coil CHEVROLET CAMARO 1967 1.G Chassis Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 280 of 659

ENGINE 6-15

2.

Install rocker arms, rocker arm balls and rocker

arm

nuts.

\

Tighten rocker arm nuts until all lash is

eliminated. .

3.

Adjust valves when lifter is on base circle of cam-

shaft lobe as follows:

a. Mark distributor housing, with chalk, at each cyl-

inder position (plug wire) then disconnect plug

wires at spark plugs and coil and remove distri-

butor cap and plug wire assembly (if not previ-

ously done).

b.

Crank engine until distributor rotor points to

number one cylinder position and breaker points

are open. Both valves on number one cylinder

may now be adjusted.

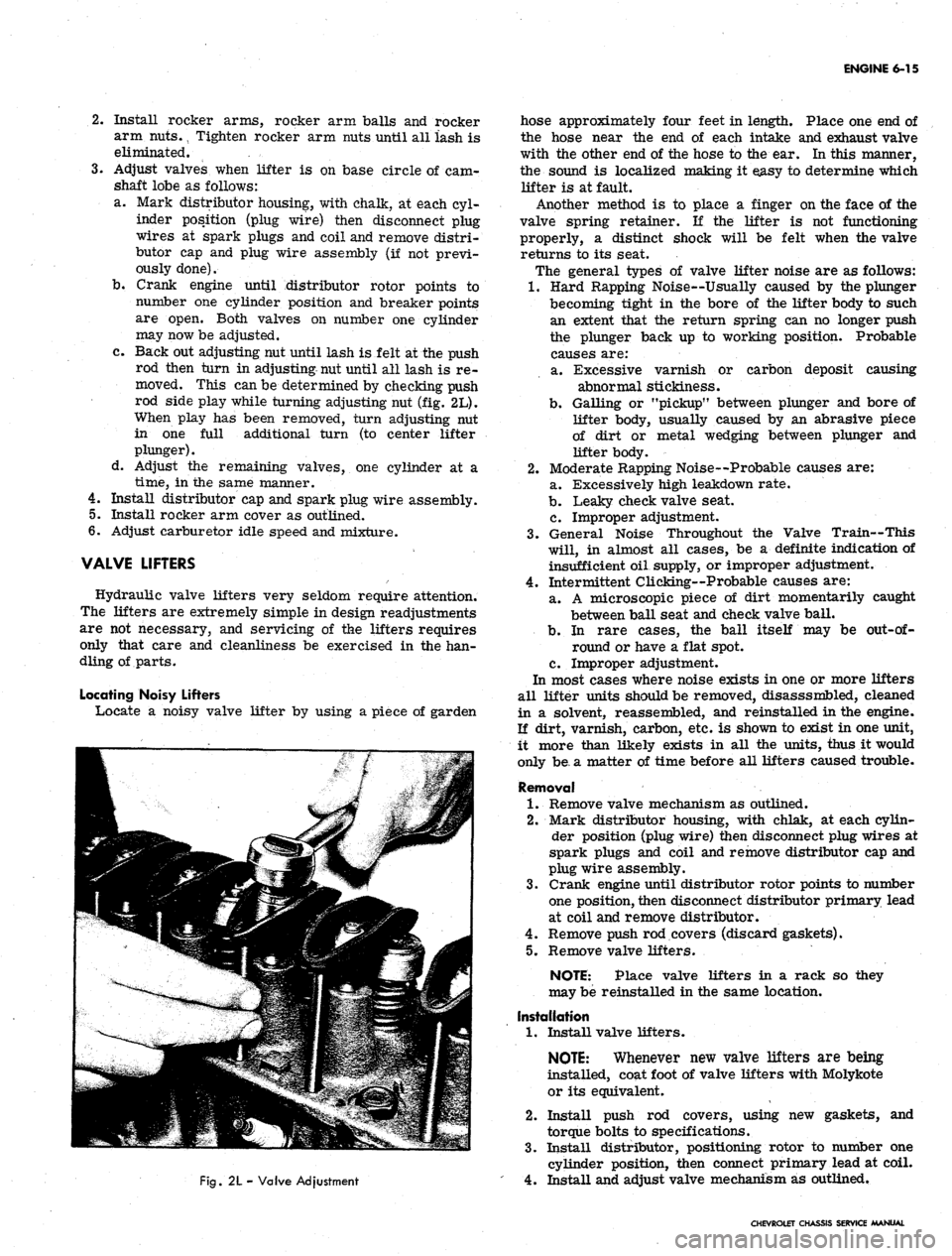

c. Back out adjusting nut until lash is felt at the push

rod then turn in adjusting nut until all lash is re-

moved. This can be determined by checking push

rod side play while turning adjusting nut (fig. 2L).

When play has been removed, turn adjusting nut

in one full additional turn (to center lifter

plunger).

d. Adjust the remaining valves, one cylinder at a

time,

in the same manner.

4.

Install distributor cap and spark plug wire assembly.

5.

Install rocker arm cover as outlined.

6. Adjust carburetor idle speed and mixture.

VALVE LIFTERS

Hydraulic valve lifters very seldom require attention.

The lifters are extremely simple in design readjustments

are not necessary, and servicing of the lifters requires

only that care and cleanliness be exercised in the han-

dling of parts.

Locating Noisy Lifters

Locate a noisy valve lifter by using a piece of garden

Fig.

2L - Valve Adjustment

hose approximately four feet in length. Place one end of

the hose near the end of each intake and exhaust valve

with the other end of the hose to the ear. In this manner,

the sound is localized making it easy to determine which

lifter is at fault.

Another method is to place a finger on the face of the

valve spring retainer. If the lifter is not functioning

properly, a distinct shock will be felt when the valve

returns to its seat.

The general types of valve lifter noise are as follows:

1.

Hard Rapping Noise--Usually caused by the plunger

becoming tight in the bore of the lifter body to such

an extent that the return spring can no longer push

the plunger back up to working position. Probable

causes are:

a. Excessive varnish or carbon deposit causing

abnormal stickiness.

b.

Galling or "pickup" between plunger and bore of

lifter body, usually caused by an abrasive piece

of dirt or metal wedging between plunger and

lifter body.

2.

Moderate Rapping Noise--Probable causes are:

a. Excessively high leakdown rate.

b.

Leaky check valve seat.

c. Improper adjustment.

3.

General Noise Throughout the Valve Train—This

will, in almost all cases, be a definite indication of

insufficient oil supply, or improper adjustment.

4.

Intermittent Clicking—Probable causes are:

a. A microscopic piece of dirt momentarily caught

between ball seat and check valve ball.

b.

In rare cases, the ball itself may be

out-of-

round or have a flat spot.

c. Improper adjustment.

In most cases where noise exists in one or more lifters

all lifter units should be removed, disasssmbled, cleaned

in a solvent, reassembled, and reinstalled in the engine.

If dirt, varnish, carbon, etc. is shown to exist in one unit,

it more than likely exists in all the units, thus it would

only be, a matter of time before all lifters caused trouble.

Removal

1.

Remove valve mechanism as outlined.

2.

Mark distributor housing, with chlak, at each cylin-

der position (plug wire) then disconnect plug wires at

spark plugs and coil and remove distributor cap and

plug wire assembly.

3.

Crank engine until distributor rotor points to number

one position, then disconnect distributor primary lead

at coil and remove distributor.

4.

Remove push rod covers (discard gaskets).

5.

Remove valve lifters.

NOTE: Place valve lifters in a rack so they

may be reinstalled in the same location.

Installation

1.

Install valve lifters.

NOTE:

Whenever new valve lifters are being

installed, coat foot of valve lifters with Molykote

or its equivalent.

2.

Install push rod covers, using new gaskets, and

torque bolts to specifications.

3.

Install distributor, positioning rotor to number one

cylinder position, then connect primary lead at coil.

4.

Install and adjust valve mechanism as outlined.

CHEVROLET CHASSIS SERVICE MANUAL

Page 281 of 659

ENGINE 6-16

5.

Adjust ignition timing and carburetor idle speed and

mixture.

VALVE STEM OIL SEAL AND/OR VALVE SPRING

Replacement

1.

Remove rocker arm cover as outlined.

2.

Remove spark plug, rocker arm and push rod on the

cylinder(s) to be serviced.

3.

Apply compressed air to the spark plug hole to hold

the valves in place.

