lock CHEVROLET CAMARO 1967 1.G Chassis Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 123 of 659

CORVETTE

BODY

1B-16

1.

Ventilator Assembly

2.

Ventilator Assembly Mounting

Screw

3.

Window Drive

Pin

Retaining Screw

4.

Regulator Mounting Screw

Fig.

34-Model 19467 Ventilator Assembly

5. Regulator

6. Ventilator Assembly Mounting

Nut - Upper

7. Ventilator Assembly Mounting

Stud - Upper

8. Ventilator Assembly Mounting

Stud - Lower

9. Ventilator Assembly Mounting

Nut -

•

Lower

DOOR LOCK AND REMOTE CONTROLS

For parts identification refer to Figure 46.

Removal

1.

Roll door window fully up.

2.

Remove door trim panel as outlined in this section.

3.

Remove two screws holding door lock remote con-

trol assembly and disengage control from lock re-

mote control rod.

4.

Remove cover from larger access hole in door inner

panel.

5. Remove two screws retaining remote locking control

assembly and disengage control from remote control

locking rod.

6. Remove 4 screws retaining lock assembly, disengage

control rods and remove lock from door pocket.

Installation

To install lock and controls follow removal assembly

in reverse order. All components should be lubricated

before installation.

OUTER HANDLE

For parts identification refer to Figure 47.

Removal

1.

Remove door trim panel as outlined in this section.

Remove larger access hole cover.

2.

Roll door window fully up.

3.

Working through access hole, remove 2 door handle

retaining screws.

4.

Remove handle from door outer surface. Retrieve

reinforcement from inside door pocket. Discard old

Installation

1.

Install new gaskets and position door handle on door

outer panel.

2.

Position reinforcement on door inner panel and in-

stall handle retaining screws.

3.

Carefully check operation of door lock.

4.

Install door trim panel as outlined in this section.

CHEVROLET CHASSIS SERVICE MANUAL

Page 124 of 659

CORVETTE BODY 1B-17

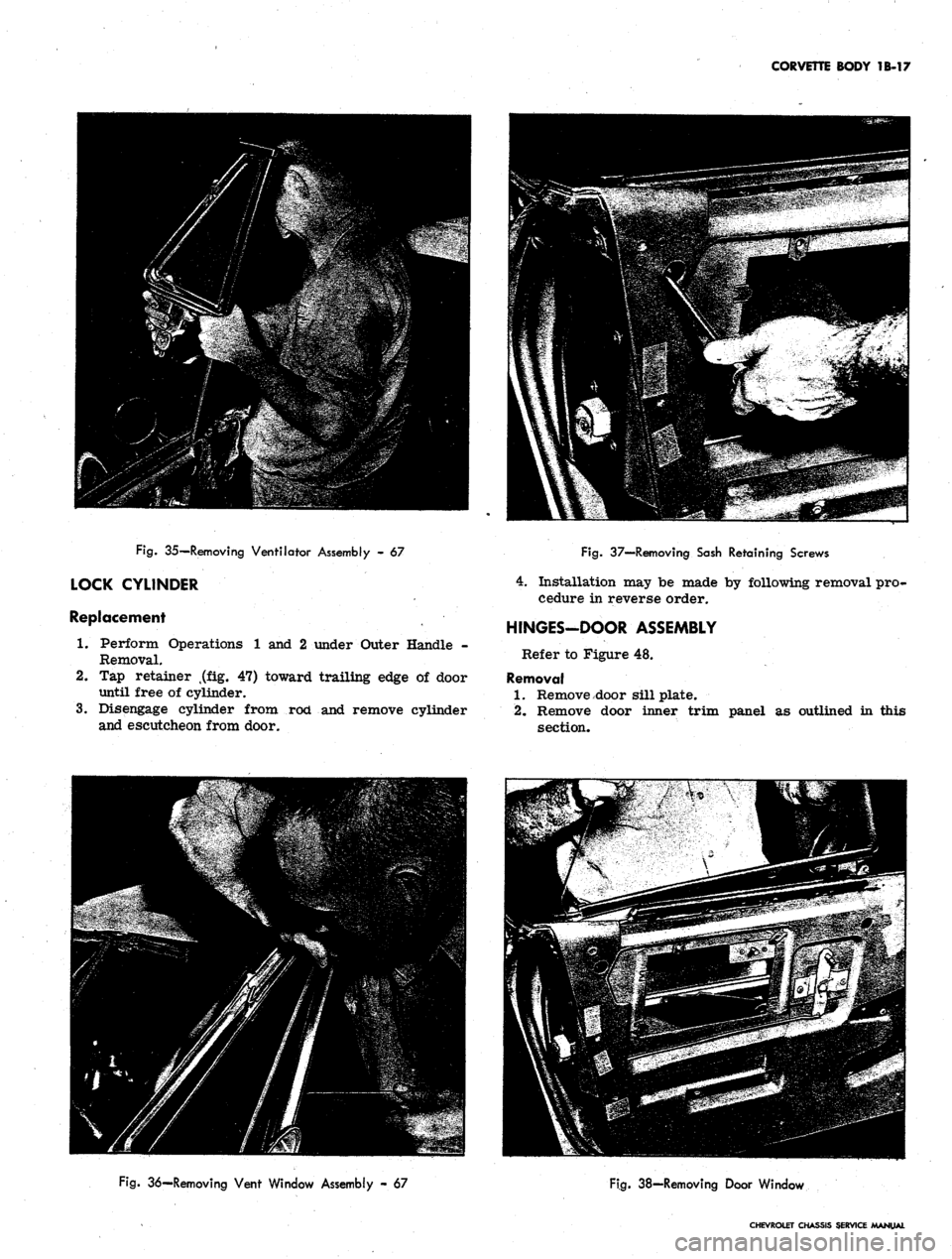

Fig.

