steering CHEVROLET CAMARO 1967 1.G Chassis Manual Online

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 476 of 659

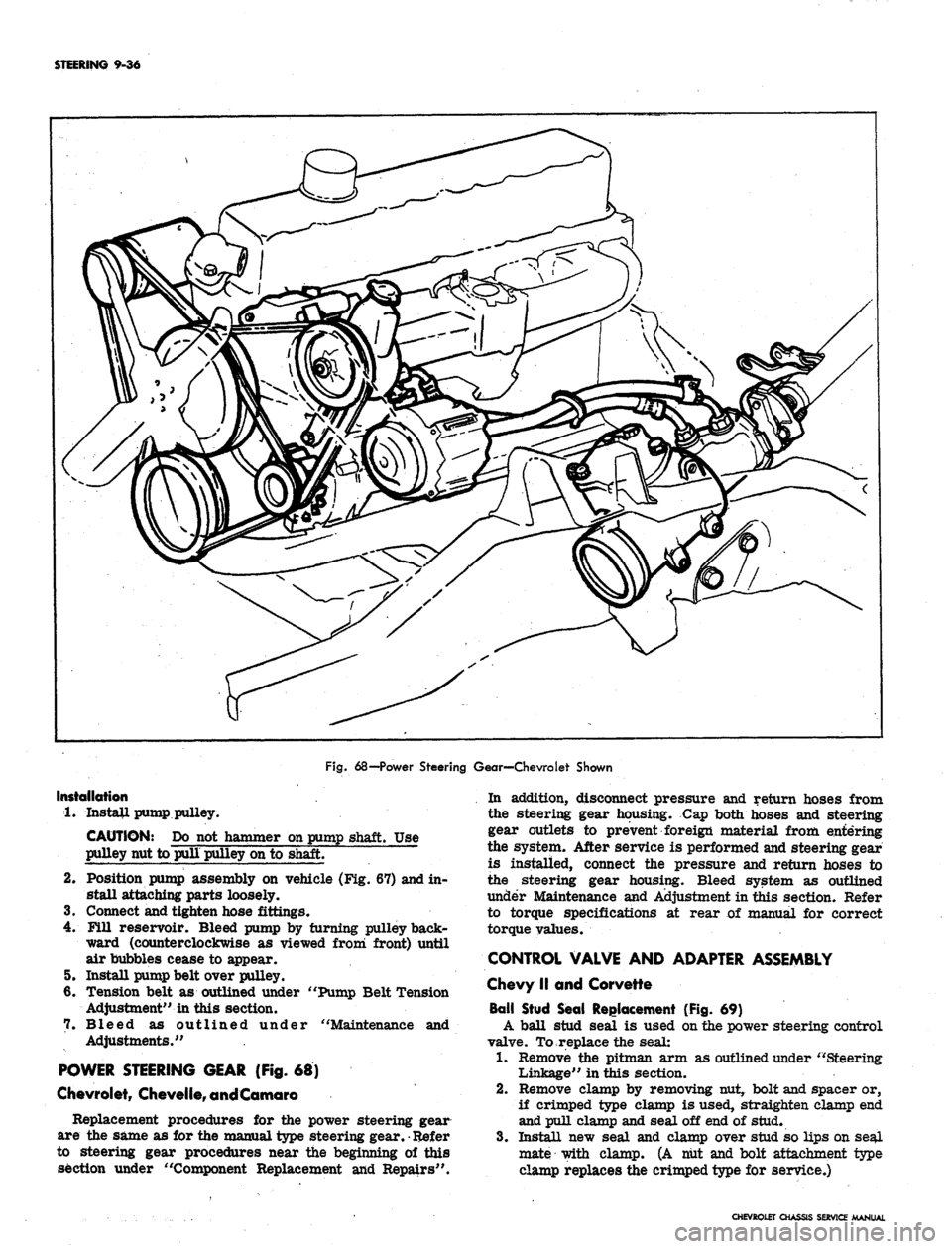

STEERING 9-36

Fig.

68—Power Steering Gear—Chevrolet Shown

Installation

1.

Install pump pulley.

CAUTION: Do not hammer on pump shaft. Use

pulley nut to pull pulley on to shaft.

2.

Position pump assembly on vehicle (Fig. 67) and in-

stall attaching parts loosely.

3.

Connect and tighten hose fittings.

4.

Fill reservoir. Bleed pump by turning pulley back-

ward (counterclockwise as viewed from front) until

air bubbles cease to appear.

5. Install pump belt over pulley.

6. Tension belt as outlined under "Pump Belt Tension

Adjustment" in this section.

7. Bleed as outlined under "Maintenance and

Adjustments."

POWER STEERING GEAR (Fig. 68)

Chevrolet,

Chevelfe,

and Comoro

Replacement procedures for the power steering gear

are the same as for the manual type steering gear.

•

Refer

to steering gear procedures near the beginning of this

section under "Component Replacement and Repairs".

In addition, disconnect pressure and return hoses from

the steering gear housing. Cap both hoses and steering

gear outlets to prevent foreign material from entering

the system. After service is performed and steering gear

is installed, connect the pressure and return hoses to

the steering gear housing. Bleed system as outlined

under Maintenance and Adjustment in this section. Refer

to torque specifications at rear of manual for correct

torque values.

