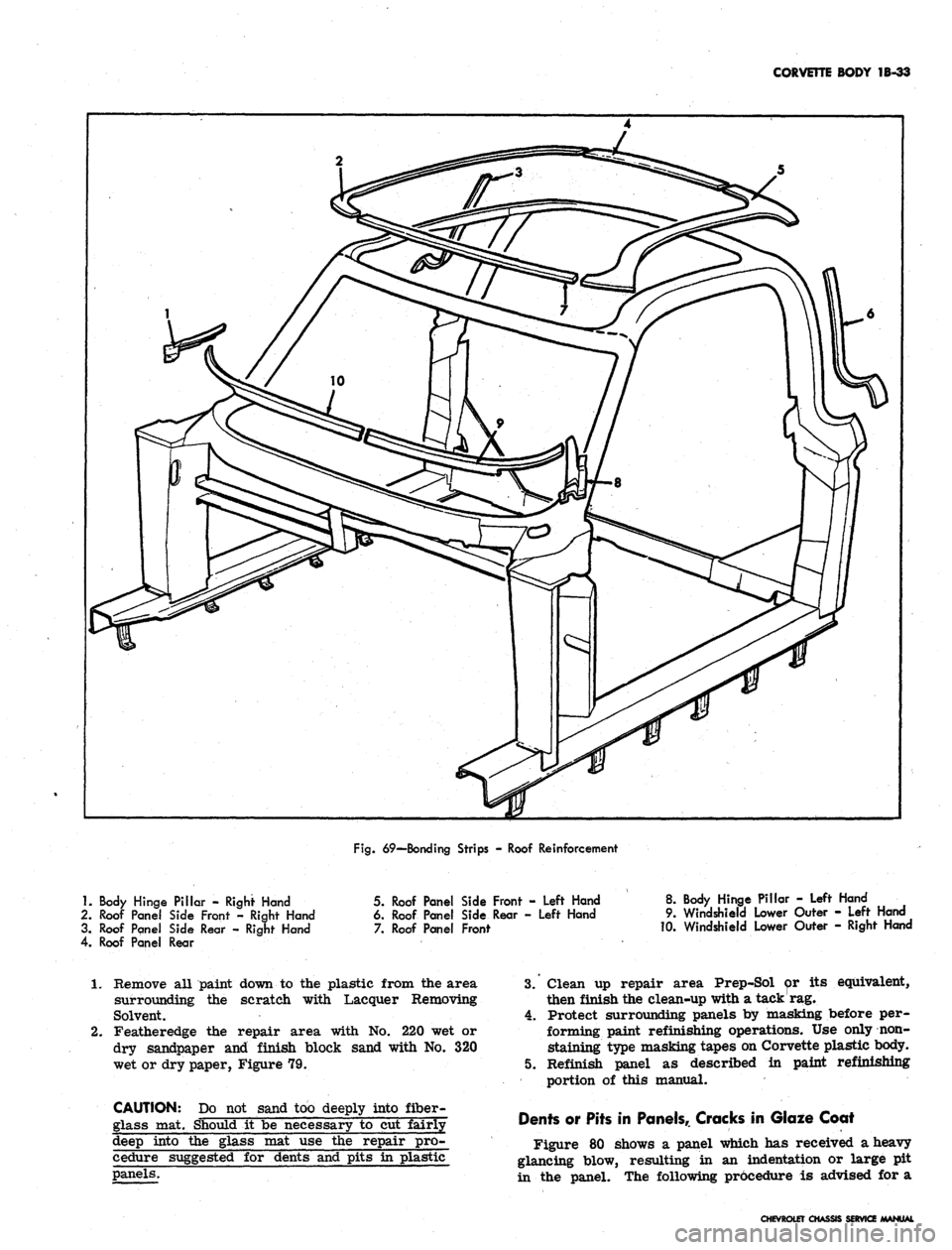

CORVETTE BODY 1B-33

Fig.

69~Bonding Strips - Roof Reinforcement

1.

Body Hinge Pillar - Right Hand

2.

Roof Panel Side Front - Right Hand

3. Roof Panel Side Rear - Right Hand

4.

Roof Panel Rear

5. Roof Panel Side Front - Left Hand

6. Roof Panel Side Rear - Left Hand

7. Roof Panel Front

8. Body Hinge Pillar - Left Hand

9. Windshield Lower Outer - Left Hand

10.

Windshield Lower Outer - Right Hand

1.

Remove all paint down to the plastic from the area

surrounding the scratch with Lacquer Removing

Solvent.

2.

Featheredge the repair area with No. 220 wet or

dry sandpaper and finish block sand with No. 320

wet or dry paper, Figure 79.

CAUTION: Do not sand too deeply into fiber-

glass mat. Should it be necessary to cut fairly

deep into the glass mat use the repair pro-

cedure suggested for dents and pits in plastic

panels.

3.

Clean up repair area Prep-Sol or its equivalent,

then finish the clean-up with a tack rag.

4.

Protect surrounding panels by masking before per-

forming paint refinishing operations. Use only non-

staining type masking tapes on Corvette plastic body.

5. Refinish panel as described in paint refinishing

portion of this manual.

