lock CHEVROLET CAMARO 1967 1.G Chassis Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 105 of 659

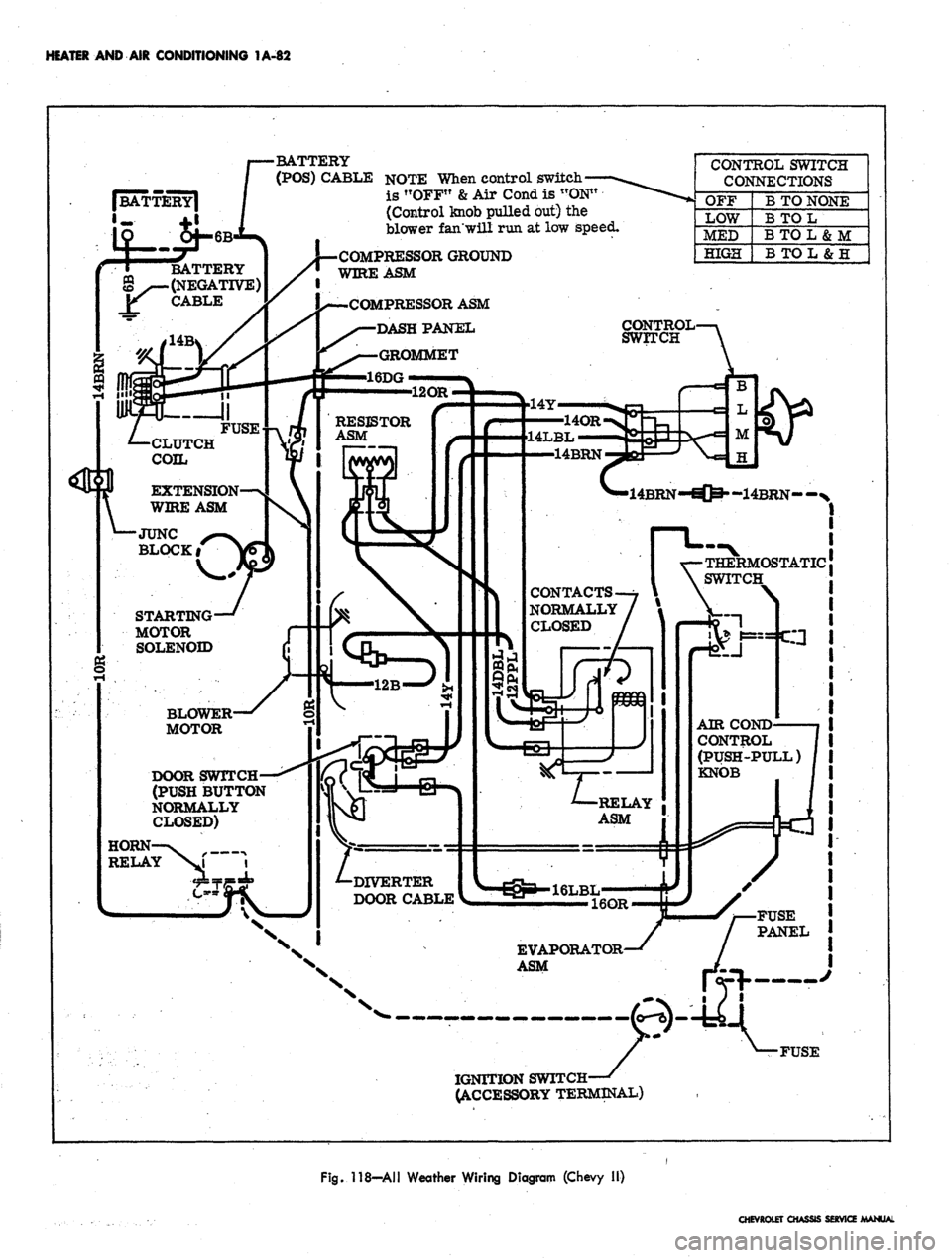

HEATER AND AIR CONDITIONING 1A-82

•BATTERY

(POS)

CABLE

NOTE

When

control

switch*

is !TOFF"

&

Air

Cond

is

"ON"

(Control

knob

pulled

but) the

blower

fan'will

run at low

speed.

CONTROL

SWITCH

CONNECTIONS

OFF

LOW

MED

HIGH

B

TO

NONE

B

TO L

BTOL&M

B

TO L

&

H

COMPRESSOR

GROUND

WIRE

ASM

BATTERY

(NEGATIVE)

CABLE

COMPRESSOR

ASM

DASHPAJSTEL

GROMMET

16DG

CONTROL

SWITCH

RESISTOR

ASM

14LBL

14BRN

CLUTCH

COIL

EXTENSION

WIRE

ASM

-14BRN--N

JUNC

BLOCKi

OSTATIC

SWITCH

CONTACTS

NORMALLY

CLOSED

STARTING

MOTOR

SOLENOID

BLOWER

MOTOR

AIR

COND

CONTROL

(PUSH-PULL)

KNOB

DOOR

SWITCH

(PUSH

BUTTON

NORMALLY

CLOSED)

RELAY

ASM

HORN

RELAY

DIVERTER

DOOR CABLE

FUSE

PANEL

EVAPORATOR

ASM

IGNITION SWITCH-

ACCESSORY TERMINAL)

Fig. 118—All Weather Wiring Diagram (Chevy II)