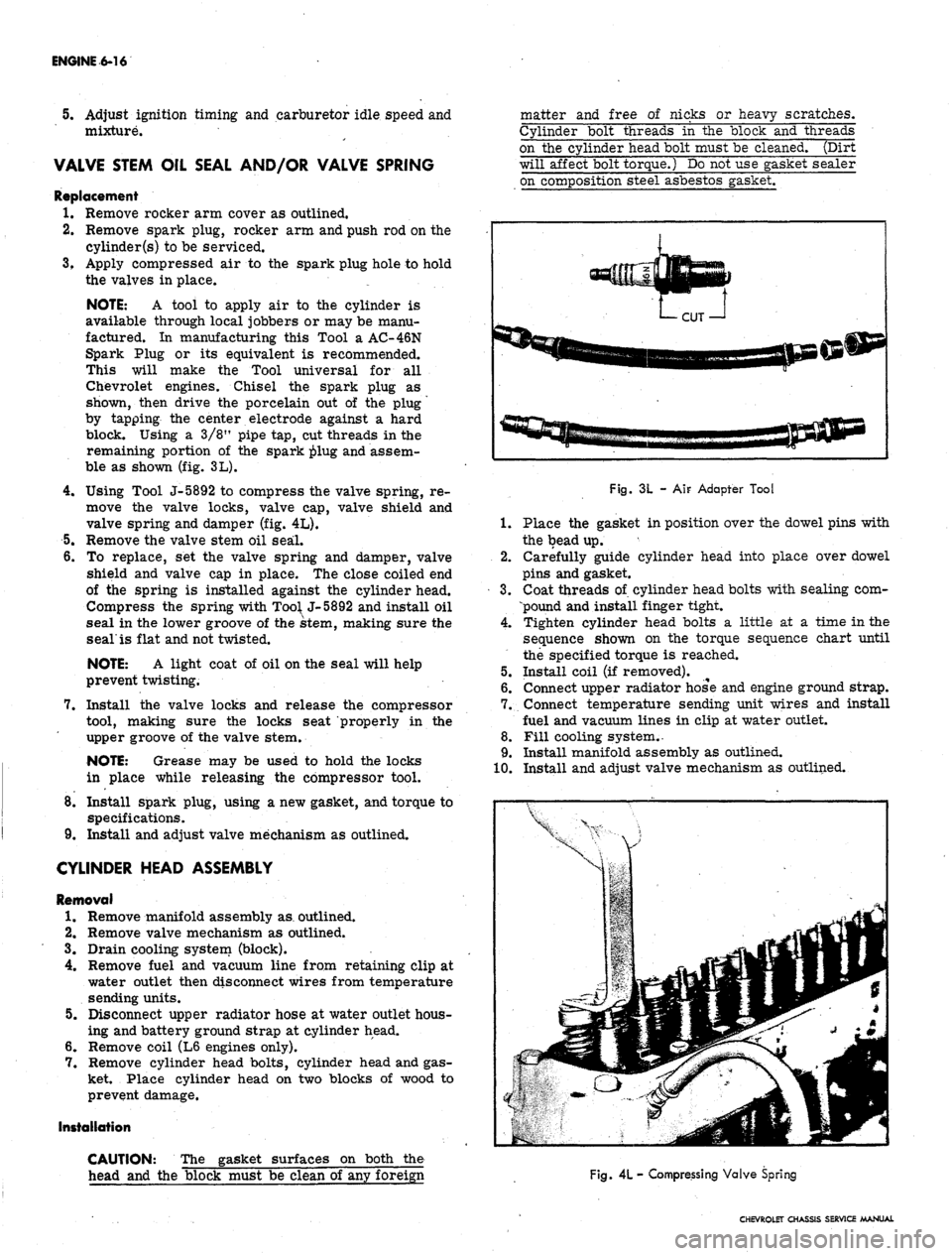

NOTE: A tool to apply air to the cylinder is

available through local jobbers or may be manu-

factured. In manufacturing this Tool a AC-46N

Spark Plug or its equivalent is recommended.

This will make the Tool universal for all

Chevrolet engines. Chisel the spark plug as

shown, then drive the porcelain out of the plug

by tapping the center electrode against a hard

block. Using a 3/8" pipe tap, cut threads in the

remaining portion of the spark ^>lug and assem-

ble as shown (fig. 3L).

4.

Using Tool J-5892 to compress the valve spring, re-

move the valve locks, valve cap, valve shield and

valve spring and damper (fig. 4L).

5.

Remove the valve stem oil seal.

6. To replace, set the valve spring and damper, valve

shield and valve cap in place. The close coiled end

of the spring is installed against the cylinder head.

Compress the spring with

Too^

J-5892 and install oil

seal in the lower groove of the stem, making sure the

seal'is flat and not twisted.

NOTE: A light coat of oil on the seal will help

prevent twisting.

7.

Install the valve locks and release the compressor

tool, making sure the locks seat properly in the

upper groove of the valve stem.

NOTE: Grease may be used to hold the locks

in place while releasing the compressor tool.

8. Install spark plug, using a new gasket, and torque to

specifications.

9. Install and adjust valve mechanism as outlined.

CYLINDER HEAD ASSEMBLY

Removal

1.

Remove manifold assembly as. outlined.

2.

Remove valve mechanism as outlined.

3.

Drain cooling system (block).

4.

Remove fuel and vacuum line from retaining clip at

water outlet then disconnect wires from temperature

sending units.

5.

Disconnect upper radiator hose at water outlet hous-

ing and battery ground strap at cylinder head.

6. Remove coil (L6 engines only).

7.

Remove cylinder head bolts, cylinder head and gas-

ket. Place cylinder head on two blocks of wood to

prevent damage.

Installation

CAUTION: The gasket surfaces on both the

head and the block must be clean of any foreign

matter and free of nicks or heavy scratches.

Cylinder bolt threads in the block and threads

on the cylinder head bolt must be cleaned. (Dirt

will affect bolt torque.) Do not use gasket sealer

on composition steel asbestos gasket.

Fig. 3L -

AIF

Adapter Tool

1.

Place the gasket in position over the dowel pins with

the bead up.

2.

Carefully guide cylinder head into place over dowel

pins and gasket.

3.

Coat threads of cylinder head bolts with sealing com-

pound and install finger tight.

4.

Tighten cylinder head bolts a little at a time in the

sequence shown on the torque sequence chart until

the specified torque is reached.

5.

Install coil (if removed).

6. Connect upper radiator hose and engine ground strap.

7.

Connect temperature sending unit wires and install

fuel and vacuum lines in clip at water outlet.

8. Fill cooling system.

•

9. Install manifold assembly as outlined.

10.

Install and adjust valve mechanism as outlined.

Fig.

4L

- Compressing Valve Spring

CHEVROLET CHASSIS SERVICE MANUAL

Page 286 of 659

ENGINE 6-21

CAUTION: Support cover

•

at sealing area.

(Tool J-971 may be used as support.)

Without Cover

Removal

1.

With crankshaft pulley and nub or torsional damper

removed, pry old seal out of cover from the front

with a large screw driver, being careful not to dam-

age the seal surface on the cover.

2.

Install new seal so that open end of seal is toward the

inside of cover and drive it into position with Tool

J-8340 (fig. 13L).

