exhaust CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 483 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 483

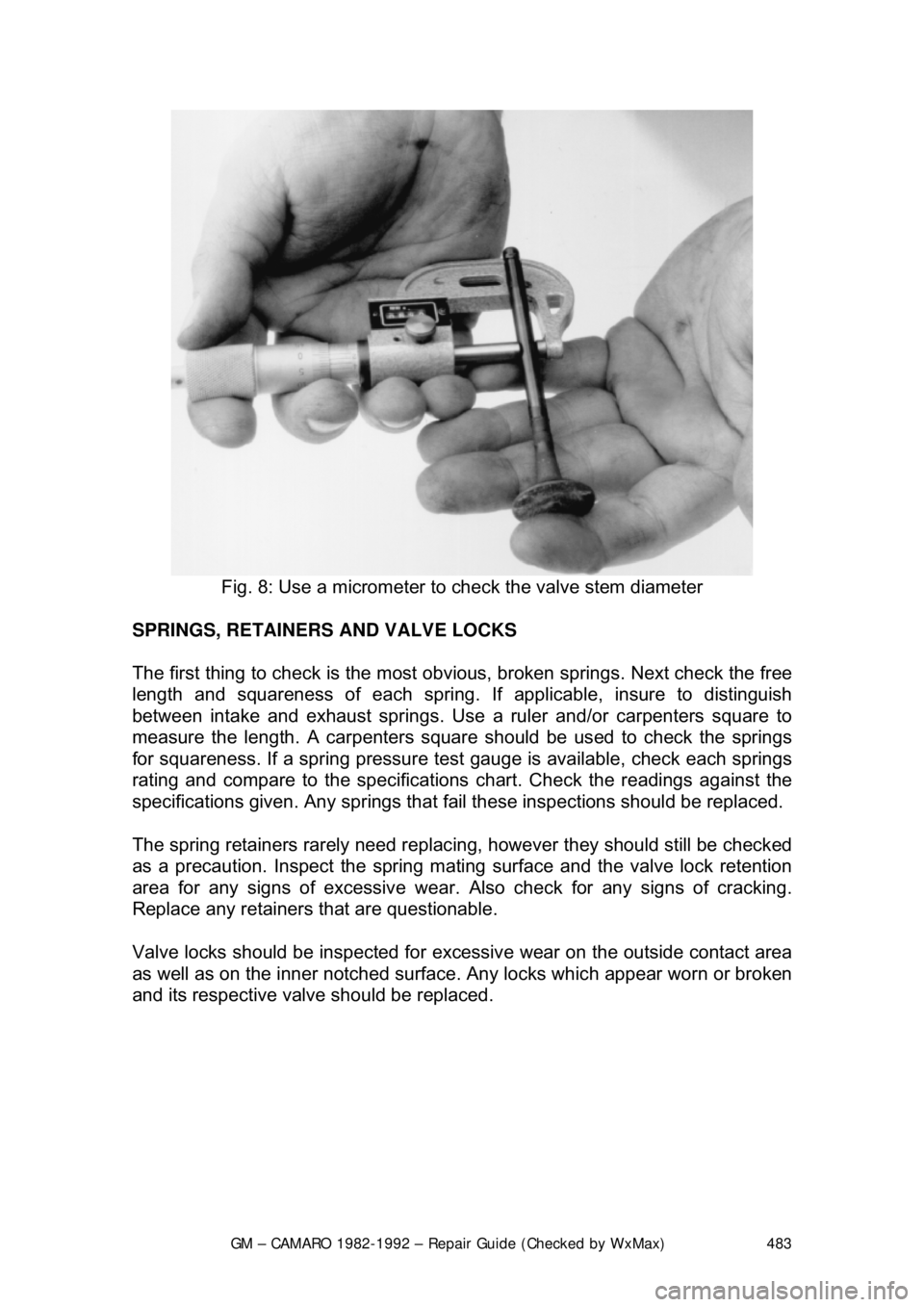

Fig. 8: Use a micrometer to check the valve stem diameter

SPRINGS, RETAINERS AND VALVE LOCKS

The first thing to check is the most obv ious, broken springs. Next check the free

length and squareness of each spring. If applicable, insure to distinguish

between intake and exhaust springs. Use a ruler and/or carpenters square to

measure the length. A car penters square should be used to check the springs

for squareness. If a spring pressure test gauge is available, check each springs

rating and compare to the specifications chart. Check the readings against the

specifications given. Any springs that fa il these inspections should be replaced.

The spring retainers rarely need replacing, however they should still be checked

as a precaution. Inspect the spring mating surface and the valve lock re\

tention

area for any signs of excessive wear. Also check for any signs of cracking.

Replace any retainers t hat are questionable.

Valve locks should be inspected for exce ssive wear on the outside contact area

as well as on the inner notched surface. Any locks which appear worn or broken

and its respective valve should be replaced.