CHEVROLET CHASSIS SERVICE MANUAL

Page 107 of 659

HEATER

AND AIR

CONDITIONING

1A-84

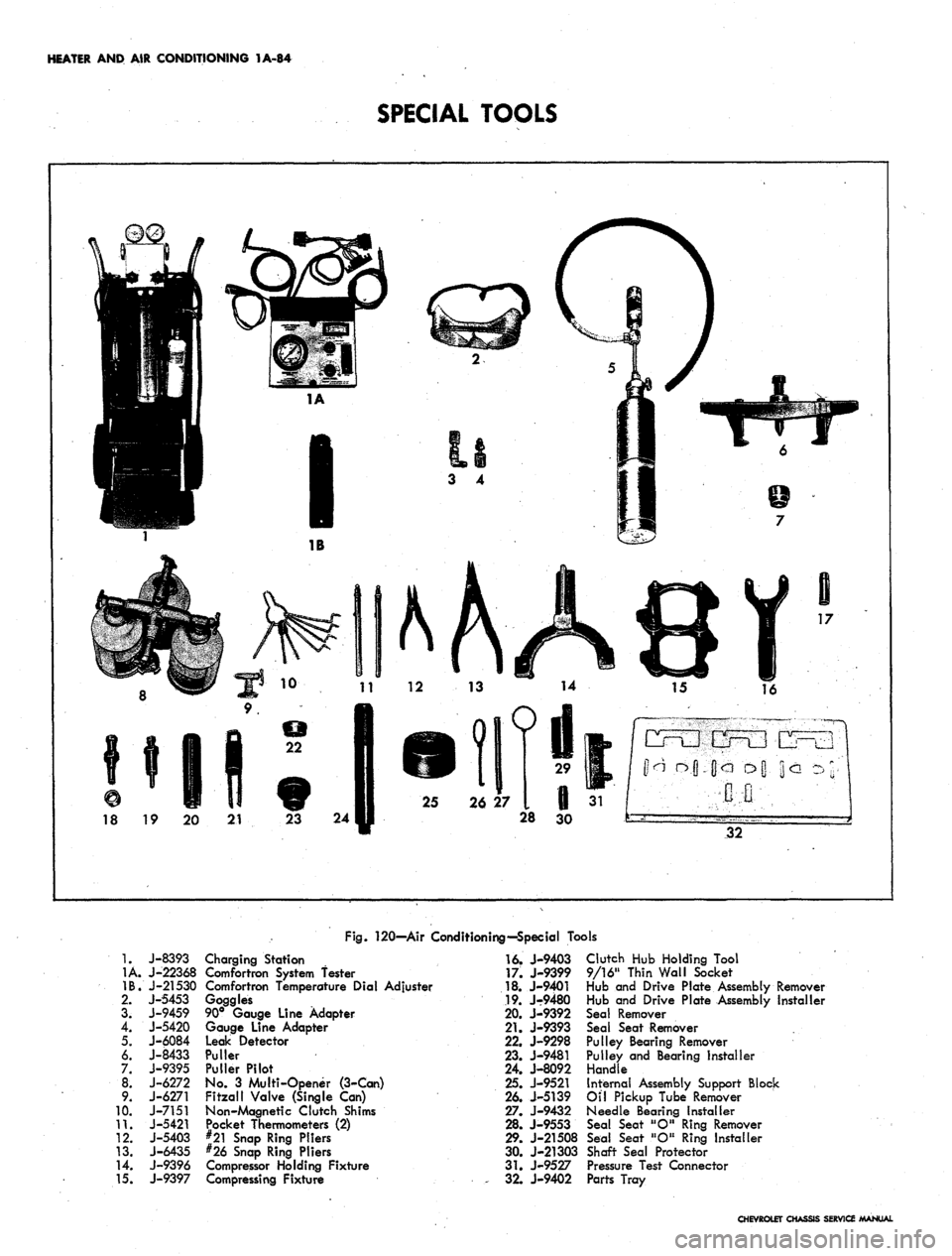

SPECIAL TOOLS

18

19 20 21 23 24

28

30

32

Fig.

120—Air Conditioning—Special Tools

1.

1A.

IB.

2.

3.

4.

5.

6.

7.

00*

9.

10.

11.

12.

13.

14.

15.

J-8393

J-22368

J-21530

J-5453

J-9459

J-5420

J-6084

J-8433

J-9395

J-6272

J-6271

J-7151

J-5421

J-5403

J-6435

J-9396

J-9397

Charging Station

Comfortron System fester

Comfortron Temperature Dial Adjuster

Goggles

90° Gauge Line Adapter

Gauge Line Adapter

Leak Detector

Puller

Puller Pilot

No.

3

Multi-Opener (3-Can)

Fitzall Valve (Single

Can)

Non-Magnetic Clutch Shims

Pocket Thermometers

(2)

#21 Snap Ring Pliers

#26 Snap Ring Pliers

Compressor Holding Fixture

Compressing Fixture

16.

J-9403

17.

J-9399

18.

J-9401

19.

J-9480

20.

J-9392

21.

J-9393

22.

J-9298

23.

J-9481

24.

J-8092

25.

J-9521

26.

J-5139

27.

J-9432

28.

J-9553

29.

J-21508

30.

J-21303

31.

J-9527

,

32.

J-9402

Clutch

Hub

Holding Tool

9/16" Thin Wall Socket

Hub

and

Drive Plate Assembly Remover

Hub

and

Drive Plate Assembly Installer

Seal Remover

Seal Seat Remover

Pulley Bearing Remover

Pulley and Bearing installer

Handle

Internal Assembly Support Block

Oil Pickup Tube Remover

Needle Bearing Installer

Seal Seat "O" Ring Remover

Seal Seat "O" Ring Installer

Shaft Seal Protector

Pressure Test Connector

Parts Tray

CHEVROLET CHASSIS SERVICE MANUAL

Page 108 of 659

SECTION

IB

CORVETTE BODY

INDEX

Page

General Description . . * • •.

•

^"i1

Maintenance and Replacements 1B-1

Front End 1B-1

Adjustments IBri

Hood 1B-1

Hood Catch 1B-2

Hood Assembly . 1B-2

Front Emblems 1B-2

Vent Grilles 1B-2

Instrument Panel Tray . 1B-2

Cowl Area Trim

....................