CAMSHAFT

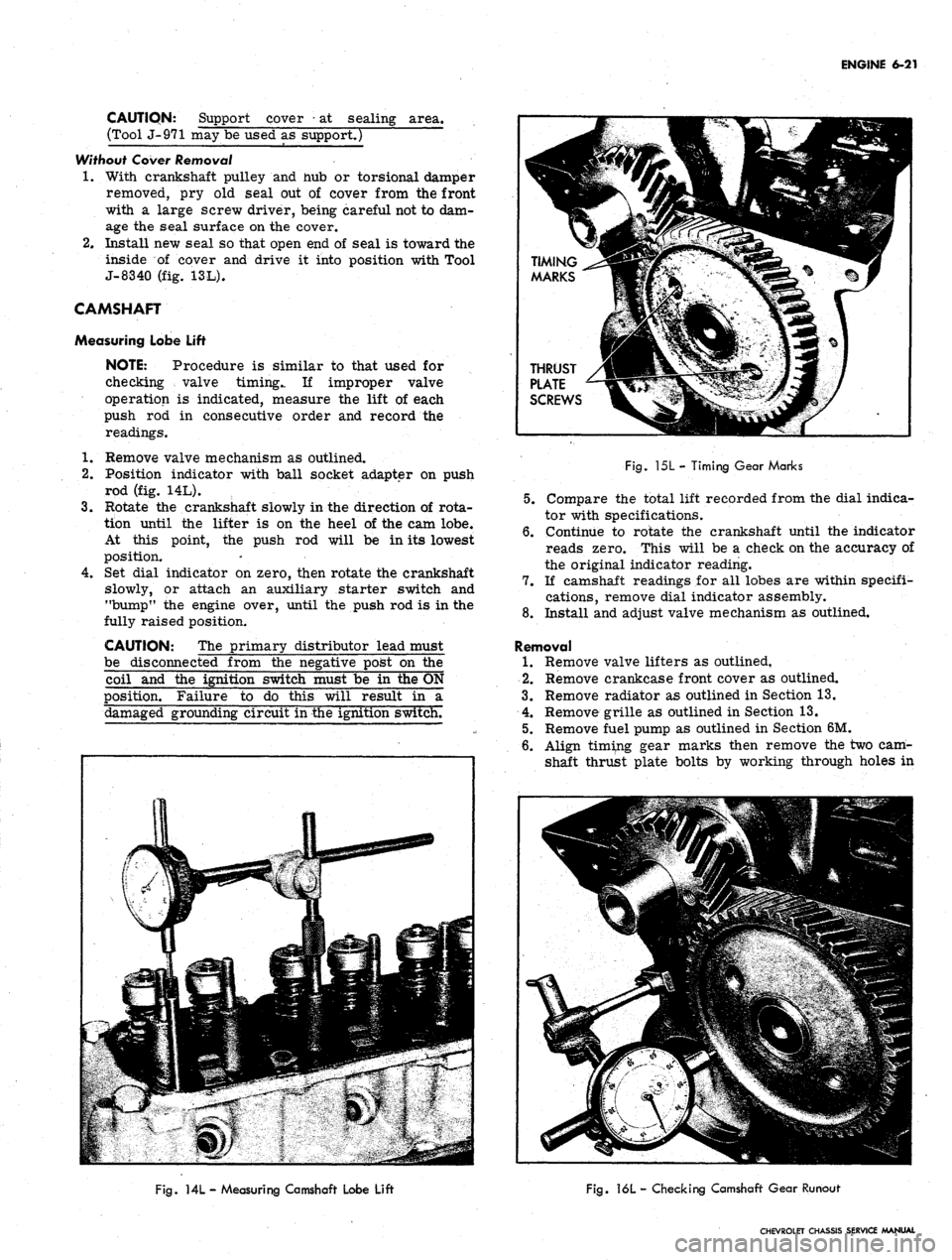

Measuring Lobe Lift

NOTE: Procedure is similar to that used for

checking valve timing.. If improper valve

operation is indicated, measure the lift of each

push rod in consecutive order and record the

readings.

1.

Remove valve mechanism as outlined.

2.

Position indicator with ball socket adapter on push

rod (fig. 14L).

3.

Rotate the crankshaft slowly in the direction of rota-

tion until the lifter is on the heel of the cam lobe.

At this point, the push rod will be in its lowest

position.

4.

Set dial indicator on zero, then rotate the crankshaft

slowly, or attach an auxiliary starter switch and

"bump" the engine over, until the push rod is in the

fully raised position.

CAUTION: The primary distributor lead must

be disconnected from the negative post on the

coil and the ignition switch must be in the ON

position. Failure to do this will result in a

damaged grounding circuit in the ignition switch.

Fig.

15L - Timing Gear Marks

5.

Compare the total lift recorded from the dial indica-

tor with specifications.

6. Continue to rotate the crankshaft until the indicator

reads zero. This will be a check on the accuracy of

the original indicator reading.

7.

If camshaft readings for all lobes are within specifi-

cations, remove dial indicator assembly.

8. Install and adjust valve mechanism as outlined.

Removal

1.

Remove valve lifters as outlined,

2.

Remove crankcase front cover as outlined.

3.

Remove radiator as outlined in Section 13.

4.

Remove grille as outlined in Section 13.

5.

Remove fuel pump as outlined in Section 6M.

6. Align timing gear marks then remove the two cam-

shaft thrust plate bolts by working through holes in

Fig.

ML - Measuring Camshaft Lobe Lift

Fig.

16L - Checking Camshaft Gear Runout

CHEVROLET CHASSIS SERVICE MANUAL

Page 290 of 659

ENGINE 6-25

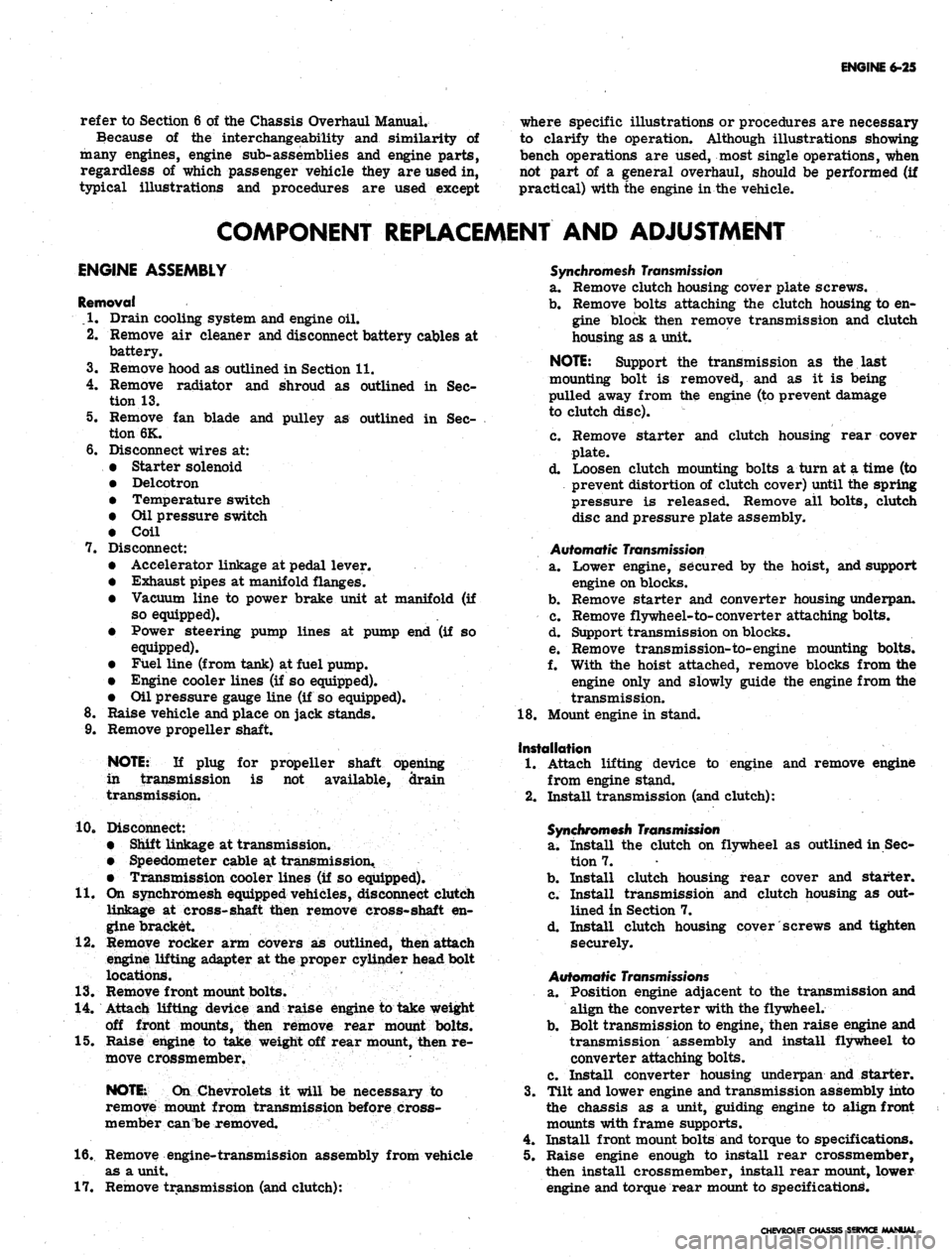

refer to Section 6 of the Chassis Overhaul Manual.

