lock CHEVROLET CAMARO 1967 1.G Chassis Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 186 of 659

FRONT SUSPENSION

3-22

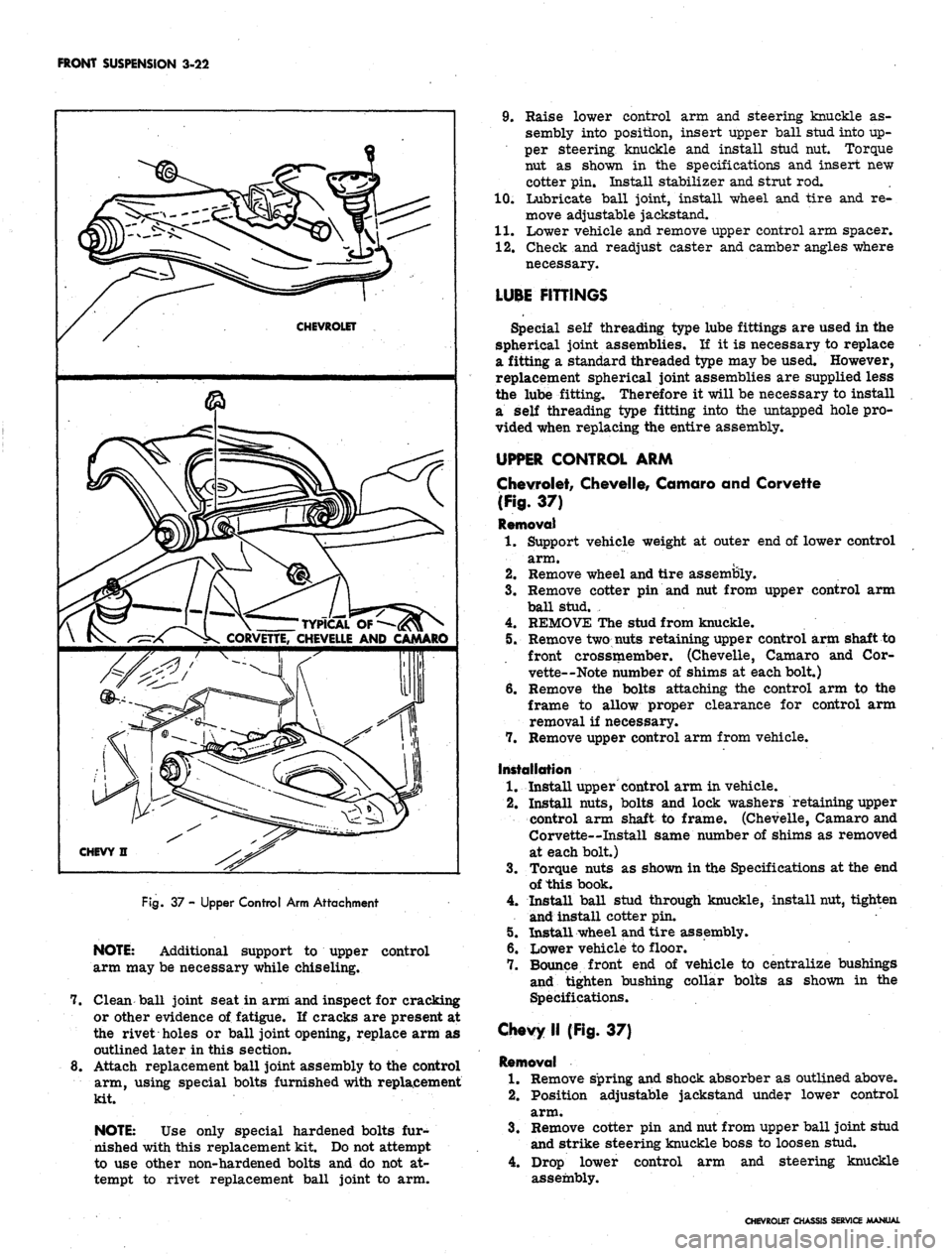

CHEVROLET

s-L 1 \

TYPICAL

OF

-^-x ^K CORVETTE, CHEVELLE AND CAMARO

CHEVY n

Rg.

37 - Upper Control Arm Attachment

NOTE:

Additional support to upper control

arm may be necessary while chiseling.

7. Clean ball joint seat in arm and inspect for cracking

or other evidence of fatigue. If cracks are present at

the rivet holes or ball joint opening, replace arm as

outlined later in this section.

8. Attach replacement ball joint assembly to the control

arm, using special bolts furnished with replacement

kit.

NOTE:

Use only special hardened bolts fur-

nished with this replacement kit. Do not attempt

to use other non-hardened bolts and do not at-

tempt to rivet replacement ball joint to arm.

9. Raise lower control arm and steering knuckle as-

sembly into position, insert upper ball stud into up-

per steering knuckle and install stud nut. Torque

nut as shown in the specifications and insert new

cotter pin. Install stabilizer and strut rod.

10.

Lubricate ball joint, install wheel and tire and re-

move adjustable jackstand.

11.

Lower vehicle and remove upper control arm spacer.

12.

Check and readjust caster and camber angles where

necessary.

LUBE FITTINGS

Special self threading type lube fittings are used in the

spherical joint assemblies. If it is necessary to replace

a fitting a standard threaded type may be used. However,

replacement spherical joint assemblies are supplied less

the lube fitting. Therefore it will be necessary to install

a self threading type fitting into the untapped hole pro-

vided when replacing the entire assembly.

UPPER CONTROL ARM

Chevrolet, Chevelle, Camaro and Corvette

(Fig.

37)

Removal

1.

Support vehicle weight at outer end of lower control

arm.

2.

Remove wheel and tire assembly.

3.

Remove cotter pin and nut from upper control arm

ball stud. ,

4.

REMOVE The stud from knuckle.

5. Remove two nuts retaining upper control arm shaft to

front crossmember. (Chevelle, Camaro and Cor-

vette—Note number of shims at each bolt.)

6. Remove the bolts attaching the control arm to the

frame to allow proper clearance for control arm

removal if necessary.

7. Remove upper control arm from vehicle.

Installation

1.

Install upper control arm in vehicle.

2.

Install nuts, bolts and lock washers retaining upper

control arm shaft to frame. (Chevelle, Camaro and

Corvette—Install same number of shims as removed

at each bolt.)

3.

Torque nuts as shown in the Specifications at the end

of this book.

4.

Install ball stud through knuckle, install nut, tighten

and install cotter pin.

5. Install wheel and tire assembly.

6. Lower vehicle to floor.

7. Bounce front end of vehicle to centralize bushings

and tighten bushing collar bolts as shown in the

Specifications.

Chevy II (Fig. 37)

Removal

1.

Remove spring and shock absorber as outlined above.

2.

Position adjustable jackstand under lower control

arm.

3.

Remove cotter pin and nut from upper ball joint stud

and strike steering knuckle boss to loosen stud.

4.

Drop lower control arm and steering knuckle

assembly.