1B-4

Rear View Mirror 1B-4

Outside 1B-4

Inside . 1B-4

Sun Visor . 1B-4

Cowl Ventilator Assembly 1B-4

Windshield ; 1B-5

Doors 1B-7

Adjustments 1B-7

Door Lock Striker 1B-7

Door Window and Vent 1B-7

Door Hinges 1B-7

Trim Panel and Inside Handles IB-11

Weatherstrip 1B-11

Door Ventilator Assembly 1B-12

19437 Model 1B-12

19467 Model 1B-13

Window Glass 1B-13

Glass Run Channel—Upper 1B-14

Window Outer Seal Assembly 1B-14

Window Inner Seal Assembly 1B-14

Glass Run Channel—Rear 1B-15

Window Regulator—Manual 1B-15

Window Regulator—Power 1B-15

Door Lock and Remote Controls 1B-16

Outer Handle . 1B-16

Lock Cylinder 1B-17

Hinges—Door Assembly . 1B-17

Rear Quarter .. . 1B-19

Door Sill and Molding . . 1B-19

Rear End . . r 1B-19

Folding Top Compartment Lid 1B-19

Adjustments . . 1B-19

1B-19

Page

Lock 1B-19

Control 1B-19

Rear Window—19437 Model 1B-21

Gas Tank Door and Rear Trim Plate.,. . . . . . . . 1B-23

Rear Filler Panel 1B-23

Spare Tire Mount 1B-23

Rugs and Interior Trim 1B-25

Cleaning Soft Trim 1B-25

Carpets and Covers—All Models 1B-26

Rear Body Trim , . 1B-26

Soft Covers 1B-26

Rigid Plastic Trim 1B-26

Garnish Moldings Plus-Headliner-19437 Model . . 1B-27

Seats 1B-27

Body Mounting 1B-27

Body Repairs . 1B-27

General Instructions . . . 1B-27

Repair Panels. 1B-28

Precautions 1B-29

Plastic Solder Kit 1B-29

Resin Kit 1B-30

Specific Repairs 1B-32

Scratched Panels-Spot Refinishing 1B-32

Dents in Panels-Surface Cracks !B-33

Cracked Panels . . 1B-35

Fractures 1B-37

Panel Replacement 1B-39

Hard Top . . 1B-41

Care and Storage 1B-41

Rear Window 1B-41

Garnish Moldings and Latches 1B-42

Headlining 1B-43

Weatherstrips and Drip Molding 1B-43

Vinyl Covering . 1B-43

Folding Top 1B-46

Care of Folding Top 1B-46

Care of Rear Window 1B-46

Adjustments 1B-48

Top Assembly, Removal and Installation 1B-49

Top Trim and Rear Window Assembly 1B-50

Frame and Linkage 1B-52

Weatherstrip 1B-52

Adding Hardtop 1B-52

Special Tools 1B-53

GENERAL DESCRIPTION

.

A

structural network

of

steel forms the backbone

of

the

Corvette body. When combined with

the

fiber-glass

re-

inforced plastic body panels,

the

steel-plastic marriage

results

in a

body with increased torsional rigidity

and

greater beaming strength.

Convertible models continue with two roof styles:

the

folding

top

and the removable hardtop. In operation, both

tops function similar to those

of

previous models. Either

top

is

standard and both

are

optional

as

determined by

the top selected

as

base equipment.

MAINTENANCE

&

REPLACEMENTS

FRONT

END

ADJUSTMENTS

(Refer to Figure

2)

Adjustments should

be

made

in

order

-

hood position

first, then catch adjustments.

Hood

The position

of the

hood

in

relation

to

the hood body

opening and the fender surfaces

is

controlled by the posi-

tion

of the

hinges and position

and

adjustment

of

catch

and bumpers.

The fore

and aft

position

of the

hood may be adjusted

CHEVROLET CHASSIS SERVICE MANUAL

Page 109 of 659

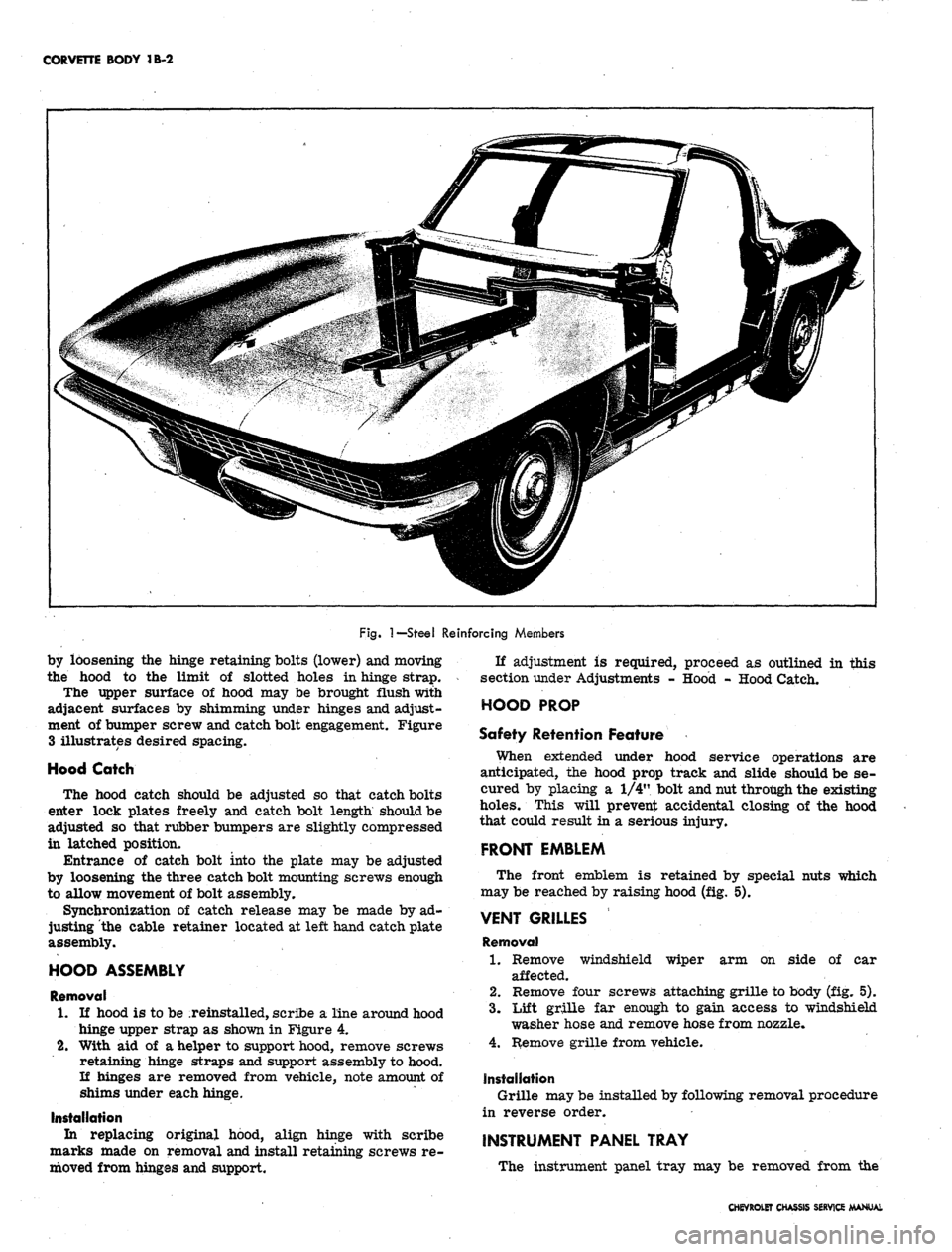

CORVETTE BODY 1B-2

Fig.

