coil CHEVROLET CAMARO 1967 1.G Chassis Manual PDF

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 618 of 659

ACCESSORIES 15-9

Adjustment- Adjust the bead chain so that it is as tight

as possible without holding the throttle open when the

carburetor is set at its lowest idle throttle position.

When connecting the bead chain (engine stopped) manually

set the fast idle cam at its lowest step and connect the

chain so that it does not hold the idle screw off the cam.

If the chain needs to be cut, cut it three beads beyond the

bead which pulls the linkage.

REGULATOR

Service - A defective regulator, that is one which is not

simply out of adjustment, must be replaced. During re-

placement, check the hoses which connect to the regulator

and replace any which are cracked or deteriorated.

Air Filter

The air filter located in the solenoid cover should be

cleaned and re-oiled at engine oil change intervals.

1.

Snap the solenoid cover off.

2.

Remove the filter and wash it in kerosene or mineral

spirits. Squeeze it dry and wet with SAE 10 engine

oil.

Squeeze out excess oil and reinstall into the

cover.

3.

Attach the cover with neoprene seal to the solenoid

housing. Be certain that the cover fits tightly to the

housing.

One regulator adjustment is possible: Engagement-

Cruising Speed Zeroing (to remove any difference be-

tween engagement and cruising speed).

NOTE:

No regulator adjustment should be

made, however, until the following items have

been checked or serviced:

1.

Bead chain properly adjusted.

2.

All hoses in good condition, properly attached, not

leaking, not pinched or kinked.

3.

Regulator air filter clean and properly oiled.

4.

Electric and vacuum release switches properly

adjusted.

Engagement—Cruising Speed Zeroing

If the cruising speed is lower than the engagement

speed, loosen the orifice tube locknut and turn the tube

outward; if higher, turn the tube inward. Each 1/8 turn

will alter the engagement-cruising speed difference one

mph. Tighten the locknut after adjustment and check the

system operation at 50 mph.

ELECTRICAL SYSTEM CHECK OUT

1.

Check fuse and connector.

2.

Check electric brake switch as follows: Unplug con-

nector at brake switch. Connect ohmmeter at points

A and B on brake switch. The ohmmeter must indi-

cate infinity when the brake pedal is depressed and

continuity when pedal is released. The cruise re-

lease brake switch (electric) is adjusted as is the

standard stop light brake switch. Replace electric

brake switch if needed.

3.

Check engagement switch and connecting wiring as

follows: Unplug push button control connector

(brown, blue, black) at electrical wiring harness con-

nector and perform the following tests. (See Fig-

ure 10)

Test #1

—

Connect ohmmeter between terminal #1 (brown

wire) and terminal #2 (blue wire). Continuity shall be

maintained until switch is depressed all the way in.

Test #2

—

Connect ohmmeter between terminal #1 (brown

wire) and terminal #3 (black). No continuity shall be

shown; however, when the button is depressed halfway,

continuity shall be indicated. When the button is pressed

all the way down, no continuity shall be shown.

Test #3 — Connect ohmmeter between terminal #2 (blue

wire) and terminal #3 (black). Button released, no con-

tinuity; however, when the button is depressed partially

and fully, continuity shall be shown.

4.

Check regulator solenoid coil, low-speed switch, and

wiring harness as follows:

a. Disconnect engagement switch wire harness con-

nector from the main wire harness connector

(brown, blue, and black wires). Connect ohm-

meter

'

between point C (blue wire in main wire

harness) and ground. (Make sure the regulator is

well grounded to chassis.) The ohmmeter should

read 45 ohms ± 2 ohms. If a resistance of

greater value is shown, then disconnect the con-

nector from the regulator and measure the re-

sistance of the blue wire from point C to D. It

should measure 40 ohms. Check the resistance

from point E (vertical bar of terminal forming T)

to ground. It should measure 5 ohms ± 1/4 ohm.

Replace either the wiring harness or solenoid as

needed if greater values are indicated. The black

harness wiring from point F to G should also be

checked for continuity.

