coil CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 357 of 659

ENGINE-ELECTRICAL 6Y-32

STARTER CIRCUIT

INDEX

Page

General Description 6Y-32

Maintenance and Adjustments . '. . 6Y-32

Resistance Checks 6Y-32

Starting Motor and Solenoid Check 6Y-33

Page

Service Operations 6Y-33

Starter Motor 6Y-33

Removal and Installation 6Y-33

GENERAL DESCRIPTION

The function of the starting system, composed of the

starting motor, solenoid and battery, is to crank the

engine. The battery supplies the electrical energy, the

solenoid completes the circuit to the starting motor, and

the motor then does the actual work of cranking the

engine.

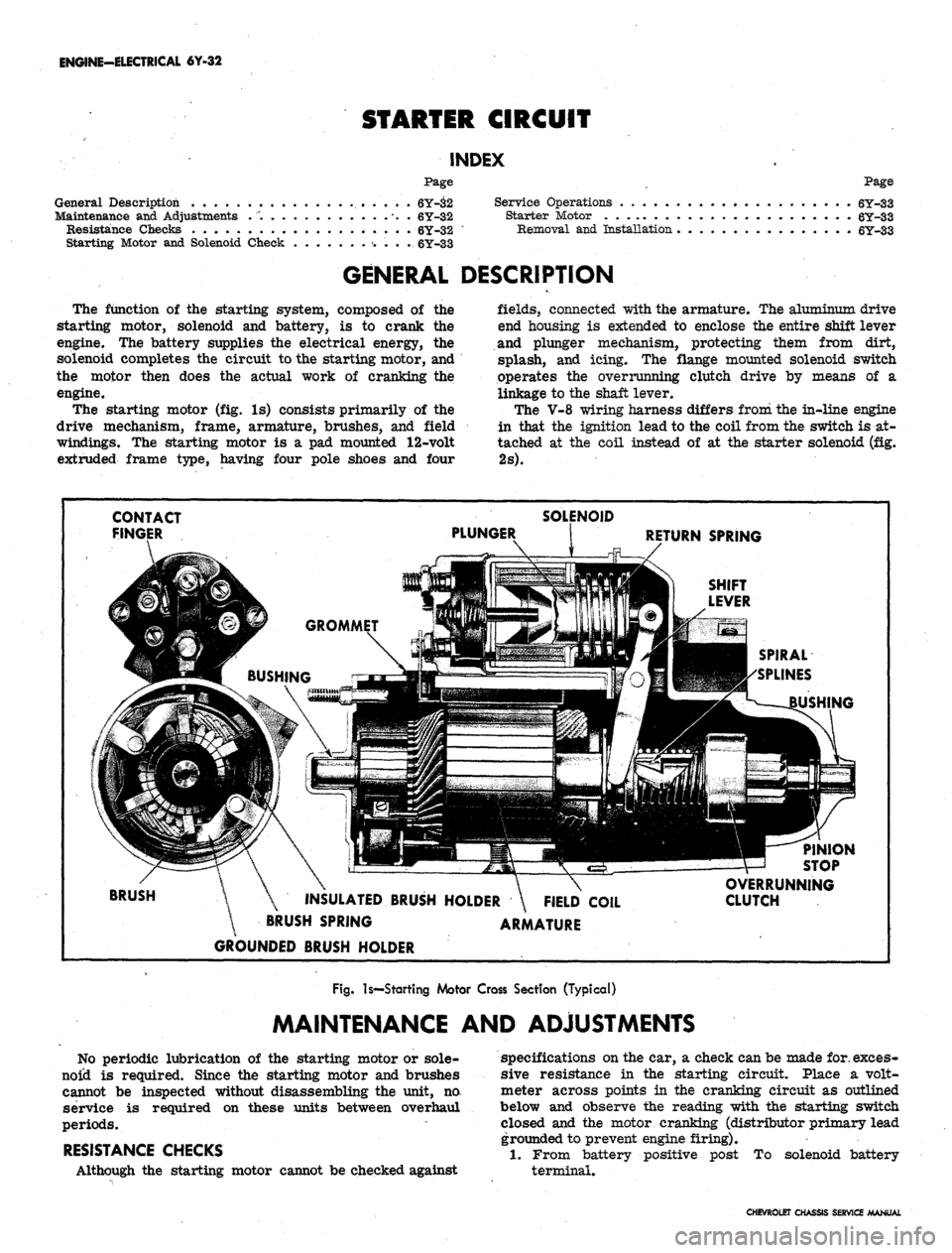

The starting motor (fig. Is) consists primarily of the

drive mechanism, frame, armature, brushes, and field

windings. The starting motor is a pad mounted 12-volt

extruded frame type, having four pole shoes and four

fields,

connected with the armature. The aluminum drive

end housing is extended to enclose the entire shift lever

and plunger mechanism, protecting them from dirt,

splash, and icing. The flange mounted solenoid switch

operates the overrunning clutch drive by means of a

linkage to the shaft lever.

The V-8 wiring harness differs from the in-line engine

in that the ignition lead to the coil from the switch is at-

tached at the coil instead of at the starter solenoid (fig.

2s).

CONTACT

FINGER

PINION

STOP

BRUSH

INSULATED BRUSH HOLDER \ FIELD COIL

BRUSH SPRING ARMATURE

GROUNDED BRUSH HOLDER

OVERRUNNING

CLUTCH

Fig.

Is—Starting Motor Cross Section (Typical)

MAINTENANCE AND ADJUSTMENTS

No periodic lubrication of the starting motor or sole-

noid is required. Since the starting motor and brushes

cannot be inspected without disassembling the unit, no.

service is required on these units between overhaul

periods.

RESISTANCE CHECKS

Although the starting motor cannot be checked against

specifications on the car, a check can be made for. exces-

sive resistance in the starting circuit. Place a volt-

meter across points in the cranking circuit as outlined

below and observe the reading with the starting switch

closed and the motor cranking (distributor primary lead

grounded to prevent engine firing).

1.

From battery positive post To solenoid battery

terminal.

CHEVROLET CHASSIS SERVICE MANUAL

Page 368 of 659

CLUTCH AND TRANSMISSIONS 7-9

6. Connect speedometer cable.

7. Install propeller shaft assembly.

8. Fill transmission with lubricant specified in Section

O.

CORVETTE TRANSMISSION REPLACEMENT

, 1. Disconnect battery ground cable.

2.

Pisassemble transmission shift control lever by un-

screwing ball from lever, lifting out

"T"

handle re-

turn spring and "T" handle, then remove the anti-

rattle bushings.

3.

Raise front and rear of vehicle.

4.