Page 487 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 487

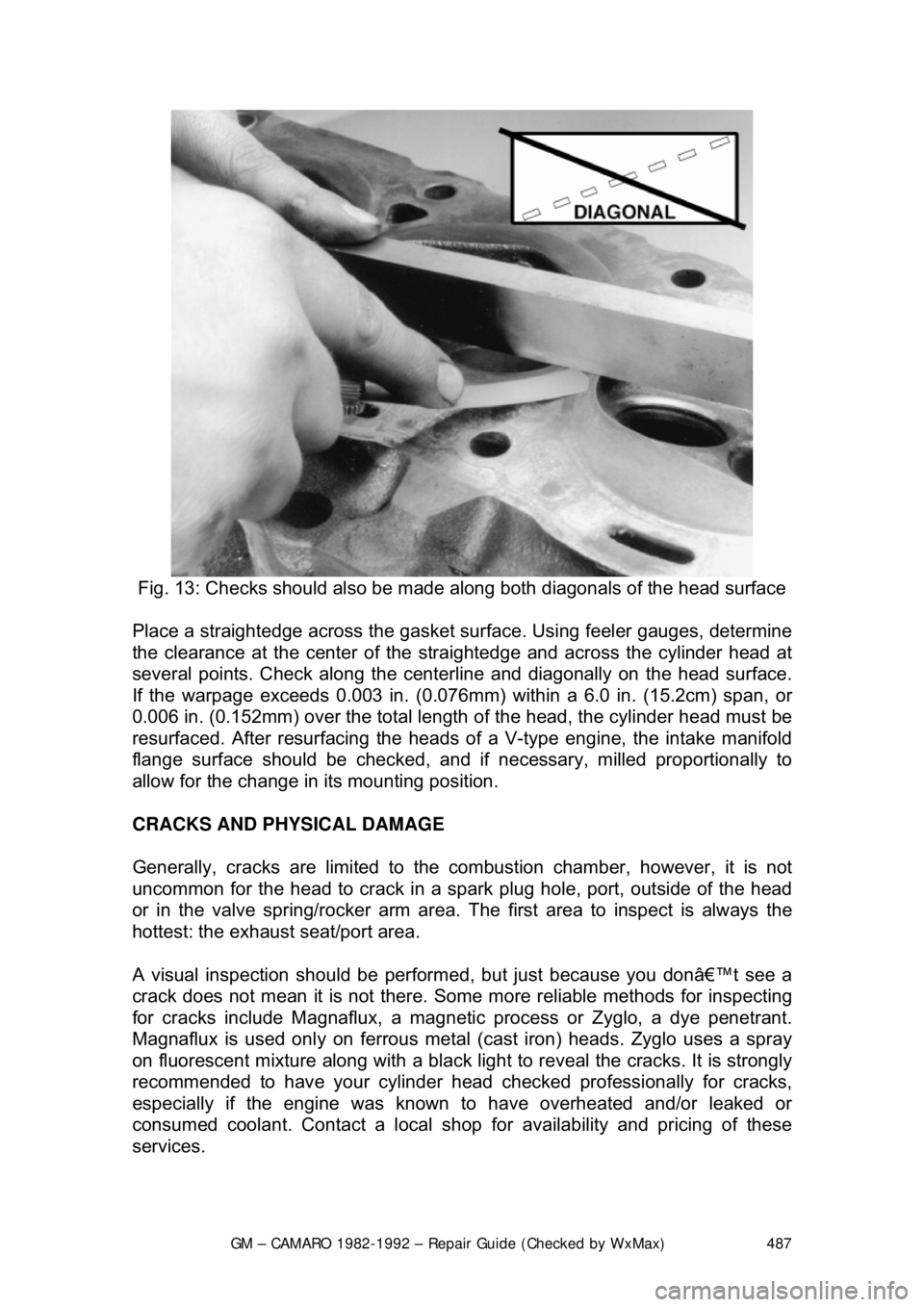

Fig. 13: Checks should also be made al ong both diagonals of the head surface

Place a straightedge across the gasket surf ace. Using feeler gauges, determine

the clearance at the cent er of the straightedge and across the cylinder head at

several points. Check along the centerli ne and diagonally on the head surface.

If the warpage exceeds 0.003 in. (0.076mm) within a 6.0 in. (15.2cm) span, or

0.006 in. (0.152mm) over the total length of the head, the cylinder head must be

resurfaced. After resurfacing the heads of a V-type engine, the intake manifold

flange surface should be checked, and if necessary, milled proportionally to

allow for the change in its mounting position.

CRACKS AND PHYSICAL DAMAGE

Generally, cracks are limited to the comb ustion chamber, however, it is not

uncommon for the head to crack in a s park plug hole, port, outside of the head

or in the valve spring/rocker arm area. The first area to inspect is always the

hottest: the exhaust seat/port area.

A visual inspection should be perform ed, but just because you don’t see a

crack does not mean it is not there. Some more reliable methods for inspecting

for cracks include Magnaflux, a magnetic process or Zyglo, a dye penetrant.

Magnaflux is used onl y on ferrous metal (cast iron) heads. Zyglo uses a spray

on fluorescent mixture along with a black light to reveal the cracks. It is strongly

recommended to have your cylinder head c hecked professionally for cracks,

especially if the engine was known to have overheated and/or leaked or

consumed coolant. Contact a local shop fo r availability and pricing of these

services.