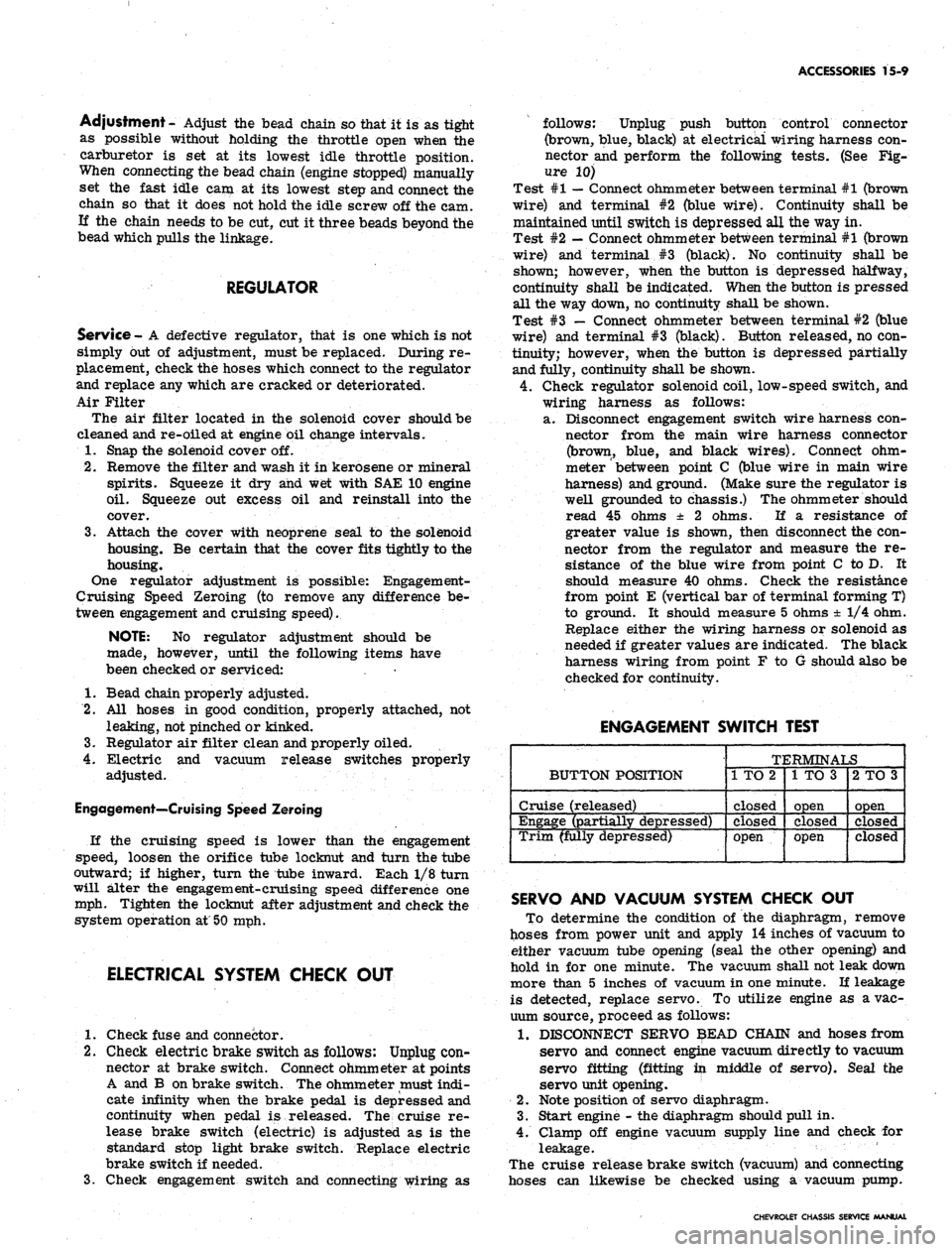

ENGAGEMENT SWITCH TEST

BUTTON POSITION

Cruise (released)

Engage (partially depressed)

Trim (fully depressed)

TERMINALS

1 TO 2

closed

Closed

open

1 TO 3

open

closed

open

2 TO 3

open

closed

closed

SERVO AND VACUUM SYSTEM CHECK OUT

To determine the condition of the diaphragm, remove

hoses from power unit and apply 14 inches of vacuum to

either vacuum tube opening (seal the other opening) and

hold in for one minute. The vacuum shall not leak down

more than 5 inches of vacuum in one minute. If leakage

is detected, replace servo. To utilize engine as a vac-

uum source, proceed as follows:

1.

DISCONNECT SERVO $EAD CHAIN and hoses from

servo and connect engine vacuum directly to vacuum

servo fitting (fitting in middle of servo). Seal the

servo unit opening.

2.

Note position of servo diaphragm.

3.

Start engine - the diaphragm should pull in.

4.

Clamp off engine vacuum supply line and check for

leakage. '

The cruise release brake switch (vacuum) and connecting

hoses can likewise be checked using a vacuum pump.