CHEVROLET CHASSIS SERVICE MANUAL

Page 187 of 659

FRONT SUSPENSION 3-23

CHEVROLET

J-7052-2

CAMARO

& CHEVELLE

J-21482

CHEVROLET

J-7052-2

CAMARO

& CHEVELLE

J-21482

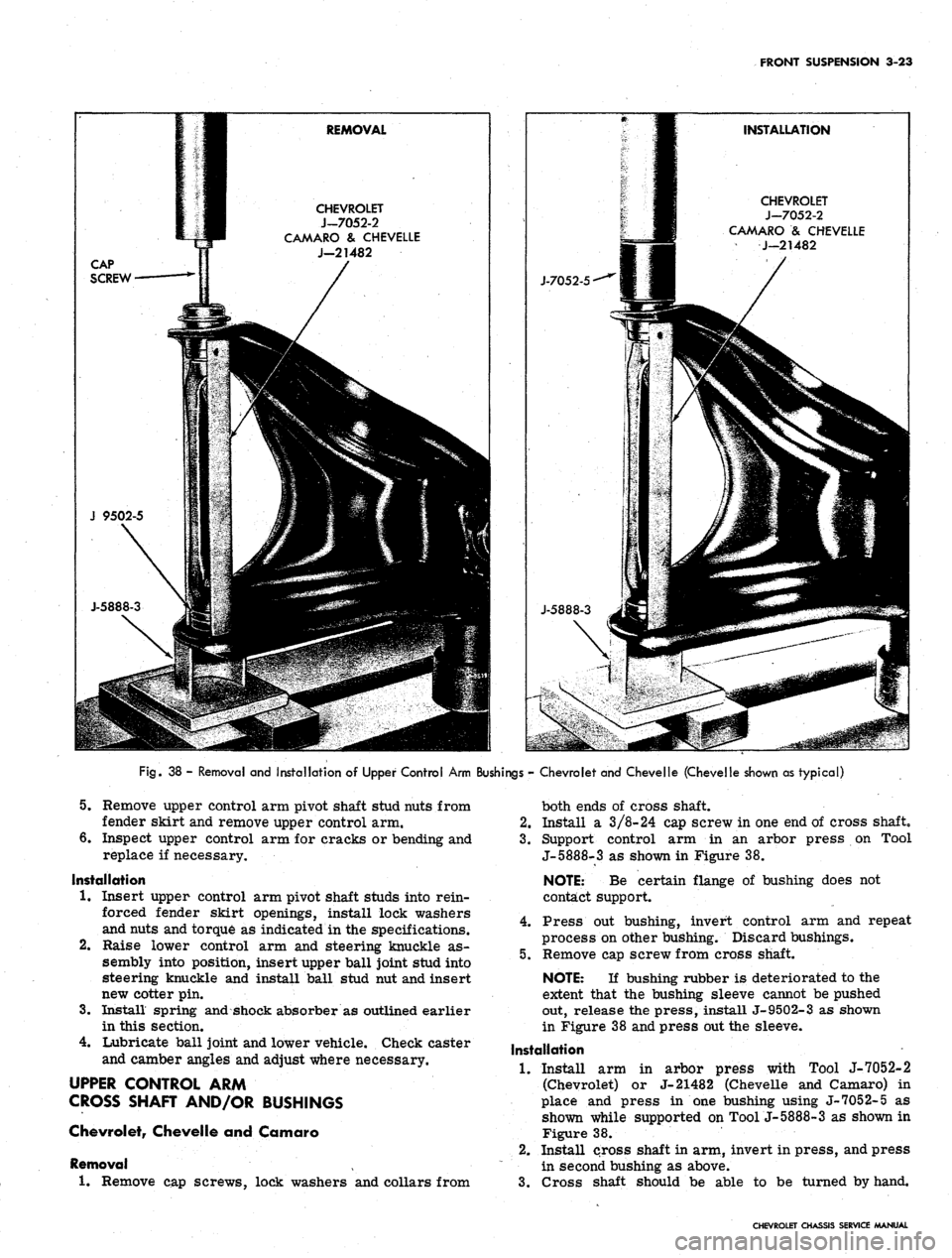

Fig.

38 - Removal and Installation of Upper Control Arm Bushings - Chevrolet and Chevelle (Chevelle shown as typical)

5.

Remove upper control arm pivot shaft stud nuts from

fender skirt and remove upper control arm.

6. Inspect upper control arm for cracks or bending and

replace if necessary.

Installation

1.

Insert upper control arm pivot shaft studs into rein-

forced fender skirt openings, install lock washers

and nuts and torque as indicated in the specifications.

Raise lower control arm and steering knuckle as-

sembly into position, insert upper ball joint stud into

steering knuckle and install ball stud nut and insert

new cotter pin.

Install spring and shock absorber as outlined earlier

in this section.

Lubricate ball joint and lower vehicle. Check caster

and camber angles and adjust where necessary.

UPPER CONTROL ARM

CROSS SHAFT AND/OR BUSHINGS

Chevrolet, Chevelle and Camaro

Removal

1.

Remove cap screws, lock washers and collars from

2.

3.

4.

both ends of cross shaft.

2.

Install a 3/8-24 cap screw in one end of cross shaft,

3.

Support control arm in an arbor press on Tool

J-5888-3 as shown in Figure 38.

NOTE: Be certain flange of bushing does not

contact support.

4.

Press out bushing, invert control arm and repeat

process on other bushing. Discard bushings.

5.

Remove cap screw from cross shaft.

NOTE: If bushing rubber is deteriorated to the

extent that the bushing sleeve cannot be pushed

out, release the press, install J-9502-3 as shown

in Figure 38 and press out the sleeve.

Installation

1.

Install arm in arbor press with Tool J-7052-2

(Chevrolet) or J-21482 (Chevelle and Camaro) in

place and press in one bushing using J-7052-5 as

shown while supported on Tool j-5888-3 as shown in

Figure 38.

2.

Install cross shaft in arm, invert in press, and press

in second bushing as above.

3.

Cross shaft should be able to be turned by hand.

CHEVROLET CHASSIS SERVICE MANUAL

Page 188 of 659

FRONT SUSPENSION 3-24

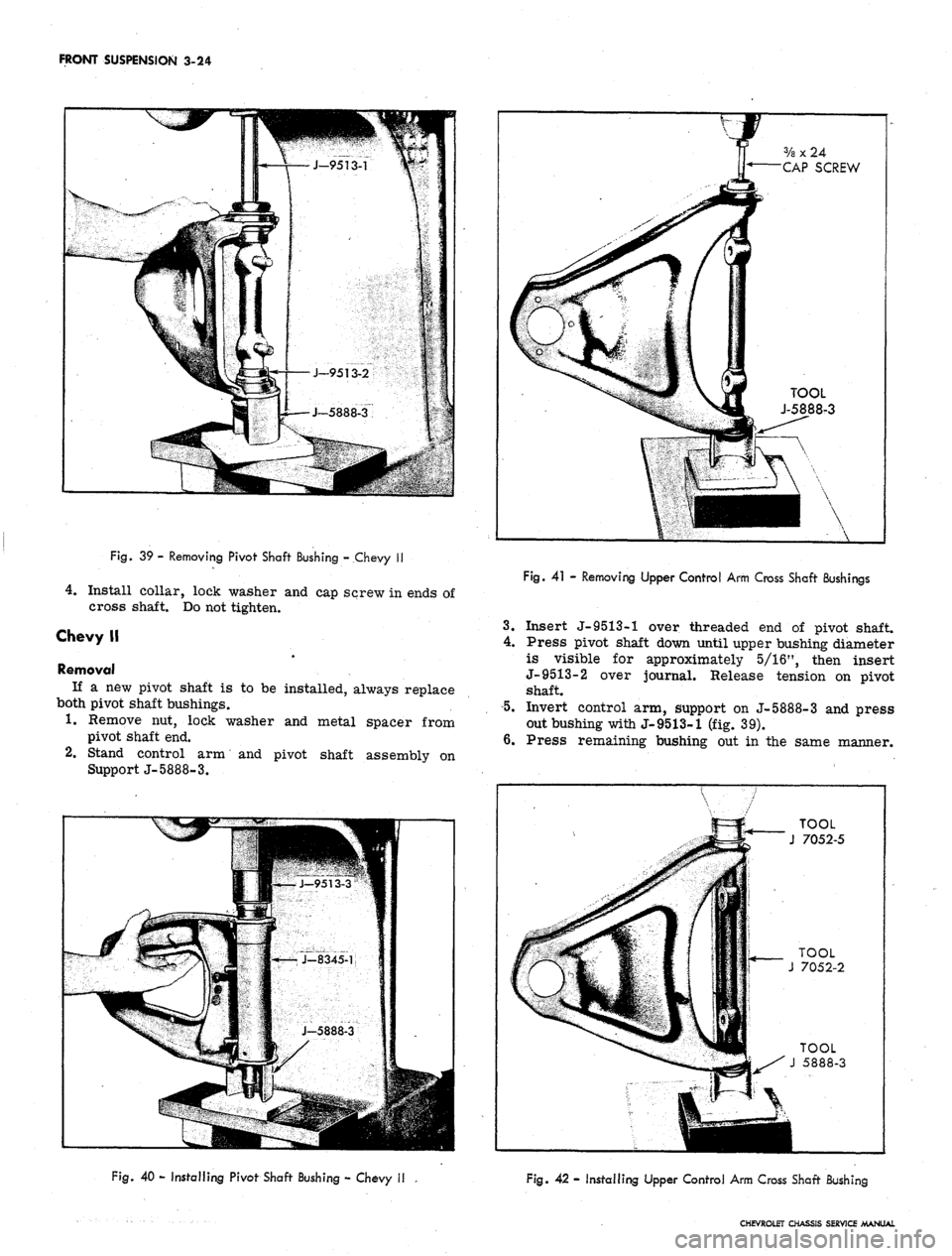

Fig.