CONTROL VALVE AND ADAPTER ASSEMBLY

Chevy II and Corvette

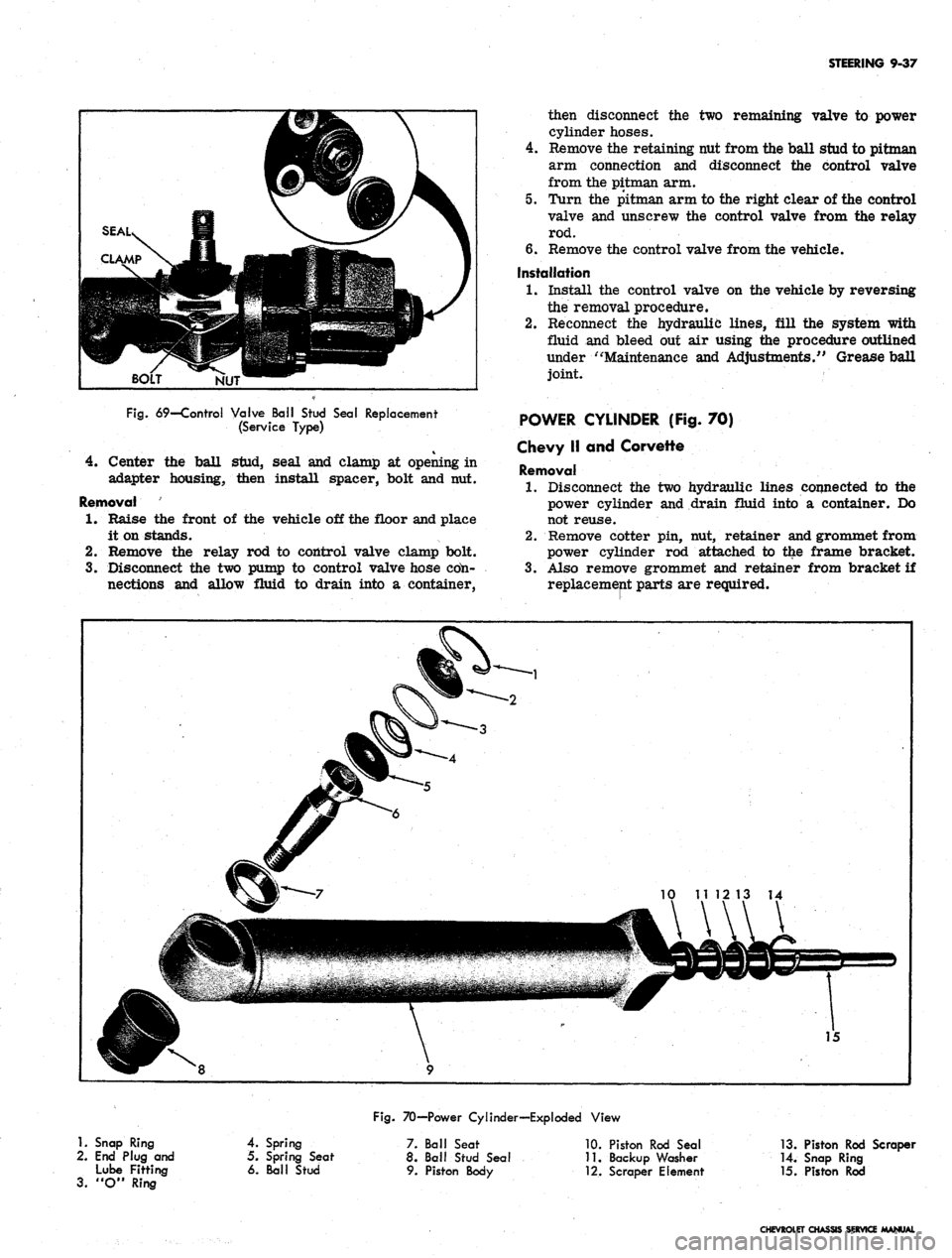

Ball Stud Seal Replacement (Fig. 69)

A ball stud seal is used on the power steering control

valve. To replace the seal:

1.

Remove the pitman arm as outlined under "Steering

Linkage" in this section.

2.

Remove clamp by removing nut, bolt and spacer or,

if crimped type clamp is used, straighten clamp end

and pull clamp and seal off end of stud.

3.

Install new seal and clamp over stud so lips on seal

mate with clamp. (A nut and bolt attachment type

clamp replaces the crimped type for service.)

CHEVROLET CHASSIS

SERVICE

MANUAL

Page 477 of 659

STEERING 9-37

NUT

Fig.

69—Control Valve Ball Stud Seal Replacement

(Service Type)

4.

Center the ball stud, seal and clamp at opening in

adapter housing, then install spacer, bolt and nut.

Removal

1.

Raise the front of the vehicle off the floor and place

it on stands.

2.

Remove the relay rod to control valve clamp bolt.

3.

Disconnect the two pump to control valve hose cdn-

nections and allow fluid to drain into a container,

then disconnect the two remaining valve to power

cylinder hoses.

4.

Remove the retaining nut from the ball stud to pitman

arm connection and disconnect the control valve

from the pitman arm.

5. Turn the pitman arm to the right clear of the control

valve and unscrew the control valve from the relay

rod.

6. Remove the control valve from the vehicle.

Installation

1.

Install the control valve on the vehicle by reversing

the removal procedure.

2.

Reconnect the hydraulic lines, fill the system with

fluid and bleed out air using the procedure outlined

under "Maintenance and Adjustments/' Grease ball

joint.