Dents or Pits in Panels,. Cracks in Glaze Coat

Figure 80 shows a panel which has received a heavy

glancing blow, resulting in an indentation or large pit

in the panel. The following procedure is advised for a

CHEVROLET CHASSIS SERVICE MANUAL

Page 141 of 659

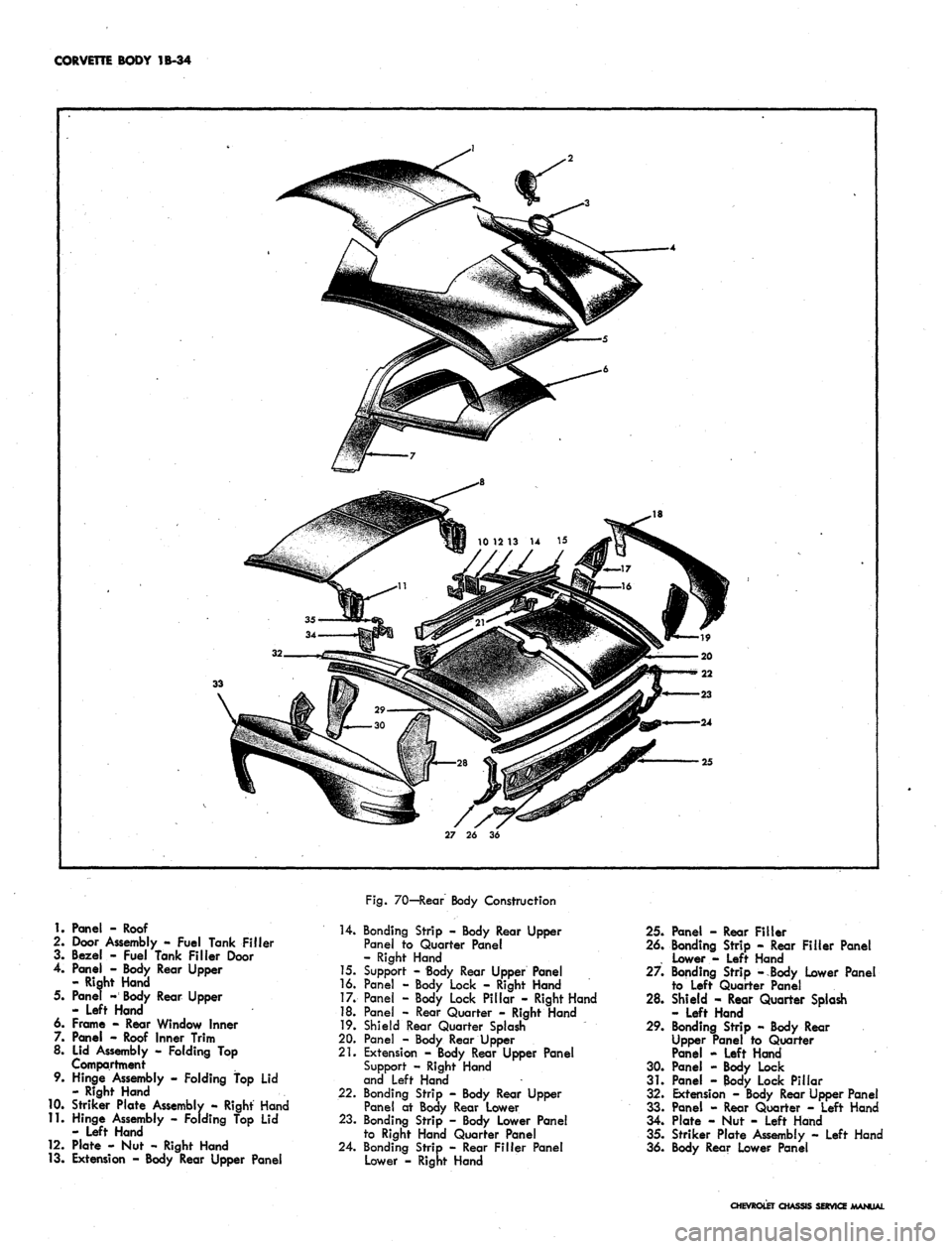

CORVETTE BODY 1B-34

1.

Panel - Roof

2.

Door Assembly - Fuel Tank Filler

3. Bezel - Fuel Tank Filler Door

4.

Panel - Body Rear Upper

- Right Hand

5. Panel - Body Rear Upper

- Left Hand

6. Frame - Rear Window Inner

7. Panel - Roof Inner Trim

8. Lid Assembly - Folding Top

Compartment

9. Hinge Assembly - Folding top Lid

- Right Hand

10.

Striker Plate Assembly - Right Hand

11.

Hinge Assembly - Folding Top Lid

- Left Hand

12.

Plate - Nut - Right Hand

13.

Extension - Body Rear Upper Panel

Fig.

70—Rear Body Construction

14.

Bonding Strip - Body Rear Upper

Panel to Quarter Panel

- Right Hand

15.

Support - Body Rear Upper Panel

16.

Panel - Body Lock - Right Hand

17.

Pane! - Body Lock Pillar - Right Hand

18.

Panel - Rear Quarter - Right Hand

19.

Shield Rear Quarter Splash

20.

Panel - Body Rear Upper

21.

Extension - Body Rear Upper Panel

Support - Right Hand

and Left Hand

22.

Bonding Strip - Body Rear Upper

Panel at Body Rear Lower

23.

Bonding Strip - Body Lower Panel

to Right Hand Quarter Panel

24.

Bonding Strip - Rear Filler Panel

Lower - Right Hand

25.

Panel - Rear Filler

26.

Bonding Strip - Rear Filler Panel

. Lower - Left Hand

27.

Bonding Strip -Body Lower Panel

to Left Quarter Panel

28.

Shield - Rear Quarter Splash

- Left Hand

29.

Bonding Strip - Body Rear

Upper Panel to Quarter

Panel - Left Hand

30.

Panel - Body Lock

31.

Panel - Body Lock Pillar

32.

Extension - Body Rear Upper Panel

33.

Panel - Rear Quarter - Left Hand

34.

Plate - Nut - Left Hand

35.

Striker Plate Assembly - Left Hand

36.

Body Rear Lower Panel

CHEVROLET CHASSIS SERVICE MANUAL

Page 156 of 659

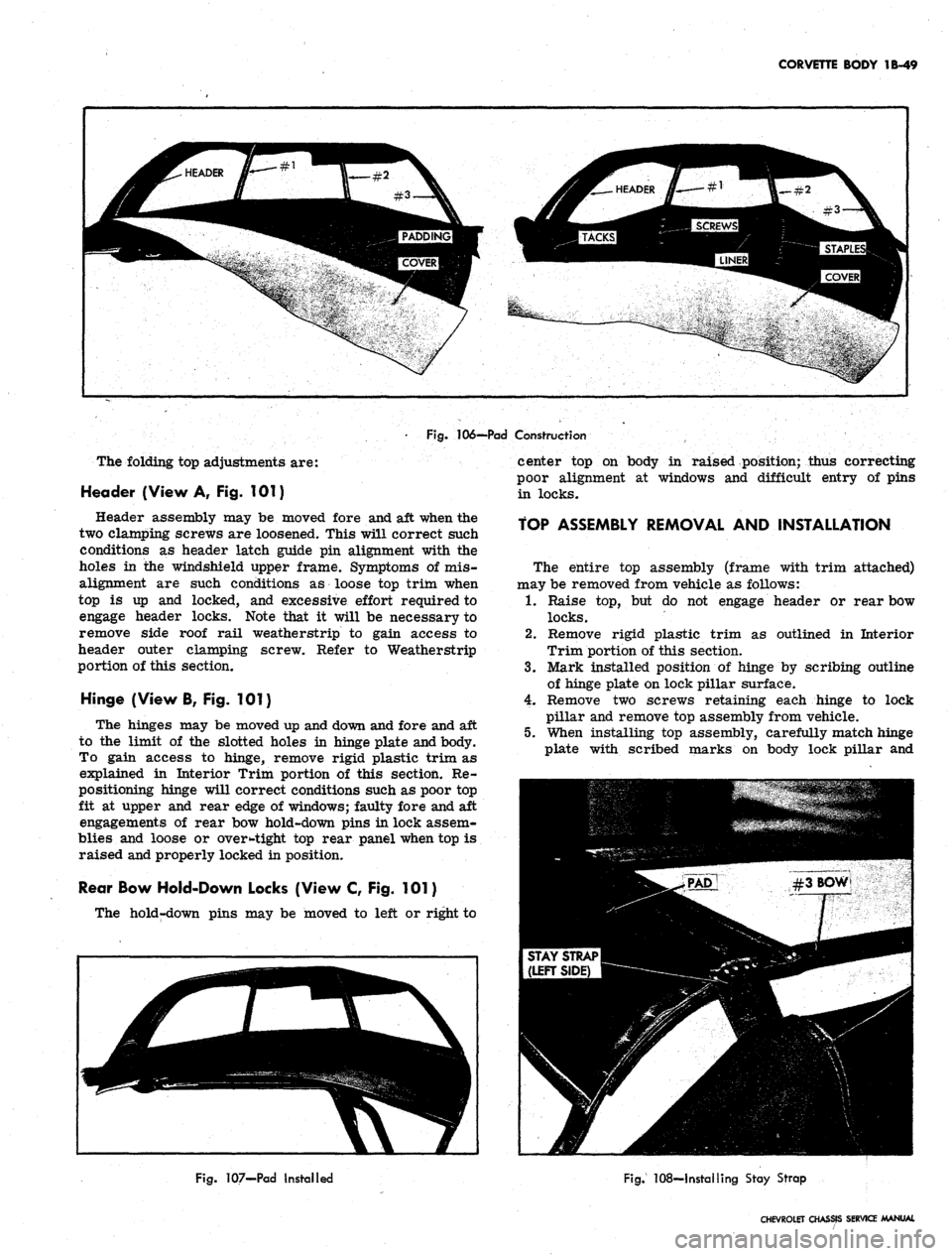

CORVETTE BODY 1B-49

Fig.

106-—Pad Construction

The folding top adjustments are:

Header (View A, Fig. 101)

Header assembly may be moved fore and aft when the

two clamping screws are loosened. This will correct such

conditions as header latch guide pin alignment with the

holes in the windshield upper frame. Symptoms of mis-

alignment are such conditions as loose top trim when

top is up and locked, and excessive effort required to

engage header locks. Note that it will be necessary to

remove side roof rail weatherstrip to gain access to

header outer clamping screw. Refer to Weatherstrip

portion of this section.