35—Removing Ventilator Assembly - 67

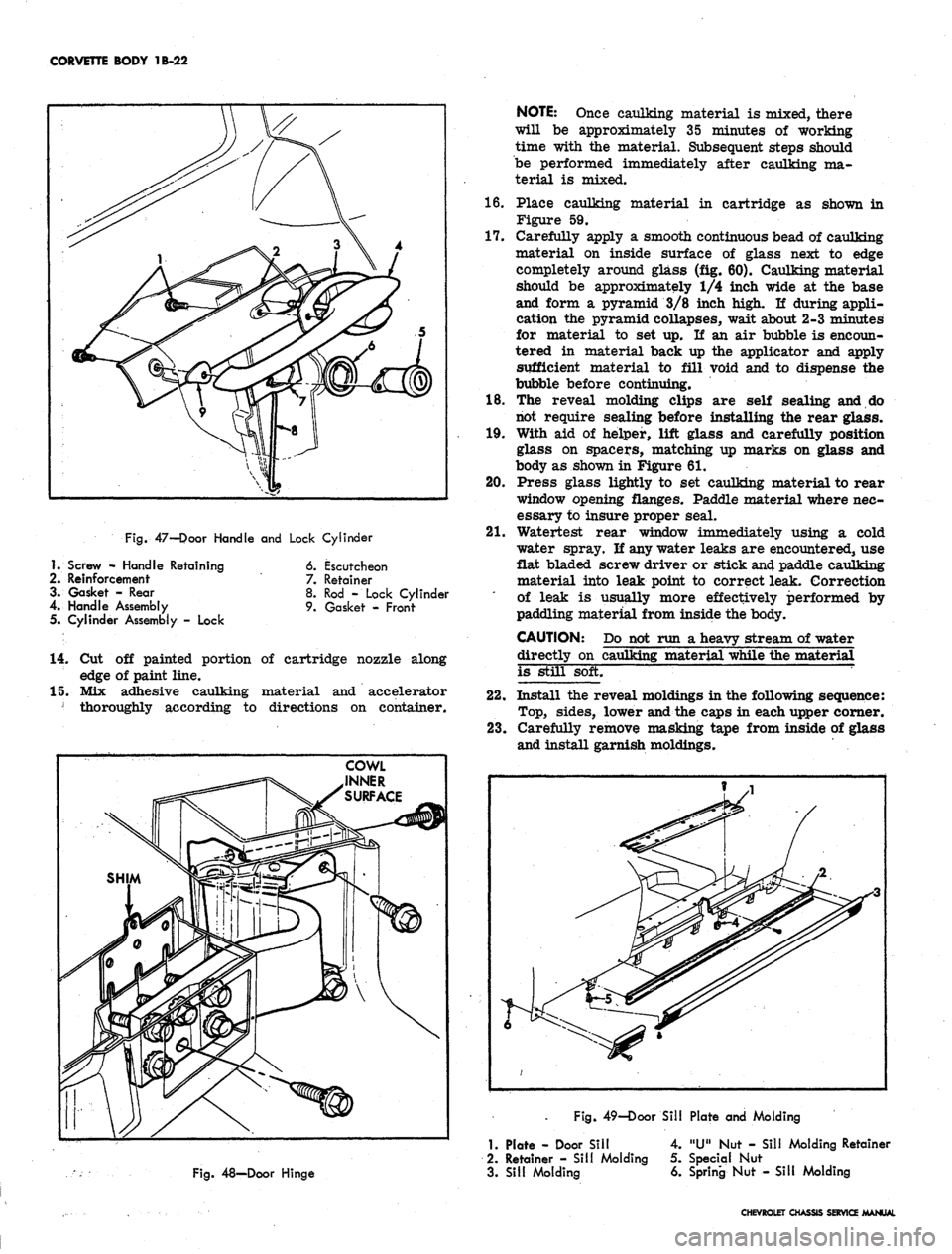

LOCK CYLINDER

Replacement

1.

Perform Operations 1 and 2 under Outer Handle -

Removal.

2.

Tap retainer t(flLg. 47) toward trailing edge of door

until free of cylinder.

3.

Disengage cylinder from rod and remove cylinder

and escutcheon from door.