Page 541 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 541

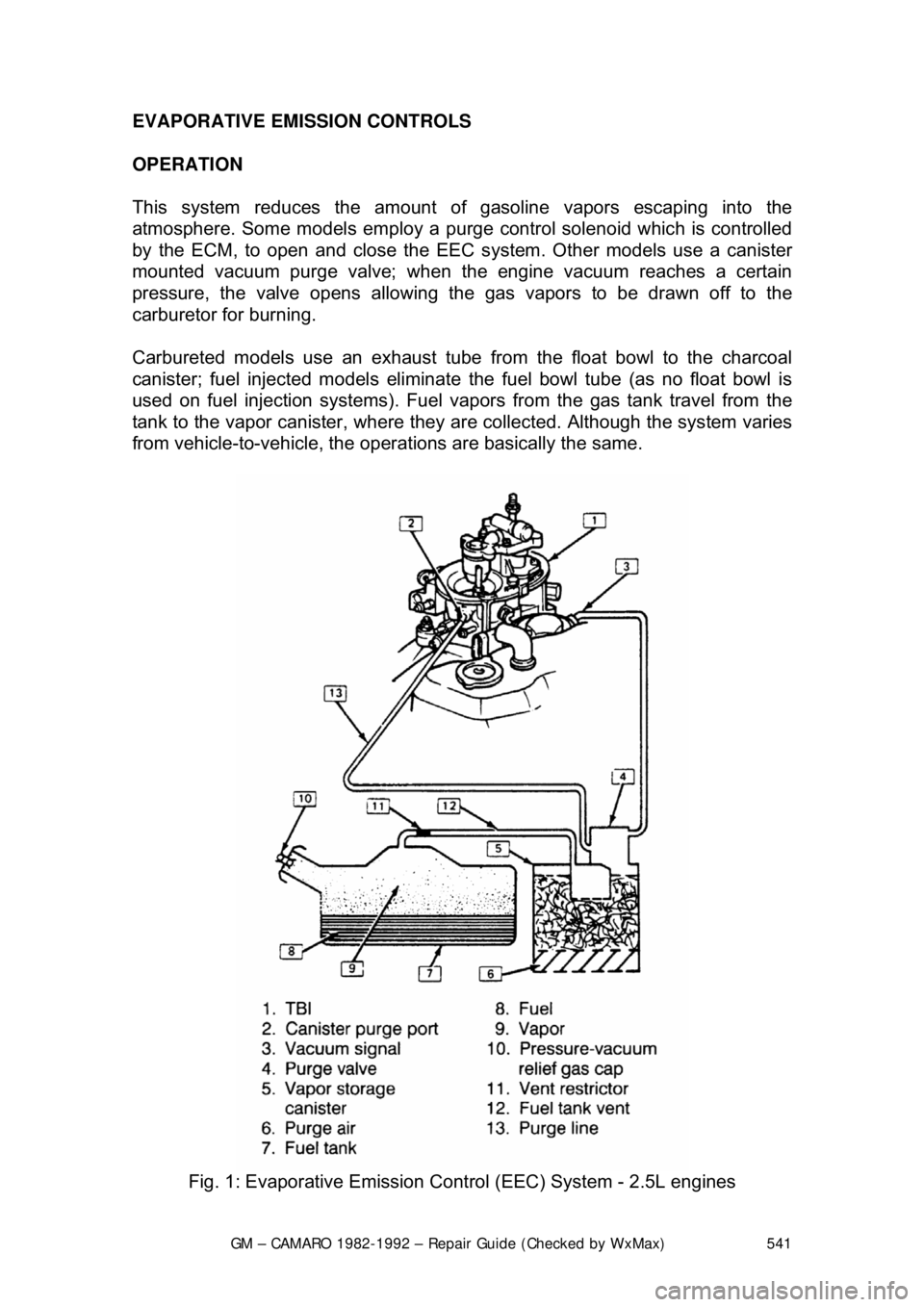

EVAPORATIVE EMISS

ION CONTROLS

OPERATION

This system reduces the amount of gasoline vapors escaping into the

atmosphere. Some models em ploy a purge control solenoid which is controlled

by the ECM, to open and close the EE C system. Other models use a canister

mounted vacuum purge valve; when the engine vacuum reaches a certain

pressure, the valve opens allowing the gas vapors to be drawn off to the

carburetor for burning.

Carbureted models use an exhaust tube fr om the float bowl to the charcoal

canister; fuel injected models eliminate the fuel bowl tube (as no float bowl is

used on fuel injection systems). Fuel vapor s from the gas tank travel from the

tank to the vapor canister , where they are collected. Although the system varies

from vehicle-to-vehicle, the operat ions are basically the same.

Fig. 1: Evaporative Emission Cont rol (EEC) System - 2.5L engines

Page 547 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 547

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

OPERATION

All models are equipped with

this system, which consists of a metering valve, a

vacuum line to the carburet or or intake manifold, and cast-in exhaust passages

in the intake manifold. The EGR valve is controlled by vacuum, which opens

and closes in response to the vacuum signals to admit exhaust gases into the

air/fuel mixture. The exhaust gases lower peak combustion temperatures,

reducing the formation of NOx. The valve is closed at idle and wide open

throttle, but is open between the two extreme positions.

There are actually four types of EGR systems: Ported, Positive Back-Pressure,

Negative Backpressure and Digital. The pr inciple of all the systems are the

same; the only difference is in the me thod used to control how the EGR valve

opens.

Too much EGR flow at idle, cruise or during cold operation may result in the

engine stalling after cold start, the engine stalling at idle after deceleration,

vehicle surge during cruise and rough idle . If the EGR valve is always open, the

vehicle may not idle. Too little or no EGR flow allows combustion temperatures

to rise, which could result in spar k knock (detonation), engine overheating

and/or emission test failure.

A Thermal Vacuum Switch (TVS) or vacuum control solenoid may sometimes\

be used in combination with the EGR va lve. The TVS will close off vacuum

during cold operation. A va cuum control solenoid uses Pulse Width Modulation

(PWM) to turn the solenoid ON and OFF numerous times a second and varies

the amount of ON time (pulse width) to vary the amount of ported vacuum

supplied the EGR valve.