1—Steel

Reinforcing Members

by loosening the hinge retaining bolts (lower) and moving

the hood to the limit of slotted holes in hinge strap.

The upper surface of hood may be brought flush with

adjacent surfaces by shimming under hinges and adjust-

ment of bumper screw and catch bolt engagement. Figure

3 illustrates desired spacing.

Hood Catch

The hood catch should be adjusted so that catch bolts

enter lock plates freely and catch bolt length should be

adjusted so that rubber bumpers are slightly compressed

in latched position.

Entrance of catch bolt into the plate may be adjusted

by loosening the three catch bolt mounting screws enough

to allow movement of bolt assembly.

Synchronization of catch release may be made by ad-

justing the cable retainer located at left hand catch plate

assembly.

HOOD ASSEMBLY

Removal

1.

If hood is to be reinstalled, scribe a line around hood

hinge upper strap as shown in Figure 4.

2.

With aid of a helper to support hood, remove screws

retaining hinge straps and support assembly to hood.

If hinges are removed from vehicle, note amount of

shims under each hinge.

Installation

In replacing original hood, align hinge with scribe

marks made on removal and install retaining screws re-

moved from hinges and support.

If adjustment is required, proceed as outlined in this

section under Adjustments - Hood - Hood Catch.

HOOD PROP

Safety Retention Feature

When extended under hood service operations are

anticipated, the hood prop track and slide should be se-

cured by placing a 1/4" bolt and nut through the existing

holes.

This will prevent accidental closing of the hood

that could result in a serious injury.

FRONT EMBLEM

The front emblem is retained by special nuts which

may be reached by raising hood (fig. 5).

wiper arm on side of car

VENT GRILLES

Removal

1.

Remove windshield

affected.

2.

Remove four screws attaching grille to body (fig. 5).

3.

Lift grille far enough to gain access to windshield

washer hose and remove hose from nozzle.

4.

Remove grille from vehicle.

Installation

Grille may be installed by following removal procedure

in reverse order.

INSTRUMENT PANEL TRAY

The instrument panel tray may be removed from the

CHEVROLET CHASSIS SERVICE MANUAL

Page 113 of 659

CORVETTE BODY

1B-6

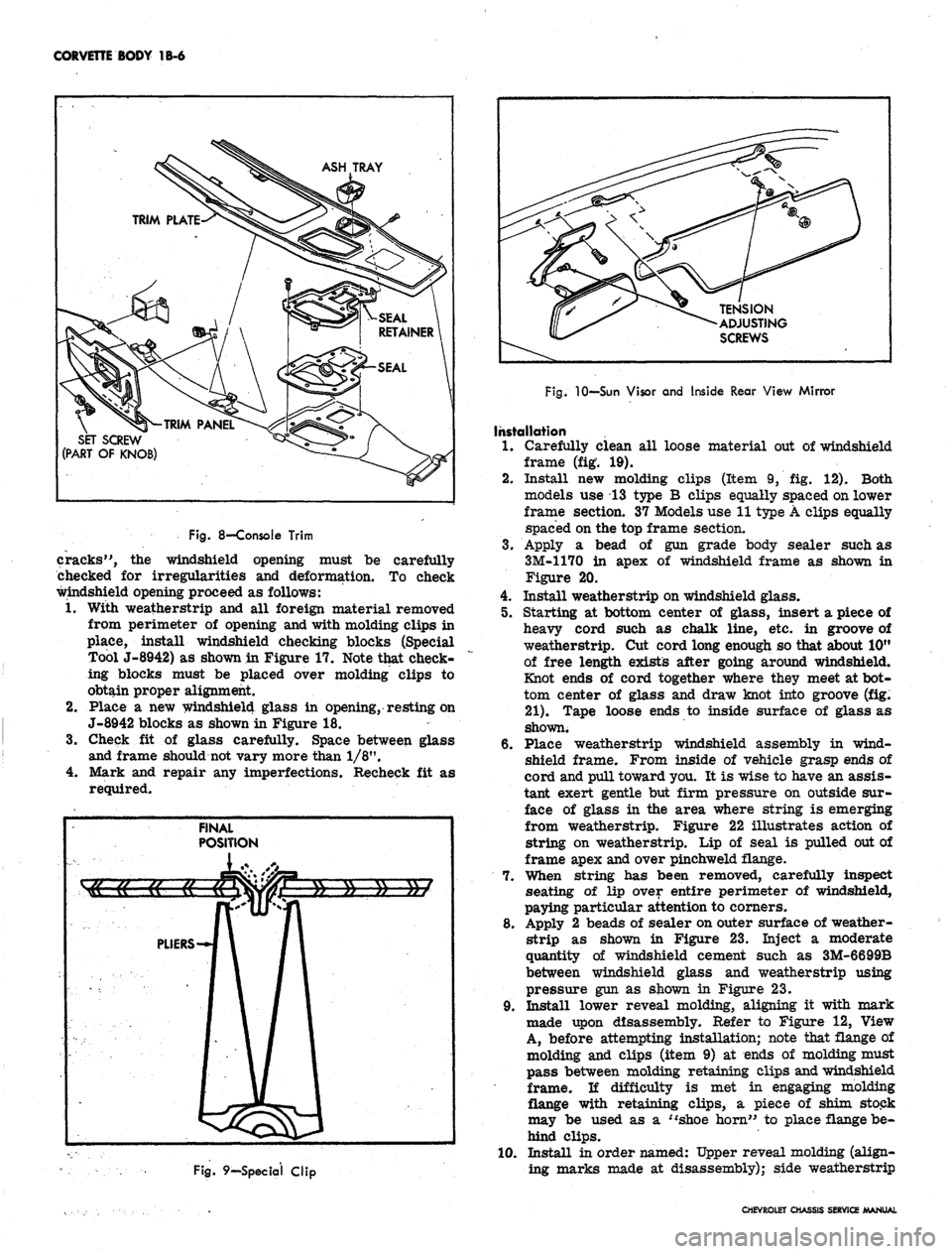

ASH TRAY

SET SCREW

(PART

OF

KNOB)

TENSION

ADJUSTING

SCREWS

Fig.