Insert a block of wood between the top of the dif-

ferential carrier housing and the underbody (to pre-

vent upward travel of the carrier when the carrier

front support is disconnected).

5. Disconnect the differential carrier front supportfrom

its frame bracket, by removing the nut on the under-

side of the biscuit mount.

6. Pry the carrier downward to relieve load while re-

moving the two center mounting bolts from the car-

rier front support. (To pry carrier downward insert

crowfoot end of a pry bar through the opening in the

carrier front support, hooking end of bar over top of

the center mounting bolt pad cast in the underside of

the carrier.)

7. Pivot carrier support downward for access to prop

shaft "U" joint.

8.

.

Disconnect prop shaft front and then rear "U" bolts.

9. Disconnect parking brake cable from ball socket at

idler lever located near center of underbody.

10.

Remove prop shaft by moving shaft forward.

11.

Remove heat deflectors from the right and left ex-

haust pipe.

12.

Remove left bank exhaust pipe.

13.

Remove right bank exhaust pipe and heat riser.

14.

Disassemble the transmission mount, as follows:

a. Remove the two bolts that attach rear mount

cushion to the rear mount bracket.

b.

Support engine under oil pan and raise engine to

remove load from rear mount cushion.

CAUTION: To avoid damage to oil pan, a suit-

able wide base, heavy wood platform should be

placed between the jack pad and the oil pan.

c. Remove the three transmission mount bracket-

to-

crossm ember bolts and remove mount bracket.

d. Remove the two bolts from mount pad to trans-

mission case and remove rubber mount cushion

and exhaust pipe "yoke".

15.

Disconnect transmission linkage by removing the

shift levers at the transmission side cover.

16.

Disconnect speedo cable at transmission extension.

17.

Remove transmission output shaft slip yoke.

NOTE:

The yoke is removed to avoid tearing

the heat reflecting pad on the underbody, when

the transmission is being removed.

18.

Remove two bolts to disconnect the transmission

gearshift control lever and bracket assembly from

its adapter plate on side of transmission. Lower

transmission assembly from the vehicle, letting the

gearshift lever slide down and through the dust boot

in the console.

19.

Remove transmission-to-clutch housing attaching

bolts.

20.

Slide transmission assembly rearward from clutch

and rotate transmission for access to the three flat

head machine screws in the control lever bracket

adapter plate. Remove adapter plate. Rotate trans-

mission back to the upright position.

21.

To allow room for transmission removal slowly

lower the rear of engine until the tachometer drive

cable at the distributor just clears the horizontal

ledge across the front of dash.

CAUTION: The tachometer cable can be easily

damaged by heavy contact with the dash. Slide

transmission rearward out of the clutch, then

tip front end of transmission downward and

lower the assembly from vehicle.

22.

Reinstall transmission assembly by performing above

steps in reverse order.

TRANSMISSION OVERDRIVE

INDEX

Page

General

Description 7-10

Maintenance

and Adjustments 7—10

Governor

Switch and Pinion .............. 7-10

Sun

Gear Solenoid Oil Seal and Control

Cable

Bracket 7-10

Case

Rear Oil Seal 7-10

Removal

7-10

Installation

. . . . . 7-10

Control

Shaft Lever and Oil Seal 7-10

Speedometer

Driven Gear 7-10

Electrical

Unit Checks 7-11

Overdrive

Relay . 7-11

Page

Air

Gap 7-11

Point

Opening 7-11

Closing

Voltage 7-11

Solenoid

. 7-11

Closing

Coil 7-11

Engaging

Spring . - 7-11

Ignition

Grounding Contact . 7-11

Governor

Switch 7-11

Kickdown

Switch 7-11

Diagnosis

- Overdrive 7-12

Mechanical

. 7-12

Electrical

7-13

CHEVROLET CHASSIS SERVICE MANUAL

Page 370 of 659

CLUTCH AND TRANSMISSIONS 7-11

UPPER ARMATURE STOP

(BEND TO ADJUST POINT OPENING)