PORTED VALVE

In the ported system, the amount of ex haust gas admitted into the intake

manifold depends on a ported vacuum signal. A ported vacuum signal is one

taken from the carburetor above the th rottle plates; thus, the vacuum signal

(amount of vacuum) is dependent on how far the throttle plates are opened.

When the throttle is closed (idle or dec eleration) there is no vacuum signal.

Thus, the EGR valve is closed, and no exhaust gas enters the intake mani\

fold.

As the throttle is opened, a vacuum is produced, which opens the EGR valve,

admitting exhaust gas into the intake manifold.

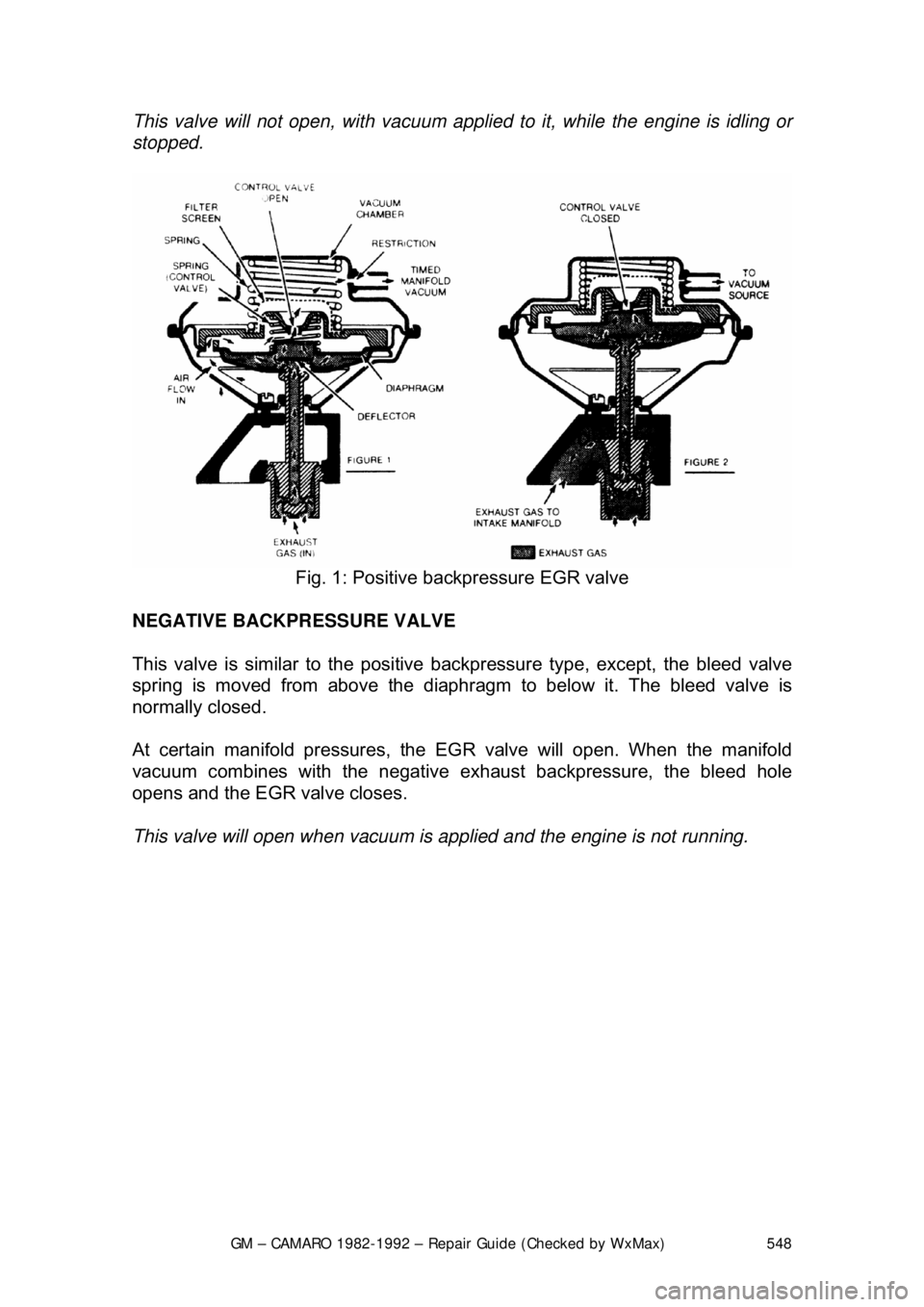

POSITIVE BACKPRE SSURE VALVE

This valve operates the same as the ported, except, it has an internal air bleed

that acts as a vacuum regulator. T he bleed valve controls the amount of

vacuum inside the vacuum chamber duri ng operation. When the valve receives

sufficient exhaust backpressure through the hollow shaft, it closes the bleed; at

this point the EGR valve opens.

Page 548 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 548

This valve will not open, wit

h vacuum applied to it, while the engine is idling or

stopped.

Fig. 1: Positive backpressure EGR valve

NEGATIVE BACKPRESSURE VALVE

This valve is similar to the positive ba ckpressure type, except, the bleed valve

spring is moved from above the diaphragm to below it. The bleed valve is

normally closed.

At certain manifold pressures, the EG R valve will open. When the manifold

vacuum combines with the negative exhaust backpressure, the bleed hole

opens and the EGR valve closes.