CHEVROLET CHASSIS SERVICE MANUAL

Page 621 of 659

ACCESSORIES 15-12

VACUUM

(WIT

P

VACUUM Llh

, AIR SUPPt

LINES

t

SUPERLIFT F

SHOCK ABSO

OPERATED AIR COMPRESSOR

H STORAGE TANK AND

RESSURE REGULATORJV

\A

4E FROM ENG«NE^"^

/ \-HEIGHT CONTROL

•^-Z n VALVE (WITH TIME

^*

EAR II

RBERS

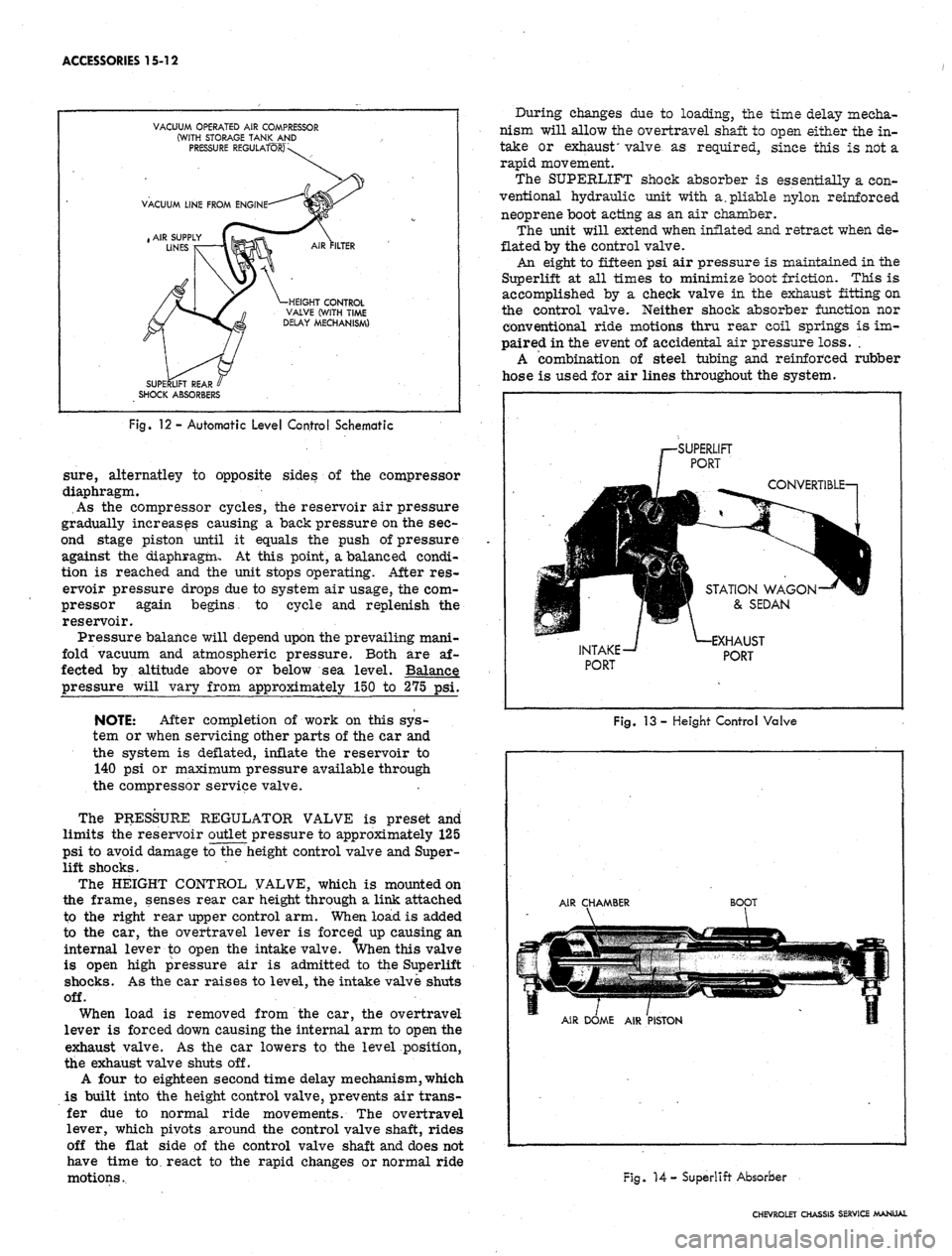

Fig.

12 - Automatic Level Control Schematic

sure,

alternatley to opposite sides of the compressor

diaphragm.

As the compressor cycles, the reservoir air pressure

gradually increases causing a back pressure on the sec-

ond stage piston until it equals the push of pressure

against the diaphragm- At this point, a balanced condi-

tion is reached and the unit stops operating. After res-

ervoir pressure drops due to system air usage, the com-

pressor again begins to cycle and replenish the

reservoir.

Pressure balance will depend upon the prevailing mani-

fold vacuum and atmospheric pressure. Both are af-

fected by altitude above or below sea level. Balance

pressure will vary from approximately 150 to 275 psi.

NOTE: After completion of work on this sys-

tem or when servicing other parts of the car and

the system is deflated, inflate the reservoir to

140 psi or maximum pressure available through

the compressor service valve.

The PRESSURE REGULATOR VALVE is preset and

limits the reservoir outlet pressure to approximately 125

psi to avoid damage to the height control valve and Super-

lift shocks.

The HEIGHT CONTROL VALVE, which is mounted on

the frame, senses rear car height through a link attached

to the right rear upper control arm. When load is added

to the car, the overtravel lever is forced up causing an

internal lever to open the intake valve, when this valve

is open high pressure air is admitted to the Superlift

shocks. As the car raises to level, the intake valve shuts

off.