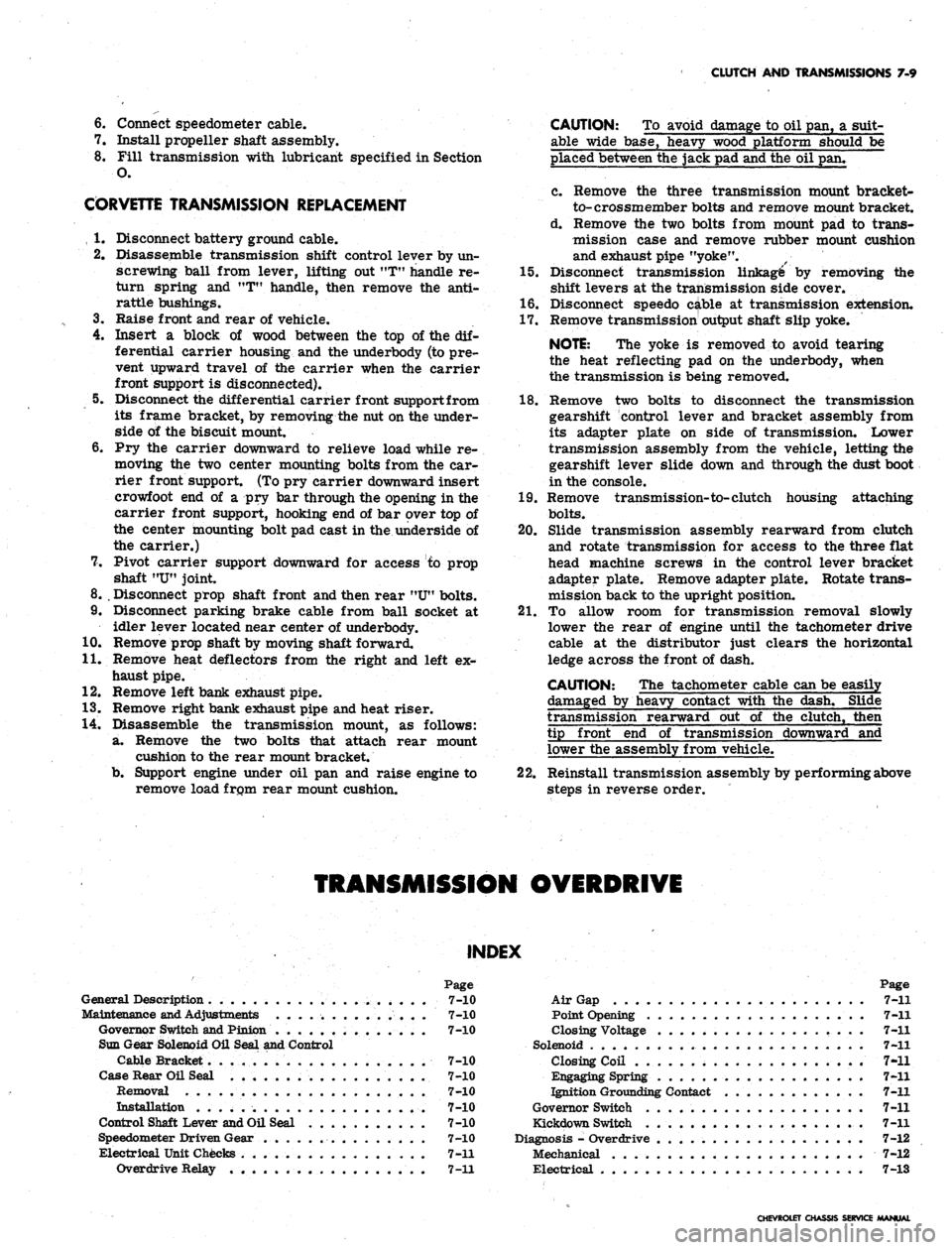

Fig.

2B-Adjusting Relay Point Opening

ELECTRICAL UNIT CHECKS

Overdrive Relay

Specifications and checking procedures for this relay

are as follows:

Specifications

Air Gap Oil inch minimum

Point Opening .025 inch

Closing Voltage

8.3-10.2

volts

Armature Sealing Voltage. ..... 11.2 volts maximum

Three checks and adjustments are required on the

overdrive relay; air gap, point opening and closing volt-

age.

The air gap contact point opening checks and adjust-

ments should be made with the battery disconnected.

Air Gap

The air gap should not normally require adjustment

unless the relay has been misadjusted. Check the air gap

with the points barely touching and adjust if necessary by

bending the lower point support (fig, IB).

Point Opening

Check the contact point opening and adjust by bending

the upper armature stop (fig. 2B).

Closing Voltage

To check the relay closing voltage, connect a potenti-

ometer or variable resistance of sufficient value (not less

than 50 ohms) in series with the "KD" terminal, connect a

voltmeter to the "IGN" and "KD" terminals. With the

ignition switch on, slowly decrease the amount of resist-

ance in order to check the relay closing voltage (the

overdrive solenoid and relay should click when the relay

closes). Adjust the closing voltage by bending the arma-

ture spring post (fig. 3B). Bend down to increase the

closing voltage and bend up to decrease the closing

voltage.

To check the sealing voltage, increase the voltage after

the relay closes until the armature seals against the

core.

Decrease the sealing voltage by reducing the relay

air gap.

Solenoid

Closing Coil

Remove solenoid from transmission, connect a jumper

wire between negative terminal of battery and mounting

flange of solenoid. Connect a second jumper wire be-

ARMATURE SPRING PQST

(BEND TO ADJUST CLOSING VOLTAGE)

Fig.

3B - Adjusting Relay Closing Voltage

tween the battery positive terminal and solenoid terminal

No.

4; this should cause the solenoid pawl to move out.

If solenoid chatters, Hold-In Coil is defective.

Engaging Spring

With jumper wire connected as in paragraph above,

(solenoid energized, plunger extended) place ball end of

solenoid against bench. Push down on solenoid. The

pawl rod should move in 3/8M under a load of not less

than 8 lbs. nor more than 12. Pawl should move out to

extended position when load is removed.

Ignition Grounding Contact

Place a test lamp between negative battery terminal

and solenoid terminal No. 6. Lamp should light when this

connection is made. Remove jumper from between nega-

tive battery terminal and solenoid terminal No. 4. Pawl

rod should snap "in" and test lamp should go out.

Governor Switch

Remove overdrive wire at governor and connect test

lamp between governor overdrive terminal and positive

terminal of battery. Drive car on road or raise on jacks.

The lamp should light at a car speed of between 26 to 30

MPH. Upon decreasing speed, the lamp should go out at

between 28 and 23.5 MPH. The car speed differential

between light "on" and light "off" should be 2 or 3 MPH.

Kickdown Switch

Disconnect the 4 wires at kickdown switch.

1.

Connect test lamp between "SW" terminal and posi-

tive terminal of battery; with switch in normal posi-

tion, lamp should light when "REL" terminal is

grounded but should not light when "IGN" or "SOL"

terminals or switch case is grounded.

2.

Connect test lamp between "IGN" terminal and posi-

tive terminal of battery; with switch stem pushed in,

lamp should light when "SOL" terminal is grounded,

but should not light when "SW" or "REL" terminals

or switch case is grounded.