This valve will open when vacuum is applied and the engine is not running.

Page 552 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 552

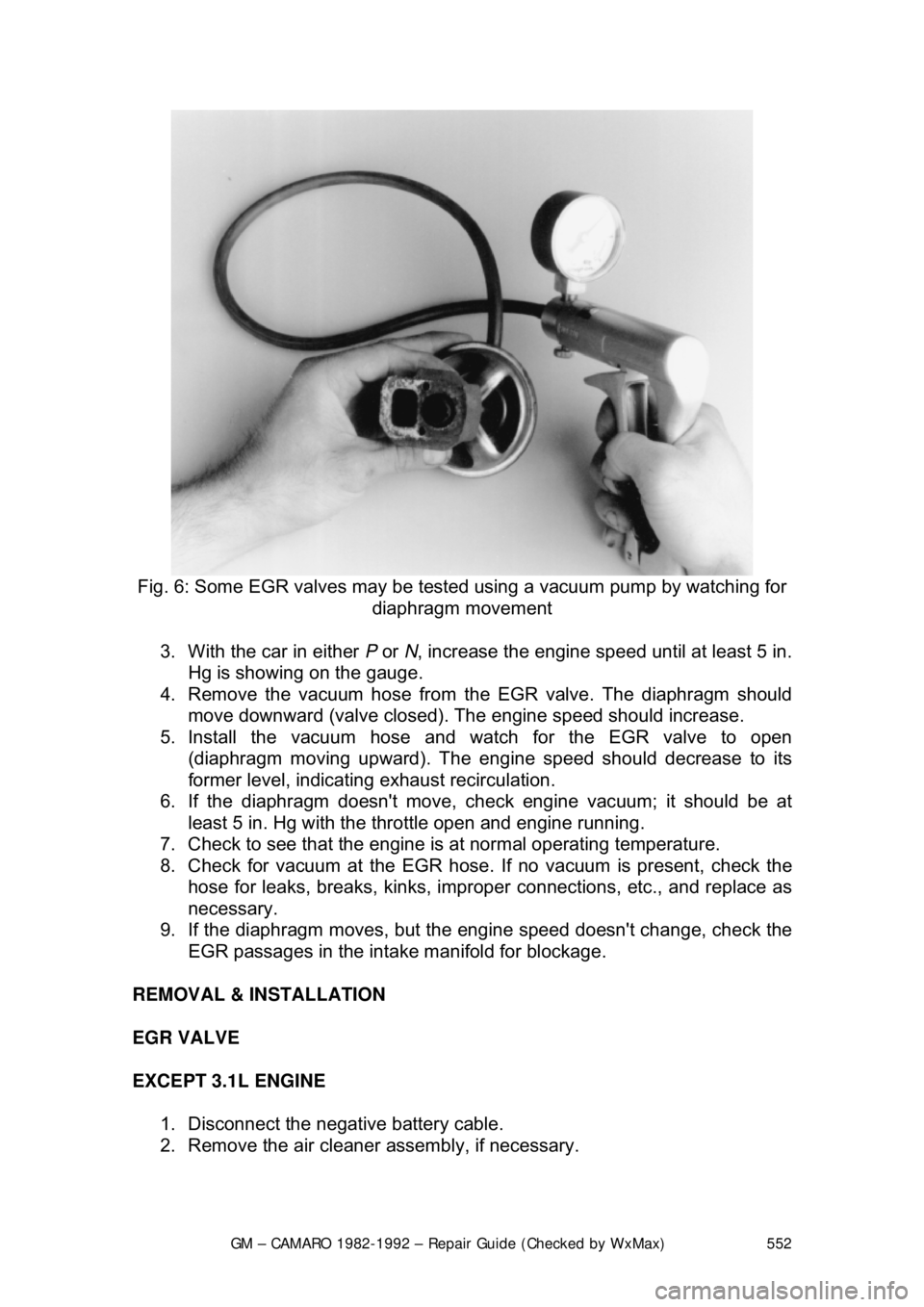

Fig. 6: Some EGR valves may be test ed using a vacuum pump by watching for

diaphragm movement

3. With the car in either P or N, increase the engine speed until at least 5 in.

Hg is showing on the gauge.

4. Remove the vacuum hose from t he EGR valve. The diaphragm should

move downward (valve closed). The engine speed should increase.

5. Install the vacuum hose and watch for the EGR valve to open (diaphragm moving upward). The engine speed should decrease to its

former level, indicating exhaust recirculation.

6. If the diaphragm doesn't move, c heck engine vacuum; it should be at

least 5 in. Hg with the throttle open and engine running.

7. Check to see that the engine is at normal operating temperature.

8. Check for vacuum at the EGR hose. If no vacuum is present, check the

hose for leaks, breaks, kinks, improper connections, etc., and replace as

necessary.

9. If the diaphragm move s, but the engine speed doesn't change, check the

EGR passages in the intake manifold for blockage.

REMOVAL & INSTALLATION

EGR VALVE

EXCEPT 3.1L ENGINE 1. Disconnect the negative battery cable.