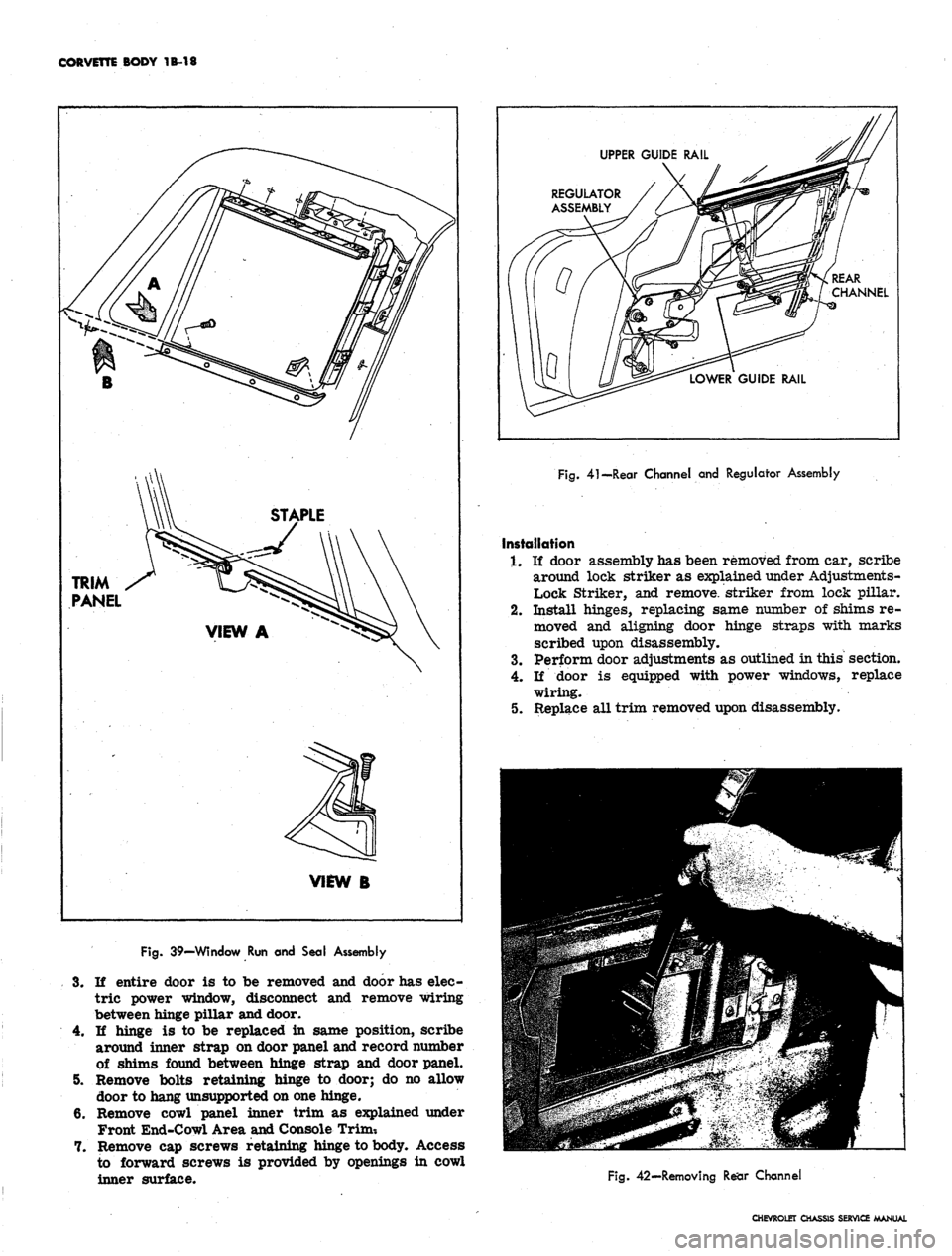

Fig.

37—Removing Sash Retaining Screws

4.

Installation may be made by following removal pro-

cedure in reverse order.

HINGES-DOOR ASSEMBLY

Refer to Figure 48.

Removal

1.

Remove door sill plate.

2.

Remove door inner trim panel as outlined in this

section.

Fig.

36—Removing Vent Window Assembly - 67

Fig.

38-Removing Door Window

CHEVROLET CHASSIS SERVICE /MANUAL

Page 125 of 659

CORVETTE BODY 18-18

TRIM

PANEL

VIEW A

view B

UPPER GUIDE

\

REGULATOR / /

ASSEMBLY / A-

RAIL ,

MS

o Y \ C^^^

Jlf

3) \ JJ

LOWER GUIDE RAIL

y

< REAR

/ CHANNEL

Fig.

41—Rear Channel and Regulator Assembly

Installation

1.

If door assembly has been removed from car, scribe

around lock striker as explained under Adjustments-

Lock Striker, and remove, striker from lock pillar.

2.

Install hinges, replacing same number of shims re-

moved and aligning door hinge straps with marks

scribed upon disassembly.

3.

Perform door adjustments as outlined in this section.

4.

If door is equipped with power windows, replace

wiring.

5.

Replace all trim removed upon disassembly.

Fig.

39—Window Run and Seal Assembly

3.

If entire door is to be removed and door has elec-

tric power window, disconnect and remove wiring

between hinge pillar and door.

4.

If hinge is to be replaced in same position, scribe

around inner strap on door panel and record number

of shims found between hinge strap and door panel.

5. Remove bolts retaining hinge to door; do no allow

door to hang unsupported on one hinge.

6. Remove cowl panel inner trim as explained under

Front End-Cowl Area and Console Trim-.

7. Remove cap screws retaining hinge to body. Access

to forward screws is provided by openings in cowl

inner surface.

Fig.

42—Removing Rear Channel

CHEVROLET CHASSIS SERVICE MANUAL

Page 126 of 659

CORVETTE BODY 1B-T9

Fig.

43—Removing Regulator Assembly

REAR QUARTER

DOOR SILL PLATE AND MOLDING

Figure 49 shows assembly details of both the door sill

plate and molding. The sill plate which retains the car-*

pet, the cowl trim windlace and lock pillar front edge

trim are retained to the body by six screws.

The molding assembly, which replaces a rocker panel,

is quickly and easily replaced by removing 10 retaining

screws. The sill molding retainer is also fastened to the

body with screws.

REAR END

FOLDING TOP COMPARTMENT LID

Adjustments

Hinges

The folding top compartment lid should be adjusted so

that in the closed position the surface of the lid is flush

with surrounding body surfaces and space between lid

edge and body is 1/16" to 3/16" at sides and 3/16" to

1/4" at rear. Whenever lid position is changed on hinges,

lock engagement must be inspected and adjusted if neces-

sary. Adjust hinge position as follows:

1.

Scribe a line on lid surface following contour of hinge

strap.

This will ease observation of lid movement

during adjustment (fig. 51).

2.

To raise or lower top surface of lid, add or remove

hinge shims.