8—Console Trim

cracks",

the

windshield opening must

be

carefully

checked

for

irregularities

and

deformation.

To

check

windshield opening proceed

as

follows:

1.

With weatherstrip

and all

foreign material removed

from perimeter

of

opening and with molding clips

in

place, install windshield checking blocks (Special

Tool J-8942)

as

shown in Figure 17. Note that check-

ing blocks must

be

placed over molding clips

to

obtain proper alignment.

2.

Place

a new

windshield glass

in

opening, resting on

J-8942 blocks

as

shown in Figure

18.

3.

Check

fit of

glass carefully. Space between glass

and frame should not vary more than 1/8".

4.

Mark

and

repair

any

imperfections. Recheck

fit as

required.

Fig.

9—Special Clip

Fig.

10—Sun Visor and Inside Rear View Mirror

Installation

1.

Carefully clean

all

loose material

out of

windshield

frame

(fig. 19).

2.

Install

new

molding clips (Item

9, fig. 12).

Both

models

use 13

type

B

clips equally spaced on lower

frame section.

37

Models use 11 type A clips equally

spaced on the top frame section.

3.

Apply

a

bead

of gun

grade body sealer such

as

3M-1170

in

apex

of

windshield frame

as

shown

in

Figure

20.

4.

Install weatherstrip on windshield glass.

5. Starting

at

bottom center

of

glass, insert

a

piece

of

heavy cord such

as

chalk line,

etc. in

groove

of

weatherstrip.

Cut

cord long enough so that about 10"

of free length exists after going around windshield.

Knot ends

of

cord together where they meet at bot-

tom center

of

glass

and

draw knot into groove

(fig.

21).

Tape loose ends

to

inside surface

of

glass

as

shown.

6. Place weatherstrip windshield assembly

in

wind-

shield frame. From inside

of

vehicle grasp ends

of

cord and pull toward you.

It is

wise to have an assis-

tant exert gentle

but

firm pressure

on

outside sur-

face

of

glass

in the

area where string

is

emerging

from weatherstrip. Figure

22

illustrates action

of

string

on

weatherstrip.

Lip of

seal

is

pulled out of

frame apex and over pinchweld flange.

7. When string

has

been removed, carefully inspect

seating

of lip

over entire perimeter

of

windshield,

paying particular attention to corners.

8. Apply

2

beads

of

sealer on outer surface

of

weather-

strip

as

shown

in

Figure

23.

Inject

a

moderate

quantity

of

windshield cement such

as

3M-6699B

between windshield glass

and

weatherstrip using

pressure gun

as

shown

in

Figure

23.

9. Install lower reveal molding, aligning

it

with mark

made upon disassembly. Refer

to

Figure

12,

View

A, before attempting installation; note that flange

of

molding

and

clips (item

9) at

ends

of

molding must

pass between molding retaining clips and windshield

frame.

li

difficulty

is met in

engaging molding

flange with retaining clips,

a

piece

of

shim stock

may

be

used

as a

"shoe horn"

to

place flange be-

hind clips.

10.

Install

in

order named: Upper reveal molding (align-

ing marks made

at

disassembly); side weatherstrip

CHEVROLET CHASSIS SERVICE MANUAL

Page 114 of 659

CORVETTE BODY

1B-7

HEAT

CONTROL

€P-

CABLE

VIEW A

HOOD RELEASE

Fig.

11—Cowl Ventilator

and

Controls

and reveal moldings; upper garnish molding; lower

garnish molding; side garnish molding; header latch

plates on 19467 Models and rear view mirror.

11.

Clean

up

excess sealer

and

cement with rag damp-

ened with oleum spirits, prep-sol

or

kerosene;

in-

stall wiper arm assemblies.

DOORS

ADJUSTMENTS

Door Lock Striker

Door lock strikers incorporate

an

inter-lock feature

consisting

of a

notch

in the

striker into which the lock

bolt housing extension engages. With

the

inter-lock

feature

it is

very important that

the

lock extension en-

gages properly

in the

striker notch

and

that, where

necessary,

the

correct striker emergency spacers

are

used to obtain proper engagement.

1.

To

adjust striker

up,

down,

in, or

out loosen striker

plate screws and shift striker and adjusting plates

as

required, then tighten screws.

2.

To determine

if

door lock striker emergency spacers

are required, apply modeling clay

or

body caulking

compound

in the

door lock striker notch where

the

lock extension engages,

and

then close

the

door

to

form

a

measurable impression in the clay

or

caulk-

ing compound,

as

shown

in

Figure

24.

Remove

all

clay

or

compound when adjustment

is

completed.

When dimension

"A"

from inside face

of

striker teeth

to center

of

lock extension

is

less than 3/16", install

emergency spacers

and

proper length striker attaching

screws.

NOTE:

Dimension

"B"

from center

of

lock

extension

to

inside face

of

striker notch should

.

never be less than 1/8".

If check indicates need

for

emergency spacers,

pro-

ceed

as

follows:

1.

With pencil, scribe position

of

striker on body pillar.

2.

Remove three door lock striker attaching screws and

remove striker

and

adjusting plates from pillar.

3.

To

install, place striker, shims and adjusting plates

within scribe marks

on

pillar

and

tighten screws.