39 - Removing Pivot Shaft Bushing - Chevy II

4.

Install collar, lock washer and cap screw in ends of

cross shaft. Do not tighten.

Chevy II

Removal

If a new pivot shaft is to be installed, always replace

both pivot shaft bushings.

1.

Remove nut, lock washer and metal spacer from

pivot shaft end.

2.

Stand control arm and pivot shaft assembly on

Support J-5888-3.

V

f

ff 3/a x 24

y* CAP SCREW

k

a

4f TOOL

i J-5888-3

••

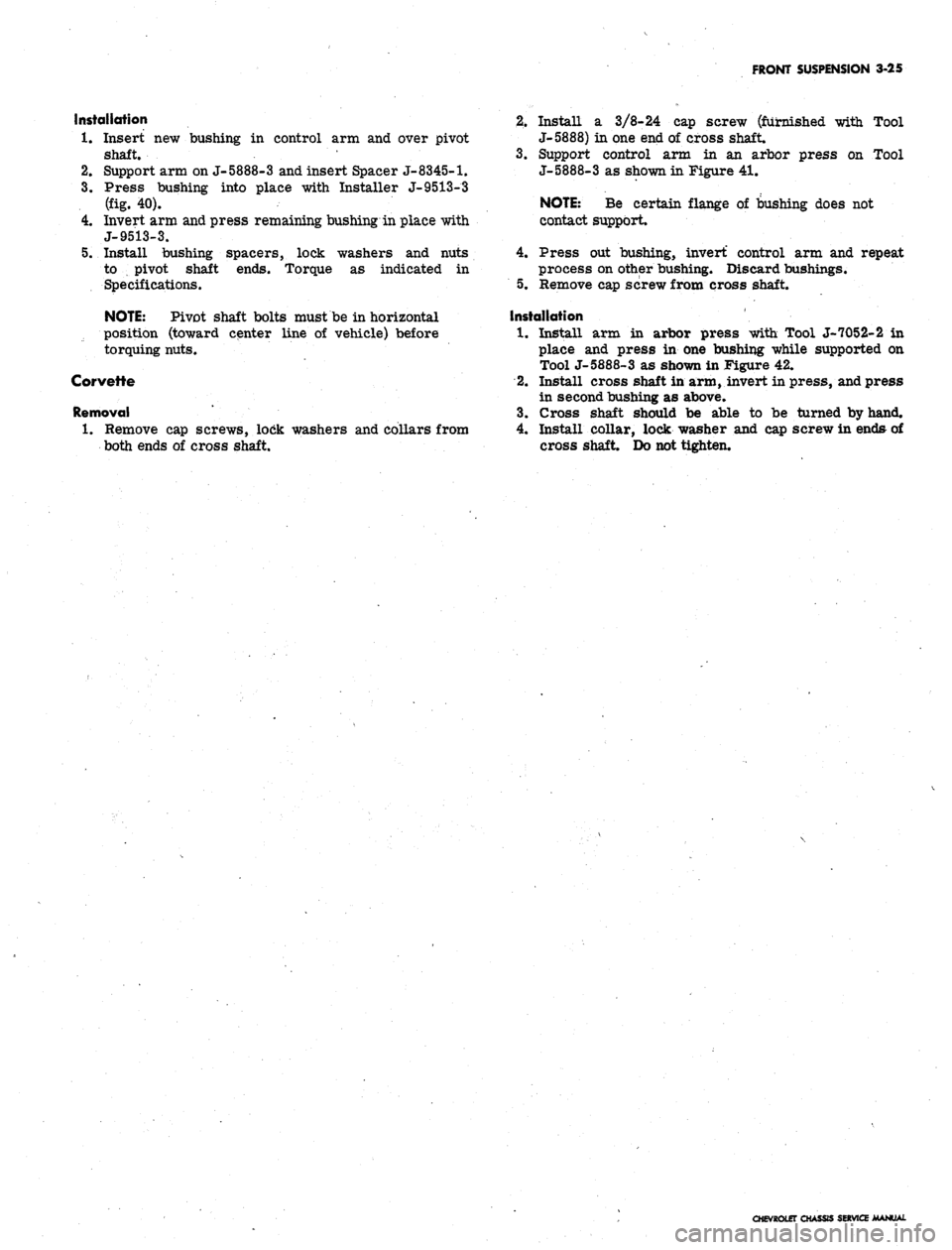

Fig.

41 - Removing Upper Control Arm Cross Shaft Bushings

3.

Insert J-9513-1 over threaded end of pivot shaft.

4.

Press pivot shaft down until upper bushing diameter

is visible for approximately 5/16", then insert

J-9513-2 over journal. Release tension on pivot

shaft.

5.

Invert control arm, support on J-5888-3 and press

out bushing with J-9513-1 (fig. 39).

6. Press remaining bushing out in the same manner.

TOOL

J 7052-5

Fig.

40 - Installing Pivot Shaft Bushing - Chevy II

Fig. 42 - Installing Upper Control Arm Cross Shaft Bushing

CHEVROLET CHASSIS SERVICE MANUAL

Page 189 of 659

FRONT SUSPENSION 3-25

Installation

1.

Insert new bushing in control arm and over pivot

shaft.

2.

Support arm on J-5888-3 and insert Spacer J-

8345-1.

5.

Press bushing into place with Installer J-9513-3

(fig. 40).

Invert arm and press remaining bushing in place with

J-9513-3.

Install bushing spacers, lock washers and nuts

to pivot shaft ends. Torque as indicated in

Specifications.

NOTE:

Pivot shaft bolts must be in horizontal

position (toward center line of vehicle) before

torquing nuts.

Corvette

Removal

1.

Remove cap screws, lock washers and collars from

both ends of cross shaft.

2.

Install a 3/8-24 cap screw (furnished with Tool

J- 5888) in one end of cross shaft.

3.

Support control arm in an arbor press on Tool

J-5888-3 as shown in Figure 41.

NOTE:

Be certain flange of bushing does not

contact support.

4.

Press out bushing, invert control arm and repeat

process on other bushing. Discard bushings.

5. Remove cap screw from cross shaft.

Installation

1.

Install arm in arbor press with Tool J-7052-2 in

place and press in one bushing while supported on

Tool J-5888-3 as shown in Figure 42.

2.

Install cross shaft in arm, invert in press, and press

in second bushing as above.

3.

Cross shaft should be able to be turned by hand.

4.

Install collar, lock washer and cap screw in ends of

cross shaft. Do not tighten.