3.

To adjust spacing between lid edges and body, loosen

hinge-to-lid screws and shift lid as required.

Lock

Lock engagement may be adjusted as follows:

1.

Striker plates may be shimmed to adjust the depth

of lock engagement in striker plate. When this ad-

justment is made, release of lock should be tested

and adjusted as required.

2.

Release of lock may be adjusted by loosening lock

assembly retaining bolts and moving lock in ap-

propriate direction to the limit of slotted holes in

, lock base. Further adjustment may be gained by

moving cable retainer in appropriate direction.

Hinges

(Refer to Figure 52)

Removal

1.

Scribe around hinge as shown in Figure 51.

2.

Hinge may be removed as an assembly by opening

top compartment lid fully and removing 3 retaining

screws. Note number of shims found between hinge

frame and compartment floor.

3.

To remove spring from hinge assembly, close top

compartment lid as far as possible and insert Tool

J-9559 between expanded coils in spring. Opening

top compartment lid fully will allow removal of

spring as shown in Figure 53.

4.

As soon as spring is removed, insert long bolt sup-

plied with J-9559 through holes in end of tool, pass-

ing it through spring, and install nut on bolt.

Spring may be removed from J-9559 or J-9559 may be

installed in a new spring, by the following method:

1.

Place a closed 6 or 8 inch "C" clamp in a vise or

fasten it to a heavy bench top (bench should be fas-

tened to floor).

2.

Hook one end of spring in clamp and the other end

in hook of chain hoist, "cherrypicker" or equivalent,

as shown in Figure 54.

3.

Stretch the spring enough to allow insertion of

J-9559. Install through bolt if spring is not to be in-

stalled on hinge at once.

installation

1.

Install same number of shims as removed or, if

repairing collision damage, etc., position hinge in

compartment, install upper mounting screws, fill

gap between floor and hinge frame with shims and

install lower mounting screw.

2.

If spring has been removed from hinge, install

spring in J-9559 and place spring on hinge with com-

partment lid raised; closing lid releases J-9559 for

removal. Upper end of spring should rest in one of

three notches yielding best lid operation. About 3

pounds pressure should be necessary to close lid.

Lock

Removal

1.

Remove cable mounting clamps. Remove retainer

from control cable assembly and disengage cable

from control.

2.

Scribe a mark on lid following outer contour of lock

assembly.

3.

Remove 3 lock assembly retaining screws and re-

move lock from compartment lid.

Installation

1.

Place lock assembly on compartment lid within

scribed line and install retaining screws.

2.

Install end of cable in control assembly and fasten

retainer securely.

3.

Test operation of lock thoroughly, adjusting if neces-

sary as outlined in this section.

Control

Removal

1.

Remove inner mounting clamps from both cables

and disengage cables from control by removing

retainers.