When load is removed from the car, the overtravel

lever is forced down causing the internal arm to open the

exhaust valve. As the car lowers to the level position,

the exhaust valve shuts off.

A four to eighteen second time delay mechanism, which

is built into the height control valve, prevents air trans-

fer due to normal ride movements. The overtravel

lever, which pivots around the control valve shaft, rides

off the flat side of the control valve shaft and does not

have time to. react to the rapid changes or normal ride

motions.

During changes due to loading, the time delay mecha-

nism will allow the overtravel shaft to open either the in-

take or exhaust' valve as required, since this is not a

rapid movement.

The SUPERLIFT shock absorber is essentially a con-

ventional hydraulic unit with a. pliable nylon reinforced

neoprene boot acting as an air chamber.

The unit will extend when inflated and retract when de-

flated by the control valve.

An eight to fifteen psi air pressure is maintained in the

Superlift at all times to minimize boot friction- This is

accomplished by a check valve in the exhaust fitting on

the control valve. Neither shock absorber function nor

conventional ride motions thru rear coil springs is im-

paired in the event of accidental air pressure loss. .

A combination of steel tubing and reinforced rubber

hose is used for air lines throughout the system.

-SUPERLIFT

PORT

STATION WAGON

& SEDAN

INTAKE

PORT

HAUST

PORT

Fig. 13 - Height Control Valve

AIR CHAMBER

BOOT

AIR DOME AIR PISTON

Fig. 14- Superlift Absorber

CHEVROLET CHASSIS SERVICE MANUAL

Page 628 of 659

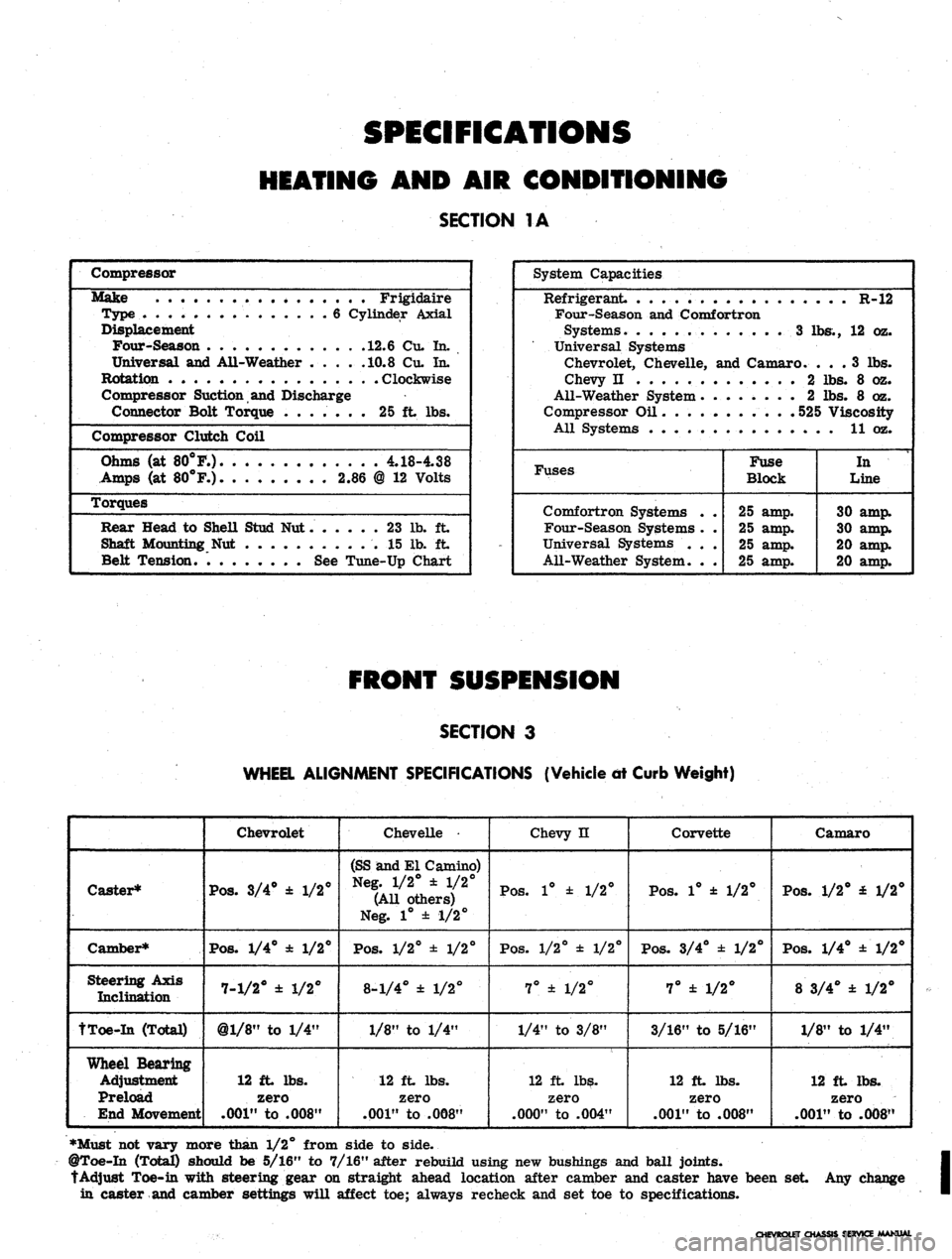

SPECIFICATIONS

HEATING

AND AIR

CONDITIONING

SECTION

1A

Compressor

Make Frigidaire

Type

. 6

Cylinder Axial

Displacement

Four-Season

12.6

Cu.

In.

Universal

and

Ail-Weather

.... .10.8 Cu. In.

Rotation Clockwise