IMPORTANT: Whenever

a

door

has

been

re-

moved

and

installed,

or

realigned,

the

door

SHOULD NOT be closed completely until

a

visual

check

is

made to determine

if

the lock extension/

will engage

in the

striker notch. Where

re-

quired, door lock striker emergency spacers

should

be

installed

so

that door

can be

closed

and

an

accurate check made to determine emer-

gency spacer requirements.

Door Window and Vent Adjustment

To move

the top of the

window

in or

out, the bottom

ends

of

both

run

channels

are

adjustable.

The

rear

channel

is

adjusted

by

loosening

the

lower

of

the two

screws

on the

rear face

of

door, "C" Figure 25, and

moving channel

as

necessary.

The

front channel

is ad-

justed

by

removing

the

trim pad and moving the Channel

in

or out by a

stud

and nut

adjustment, "B" Figure 25.

The

top end of the

rear channel

is

not adjustable in

or

out.

On 19467 models

an

adjustment

may be

made

to the

closed-door relationship

of the

vent assembly

to the

windshield frame. This adjustment

is

controlled

by the

stud-nut assembly "B" Figure

25.

The closed position

of the

window

is

controlled

by

bumper assemblies located

at

each end

of

window frame

as shown

in

Figure

26.

^

Access

to

bumper retaining

screw

may be

gained through holes

"D" and

"E"

in

Figure

25.

Door Hinges

The position

of the

door assembly in the body opening

is adjusted

by the

striker plate position covered

pre-

viously

and the

position

of the

door

on

the hinge rear

CHEVROLET

a

SERVICE

Page 116 of 659

CORVETTE BODY 1B-9

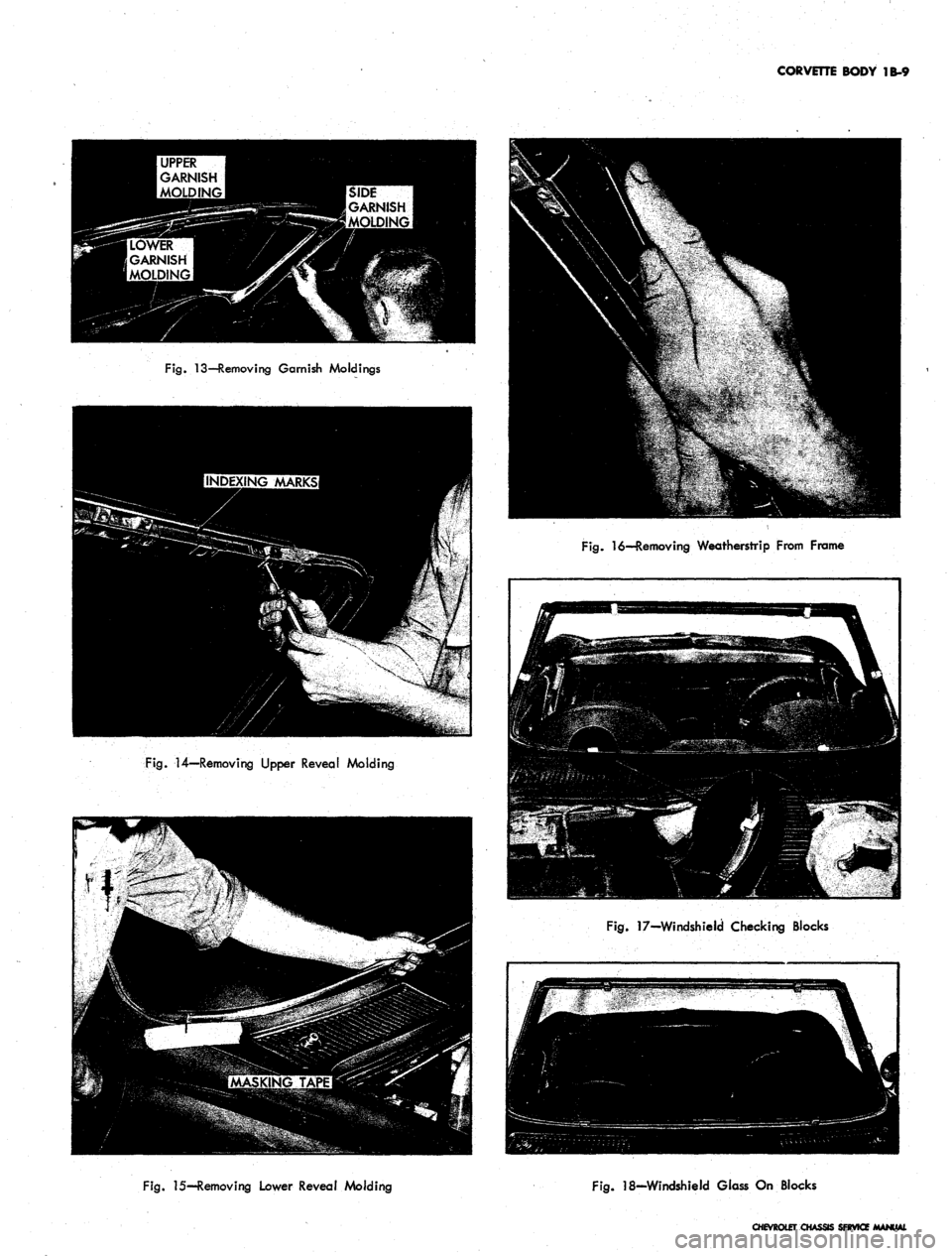

Fig.

13—Removing Garnish Moldings

Fig.

14—Removing Upper Reveal Molding

Fig.

16—Removing Weatherstrip From Frame

Fig.

17-Windshield Checking Blocks

Fig.

15—Removing Lower Reveal Molding

Fig.