CHEVROLET CHASSIS SERVICE MANUAL

Page 196 of 659

REAR SUSPENSION AND DRIVE LINE 4-6

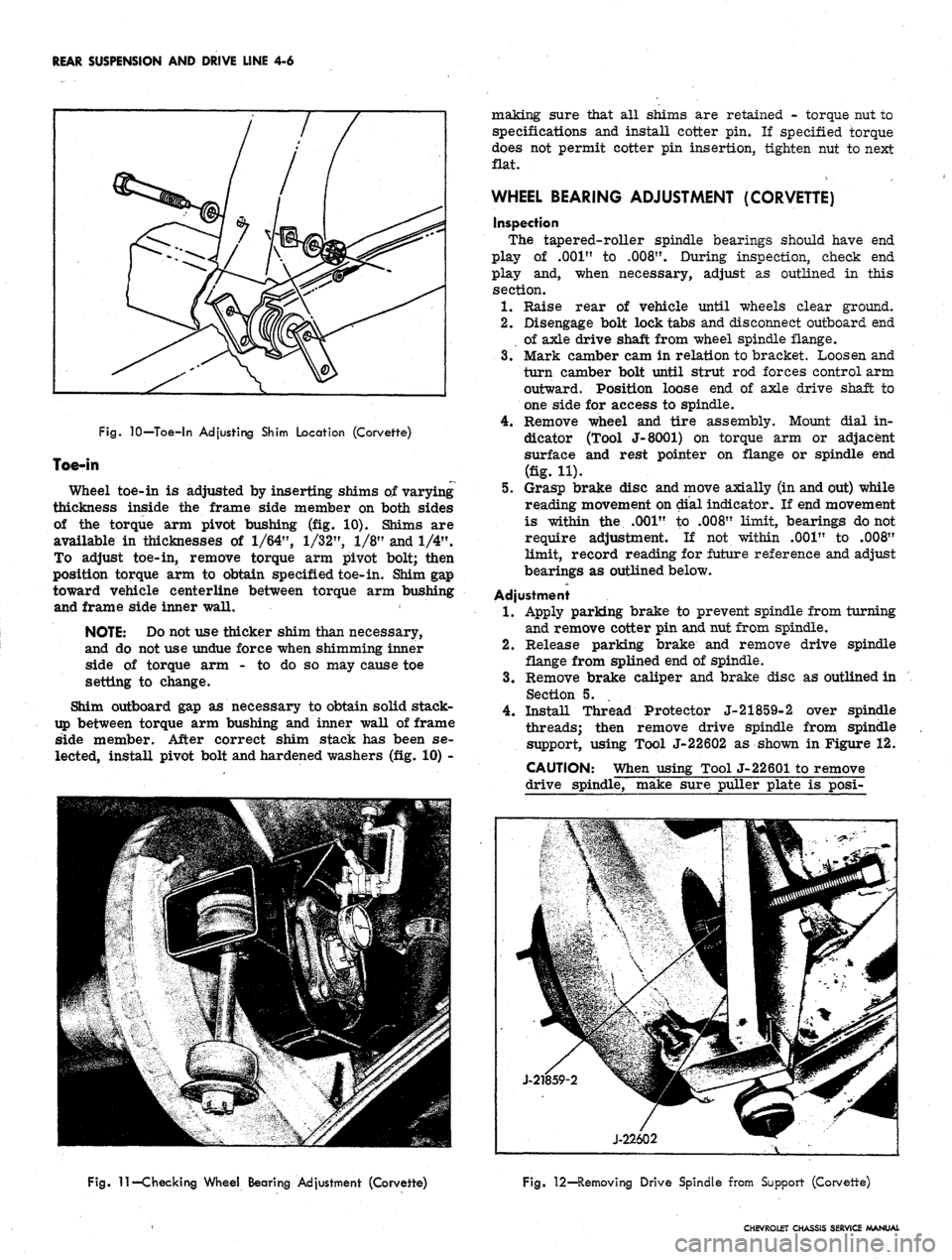

Fig.

10—Toe-in Adjusting Shim Location (Corvette)

Toe-in

Wheel toe-in is adjusted by inserting shims of varying

thickness inside the frame side member on both sides

of the torque arm pivot bushing (fig. 10). Shims are

available in thicknesses of

1/64",

1/32",

1/8" and 1/4".

To adjust toe-in, remove torque arm pivot bolt; then

position torque arm to obtain specified toe-in. Shim gap

toward vehicle centerline between torque arm bushing

and frame side inner wall.

NOTE: Do not use thicker shim than necessary,

and do not use undue force when shimming inner

side of torque arm - to do so may cause toe

setting to change.

Shim outboard gap as necessary to obtain solid stack-

up between torque arm bushing and inner wall of frame

side member. After correct shim stack has been se-

lected, install pivot bolt and hardened washers (fig. 10) -

making sure that all shims are retained - torque nut to

specifications and install cotter pin. If specified torque

does not permit cotter pin insertion, tighten nut to next

flat.

WHEEL BEARING ADJUSTMENT (CORVETTE)

inspection

The tapered-roller spindle bearings should have end

play of .001" to

.008".

During inspection, check end

play and, when necessary, adjust as outlined in this

section.

1.

Raise rear of vehicle until wheels clear ground.

2.

Disengage bolt lock tabs and disconnect outboard end

of axle drive shaft from wheel spindle flange.

3.

Mark camber cam in relation to bracket. Loosen and

turn camber bolt until strut rod forces control arm

outward. Position loose end of axle drive shaft to

one side for access to spindle.

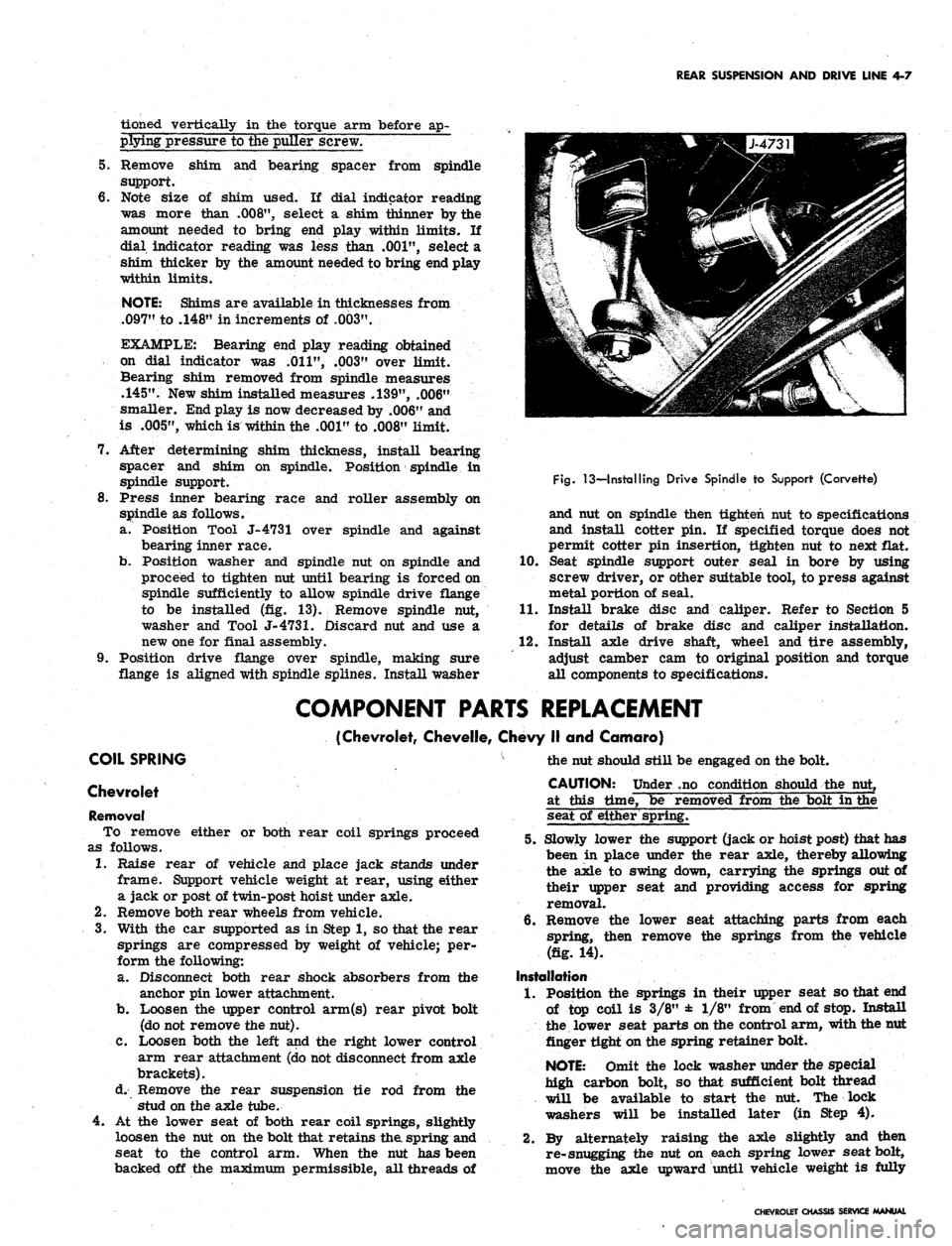

4.