Because of the interchangeability and similarity of

many engines, engine sub-assemblies and engine parts,

regardless of which passenger vehicle they are used in,

typical illustrations and procedures are used except

where specific illustrations or procedures are necessary

to clarify the operation. Although illustrations showing

bench operations are used, most single operations, when

not part of a general overhaul, should be performed (if

practical) with the engine in the vehicle.

COMPONENT REPLACEMENT AND ADJUSTMENT

ENGINE ASSEMBLY

Removal

• .1. Drain cooling system and engine oil.

2.

Remove air cleaner and disconnect battery cables at

battery.

3.

Remove hood as outlined in Section 11.

4.

Remove radiator and shroud as outlined in Sec-

tion 13.

5. Remove fan blade and pulley as outlined in Sec-

tion 6K.

6. Disconnect wires at:

• Starter solenoid

• Delcotron

• Temperature switch

• Oil pressure switch

• Coil

7. Disconnect:

• Accelerator linkage at pedal lever.

• Exhaust pipes at manifold flanges.

• Vacuum line to power brake unit at manifold (if

so equipped),

• Power steering pump lines at pump end (if so

equipped).

• Fuel line (from tank) at fuel pump.

• Engine cooler lines (if so equipped).

• Oil pressure gauge line (if so equipped).

8. Raise vehicle and place on jack stands.

9. Remove propeller shaft.

NOTE:

If plug for propeller shaft opening

in transmission is not available, drain

transmission.

10.

Disconnect:

• Shift linkage at transmission.

• Speedometer cable at transmission.

• Transmission cooler lines (if so equipped).

11.

On synchromesh equipped vehicles, disconnect clutch

linkage at cross-shaft then remove cross-shaft en-

gine bracket.

12.

Remove rocker arm covers as outlined, then attach

engine lifting adapter at the proper cylinder head bolt

locations.

13.

Remove front mount bolts.

14.

Attach lifting device and raise engine to take weight

off front mounts, then remove rear mount bolts.

15.

Raise engine to take weight off rear mount, then re-

move crossmember.

NOTE:

On Chevrolets it will be necessary to

remove mount from transmission before cross-

member can be removed.

16.

Remove engine-transmission assembly from vehicle

as a unit.

17.

Remove transmission (and clutch):

Synchromesh Transmission

a. Remove clutch housing cover plate screws.

b.

Remove bolts attaching the clutch housing to en-

gine block then remove transmission and clutch

housing as a unit.

NOTE:

Support the transmission as the last

mounting bolt is removed, and as it is being

pulled away from the engine (to prevent damage

to clutch disc).

c. Remove starter and clutch housing rear cover

plate.

d. Loosen clutch mounting bolts a turn at a time (to

prevent distortion of clutch cover) until the spring

pressure is released. Remove all bolts, clutch

disc and pressure plate assembly.

Automatic

Transmission

a. Lower engine, secured by the hoist, and support

engine on blocks.

b.

Remove starter and converter housing underpan.

c. Remove flywheel-to-converter attaching bolts.

d. Support transmission on blocks.

e. Remove transmission-to-engine mounting bolts.

f. With the hoist attached, remove blocks from the

engine only and slowly guide the engine from the

transmission.

18.

Mount engine in stand.

Installation

1.

Attach lifting device to engine and remove engine

from engine stand.

2.

Install transmission (and clutch):

Synchromesh Transmission

a. Install the clutch on flywheel as outlined in Sec-

tion 7.

b.

Install clutch housing rear cover and starter.

c. Install transmission and clutch housing as out-

lined in Section 7.

d. Install clutch housing cover screws and tighten

securely.

Automatic

Transmissions

a. Position engine adjacent to the transmission and

align the converter with the flywheel.

b.

Bolt transmission to engine, then raise engine and

transmission assembly and install flywheel to

converter attaching bolts.

c. Install converter housing underpan and starter.

3.

Tilt and lower engine and transmission assembly into

the chassis as a unit, guiding engine to align front

mounts with frame supports.

4.

Install front mount bolts and torque to specifications.

5. Raise engine enough to install rear crossmember,

then install crossmember, install rear mount, lower

engine and torque rear mount to specifications.

CHEVROLET CHASSIS SERVICE MANUAL

Page 291 of 659

ENGINE 6-26

6. Remove lifting device and lifting adapter then install

rocker arm covers as outlined.

7.

On synchromesh equipped vehicles, install clutch

cross-shaft engine bracket, then adjust and connect

clutch as outlined in Section 7.

8. Connect:

• Speedometer cable.

• Shift linkage at transmission.

• Transmission cooler lines (if so equipped).

9. Install propeller shaft.

10.

Remove jack stands and lower vehicle.

11.

Connect: \ '

Power steering pump lines (if so equipped).

Vacuum line to power brake unit (if so equipped).

Exhaust pipes at manifold flanges.

Accelerator linkage at pedal lever.

Fuel line at fuel pump.

Engine cooler lines (if so equipped).

Oil pressure gauge lines (if so equipped).

12.

Connect wires at:

Coil

Oil pressure switch

Temperature switch

Delcotron

Starter solenoid

13.

Install pulley, fan blade and fan belt as outlined in

Section 6K.

14.

Install radiator and shroud as outlined in Section 13.

15.

Install and adjust hood as outlined in Section 11.

16.

Connect battery cables.

17.

Fill with coolant, engine oil and transmission oil,

then start engine and check for leaks.

18.

Perform necessary adjustments and install air

cleaner.

INTAKE MANIFOLD

Removal

1.

Drain radiator and remove air cleaner.

2.

Disconnect:

Battery cables at battery.

Upper radiator and heater hose at manifold.

Accelerator linkage at pedal lever.

Fuel line at carburetor. ;

Wires at temperature sending switch and coil

(both sides).

Power brake hose at carburetor base.

Spark advance hose at distributor.

Crankcase ventilation hoses (as required).

3.

Remove distributor cap and mark rotor position with

chalk. Remove distributor clamp and distributor,

then position distributor cap rearward clear of

manifold.

4.

Remove coil.

5.

Remove manifold-to-head attaching bolts, then re^

move manifold, (with carburetor on) from engine and

discard gaskets and seals.

6. If manifold is to be replaced,,transfer:

Carburetor and carburetor mounting studs.

Temperature sending switch.

Water outlet and thermostat (use new gasket).

Heater hose adapter.

Choke coil.

Installation

1.