Compressor Suction

and

Discharge

Connector Bolt Torque

.......

25 ft lbs.

Compressor Clutch Coil

Ohms

(at

80°F.).

4.18-4.38

Amps

(at

80°F.)

2.86 @ 12

Volts

Torques

Rear Head

to

SheU Stud

Nut 23 lb. ft

Shaft Mounting

Nut 15 lb. ft

Belt Tension.

See

Tune-Up Chart

System Capacities

Refrigerant

R-12

Four-Season

and

Comfortron

Systems.

............

3 lbs., 12 oz.

Universal Systems

Chevrolet, Chevelle,

and

Camaro.

... 3 lbs.

Chevy

n 2 lbs. 8 oz.

All-Weather System

2 lbs. 8 oz.

Compressor

Oil 525

Viscosity

All Systems

11 oz.

Fuses

Comfortron Systems

.

Four-Season Systems

.

Universal Systems

. .

All-Weather System.

.

Fuse

Block

25

amp.

25

amp.

25

amp.

25

amp.

In

Line

30

amp.

30

amp.

20

amp.

20

amp.

SECTION

3

WHEEL ALIGNMENT SPECIFICATIONS (Vehicle

dt

Curb Weight)

Caster*

Camber*

Steering Axis

Inclination

tToe-In (Total)

Wheel Bearing

Adjustment

Preload

End Movement

Chevrolet

Pos.

3/4° ± 1/2°

Pos.

1/4° ± 1/2°

7-1/2° ± 1/2°

@l/8"

to 1/4"

12 ft lbs.

zero

.001"

to .008"

Chevelle •

(SS and El Camino)

Neg. 1/2° ± 1/2°

(All others)

Neg. 1° ± 1/2°

Pos.

1/2° ± 1/2°

8-1/4° ± 1/2°

1/8" to 1/4"

12 ft lbs.

zero

.001"

to .008"

Chevy n

Pos.

1° ± 1/2°

Pos.

1/2° ± 1/2°

7° ± 1/2°

1/4" to 3/8"

12 ft lbs.

zero

.000"

to .004"

Corvette

Pos.

1° ± 1/2°

Pos.

3/4° ± 1/2°

7° ± 1/2°

3/16" to 5/16"

12 ft lbs.

zero

.001"

to .008"

Camaro

Pos.

1/2° £ 1/2°

Pos.

1/4° ±1/2°

8 3/4° ± 1/2°

1/8" to 1/4"

12 ft lbs.

zero

.001"

to .008"

•Must not vary more than 1/2° from side to side.

@Toe-In (Total) should be 5/16" to 7/16" after rebuild using new bushings and ball joints.

tAdjust Toe-in with steering gear on straight ahead location after camber and caster have been set Any change

in caster and camber settings will affect toe; always recheck and set toe to specifications.