Remove wheel and tire assembly. Mount dial in-

dicator (Tool J-8001) on torque arm or adjacent

surface and rest pointer on flange or spindle end

(fig. H).

5.

Grasp brake disc and move axially (in and out) while

reading movement on dial indicator. If end movement

is within the .001" to .008" limit, bearings do not

require adjustment. If not within .001" to .008"

limit, record reading for future reference and adjust

bearings as outlined below.

Adjustment

1.

Apply parking brake to prevent spindle from turning

and remove cotter pin and nut from spindle.

2.

Release parking brake and remove drive spindle

flange from splined end of spindle.

3.

Remove brake caliper and brake disc as outlined in

Section 5.

4.

Install Thread Protector J-21859-2 over spindle

threads; then remove drive spindle from spindle

support, using Tool J-22602 as shown in Figure 12.

CAUTION: When using Tool J-22601 to remove

drive spindle, make sure puller plate is posi-

Fig.

11—Checking Wheel Bearing Adjustment (Corvette)

Fig. 12—Removing Drive Spindle from Support (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 197 of 659

REAR SUSPENSION AND DRIVE LINE 4-7

tioned vertically in the torque arm before ap-

plying pressure to the puller screw.

5.

Remove shim and bearing spacer from spindle

support.

6. Note size of shim used. If dial indicator reading

was more than

.008",

select a shim thinner by the

amount needed to bring end play within limits. If

dial indicator reading was less than

.001",

select a

shim thicker by the amount needed to bring end play

within limits.

NOTE: Shims are available in thicknesses from

.097"

to .148" in increments of

.003".

EXAMPLE: Bearing end play reading obtained

on dial indicator was

.011",

.003" over limit.

Bearing shim removed from spindle measures

.145".

New shim installed measures .139", .006"

smaller. End play is now decreased by .006" and

is

.005",

which is within the .001" to .008" limit.

7.

After determining shim thickness, install bearing

spacer and shim on spindle. Position spindle in

spindle support.

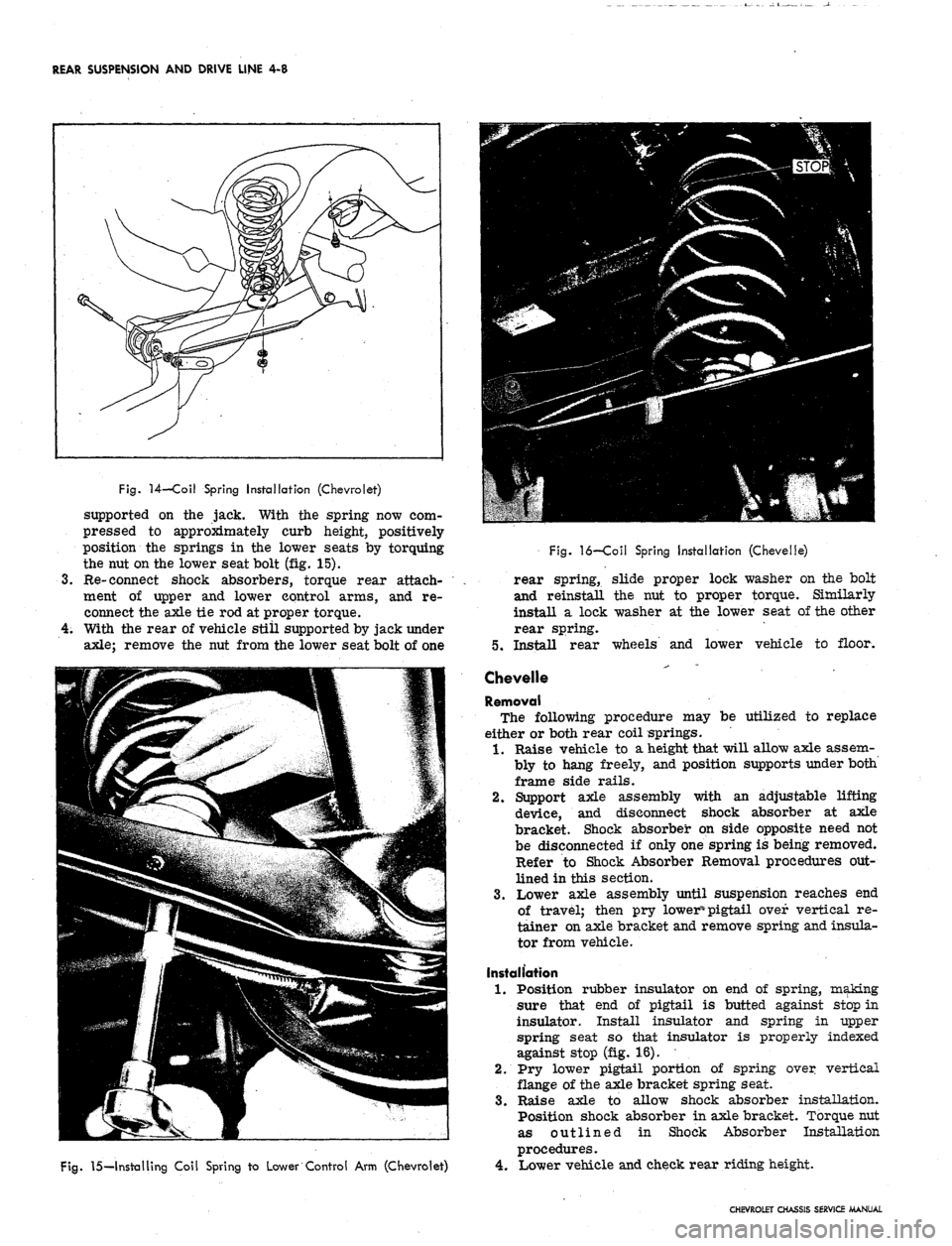

8. Press inner bearing race and roller assembly on

spindle as follows.

a. Position Tool J-4731 over spindle and against

bearing inner race.

b.

Position washer and spindle nut on spindle and

proceed to tighten nut until bearing is forced on

spindle sufficiently to allow spindle drive flange

to be installed (fig. 13). Remove spindle nut,

washer and Tool

J-4731.

Discard nut and use a

new one for final assembly.

9. Position drive flange over spindle, making sure

flange is aligned with spindle splines. Install washer

Fig.

13—Installing Drive Spindle to Support (Corvette)

and nut on spindle then tighten nut to specifications

and install cotter pin. If specified torque does not

permit cotter pin insertion, tighten nut to next flat.

10.

Seat spindle support outer seal in bore by using

screw driver, or other suitable tool, to press against

metal portion of seal.

11.

Install brake disc and caliper. Refer to Section 5

for details of brake disc and caliper installation.

12.

Install axle drive shaft, wheel and tire assembly,

adjust camber cam to original position and torque

all components to specifications.