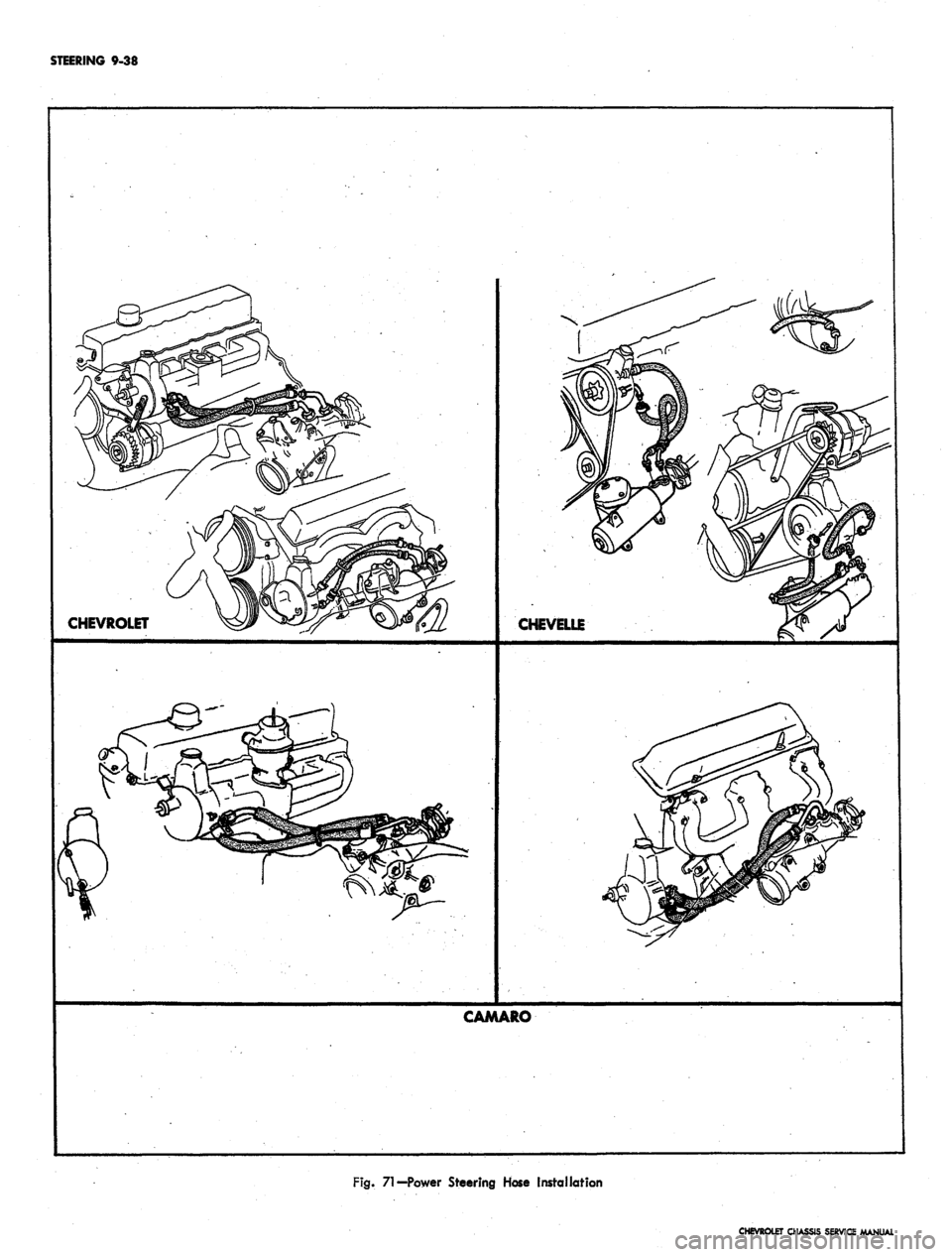

POWER CYLINDER (Fig. 70)

Chevy II and Corvette

Removal

1.

Disconnect the two hydraulic lines connected to the

power cylinder and drain fluid into a container. Do

not reuse.

2.

Remove cotter pin, nut, retainer and grommet from

power cylinder rod attached to the frame bracket.

3.

Also remove grommet and retainer from bracket if

replacement parts are required.

1.

Snap Ring

2.

End Plug and

Lube Fitting

3.

"O" Ring

Fig.

70—Power Cylinder—Exploded View

4.

Spring

5. Spring Seat

6. Ball Stud

7. Ball Seat

8. Ball Stud Seal

9. Piston Body

10.

Piston Rod Seal

11.

Backup Washer

•12.

Scraper Element

13.

Piston Rod Scraper

14.

Snap Ring

15.

Piston Rod

CHEVROLET CHASSIS SERVICE MANUAL

Page 478 of 659

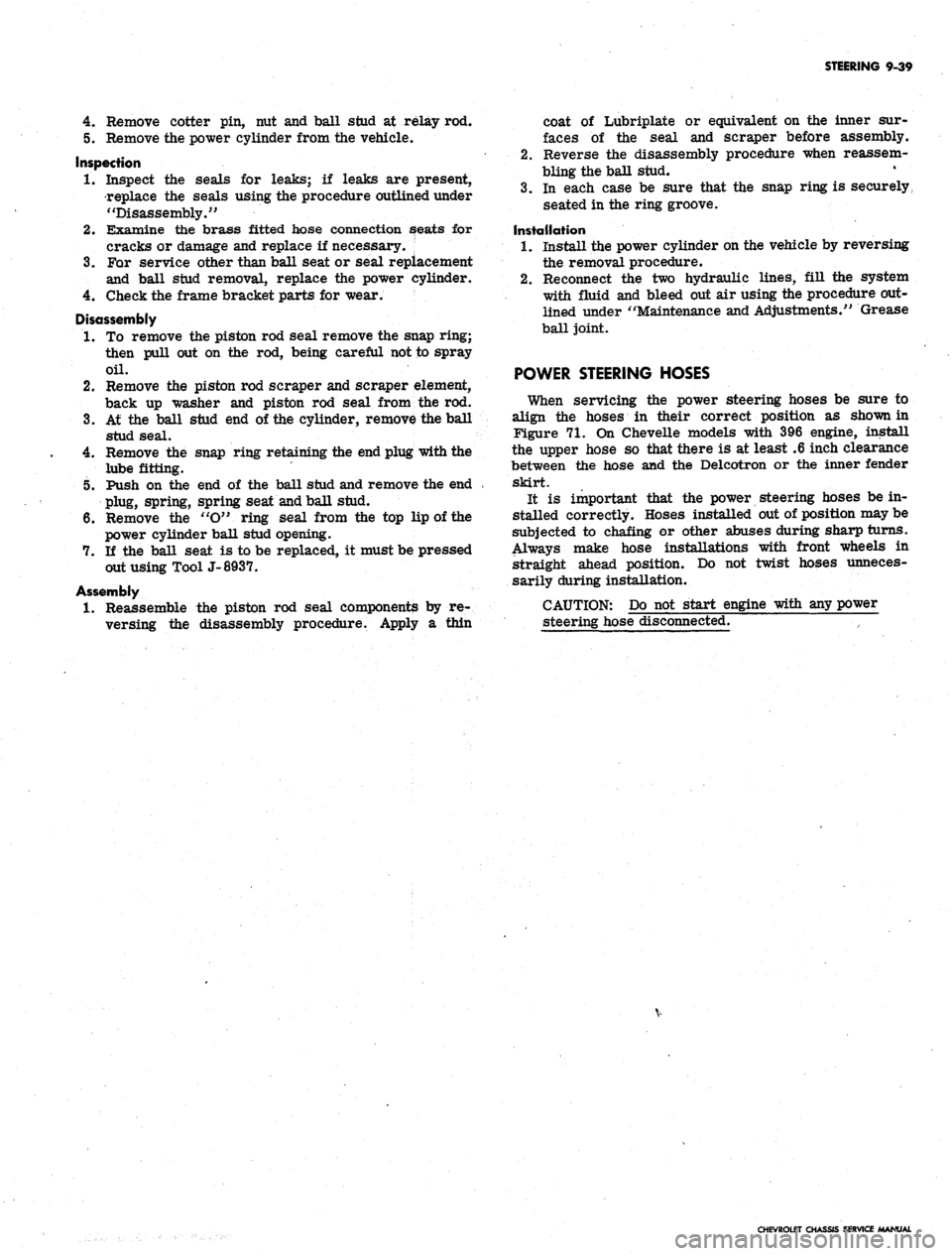

STEERING 9-38

CHEVROLET

CHEVELLE

CAMARO

Fig.

71—Power Steering Hose Installation

CHEVROLET CHASSIS SERVICE MANUAL

Page 479 of 659

STEERING 9-39

4.

Remove cotter pin, nut and ball stud at relay rod.

5. Remove the power cylinder from the vehicle.

Inspection

1.

Inspect the seals for leaks; if leaks are present,

replace the seals using the procedure outlined under

"Disassembly."

2.