CHEVROLET CHASSIS SERVICE MANUAL

Page 372 of 659

CLUTCH AND TRANSMISSIONS 7-13

PULL-IN

WINDING

li

HOLD-IN

WINDING

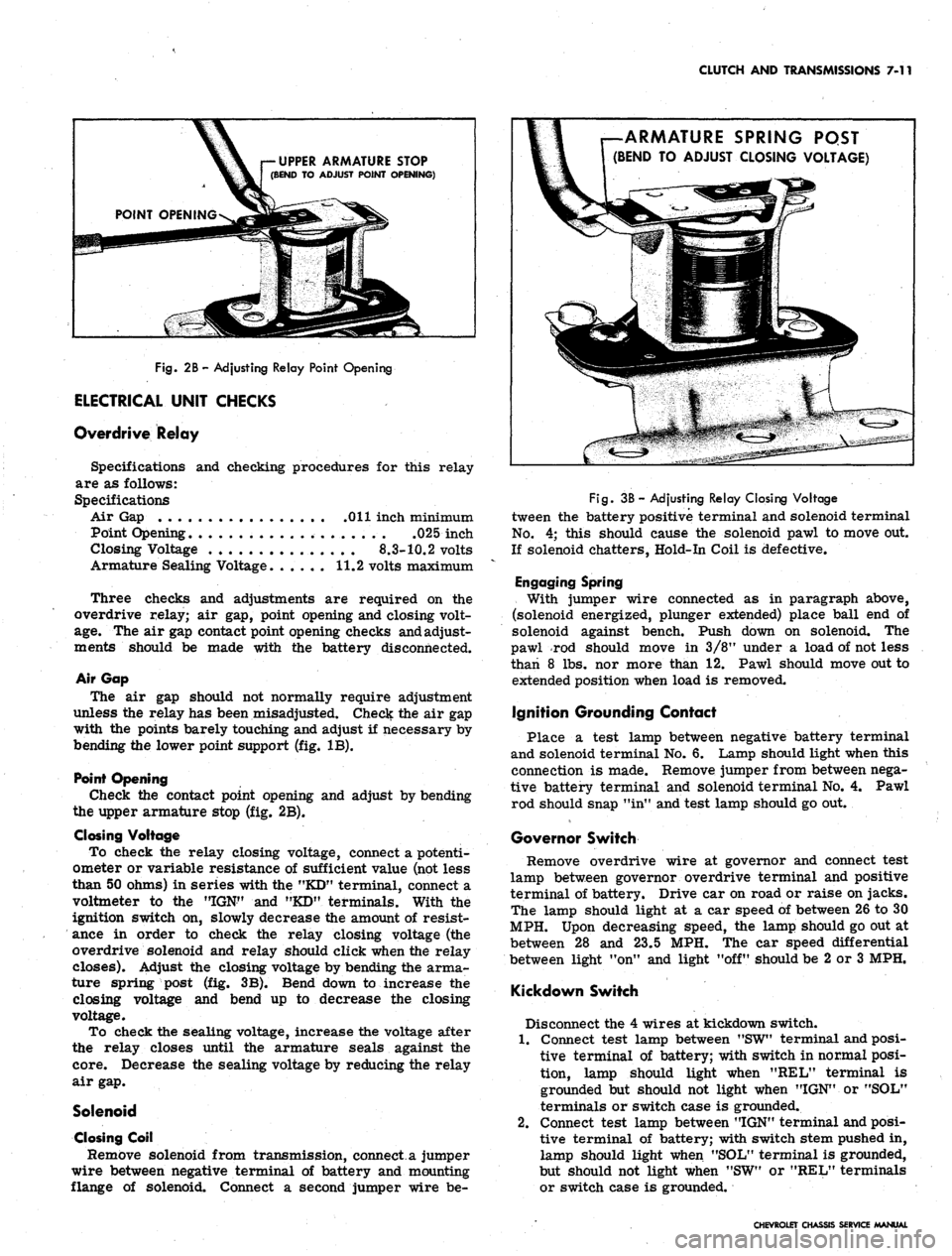

Fig.

4B -

Overdrive Electrical Circuit Wiring Diagram

ELECTRICAL

Any one of the following general complaints may be due

to electrical trouble in the overdrive circuit.

1.

Does not engage.

2.

Does not release.

3.

Does not kickdown from overdrive.

These troubles may be traced and remedied as de-

scribed in the following paragraphs.

1.

Does not engage

a. With the ignition switch on, ground the "KD" ter-

minal of the solenoid relay with a jumper lead.

If the solenoid clicks, the relay and solenoid cir-

cuits are in operating condition. If no click is

heard in the relay, check the fuse and replace if

defective.

b.

If the fuse is good, use a second jumper lead to

connect the "SOL" and "BAT" terminals of the

relay. If a click is now heard in the solenoid, the

relay is probably at fault and should be repaired

or replaced.

c. If the solenoid does not click in Step b, check the

wiring to the No. 4 terminal of the solenoid and

replace if necessary. If the wiring is not defec-

tive,

the trouble is probably in the solenoid. Re-

move the solenoid cover, examine the solenoid

contacts in series with the pull-in winding and

clean if necessary. Test again for clicks, as in

Step b, after replacing solenoid cover and lead

wires.

Replace the solenoid if trouble has not

been corrected.

d. If the relay and solenoid circuits are in good con-

dition as determined in Step a, leave the ignition

switch on and make sure the manual control knob

is in the overdrive position. Ground one and then

the other of the two terminals next to the stem of

the kickdown switch (identified as "SW" and

?fREL"). K the solenoid clicks when one terminal

is grounded but not the other, replace the switch.

If the solenoid does not click when either of the

terminals is grounded, check the wiring between

the relay and the kickdown switch and replace if

defective.

e. If the solenoid clicks as each terminal is grounded

in Step d, ground the governor switch terminal.

If the solenoid clicks, the governor switch may be

defective. If the solenoid does not click, check

the wiring between the kickdown and governor

switches and replace if necessary.

2.

Does not release

a. Remove the connection to the "KD" terminal of

the relay. If this release overdrive, look for a

grounded control circuit between the relay and

governor switch.

b.

If the overdrive is not released in Step a, dis-

connect the lead to the "SOL" terminal of relay.

If this releases the overdrive, replace the relay.

3.

Does not kickdown from overdrive

a. With the engine running, connect a jumper lead

between the No. 6 terminal of the solenoid and

ground. Operate the kickdown switch by hand.

This should stop the engine. If it does, the sole-

noid is probably defective and it should be checked

for dirty ground-out contacts or other defects

within the ground-out circuit of the solenoid (fig.

4B).

Clean the contacts or replace the contact

plate as required.

b.

If the engine does not stop in Step a, ground one

and then the other of the two terminals (Identified

as "IGN" and "SOL") farthest from the sfem of

the kickdown switch. The engine should stop when

one of the two terminals (IGN) is grounded. If

the engine does not stop when the terminal is

grounded, the wiring or connections to the switch

between the switch and coil are defective. When

the btlier terminal (SOL) is grounded, the engine

should stop when the kickdown switch is operated.

If the engine does not stop when the kickdown

switch is operated with the second terminal

grounded, the kickdown switch is defective. If

the trouble is in the kickdown switch, adjust the

linkage to give more travel of the switch rod.

If this does not correct the trouble, replace the

kickdown switch.

If the kickdown switch operates as it should,

check for an open circuit in the wiring between

the kickdown switch and the No. 6 terminal of the

solenoid.

c. If the trouble is not located by the above checks,

the upper contacts of the kickdown switch may not

be opening. To check for this condition, ground

the overdrive control circuit at the governor

switch. This should cause the solenoid to click.

Operate the kickdown switch by hand. This should

cause a second click as the solenoid releases.

If there is no second click, adjust the linkage to

give more travel of the switch rod. If this does

not correct the trouble, replace the kickdown

switch.

CHEVROLET CHASSIS SERVICE MANUAL

Page 382 of 659

CLUTCH

AND

TRANSMISSIONS

7-23

Assembly (Fig.

4X)

1.

With detent spring tang projecting

up

over

the 3rd

and

4th

shifter shaft cover opening install

the

first

and second detent

cam

onto

the

detent

cam

pivot

pin.

With

the

detent spring tang projecting

up

over

the

first

and

second shifter shaft cover hole install

the

3rd

and 4th

detent

cam,

NOTE:

The 1-2

detent

cam has a

.090" greater

contour

on the

inside detent notch.

2.

3.

Install detent

cam

retaining

"C"

ring

to

pivot shaft,

and hook spring into detent

cam

notches.