2. Remove the air cleaner assembly, if necessary.

Page 553 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 553

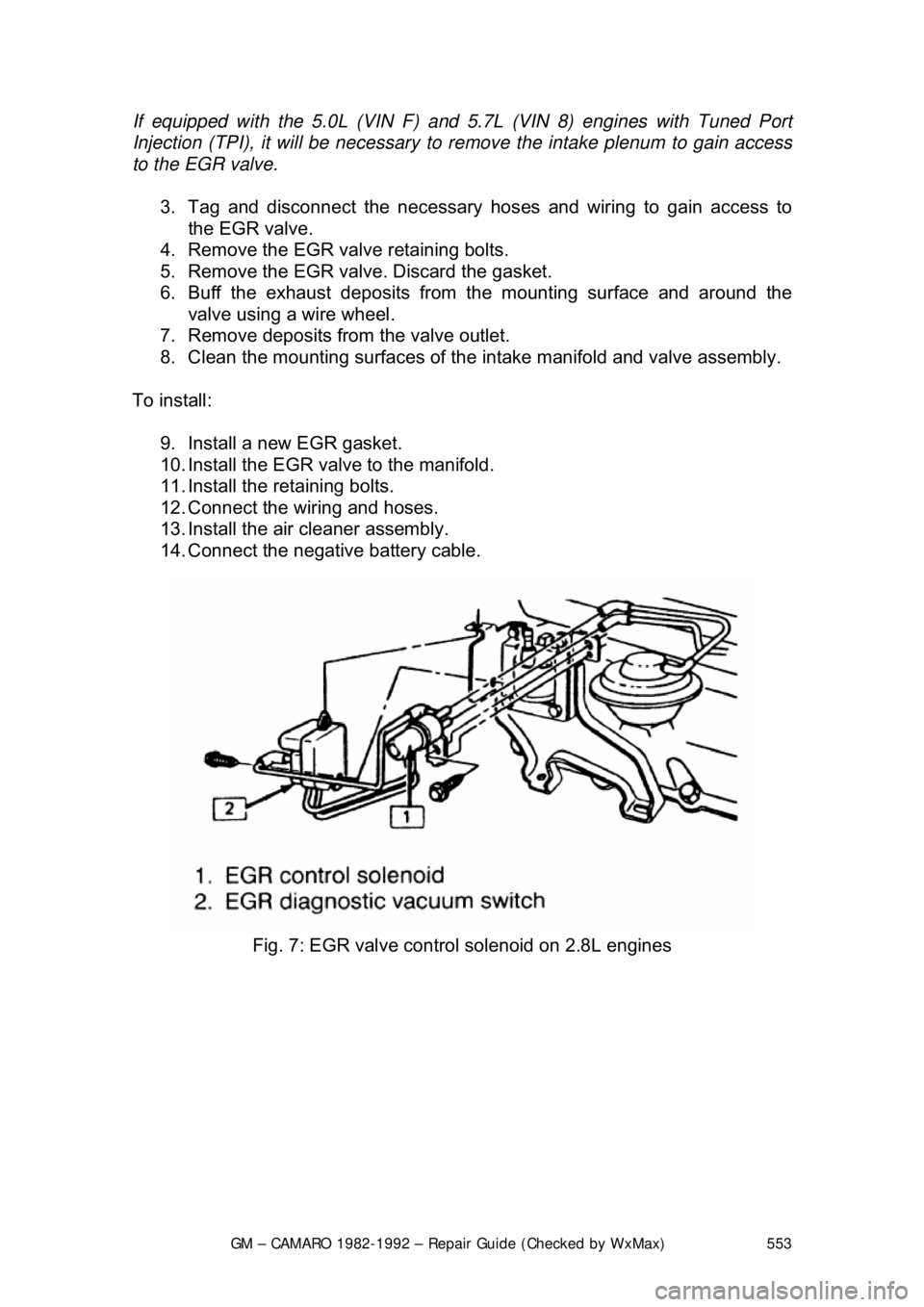

If equipped with the 5.0L (VIN F) and 5.7L

(VIN 8) engines with Tuned Port

Injection (TPI), it will be necessary to remove the intake plenum to gain access

to the EGR valve.

3. Tag and disconnect the necessary hos es and wiring to gain access to

the EGR valve.

4. Remove the EGR valve retaining bolts.

5. Remove the EGR valve. Discard the gasket.

6. Buff the exhaust deposits from the mounting surface and around the

valve using a wire wheel.

7. Remove deposits from the valve outlet.

8. Clean the mounting surfaces of the intake manifold and valve assembly.

To install: 9. Install a new EGR gasket.