Hinge (View B, Fig. 101)

The hinges may be moved up and down and fore and aft

to the limit of the slotted holes in hinge plate and body.

To gain access to hinge, remove rigid plastic trim as

explained in Interior Trim portion of this section. Re-

positioning hinge will correct conditions such as poor top

fit at upper and rear edge of windows; faulty fore and aft

engagements of rear bow hold-down pins in lock assem-

blies and loose or oversight top rear panel when top is

raised and properly locked in position.

Rear Bow Hold-Down Locks (View C, Fig. 101)

The hold-down pins may be moved to left or right to

center top on body in raised position; thus correcting

poor alignment at windows and difficult entry of pins

in locks.

TOP ASSEMBLY REMOVAL AND INSTALLATION

The entire top assembly (frame with trim attached)

may be removed from vehicle as follows:

1.

Raise top, but do not engage header or rear bow

locks.

2.

Remove rigid plastic trim as outlined in Interior

Trim portion of this section.

3.

Mark installed position of hinge by scribing outline

of hinge plate on lock pillar surface.

4.

Remove two screws retaining each hinge to lock

pillar and remove top assembly from vehicle.

5.

When installing top assembly, carefully match hinge

plate with scribed marks on body lock pillar and

Fig.

107-Pad Installed

Fig.

108—Installing Stay Strap

CHEVROLET CHASSIS SERVICE MANUAL

Page 158 of 659

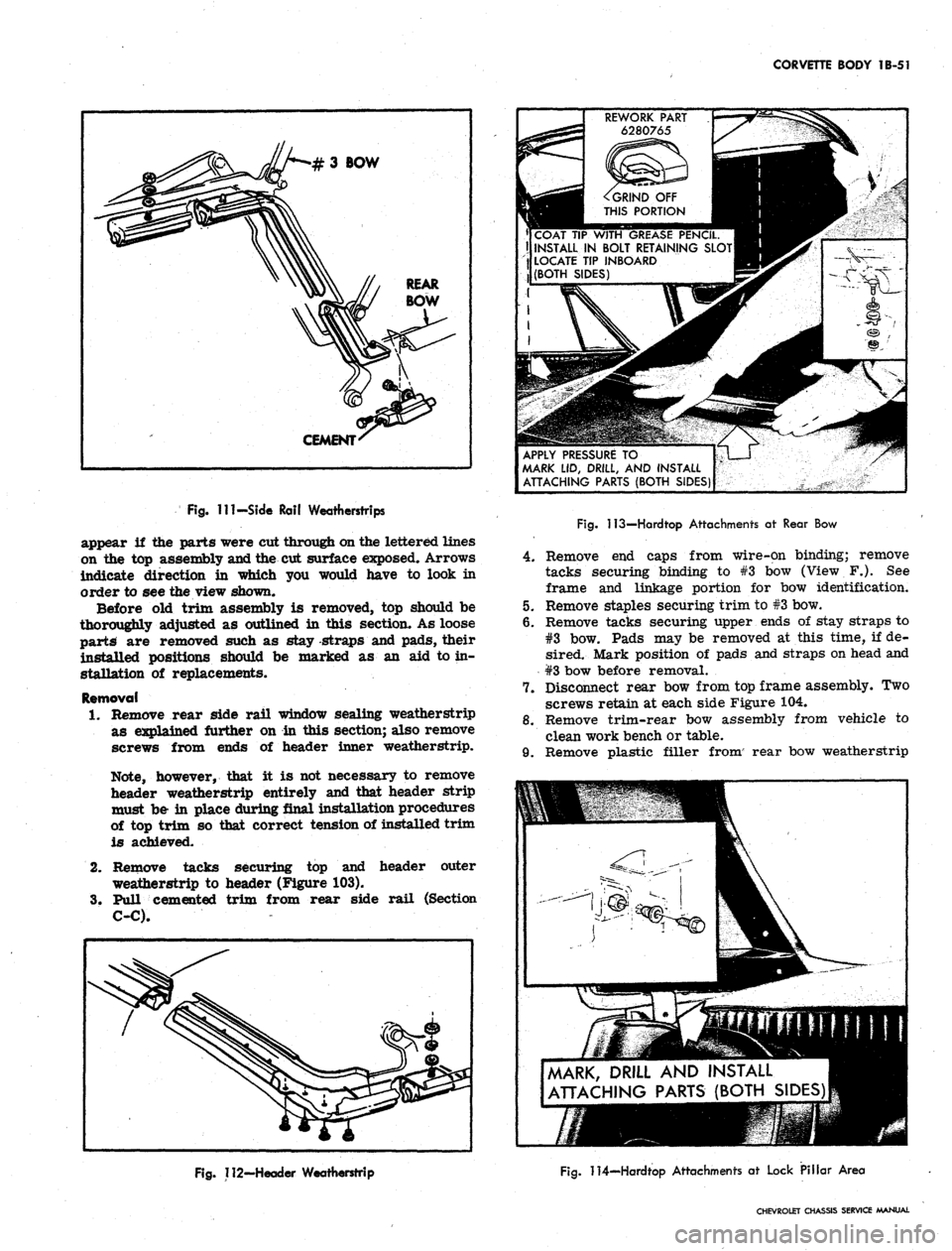

CORVETTE BODY

1B-51

Fig.

Ill-Side Rail Weatherstrips

appear

if the

parts were cut through on the lettered lines

on

the top

assembly and the

cut

surface exposed. Arrows

indicate direction

in

which

you

would have

to

look

in

order

to see

the view shown.

Before

old

trim assembly

is

removed,

top

should

be

thoroughly adjusted

as

outlined

in

this section.

As

loose

parts

are

removed such

as

stay -straps

and

pads, their

installed positions should

be

marked

as an aid to in-

stallation

of

replacements.

Removal

1.

Remove rear side rail window sealing weatherstrip

as explained further

on in

this section; also remove

screws from ends

of

header inner weatherstrip.

Note, however, that

it is not

necessary

to

remove

header weatherstrip entirely

and

that header strip

must

be- in

place during final installation procedures

of

top

trim

so

that correct tension

of

installed trim

is achieved.

2.

Remove tacks securing

top and

header outer

weatherstrip

to

header (Figure

103).

3.

Pull cemented trim from rear side rail (Section

C-C).

REWORK PART

6280765

^GRIND

OFF

THIS PORTION

COAT

TIP

WITH GREASE PENCIL.

II INSTALL

IN

BOLT RETAINING SLOT

LOCATE

TIP

INBOARD

(BOTH SIDES)

APPLY PRESSURE

TO

MARK

LID,

DRILL,

AND

INSTALL

ATTACHING PARTS (BOTH SIDES)

Fig.

113—Hardtop Attachments

at

Rear

Bow

4.

Remove end caps from wire-on binding; remove

tacks securing binding to #3 bow (View F.). See

frame and linkage portion for bow identification.

5.

Remove staples securing trim to #3 bow.

6. Remove tacks securing upper ends of stay straps to

#3 bow. Pads may be removed at this time, if de-

sired. Mark position of pads and straps on head and

#3 bow before removal.

7.

Disconnect rear bow from top frame assembly. Two

screws retain at each side Figure 104.

8. Remove trim-rear bow assembly from vehicle to

clean work bench or table.

9. Remove plastic filler from' rear bow weatherstrip

MARK, DRILL

AND

INSTALL

ATTACHING PARTS (BOTH SIDES)

Fig.

112-Header Weatherstrip

Fig.