COMPONENT PARTS REPLACEMENT

(Chevrolet, Chevelle, Chevy II and Camaro)

COIL SPRING

Chevrolet

Removal

To remove either or both rear coil springs proceed

as follows.

1.

Raise rear of vehicle and place jack stands under

frame. Support vehicle weight at rear, using either

a jack or post of twin-post hoist under axle.

2.

Remove both rear wheels from vehicle.

3.

With the car supported as in Step 1, so that the rear

springs are compressed by weight of vehicle; per-

form the following:

a. Disconnect both rear shock absorbers from the

anchor pin lower attachment.

b.

Loosen the upper control arm(s) rear pivot bolt

(do not remove the nut).

C. Loosen both the left and the right lower control

arm rear attachment (do not disconnect from axle

brackets).

d. Remove the rear suspension tie rod from the

stud on the axle tube.

4.

At the lower seat of both rear coil springs, slightly

loosen the nut on the bolt that retains the spring and

seat to the control arm. When the nut has been

backed off the maximum permissible, all threads of

the nut should still be engaged on the bolt.

CAUTION: Under ,no condition should the nut,

at this time, be removed from the bolt in the

seat of either spring.

5.

Slowly lower the support (jack or hoist post) that has

been in place under the rear axle, thereby allowing

the axle to swing down, carrying the springs out of

their upper seat and providing access for spring

removal.

6. Remove the lower seat attaching parts from each

spring, then remove the springs from the vehicle

(fig. 14).

Installation

1.

Position the springs in their upper seat so that end

of top coil is 3/8" ± 1/8" from end of stop. Install

the lower seat parts on the control arm, with the nut

finger tight on the spring retainer bolt.

NOTE: Omit the lock washer under the special

high carbon bolt, so that sufficient bolt thread

will be available to start the nut. The lock

washers will be installed later (in Step 4).

2.

By alternately raising the axle slightly and then

re-snugging the nut on each spring lower seat bolt,

move the axle upward until vehicle weight is fully

CHEVROLET CHASSIS SERVICE MANUAL

Page 198 of 659

REAR SUSPENSION AND DRIVE LINE 4-8

Fig.

14—Coil Spring Installation (Chevrolet)

supported on the jack. With the spring now com-

pressed to approximately curb height, positively

position the springs in the lower seats by torquing

the nut on the lower seat bolt (fig. 15).

Re-connect shock absorbers, torque rear attach-

ment of upper and lower control arms, and re-

connect the axle tie rod at proper torque.

With the rear of vehicle still supported by jack under

axle;

remove the nut from the lower seat bolt of one

Fig.

15—Installing Coil Spring to Lower Control Arm (Chevrolet)

Fig.

16—Coil Spring Installation (Chevelle)

rear spring, slide proper lock washer on the bolt

and reinstall the nut to proper torque. Similarly

install a lock washer at the lower seat of the other

rear spring.

5.

Install rear wheels and lower vehicle to floor.

Chevelle

Removal

The following procedure may be utilized to replace

either or both rear coil springs.

1.

Raise vehicle to a height that will allow axle assem-

bly to hang freely, and position supports under both

frame side rails.

2.

Support axle assembly with an adjustable lifting

device, and disconnect shock absorber at axle

bracket. Shock absorber on side opposite need not

be disconnected if only one spring is being removed.

Refer to Shock Absorber Removal procedures out-

lined in this section.

3.

Lower axle assembly until suspension reaches end

of travel; then pry lower% pigtail over vertical re-

tainer on axle bracket and remove spring and insula-

tor from vehicle.

Installation

1.

Position rubber insulator on end of spring, making

sure that end of pigtail is butted against stop in

insulator. Install insulator and spring in upper

spring seat so that insulator is properly indexed

against stop (fig. 16).

2.

Pry lower pigtail portion of spring over vertical

flange of the axle bracket spring seat.

3.

Raise axle to allow shock absorber installation.

Position shock absorber in axle bracket. Torque nut

as outlined in Shock Absorber Installation

procedures.

4.

Lower vehicle and check rear riding height.

CHEVROLET CHASSIS SERVICE MANUAL

Page 200 of 659

REAR SUSPENSION AND DRIVE LINE 4-10

Fig.

22—Rear Spring Shackle Exploded View—Station Wagon

(Chevy II)

4.

Place upper spring pad cushion on spring. Raise

spring, making sure spring cushion ribs index with

locating ribs in axle housing spring seat, and insert

spring front eye and bushing in frame bracket. In-

stall spring eye bolt, bushing, retainer, lock washer

and nut. Do not torque at this point.

5.

Place lower spring pad cushion on spring, indexing

it over locating dowel.

NOTE: Upper pad correctly installed when

aligned with lower pad.

6. Place lower mounting plate into position over lo-

cating dowel on spring pad, install four locknuts and

insert shock absorber lower eye bolt.

7.

Remove adjustable jackstands, lower vehicle to floor

and bounce several times. Torque all affected parts

to specifications. Incorrect bushing preload may

result if spring eye bolts are torqued prior to

lowering vehicle.

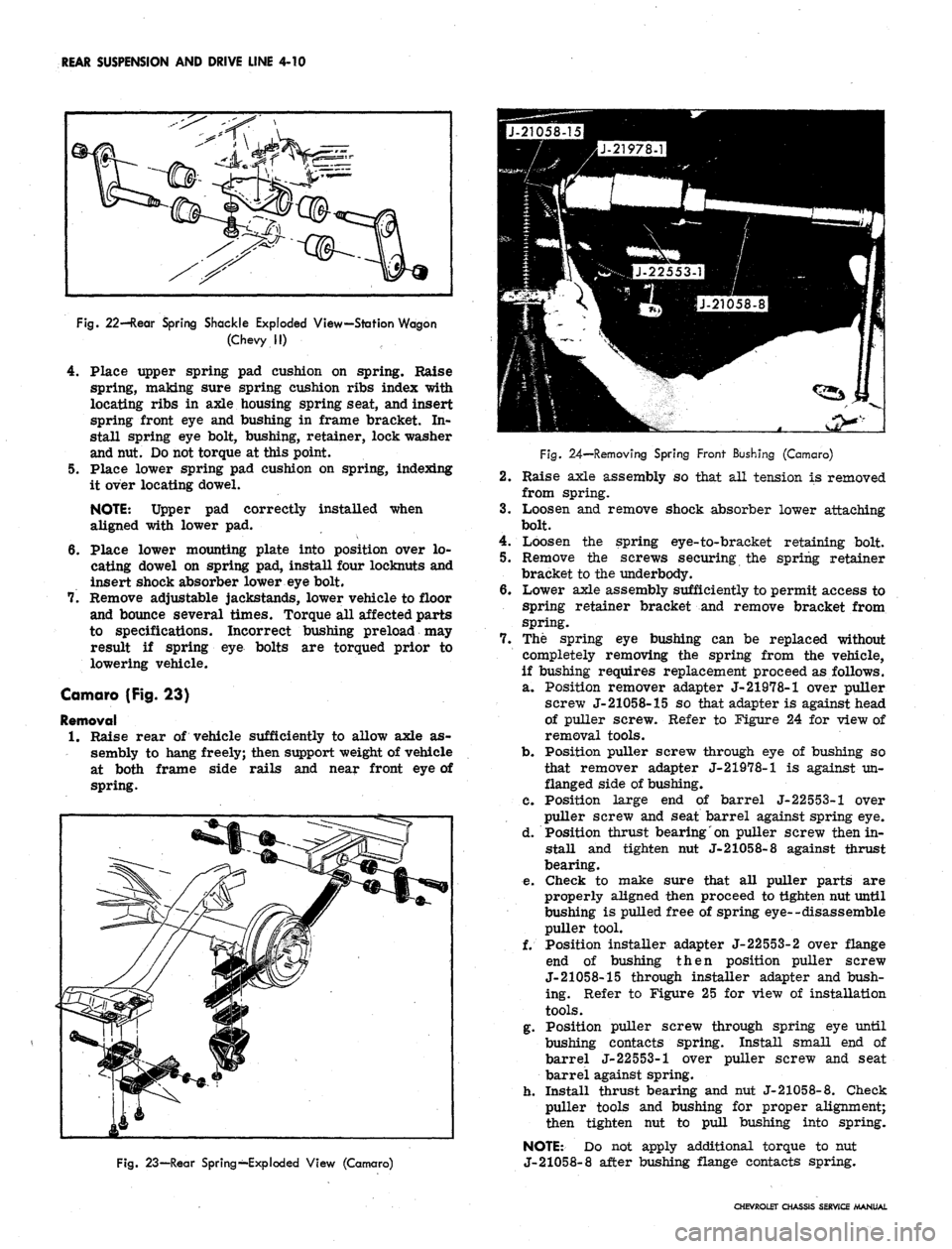

Camaro (Fig. 23)

Removal

1.