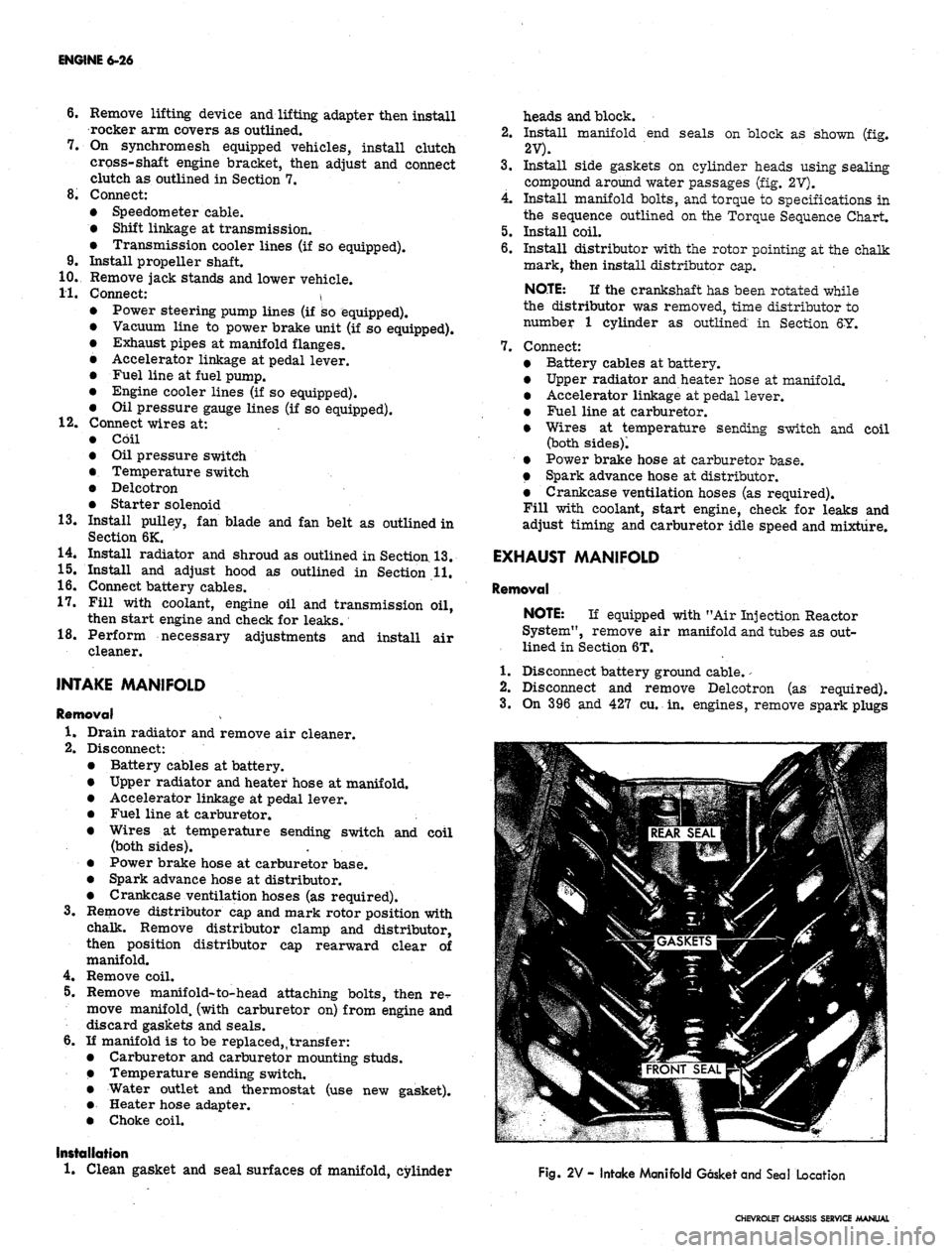

Clean gasket and seal surfaces of manifold, cylinder

heads and block.

2.

Install manifold end seals on block as shown (fig.

2V).

3.

Install side gaskets on cylinder heads using sealing

compound around water passages (fig. 2V).

4.

Install manifold bolts, and torque to specifications in

the sequence outlined on the Torque Sequence Chart.

5.

Install coil.

6. Install distributor with the rotor pointing at the chalk

mark, then install distributor cap.

NOTE:

If the crankshaft has been rotated while

the distributor was removed, time distributor to

number 1 cylinder as outlined in Section 6Y.

7.

Connect:

Battery cables at battery.

Upper radiator and heater hose at manifold.

Accelerator linkage at pedal lever.

Fuel line at carburetor.

Wires at temperature sending switch and coil

(both sides)!

Power brake hose at carburetor base.

Spark advance hose at distributor.

Crankcase ventilation hoses (as required).

Fill with coolant, start engine, check for leaks and

adjust timing and carburetor idle speed and mixture.

EXHAUST MANIFOLD

Removal

NOTE:

If equipped with "Air Injection Reactor

System", remove air manifold and tubes as out-

lined in Section 6T.

1.

Disconnect battery ground cable.

-

2.

Disconnect and remove Delcotron (as required).

3.

On 396 and 427 cu. in. engines, remove spark plugs

Fig. 2V - Intake Manifold Gasket and Seal Location

CHEVROLET CHASSIS SERVICE MANUAL

Page 294 of 659

ENGINE 6-29

an extent that the return spring can no longer push

the plunger back up to working position. Probable

causes are:

a. Excessive varnish or carbon deposit causing ab-

normal stickiness.

b.

(Sailing or "pick-up" between plunger and bore of

lifter body, usually caused by an abrasive piece of

dirt or metal wedging between plunger and lifter

body.

2.

Moderate Rapping Noise--Probable causes are:

a. Excessively high leakdown rate.

b.

Leaky check valve seat.

c. Improper adjustment.

3.

General Noise Throughout the Valve Train-rThis

will, in almost all cases, be a definite indication of

insufficient oil supply, or improper adjustment.

4.

Intermittent Clicking—Probable causes are:

a. A microscopic piece of dirt momentarily caught

between ball seat and check valve ball.

b.

In rare cases, the ball itself may be out-of-round

or have a flat spot.

c. Improper adjustment.

In most cases where noise exists in one or more lifters

all lifter units should be removed, disassembled, cleaned

in a solvent, reassembled, and reinstalled in the engine.

If dirt, corrosion, carbon, etc. is shown to exist in one

unit, it more than likely exists in all the units, thus it

would only be a matter of time before all lifters caused

trouble.

Removal

1.

Remove intake manifold as outlined.

2.

Remove valve mechanism as outlined.

3.

Remove valve lifters.

NOTE: Place valve lifters in a rack so they

may be reinstalled in the same location.

Installation

1.

Install valve lifters.

NOTE: Whenever new valve lifters are being

installed coat foot of valve lifters with Molykote

or its equivalent.

2.

Install intake manifold as outlined.

3.

Install and adjust valve mechanism as outlined.

VALVE STEM OIL SEAL AND/OR VALVE SPRING

Replacement

1.

Remove rocker arm cover(s) as outlined.

2.

Remove spark plug, rocker arm and push rod on the

cylinders to be serviced.

3.

Apply compressed air to the spark plug hole to hold

tl*e valves in place.

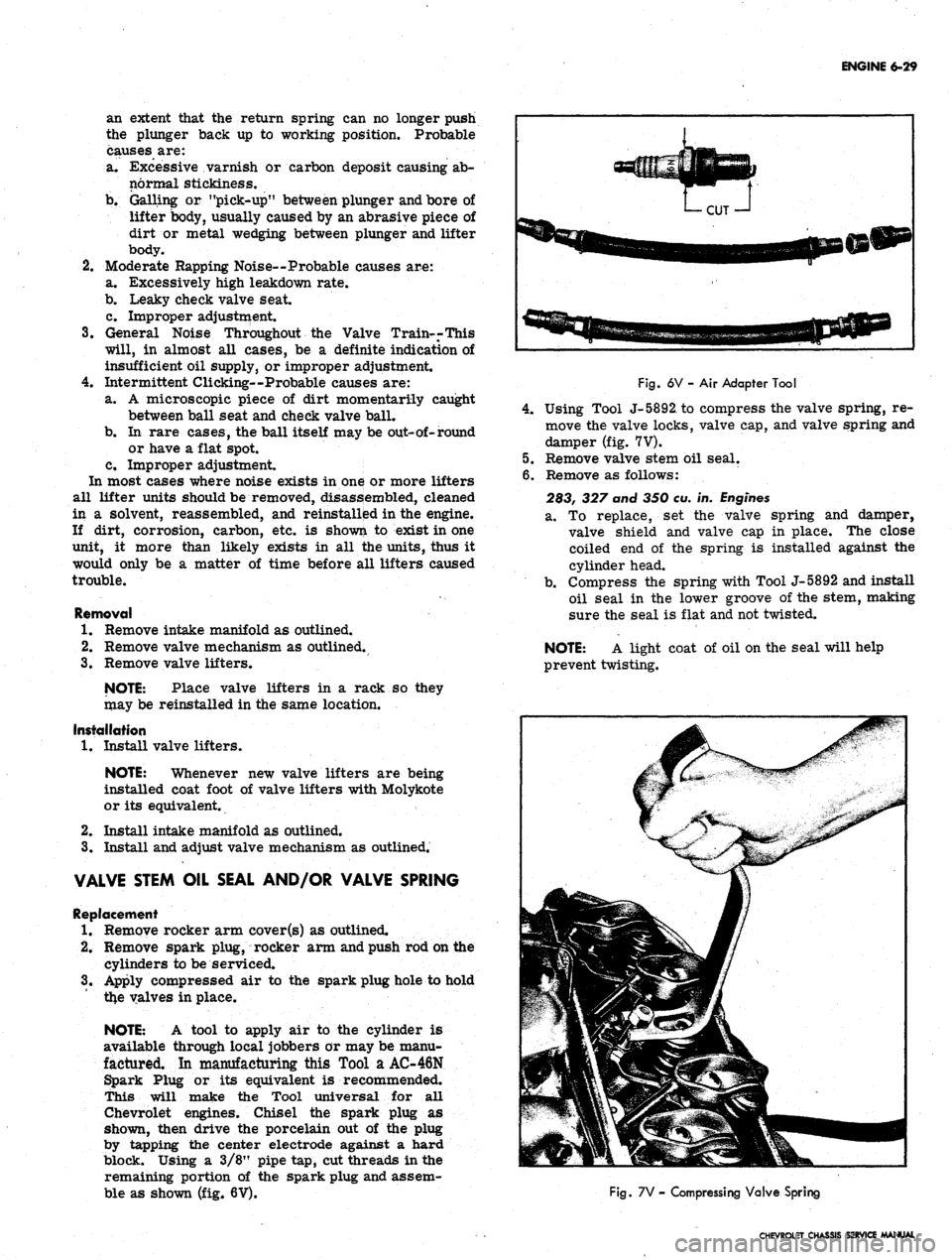

NOTE: A tool to apply air to the cylinder is

available through local jobbers or may be manu-

factured. In manufacturing this Tool a AC-46N

Spark Plug or its equivalent is recommended.