114—Hardtop Attachments

at

Lock Pillar Area

CHEVROLET CHASSIS SERVICE MANUAL

Page 159 of 659

CORVETTE BODY 1B-52

and pull weatherstrip and trim from rear bow.

Section A-A shows installed position of these com-

ponents. Refer also to figure 105.

installation

1.

Find and mark center of header, #3 bow, rear bow

and leading and trailing edges of top trim. Align

these marks during installation and recheck their

alignment from time to time while installation is in

progress, especially during tacking or stapling.

2.

Assemble top trim and weatherstrip to rear bow,

referring to Section A-A and Figure 105. Note that

filler strip locks this assembly together and goes

in last. Align center marks.

3.

If new pads are required, install at this time, align-

ing with marks made when old pads were removed.

Figure 106 shows pad construction; Figure 107 shows

pad installed.

4.

Install top trim-rear bow assembly on top frame

with four screws removed at disassembly.

5.

Lock down rear bow in desired "top up" position.

Pull up stay straps and staple or tack to #3 bow

(fig. 108).

6. Pull leading edge of trim iip to header and align

center marks. Smooth out fabric and clamp, tack

or staple temporarily to header.

7.

Draw window extension up to #3 bow, aligning cen-

tering marks. Turn an ample amount of fabric under

and tack to #3 bow. Apply neoprene trim cement,

GM Part #3695016 or equivalent, to area shown in

View D of Figure 102. Follow directions on package.

8. Draw roof portion of trim over #3 bow, align marks

and tack on staple.

9. Trim off excess material and install wire-on binding

as shown in Figure 109 and View D of Figure 102.

Install binding caps.

10.

Remove temporary clamps or fastenings holding trim

to header.

11.

With header locked down, pull trim assembly up tight

and mark for final installation.

12.

Apply trim cement to header and rear side rail.

13.

Release header from windshield. Tack or staple trim

to header (fig. 103).

14.

Apply trim to rear side frame, previously cemented.

15.

Install weatherstrips which were removed at dis-

assembly and install retaining screws in header

weatherstrip.

16.

Make any adjustments necessary, following instruc-

tions listed under Folding Top—Adjustments.

FRAME AND LINKAGE

Figure 110 illustrates construction features of the

folding top frame and linkage. Various cross sections in

Figure 110 show the pivoting joints and their assembly.

If an operation is being performed which requires

removal of folding top trim, follow directions in this

section. The entire frame assembly may be removed and

replaced as a unit. Follow instructions for Folding Top

Trim and Rear Window Assembly and Top Assembly—

Removal and Installation.

The pivoting joints should be lubricated with light

machine oil once a year. Apply oil sparingly so as not

to stain top trim.

WEATHERSTRIP

Side Rail Weatherstrip

Figure 111 illustrates installation of side rail weather-

strip which acts to seal window opening. The weather-

strip is held in place by studs which are part of the

weatherstrip assembly, and by neoprene base cement

which is applied between weatherstrip and side rail

surface.

When replacing weatherstrip remove all rust, old

cement and foreign material from the surfaces to be

cemented, to assure successful bonding. Use only good

quality neoprene cement suitable for weatherstrip

application.

Header Weatherstrip

Weatherstrip assembly is retained to the header panel

by a combination of studs, sheet metal screws and special

fasteners as shown in Figure 112, along with neoprene

base weatherstrip cement.

Figure 99 shows' a cross section of weatherstrip taken

through a special fastener. To replace fastener, rotate

ninety degrees to align fastener head with slot. Follow

directions for cementing in the Side Rail Weatherstrip

instructions preceding this write up.

ADDING HARDTOP (ROOF PANEL ASSEMBLY)

An available roof panel assembly (hardtop) complete

can be added to convertible model Corvettes. The hard-

ware is included with the panel assembly.

Reworking of a plastic part (one for each side of the

roof panel) can be used as a marker for drilling of two

required holes in the folding top compartment lid* Hard-

ware is attached at four locations — two on the lid and

two (one each side) at the lock pillar area as follows:

1.

Rework two plastic retainers (#6280765) (used on

Chevrolet and Corvair door inner panels for trim

retention) as shown by Figure 113.

2.

Slide the reworked plastic retainers into the bolt re-

tainer slots on each side of the hardtop rear bow

(position plastic tip inboard).

3.

Mark the hardtop reveal molding at the approximate

location of the two plastic retainers,

4.

Mark the tips of the two plastic retainers with a

china marker pencil.

5.

Close the soft top compartment lid.

6. With aid of an ^assistant, position front of hardtop

onto header and lower onto vehicle. Do not fasten

latches at windshield header.

7.

Apply hand pressure at reveal molding marks.

8. Mark roof panel attachment hole location at each

lock pillar area (fig. 114).

9. With aid of an assistant, lift roof panel straight up

off body and set roof panel aside.

10.

Mark the drill position at the four china marks with

a center punch.

11.

Place a 2" x 4" board under the top compartment lid

to prevent drill damage to folding top material. Make

certain the compartment lid is securely locked

before drilling.

12.

Drill 1/8" pilot hole at the 4 marked locations.

CHEVROLET CHASSIS SERVICE MANUAL

Page 160 of 659

CORVETTE BODY 1B-53

13.

Drill 1/2" hole at pilot hole locations.

14..

Insert ferrules furnished for holes drilled in top

compartment lid. Crimp ferrule tabs.

15.

With aid of an assistant, place the hardtop onto the

vehicle and install attaching parts at all four loca-

tions.

Lock latches at windshield header.