CHEVROLET CHASSIS SERVICE MANUAL

Page 127 of 659

CORVETTE BODY

1B-20

DOOR

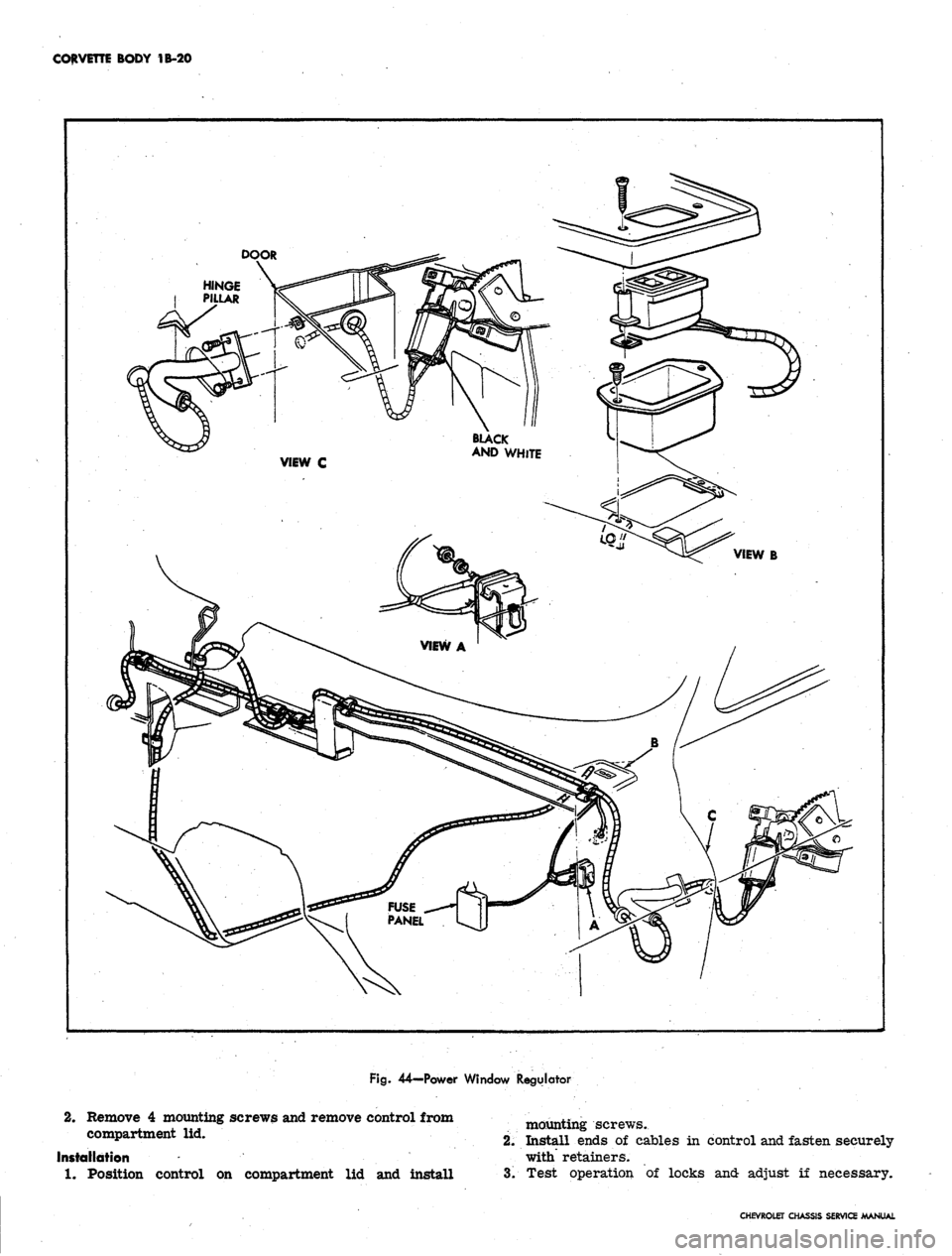

Fig.

44—Power Window Regulator

2.

Remove

4

mounting screws and remove control from

compartment

lid.

Installation

*

1.

Position control

on

compartment

lid and

install

mounting screws.

2.

Install ends of cables in control and fasten securely

with retainers.

3.

Test operation of locks and adjust if necessary.

CHEVROLET CHASSIS SERVICE MANUAL

Page 128 of 659

CORVETTE BODY 1B-21

Fig.

45—

Locking Regulator Arm in Place

REAR WINDOW-ADHESIVE CAULKED-

19437 MODEL

For parts identification refer to Figure 55.

1.

Remove the 2 rear window garnish moldings by re-

moving the 14 attaching screws.

2.

Pry molding caps from reveal moldings.

3.

Carefully remove lower, side, and top reveal mold-

ings after marking their position on body with tape.

4.

Secure one end of steel music wire to piece of wood

for handle. Insert other end through caulking mater-

ial at lower corner of rear window; then secure end

of wire to another piece of wood (fig. 56).

5. With the aid of helper, carefully cut through caulking

material (using a sawing motion) with the steel wire;

up side of window, across top, down opposite side,

and across bottom of window.

6. Remove old glass from window opening.

7. Using a sharp scraper or wood chisel, remove ad-

hesive caulking material from body pinchweld flange.

NOTE:

It is not necessary to clean off all the

old caulking material completely from body

opening; however, there should not be any loose

pieces of caulking material left in the opening.

8. Check all reveal molding retaining clips for damage

(24 required). Replace those that are bent or dis-

torted with clips provided in kit.

9. Using weatherstrip adhesive, cement rubber spacers

at bottom, sides, and top of window opening. The

step-type spacers are used at bottom and sides, the

flat type are used at the top, sides, and bottom of

window opening as shown on Figure 55.

10.

Using suction cup holders, position replacement

glass in body opening. Carefully check relationship

of glass to body pinchweld completely around open-

ing. The overlap of glass to body pinchweld and re-

taining flanges should be equal with a minimum over-

lap of 3/16M. Where necessary, position shims under

the lower spacers to obtain required overlap of glass

to body upper and lower flanges.

11.

After proper glass to pinchweld relationship has

been attained, mark position with grease pencil on

glass and body as shown in Figure 57.

12.

Remove glass from body opening and place on pro-

tected surface.

13.

Clean inside edge surface of glass so that glass is

free of any foreign material (oil, grease, etc.).

Using 3/4" masking tape, place tape approximately

1/2 inch from edge of inside surface of glass com-

pletely around glass. Then apply a film of silane

primer to inside edge surface completely around

glass,

also apply silane primer to sealing surface

of pinchweld as shown in Figure 58.

Fig.

46—Door Lock and Remote Controls

1.

Door Lock Remote Control

Assembly

2.

Door Lock Remote Control Knob

3. Door Lock Remote Control Rod

4.

Remote Control Locking Rod

5. Remote Locking Control

Assembly

6. Lock Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 129 of 659

CORVETTE BODY 1B-22

16.

17.

Fig.

47-Door Handle and Lock Cylinder

18.

19.

20.

21.

1.

Screw - Handle Retaining

2.

Reinforcement

3. Gasket - Rear

4.

Handle Assembly

5. Cylinder Assembly - Lock

6. Escutcheon

7.

Retainer

8. Rod - Lock Cylinder

9. Gasket - Front

14.

Cut off painted portion of cartridge nozzle along

edge of paint line.

15.

Mix adhesive caulking material and accelerator

] thoroughly according to directions on container.

NOTE:

Once caulking material is mixed, there

will be approximately 35 minutes of working

time with the material. Subsequent steps should

be performed immediately after caulking ma-

terial is mixed.

Place caulking material in cartridge as shown in

Figure 59.

Carefully apply a smooth continuous bead of caulking

material on inside surface of glass next to edge

completely around glass (fig. 60). Caulking material

should be approximately 1/4 inch wide at the base

and form a pyramid 3/8 inch high. If during appli-

cation the pyramid collapses, wait about 2-3 minutes

for material to set up. If an air bubble is encoun-

tered in material back up the applicator and apply

sufficient material to fill void and to dispense the

bubble before continuing.

The reveal molding clips are self sealing and do

not require sealing before installing the rear glass.

With aid of helper, lift glass and carefully position

glass on spacers, matching up marks on glass and

body as shown in Figure 61.

Press glass lightly to set caulking material to rear

window opening flanges. Paddle material where nec-

essary to insure proper seal.