18-Windshield Glass On Blocks

CHEVROLET CHASSIS SERVICE

Page 117 of 659

CORVETTE BODY IB-10

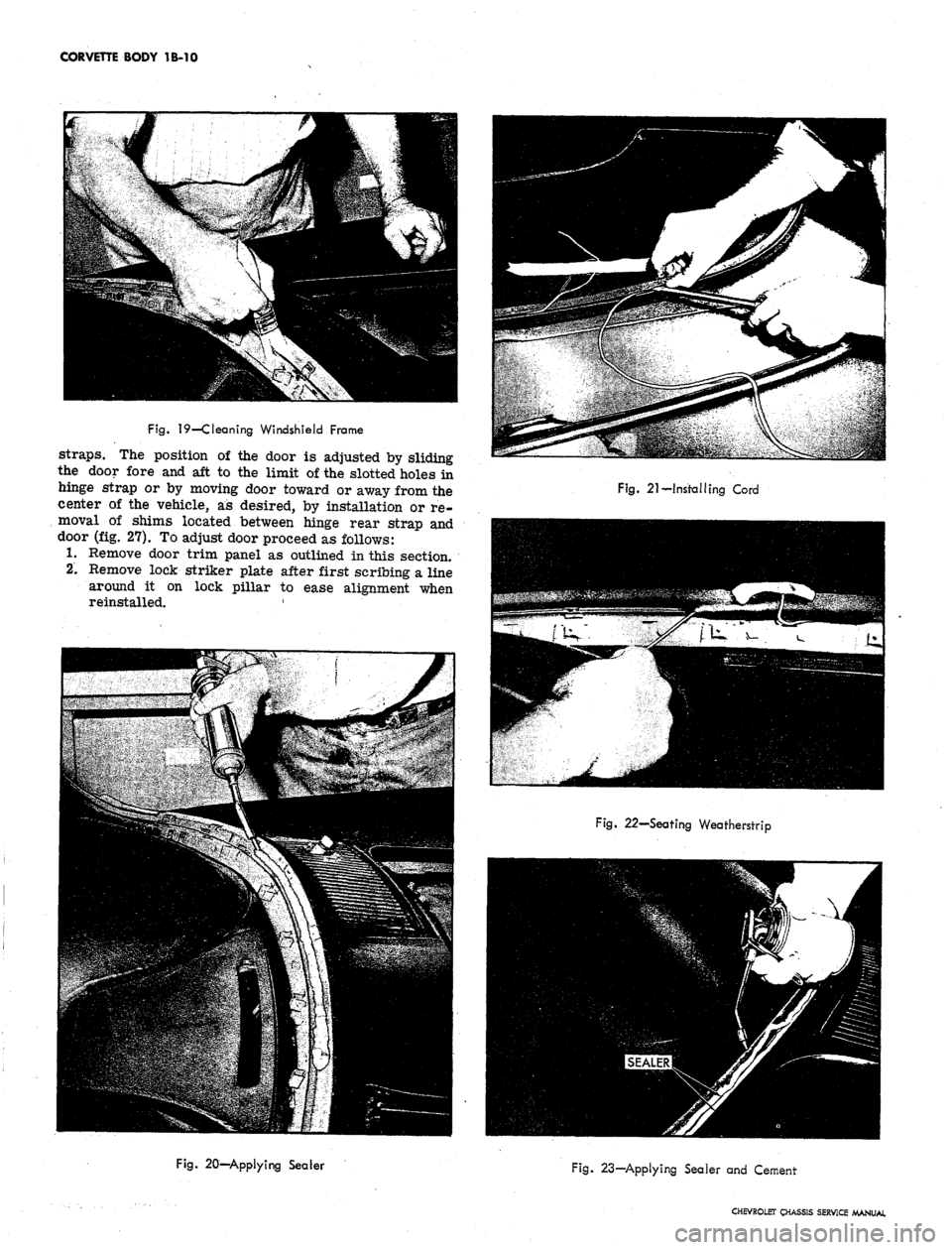

Fig.

19—Cleaning Windshield Frame

straps.

The position of the door is adjusted by sliding

the door fore and aft to the limit of the slotted holes in

hinge strap or by moving door toward or away from the

center of the vehicle, as desired, by installation or re-

moval of shims located between hinge rear strap and

door (fig. 27). To adjust door proceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Remove lock striker plate after first scribing a line

around it on lock pillar to ease alignment when

reinstalled. '

Fig. 21-Installing Cord

Fig. 22—Seating Weatherstrip

Fig. 20—Applying Sealer

Fig. 23—Applying Sealer and Cement

CHEVROLET CHASSIS SERVICE MANUAL

Page 118 of 659

CORVETTE BODY 1B-11

CLAYOfc

CAULKING

COMPOUND

Fig. 26-Window Rear Stop - Typical

Fig. 24—Checking Adjustment of Striker

3.

Adjust door as required. Location of hinge retaining

bolts may be seen in Figure 25 at "A". Do not allow

doors to hang on one hinge without support.

4.

Install trim pad and lubricate door "hold opens" and

hinges with Lubriplate or its equivalent.

NOTE:

After performing any door adjustment,

the window and door post should be checked for

alignment and adjusted as necessary. In addi-

tion,

never slam the door after adjustment with-

out first checking the door lock and striker plate

engagement. An adjustment may be necessary.

TRIM PANEL, AND INSIDE HANDLES

Figure 29 is an exploded view of integral arm rest,

inside handles, and trim panel fastenings.

Removal of trim panel may be accomplished as

follows:

1.

Remove two screws under arm rest.

2.

Using Tool J-7797, remove clips retaining window

crank and lock remote control as shown in Figure 28.

3.

Remove knob from door lock control by turning

counter-clockwise.

4.

Remove 2 screws retaining inside pull handle.

5. Remove sheet metal screws and special washers

retaining trim panel to door assembly.

6. Pull trim panel out. at bottom, tap bottom edge of

trim panel with hand to disengage from top of door.

Remove trim panel from vehicle.

WEATHERSTRIP

Figure

30

illustrates both 19437 and 19467 model door

COWL

Fig.

25-Door Adjustment Points

Fig.