10. Install the EGR valve to the manifold.

11. Install the retaining bolts.

12. Connect the wiring and hoses.

13. Install the air cleaner assembly.

14. Connect the negative battery cable.

Fig. 7: EGR valve control solenoid on 2.8L engines

Page 559 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 559

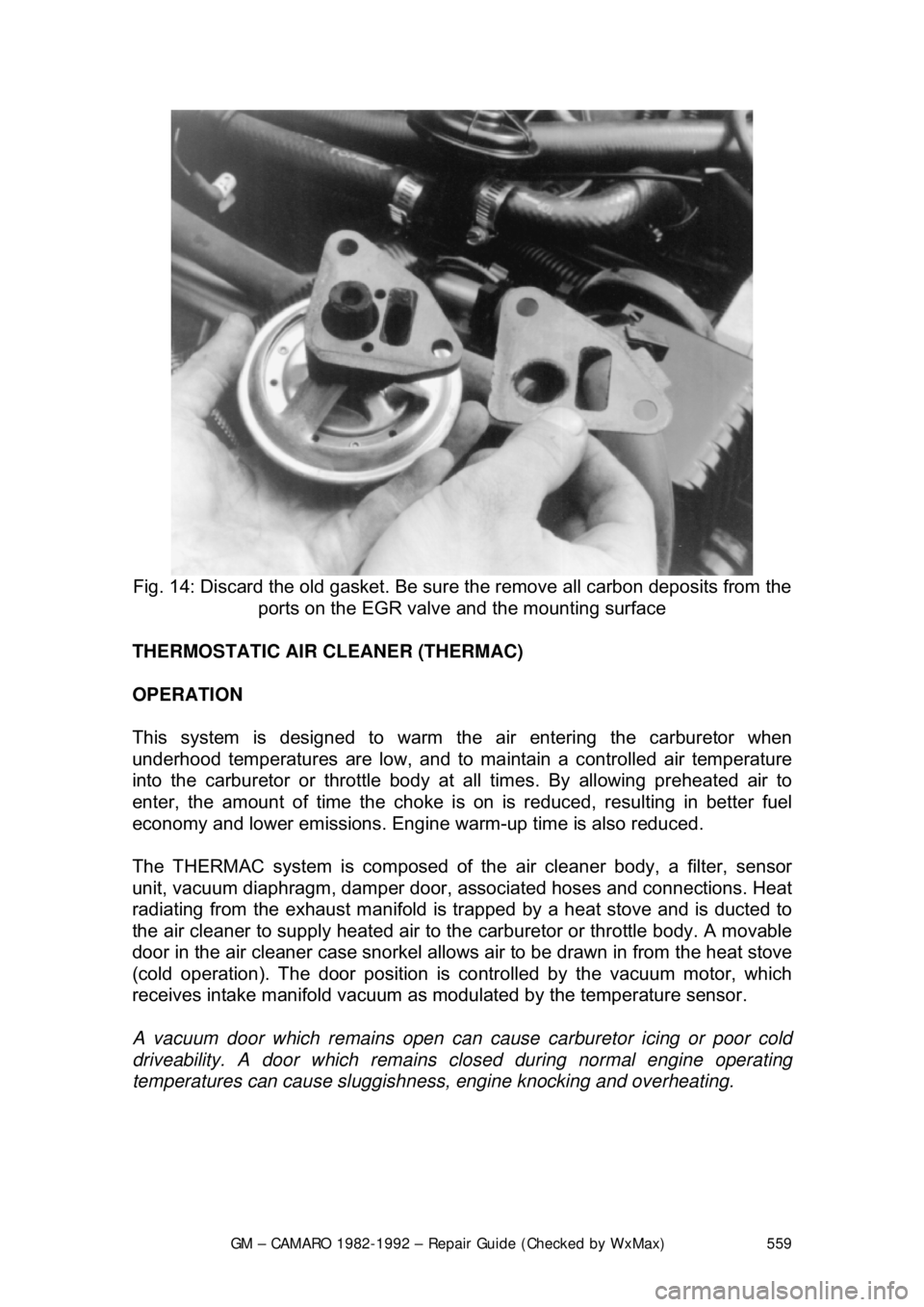

Fig. 14: Discard the old gasket. Be sure the remove all carbon deposits from the

ports on the EGR valve and the mounting surface

THERMOSTATIC AIR CLEANER (THERMAC)

OPERATION

This system is designed to warm the air entering the carburetor when

underhood temperatures are low, and to ma intain a controlled air temperature

into the carburetor or throttle body at all times. By allowing preheated air to

enter, the amount of time t he choke is on is reduced, resulting in better fuel

economy and lower emissions. Engine warm-up time is also reduced.

The THERMAC system is composed of th e air cleaner body, a filter, sensor

unit, vacuum diaphragm, damper door, a ssociated hoses and connections. Heat

radiating from the exhaust manifold is tr apped by a heat stove and is ducted to

the air cleaner to supply heated air to t he carburetor or throttle body. A movable

door in the air cleaner case snorkel allows air to be drawn in from the heat stove

(cold operation). The door position is co ntrolled by the vacuum motor, which

receives intake manifold vacuum as modulated by the temperature sensor.

A vacuum door which remain s open can cause carburetor icing or poor cold

driveability. A door which remains clos ed during normal engine operating

temperatures can cause sluggishne ss, engine knocking and overheating.