Examine the brass fitted hose connection seats for

cracks or damage and replace if necessary.

3.

For service other than ball seat or seal replacement

and ball stud removal, replace the power cylinder.

4.

Check the frame bracket parts for wear.

Disassembly

1.

To remove the piston rod seal remove the snap ring;

then pull out on the rod, being careful not to spray

oil.

2.

Remove the piston rod scraper and scraper element,

back up washer and piston rod seal from the rod.

3.

At the ball stud end of the cylinder, remove the ball

stud seal.

4.

Remove the snap ring retaining the end plug with the

lube fitting.

5. Push on the end of the ball stud and remove the end

plug, spring, spring seat and ball stud.

6. Remove the "O" ring seal from the top lip of the

power cylinder ball stud opening.

7. If the ball seat is to be replaced, it must be pressed

out using Tool J-8937.

Assembly

1.

Reassemble the piston rod seal components by re-

versing the disassembly procedure. Apply a thin

coat of Lubriplate or equivalent on the inner sur-

faces of the seal and scraper before assembly.

2.

Reverse the disassembly procedure when reassem-

bling the ball stud.

3.

In each case be sure that the snap ring is securely,

seated in the ring groove.

Installation

1.

Install the power cylinder on the vehicle by reversing

the removal procedure.

2.

Reconnect the two hydraulic lines, fill the system

with fluid and bleed out air using the procedure out-

lined under "Maintenance and Adjustments." Grease

ball joint.

POWER STEERING HOSES

When servicing the power steering hoses be sure to

align the hoses in their correct position as shown in

Figure 71. On Chevelle models with 396 engine, install

the upper hose so that there is at least .6 inch clearance

between the hose and the Delcotron or the inner fender

skirt.

It is important that the power steering hoses be in-

stalled correctly. Hoses installed out of position may be

subjected to chafing or other abuses during sharp turns.

Always make hose installations with front wheels in

straight ahead position. Do not twist hoses unneces-

sarily during installation.

CAUTION: Do not start engine with any power

steering hose disconnected.

CHEVROLET CHASSIS SERVICE MANUAL

Page 480 of 659

STEERING 9-40

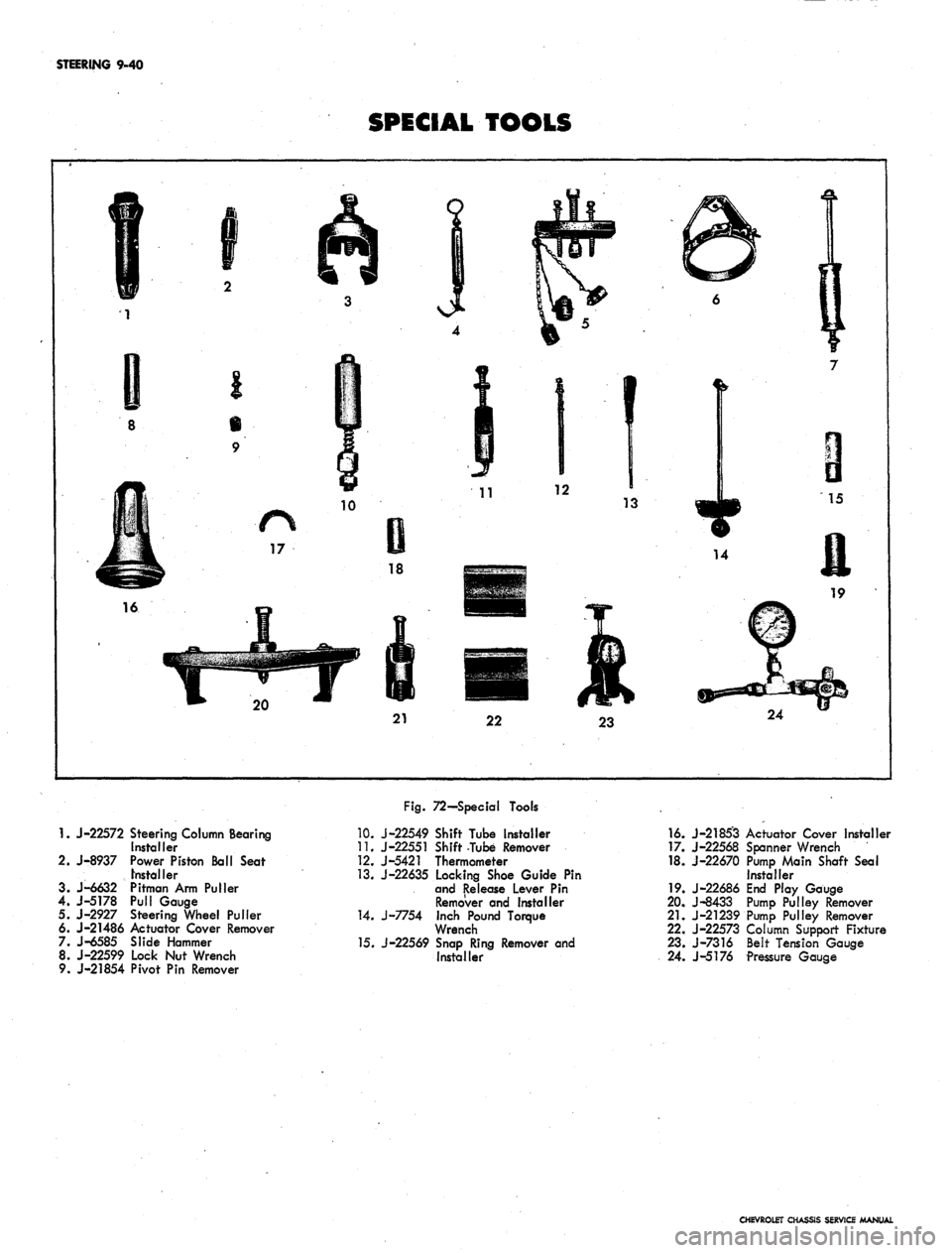

SPECIAL TOOLS

1.

J-22572 Steering Column Bearing

Installer

2.

J-8937 Power Piston Ball Seat

Installer

3. J-6632 Pitman Arm Puller

4.

J-5178 Pull Gauge

5. J-2927 Steering Wheel Puller

6. J-21486 Actuator Cover Remover

7. J-6585 Slide Hammer

8. J-22599 Lock Nut Wrench

9. J-21854 Pivot Pin Remover

Fig.

72—Special Tools

10.

J-22549 Shift Tube Installer

11.

J-22551 Shift Tube Remover

12.

J-5421 Thermometer

13.

J-22635 Locking Shoe Guide Pin

and Release Lever Pin

Remover and Installer

14.