Install

1-2 and 3-4

shifter shaft assemblies

in

cover

being careful

not to

damage seals. Install both shift

forks

to

shifter shaft assemblies, lifting

up on

detent

cam

to

allow forks

to

fully seat into position.

4.

Install reverse detent ball

and

spring

to

cover, then

install reverse shifter shaft assembly

to

cover.

5.

Install outer shifter levers, flat washers, lock wash-

ers

and

bolts.

Installation

1.

Shift shifter levers into neutral detent (center) posi-

tion. Position cover gasket

on

case.

2.

Carefully position side cover into place making sure

the shift forks

are

aligned with their respective

mainshaft clutch sliding sleeves.

Install cover attaching bolts

and

tighten evenly

to

specified torque.

Remove filler plug

and add

lubricant specified

in

Section

0, to

level

of

filler plug hole.

3.

4.

ALUMINUM POWERGLIDE

INDEX

Page

General

Description

7-23

Maintenance

and

Adjustments .............. 7—23

Oil

Level Check

7-23

Periodic

Oil

Change

7-24

Periodic

Low

Band Adjustment

7-24

Manual

Shift Linkage Check

and

Adjust

7-24

Floor

Shift Linkage

7-25

Floor

Mounted Control Lever

and

Bracket

Assembly

7-29

Throttle

Valve Linkage

.... 7-29

Neutral

Safety Switch

.. . 7-30

Throttle

Return Check Valve (Dashpot)

7-30

Component

Parts Replacement

7-30

Transmission

Replacement .............. 7—30

Page

Other

Service Operations

7-32

Diagnosis

7-32

Warming

Up

Transmission

7-32

Shop

Warm

Up , 7-32

Road

Warm

Up 7-32

Checking

Fluid Level

and

Condition

7-32

Manual

Linkage

7-32

Oil

Leaks

7-33

Basic

Pressure Checks

7-33

Wide

Open Throttle Upshift Pressure Check

.... 7-33

Idle

Pressure

in

Drive Range

7-33

Manual

"Low"

Range Pressure Check .......

7-33

Drive

Range Overrun (Coast) Pressure

.

.......

7-33

Powerglide

Shift Points

. . 7-35

GENERAL DESCRIPTION

The case

and

converter housing

of the two

speed alumi-

num Powerglide Transmission

is a

single case aluminum

unit. When

the

manual control

is

placed

in the

drive

po-

sition,

the

transmission automatically shifts

to low

gear

for initial vehicle movement.

As the car

gains speed

and

depending

on

load

and

throttle position,

an

automatic shift

is made

to

high gear.

A

forced downshift feature

pro-

vides

a

passing gear

by

returning

the

transmission

to low

range.

The

oil

pump assembly

is a

conventional gear type

and

the

oil

pump housing

is of the

large diameter type acting

as

the

front bulkhead

of the

transmission.

The

torque

converter

is a

conventional three element welded design

bolted

to the

engine flywheel which drives through

a

two-

speed planetary gearset.

The

high clutch assembly

is

typical

of the

designs used

in

this type transmission.

The

aluminum Powerglide uses

an

output shaft mounted

gov-

ernor which requires

a

hole through

the

output shaft.

The

reverse clutch assembly

is a

multiple disc type clutch.

The steel plates

are

splined directly

to the

case while

the

face plates

are

splined

to the

internal

or

ring gear.

The

clutch piston operates within

the

rear portion

of the

case.

The internal diameter

of the

pistoh

is

sealed to

an

integral

hub portion

of the

case rear bulkhead.

The

outside

dia-

meter

is

sealed

to a

machined portion

of the

case.

The

piston

is

hydraulically applied

and is

released

by

separate

coil springs.

The

valve body assembly

is

bolted

to the

bottom

of the

transmission case

and is

accessible

for

service

by

removing

the oil pan

assembly.

The

valve

body consists

of an

upper

and

lower body located

on

either

side

of a

transfer plate.

The

vacuum modulator

is lo-

cated

on the

left rear face

of the

transmission case.

The

modulator valve bore

is

located

in the

upper valve body.

MAINTENANCE

AND

ADJUSTMENTS

OIL LEVEL CHECK

The transmission

oil

level should

be

checked period-

ically

as

recommended

in

Section

0. Oil

should

be

added

only when level

is on or

below

the

"ADD" mark

on the dip

stick with

oil hot or at

operating temperature.

The oil

level

dip

stick

is

located

at the

right rear

of the

engine

compartment. Fill with

oil

specified

in

Section

0.

In order

to

check

oil

level accurately,

the

engine should

be idled with

the

transmission

oil hot and the

control

lever

in

neutral (N) position.

It

is

important that

the oil

level

be

maintained

no

higher than

the

"FULL" mark

on the

transmission

oil

level gauge.