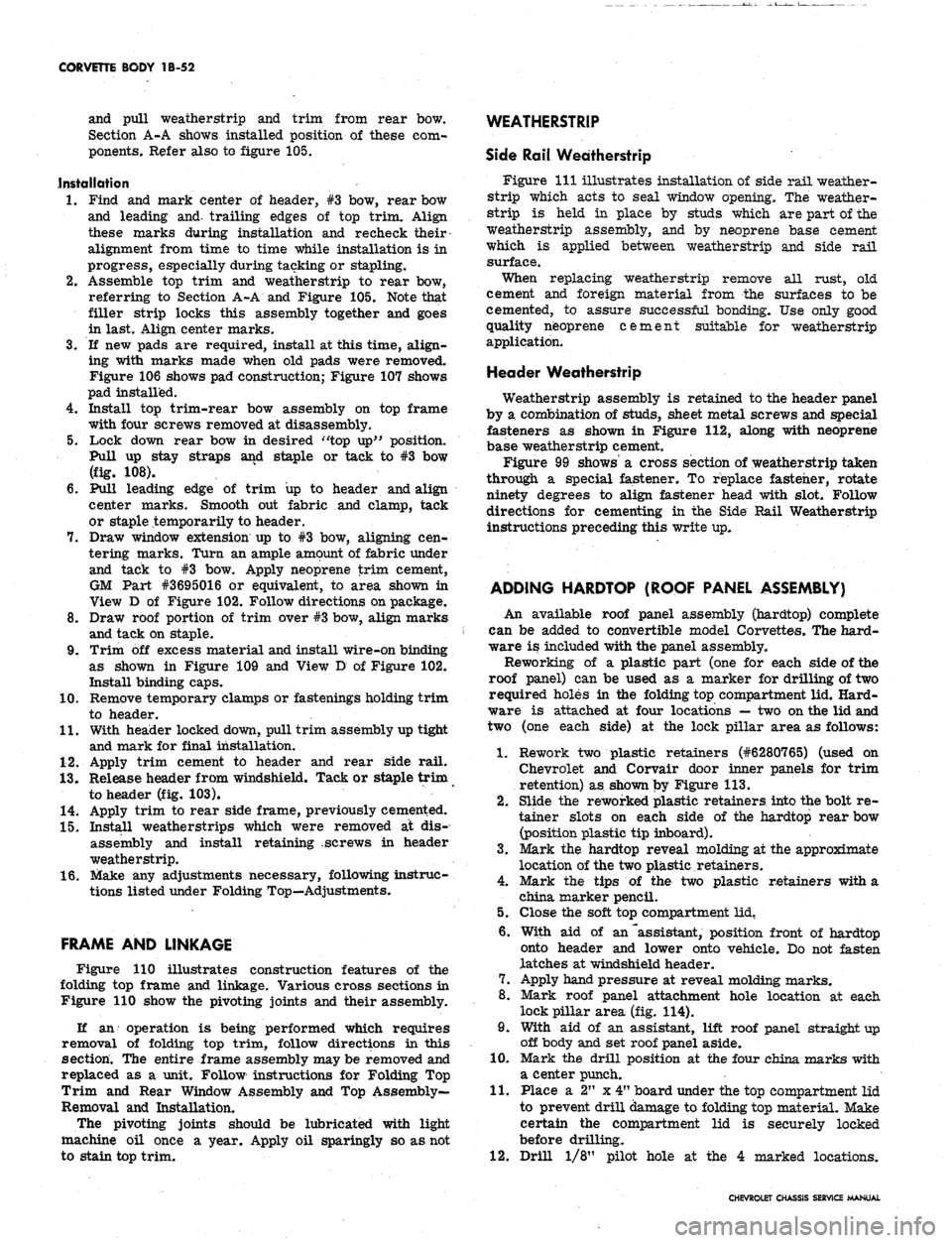

SPECIAL TOOLS

1.

J9559 - Hood Spring

Tool

Fig.

115-Special Tools

2.

J7797 - Door Handle

Clip Remover

3. J8942 - Windshield Opening

Checking Blocks

CHEVROLET CHASSIS SERVICE MANUAL

Page 167 of 659

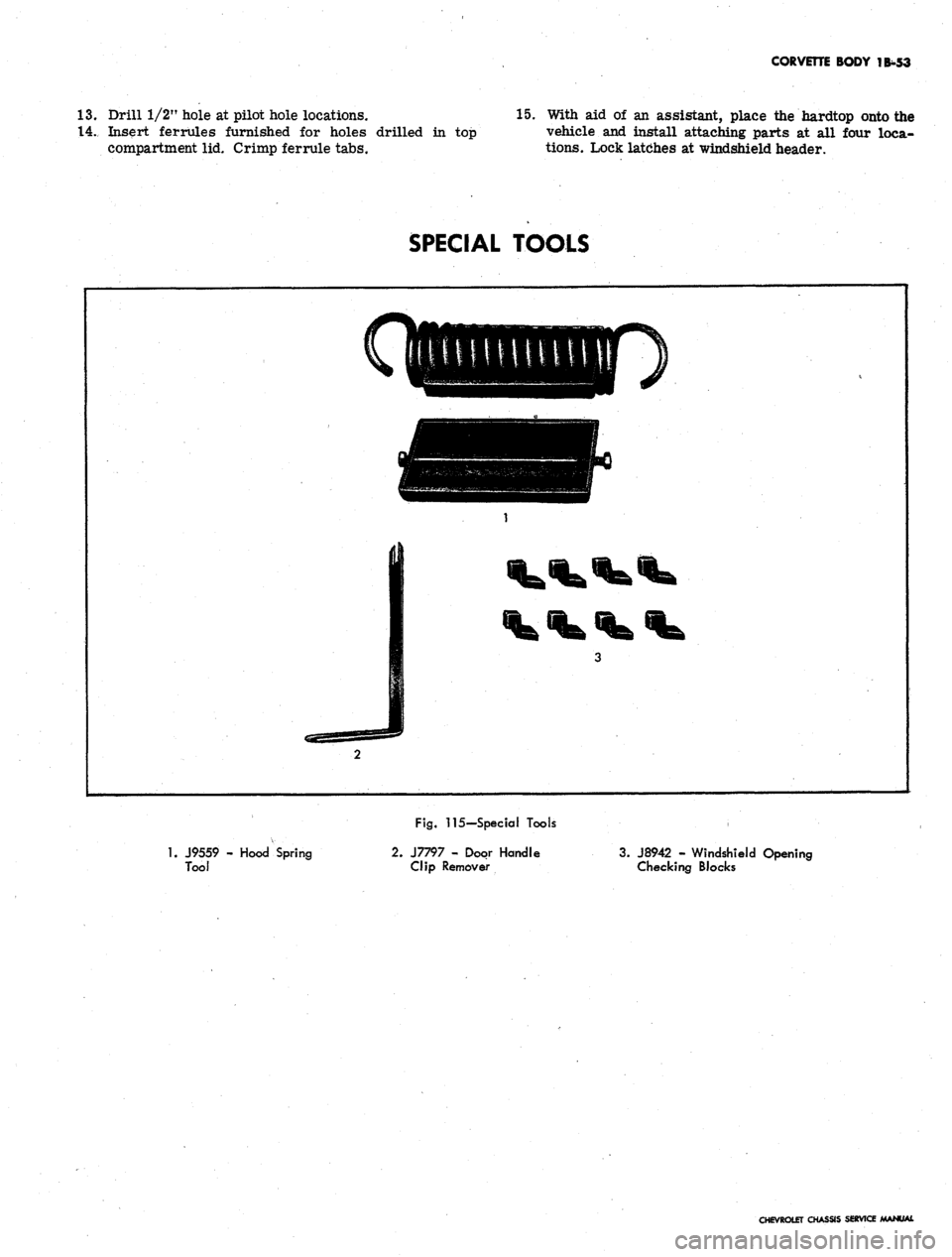

FRONT SUSPENSION 3-3

by means of a lower control arm inner pivot cam; on the

Chevelle, Camaro and Corvette by means of upper control

arm inner support shaft shims.

Caster angle is adjusted, on the Chevrolet and Chevy n

by means of a strut rod which runs from the lower con-

trol arm forward to a frame brace; on the Chevelle,

Camaro and Corvette by means of upper control arm

inner support shaft shims.

A stabilizer bar is used on all Chevelle and Corvette

models. Chevrolet Impalas, station wagons and V-8

engine equipped models are fitted with the stabilizer bar.

UPPER CONTROL ARM

STABILIZER

SPRING

LOWER CONTROL ARM

STEERING KNUCKLE

Fig.

3 - Front Suspension - Corvette

MAINTENANCE AND ADJUSTMENTS

Maintenance intervals recommended for lubrication of

front suspension components have been fully covered in

Section 0 of this manual. Only actual adjustment proce-

dures will be covered here.

NOTE:

Unless otherwise indicated all proce-

dures will apply to all five vehicles covered in

this manual.

FRONT WHEEL BEARING ADJUSTMENT

Proper front wheel bearing adjustment has a definite

bearing on the safe operation of a vehicle. Improperly

adjusted front wheel bearings will result in a lack of

steering stability causing wheel wander, shimmy and ex-

cessive tire wear. Very accurate adjustment is possible

because the spindles are drilled both vertically and hori-

zontally and the adjusting nuts are slotted in all six sides.

NOTE:

Wheel bearings should not

be.

repacked

or adjusted as a part of "New Car Conditioning".

1.

With wheel raised, remove hub cap and dust cap and

then remove the cotter pin from the end of the

spindle.

2.

While rotating wheel, tighten spindle nut to 12 lbs. ft

torque.

3.

Back off adjusting nut one flat and insert cotter pin.

If slot and pin hole do not line up, back off the adjust-

ing nut an additional 1/2 flat or less as required to

insert cotter pin.

4.

Spin the wheel to check that it rolls freely and then

lock the cotter pin by spreading the end and bending

it around.