J-7754 Inch Pound Torque

Wrench

15.

J-22569 Snap Ring Remover and

Installer

16.

J-2185'3

17.

J-22568

18.

J-22670

19.

J-22686

20.

J-8433

21.

J-21239

22.

J-22573

23.

J-7316

24.

J-5176

Actuator Cover Installer

Spanner Wrench

Pump Main Shaft Seal

Installer

End Play Gauge

Pump Pulley Remover

Pump Pulley Remover

Column Support Fixture

Belt Tension Gauge

Pressure Gauge

CHEVROLET CHASSIS SERVICE MANUAL

Page 485 of 659

WHEELS AND TIRES 10-5

WHEELS

The wheel and tire assembly should be removed from

vehicles equipped with disc brakes to properly perform

balancing operations. This is necessary due to drag of

the spring loaded brake shoes on the disc.

Static Balancing (W/Tire)

Static Balance (still balance) is the equal distribution

of weight of the wheel and tire assembly about the axis

of rotation so that the assembly has no tendency to rotate

by

itself.

Static unbalance causes the pounding action of

the front wheels that is called "tramp".

To correct static unbalance (front and rear): The

quickest and best methods to correct static unbalance

are through the use of wheel balancers which are com-

mercially available. Refer to the Information and in-

structions included with these balaricers.

Dynamic Balancing (W/Tire)

Dynamic Balance (running balance) requires the wheel

to be not only in static balance, but balanced and running

smoothly while turning on an axis which runs through the

centerline of the wheel and tire perpendicular to the axis

of rotation.

The quickest and best methods of testing and correcting

dynamic unbalance are by the use of dynamic wheel

balancers which are commercially available. These bal-

ancers include all necessary information on where and

how the balancing weights should be placed. The follow-

ing information, however, will help in the correction of

dynamic balance.

NOTE:

Before attempting to balance the

wheels, check to be certain that no foreign

matter has been trapped in the wheel ventila-

tion slots or in the accessory wheel discs. This

is especially important if the vehicle has been

run in soft mud and then parked in freezing

weather.

When a wheel that is statically unbalanced is dynam-

ically in balance the dynamic balance can be retained

while correcting "the static balance by installing the cor-

rective weights so that half of the weight required is

placed on the inner edge of the rim and the other half

on the outer edge of the rim.

Dynamic unbalance can be corrected without destroying

static balance by installing weights so half of weight

required for dynamic balance is placed on the rim op-

posite the heavy point, while the other half is placed 180°

away and on the opposite side of the rim.

NOTE:

Vehicles with wire wheel covers should

have the wheels balanced with the wire wheel

covers installed on the wheels.

Run Out (W/OTire)

The wheels should not run out (wobble) more than

1/16" as measured on the side of the rim at the base

of the tire. Excessive run-out is the result of a bent

wheel, an improperly mounted wheel, worn knuckle bear-

ings or steering connections. These parts should be

checked for correct adjustment, proper alignment and

wear whenever excessive run-out is encountered.

The wheels should also run concentric with the steering

knuckle spindle within 1/16 inch as measured on the tire

bead seat of the rim with the tire removed.

Wheel run-out, eccentricity and balance are closely

associated with steering and front wheel alignment.

Further information on these subjects will be found under

"Suspension".

Cleaning Aluminum Wheels

Do not use wire brush or abrasive cleaners when

cleaning wheels. Use only cleaners that will not react

with aluminum.

SERVICE OPERATIONS

TIRES

Removal

Dismounting tubeless tires presents no problems if the

correct procedures are used and the following precau-

tions observed.

1.

Remove the valve cap and valve core. Let out all the

air.

2.

Press the inner side of the tire into the rim well.

Use bead loosening tool or if regular tire irons are

used, take particular care not to injure or tear the

sealing ribs on the bead.

CAUTION: Never use tire irons with sharp

edges or corners.

3.

Using tire irons on the opposite side, remove bead,

taking small "bites" around the rim.

4.

Turn the tire over, and use two tire irons, one be-

tween the rim flange and the bead to pry the rim

upward, the other iron to pry outward between the

bead seat and the bead.

Installation

Extreme care must be exercised to prevent injury to

the sealing bead and circumferential bead when forcing

tire over rim.

1.

Apply a light film of Ruglyde or other suitable rubber

lubricant to sealing bead of tire.

NOTE:

The use of excessive lubrication may

lead to rim slippage and subsequent breaking of

air seal.

2.

Carefully mount the outer bead in usual manner by

using tire irons, taking small "bites" around rim,

being careful not to injure the tire bead.

CAUTION: DO NOT use a hammer, as damage

to the bead will result.

3.

Install the inner bead in the same manner.

NOTE:

If a seal cannot be effected in the fore-

going manner with the rush of air it can be

, accomplished by applying to the circumference

of the tire a tire mounting band or heavy sash

cord and tightening with the use of a tire iron.

On tire mounting machines, bouncing the tire

assembly is not required. The tire should be

CHEVROLET CHASSIS SERVICE MANUAL

Page 502 of 659

CHASSIS SHEET METAL 11-15

FRONT FENDER TRIM

If fender spear molding is to be replaced without re-

moving fender from vehicle, proceed as follows:

1.

Perform Operations 2 and 5 only of Front Fender

Assembly—Removal.

2.

Pull rear* end of fender away from body far enough

to insert a short piece of 2 x 4 between lower rear

corner of fender and rocker panel extension.

3.

It should now be possible to gain access to first and

second retaining nuts forward of rear end of fender.

All other nuts can be reached from front wheel

opening.

SKIRT ASSEMBLY

Removal

1.

Remove hood and hinge assemblies as outlined in

this section.

2.

Remove grille and radiator support as outlined in

Section ia.

3.

Remove fender assembly as outlined in this section.

4.

Raise car from floor and place jack stands under

rocker panel extension.

5.

Remove suspension bumper support, shock absorber,

front spring and stabilizer link as outlined in Section

3.

6. If removing left skirt assembly, remove steering

gear mounting bolts, power steering hose clamp (if

so equipped) and outer (left) clutch cordon shaft

bracket (if so equipped).

7.

Remove tie rod ball stud from steering arm as out-

lined in Section 9.

8. Support engine and remove engine mount cushion as

outlined in Section 6.

9. Remove spring clip from brake line junction which

passes through skirt and remove junction from skirt

(see Section 5).

10.

Remove four bolts retaining front crossmember to

skirt.

11.

Remove four bolts retaining skirt assembly to dash

front brace. Remove 3 bolts retaining upper end of

skirt to dash (fig. 26); record shims removed.

12.