DO NOT

OVERFILL,

for

when

the oil

level

CHEVROLET CHASSIS SERVICE MANUAL

Page 493 of 659

CHASSIS SHEET METAL 11-6

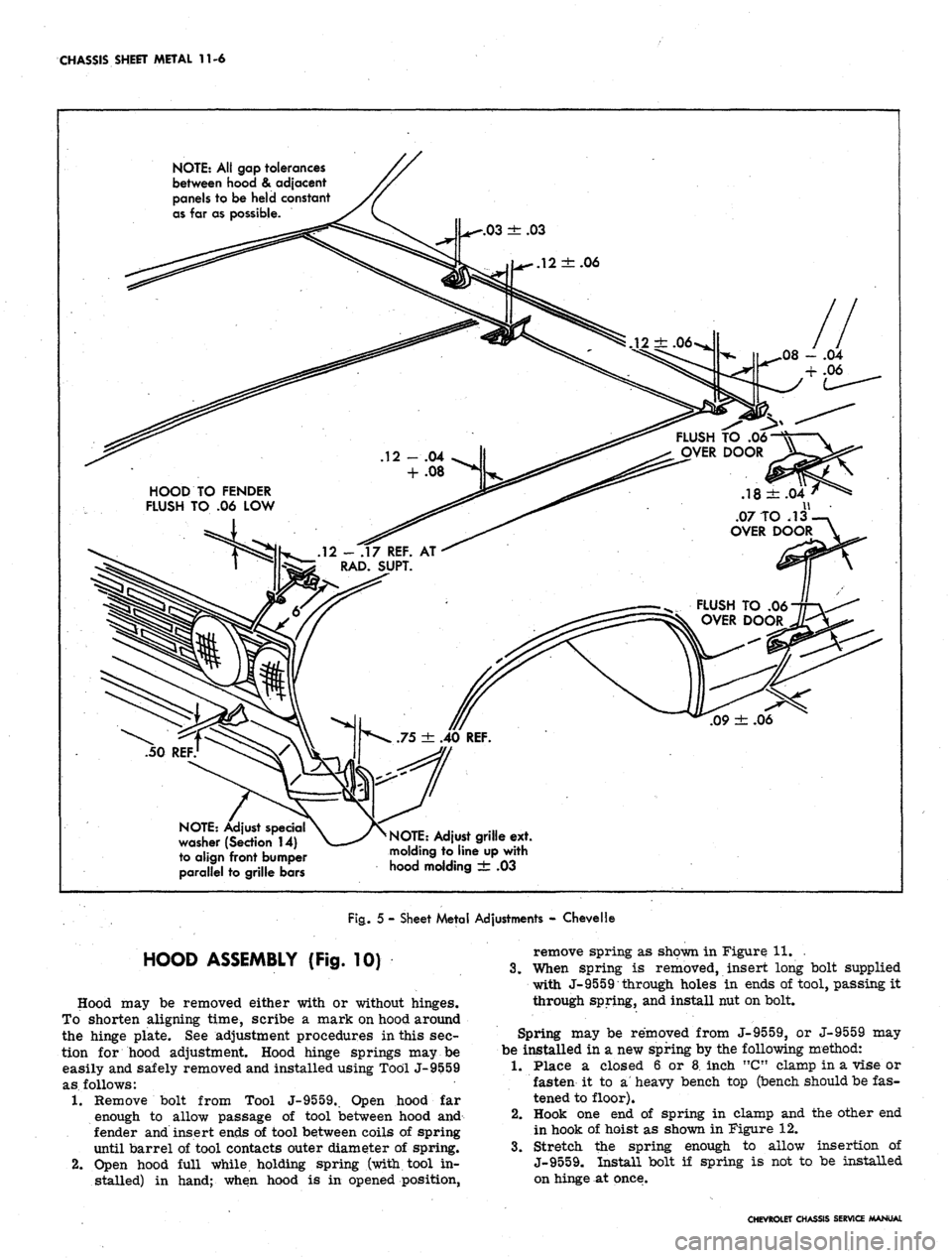

NOTE:

All gap tolerances

between hood & adjacent

panels to be held constant

as far as possible.

FLUSH

TO .06

OVER

DOOR

HOOD

TO

FENDER

FLUSH

TO .06 LOW

12 - .17 REF. AT

RAD.

SUPT.

.18 it .04

.07 TO J3l.

OVER

DOOR

FLUSH

TO .06

OVER

DOOR

X

.09 ± .06

.75

± .40 REF.

NOTE:

washer (Section 14)

to align front bumper

parallel to grille bars

NOTE:

Adjust grille ext.

molding to line up with

hood molding ± .03

Fig.

5 - Sheet Metal Adjustments - Chevelle

HOOD ASSEMBLY (Fig. 10)

Hood may be removed either with or without hinges.

To shorten aligning time, scribe a mark on hood around

the hinge plate. See adjustment procedures in this sec-

tion for hood adjustment. Hood hinge springs may be

easily and safely removed and installed using Tool J-9559

as follows:

1.

Remove bolt from Tool J-9559.. Open hood far

enough to allow passage of tool between hood and

fender and insert encls of tool between coils of spring

until barrel of tool contacts outer diameter of spring.

2.

Open hood full while holding spring (with tool in-

stalled) in hand; when hood is in opened position,

remove spring as shown in Figure 11. .

3.

When spring is removed, insert long bolt supplied

with J-9559 through holes in ends of tool, passing it

through spring, and install nut on bolt.

Spring may be removed from J-9559, or J-9559 may

be installed in a new spring by the following method:

1.

Place a closed 6. or 8. inch "CTt clamp in a vise or

fasten it to a' heavy bench top (bench should be fas-

tened to floor).

2.

Hook one end of spring in clamp and the other end

in hook of hoist as shown in Figure 12.

3.

Stretch the spring enough to allow insertion of

J-9559. Install bolt if spring is not to be installed

on hinge at once.

CHEVROLET CHASSIS SERVICE MANUAL

Page 505 of 659

CHASSIS SHEET METAL 11-18

b.

Check and adjust front wheel alignment as out-

lined in Section 3.

c. Check and adjust headlamp aiming as outlined in

Section 12.