LET CHASSIS SERVICE MANUAL

Page 635 of 659

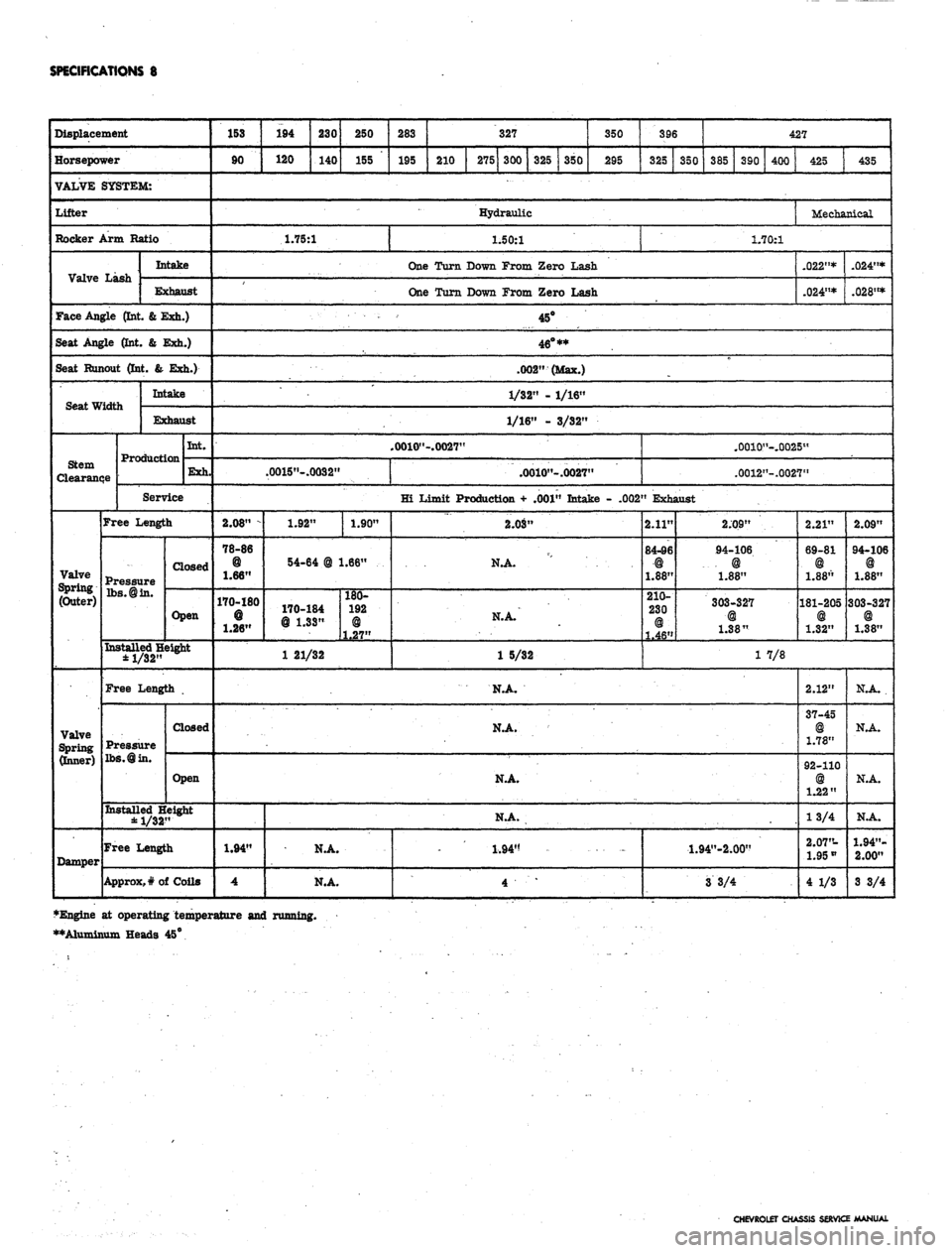

SPECIFICATIONS

8

Displacement

Horsepower

VALVE SYSTEM:

Lifter

Rocker

Arm

Ratio

Valve Lash

Intake

Exhaust

Face Angle

(Int.

&

Exh.

Seat Angle

(Int. & Exh.)

Seat Runout

(Int. & Exh.)

Seat Width

Stem

Clearani

Valve

Spring

(Outer)

Valve

Spring

(Inner)

Damper

Intake

Exhaust

Production

Int.

Exh.

Service

Free Length

Pressure

lbs.

@

in.

Closed

Open

Installed Height

±1/32"

Free Length

Pressure

lbs.

@

in.

Closed

Open

Installed Height

±1/32"

Free Length

Approx,# of Coils

153

90

194

120

230

140

250

155

283

195

327

210

275

300

325

350

350

295

39e

325

350

427

385

390

400

425

435

1.75:1

Hydraulic

1.50:1

One

One

Mechanical

1.70:1

Turn Down From Zero Lash

Turn Down From Zero Lash

.022"*

.024"*

.024"*

.028"*

...••:•:••

••-•. , 45« •

46°**

.002"

(Max.)

1/32" - 1/16"

1/16" - 3/32"

.0015"-.0032"

.0010"

-.0027"

.0010"-.0027"

<0010It-.0025"

.0012

'-.0027"

Hi Limit Production

+ .001"

Intake

- .002"

Exhaust

2.08"

78-86

@

1.66"

170-180

@

1.26"

1.92"

54-64 @

170-184

@

1.33"

1.90"

1.66"

180-

192

@

1.27"

1

21/32

2.03"

.

. N.A. ' ' .

N.A."

1

5/32

2.11"

84-96

@

1.88"

210-

230

@

1.46"

2.09"

94-106

...©••

1.88"

303-327

@

1.38"

1

2.21"

69-81

@

1.88"

181-205

@

1.32"

7/8

N.A.

1.94tf

4

N.A.

N.A.

N.A.

N.A.

N.A.