Remove skirt assembly with remaining suspension

parts attached as shown in Figure 27.

13.

Suspension parts may be detached as outlined in

Section 3.

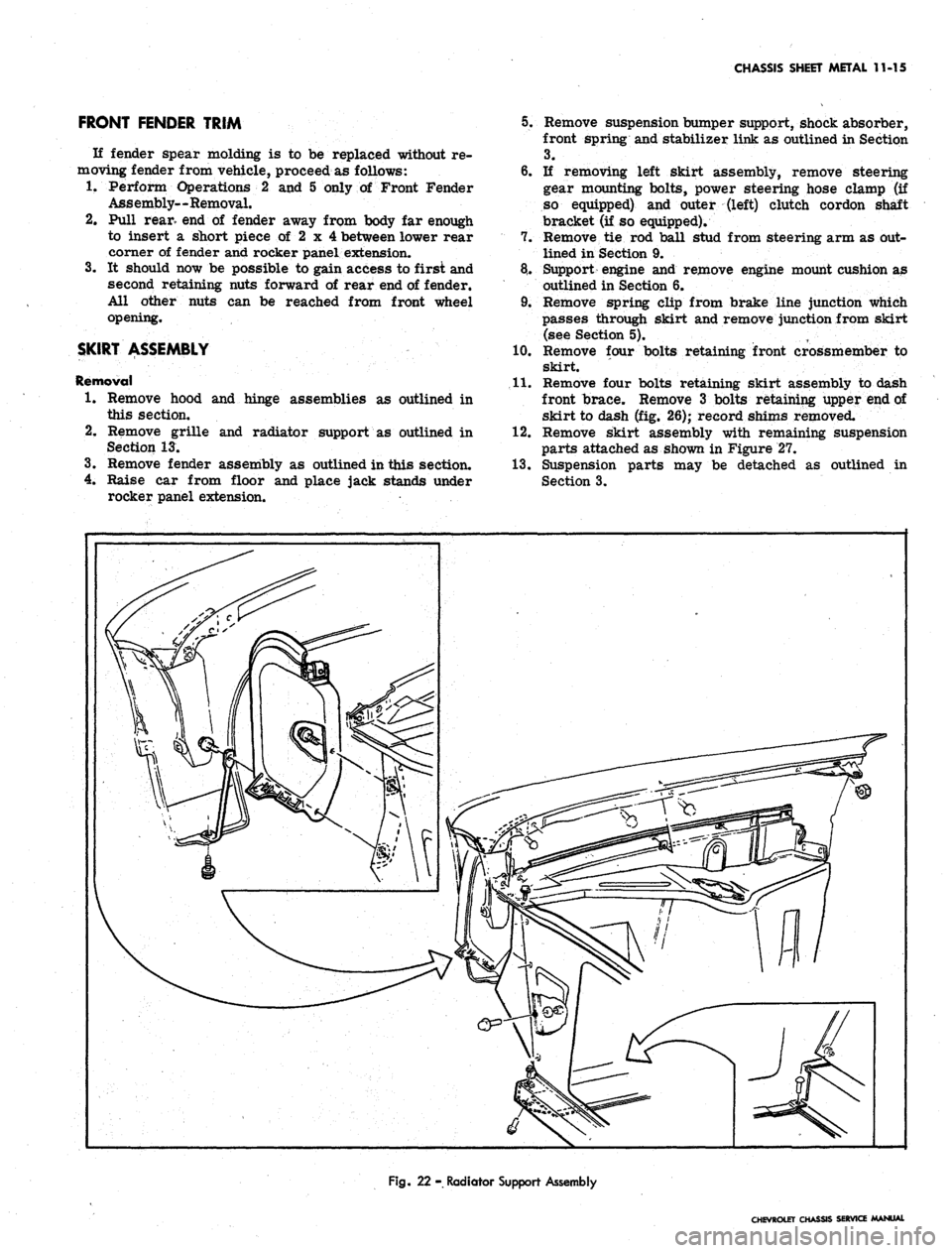

Fig.

22 - Radiator Support Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 504 of 659