NOTE:

Bearings should have zero preload and

.001"

to .008" end movement when properly ad-

justed on Chevrolet, Chevelle, Camaro and Cor-

vette; .000" to .004" on Chevy H.

5.

Install dust cap, hub cap or wheel disc and lower

wheel.

6. Perform the same operation on each front wheel.

CHEVROLET CHASSIS SERVICE MANUAL

Page 169 of 659

FRONT SUSPENSION 3-5

FRONT END ALIGNMENT

Front end alignment, that is alignment of the inter-

related steering components of the front suspension sys-

tem, must be correctly maintained to assure ease and

stability of steering and satisfactory tire life.

Alignment Preliminary Steps

Several different types of machines are available for

checking all the factors of front end alignment. The in-

structions furnished with each particular machine should

be followed. In all cases, however, checks should be

made with the vehicle level and at curb weight.

Since steering complaints are not always the result of

improper alignment a check should be made to see if any

of the following conditions exist. Any such conditions

should be corrected before proceeding further.

1.

Steering gear loose or improperly adjusted.

2.

Steering gear housing loose at frame.

3.

Excessive wear or play in spherical joints or steer-

ing shaft coupling.

4.

Tie rod or steering connections loose.

5.

Improper front spring heights.

6. Unbalanced or underinflated tires.

7.

Improperly adjusted wheel bearings.

8. Shock absorbers not operating properly.

Wheel alignment should always be made with the vehi-

cle rolled forward taking out any slack in the same man-

ner as when the vehicle is traveling forward.