1,94"

4

: •

1.94"-2.00"

3

3/4

2.12"

37-45

@

1.78"

92-110

@

1.22"

13/4

2.07'*-

1.95

»

4

1/3

2.09"

94-106

®

1.88"

303-327

@

1.38"

N.A.

.

N.A.

NJl.

1.94"-

2.00"

3 3/4

*Engine at operating temperature and running.

••Aluminum Heads 45°

CHEVROLET CHASSIS SERVICE MANUAL

Page 643 of 659

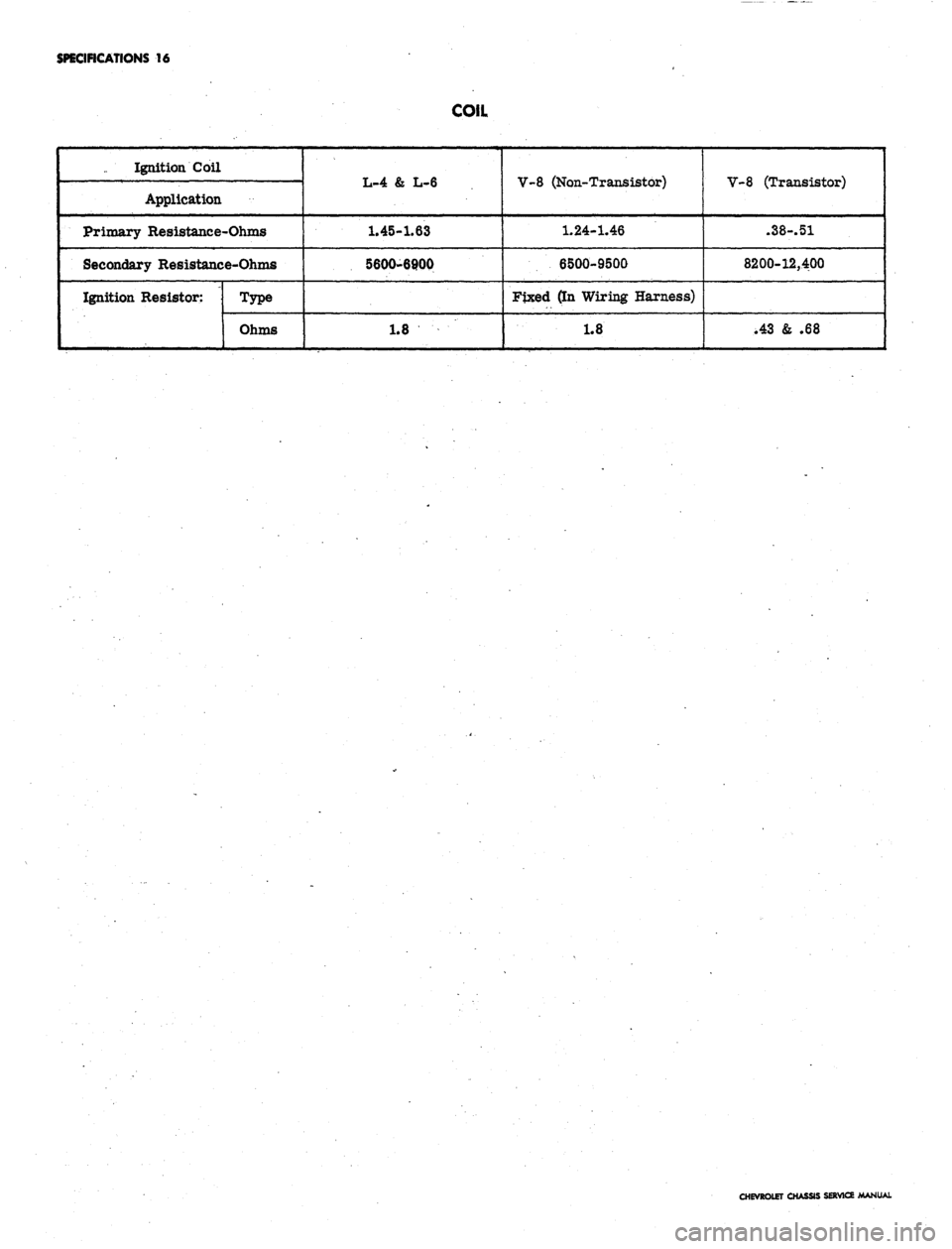

SPECIFICATIONS

16

COIL

Ignition Coil

Application

Primary Resistance-Ohms

Secondary Resistance-Ohms

Ignition Resistor:

Type

Ohms

L-4 & L-6

1.45-1.63

5600-6900

1.8

V-8 (Non-Transistor)

1.24-1.46

6500-9500

Fixed (In Wiring Harness)

1.8

V-8 (Transistor)