Watertest rear window immediately using a cold

water spray. If any water leaks are encountered, use

flat bladed screw driver or stick and paddle caulking

material into leak point to correct leak. Correction

of leak is usually more effectively performed by

paddling material from inside the body.

CAUTION: Do not run a heavy stream of water

directly on caulking material while the material

is still soft.

22.

Install the reveal moldings in the following sequence:

Top,

sides, lower and the caps in each upper corner.

23.

Carefully remove masking tape from inside of glass

and install garnish moldings.

Fig.

49—Door Sill Plate and Molding

Fig.

48—Door Hinge

1.

Plate - Door Sill

2.

Retainer - Sill Molding

3. Sill Molding

4.

"U" Nut - Sill Molding Retainer

5. Special Nut

6. Spring Nut - Sill Molding

CHEVROLET CHASSIS SERVICE MANUAL

Page 130 of 659

CORVETTE BODY 1B-23

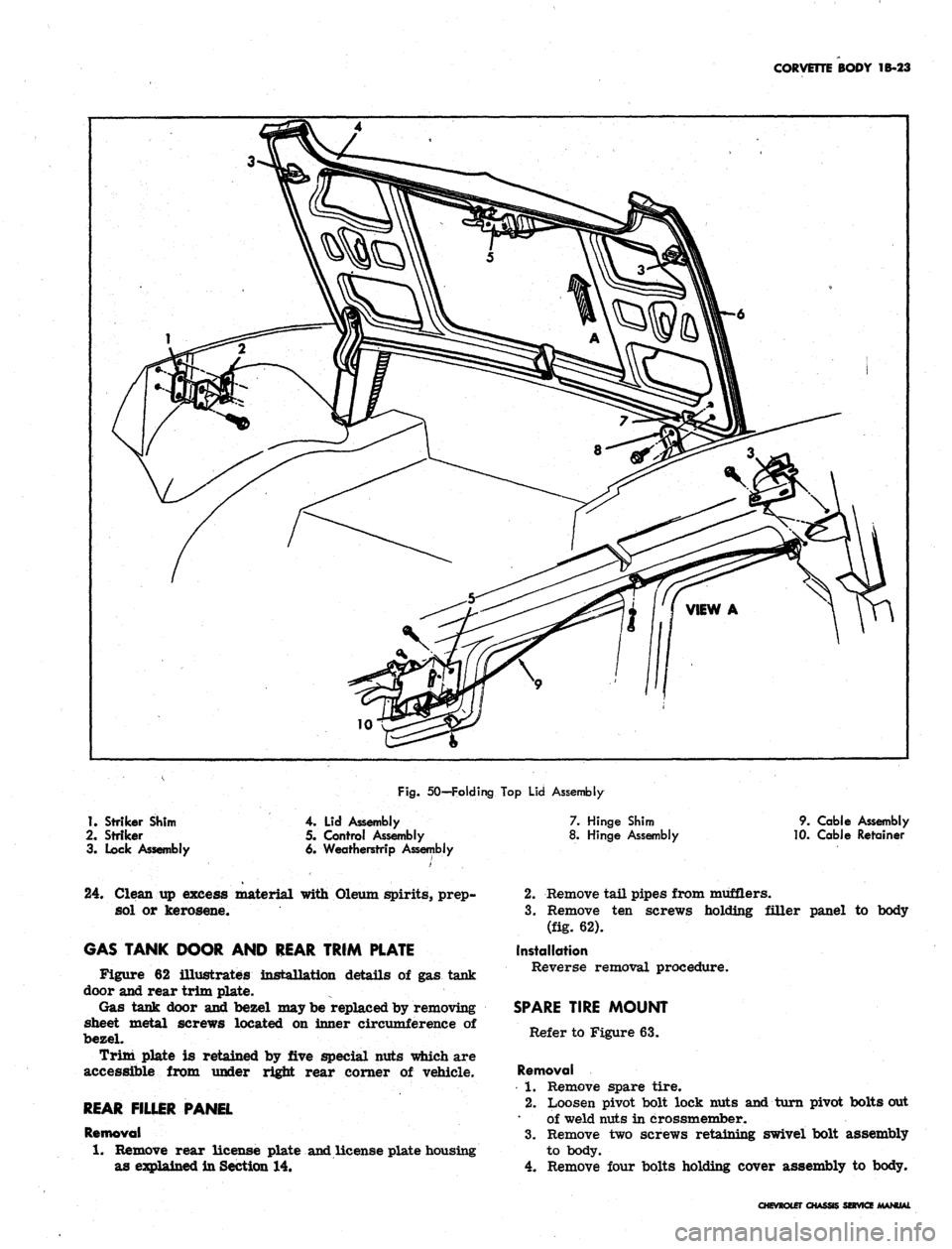

Fig.

50—Folding Top Lid Assembly

1.

Striker Shim

2.

Striker

3. Lock Assembly

4. Lid Assembly

5. Control Assembly

6. Weatherstrip Assembly

7. Hinge Shim

8. Hinge Assembly

9. Cable Assembly

10.

Cable Retainer

24.

Clean up excess material with Oleum spirits, prep-

sol or kerosene.

GAS TANK DOOR AND REAR TRIM PLATE

Figure 62 illustrates installation details of gas tank

door and rear trim plate.

Gas tank door and bezel may be replaced by removing

sheet metal screws located on inner circumference of

bezel.

Trim plate is retained by five special nuts which are

accessible from under right rear corner of vehicle.

REAR FILLER PANEL

Removal

1.

Remove rear license plate and license plate housing

as explained in Section 14.

2.

Remove tail pipes from mufflers.

3.

Remove ten screws holding filler panel to body

(fig. 62).