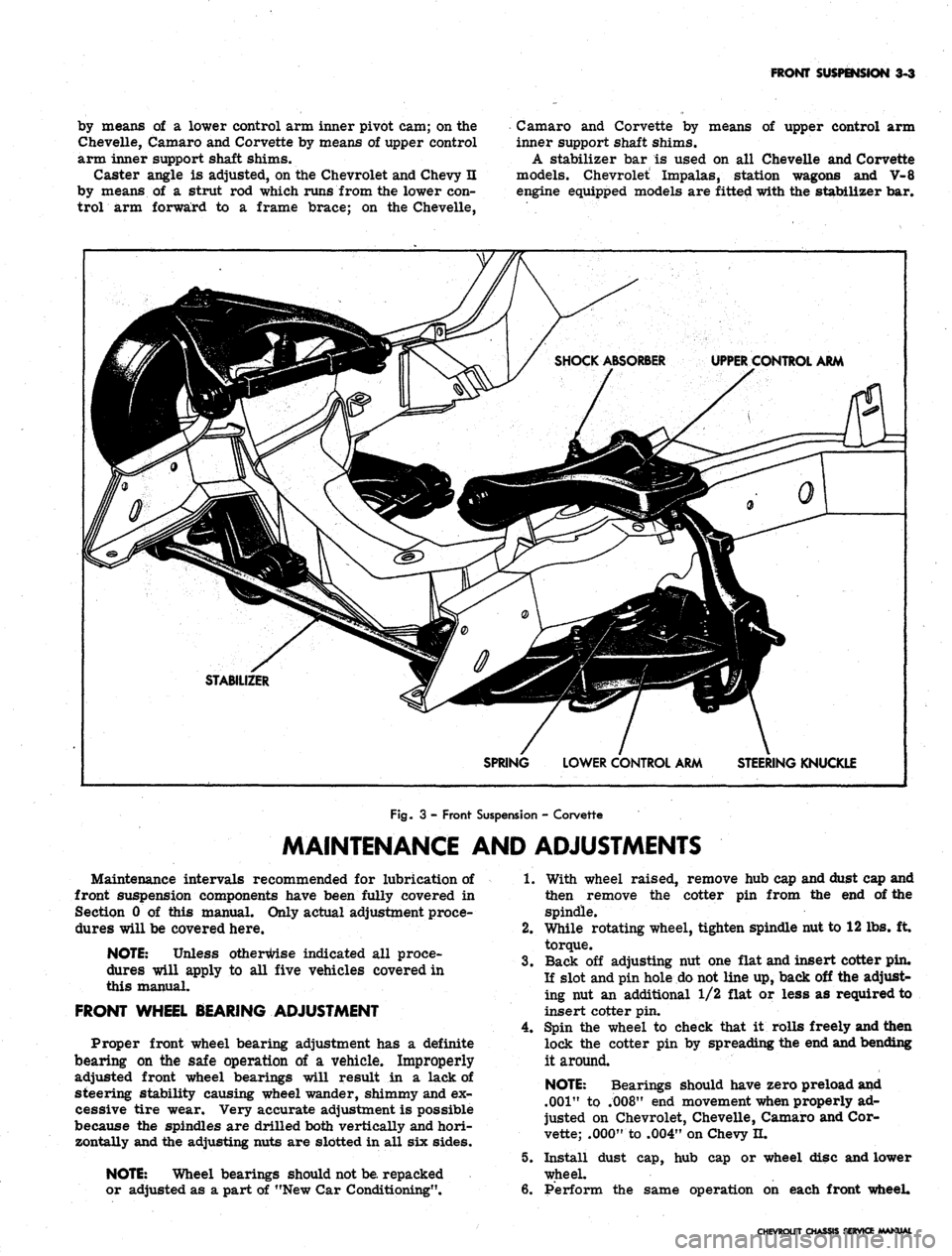

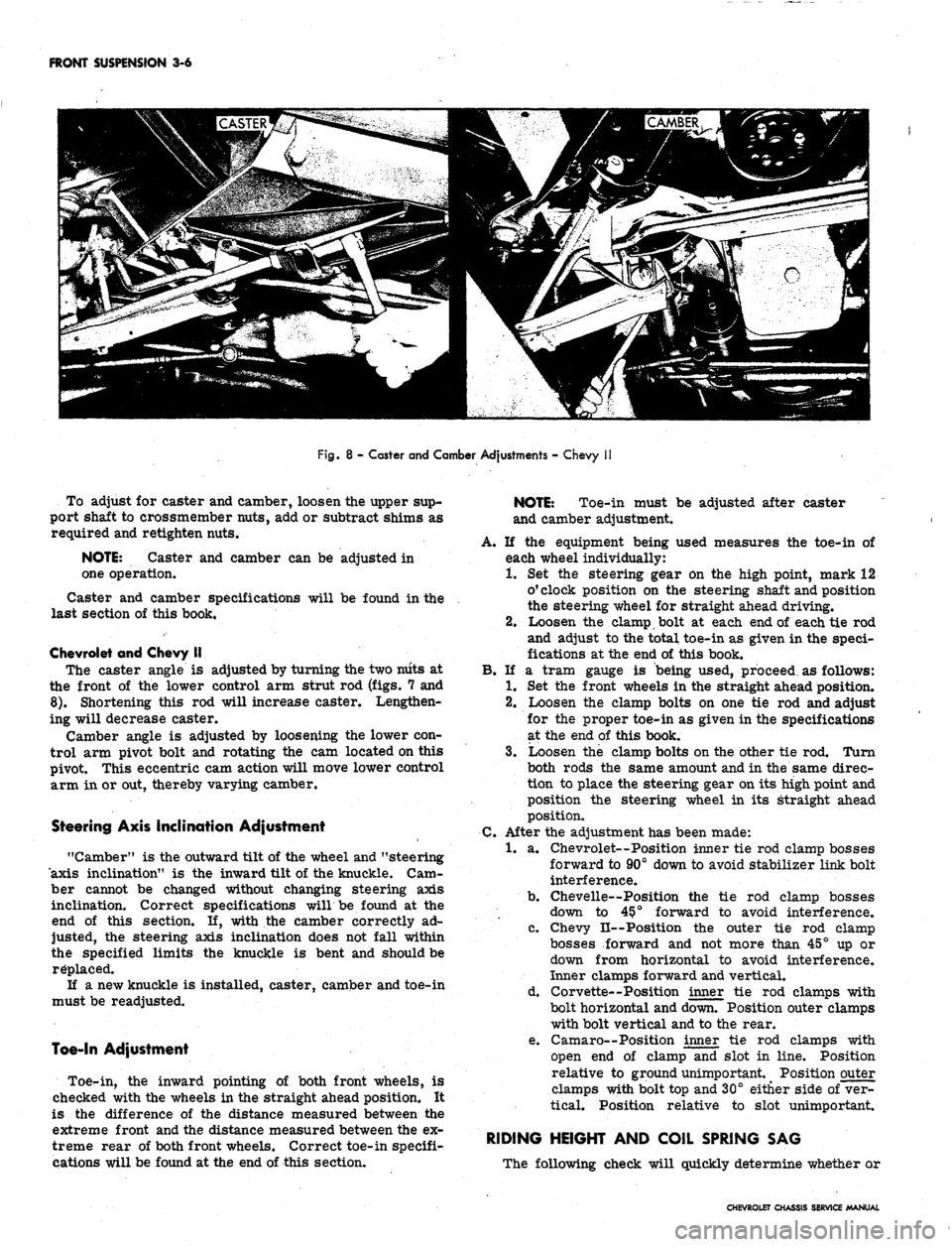

Caster and Camber Adjustment

NOTE: Before adjusting caster and camber

angles, the front bumper should be raised and

quickly released to allow car to return to its

normal height.

Chevelle, Camaro and Corvette

Caster and camber adjustments are made by means of

shims inserted between the upper control arm inner sup-

port shaft and the support bracket attached to the frame

(fig. 6). Shims may be added, subtracted or transferred

to change the readings as follows:

Fig.

6 - Caster and Camber Adjustment - Chevelle

Typical of Corvette and Camaro

Caster - change shims at either the front or rear of

the shaft.

The addition of shims at the front bolt or removal

of shims at the rear bolt will decrease positive

caster. One shim (1/3 2") will change caster (ap-

prox.) 1/4°.

Camber - change shims at both the front and rear of

the shaft.

Adding an equal number of shims at both front and

rear of the support shaft will decrease positive cam-

ber. One shim (1/32") at each location will move

camber (approx.) 1/5° (Chevelle and Camaro); 1/6°

(Corvette).

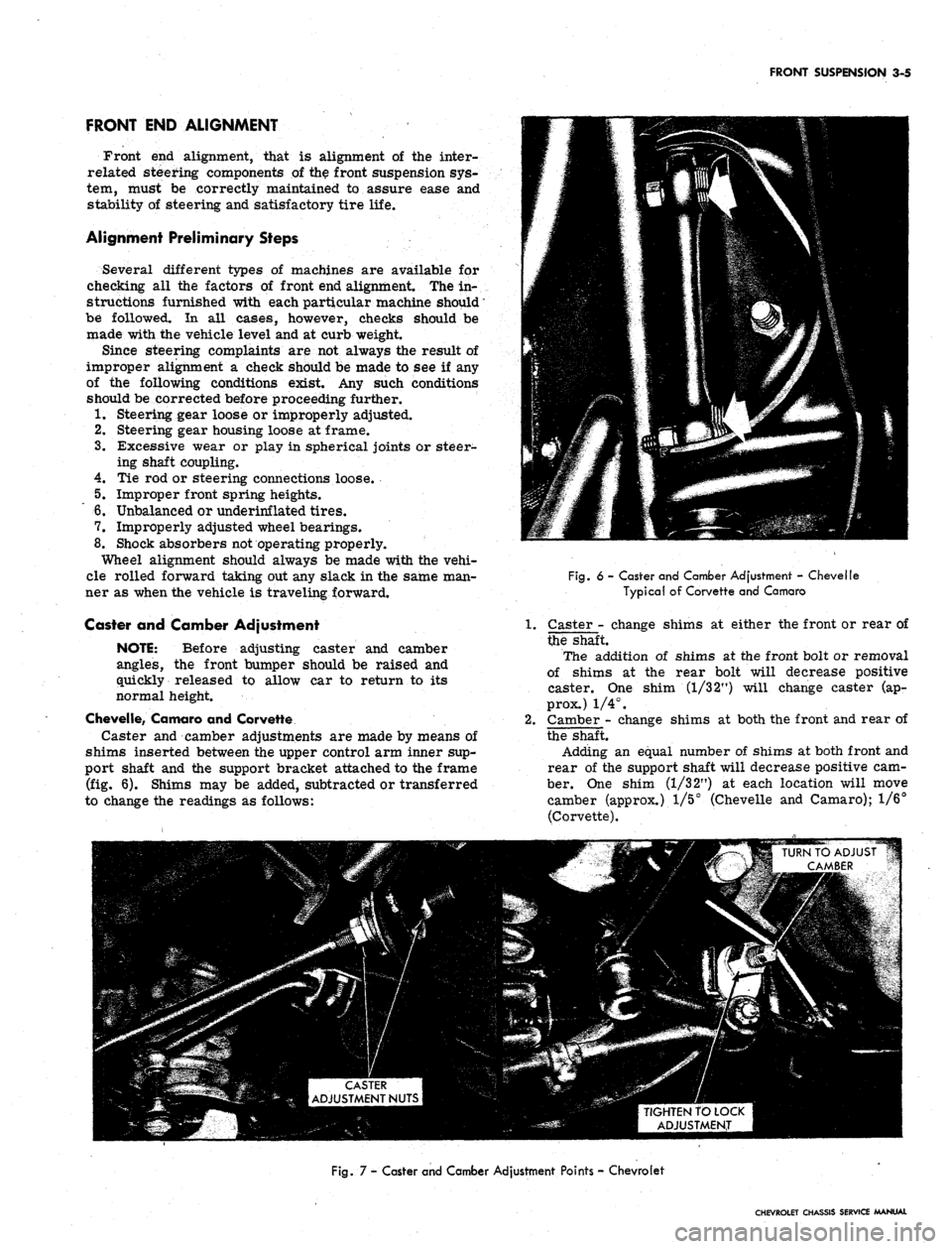

TIGHTEN TO LOCK

ADJUSTMENT

Fig.

7 - Caster and Camber Adjustment Points - Chevrolet

CHEVROLET CHASSIS SERVICE MANUAL

Page 170 of 659

FRONT SUSPENSION 3-6

Fig.

8 - Caster and Camber Adjustments - Chevy

To adjust for caster and camber, loosen the upper sup-

port shaft to crossmember nuts, add or subtract shims as

required and retighten nuts.

NOTE:

Caster and camber can be adjusted in

one operation.

Caster and camber specifications will be found in the

last section of this book.

Chevrolet and Chevy II

The caster angle is adjusted by turning the two niits at

the front of the lower control arm strut rod (figs. 7 and

8).

Shortening this rod will increase caster. Lengthen-

ing will decrease caster.

Camber angle is adjusted by loosening the lower con-

trol arm pivot bolt and rotating the cam located on this

pivot. This eccentric cam action will move lower control

arm in or out, thereby varying camber.

Steering Axis Inclination Adjustment

"Camber" is the outward tilt of the wheel and "steering

axis inclination" is the inward tilt of the knuckle. Cam-

ber cannot be changed without changing steering axis

inclination. Correct specifications willbe found at the

end of this section. If, with the camber correctly ad-

justed, the steering axis inclination does not fall within

the specified limits the knuckle is bent and should be

replaced.

If a new knuckle is installed, caster, camber and toe-in

must be readjusted.

Toe-In Adjustment

Toe-in, the inward pointing of both front wheels, is

checked with the wheels in the straight ahead position. It

is the difference of the distance measured between the

extreme front and the distance measured between the ex-

treme rear of both front wheels. Correct toe-in specifi-

cations will be found at the end of this section.