CHASSIS SHEET METAL 11-17

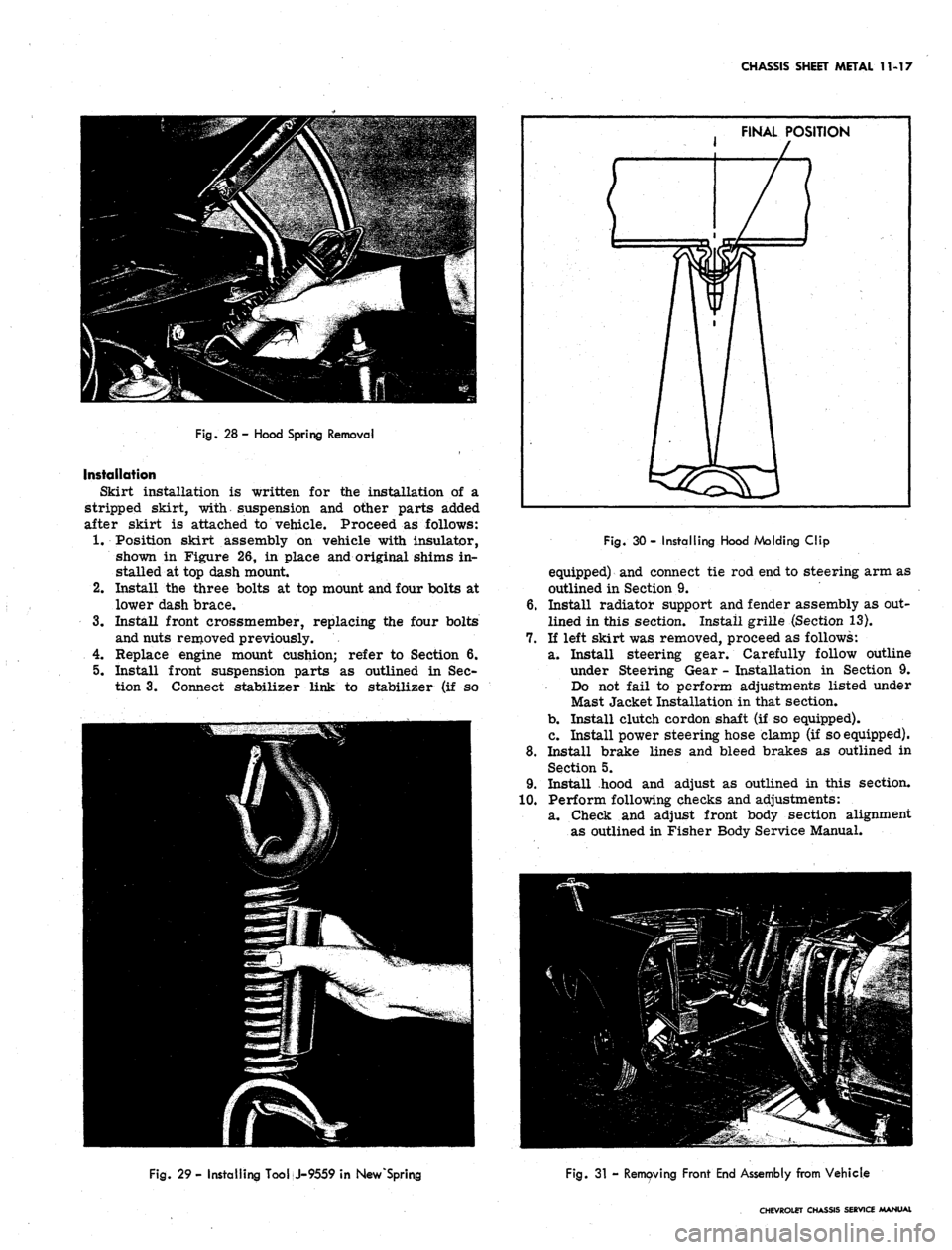

Fig.

28- Hood Spring Removal

Installation

Skirt installation is written for the installation of a

stripped skirt, with suspension and otiier parts added

after skirt is attached to vehicle. Proceed as follows:

1.

Position skirt assembly on vehicle with insulator,

shown in Figure 26, in place and original shims in-

stalled at top dash mount

2.

Install the three bolts at top mount and four bolts at

lower dash brace.

3.

Install front crossmember, replacing the four bolts

and nuts removed previously.

4.

Replace engine mount cushion; refer to Section 6.

5.

Install front suspension parts as outlined in Sec-

tion 3. Connect stabilizer link to stabilizer (if so

FINAL POSITION

Fig.

30 - Installing Hood Molding Clip

equipped) and connect tie rod end to steering arm as

outlined in Section 9.

6. Install radiator support and fender assembly as out-

lined in this section. Install grille (Section 13).

7.

If left skirt was removed, proceed as follows:

a. Install steering gear. Carefully follow outline

under Steering Gear - Installation in Section 9.

Do not fail to perform adjustments listed under

Mast Jacket Installation in that section.

b.

Install clutch cordon shaft (if so equipped).

c. Install power steering hose clamp (if so equipped).

8. Install brake lines and bleed brakes as outlined in

Section 5.

9. Install hood and adjust as outlined in this section.

10.

Perform following checks and adjustments:

a. Check and adjust front body section alignment

as outlined in Fisher Body Service Manual.

Fig.

29 - Installing Tool J-9559 in Nev/Spring

Fig.

31 - Removing Front End Assembly from Vehicle

CHEVROLET CHASSIS SERVICE MANUAL

Page 505 of 659

CHASSIS SHEET METAL 11-18

b.

Check and adjust front wheel alignment as out-

lined in Section 3.

c. Check and adjust headlamp aiming as outlined in

Section 12.

HOOD ASSEMBLY

Hood may be removed either with or without hinges.

To shorten aligning time, hood hinge plates may be lo-

cated by scribing a mark on hood and/or body which

outlines entire plate. See Maintenance and Adjustments -

Hood Hinge for hood adjustment procedure. Hood hinge

springs may be easily and safely removed and installed.

through the use of Tool J-9559 as follows:

1.

With hood opened only far enough to allow passage of

mechanic's arm between hood and fender, insert ends

of J-9559 (through bolt removed) between coils of

spring until barrel of tool contacts outer diameter

of spring.

2.

Open hood fully while still holding spring (with tool

installed) in hand; when hood is near fully opened

position, spring may be removed as shown in Figure

28.

3.

As soon as spring is removed, insert long bolt sup-

plied with J-9559 through holes in end of tool, pass-

ing it through spring, and install nut on bolt.

Spring may be removed from J-9559 or J-9559 may be

installed in a new spring by the following method:

1.

Place a closed 6 or 8 inch "C" clamp in a vise or

fasten it to a heavy bench top (bench should be fas-

tened to floor).

2.

Hook one end of spring in clamp and the other end

in hook of a hoist as shown in Figure 29.

3.

Stretch the spring enough to allow insertion of

J-9559. Install through bolt if spring is not to be

installed on hinge at once.

HOOD CATCH AMD LOCK (Fig. 19)

Removal

1.

Remove catch assembly as follows:

a. Remove screws retaining catch assembly to radi-

ator support.

b.

Remove screws retaining catch assembly to catch

support assembly.

c* Remove screws retaining catch assembly to grille

upper bar.

2.

Before removing hood lock plate from hood, locate

position on hood by scribing around base of lock

plate. Remove screws retaining lock plate to hood

and remove lock plate from vehicle.

Installation

1.

Install both catch and lock assemblies in reverse

order of removal procedure.

2.

Align as outlined under Maintenance and Adjust-

ments - Hood Catch.

HOOD TRIM

Crown Molding

Hood crown molding is retained by clips installed on

underside of hood. Clips may be removed by carefully

pressing them off molding mounting studs with screw

driver.

When installing a new molding, force clips onto mount-

ing studs as far as possible and then clench clips with

long-nosed pliers to eliminate gap between molding and

hood, as shown in Figure 30.

Emblem

The hood emblem is retained by four nuts which are

accessible from under the hood.

COWL VENT GRILLE

The cowl vent grille replacement procedure for Chevy

U is the same as for Chevrolet and Chevelle. Refer to

Chevrolet and Chevelle Cowl Vent Grille replacement

procedure and see Figure 16.

FRONT END ASSEMBLY

The Chevy n front end body design allows for removal

of the entire front end of the vehicle without disassembly

of front suspension of sheet metal. One man may remove

and transport the front end assembly using only a floor

jack placed under the crossmember and the vehicle front

wheels. Figure 31 illustrates the assembly in process

of removal with jack stand in position under rocker panel.

Proceed with removal

as.

follows:

Removal

1.

Remove hood assembly as outlined in this section.

2.

Remove engine assembly as outlined in Section 6.

On 4 cylinder models, replace crossmember.

3.

Raise car from floor and install jack stands as

shown in Figure 31.

4.

Remove pitman arm from steering gear as outlined

in Section 9.

5.

Remove steering gear mounting bolts from skirt

assembly.

6. Remove 4 bolts securing each skirt assembly to

lower dash brace.

7.

Remove fender-to-rocker extension mounting screws

and record shimming.