Installation

Reverse removal procedure.

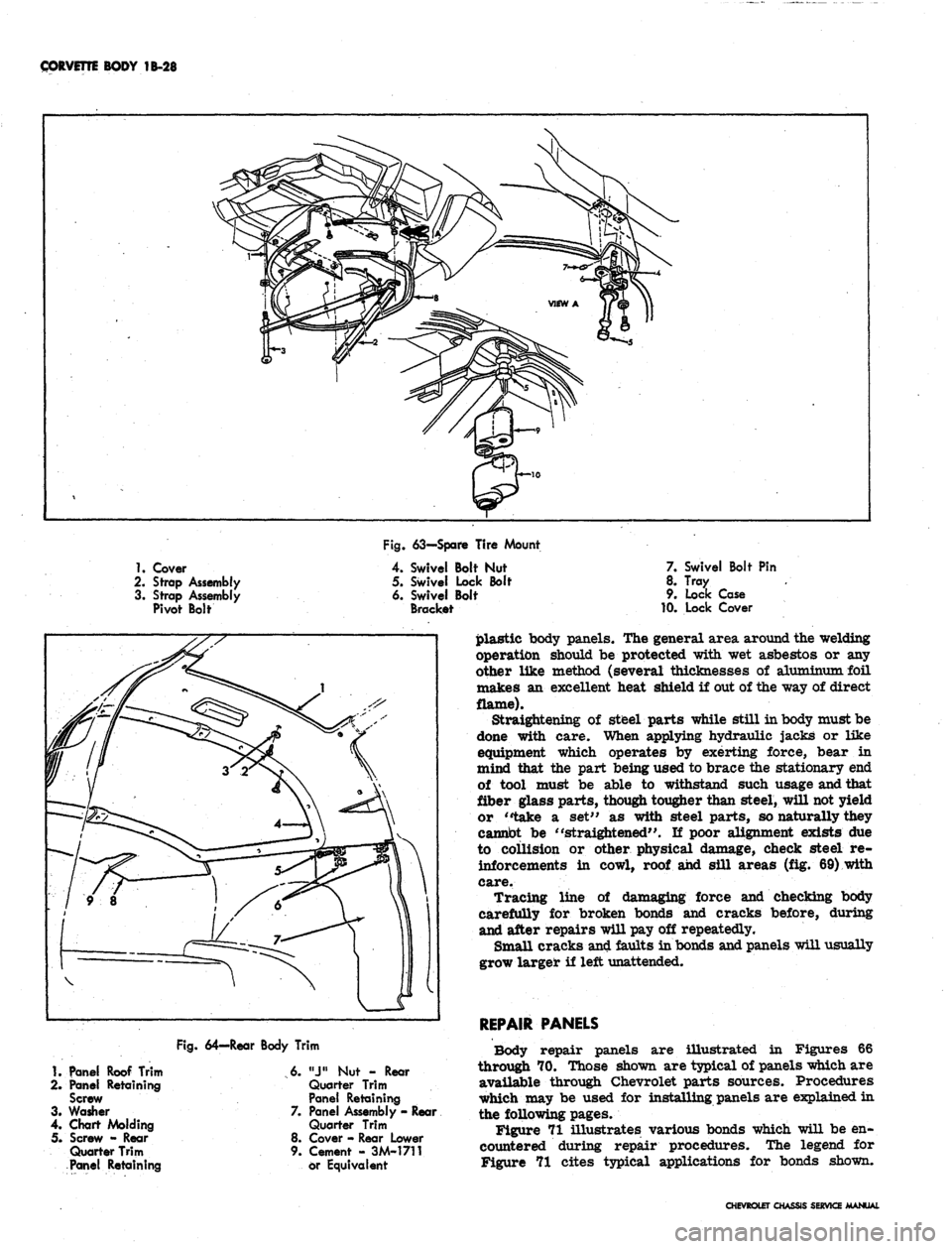

SPARE TIRE MOUNT

Refer to Figure 63.

Removal

1.

Remove spare tire.

2.

Loosen pivot bolt lock nuts and turn pivot bolts out

of weld nuts in crossmember.

3.

Remove two screws retaining swivel bolt assembly

to body.

4.

Remove four bolts holding cover assembly to body.

CHEVROLET CHASSIS SERVICE

Page 135 of 659

CORVETTE BODY 1B-28

Fig. 63—Spare Tire Mount

1.

Cover

2.

Strap Assembly

3. Strap Assembly

Pivot Bolt

Swivel Bolt Nut

Swivel Lock Bolt

Swivel Bolt

Bracket

7. Swivel Bolt Pin

8. Tray

9. Lock Case

10.

Lock Cover

1.

Panel Roof Trim

2.

Panel Retaining

Screw

3. Washer

4.

Chart Molding

5. Screw - Rear

Quarter Trim

Panel Retaining

Fig.

64—Rear Body Trim

6.

"J"

Nut - Rear

Quarter Trim

Panel Retaining

7. Panel Assembly - Rear

Quarter Trim

8. Cover - Rear Lower

9. Cement - 3M-1711

or Equivalent

plastic body panels. The general area around the welding

operation should be protected with wet asbestos or any

other like method (several thicknesses of aluminum foil

makes an excellent heat shield if out of the way of direct

flame).

Straightening of steel parts while still in body must be

done with care. When applying hydraulic jacks or like

equipment which operates by exerting force, bear in

mind that the part being used to brace the stationary end

of tool must be able to withstand such usage and that

fiber glass parts, though tougher than steel, will not yield

or "take a set" as with steel parts, so naturally they

cannot be "straightened". If poor alignment exists due

to collision or other physical damage, check steel re-

inforcements in cowl, roof and sill areas (fig. 69) with

care.