Page 562 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 562

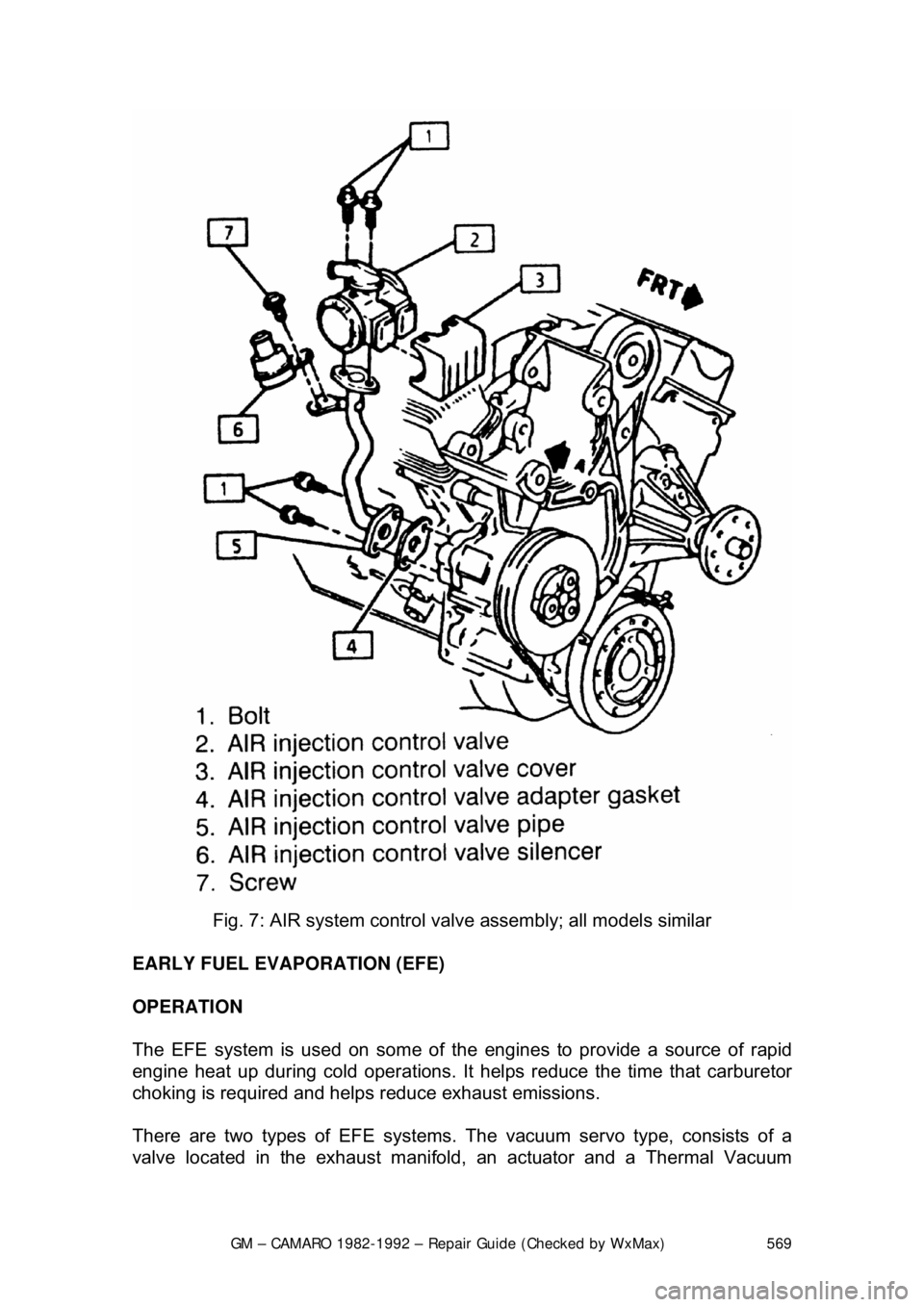

Air is injected into either the exhaust

port(s), the exhaust manifold(s) or the

catalytic converter by an engine driven ai r pump. The system is in operation at

all times and will bypass air only mom entarily during deceleration and at high

speeds. The bypass function is performed by the air control valve, while the

check valve protects the air pump by pr eventing any backflow of exhaust gases.

The AIR system helps r educe HC and CO content in the exhaust gases by

injecting air into the exhaust ports dur ing cold engine operation. This air

injection also helps the catalytic conv erter to reach the proper temperature

quicker during warmup. When the engine is warm (Closed Loop), the AIR

system injects air into the beds of a th ree-way converter to lower the HC and

the CO content in the exhaust.

The system utilizes the following components:

1. An engine driven AIR pump.

2. AIR Control valves (Air Control, Air Switching).

3. Air flow and control hoses.

4. Check valves.

5. A dual-bed, three-way catalytic converter.

6. A deceleration back-fire control valve - 2.8L engine only.

The belt driven, vane-type air pump is lo cated at the front of the engine and

supplies clean air to the AIR system fo r purposes already stated. When the

engine is cold, the Electronic Control Module (ECM) energizes an AIR control

solenoid. This allows air to flow to the AIR switching valve. The AIR switching

valve is then energized to direct air to the exhaust ports.

When the engine is warm, the ECM de-energ izes the AIR switching valve, thus

directing the air between the beds of the catalytic converter. This provides

additional oxygen for the ox idizing catalyst in the second bed to decrease HC

and CO, while at the same time keeping oxygen levels low in the first bed,

enabling the reducing catalyst to effect ively decrease the levels of NOx.

If the AIR control valve detects a r apid increase in manifold vacuum

(deceleration), certain operat ing modes (wide open throttle, etc.) or if the ECM

self-diagnostic system detects any problem in the system, air is diverted to the

air cleaner or directly into the atmosphere.

The primary purpose of the EC M's divert mode is to prevent backfiring. Throttle

closure at the beginning of deceleration will temporarily create air/fuel mixtures

which are too rich to burn completely . These mixtures become burnable when

they reach the exhaust if combined with the injection ai r. The next firing of the

engine will ignite this mixt ure causing an exhaust backf ire. Momentary diverting

of the injection air from the exhaust prevents this.

The AIR system check valves and hoses should be checked periodically for any

leaks, cracks or deterioration.

Page 569 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 569

Fig. 7: AIR system control valv e assembly; all models similar

EARLY FUEL EVAPORATION (EFE)

OPERATION

The EFE system is used on some of the engines to provide a source of rapid

engine heat up during cold operations. It hel ps reduce the time that carburetor

choking is required and helps reduce exhaust emissions.

There are two types of EF E systems. The vacuum servo type, consists of a

valve located in the exhaust manifold , an actuator and a Thermal Vacuum