27-Door Hinge

CHEVROLET CHASSIS SERVICE MANUAL

Page 122 of 659

CORVETTE BODY 1B-15

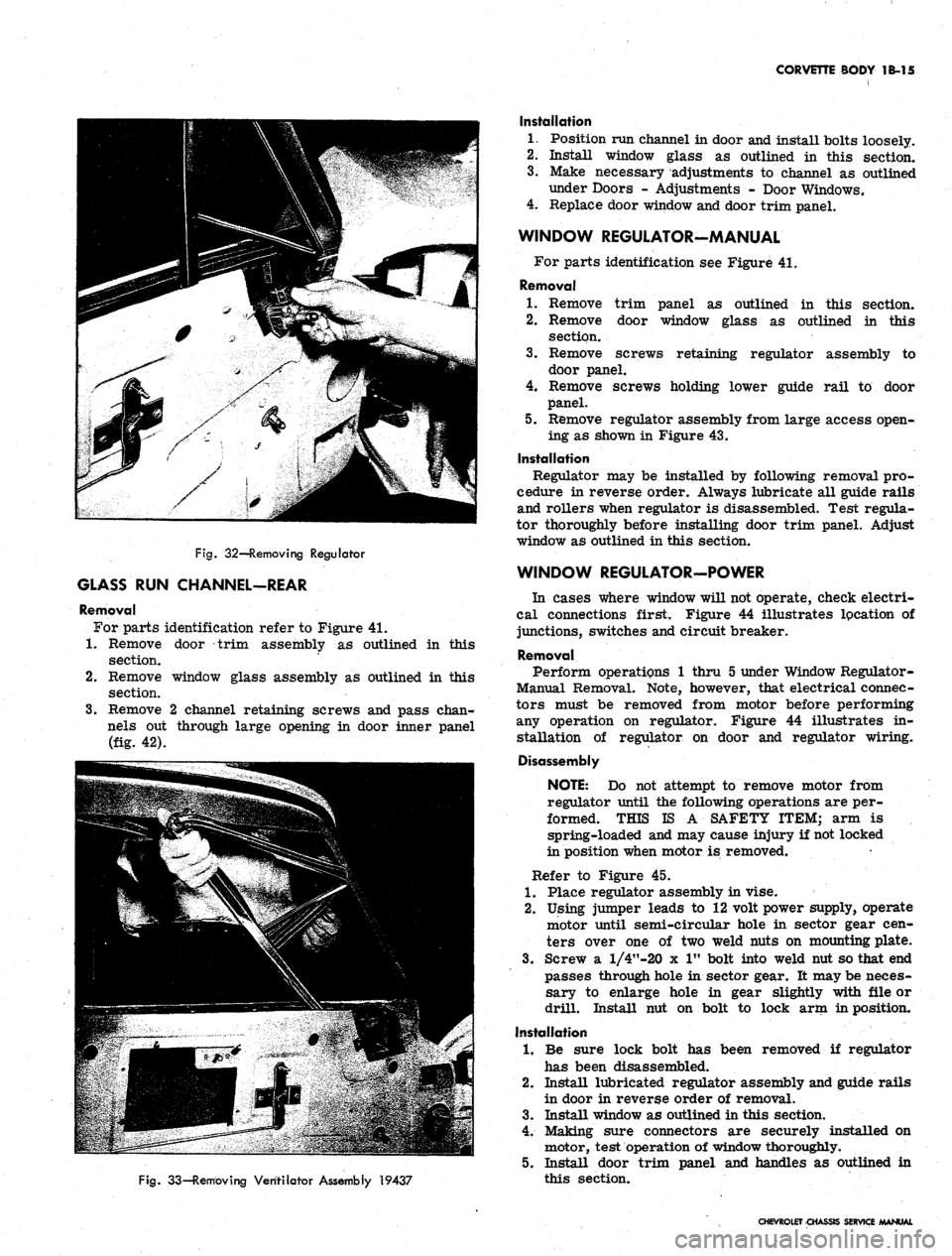

Fig.

32—Removing Regulator

GLASS RUN CHANNEL-REAR

Removal

For parts identification refer to Figure 41.

1.

Remove door trim assembly as outlined in this

section.

2.

Remove window glass assembly as outlined in this

section.

3.

Remove 2 channel retaining screws and pass chan-

nels out through large opening in door inner panel

(fig. 42).

Fig.

33—Removing Ventilator Assembly 19437

Installation

1.

Position run channel in door and install bolts loosely.

2.

Install window glass as outlined in this section.

3.

Make necessary adjustments to channel as outlined

under Doors - Adjustments - Door Windows.

4.

Replace door window and door trim panel.

WINDOW REGULATOR-MANUAL

For parts identification see Figure 41.

Removal

1.

Remove trim panel as outlined in this section.

2.

Remove door window glass as outlined in this

section.

3.

Remove screws retaining regulator assembly to

door panel.

4.

Remove screws holding lower guide rail to door

panel.

5. Remove regulator assembly from large access open-

ing as shown in Figure 43.

Installation

Regulator may be installed by following removal pro-

cedure in reverse order. Always lubricate all guide rails

and rollers when regulator is disassembled. Test regula-

tor thoroughly before installing door trim panel. Adjust

window as outlined in this section.

WINDOW REGULATOR-POWER

In cases where window will not operate, check electri-

cal connections first. Figure 44 illustrates lpcation of

junctions, switches and circuit breaker.

Removal

Perform operations 1 thru 5 under Window Regulator-

Manual Removal. Note, however, that electrical connec-

tors must be removed from motor before performing

any operation on regulator. Figure 44 illustrates in-

stallation of regulator on door and regulator wiring.

Disassembly

NOTE:

Do not attempt to remove motor from

regulator until the following operations are per-

formed. THIS IS A SAFETY ITEM; arm is

spring-loaded and may cause injury if not locked

in position when motor is removed.

Refer to Figure 45.

1.

Place regulator assembly in vise.

2.

Using jumper leads to 12 volt power supply, operate

motor until semi-circular hole in sector gear cen-

ters over one of two weld nuts on mounting plate.

3.

Screw a l/4"-20 x 1" bolt into weld nut so that end

passes through hole in sector gear. It may be neces-

sary to enlarge hole in gear slightly with file or

drill. Install nut on bolt to lock arm in position.

Installation

1.

Be sure lock bolt has been removed if regulator

has been disassembled.

2.

Install lubricated regulator assembly and guide rails

in door in reverse order of removal.

3.

Install window as outlined in this section.

4.

Making sure connectors are securely installed on

motor, test operation of window thoroughly.

5. Install door trim panel and handles as outlined in

this section.

CHEVROLET CHASSIS SERVICE MANUAL