.38-.51

8200-12,400

.43 & .68

CHEVROLET CHASSIS SERVICE MANUAL

Page 654 of 659

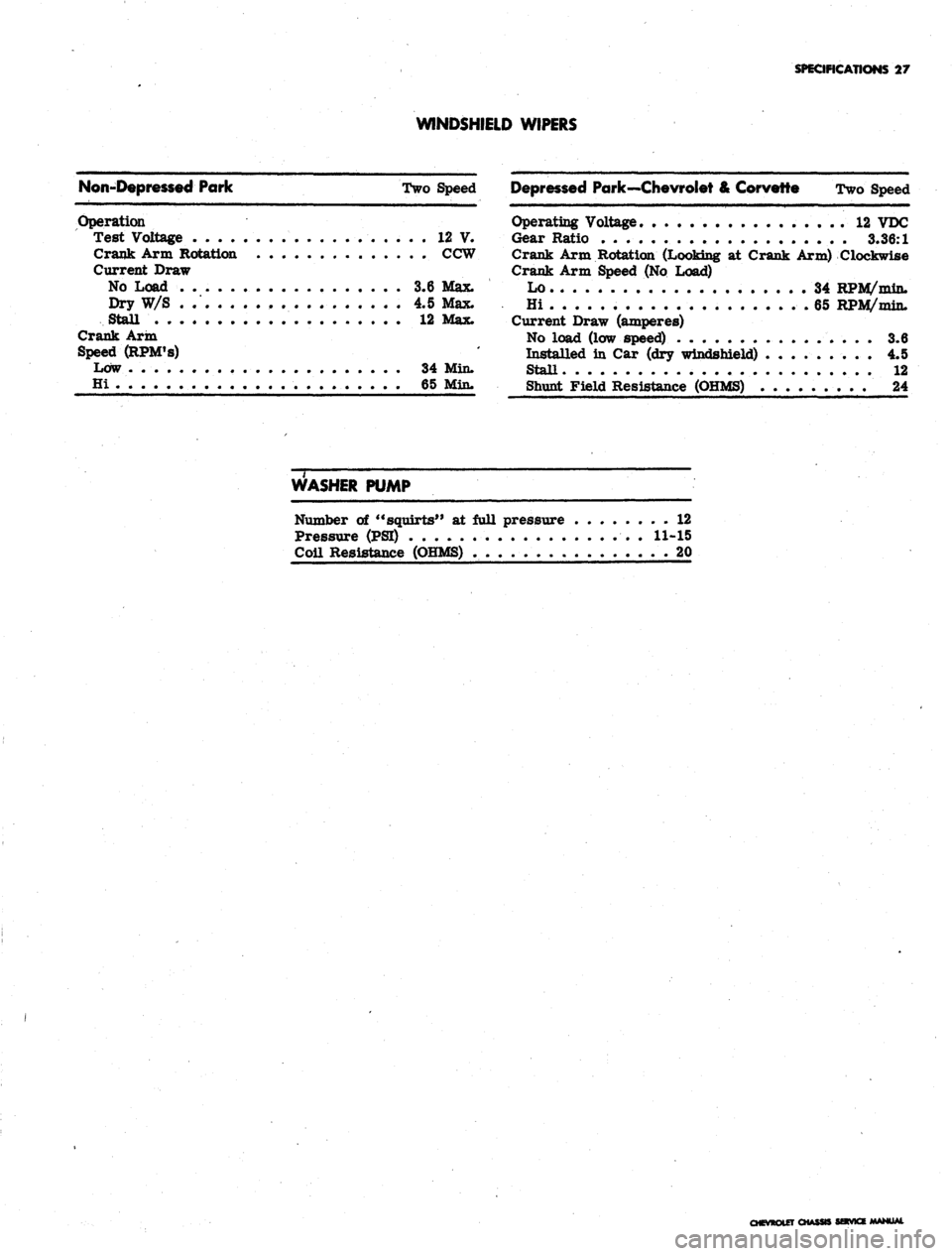

SPECIFICATIONS 27

WINDSHIELD WIPERS

Non-Depressed Park Two

Speed

Operation

Test Voltage 12 V.

Crank Arm Rotation CCW

Current Draw

No Load 3.6 Max.

Dry W/S . . , .4.5 Max.

Stall . 12 Max.

Crank Arm

Speed (RPM's)

Low 34 Min.

Hi 65 Min.

Depressed Park—Chevrolet & Corvette Two Speed

Operating Voltage 12 VDC

Gear Ratio 3.36:1

Crank Arm Rotation (Looking at Crank Arm) Clockwise

Crank Arm Speed (No Load)

Lo.

34 RPH^/min.

Hi .65 RPM/min.

Current Draw (amperes)

No load (low speed) 3.6

Installed in Car (dry windshield) ......... 4.5

Stall . 12

Shunt Field Resistance (OHMS) 24

WASHER PUMP

Number of "squirts" at full pressure 12

Pressure (PSI) . 11-15

Coil Resistance (OHMS) . . 20

CHEVROLET CHASSIS SStVK* MANUAL