This will make the Tool universal for all

Chevrolet engines. Chisel the spark plug as

shown, then drive the porcelain out of the plug

by tapping the center electrode against a hard

block. Using a 3/8" pipe tap, cut threads in the

remaining portion of the spark plug and assem-

ble as shown (fig. 6V).

Fig.

6V - Air Adapter Tool

4.

Using Tool J-5892, to compress the valve spring, re-

move the valve locks, valve cap, and valve spring and

damper (fig. 7V).

5.

Remove valve stem oil seal.

6. Remove as follows:

283, 327 and 350 eu. in.

Engines

a. To replace, set the valve spring and damper,

valve shield and valve cap in place. The close

coiled end of the spring is installed against the

cylinder head.

b.

Compress the spring with Tool J-5892 and install

oil seal in the lower groove of the stem, making

sure the seal is flat and not twisted.

NOTE: A light coat of oil on the seal will help

prevent twisting.

Fig.

7V - Compressing Valve Spring

CHEVROLET CHASSIS SERVICE MANUAL

Page 302 of 659

ENGINE 6-37

Fig.

27V—Removing Camshaft

4.

Set dial indicator on zero, then rotate the damper

slowly, or attach an auxiliary starter switch and

"bump" the engine over, until the push rod is in the

fully raised position.

CAUTION: The primary distributor lead must

be disconnected from the negative post on the

coil and the ignition switch must be in the on

position. Failure to do this will result in a dam-

aged grounding circuit in the ignition switch.

5.

Compare the total lift recorded from the dial indica-

tor with specifications.

6. Continue to rotate the crankshaft until the indicator

reads zero. This will be a check on the accuracy of

the original indicator reading.

7.

If camshaft readings for all lobes are within specifi-

cations, remove dial indicator assembly.

8. Install and adjust valve mechanism as outlined.

Removal

1.

Remove valve lifters as outlined.

2.

Remove crankshaft front cover as outlined.

3.

Remove grille as outlined in Section 13.

4.

Remove fuel pump push rod as outlined * in Sec-

tion 6M.

5.

Complete camshaft removal as follows:

CAUTION: All camshaft journals are the same

diameter and care must be used in removing

camshaft to avoid damage to bearings.

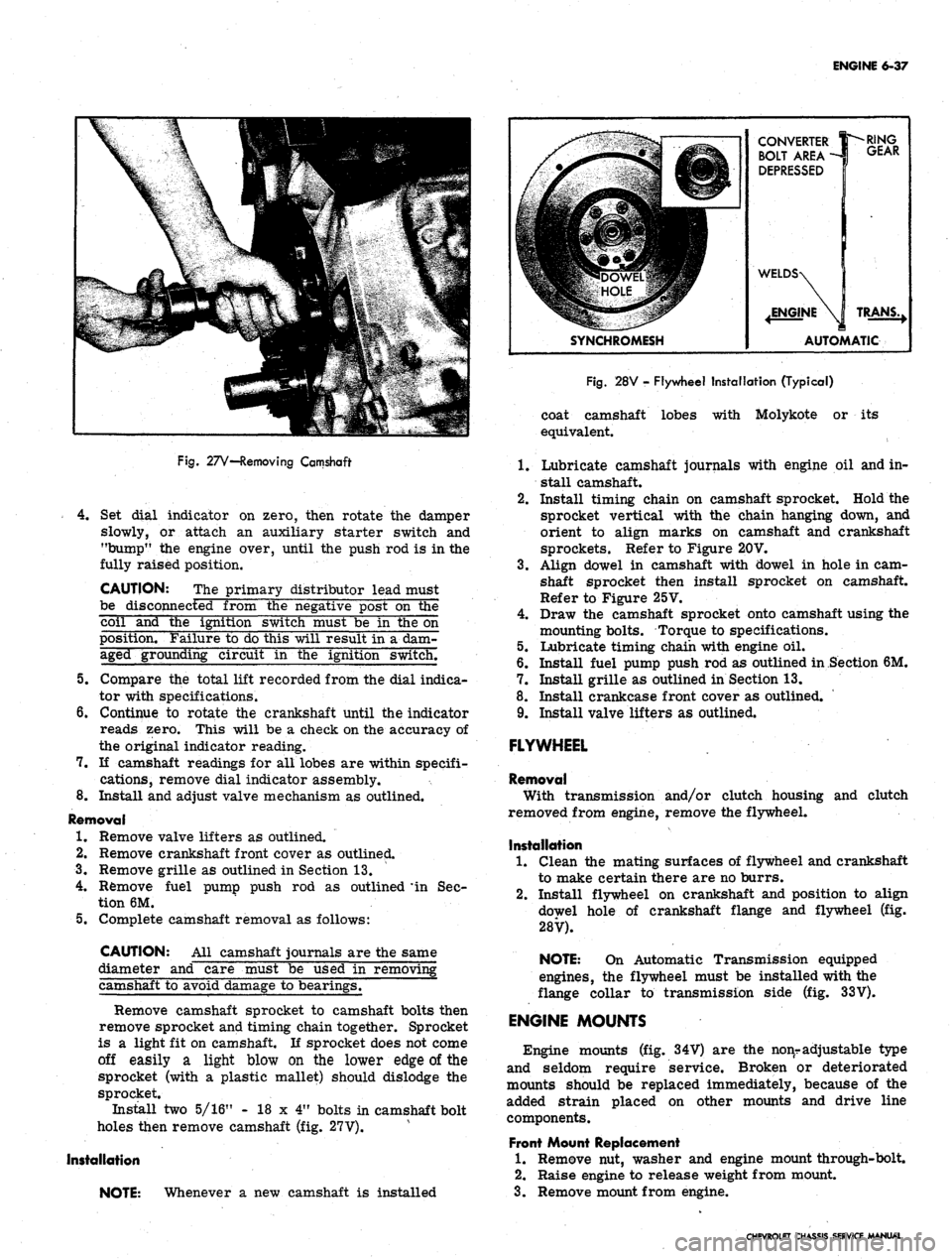

Remove camshaft sprocket to camshaft bolts then

remove sprocket and timing chain together. Sprocket

is a light fit on camshaft. If sprocket does not come

off easily a light blow on the lower edge of the

sprocket (with a plastic mallet) should dislodge the

sprocket.

Install two 5/16" - 18 x 4" bolts in camshaft bolt

holes then remove camshaft (fig. 27V).

Installation

NOTE: Whenever a new camshaft is installed

CONVERTER

BOLT AREA -

DEPRESSED

SYNCHROMESH

RING

GEAR

TRANS.,

AUTOMATIC

Fig.

28V - Flywheel Installation (Typical)

coat camshaft lobes with Molykote or its

equivalent.

1.

Lubricate camshaft journals with engine oil and in-

stall camshaft.

2.

Install timing chain on camshaft sprocket. Hold the

sprocket vertical with the chain hanging down, and

orient to align marks on camshaft and crankshaft

sprockets. Refer to Figure 20V.

3.

Align dowel in camshaft with dowel in hole in cam-

shaft sprocket then install sprocket on camshaft.

Refer to Figure 25V.

4.

Draw the camshaft sprocket onto camshaft using the

mounting bolts. Torque to specifications.

5.

Lubricate timing chain with engine oil.

6. Install fuel pump push rod as outlined in Section 6M.

7.

Install grille as outlined in Section 13.

8. Install crankcase front cover as outlined.

9. Install valve lifters as outlined.

FLYWHEEL

Removal

With transmission and/or clutch housing and clutch

removed from engine, remove the flywheel.

Installation

1.

Clean the mating surfaces of flywheel and crankshaft

to make certain there are no burrs.

2.

Install flywheel on crankshaft and position to align

dowel hole of crankshaft flange and flywheel (fig.

28V).