Raise rear of vehicle sufficiently to allow axle as-

sembly to hang freely; then support weight of vehicle

at both frame side rails and near front eye of

spring.

Fig.

23—Rear Spring—Exploded View (Camaro)

Fig.

24—Removing Spring Front Bushing (Camaro)

2.

Raise axle assembly so that all tension is removed

from spring.

3.

Loosen and remove shock absorber lower attaching

bolt.

4.

Loosen the spring eye-to-bracket retaining bolt.

5.

Remove the screws securing the spring retainer

bracket to the underbody.

6. Lower axle assembly sufficiently to permit access to

spring retainer bracket and remove bracket from

spring.

7.

The spring eye bushing can be replaced without

completely removing the spring from the vehicle,

if bushing requires replacement proceed as follows.

a. Position remover adapter J-21978-1 over puller

screw J-21058-15 so that adapter is against head

of puller screw. Refer to Figure 24 for view of

removal tools.

b.

Position puller screw through eye of bushing so

that remover adapter J-21978-1 is against un-

flanged side of bushing.

C. Position large end of barrel J-22553-1 over

puller screw and seat barrel against spring eye.

d. Position thrust bearing on puller screw then in-

stall and tighten nut J-21058-8 against thrust

bearing.

e. Check to make sure that all puller parts are

properly aligned then proceed to tighten nut until

bushing is pulled free of spring eye--disassemble

puller tool.

f. Position installer adapter J-22553-2 over flange

end of bushing then position puller screw

J-21058-15 through installer adapter and bush-

ing. Refer to Figure 25 for view of installation

tools.

g. Position puller screw through spring eye until

bushing contacts spring. Install small end of

barrel J-22553-1 over puller screw and seat

barrel against spring.

h. Install thrust bearing and nut J-21058-8. Check

puller tools and bushing for proper alignment;

then tighten nut to pull bushing into spring.

NOTE: Do not apply additional torque to nut

J-21058-8 after bushing flange contacts spring.

CHEVROLET CHASSIS SERVICE MANUAL

Page 202 of 659

REAR SUSPENSION AND DRIVE LINE 4-12

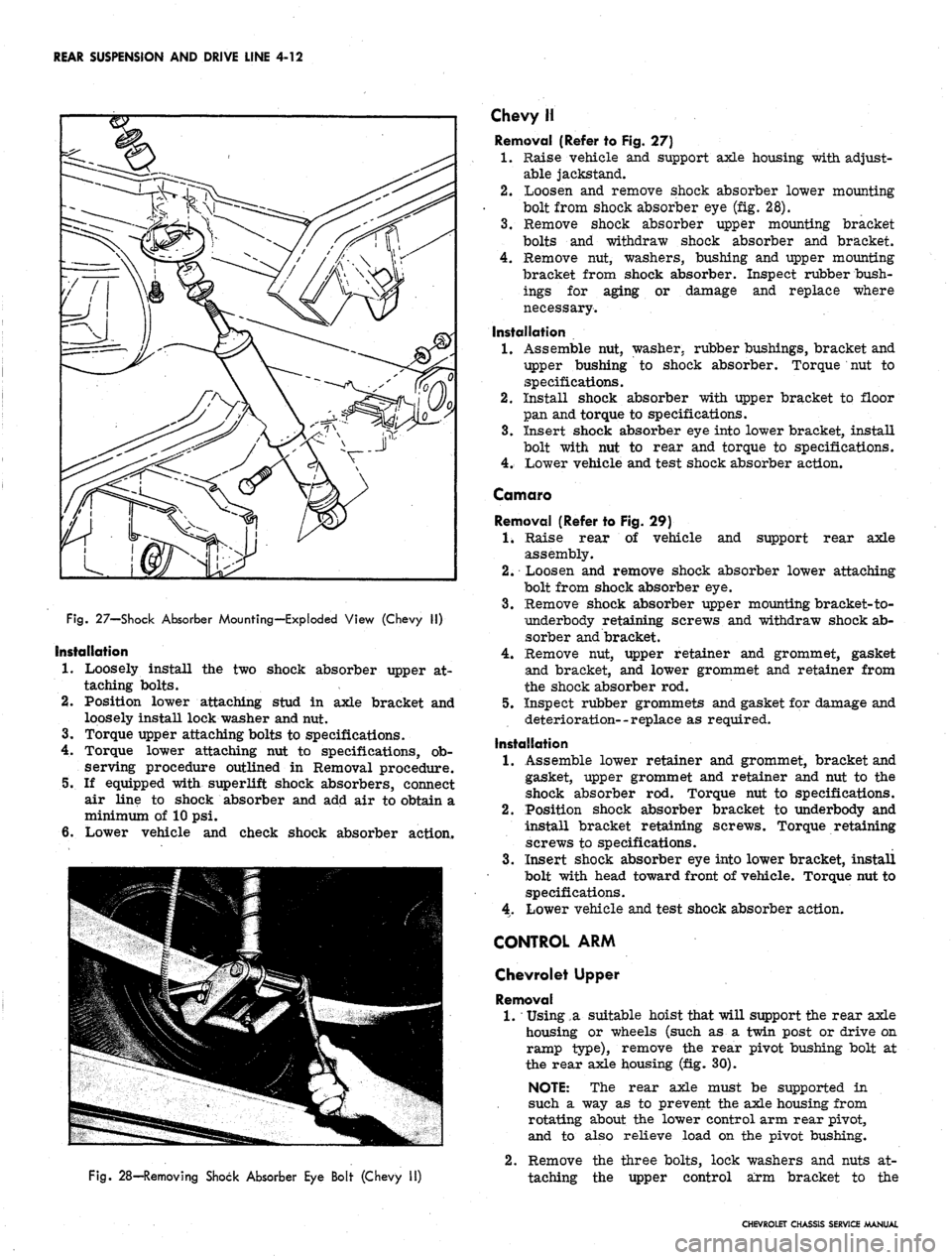

Fig.

27—Shock Absorber Mounting—Exploded View (Chevy II)

Installation

1.

Loosely install the two shock absorber upper at-

taching bolts.

2.

Position lower attaching stud in axle bracket and

loosely install lock washer and nut.

3.

Torque upper attaching bolts to specifications.

4.

Torque lower attaching nut to specifications, ob-

serving procedure outlined in Removal procedure.

5.

If equipped with superlift shock absorbers, connect

air line to shock absorber and add air to obtain a

minimum of 10 psi.

6. Lower vehicle and check shock absorber action.

Fig.

28—Removing Shock Absorber Eye Bolt (Chevy II)

Chevy H

Removal (Refer to Fig. 27)

1.

Raise vehicle and support axle housing with adjust-

able jackstand.

2.

Loosen and remove shock absorber lower mounting

bolt from shock absorber eye (fig. 28).

3.

Remove shock absorber upper mounting bracket

bolts and withdraw shock absorber and bracket.

4.

Remove nut, washers, bushing and upper mounting

bracket from shock absorber. Inspect rubber bush-

ings for aging or damage and replace where

necessary.