NOTE:

Toe-in must be adjusted after caster

and camber adjustment.

A. If the equipment being used measures the toe-in of

each wheel individually:

1.

Set the steering gear on the high point, mark 12

o'clock position on the steering shaft and position

the steering wheel for straight ahead driving.

2.

Loosen the clamp bolt at each end of each tie rod

and adjust to the total toe-in as given in the speci-

fications at the end of this book.

B.

If a tram gauge is being used, proceed as follows:

1.

Set the front wheels in the straight ahead position.

2.

Loosen the clamp bolts on one tie rod and adjust

for the proper toe-in as given in the specifications

at the end of this book.

3.

Loosen the clamp bolts on the other tie rod. Turn

both rods the same amount and in the same direc-

tion to place the steering gear on its high point and

position the steering wheel in its straight ahead

position.

C.

After the adjustment has been made:

1.

a. Chevrolet—Position inner tie rod clamp bosses

forward to 90° down to avoid stabilizer link bolt

interference.

b.

Chevelle—Position the tie rod clamp bosses

down to 45?° forward to avoid interference.

c. Chevy II--Position the outer tie rod clamp

bosses forward and not more than 45° up or

down from horizontal to avoid interference.

Inner clamps forward and vertical.

d. Corvette--Position inner tie rod clamps with

bolt horizontal and down. Position outer clamps

with bolt vertical and to the rear.

e. Camaro—Position inner tie rod clamps with

open end of clamp and slot in line. Position

relative to ground unimportant. Position outer

clamps with bolt top and 30° either side of ver-

tical. Position relative to slot unimportant.

RIDING HEIGHT AND COIL SPRING SAG

The following check will quickly determine whether or

CHEVROLET CHASSIS SERVICE MANUAL

Page 174 of 659

FRONT SUSPENSION 3-10

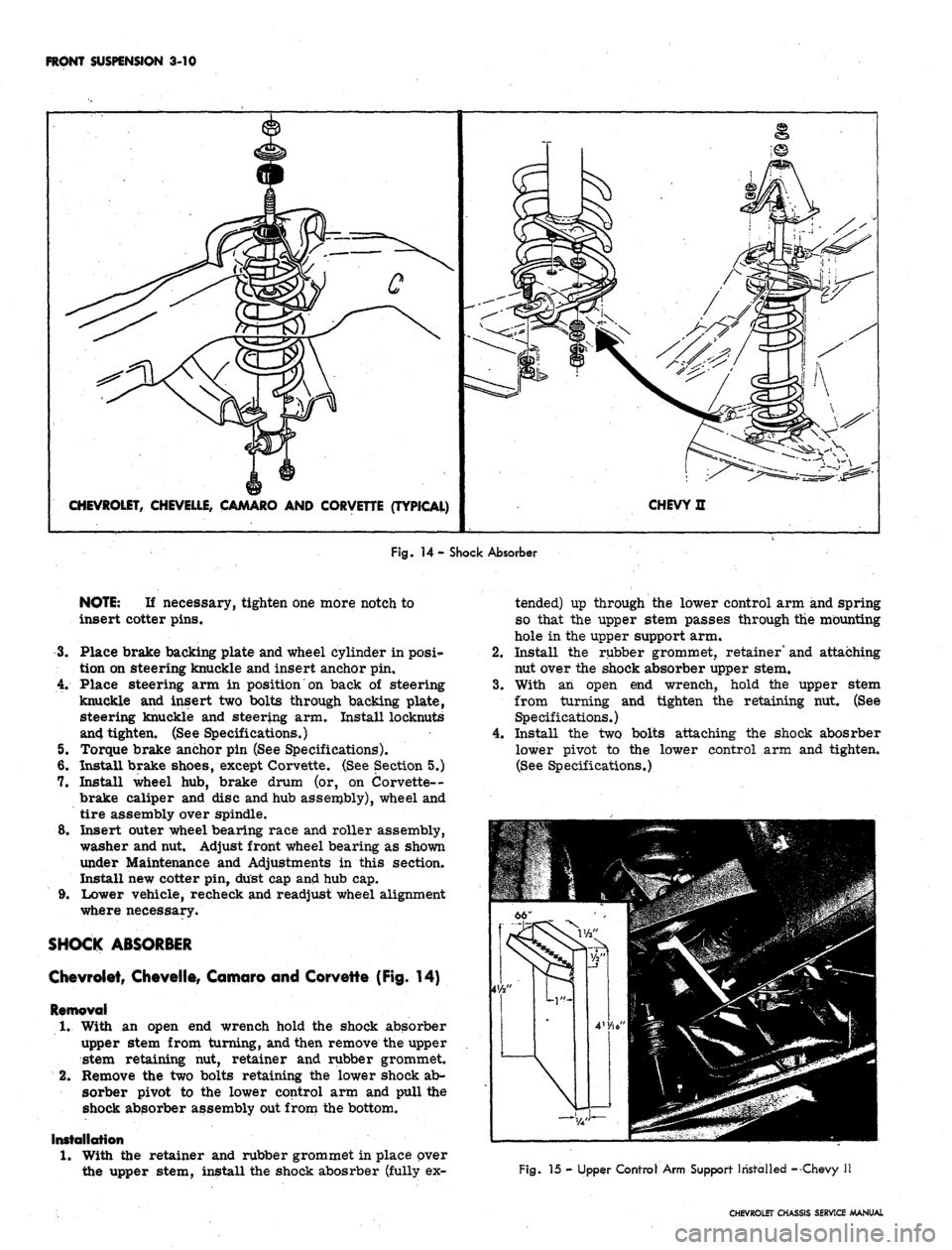

CHEVROLET, CHEVELLE, CAMARO AND CORVETTE (TYPICAL)

CHEVY H

Fig.

14- Shock Absorber

NOTE:

If necessary, tighten one more notch to

insert cotter pins.

3.

Place brake backing plate and wheel cylinder in posi*-

tion on steering knuckle and insert anchor pin.

4.

Place steering arm in position on back of steering

knuckle and insert two bolts through backing plate,

steering knuckle and steering arm. Install locknuts

and tighten. (See Specifications.)

5. Torque brake anchor pin (See Specifications).

6. Install brake shoes, except Corvette. (See Section 5.)

7. Install wheel hub, brake drum (or, on Corvette--

brake caliper and disc and hub assembly), wheel and

tire assembly over spindle.

8. Insert outer wheel bearing race and roller assembly,

washer and nut. Adjust front wheel bearing as shown

under Maintenance and Adjustments in this section.

Install new cotter pin, dust cap and hub cap.

9. Lower vehicle, recheck and readjust wheel alignment

where necessary.

SHOCK ABSORBER

Chevrolet, Chevelle, Comoro and Corvette (Fig. 14)

Removal

1.

With an open end wrench hold the shock absorber

upper stem from turning, and then remove the upper

stem retaining nut, retainer and rubber grommet.

2.

Remove the two bolts retaining the lower shock ab-

sorber pivot to the lower control arm and pull the

shock absorber assembly out from the bottom.

Installation

1.

With the retainer and rubber grommet in place over

the upper stem, install the shock abosrber (fully ex-

tended) up through the lower control arm and spring

so that the upper stem passes through the mounting

hole in the upper support arm.

2.

Install the rubber grommet, retainer' and attaching

nut over the shock absorber upper stem.

3.

With an open end wrench, hold the upper stem

from turning and tighten the retaining nut. (See

Specifications.)

4.

Install the two bolts attaching the shock abosrber

lower pivot to the lower control arm and tighten.

(See Specifications.)

Fig.

15 - Upper Control Arm Support Installed - Chevy II

CHEVROLET CHASSIS SERVICE MANUAL