NOTE: On Automatic Transmission equipped

engines, the flywheel must be installed with the

flange collar to transmission side (fig. 33V).

ENGINE MOUNTS

Engine mounts (fig. 34V) are the nonr adjustable type

and seldom require service. Broken or deteriorated

mounts should be replaced immediately, because of the

added strain placed on other mounts and drive line

components.

Front Mount Replacement

1.

Remove nut, washer and engine mount through-bolt.

2.

Raise engine to release weight from mount.

3.

Remove mount from engine.

CHEVROLET CHASSIS SERVICE MANUAL

Page 309 of 659

SECTION 6M

ENGINE FUEL

CONTENTS OF THIS SECTION

Page

Carburetors 6M-1 Fuel Pumps .

Air Cleaners 6M-7 Special Tools

Page

6M-10

6M-12

CARBURETORS

INDEX

Page

General Description 6M-1

Service Procedures 6M-1

Preliminary Checks 6M-1

Idle Speed and Mixture Adjustment ........... 6M-1

Fast Idle Adjustment .................. 6M-3

Choke Adjustment 6M-3

Float Adjustment 6M-4

Page

Additional Adjustments 6M-4

Removal 6M-4

Test Before Installation 6M-5

Installation 6M-5

Fuel Filter Maintenance 6M-5

Choke Coil Replacement 6M-5

Throttle Linkage Adjustment . . 6M-6

GENERAL DESCRIPTION

Various carburetors (fig. lc) are used with Chevrolet,

Chevelle, Chevy II, Camaro and Corvette passenger

vehicles. These carburetors are designed to meet the

particular requirements of engines, transmissions and

vehicles, therefore carburetors that look alike are not

always interchangeable. (Refer to carburetor part num-

ber and/or specifications.)

Because many service procedures for the various

carburetors are similar, typical illustrations and pro-

cedures are used except where specific illustrations or

procedures are necessary to clarify the operation.

This section covers removal, installation and adjust-

ments (on engine) of carburetors. Also covered in this

section are maintenance procedures for choke coils,

throttle linkage and fuel filters. For carburetor .over-

haul procedures and additional adjustments (bench), re-

fer to Section 6M of the Overhaul Manual under the

carburetor being serviced.

Specifications for carburetors are located in the back

of this manual.

SERVICE PROCEDURES

Preliminary Checks

1.

Thoroughly warm-up engine. If the engine is cold,

allow to run for at least 15 minutes.

2.

Inspect torque of carburetor to intake manifold bolts

and intake manifold to cylinder head bolts to exclude

the possibility of air leaks.

3.

Inspect manifold heat control valve (if used) for free-

dom of action and correct spring tension.

Idle Speed and Mixture Adjustment (Except Air Injection

Reactor System)

NOTE:

This adjustment should be performed

with engine at operating temperature and park-

ing brake applied.

1.

Remove Air Cleaner.

2.

Connect tachometer and vacuum gauge to engine, then

set hand brake and shift transmission into neutral.

3.

As a preliminary adjustment, turn idle mixture

screws lightly to seat and back out 1-1/2 turns.

CAUTION: Do not turn idle mixture screw

tightly against seat or damage may result.

4.

With engine running (choke wide open) adjust idle

speed screw to specified idle speed, (automatic

transmission in drive, synchronized transmission in

neutral).

5. Adjust idle mixture screw to obtain highest steady

vacuum at specified idle speed.

NOTE:

On air conditioned vehicles, turn air

conditioning to the "on" position and hold the

hot idle compensator valve closed while adjust-

ing idle speed and idle mixture screws.

NOTE:

On Rochester BV carburetors the idle

mixture screw should be turned out 1/4 turn

from the "lean roll" position. The definition

of "lean roll" point is a 20 to 30 rpm drop

in engine speed obtained by leaning the idle

mixture.

6. Repeat Steps 4 and5 as needed for final adjustment.

NOTE:

If necessary, final adjustment of the \

carburetor may be made with the air cleaner

installed.

7. Turn engine off, remove gauges and install air

clearer.

CHEVROLET CHASSIS SERVICE MANUAL

Page 313 of 659

ENGINE FUEL 6M-5

3.

Disconnect choke rod or choke cable.

4.

Disconnect accelerator linkage.

5.

If equipped with Automatic transmission, discon-

nect TV linkage.

6. Remove carburetor attaching nuts and/or bolts and

remove carburetor.

Test Before Installation -

It is good shop practice to fill the carburetor bowl

before installing the carburetor. This reduces the strain

on the starting motor and battery and reduces the pos-

sibility of backfiring while attempting to start the engine.

A fuel pump clamped to the bench, a small supply of fuel

and the necessary fittings enable the carburetor to be

filled1 and the operation of the float and'intake needle and

seat to be checked. Operate the throttle several times

and check the discharge from the pump jets before in-

stalling the carburetor.

Installation

1.

Be certain throttle body and intake manifold sealing

surfaces are clean.

2.

Install new carburetor to manifold flange gasket (if

required).

3.

Install carburetor over manifold studs.

4.

Start vacuum and fuel lines at carburetor.

5.

Install attaching nuts and/or bolts and tighten

securely.

6. Tighten fuel and vacuum lines.

7.

Connect and adjust accelerator and TV linkage.

8. Connect choke tube or choke rod.

9. Adjust idle speed and mixture, then install air

cleaner. #

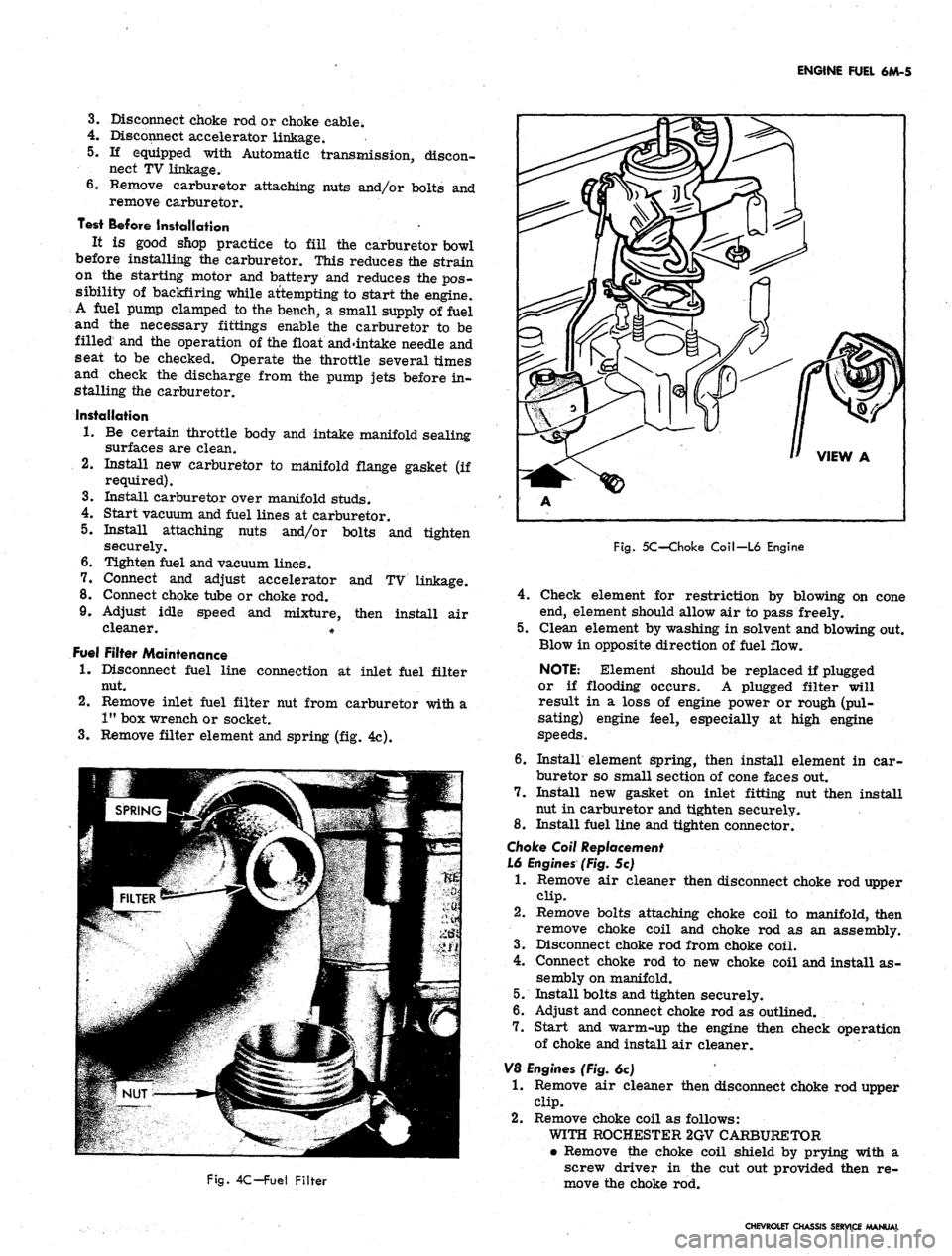

Fuel Filter Maintenance

1.