Installation

1.

Assemble nut, washer, rubber bushings, bracket and

upper bushing to shock absorber. Torque nut to

specifications.

2.

Install shock absorber with upper bracket to floor

pan and torque to specifications.

3.

Insert shock absorber eye into lower bracket, install

bolt with nut to rear and torque to specifications.

4.

Lower vehicle and test shock absorber action.

Comoro

Removal (Refer to Fig. 29)

1.

Raise rear of vehicle and support rear axle

assembly.

2.

Loosen and remove shock absorber lower attaching

bolt from shock absorber eye.

3.

Remove shock absorber upper mounting bracket-to-

iiinderbody retaining screws and withdraw shock ab-

sorber and bracket.

4.

Remove nut, upper retainer and grommet, gasket

and bracket, and lower grommet and retainer from

the shock absorber rod.

5.

Inspect rubber grommets and gasket for damage and

deterioration--replace as required.

Installation

1.

Assemble lower retainer and grommet, bracket and

gasket, upper grommet and retainer and nut to the

shock absorber rod. Torque nut to specifications.

2.

Position shock absorber bracket to underbody and

install bracket retaining screws. Torque retaining

screws to specifications.

3.

Insert shock absorber eye into lower bracket, install

bolt with head toward front of vehicle. Torque nut to

specifications.

4.

Lower vehicle and test shock absorber action.

CONTROL ARM

Chevrolet Upper

Removal

1.

*

Using,a suitable hoist that will support the rear axle

housing or wheels (such as a twin post or drive on

ramp type), remove the rear pivot bushing bolt at

the rear axle housing (fig. 30).

NOTE: The rear axle must be supported in

such a way as to prevent the axle housing from

rotating about the lower control arm rear pivot,

and to also relieve load on the pivot bushing.

2.

Remove the three bolts, lock washers and nuts at-

taching the upper control arm bracket to the

CHEVROLET CHASSIS SERVICE MANUAL

Page 204 of 659

REAR SUSPENSION AND DRIVE LINE 4-14

Fig.

32—Upper Control Arm Bushing Installation (Chevrolet)

Installation

1.

Position rear of control arm into axle bracket and

loosely install the pivot bolt.

2.

Align the forward end of the control arm with the

rear crossmember and install front bracket bolts

through holes. Raise or lower nose of carrier as

/ required to help align bracket and crossmember.

3.

Install crossmember reinforcement plate, lock

washers and nuts to retain bracket in place.

4.

Position vehicle so that weight is on suspension

components and torque all affected parts to

specifications.

Chevrolet Lower

Removal

1.

Raise vehicle and remove shock absorber and spring

as outlined in this section.

NOTE:

If both rear suspension lower control

arms are to be removed, support the rear axle

in such a manner to prevent damage to brake

lines and to prevent assembly from falling.

2.

Note position of control arm in forward attaching

bracket and disconnect control arm at forward and

rearward attaching points. Remove assembly from

vehicle.

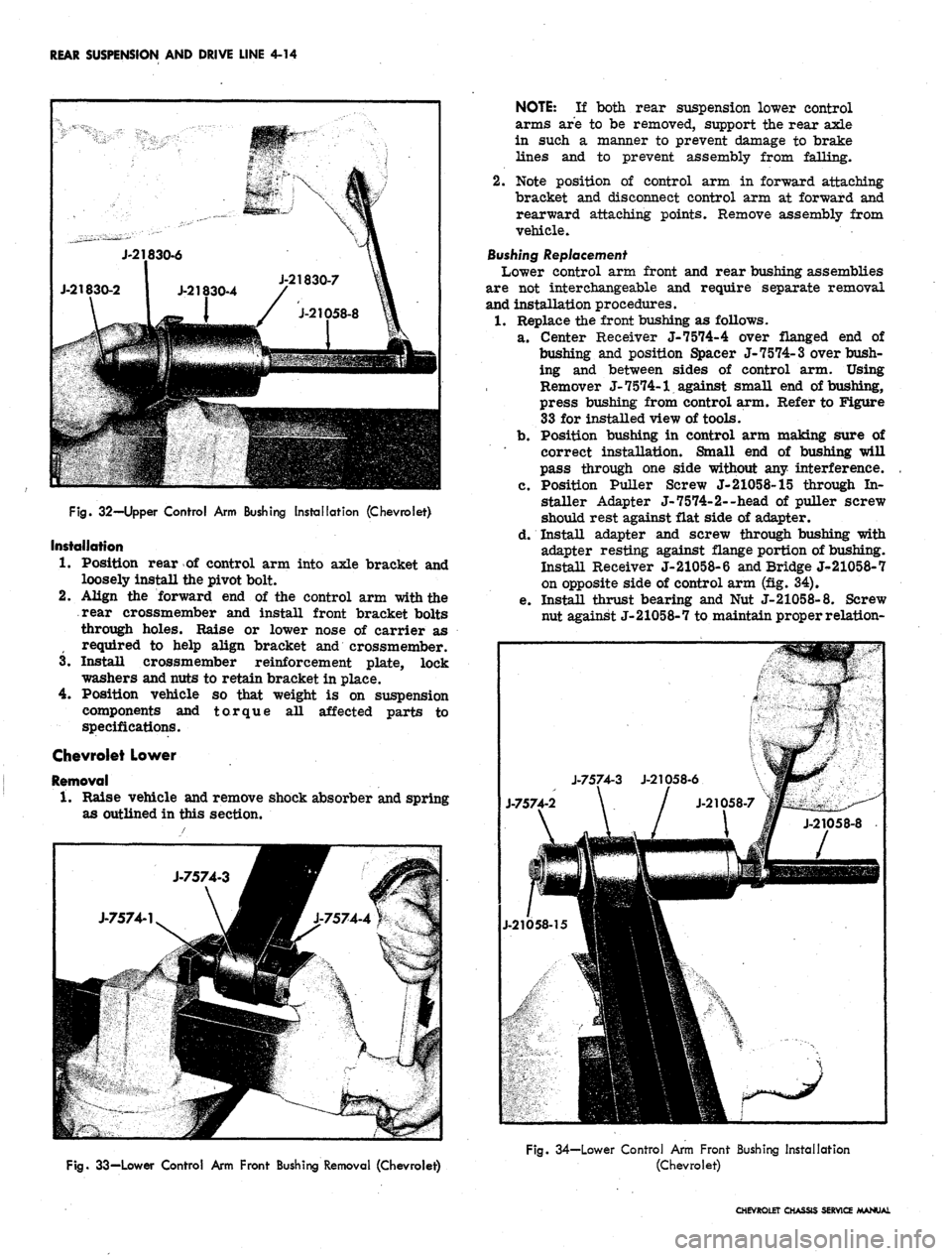

Bushing Replacement

Lower control arm front and rear bushing assemblies

are not interchangeable and require separate removal

and installation procedures.

1.

Replace the front bushing as follows.

a. Center Receiver J-7574-4 over flanged end of

bushing and position Spacer J-7574-3 over bush-

ing and between sides of control arm. Using

Remover J- 7574-1 against small end of bushing,

press bushing from control arm. Refer to Figure

33 for installed view of tools.

b.

Position bushing in control arm making sure of

correct installation. Small end of bushing will

pass through one side without any interference.

c. Position Puller Screw J-21058-15 through In-

staller Adapter J-7574-2--head of puller screw

should rest against flat side of adapter.

d. Install adapter and screw through bushing with

adapter resting against flange portion of bushing.

Install Receiver J-21058-6 and Bridge J^-21058-7

on opposite side of control arm (fig. 34).

e. Install thrust bearing and Nut J-21058-8. Screw

nut against J-21058-7 to maintain proper relation-

Fig.

33—Lower Control Arm Front Bushing Removal (Chevrolet)

Fig. 34—Lower Control Arm Front Bushing Installation

(Chevrolet)

CHEVROLET CHASSIS SERVICE MANUAL