8. Remove brake hydraulic line and fuel line from right

hand skirt.

9. Position floor jack or equivalent under front cross-

member.

10.

Remove hydraulic line from main cylinder.

11.

Remove fender-to-cowl mounting screws and record

shimming.

12.

Remove upper skirt-to-dash mounting screws and

record shimming.

13.

Remove front end from vehicle as shown in Figure

31.

Inspection

If car has been involved in a collision, it is advisable

to carefully inspect cowl and dash area for damage. Pay

particular attention to welds, cage nuts, weld nuts and

skirt mounting surfaces. Cage and weld nuts may be

repaired by outright replacement (the best method), or

by the installation of spiral thread inserts. If the spiral

inserts are used, follow the instructions furnished by the

manufacturer. -

Installation

%, position front end assembly at upper dash mounts

and lower dash support, align screw holes with drift

punch and install all mounting screws and bolts

loosely; do not tighten until all screws and bolts are

started. Replace original shimming.

CHEVROLET CHASSIS SERVICE MANUAL

Page 506 of 659

5.

6.

7.

8.

2.

Install all fender mounting screws, replacing original

shimming. Refer to removal procedure for screw

location.

3.

Install hydraulic lines at main cylinder and right

hand skirt. Install fuel line at right hand skirt.

4.

Install steering gear as outlined in Section 9. Do

not fail to perform adjustment procedure listed under

Mast Jacket - Installation.

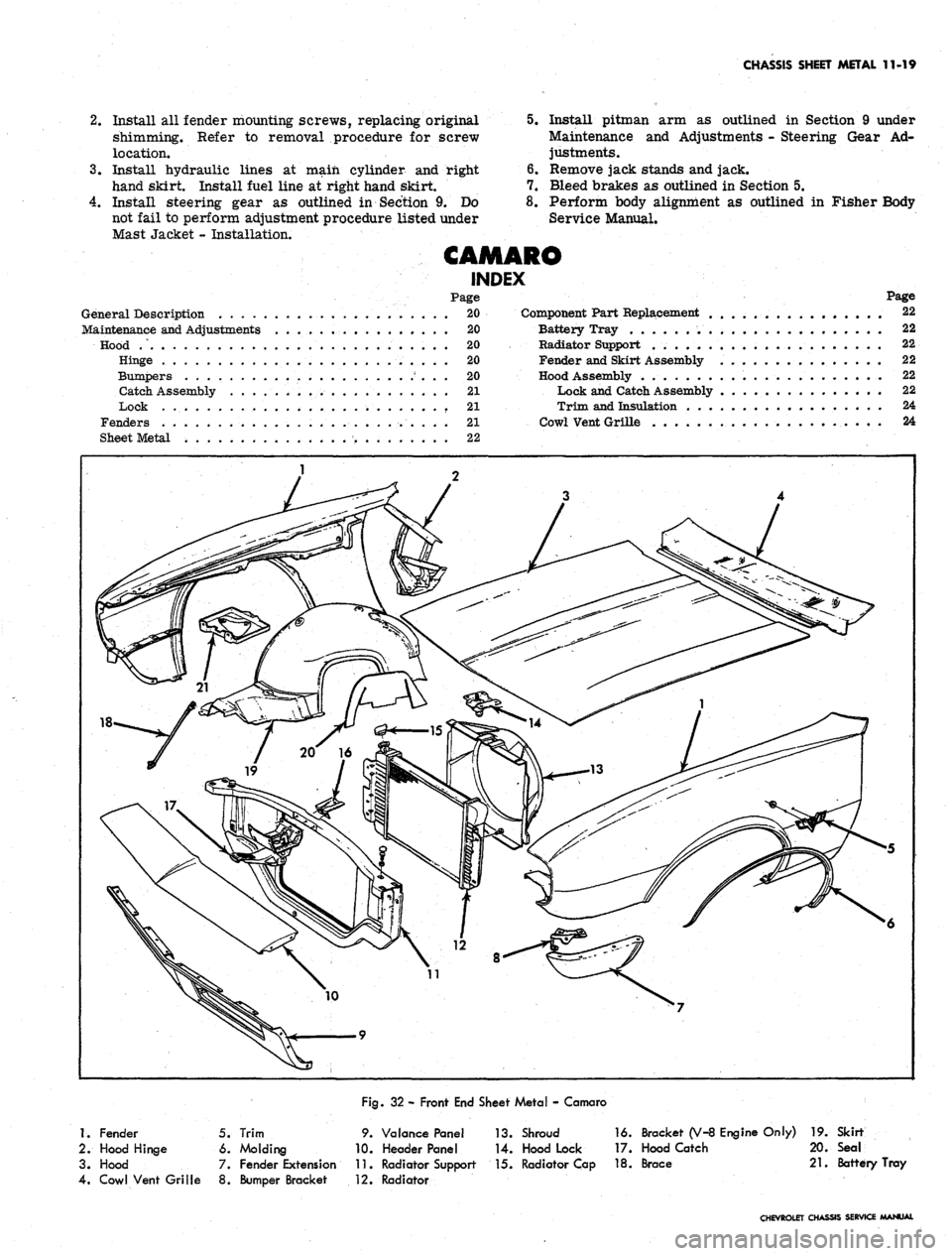

CAMARO

INDEX

Page

General Description 20

Maintenance and Adjustments 20

Hood / . 20

Hinge 20

Bumpers ' . . . 20

Catch Assembly 21

Lock . 21

Fenders 21

Sheet Metal 22

CHASSIS SHEET METAL 11-19

Install pitman arm as outlined in Section 9 under

Maintenance and Adjustments - Steering Gear Ad-

justments.

Remove jack stands and jack.

Bleed brakes as outlined in Section 5.

Perform body alignment as outlined in Fisher Body

Service Manual.

Page

Component Part Replacement . 22

Battery Tray 22

Radiator Support 22

Fender and Skirt Assembly 22

Hood Assembly . 22

Lock and Catch Assembly 22

Trim and Insulation . . . 24

Cowl Vent Grille . . 24

Fig.

32 - Front End Sheet Metal - Camaro

1.

Fender

2.

Hood Hinge

3. Hood

4.

Cowl Vent Grille

5. Trim

6. Molding

7. Fender Extension

8. Bumper Bracket

9. Valance Pane!

10.

Header Panel

11.

Radiator Support

12.

Radiator

13.

14.

15.

Shroud

Hood Lock

Radiator Cap

16.

17.

18.

Bracket (V-8

Hood Catch

Brace

Engine

Only)

19.

20.

21.

Skirt

Seal

Battery

Tray

CHEVROLET CHASSIS SERVICE MANUAL