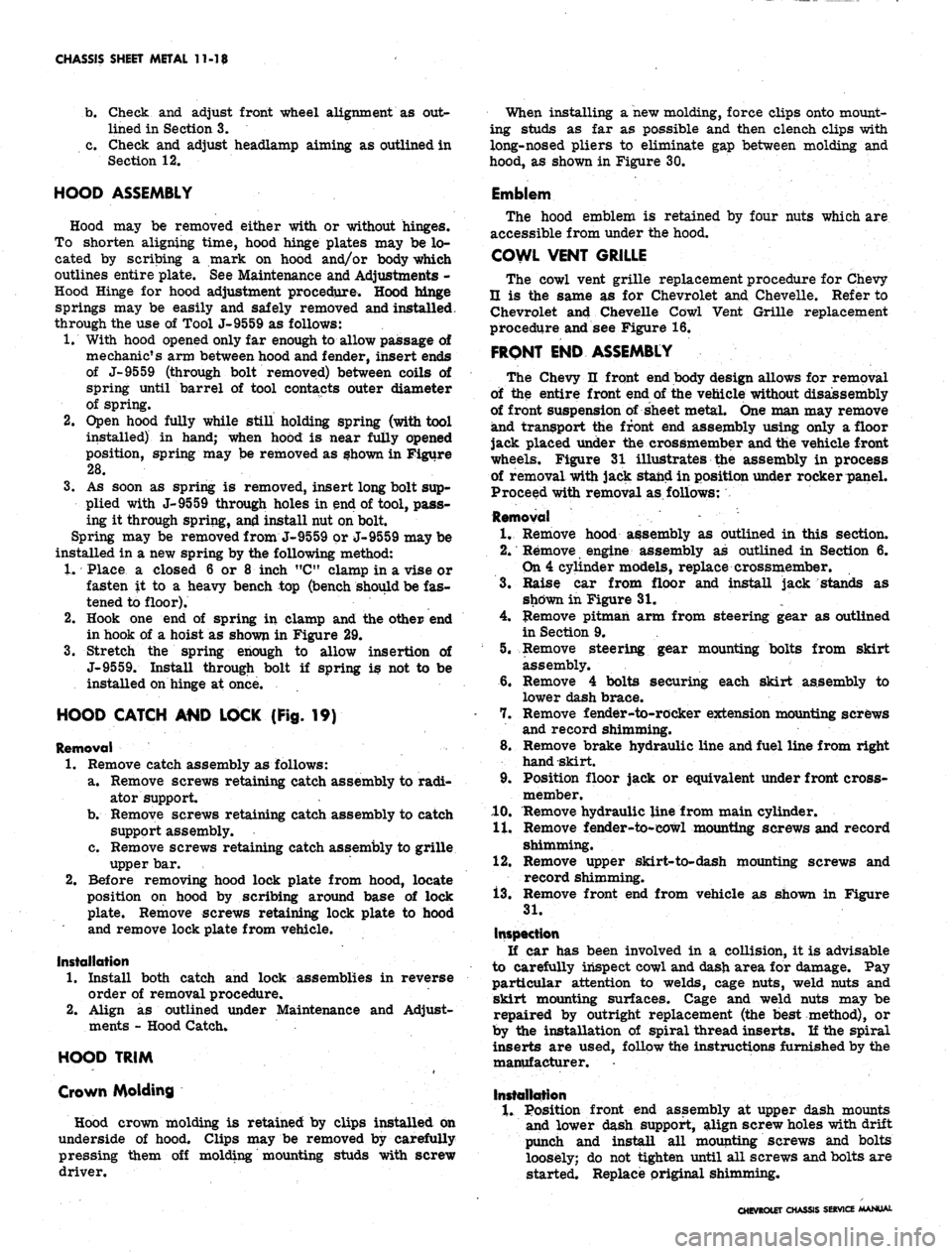

HOOD ASSEMBLY

Hood may be removed either with or without hinges.

To shorten aligning time, hood hinge plates may be lo-

cated by scribing a mark on hood and/or body which

outlines entire plate. See Maintenance and Adjustments -

Hood Hinge for hood adjustment procedure. Hood hinge

springs may be easily and safely removed and installed.

through the use of Tool J-9559 as follows:

1.

With hood opened only far enough to allow passage of

mechanic's arm between hood and fender, insert ends

of J-9559 (through bolt removed) between coils of

spring until barrel of tool contacts outer diameter

of spring.

2.

Open hood fully while still holding spring (with tool

installed) in hand; when hood is near fully opened

position, spring may be removed as shown in Figure

28.

3.

As soon as spring is removed, insert long bolt sup-

plied with J-9559 through holes in end of tool, pass-

ing it through spring, and install nut on bolt.

Spring may be removed from J-9559 or J-9559 may be

installed in a new spring by the following method:

1.

Place a closed 6 or 8 inch "C" clamp in a vise or

fasten it to a heavy bench top (bench should be fas-

tened to floor).

2.

Hook one end of spring in clamp and the other end

in hook of a hoist as shown in Figure 29.

3.

Stretch the spring enough to allow insertion of

J-9559. Install through bolt if spring is not to be

installed on hinge at once.

HOOD CATCH AMD LOCK (Fig. 19)

Removal

1.

Remove catch assembly as follows:

a. Remove screws retaining catch assembly to radi-

ator support.

b.

Remove screws retaining catch assembly to catch

support assembly.

c* Remove screws retaining catch assembly to grille

upper bar.

2.

Before removing hood lock plate from hood, locate

position on hood by scribing around base of lock

plate. Remove screws retaining lock plate to hood

and remove lock plate from vehicle.

Installation

1.

Install both catch and lock assemblies in reverse

order of removal procedure.

2.

Align as outlined under Maintenance and Adjust-

ments - Hood Catch.

HOOD TRIM

Crown Molding

Hood crown molding is retained by clips installed on

underside of hood. Clips may be removed by carefully

pressing them off molding mounting studs with screw

driver.

When installing a new molding, force clips onto mount-

ing studs as far as possible and then clench clips with

long-nosed pliers to eliminate gap between molding and

hood, as shown in Figure 30.

Emblem

The hood emblem is retained by four nuts which are

accessible from under the hood.

COWL VENT GRILLE

The cowl vent grille replacement procedure for Chevy

U is the same as for Chevrolet and Chevelle. Refer to

Chevrolet and Chevelle Cowl Vent Grille replacement

procedure and see Figure 16.

FRONT END ASSEMBLY

The Chevy n front end body design allows for removal

of the entire front end of the vehicle without disassembly

of front suspension of sheet metal. One man may remove

and transport the front end assembly using only a floor

jack placed under the crossmember and the vehicle front

wheels. Figure 31 illustrates the assembly in process

of removal with jack stand in position under rocker panel.

Proceed with removal

as.

follows:

Removal

1.

Remove hood assembly as outlined in this section.

2.

Remove engine assembly as outlined in Section 6.

On 4 cylinder models, replace crossmember.

3.

Raise car from floor and install jack stands as

shown in Figure 31.

4.

Remove pitman arm from steering gear as outlined

in Section 9.

5.

Remove steering gear mounting bolts from skirt

assembly.

6. Remove 4 bolts securing each skirt assembly to

lower dash brace.

7.

Remove fender-to-rocker extension mounting screws

and record shimming.

8. Remove brake hydraulic line and fuel line from right

hand skirt.

9. Position floor jack or equivalent under front cross-

member.

10.

Remove hydraulic line from main cylinder.

11.

Remove fender-to-cowl mounting screws and record

shimming.

12.

Remove upper skirt-to-dash mounting screws and

record shimming.

13.

Remove front end from vehicle as shown in Figure

31.

Inspection

If car has been involved in a collision, it is advisable

to carefully inspect cowl and dash area for damage. Pay

particular attention to welds, cage nuts, weld nuts and

skirt mounting surfaces. Cage and weld nuts may be

repaired by outright replacement (the best method), or

by the installation of spiral thread inserts. If the spiral

inserts are used, follow the instructions furnished by the

manufacturer. -

Installation

%, position front end assembly at upper dash mounts

and lower dash support, align screw holes with drift

punch and install all mounting screws and bolts

loosely; do not tighten until all screws and bolts are

started. Replace original shimming.

CHEVROLET CHASSIS SERVICE MANUAL

Page 561 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-49

BELLOWS

AND

SPRING

HOUSING

COIL

AND

POLE

ASSEMBLY

VALVE

ASSEMBLY

RATCHET

PAWL

ASSEMBLY

RATCHET

WHEEL

ACTUATOR

PLUNGER

ARM

ACTUATOR

PIN

HOLDING CONTACTS

OPEN

RAMP TANG

PLUNGER

ARM

Fig.

73 -

Releasing

Pump from

Lockout Position

Fig.

72 -

Washer

Pump

Mechanism

REMOVAL AND INSTALLATION

Removal of the washer pump from the wiper motor

consists of:

1.