Tracing line of damaging force and checking body

carefully for broken bonds and cracks before, during

and after repairs will pay off repeatedly.

Small cracks and faults in bonds and panels will usually

grow larger if left unattended.

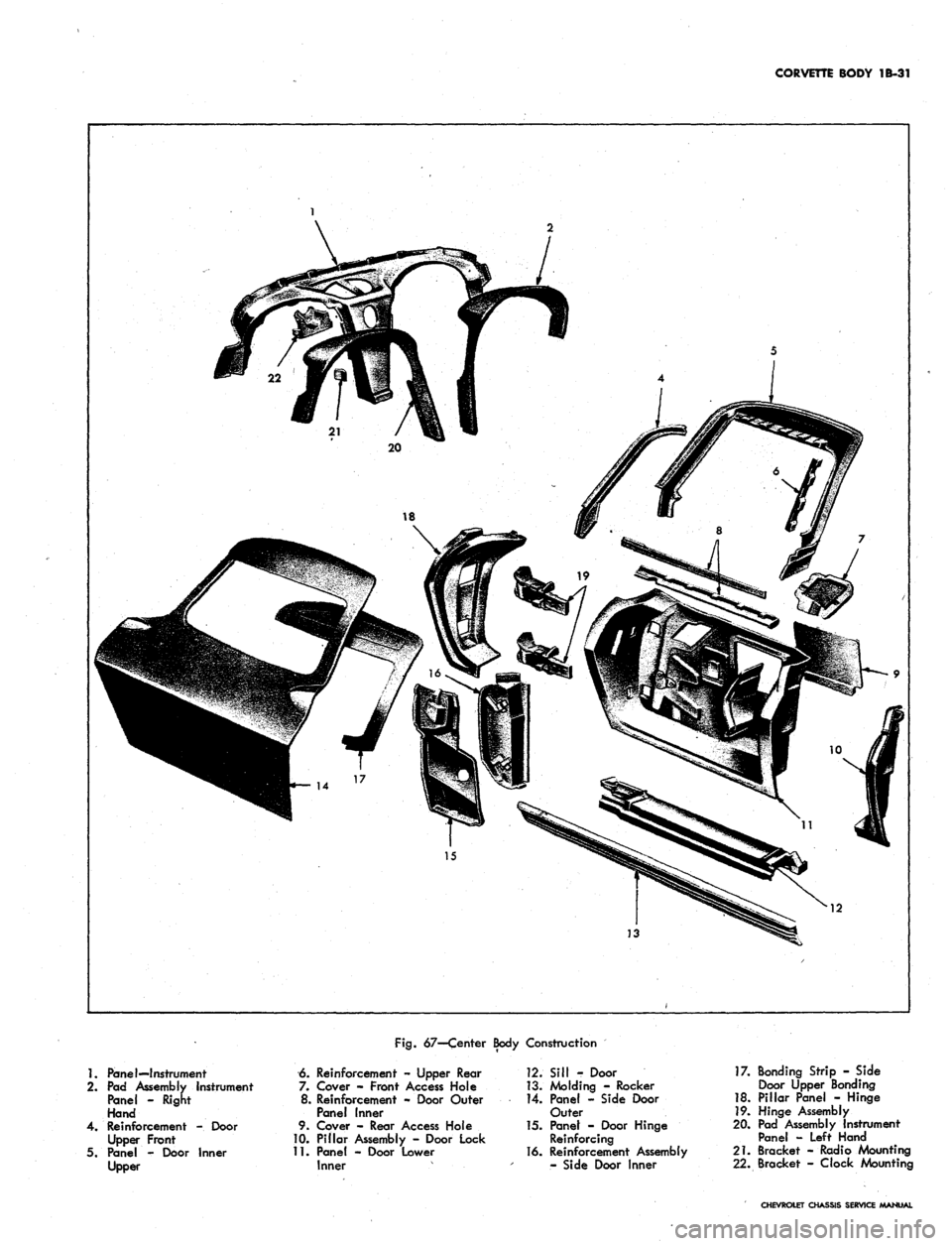

REPAIR PANELS

Body repair panels are illustrated in Figures 66

through 70. Those shown are typical of panels which are

available through Chevrolet parts sources. Procedures

which may be used for installing panels are explained in

the following pages.

Figure 71 illustrates various bonds which will be en-

countered during repair procedures. The legend for

Figure 71 cites typical applications for bonds shown.

CHEVROLET CHASSIS SERVICE MANUAL

Page 138 of 659

CORVETTE BODY 1B-31

1

^JS^ST**-

Fig.

67—Center Body Construction

1.

Panel—Instrument

2.

Pad Assembly Instrument

Panel - Right

Hand

4.

Reinforcement -. Door

Upper Front

5. Panel - Door Inner

Upper

6. Reinforcement - Upper Rear

7. Cover - Front Access Hole

8. Reinforcement - Door Outer

Panel inner

9. Cover - Rear Access Hole

10.

Pillar Assembly - Door Lock

11.

Panel - Door Lower

Inner

12.

Sill - Door

13.

Molding - Rocker

14.

Panel - Side Door

Outer

15.

Panet - Door Hinge

Reinforcing

16.

Reinforcement Assembly

- Side Door Inner

17.

Bonding Strip - Side

Door Upper Bonding

18.

Pillar Panel - Hinge

19.

Hinge Assembly

20.

Pad Assembly Instrument

Panel - Left Hand

21.

Bracket - Radio Mounting

22.

Bracket - Clock Mounting

CHEVROLET CHASSIS SERVICE MANUAL