Disconnect fuel line connection at inlet fuel filter

nut.

2.

Remove inlet fuel filter nut from carburetor with a

1"

box wrench or socket.

3.

Remove filter element and spring (fig. 4c).

Fig. 5C-Choke Coil-L6 Engine

4.

Fig. 4C-Fuel Filter

Check element for restriction by blowing on cone

end, element should allow air to pass freely.

5.

Clean element by washing in solvent and blowing out.

Blow in opposite direction of fuel flow.

NOTE: Element should be replaced if plugged

or if flooding ocpurs. A plugged filter will

result in a loss of engine power or rough (pul-

sating) engine feel, especially at high engine

speeds.

6. Install element spring, then install element in car-

buretor so small section of cone faces out.

7.

Install new gasket on inlet fitting nut then install

nut in carburetor and tighten securely.

8. Install fuel line and tighten connector.

Choke Coil Replacement

L6 Engines (Fig. 5c)

1.

Remove air cleaner then disconnect choke rod upper

clip.

2.

Remove bolts attaching choke coil to manifold, then

remove choke coil and choke rod as an assembly.

3.

Disconnect choke rod from choke coil.

4.

Connect choke rod to new choke coil and install as-

sembly on manifold.

5.

Install bolts and tighten securely.

6. Adjust and connect choke rod as outlined.

7.

Start and warm-up the engine then check operation

of choke and install air cleaner.

V8 Engines (Fig. 6c)

1.

Remove air cleaner then disconnect choke rod upper

clip.

2.

Remove choke coil as follows:

WITH ROCHESTER 2GV CARBURETOR

• Remove the choke coil shield by prying with a

screw driver in the cut out provided then re-

move the choke rod.

CHEVROLET CHASSIS SERVICE MANUAL

Page 314 of 659

ENGINE FUEL 6M-6

Fig.

6C-Choke Coil-V8 Engine

• Remove bracket and choke coil assembly.

WITH ROCHESTER 4MV AND

HOLLEY CARBURETORS

• Remove the choke coil shield by prying with a

screw driver in the cut out provided then lift

shield carefully over rod.

• Remove choke rod, bracket screw and choke

coil assembly

3.

Install a new choke coil assembly being sure the

locating tab is in the forward hole of the intake

manifold then install mounting screw.

4.

Complete installation as follows:

WITH ROCHESTER 2GV CARBURETOR

• Check that the choke rod eye of the coil is

below the stop tab on the bracket then install

the choke

ro

• Install the choke coil shield over the choke coil

and move shield to best fit along manifold.

WITH ROCHESTER 4MV AND

HOLLEY CARBURETORS

• Install the choke rod and adjust as necessary

(without choke coil shield installed).

• Disconnect choke rod upper end and lower choke

coil shield over choke rod and install over choke

coil.

• Move shield to best fit along manifold and con-

nect upper end of choke rod.

5. Be sure choke valve moves freely from full open

to full closed position.

6. Start and warm up the engine and check operation

of the choke.

7. Install the air cleaner.

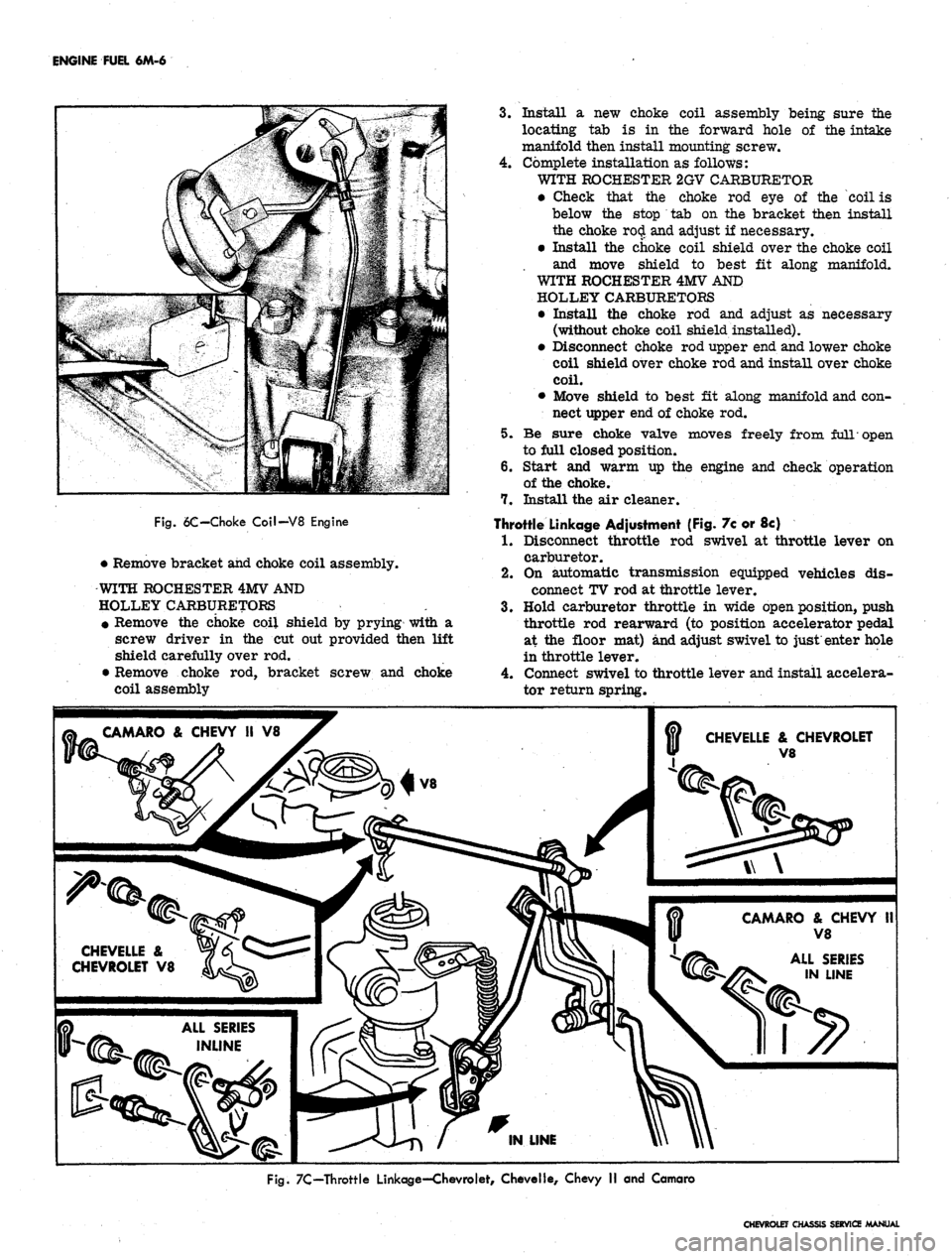

Throttle Linkage Adjustment (Fig. 7c or 8c)

1.

Disconnect throttle rod swivel at throttle lever on

carburetor.

2.

On automatic transmission equipped vehicles dis-

connect TV rod at throttle lever.

3.

Hold carburetor throttle in wide open position, push

throttle rod rearward (to position accelerator pedal

at the floor mat) and adjust swivel to just enter hole

in throttle lever.

4.

Connect swivel to throttle lever and install accelera-

tor return spring.

CAMARO & CHEVY II V8

CHEVELLE & CHEVROLET

V8

CAMARO

&

CHEVY

II

V8

CHEVELLE &

CHEVROLET V8

ALL SERIES

IN LINE

ALL SERIES

INLINE

Fig.

7C—Throttle Linkage—Chevrolet, Chevelle, Chevy II and Camaro

CHEVROLET CHASSIS SERVICE MANUAL