Disconnect wiring harness and washer hoses from

washer.

2.

Remove the two pump-to-wiper retaining screws and

remove washer from wiper (fig. 66).

3.

Reverse removal procedure to install assembly.

DISASSEMBLY-ASSEMBLY

Refer to Figure

1.

Remove washer pump cover.

2.

Relay

a. To remove relay unsolder coil leads from

terminals.

NOTE:

No coil polarity is necessary when re-

soldering coil leads.

b.

Remove coil retainer clip and slip coil assembly

out of mounting bracket.

3.

Ratchet Pawl

a. To remove ratchet pawl disengage spring from

ratchet pawl and slide ratchet pawl from shaft.

CAUTION: Be sure spring is properly assem-

bled before replacing washer pump cover.

Terminal Board

a. Remove terminal board attaching screws, ratchet

dog and board from washer base.

Ratchet Wheel

a. Remove lock ring from shaft.

b.

Slide ratchet wheel from shaft.

Valve Assembly

a. To remove valve assembly remove screws that

secure valve assembly to bellows housing.

CAUTION: It may be necessary to carefully

pry bellows lip out of the valve body groove.

Bellows

a. To remove bellows first remove valve assembly.

b.

Manually operate pump clockwise to release pump

from 'lock-out" position (fig, 73).

c. Hold bellows plunger arm from moving, then push

in against bottom of bellows with thumb and twist

bellows spring from housing.

Actuator Pin

a. Remove actuator pin retaining spring and slide

pin from washer base.

Reverse disassembly procedure to assemble washer.

DEPRESSED PARK 2-SPEED WIPER

CHEVROLET

GENERAL DESCRIPTION

The Type "C" two speed electric wiper assembly (fig.

74) incorporates a depressed park type (blades park

against windshield lower molding when the motor is

turned off) motor and gear train. The wiper has a com-

pound wound 12 volt motor and a gear box section con-

taining the gear mechanism and relay control. The motor

armature is fitted with a worm gear which drives the

main gear assembly and crank arm.

The relay control, consisting of a relay coil, relay

armature and switch assembly, is located in the gear box

section bid controls the starting and stopping of the wiper

through a latching mechanism (fig. 75).

An electric washer pump is mounted on the gear box

section of the wiper and is driven by the wiper unit gear

assembly (fig* 75).

The overhaul procedures for the wiper are broken down

into three major areas: The motor section, gear box

section and washer pump section. Each section maybe

serviced independently of the other.

CHEVROLET CHASSIS SEftVKX

Page 562 of 659

ELECTRICAL-BODY AND CHASSIS 12-50

SERVICE OPERATIONS

MOTOR SECTION

DISASSEMBLY

NOTE:

Motor section

may be

disassembled

independently

of

the gear box.

Brush Plate and Circuit Breaker Removal

1.

Scribe

a

reference line along the side of the casting

and end cap to insure proper re-assembly.

2.

Remove the two motor thru bolts.

3.

Feed exposed excess length

of

motor leads thru the

casting grommet

and

carefully back

the

case

and

field assembly plus

the

armature away from

the

casting (fig. 76).

NOTE:

It may be

necessary

to

remove

the

armature end play adjusting screw and insert

a

rod thru

the

opening

in

order to apply pressure

against the end of the armature.

4.

Unsolder

the

black lead from circuit breaker

(fig.

77).

5.

Straighten

out the 4

tabs that secure the brush plate

to the field coil retainers (fig. 77).

CAUTION:

Be

careful

not to

break

any of

the

retainer tabs.

6. Install

"U"

shaped brush retainer clip over brush

holder that has brush lead attached to circuit breaker

(fig. 78).

7.

Holding

the

opposite brush from that retained in Step

6, carefully lift

the

brush holder

off the

mounting

tabs

far

enough

to

clear

the

armature commutator

(fig. 78).

8. Allow

the

brush, held

in

Step

7, to

move out

of its

holder. Remove

the

brush spring

and

lift the brush

holder

off

the armature shaft.

Armature Removal

1.

Follow Steps

1

thru

8

under brush plate removal.

2.

Lift armature out

of

case and field assembly.

3.

Remove thrust ball from

end of

armature shaft

as

PUMP

ASSEMBLY

CAM SLOT

DRIVE PLATE

AND

ASSEMBLY

RELAY SWITCH

ASSEMBLY

WASHER PUMP

DRIVE

PIN

Fig.

75

-

Wiper and Washer

Pump

Mechanism

required and save

for

reassembly.

NOTE: Thrust ball

may be

easily removed

with

a

magnet.

MOUNTING

GROMMET

WASHER PUMP COVER

RETAINING RING

STAKE MARKS -

CASE

TO

FIELD

LAMINA

(4

PLACES)

Fig. 74 - Depressed Park 2-Speed Wiper

Fig. 76 - Wiper Motor Separation

CHEVROLET CHASSIS SERVICE MANUAL

Page 563 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-51

7^5

CUT MOTOR LEADS

GENERALAREA

FOR

in|i

BRUSH PLATE

ASSEMBIYI^^H

RETAINER TAB (4)__J^^H

BLACK

LEAD

TO §HH

CIRCUIT BREAKER»^^—

CIRCUIT

F^H^^^^^B

BREAKER)

^^SH^P

IN

THIS

m

•I

i

ii

ii ii H^MWii^A'

I^BRT^i"

BRUSH

•^^k RETAINER CLIP

•

SPUCENOTES:

•

1-SOLID

BLACK

TO

•

SHUNT FIELD COIL

5

2-SERIES

FIELD COIL

I

TO

BLACK WITH PINK

H STRIPE LEAD

w

Fig.

77

-

Circuit Breaker

Case and Field Assembly Removal

1.

Remove brush plate and armature.

2.

The end

case

and

field assembly

is

serviced

as

a

DRIVE PLATE

&*

ASSEMBLY

DRIVE PAWL

IN

PARK POSITION

IN

RELAY SWITCH SLOT

RELAY SWITCH ASSEMBLY

Fig.

79-

Drive Pawl

in

Full Park Position

unit.

To

free

the

field

and

case assembly,

cut the

solid black and black with pink stripe leads

in a

lo-

cation convenient

for

splicing

-

preferably near

the

wiper terminal board. Refer to Figure

76.

Remove steel thrust plate and rubber disc from case

bearing

as

required.

DRIVE

PAWL

ENGAGING

LATCH

ARM

Fig.

78

-

Removing Brush Holder

Fig.

80

-

Relay Assembly

CHEVROLET

CHASSIS SERVICE MANUAL